2500A Serie

s

2500A Series Microwave Synthesizer Operations Manual

34172, Revision C, March 2008

All technical data and specifications in this publication are subject to change without prior notice and do not

represent a commitment on the part of Giga-tronics, Incorporated.

© 2004 Giga-tronics Incorporated. All rights reserved. Printed in the USA.

WARRANTY

Giga-tronics 2500A Series instruments are

warranted against defective materials and

workmanship for four years from date of shipment.

Giga-tronics will at its option repair or replace

products that are proven defective during the

warranty period. This warranty DOES NOT cover

damage resulting from improper use, nor

workmanship other than Giga-tronics service.

There is no implied warranty of fitness for a

particular purpose, nor is Giga-tronics liable for any

consequential damages. Specification and price

change privileges are reserved by Giga-tronics.

MODEL NUMBERS

The 2500A Series has model numbers for each instrument with a specific frequency range as described in Chapter 1.

All models are referred to in this manual by the general term 2500A, except where it is necessary to make a

distinction between the models. In these cases, the specific model number(s) will be used.

Giga-tronics, Incorporated

4650 Norris Canyon Road

San Ramon, California 94583

TEL: 800.726.4442

925.328.4650

FAX: 925.328.4700

www.gigatronics.com

Declaration of Conformity

Application of Council Directive(s)

Standard(s) to which Conformity is Declared:

89/336/EEC and 73/23/EEC EMC Directive and Low Voltage Directive

EN61010-1 (1993) Electrical Safety

EN61326-1 (1997) EMC - Emissions & Immunity

Manufacturer’s Name: Manufacturer’s Address:

Giga-tronics, Incorporated 4650 Norris Canyon Road

San Ramon, California 94583

U.S.A.

Type of Equipment: Model Series Number:

Microwave Synthesizer 2500A Series

Model Numbers In Series:

2508A, 2520A, 2526A, 2540A

2508AS, 2520AS, 2526AS, 2540AS

Declaration of Conformity on file. Contact Giga-tronics, Inc.

4650 Norris Canyon Rd.

San Ramon, CA 94583

Ph: 1-925-328-4650

Fx: 1-925-328-4700

About The Publication

Preface

This publication provides an overview and describes local (front panel) operation, remote operation,

specifications, and performance verification of the Giga-tronics 2500A family of Microwave Synthesizers. This Preface contains chapter descriptions, a record of changes made to the publication since its production, and a description of the special configurations. Changes that occur after production of this

publication, and Special Configuration data will be inserted as loose bound pages in the publication

binder. Please insert and/or replace the indicated pages as detailed in the Technical Publication Instructions included with new and/or replacement pages.

Chapters:

1- Introduction

This chapter contains an overview of the 2500A, basic system information, and input and output descriptions.

2 - Front Panel Operation

This chapter contains information about front panel operation of the instrument. Controls, features, and

menus are described, operating tasks are explained, and factory default settings are listed.

3- Remote Operation

This chapter contains information about remote operation of the instrument over the General Purpose

Interface Bus (GPIB) or RS-232.

4- Specifications & Performance Verification

This chapter contains 2500A specifications and step-by-step procedures to verify 2500A Series Microwave Synthesizer performance.

Appendices:

A- Accessories and Options

This appendix describes the accessories and options that are available for the 2500A Series Microwave

Synthesizers. Each accessory and option is described under its respective heading.

B - Error Messages

This appendix provides a description of the various error messages and other user messages that might be

encountered during instrument operation.

Index

A subject listing of contents.

2500A Series Operation Manual, 34172 Revision C, March 2008

Conventions

The following safety conventions are used in this publication. Additional conventions not included here are

defined at the time of usage.

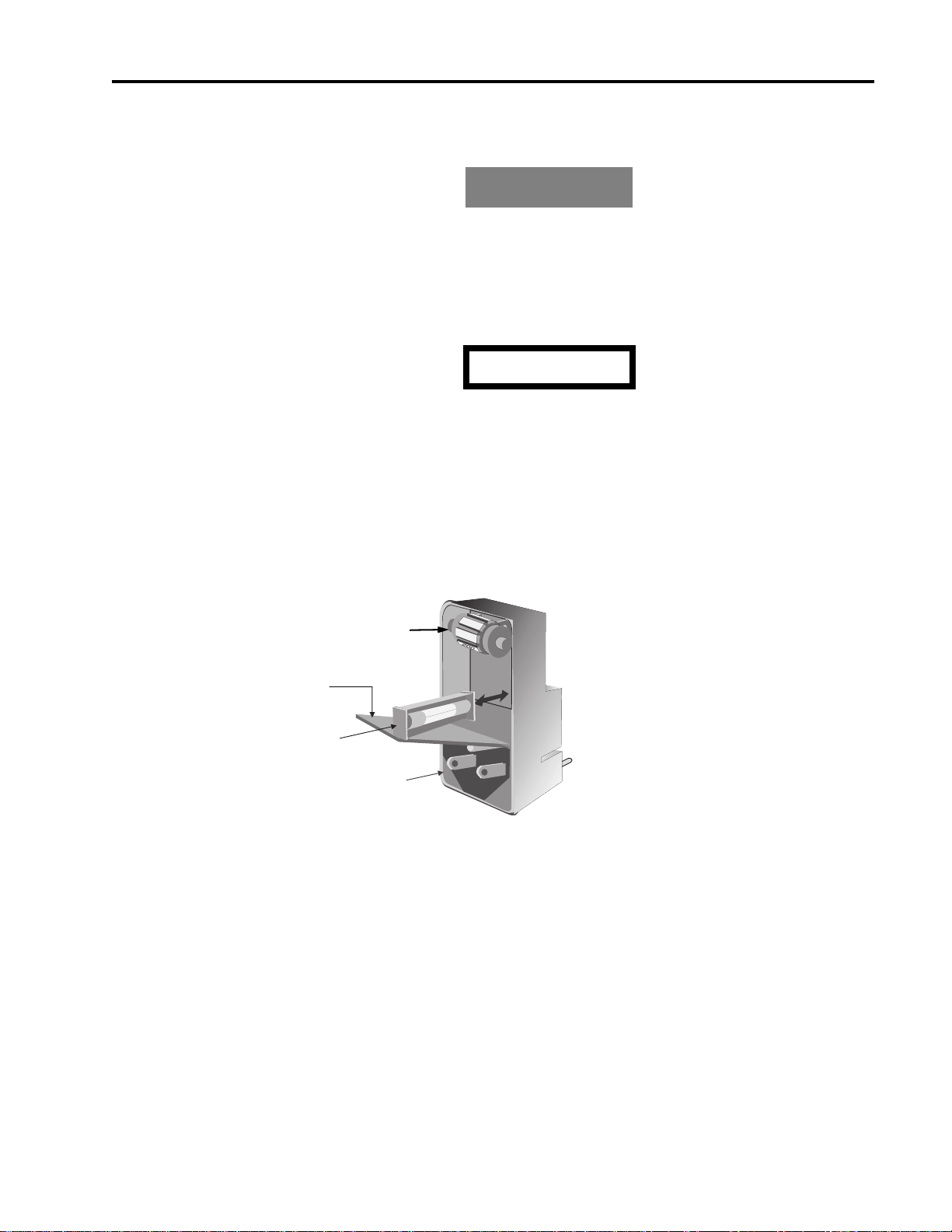

Warning

WARNING

The WARNING statement is encased in gray and centered in the page. This calls

attention to a situation, or an operating or maintenance procedure or practice, which if

not strictly corrected or observed, could result in injury or death of personnel. An

example is the proximity of high voltage.

Caution

CAUTION

The CAUTION statement is enclosed with single lines and centered in the page. This

calls attention to a situation, or an operating or maintenance procedure, or practice,

which if not strictly corrected or observed, could result in temporary or permanent

damage to the equipment, or loss of effectiveness.

Notes

NOTE: A NOTE Highlights or amplifies an essential operating or maintenance procedure, practice,

condition or statement.

6 2500A Series Operation Manual, 34172 Revision C, March 2008

Configuration Data

Giga-tronics: Serial, Code, Models, Option or Configuration Label

Examine the code, model number, serial number, and option/configuration label affixed to the rear panel of the

2500A Microwave Synthesizer.

Code Number

Each instrument has a two-digit code, referred to as the Manufacturing Configuration Code.

Model Number

Each instrument has a four-digit model number in the form 25XX, and one or two character suffix which designates the series:

- 25XXB - Benchtop model

- 25XXS - ATE model

The frequency range of the instrument is designated by the model number:

- 2508A - 0.1 MHz to 8 GHz

- 2520A - 0.1 MHz to 20 GHz

- 2526A - 0.1 MHz to 26.5 GHz

- 2540A - 0.1 MHz to 40 GHz

Serial Number

Each instrument has a seven-digit serial number, shown on the label of the rear panel.

Option Number(s)

When options are installed, one or more 2 digit numbers are listed on the “Opt.” line and correspond to

options installed in the instrument. Option numbers are explained in Appendix A.

Special Configurations

When the accompanying product has been configured for user-specific application(s), supplemental pages will

be inserted at the front of the publication binder. Remove the indicated page(s) and replace it (them) with the

furnished Special Configuration supplemental page(s).

If the “Opt.” line contains a three digit number (for example, 641), there is combination of options and/or special modifications installed in the instrument. Information relating to these special configurations is contained

in supplemental pages included with the manual.

