Page 1

Giga-tronics 2400 and 2500 Series Microwave Signal Generators

2400 and 2500 Series

Microwave Signal Generators

Programming Manual, Part Number 34783, Rev A, July 2009

Programming Manual

Page 2

Giga-tronics 2400 and 2500 Series Microwave Signal Generators

tronics 2400/2500 Series instruments are warranted

nd workmanship for one year from

tronics will at its option repair or replace

products that are proven defective during the warranty period.

This warranty DOES NOT cover damage resulting from improper

tronics service. There is

no implied warranty of fitness for a particular purpose, nor is

tronics liable for any consequential damages. Specification

All technical data and specifications in this publication are subject to change without prior notice and do

not represent a commitment on the part of Giga-tronics, Incorporated.

© 2009 Giga-tronics Incorporated. All rights reserved. Printed in the U.S.A.

Gigaagainst defective materials a

date of shipment. Giga-

use, nor workmanship other than Giga-

Gigaand price change privileges are reserved by Giga-tronics.

CONTACT INFORMATION

Giga-tronics, Incorporated

4650 Norris Canyon Road

San Ramon, California 94583

Telephone: 800.726.4442 (only within the United States)

925.328.4650

Fax: 925.328.4700

On the Internet: www.gigatronics.com

Warranty

Programming Manual, Part Number 34783, Rev A, July 2009

Page 3

Giga-tronics 2400 and 2500 Series Microwave Signal Generators

Regulatory Compliance Information

This product complies with the essential requirements of the following applicable European

Directives, and carries the CE mark accordingly.

89/336/EEC and 73/23/EEC EMC Directive and Low Voltage Directive

EN61010-1 (1993) Electrical Safety

EN61326-1 (1997) EMC – Emissions and Immunity

Manufacturer’s Name: Manufacturer’s Address

Giga-tronics, Incorporated 4650 Norris Canyon Road

San Ramon, California 94583

U.S.A.

Type of Equipment: Model Series Number

Microwave Signal Generator 2400 Series

2500 Series

Model Numbers:

2408C, 2420C, 2426C,

2440C

2508B, 2520B, 2526B,

2540B, 2550B

Declaration of Conformity on file. Contact Giga-tronics at the following;

Giga-tronics, Incorporated

4650 Norris Canyon Road

San Ramon, California 94583

Telephone: 800.726.4442 (only within the United States)