2500A Series Operation Manual, 34172 Revision C, March 2008

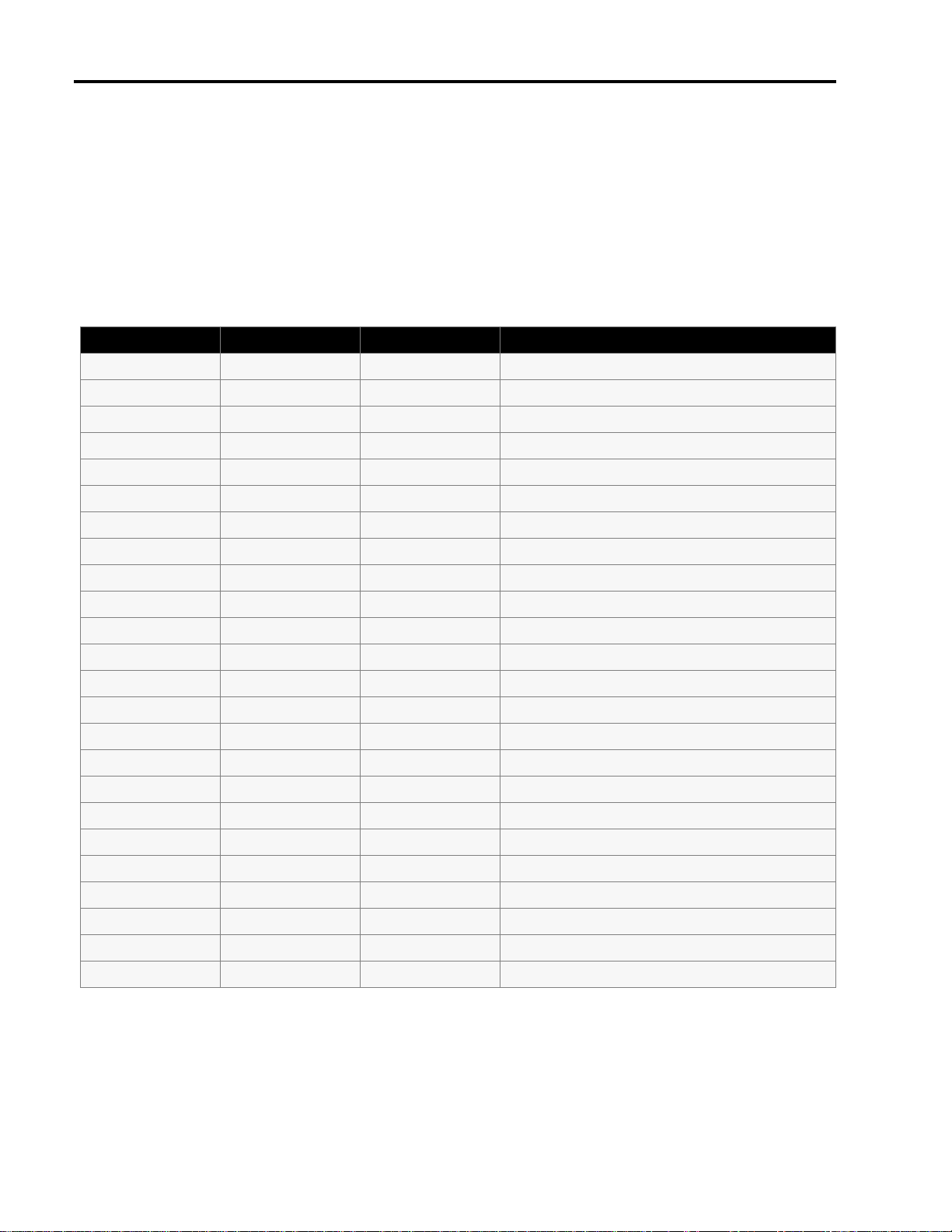

Record of Publication

Changes

This table is provided for your convenience to maintain a permanent record of publication change data.

Replacement pages will be issued as a TPCI (Technical Publication Change Instruction), and will be

inserted at the front of the binder. Remove the corresponding old pages, insert the new pages, and

record the changes here.

TCPI Number TPCI Issue Date Date Entered Comments

8 2500A Series Operation Manual, 34172 Revision C, March 2008

CHAPTER 1: 2500A INTRODUCTION

1.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.1.1 2500A Frequency Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.1.2 2500A Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.1.3 Items Furnished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.1.4 Items Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.1 Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.2 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.4 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.5 Line Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.6 Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.2.7 Reshipment Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3.1 Front Panel Connector (RF Output). . . . . . . . . . . . . . . . . . . . . . . . 19

1.3.2 Rear Panel Interface and I/O Connectors. . . . . . . . . . . . . . . . . . . . 19

Table of Contents

1.2.5.1 Line Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CHAPTER 2: FRONT PANEL OPERATION

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 Front Panel At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2.1 Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3 2500A Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.3.1 Menu System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.3.1.1 Menu Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.3.2 CW Menu Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3.2.1 Cable Cal Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.3.3 RAMP Menu Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.3.3.1 Ramp Freq 1 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.3.3.2 Ramp Freq 2 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3.3.3 Ramp Power Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.3.4 Step Sweep Freq Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.4 SYSTEM Menu Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.4.1 System 1 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.4.2 System 2 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.3.4.3 System Menu 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.3.4.4 System Menu 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2500A Series Operation Manual, 34172 Revision C, March 2008

9

2.3.5 AM Menu Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.3.5.1 External AM Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.3.5.2 AM - Internal Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.3.5.3 AM - Internal Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.3.6 FM Menu Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.3.6.1 FM - External Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.3.6.2 FM - Internal Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.3.6.3 DC FM Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.3.7 PM Menu Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.3.7.1 PM - External Source Menu . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.3.7.2 PM Internal-Continuous Menu . . . . . . . . . . . . . . . . . . . . . . . 47

2.3.7.3 PM Internal-Gated Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.3.7.4 PM Internal-Triggered Menu . . . . . . . . . . . . . . . . . . . . . . . . 50

2.3.8 Language Menu Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.3.8.1 Language Menu 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.3.8.2 Language Menu 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.3.8.3 Language Menu 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2.4 Front Panel Operating Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.4.1 Power-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.4.1.1 Normal Power-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.4.1.2 Errors During Power-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.4.2 Basic Operating Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.4.2.1 Resetting the System/Sanitization Procedure . . . . . . . . . . . . 57

2.4.2.2 Entering and Modifying Parameters . . . . . . . . . . . . . . . . . . . 57

2.4.3 Signal Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.4.3.1 Generating a CW Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.4.3.2 Generating an External ALC Leveled Signal . . . . . . . . . . . . 60

2.4.3.3 Using the Ref Tune Feature . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.4.3.4 Cable Correction Function . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.4.3.4 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.4.3.5 Configuring the 8650A Universal Power Meter . . . . . . . . . . 64

2.4.3.6 Configuring the Cable Correction Setup. . . . . . . . . . . . . . . . 64

2.4.3.7 Generating a Frequency Swept Signal . . . . . . . . . . . . . . . . . 65

2.4.3.8 Generating a Power Swept Signal. . . . . . . . . . . . . . . . . . . . . 65

2.4.3.9 Generating an Externally Pulse Modulated Signal . . . . . . . . 66

2.4.4 Remote Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.4.4.1 Setting the GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.4.4.2 Selecting the Remote Language . . . . . . . . . . . . . . . . . . . . . . 68

CHAPTER 3: REMOTE OPERATION

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10 2500A Series Operation Manual, 34172 Revision C, March 2008

3.1.1 What is Automation Xpress? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.1.2 Computer Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.2 SCPI Command Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.2.1 SCPI Command Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.2.2 SCPI Command Subsystems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.2.2.1 Output Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.2.2.2 Source Subsystem - CW Mode . . . . . . . . . . . . . . . . . . . . . . . 72

3.2.2.3 Source Subsystem - Correction. . . . . . . . . . . . . . . . . . . . . . . 73

3.2.2.4 Source Subsystem - List Mode . . . . . . . . . . . . . . . . . . . . . . . 73

3.2.2.5 Status Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.2.2.6 System Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.2.2.7 Trigger Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.2.2.8 Source Subsystem - Ramp Sweep. . . . . . . . . . . . . . . . . . . . . 77

3.2.2.9 Source Subsystem- Modulation . . . . . . . . . . . . . . . . . . . . . . 78

3.3 IEEE 488.2 Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.4 2500A Specific Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.5 Status Register System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.5.1 Status Byte (STB) and Service Request Enable (SRE)

Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.5.2 Standard Event Status (ESR) and Standard Event Status

Enable (ESE) Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.5.3 Questionable Status Condition and Enable Registers . . . . . . . . . . 85

3.5.4 List Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.5.4.1 Example: List Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

CHAPTER 4: SPECIFICATIONS & PERFORMANCE VERIFICATION

4.1 Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.2.1 Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.2.1.1 Frequency Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.2.2 Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.2.3 Spectral Purity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4.2.4 List Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.2.5 Amplitude Modulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4.2.6 Frequency Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4.2.7 Pulse Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4.2.8 External ALC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.2.9 Internal Modulation Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4.2.10 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.3 Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.3.1 Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2500A Series Operation Manual, 34172 Revision C, March 2008

11

4.3.2 Performance Tests: All 2500A Series . . . . . . . . . . . . . . . . . . . . . . 99

4.3.2.1 Frequency Range, Resolution & Accuracy. . . . . . . . . . . . . . 99

4.3.2.2 Spectral Purity Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4.3.2.3 RF Output Power Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4.3.3 Performance Tests: 2500A Series . . . . . . . . . . . . . . . . . . . . . . . . . 104

4.3.3.1 Amplitude Modulation Tests . . . . . . . . . . . . . . . . . . . . . . . . 104

4.3.3.2 Frequency Modulation Tests. . . . . . . . . . . . . . . . . . . . . . . . . 107

4.3.3.3 Pulse Modulation Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.3.3.4 Internal Modulation Generator Tests . . . . . . . . . . . . . . . . . . 114

4.3.4 2500A Series Test Datasheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

APPENDIX A: ACCESSORIES & OPTIONS

A.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

A.2 List of Accessories and Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

APPENDIX B: ERROR MESSAGES

B.1 Start-Up Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

B.2 NVRAM Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

B.2.1 NVRAM Reset Due to a Firmware Upgrade . . . . . . . . . . . . . . . . 127

B.2.2 NVRAM Reset Due to a Battery Failure . . . . . . . . . . . . . . . . . . . 127

B.2.3 NVRAM Reset Due to a Checksum Failure . . . . . . . . . . . . . . . . . 127

B.3 Remote Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

12 2500A Series Operation Manual, 34172 Revision C, March 2008

2500A Introduction

1

1.1 Overview

The Giga-tronics 2500A Microwave Synthesizers deliver industry-leading performance combining outstanding low phase noise performance, high output power, and fast switching simultaneously. These features of the 2500A Synthesizer family make it an excellent test solution for a wide range of CW,

modulation, swept frequency, and fast frequency switching RF and Microwave applications in both R&D

and manufacturing environments. All 2500A Synthesizers comply with MIL-PRF-28800F, Class 3.

The 2500A Synthesizer family is available in two series, with four unique models within each series.

Table 1-1 lists the model numbers, and the frequency ranges covered by each model.

2500A Series. The 2500A Series includes frequency ranges from 100 kHz to 8 GHz, 20 GHz,

26.5 GHz, and 40 GHz. In addition, external ALC, ramp frequency and power sweep, high stability timebase, 100 MHz reference output, DC-FM, AM, FM, and Pulse capability, and Automation Xpress Interface software and rack ears are all standard features.

1.1.1 2500A Frequency Ranges

Table 1-1 shows the various models of the 2500A Series Microwave Synthesizers, and their respective

RF output frequency ranges:

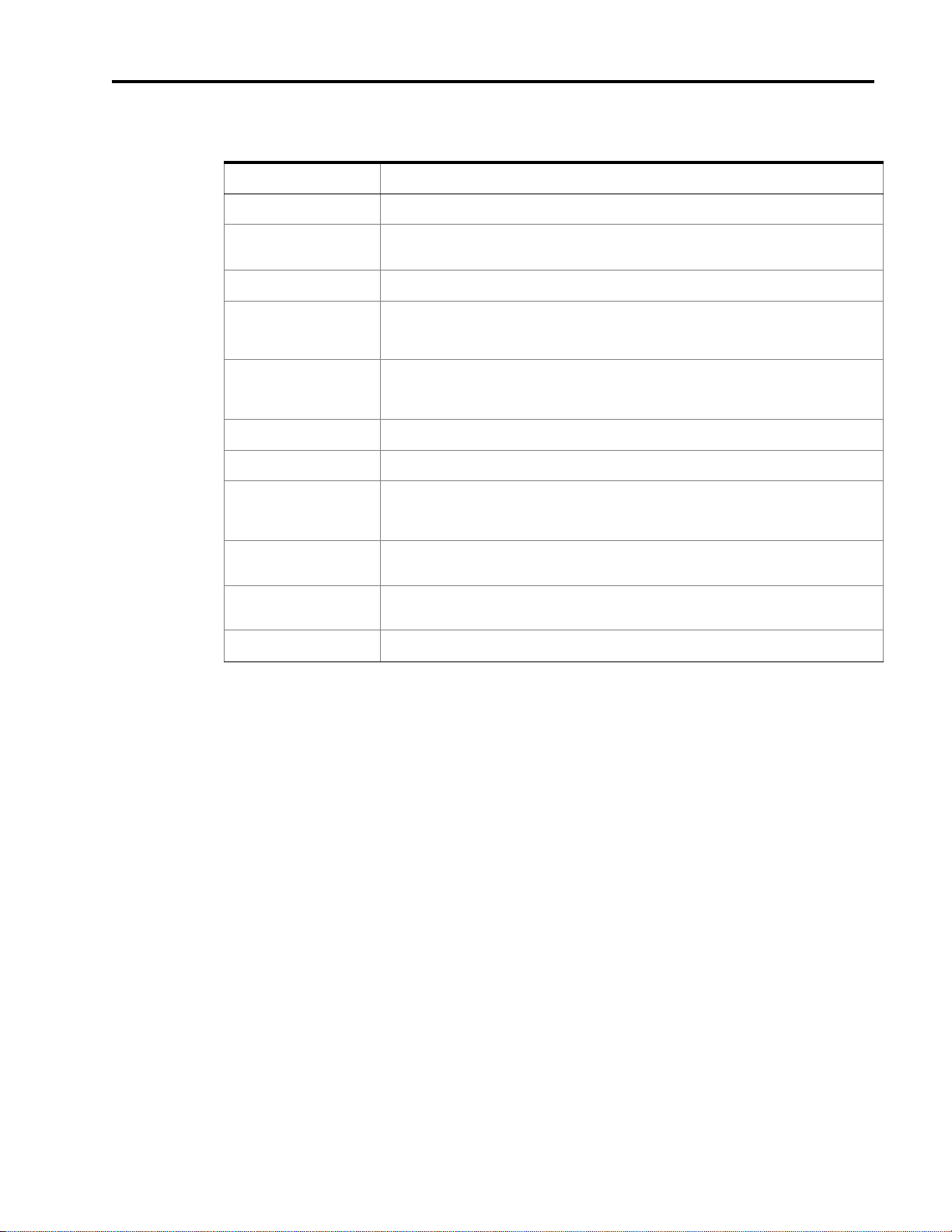

Table 1-1: 2500A Frequency Ranges

Models Frequency Range

2508A/2508AS 100 kHz to 8 GHz

2520A/2508AS 100 kHz to 20.199 GHz

2526A/2508AS 100 kHz to 26.5 GHz

2540A/2508AS 100 kHz to 40 GHz

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 1: 2500A Introduction

1.1.2 2500A Options

The following briefly describes the options that are available within the various series of the 2500A.

Appendix A further describes the options:

• Option 17A- Delete Modulation

• Option 17B - Delete Modulation Function Generator

• Option 18- Delete 10 MHz - 2 GHz Frequency Extension

• Option 23 - Type N Connector (2520 Models only)

• Option 26- Delete 90 dB Step Attenuator

• Option 31- Reduced Frequency Switching and Pulse Width Performance

• Option 44- Delete Display Front panel

• Option 46- Rack Slide Kit

• Option 55- Command Sets

• 55A - HP 8370

• 55B - HP 8340

• 55C - HP 8673

• 55D - HP 8662

• 55E - Systron-Donner 1720

• 55F - Wavetek 90X

• 55G - HP 8350

• 55H - HP 8360

1.1.3 Items Furnished

Accessories and Options are detailed in Appendix A of this publication. In addition to the options and/or

accessories specifically ordered, the following items are furnished with the instrument:

• Operation Manual

• USB 1.1/RS-232 Cable Adapter

• Power Cord, 6 ft.

• Giga-tronics Automation Xpress Software Package

1.1.4 Items Required

No special items are required to operate the 2500A Series during local (front panel) operation. Remote

operation requires some of the following items depending on the interface used:

• IEEE 488 Interface Cable

• PC with GPIB, RS-232, or USB

14 2500A Series Operation Manual, 34172 Revision C, March 2008

• Standard 9 Pin Type D Serial Cable

Test equipment required for performance verification is described in Chapter 4.

1.2 General Information

All instruments are shipped in operational condition. No special installation procedures are required.

Each 2500A Series model must pass rigorous inspections and tests prior to shipment. Following installation, a performance verification should be performed to ensure that operation has not been impaired during shipment. The following below apply to all models:

• Unless otherwise stated, warm-up time of 30 minutes for normal operation

• Performance Verification procedures are outlined in Chapter 4

1.2.1 Receiving Inspection

General Information

Use care when removing the instrument from the carton and immediately inspect for physical damage,

such as bent or broken connectors on the front and rear panels, dents or scratches on the panels, broken

handles, etc. Check the shipping carton for evidence of physical damage and immediately report any

damage to the carrier.

1.2.2 Cooling

A cooling fan is installed in all 2500A Series instruments. The cooling air intake is located on the rear

panel. Care must be taken to avoid obstructing the flow of air into the instrument.

1.2.3 Cleaning

The air intake screen should be cleaned whenever a significant amount of dust has accumulated on it.

Whenever the instrument covers are removed, the interior should be blown out with a dry air at a low

velocity.

1.2.4 Power

All 2500A models contain primary and standby power with internal switching. The instrument automatically senses input line voltage in the range of 90 to 253 Vac, 47 to 440 Hz. There are no manual voltage

adjustments or selection controls (the voltage select wheel within the power module is not used in the

2500A). All 2500A Series have a 3-Wire power cord with a 3-terminal polarized plug for connection to

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 1: 2500A Introduction

the power source and safety ground. The power cord must not exceed 3 meters (9 feet) to meet safety

requirements.

16 2500A Series Operation Manual, 34172 Revision C, March 2008

The safety ground is connected directly to the chassis. If a 3-to-2 wire adapter is to be used, be sure

to connect the ground lead from the adapter to earth ground. Failure to do this poses a shock hazard.

DO NOT position the equipment so that it is difficult to remove the AC line cord.

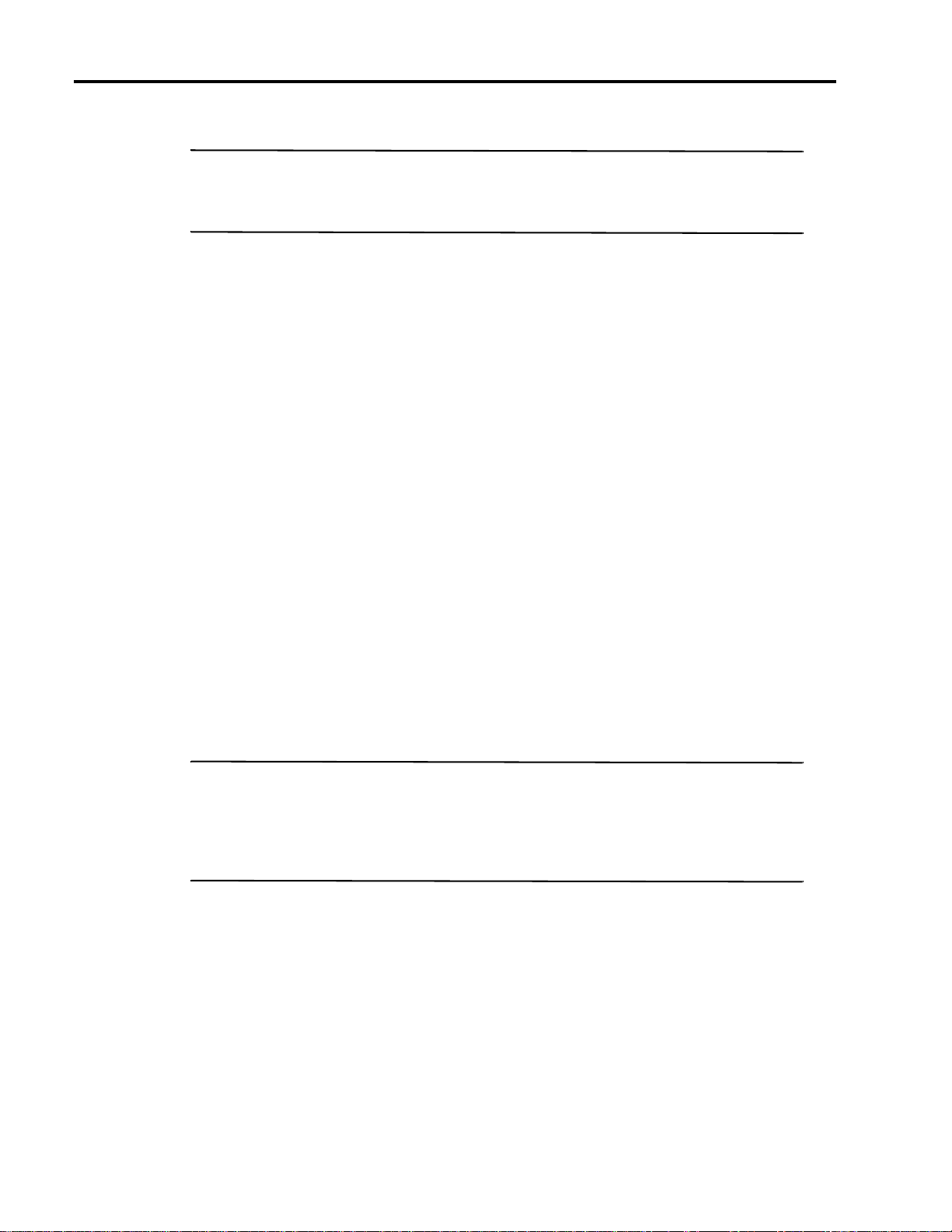

1.2.5 Line Fuse

WARNING

CAUTION

WARNING

General Information

All 2500A Series models have a line fuse holder on the rear panel. The power line fuse is 2A, SlowBlow, 250V, Type T. See Figure 1-1 below for the location of the line fuse.