925.328.4650

Fax: 925.328.4700

Programming Manual, Part Number 34783, Rev A, July 2009

Page 4

Giga-tronics 2400 and 2500 Series Microwave Signal Generators

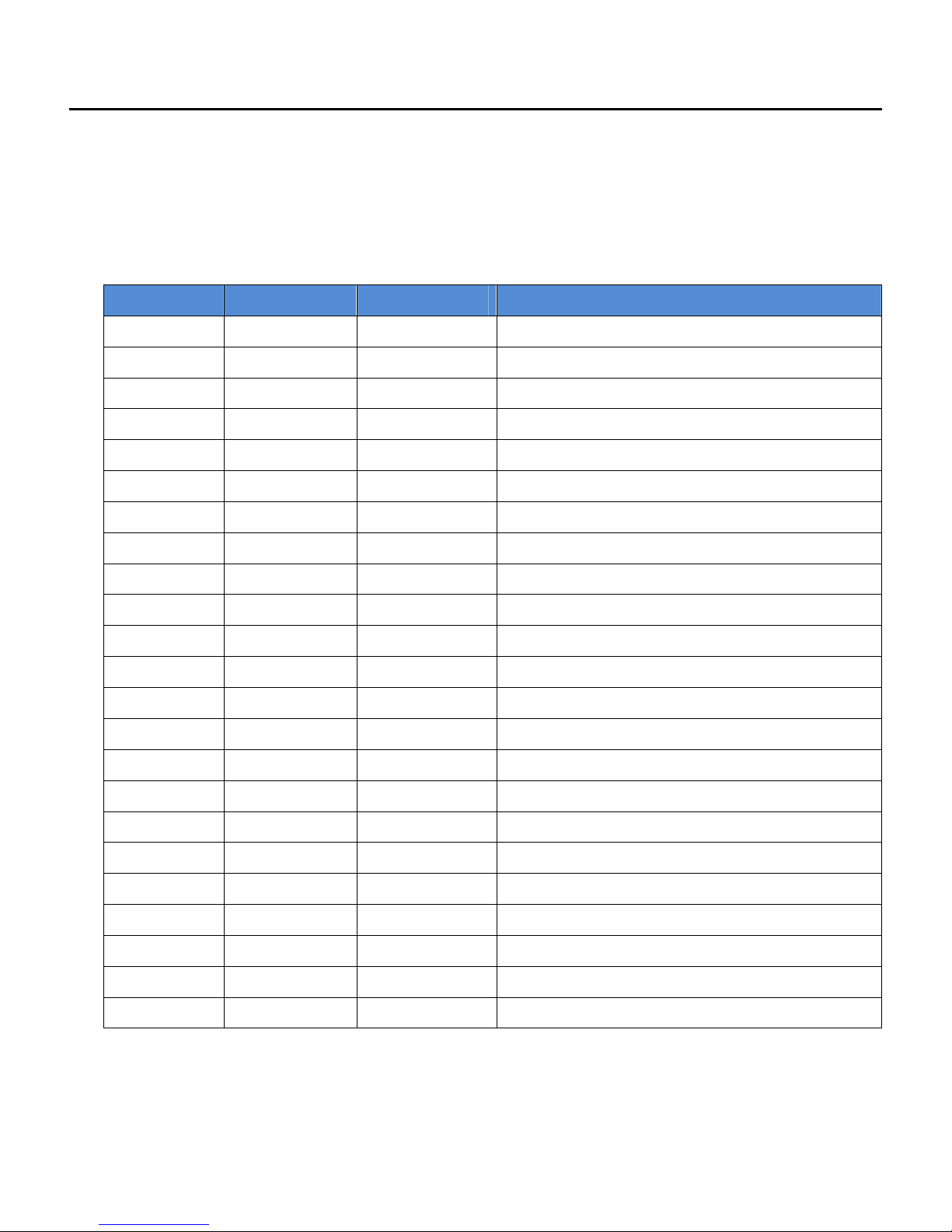

Record of changes to this Manual

Use the table below to maintain a permanent record of changes to this document. Replacement pages

will be issued as a TPCI (Technical Publication Change Instruction), and will be inserted at the front of

the binder. Remove the corresponding old pages, insert the new pages, and record the changes here. Do

the same thing with TCPI pages that are issued after you have received this manual.