Not Used

COVER

FUSE AND

FUSE HOLDER

AC POWER

INPUT

Figure 1-1: Fuse Holder

1.2.5.1 Line Fuse Replacement

Open the housing cover. Pull out the small drawer on the right side of the housing (marked with an

arrow) and remove the old fuse. Replace with a new fuse, insert the drawer and close the housing cover,

see Figure 1-1, above.

1

1

0

1

2

0

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 1: 2500A Introduction

NOTE: The voltage select wheel shown in Figure 1-1, above, can be set at any position. Its position

has no effect on the 2500A line voltage, as the 2500A line voltage is auto-sensing and autosetting.

1.2.6 Calibration Cycle

Giga-tronics recommends a calibration cycle of two years for the 2500A.

1.2.7 Reshipment Preparation

If it is necessary to return the instrument to the factory, protect it during reshipment using the best packaging materials available. If possible, reuse the original shipping container. If the original shipping container is not available, use a strong carton (350lbs./ sq.in. bursting strength) or a wooden box. Wrap the

instrument in heavy paper or plastic before placing it into the shipping container. Completely fill the

areas on all sides of the instrument with packaging material. Take extra precaution to protect the front

and rear panels. Seal the package with strong tape or metal bands. Mark the outside of the package as follows:

FRAGILE - DELICATE INSTRUMENT

If corresponding with the factory or local Giga-tronics sales office regarding reshipment, please provide

the model and serial number. If the instrument is being returned for repair, be sure to enclose all relevant

information regarding the problem that has been found.

NOTE: If returning an instrument to Giga-tronics for service, first contact Customer Service so that a

return authorization number (RMA) can be assigned. Contact Giga-tronics via email

(repairs@gigatronics.com) or by phone (800.726.4442). The 800 number is only valid within

in the United States. Contact can also occur via our domestic line at (925.328.4640) or Fax at

(925.328.4702).

1.3 Inputs and Outputs

The input and output connectors are shown in figures 1-2 and 1-3. Table 1-3 contains the front and rear

panel I/O connector functional descriptions for all 2500A Series models.

18 2500A Series Operation Manual, 34172 Revision C, March 2008

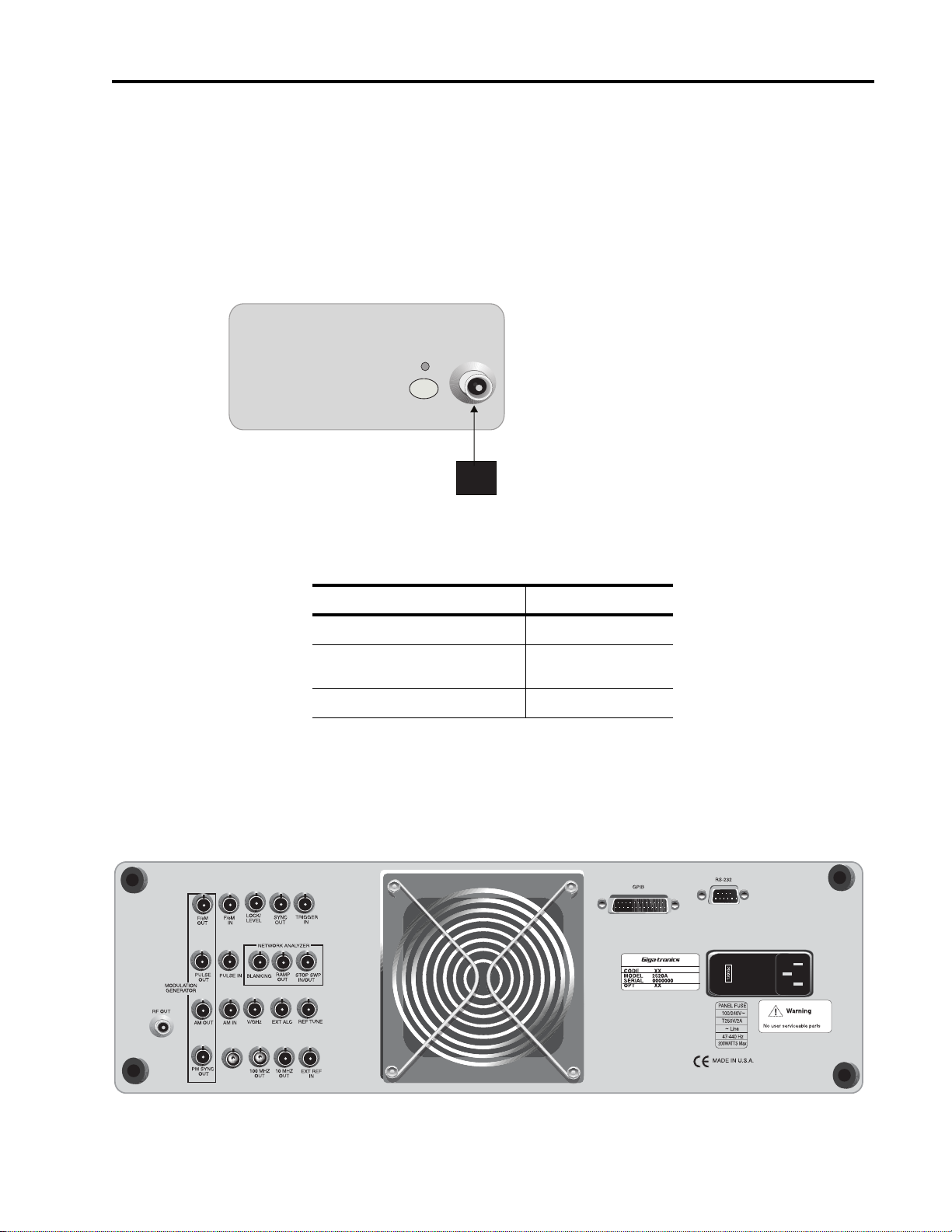

1.3.1 Front Panel Connector (RF Output)

This is the instrument’s RF output. It is located on the front panel of 2500B Series Synthesizer models,

and on the rear panel of versions of 2500S Series models.

The type of RF connector that is supplied depends on the frequency range of the instrument. Figure 1-2

shows the general location of the front panel RF output connector on 2500B Series models, and

Table 1-2 indicates by model the type of RF connector that is supplied.

RF

ON

RF OUT

Figure 1-2: Series 2500B Front Panel Output

ALC IN

Inputs and Outputs

Table 1-2: RF Connector Types

Models RF Connector Type

2508A/2508AS N (f)

2520A/2520AS

2526A/2526AS

2540A/2540AS K (f)

SMA (f)

1.3.2 Rear Panel Interface and I/O Connectors

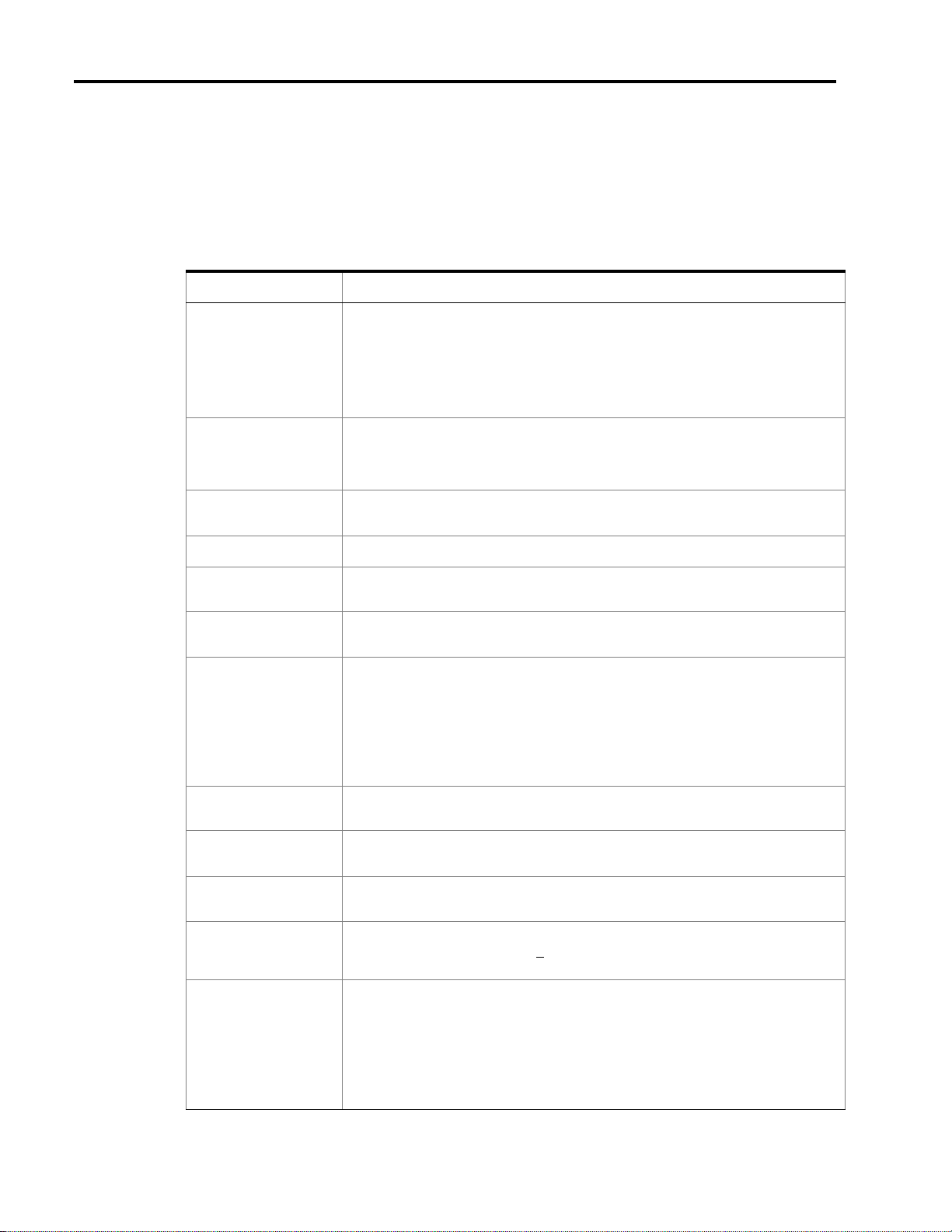

This section defines the functions of the 2500A Series rear panel connectors (see Figure 1-3).

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 1: 2500A Introduction

Figure 1-3: 2500A Rear Panel

All rear panel I/O connectors explained in this section are type BNC unless otherwise stated. Some connectors may not be supported because of installed options. For example, Modulation and Modulation

Generator connectors are not active with Option 17A or 17B. Table 1-3 describes the 2500A rear panel

I/O connectors.

Table 1-3: 2500A Rear Panel I/O Connector Descriptions

Connector Label Description

EXT ALC In external leveling, the output of the 2500B is detected by either a positive or negative

crystal detector or power meter with an analog output. The signals from these devices

are connected to the ALC circuitry of the 2500B which is used to compensate for

standing wave effects or cable and component losses at the input of the device under

test.

See Section 4.2.8 for External ALC specifications

RF OUT The RF signal output for the instrument. See Table 1-2 for RF connector types.

It is located on the front panel for all 2500B Series instruments and rear panel for all

2500S Series instruments.

FM OUT

1

The internal modulation generator output;

2 Vp-p into 10k Ω.

PULSE OUT

AM OUT

1

1

A +4V video representation of the pulsed RF output signal.

The internal modulation generator output;

2 Vp-p into 10k Ω.

PM SYNC OUT

1

A synchronization output pulse of >75 ns width, TTL level that can be delayed relative

to the leading edge of the video signal at the PULSE OUT connector.

2

FM IN

A 50 Ω input for an external FM signal. The input signal can be any waveform

compatible within bandwidth considerations. A 1 Vp input produces maximum

deviation.

An externally supplied DC signal can be applied to modulate the frequency of the CW

output using this connector.

See Section 4.2.6 for DC FM specifications

AM IN

2

A 600 Ω input for an external AM signal. The input signal can be any waveform

compatible within bandwidth considerations. A 1 Vp-p input produces 50% AM depth.

PULSE IN/PM TRIG IN2A Pulse Modulation Input for external pulse gating, pulse triggering or external Pulse In.

The input parameters are +5 volt, 50 Ω

LOCK/LEVEL +5 volt indicator, active high when the 2500A is phase locked and output leveled. The

Lock and Level indicator is valid for CW mode only.

REF TUNE A 0 to +10 volts, high impedance input for tuning the internal reference for adjusting the

output frequency approximately +

5 ppm. Do not exceed +15 volts or apply a negative

voltage greater than -1 volt.

SYNC OUT In List mode, the unit can be set to generate a pulse at this output when a specified list

point is reached. The output can be delayed from the start of the list point up to a

maximum of 10 msec. The pulse width of the SYNC OUT signal is determined by the

following parameters: pulse width = Step Time - Sync Delay - 10 usec

In Ramp operation, the pulse occurs at the start of each ramp sweep.

In either case, the output pulse is +5 volt.

20 2500A Series Operation Manual, 34172 Revision C, March 2008

Inputs and Outputs

Table 1-3: 2500A Rear Panel I/O Connector Descriptions

Connector Label Description

TRIGGER IN Used to trigger a List. Accepts a TTL level signal of > 50 ns width.

BLANKING A +5 volt output signal occurring at band crossings, filter switches, and retraces for the

duration of those events.

RAMP OUT A 0 to 10 volt ramp output scaled to the frequency sweep.

STOP SWP IN/OUT Stop Sweep I/O is a 5 volt, 2 K Ω, active low signal that temporarily interrupts an

instrument frequency or power ramp sweep. This feature is only available with 2500B

models with option 55 and 2500S models with options 55 and 44.

V/GHz An output voltage that is directly proportional to output frequency. For 26 and 40 GHz

models, the output is 0.25 volts per GHz. For 8 and 20 GHz models, the output is 0.5

volts per GHz.

100 MHz OUT A +5 dBm typical, AC coupled, 100 MHz low noise reference output signal into 50 Ω

10 MHz OUT A 2 Vp-p 10 MHz square wave reference output signal into 50 Ω.

EXT REF IN The external reference input. Can be either a 10 MHz input that is >-5.0 dBm into 50 Ω

or a 100 MHz input > +5 dBm. The 100 MHz input level should not exceed +8 dBm for

best performance.

GPIB A 24-pin IEEE STD 488.2 connector for control of the instrument during remote

operation using GPIB.

RS-232 A DB-9 connector for control of the instrument during remote operation using RS-232

serial communications.

AC Power Input 90-253 VAC, auto-sensing, 47 Hz to 440 Hz.

1. Not available with Option 17A or 17B.

2. Not available with Option 17A

.

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 1: 2500A Introduction

22 2500A Series Operation Manual, 34172 Revision C, March 2008

Front Panel Operation

2

2.1 Introduction

This chapter describes how to operate the 2500A Series from the front panel.

The information in this chapter pertains primarily to the 2500A Series of Gigatronics Microwave Synthesizers. Note, however, that while the menus, key sequences, etc., presented in this chapter pertain primarily to front panel operation, the features explained are universal for either the front panel or remote

operating modes.

NOTE: Chapter 3 provides instructions on using the 2500A Series from a remote host computer over

the General Purpose Interface Bus (GPIB), an RS-232 serial connection, USB or Ethernet.

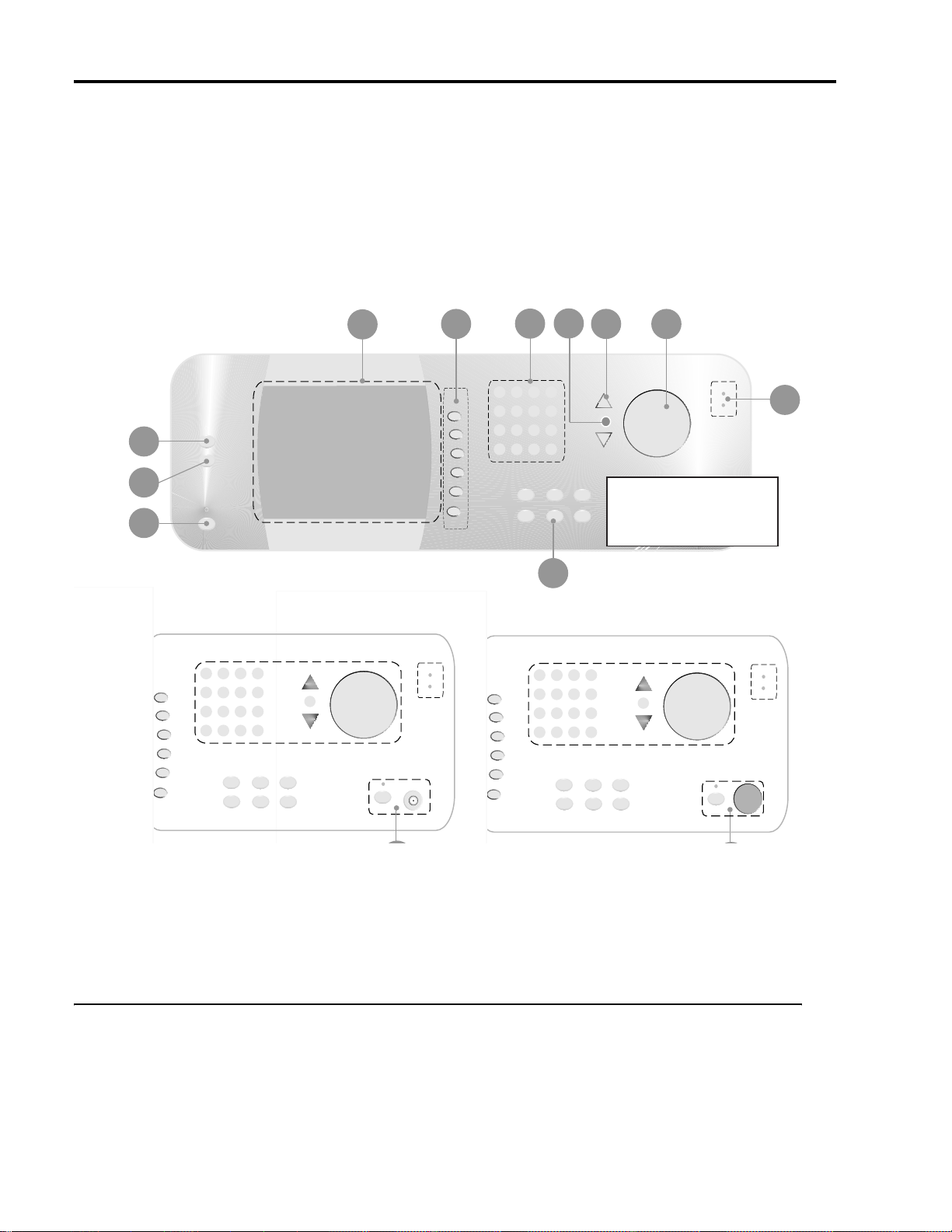

2.2 Front Panel At a Glance

The 2500A Series front panel contains the controls and display for local operation of the instrument.

Some functions are not available from the front panel; they require use of a PC with a compatible remote

interface. Front panel controls are grouped according to the functions they perform. Descriptions for the

front panel controls are referenced to the numbers depicted in Figure 2-1 on the next page.

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

4

5

6

8

7

9

10

3

2

1

Microwave Synthesizers

Bottom Sectional Differential

See A for 2500A Series

See B for 2500AS S eries

12

Front Panel Layout of 2500 Series Microwave Synthesizers

Figure 2-1: 2500A Front Panel with Callouts

2.2.1 Front Panel Description

Power

The main power switch for the 2500A, which is used to set the power either to on or standby. A blue

indicator indicates that main power button is blue, an amber indicator indicates that the main power is off

but power is applied to the internal timebase oscillator.

24 2500A Series Operation Manual, 34172 Revision C, March 2008

LOCAL Button

1

PRESET Button

Front Panel At a Glance

Allows front panel access when the unit is in remote mode. If the unit is already in local mode, pressing

this button accesses menus that allow you to choose the remote command language to be used by the

instrument while remote operation.

Presets the 2500A to factory defaults, or initializes NVRAM.

2

3

Display

4

Interactive Softkeys

Data Entry Keypad

• Pressing the PRESET button momentarily presets instrument settings to factory default values, but

does not affect system memory locations, display contrast, or the GPIB address.

• Pressing and holding the PRESET button while the unit is powering up initializes NVRAM, which

includes presetting instrument settings to factory default values as well as initializing all ten system

memory locations, the display contrast, and the GPIB address.

Displays current instrument settings, as well as the menus that allow you to modify the settings. The

group of instrument settings and associated menu items that are currently displayed is called the active

display.