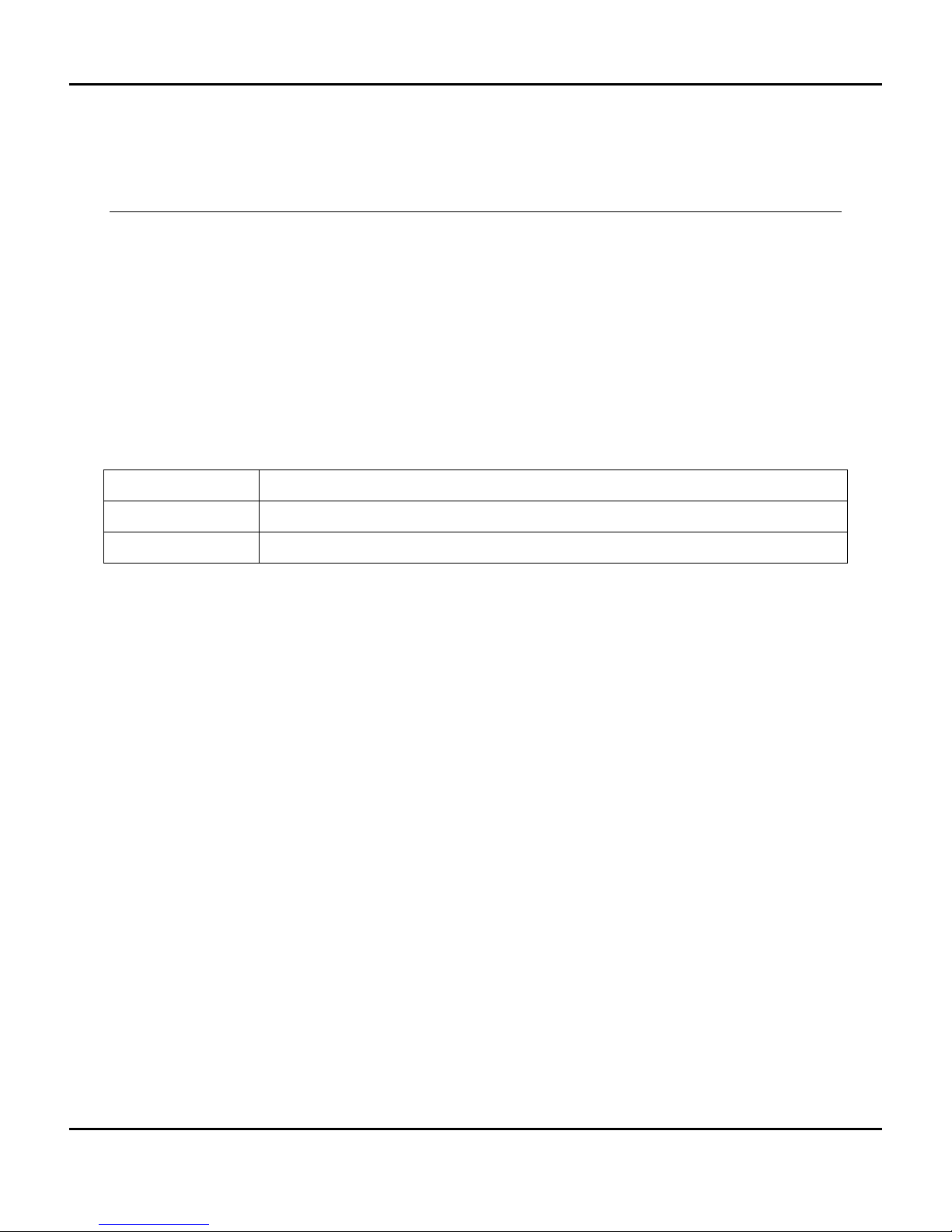

TPCI Number TPCI Issue Date Date Entered Comments

Programming Manual, Part Number 34783, Rev A, July 2009

Page 5

Giga-tronics 2400 and 2500 Series Microwave Signal Generators

Table of Contents

Table of Contents...........................................................................................................................................i

Chapter 1. Safety ....................................................................................................................................1

1.1 Unsafe Operating Conditions........................................................................................................1

1.2 Safety Warnings Used in This Manual ..........................................................................................1

1.2.1 Personal Safety Alert.............................................................................................................1

1.2.2 Equipment Safety Alert.........................................................................................................1

1.2.3 Notes.....................................................................................................................................1

Chapter 2. Introduction ..........................................................................................................................3

2.1 Overview.......................................................................................................................................3

2.2 Physical Description of the 2400/2500.........................................................................................4

Chapter 3. Hardware Interfaces .............................................................................................................5

3.1 Introduction ..................................................................................................................................5

3.2 Configure the 2400/2500 Hardware Interface .............................................................................6

3.2.1 Using the Included USB Cable...............................................................................................6

3.2.2 Assign a GPIB Address to the 2400/2500..............................................................................6

3.2.3 Configure the Computer’s RS-232 for Remote Operation....................................................6

3.2.4 Configure the 2400/2500 Ethernet Connection ...................................................................7

Chapter 4. Programming Interfaces .......................................................................................................9

4.1 Introduction ..................................................................................................................................9

4.2 Select the Remote Programming Language..................................................................................9

4.3 Dynamic Link Library (DLL)..........................................................................................................10

4.3.1 Adding the DLL to Programming Projects...........................................................................10

4.3.2 Programming Examples Using the DLL ...............................................................................11

4.3.3 DLL Functions ......................................................................................................................17

4.4 SCPI Command Set......................................................................................................................96

4.4.1 SCPI Command Format .......................................................................................................96

4.4.2 SCPI Commands ..................................................................................................................97

4.5 IEEE 488.2 Common Commands...............................................................................................120

4.6 GT-12000 Native Commands ....................................................................................................122

4.6.1 GT-12000 Native Commands: CW and System.................................................................122

4.6.2 GT-12000 Native Commands: List Mode ..........................................................................123

4.6.3 GT-12000 Native Commands: Amplitude Modulation .....................................................125

4.6.4 GT-12000 Native Commands: Frequency Modulation .....................................................126

4.6.5 GT-12000 Native Commands: Phase Modulation.............................................................127

4.6.6 GT-12000 Native Commands: Pulse Modulation..............................................................128

4.7 Emulation..................................................................................................................................129

4.7.1 HP 834X Emulation Commands ........................................................................................129

Programming Manual, Part Number 34783, Rev A, July 2009 i

Page 6

Giga-tronics 2400 and 2500 Series Microwave Signal Generators

4.7.2 HP 8663 Emulation Commands ........................................................................................132

4.7.3 HP 8673 Emulation Commands ........................................................................................134

4.7.4 HP 8360 Emulation Commands ........................................................................................138

4.7.5 HP 8370 Emulation Commands ........................................................................................139

4.7.6 GT900 Emulation Commands ...........................................................................................140

4.7.7 Option 55F: Wavetek 90X Emulation Commands.............................................................142

4.7.8 Systron Donner 16XX Emulation Commands....................................................................143

Chapter 5. Automation Xpress............................................................................................................149

5.1 Introduction ..............................................................................................................................149

5.1.1 Benefits of Using Automation Xpress ...............................................................................149

5.2 Install Automation Xpress.........................................................................................................150

5.3 Start Automation Xpress...........................................................................................................152

5.4 Automation Xpress GUI Description .........................................................................................154

5.4.1 Tool Bar .............................................................................................................................155

5.4.2 Indicators and RF Button...................................................................................................165

5.5 Auto Programmer .....................................................................................................................167

5.5.1 Introduction ......................................................................................................................167

5.5.2 Auto Programmer Examples.............................................................................................168

Chapter 6. Status Register System......................................................................................................171