Menus are accessed by pressing the menu buttons. The menus appear along the right-hand side of the display adjacent to the interactive softkeys. To select a particular menu item, press the adjacent interactive

softkey. Modify the parameter using the data entry keypad, step-up/step-down buttons, or knob.

Selects the menu items adjacent to them in the display for modification.

A 12-button numeric keypad and adjacent Units buttons for direct entry of instrument parameters.

STEP SIZE Button

5

Selects and allows editing of the step size used by the Step Up/Down buttons and rotary knob. To change

a step size, choose a menu item, press the STEP SIZE button, enter the step size using the keypad, then

press the appropriate units button.

6

Step Up/Down Buttons

Increases or decreases the selected parameter in the display by the amount specified by the step size.

7

Rotary Knob

Increases or decreases the parameter that is selected in the display. When a maximum or minimum limit

is reached, a message will be displayed at the bottom of the display indicating that the parameter limit

has been reached.

8

Front Panel LED indicators

The front panel indicators are located in several places.

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

9

10

RF Output

Menu Buttons

11

Unleveled Indicator. This indicator is lit when the 2500A output is operating in an unleveled state.

External Reference (Ext Ref) Indicator. This indicator is lit when the 2500A is operating with an

external reference applied.

RF On/Off Indicator. This indicator, which is located above the RF ON button, is blue when the 2500A

RF output is active. When the RF output is inactive, the indicator is not lit.

Power Indicator. This indicator, which is above the main power button, is blue when the unit is on, and

amber when the unit is in standby mode.

This is the RF output section for 2500A Series instruments. The 2500A series connector is located on the

lower left portion of the front panel.

CW Button. Pressing this button displays the CW Menu, which shows parameters related to the CW

functions of the instrument, and the Cable Correction functions and their associated menu items.

RAMP Button. Pressing this button displays either the Ramp Freq or Ramp Power Menu, which shows

parameters related to either the frequency or power ramp (sweep) functions of the instrument, and their

associated menu items.

SYSTEM Button. Pressing this button displays either the System 1 or System 2 Menu, which shows

parameters related to certain system-level functions, and their associated menu items.

12

AM Button. Amplitude modulation is not available on the 2500A.

FM Button. Frequency Modulation is not available on the 2500A.

PM Button. Pressing this button displays the External PM Menu which shows parameters related to the

pulse modulation functions of the instrument, and their associated menu items.

2.3 2500A Menus

This section provides a brief overview of the 2500A’s display and menus, and explains each of the

2500A menus in more detail.

26 2500A Series Operation Manual, 34172 Revision C, March 2008

2.3.1 Menu System Overview

SYSTEM 1

OFS SLP

To Register (0-9)

No register has been saved

8

ON

Save

Recall

Sound

Contrast

Auto

Attenuation

System 2

Menu

AM FM PM

Contrast must be <= 15

Menu Area

Mode Indicators

Menu Name

Parameter Area

Error/Step Size Area

Display

Interactive

Softkeys

2.3.1.1 Menu Buttons

Most 2500A features and functions are accessed through a series of menus. The menus are accessed by

pressing one of the menu buttons that are on the front panel of the instrument. As an example, to access

the System menus, press the SYSTEM button:

The following menu buttons are available:

CW, RAMP, SYSTEM, PM, LOCAL.

2500A Menus

The 2500A’s front panel display is divided into several functional areas, as shown in Figure 2-2:

Figure 2-2: Functional Areas of the 2500A Display

The following explains each of the functional areas of the display shown in Figure 2-2:

Menu Name. This is the name of the menu that is currently shown in the front panel display. The menu

that is currently shown is called the active menu.

2500A Series Operation Manual, 34172 Revision C, March 2008

Menu Area. This area displays the various menu choices that are available in the active menu. The row

containing the menu item and parameter that is currently selected is surrounded by bold lines.

Chapter 2: Front Panel Operation

Parameter Area. This area displays the current values of the instrument settings that are associated with

the active menu. Parameters can be modified.

Error/Step Size Area. If applicable, this area shows the currently set step size for the parameter that is

selected for modification. Certain non-error user messages might also be displayed in this area.

Mode Indicators. Indicators will appear in this area of the display if the instrument is currently in any of

several operating modes. If the instrument is currently in a given operating mode, its indicator will

appear regardless of the menu that is currently active. The following indicators are available:

OFS - Appears if a power offset of greater than 0 dB is set in the CW menu.

SLP - Appears if a power slope of greater than 0 dB/GHz is set in the CW menu.

PM - Appears if either internal or external pulse modulation is currently enabled.

EXT. LEVEL - Appears if the ALC is set to External.

UNLK - Appears if the Phase Lock Loop is unlocked.

OVEN COLD - Appears if the internal temperature of the 2500A has not reached operational tem-

perature. It is not recommended to use the 2500A while this indicator is active.

2.3.2 CW Menu Descriptions

The CW menus display the instrument’s currently set CW (continuous wave) frequency, power level,

power offset, and power slope, and allows you to make changes to those settings. The Cable Cal menu

allows you to perform and a apply a cable offset correction to the CW menu power level setting. The

Cable Cal feature requires a Giga-tronics 8650A series power meter or any power meter with a SCPI

compatible command set. To access the CW menu, press the front panel CW menu button:

There are two menus associated with the CW menu button. Figure 2-3 shows the CW menu:

28 2500A Series Operation Manual, 34172 Revision C, March 2008

CW MENU

2500A Menus

6.00 GHz

3.21 dBm

0.00 dB

0.00 dB/GHz

0 Degrees

Step Size: 0.1 Hz

Frequency

Power

Power Offset

Power Slope

Phase

Cable Cal

Menu

Figure 2-3: CW Menu with Interactive Softkeys

The following explains each item in the CW menu:

Frequency. This menu item displays and allows you to modify the instrument’s CW frequency. The

range of the CW frequency parameter is dependent on the model number of the instrument.

Power. This menu item displays and allows you to modify the instrument’s output power level. The

range of the output power level depends on the following configuration and settings of the instrument:

Power Offset. This menu item displays and allows you to modify the instrument’s power offset. The

power offset feature increases the instrument’s output power by the amount of the power offset setting,

without changing the power level as shown in the Display. This allows you to compensate for the insertion or conversion loss of components that are attached to the instrument’s RF output. An example

appears in Figure 2-4.

2400LMicrowave Synthesizer

Power Level Setting = +10 dBm

Power Offset Setting = 2.23 dB

Figure 2-4: Power Offset Example

The Power Offset indicator (OFS) appears in the upper right-hand corner of the display when any power

offset value greater than 0.00 dB is entered.

Power Slope. This menu item displays and allows you to modify the instrument’s power slope. The

power slope feature increases the instrument’s output power linearly as a function of the output frequency. The power slope function allows you to automatically compensate for insertion/conversion

losses of components attached to the instrument’s RF output that exhibit a linear loss characteristic with

2500A Series Operation Manual, 34172 Revision C, March 2008

RF Mixer

×

Conversion Loss = 2.23 dB

+10 dBm is present

at the output of

the RF mixer

Chapter 2: Front Panel Operation

frequency. The Power Slope indicator (SLP) appears in the upper right-hand corner of the display when

any power slope value greater than 0.00 dB/GHz is entered.

Phase Adjust. This menu item displays and allows you to modify the phase of the output signal. The

phase of the signal is maintained until the phase is readjusted or whenever the instrument frequency setting is changed. When the instrument frequency setting is changed, the phase adjust setting is reset to 0

degrees. Phase Adjust is specified for a minimum frequency range of 500 MHz to the maximum frequency range of the instrument. Phase adjust is available for frequencies below 500 MHz however the

output response time of the phase adjust is decreased.

Specifications:

Frequency: 500 MHz to maximum frequency

Range:

Accuracy: <0.2

±360 degrees

°, typical

2.3.2.1 Cable Cal Menu

This menu allows you to generate an offset table for use with the power level setting in the CW menu

using the pre-selected power meter and RS-232 interface. Figure 2-5 shows the Cable Cal RS-232 menu.

A similar menu is displayed if an Agilent EPM power meter is selected.

Cable Cal: RS-232

Cable Cal Cleared

1. Connect NULL modem cable between 2400B & 8650A RS-232 ports

2. Connect BNC cable between 2400B Sync Out and 8650A Trig In

3 Connect calibrated sensor on 8650A Chan A to 2400B RF Out cable

4. Set 8650 RS232 baud rate to 38400 and press Start Cable Cal

Cable Cal sweeps from 10 MHz to 20 GHz.

Cable Cal Setup

Use appropriate sensor

Figure 2-5: Cable Cal RS-232 Menu

2.3.3 RAMP Menu Descriptions

The RAMP menus display the instrument’s currently set ramp frequency sweep and ramp power sweep

settings, and allow you to make changes to those settings.

Start

Cable Cal

Clear

Cable Cal

CW

Menu

There are 7 menus associated with the RAMP menu button. There is one top level menu that alllows

access to any of the 6 sweep function menus. Figure 2-6 shows the Sweep Main Menu.

30 2500A Series Operation Manual, 34172 Revision C, March 2008

Figure 2-6: Top Level Sweep Menu

Ramp Freq Start/Stop Sweep Menu. Pressing this softkey invokes the Ramp Freq Start/Stop menu in

the display. See “Ramp Freq 1 Menu”, for Ramp Freq menu item descriptions.

Ramp Freq Center/Span Sweep Menu. Pressing this softkey invokes the Ramp Freq Center/Span

menu in the display. See “Ramp Freq 2 Menu”, for Ramp Freq menu item descriptions.

Ramp Power Sweep Menu. Pressing this softkey invokes the Ramp Power Sweep menu in the display.

See “Ramp Power Menu”, for Ramp Power menu item descriptions.

Step Freq Sweep Menu. Pressing this softkey invokes the Step Freq Sweep menu in the display. See

“Step Sweep Freq Menu”, for Step Frequency Sweep menu item descriptions.

2.3.3.1 Ramp Freq 1 Menu

The Ramp Freq 1 menu will generate a frequency sweep where the start and stop frequencies are specified. The Ramp Freq 1 menu allows you to view and modify settings related to the instrument’s frequency sweep features. When this menu is used, the frequency of the RF output can be swept linearly

from a predetermined start frequency to a predetermined stop frequency in a predetermined sweep time.

2500A Menus

NOTE: As soon as any Ramp or Step menu is chosen, the instrument calculates the sweep, then

begins sweeping the output frequency. The ramp is recalculated whenever a parameter is

changed. During calculations, the following message is shown at the bottom of the display:

Preparing sweeping data...

When the calculations are complete and the output is actively sweeping, the following message is shown:

Ramp sweeping

Figure 2-7 shows the Ramp Freq 1menu:

RAMP FREQ 1

10.00 MHz

20.0 GHz

0.00 dBm

1.00 Sec

Start Frequency

Stop Frequency

Power

Sweep Time

401

Ramp sweeping

Resolution

Ramp Freq 2

Menu

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

Figure 2-7: Ramp Freq Menu with Interactive Softkeys

The following explains each item in the Ramp Freq menu:

Start Frequency. This menu item displays and allows you to modify the ramp start frequency. This is

the frequency that will be used as the starting frequency of the frequency sweep. Note that the start frequency must be less than the stop frequency. If the start frequency is set higher than the stop frequency,

the stop frequency is automatically adjusted to the same value.

Stop Frequency. This menu item displays and allows you to modify the ramp stop frequency. This is the

frequency that will be used as the ending frequency of the frequency sweep. Note that the stop frequency

must be greater than the start frequency. If it is set lower than the start frequency, the start frequency is

automatically adjusted to the same value.

Power. This menu item displays and allows you to modify the output power level to be used during the

frequency sweep. The range of the power level depends on the following configuration and settings of

the instrument:

Sweep Time. This menu item allows you to view and modify the sweep time. This is the amount of time

that elapses for one cycle of a frequency sweep to complete.

Resolution. This menu item allows you to view and modify the sweep step resolution. The sweep step

resolution can be set to 401, 801 and 1601 frequency steps.

Ramp Freq 2 Menu. Pressing this softkey invokes the Ramp Freq 2 menu (Center/Span Frequency)

menu in the display.

2.3.3.2 Ramp Freq 2 Menu

The Ramp Freq 2 Menu will generate a ramp frequency sweep where the center frequency and sweep

span paramters are specified. The menu allows you to view and modify settings related to the instrument’s frequency sweep features. When this menu is used, the frequency of the RF output can be swept

linearly referenced from the center frequency with a predetermined span frequency in a predetermined

sweep time.

Figure 2-8 shows the Ramp Freq Start/Stop menu:

RAMP FREQ 2

10.00 MHz

20.0 GHz

0.00 dBm

Center Freq

Span

Power

1.00 Sec

401

Ramp Sweeping

Sweep Time

Resolution

Ramp Power

Menu

Figure 2-8: Center/Span Ramp Freq Menu with Interactive Softkeys

32 2500A Series Operation Manual, 34172 Revision C, March 2008

2500A Menus

The following explains each item in the Ramp Freq Center/Span menu:

Center Frequency. This menu item displays and allows you to modify the ramp start frequency. This is

the frequency that will be used as the starting frequency of the frequency sweep. Note that the start frequency must be less than the stop frequency. If the start frequency is set higher than the stop frequency,

the stop frequency is automatically adjusted to the same value.

Span Frequency. This menu item displays and allows you to modify the ramp span frequency. The span

determines the range of the frequency weep beginning at half the value of the span setting lower than the

center frequency and ending at a frequency one half the value of the span setting higher than the center

frequency.

Power. This menu item displays and allows you to modify the output power level to be used during the

center/span frequency sweep. The range of the power level can be set to any valid power setting of the

instrument.

Sweep Time. This menu item allows you to view and modify the sweep time. This is the amount of time

that elapses for one cycle of a frequency sweep to complete.

Resolution. This menu item allows you to view and modify the sweep step resolution. The sweep step

resolution can be set to 401, 801 and 1601 frequency steps.

Ramp Power Menu. Pressing this softkey invokes the Ramp Power menu in the display. See “Ramp

Power Menu”, below, for Ramp Power menu item descriptions.

2.3.3.3 Ramp Power Menu

The Ramp Power menu allows you to view and modify settings related to the instrument’s power sweeping feature. When this feature is used, the power level of the RF output sweeps linearly from a predetermined start power level to a predetermined stop power level in a predetermined amount of time, then

repeats. The power level can sweep from a lower to a higher power level, or vice versa. The output frequency is held at the same value during a power sweep. The maximum settable range for ramp power

sweep is 45 dB.

NOTE: As soon as the Ramp Power menu is chosen, the instrument calculates the ramp, then begins

sweeping the output power. The ramp is recalculated whenever a parameter is changed. During calculations, the following message is shown at the bottom of the display:

Preparing sweeping data...

When the calculations are complete and the output is actively sweeping, the following message is shown:

Ramp sweeping

Figure 2-9 shows the Ramp Power menu:

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

RAMP POWER

0.00 dBm

10.00 dBm

10.00 GHz

25.00 Sec

0

Ramp Sweeping

Start Power

Stop Power

Frequency

Sweep Time

Attenuation

Step Sweep

Menu

Figure 2-9: Ramp Power Menu with Interactive Softkeys

The following explains each item in the Ramp Power menu:

Start Power. This menu item displays and allows you to modify the ramp start power level. This is the

power level that will be used as the beginning of the power level sweep.

The range for the start power parameter is -20 dBm to +25 dBm if the 90 dB step attenuator is not

installed in the instrument. If the 90 dB step attenuator is installed, the start power range is from 25 dB

above to 20 dB below the step attenuator setting chosen.

Stop Power. This menu item displays and allows you to modify the ramp stop power level. This is the

power level that will be used as the end point of the power level sweep.

The range for the stop power parameter is -20 dBm to +25 dBm if the 90 dB step attenuator is not

installed in the instrument. If the 90 dB step attenuator is installed, the stop power range is from 25 dB

above to 20 dB below the step attenuator setting chosen.

Frequency. This menu item displays and allows you to modify the output frequency to be used during

the power level sweep. The range of the frequency parameter is dependent on the model number of the

instrument.

Sweep Time. This menu item allows you to view and modify the sweep time. This is the amount of time

that elapses for one cycle of a power level sweep to complete.

Attenuation. This menu item allows you to select a range of the step attenuator if it is installed in the

instrument. The step attenuator can insert up to 90 dB of attenuation into the RF output path of the instrument, in selectable 10 dB steps.

Step Sweep Menu. Pressing this softkey invokes the Ramp Freq menu in the display. See “Ramp Freq 1

Menu”, above, for Ramp Freq menu item descriptions.

2.3.3.4 Step Sweep Freq Menu

The Step Sweep menu allows you to view and modify settings related to the instrument’s frequency

sweeping feature. When this feature is used, the frequency of the RF output sweeps linearly from a predetermined start frequency to a predetermined stop frequency in a predetermined sweep time, then

34 2500A Series Operation Manual, 34172 Revision C, March 2008

2500A Menus

repeats. The sweep occurs in a set number of equal increments, as determined by the Resolution setting.

The output power is held at the same level during a frequency sweep.

NOTE: As soon as theStep Swep menu is chosen, the instrument calculates the ramp, then begins

sweeping the output frequency. The ramp is recalculated whenever a parameter is changed.

During calculations, the following message is shown at the bottom of the display:

Preparing sweeping data...

When the calculations are complete and the output is actively sweeping, the following message is shown:

Step sweeping

Figure 2-10 shows the Step Sweep menu:

RAMP FREQ

10.00 MHz

20.0 GHz

0.00 dBm

1.00 Sec

401

Start Frequency

Stop Frequency

Power

Sweep Time

Resolution

Ramp Power

Menu

Figure 2-10: Ramp Freq Menu with Interactive Softkeys

The following explains each item in the Ramp Freq menu:

Start Frequency. This menu item displays and allows you to modify the ramp start frequency. This is

the frequency that will be used as the starting frequency of the frequency sweep. Note that the start frequency must be less than the stop frequency. If the start frequency is set higher than the stop frequency,

the stop frequency is automatically adjusted to the same value.

Stop Frequency. This menu item displays and allows you to modify the ramp stop frequency. This is the

frequency that will be used as the ending frequency of the frequency sweep. Note that the stop frequency

must be greater than the start frequency. If it is set lower than the start frequency, the start frequency is

automatically adjusted to the same value.

Power. This menu item displays and allows you to modify the output power level to be used during the

frequency sweep. The range of the power level depends on the following configuration and settings of

the instrument:

Step Ti me. This menu item allows you to view and modify the step time. This is the amount of time that

a single frequency step is executed. When the last frequency in the step sweep is executed and com-

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

pleted, the sweep continues with the start frequency and cycles continuously until a change in the menu

made or

Step Size. This menu item allows you to view and modify the frequency step size. The step size can be

set to the minimum frequency resolution of the synthesizer to the maximum frequency range of the synthesizer.

Ramp Freq 1 Menu. Pressing this softkey invokes the Ramp Freq 1 menu in the display. See “Ramp

Freq 1 Menu”, below, for Ramp Power menu item descriptions.

2.3.4 SYSTEM Menu Descriptions

The System menus provide access to system-level settings, such as memory storage locations, GPIB

address configuration, display contrast, and system volume control. System information, including the

model number, serial number, firmware version, etc., can also be displayed. To access the

System menus, press the front panel SYSTEM menu button:

There are three menus associated with the SYSTEM menu button.

2.3.4.1 System 1 Menu

The System 1 menu allows you to save instrument states to non-volatile memory and subsequently recall

them, and view and set the display contrast, turn system sound (audio feedback) on or off, and view and

configure the step attenuator if the 90 dB step attenuator is installed.

Figure 2-11 shows the System 1 menu:

SYSTEM 1

To Register (0-9)

No register has been saved

8

ON

Auto

Figure 2-11: System 1 Menu with Interactive Softkeys

Save

Recall

Contrast

Sound

Attenuation

System 2

Menu

The following explains each item in the System 1 menu:

36 2500A Series Operation Manual, 34172 Revision C, March 2008

2500A Menus

Save. This menu item allows you to save the current state of the instrument to non-volatile memory, so

that the saved state can subsequently be restored. The 2500A contains ten registers, numbered 0 through

9, into which instrument states can be saved. Note that saving an instrument state to a given register overwrites any state that might have previously been stored in that register.

To save the current instrument configuration to a given register, select the Save menu item, enter the

number of the register into which you wish to save the configuration using the numeric keypad, then

press any units button.

Only the numeric keypad can be used to enter a register number; the step up/step down buttons and

rotary knob cannot be used.

Recall. This menu item allows you to recall a previously saved instrument state from any of the ten storage registers contained in the instrument’s non-volatile memory.

The parameter area in the display shows the following text:

From Register (X)

Where X is the list of registers, separated by commas, that currently have an instrument state saved in

them. For example, if instrument states are currently stored in registers 1, 2, and 5, the parameter area

would read as follows:

From Register (1, 2, 5)

If none of the registers have instrument states saved to them, as would be the case after the instrument’s

memory is cleared, the following is displayed in the parameter area:

No register has been saved

To recall a previously saved instrument configuration, press the Recall softkey, enter the number of the

register from which you wish to recall the configuration using the numeric keypad, then press any units

button.

Only the numeric keypad can be used to enter a register number; the step up/step down buttons and

rotary knob cannot be used.

Contrast. This menu item allows you to set the contrast of the instrument’s front panel display. The contrast range is 1 to 15, where 1 represents most contrast and results in the darkest display, and 15 represents least contrast and results in the lightest display.

Sound. This menu item allows you to enable or disable (mute) the system sound.

The available selections are ON and MUTE. When Sound is set to ON, the instrument provides audio

feedback whenever a button is pressed or the knob is rotated, and an operational error notification is

emitted when an error condition occurs, such as when an improper button sequence is pressed, a parameter limit is exceeded, etc.

Attenuation. This menu item provides control of the step attenuator if it is installed in the instrument.

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

The step attenuator can insert up to 90 dB of attenuation into the RF output path of the instrument. It is

switchable in 10 dB steps, and can be set to automatically switch as the instrument’s power level is varied, or it can be manually set to insert a fixed amount of attenuation.

System 2 Menu. Pressing this softkey invokes the System 2 Menu in the display. See “System 2 Menu”,

below, for System 2 Menu item descriptions.

2.3.4.2 System 2 Menu

The System 2 menu allows you to view and modify the instrument’s GPIB address, ALC setting, and

view system information.

Figure 2-12 shows the System 2 menu:

SYSTEM 2

6

Internal

General Information

Model: GT2520A

Version: XXXX

Serial Number: XXXX

Build Date/Time: Dec 1 2006, 18:40:31

GPIB Address

ALC

System 3

Menu

Figure 2-12: System 2 Menu with Interactive Softkeys

The following explains each item in the System 2 menu:

GPIB Address. This menu item allows you to set the instrument’s General-Purpose Interface Bus

(GPIB) address. The GPIB address range is 1 to 30.

ALC. This menu item allows you to set the instrument's ALC input. The ALC input settings are Internal,

Positive Detector, Negative Detector and Power Meter. External ALC enables the instrument to compensate for device transmission losses without user intervention.

General Information. This field displays 2500A system information. This information is for display

only; it has no associated menu choice. The following information is displayed:

• Model - This is the specific model number of the instrument.

• Version - This is the specific firmware version installed in the instrument.

• Serial Number - This is the instrument’s serial number.

• Build Date/Time - This is the date and time when the firmware version was created.

System 3 Menu Pressing this softkey invokes the System 3 Menu in the display.

38 2500A Series Operation Manual, 34172 Revision C, March 2008

2.3.4.3 System Menu 3

The System 3 menu allows you to tune the output frequency over a range of 500 ppm using the REF

TUNE feature.

Figure 2-13 shows the System 3 menu.

SYSTEM 3

Disabled

External Tune

Input

System 4

Menu

2500A Menus

Figure 2-13: System 3 menu with Interactive Softkeys.

External Tune Input. This menu item allows you to enable or disable the instrument’s Reference Tune

feature.

System 4 Menu Pressing this softkey invokes the System 4 Menu in the display.

2.3.4.4 System Menu 4

The System Menu 4 allows you to set up the 2500A for remote operations using the LAN connection.

Figure 2-14 shows the System 4 menu.

SYSTEM 4

On/Off

123.456.789.012

123.456.789.012

Connection Established/Lost

DHCP

IP Address

Subnet Mask

Link Status

System 1

Menu

Figure 2-14: System 4 menu with interactive Sofkeys

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

DHCP. This menu item allows you to configure the 2500A Dynamic Host Configuration Protocol to be

set manually or allow a DHCP server to obtain the IP and Subnet Mask. When the DHCP is set to Off,

the previously stored static IP address will be displayed.

IP Address. This menu item allows you to set the instrument’s IP (Internet Protocol) address. The range

for each of the sections is 0 to 255.

Subnet Mask. This menu item allows you to set the instrument’s Subnet Mask. The range for each of the

sections is 0 to 255.

Connection Established/Lost. This menu item serves as a link status indicating whether the 2500A ethernet connection is established or disconnected.

The default port number for the 2500A series is 2550

2.3.5 AM Menu Descriptions

The AM menus provide access to the internal and external amplitude modulation features of the instrument. To access the main AM menus, press the front panel AM menu button:

There are three menus that can be accessed from the main AM Menu.

Figure 2-15 shows the main AM menu.

Figure 2-15: AM Main Menu with Interactive Soft Keys

AM Ext Menu. Pressing this softkey invokes the externally driven Amplitude Modulation menu in the

display. See “External AM Menu”, for AM Ext menu item descriptions.

AM Int Menu. Pressing this softkey invokes the internally driven Amplitude Modulation menu in the

display. See “AM - Internal Waveform”, for AM Int menu item descriptions.

AM Int Noise Menu. Pressing this softkey invokes the Amplitude Modulation Internal Noise menu in

the display. See “AM - Internal Noise”, for AM Ext menu item descriptions.

2.3.5.1 External AM Menu

The AM - External Menu allows you to view and modify settings related to external amplitude modulation mode, which is used when the modulating signal is to be provided externally. In external AM mode,

the RF output signal is modulated according to the signal that is applied to the rear panel

AM IN connector.

Figure 2-16 shows the AM External Menu:

40 2500A Series Operation Manual, 34172 Revision C, March 2008

AM - External

2500A Menus

On/Off

0.00% / V

AM

Sensitivity

Figure 2-16: AM - External menu with Interactive Softkeys

The following explains each item in the AM - External menu:

AM. This menu item turns amplitude modulation on and off. Note that this setting only enables or disables amplitude modulation; it is the active menu, that is, the menu that is currently being displayed, that

determines the AM mode that is used. Pressing either the adjacent soft key or the Step Up or Step Down

buttons toggle the AM state.

The AM indicator is displayed in the upper right-hand corner of the display when amplitude modulation

is turned on.

Sensitivity. This menu item allows you to view and modify the AM sensitivity setting. AM sensitivity

determines the percentage of modulation produced per volt of input into the AM IN connector.

The AM sensitivity can be modified using either the numeric keypad, the step up/step down buttons, or

the rotary knob. The AM sensitivity range is 0 to 95%/volt, and the step size can be set in the range of

0.10 to 47.5%/volt.

2.3.5.2 AM - Internal Waveform

The AM - Internal Waveform menu allows you to view and modify settings related to an internal amplitude modulation mode in which the modulating signal is an internally-generated sine, triangle, ramp, or

square waveform (the signal at the AM IN connector is not used).

Figure 2-17 shows the AM - Internal Waveform menu:

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

AM - Internal Waveform

On/Off

30.00%

1.00 KHz

Ramp

AM

Depth

Rate

Waveform

Figure 2-17: AM - Internal Waveform with Interactive Softkeys

The following explains each item in the AM- Internal Waveform menu:

AM. TThis menu item turns amplitude modulation on and off. Note that this setting only enables or disables amplitude modulation; it is the active menu, that is, the menu that is currently being displayed, that

determines the AM mode that is used. Pressing either the adjacent soft key or the Step Up or Step Down

buttons toggle the AM state.

Depth. This menu item allows you to view and modify the AM depth setting, which is the extent of the

variation of the modulated RF output signal’s amplitude expressed as a percentage.

Rate. This menu item allows you to view and modify the rate (frequency) of the internal modulating signal.

Wav eform. This menu item allows you to view and choose the type of waveform used as the internal

modulating signal. The available selections are Sine, Triangle (symmetrical triangle wave), Ramp (positive going ramp), or Square (50% duty cycle square wave).

2.3.5.3 AM - Internal Noise

The AM - Internal Noise menu allows you to view and modify settings related to an internal amplitude

modulation mode in which the modulating signal is an internally-generated Gaussian noise source (the

signal at the AM IN connector is not used).

Figure 2-18 shows the AM - Internal Noise menu:

42 2500A Series Operation Manual, 34172 Revision C, March 2008

AM - Internal Noise

2500A Menus

On/Off

0.00% / V

AM

Depth

Figure 2-18: AM - Internal Noise with Interactive Softkeys

The following explains each item in the AM - Internal Noise menu:

AM. This menu item turns amplitude modulation on and off. Note that this setting only enables or disables amplitude modulation; it is the active menu, that is, the menu that is currently being displayed, that

determines the AM mode that is used. Pressing either the adjacent soft key or the Step Up or Step Down

buttons toggle the AM state.

Depth. This menu item allows you to view and modify the AM depth setting, which is the extent of the

variation of the modulated RF output signal’s amplitude expressed as a percentage.

AM Main Menu

2.3.6 FM Menu Descriptions

The FM menus provide access to the internal and external frequency modulation features of the instrument. To access the FM Main menu, press the front panel FM menu button:

AM Ext Menu

AM Int Menu

AM Int Noise Menu

2500A Series Operation Manual, 34172 Revision C, March 2008

Chapter 2: Front Panel Operation

There are three FM that can be accessed.

2.3.6.1 FM - External Menu

The FM -External menu allows you to view and modify settings related to external frequency modulation

mode, which is used when the modulating signal is to be provided externally. In external FM mode, the

RF output signal is modulated according to the signal that is applied to the rear panel

FM/

φM IN connector.

Figure 2-19 shows the FM - External menu:

FM - External

On/Off

0.00 Hz / Volt

FM

Sensitivity

Figure 2-19: FM - External Menu with Interactive Softkeys

The following explains each item in the FM - External menu:

FM. This menu item turns frequency modulation on and off. Note that this setting only enables or disables amplitude modulation; it is the active menu, that is, the menu that is currently being displayed, that

determines the FM mode that is used. Pressing either the adjacent soft key or the Step Up or Step Down

buttons toggle the FM state.

Sensitivity. This menu item allows you to view and modify the external FM sensitivity setting, which

determines how much the RF output deviates in frequency per volt of signal at the rear panel FM/

φM IN

connector.

2.3.6.2 FM - Internal Menu

The FM - Internal menu allows you to view and modify settings related to an internal frequency modulation mode in which the modulating signal is an internally-generated sine, triangle, ramp, or square waveform (the signal at the FM/φM IN connector is not used).

Figure 2-20 shows the FM - Internal menu:

44 2500A Series Operation Manual, 34172 Revision C, March 2008

FM - Internal

2500A Menus

On/Off

0.00 Hz

10.00 kHz

Sine

FM

Deviation

Rate

Waveform

Figure 2-20: FM - Internal with Interactive Softkeys

The following explains each item in the FM - Internal menu:

FM. This menu item turns FM - Internal on and off. FM - Internal is an internally driven modulation

requiring a + 1 V peak to peak input for maximum deviation. FM - Internal can only be activated or deactivated using the step up/step down buttons.

Deviation. This menu item allows you to view and modify the FM deviation setting, which determines

how much the RF output deviates in frequency when modulated by the internal source.