6.1 Introduction ..............................................................................................................................171

6.2 Status Byte and Service Request Enable Registers ...................................................................173

6.3 Standard Event Status and Standard Event Status Enable Registers........................................174

6.4 Questionable Status Condition and Enable Registers...............................................................175

Chapter 7. 2400/2500 Specific Commands ........................................................................................177

Chapter 8. List Mode Operation .........................................................................................................179

Chapter 9. LabVIEW Drivers................................................................................................................181

9.1 Overview...................................................................................................................................181

9.2 LabVIEW Drivers........................................................................................................................183

9.2.1 LabVIEW Drivers for DLL Functions...................................................................................183

9.2.2 Non-DLL LabVIEW Drivers.................................................................................................187

Appendix A. Remote Error Messages....................................................................................................189

Appendix B. DLL Error Messages...........................................................................................................193

Appendix C. FM Sensitivity/Deviation RangeTable ...............................................................................197

ii Programming Manual, Part Number 34783, Rev A, July 2009

Page 7

Giga-tronics 2400 and 2500 Series Microwave Signal Generators 1. Safety

Chapter 1. Safety

1.1 Unsafe Operating Conditions

If you notice any of the following conditions while operating electronics equipment, IMMEDIATELY

de-energize the equipment.

• The instrument fails to operate normally, or operates erratically.

• The power cable, receptacle, or plug on the instrument is damaged

• The instrument causes electrical shock or operates at abnormally high temperature.

• A liquid or foreign substance falls into the instrument

• The instrument generates an abnormal sound, smell, smoke, or sparking light.

If any of the above conditions occurs, contact Giga-tronics to get the instrument repaired.

WARNING

cause death or serious damage to the instrument and any equipment connected to it.

Continuing to operate the instrument with any of the above conditions could

1.2 Safety Warnings Used in This Manual

1.2.1 Personal Safety Alert

WARNING: Indicates a hazardous situation which, if not avoided, could result in

WARNING

death or serious injury.

1.2.2 Equipment Safety Alert

CAUTION

CAUTION: Indicates a situation which can damage or adversely affect the 2400 and 2500

or associated equipment.

1.2.3 Notes

Notes are denoted and used as follows:

NOTE: Highlights or amplifies an essential operating or maintenance procedure, practice,

condition or statement.

Programming Manual, Part Number 34783, Rev A, July 2009 1

Page 8

1. Safety Giga-tronics 2400 and 2500 Series Microwave Signal Generators

This page is intentionally blank

2 Programming Manual, Part Number 34783, Rev A, July 2009

Page 9

Giga-tronics 2400 and 2500 Series Microwave Signal Generators 2. Introduction

Chapter 2. Introduction

2.1 Overview

Manual Convention:

• For simplicity, when generically referring to Giga-tronics Microwave Signal Generators in the

2400 and 2500 Series, the term “2400/2500” may be used. Specific models within either series

are referred to when necessary.

This manual describes how to program and remotely control the 2400/2500 and 2500B Series

Microwave Signal Generators for automated testing.

Giga-tronics designed the 2400/2500 for high performance and flexibility, and accordingly, there are

different ways to set up the instrument for automated testing. All methods for setting up the 2400/2500

for automated testing are described in this manual.

However, the easiest and most effective way to use the 2400/2500 for automated testing is through

Automation Xpress, an automated testing application developed by Giga-tronics that is included on the

CD-ROM that shipped with the 2400/2500.

Automation Xpress provides the fastest switching of power and frequency during automated testing.

This maximizes device throughput, keeping your testing costs as low as possible.

Features of Automation Xpress:

• 1.0 ms frequency and power switching during testing

• Eliminate the need to learn GPIB or other native language commands by using the Auto

Programming feature, which automatically records a sequence of actions and converts those

actions into program code. You can then import this code into the program environment of your

choice, such as Visual C++ or Visual Basic.

• The Xpress Auto-programming feature virtually eliminates training time by providing scripts and

sequences guaranteed for accuracy.

• Transit and execution times for single-function calls such as changing CW frequency are ten

times faster using Automation Xpress compared to standard message-based commands.

• Automation Xpress sends large amounts of data (i.e., large lists) more than 100 times faster than

SCPI commands.

Programming Manual, Part Number 34783, Rev A, July 2009 3

Page 10

2. Introduction Giga-tronics 2400 and 2500 Series Microwave Signal Generators

2.2 Physical Description of the 2400/2500

If you need information about the controls, indicators, display, or any other physical aspects of the

2400/2500, refer to the Operation Manual for the series you are interested in:

2400/2500 Operation Manual part number: 34802

2500B Operation Manual part number: 34737

4 Programming Manual, Part Number 34783, Rev A, July 2009

Page 11

Giga-tronics 2400/2500 Series Microwave Signal Generators 3. Hardware Interfaces

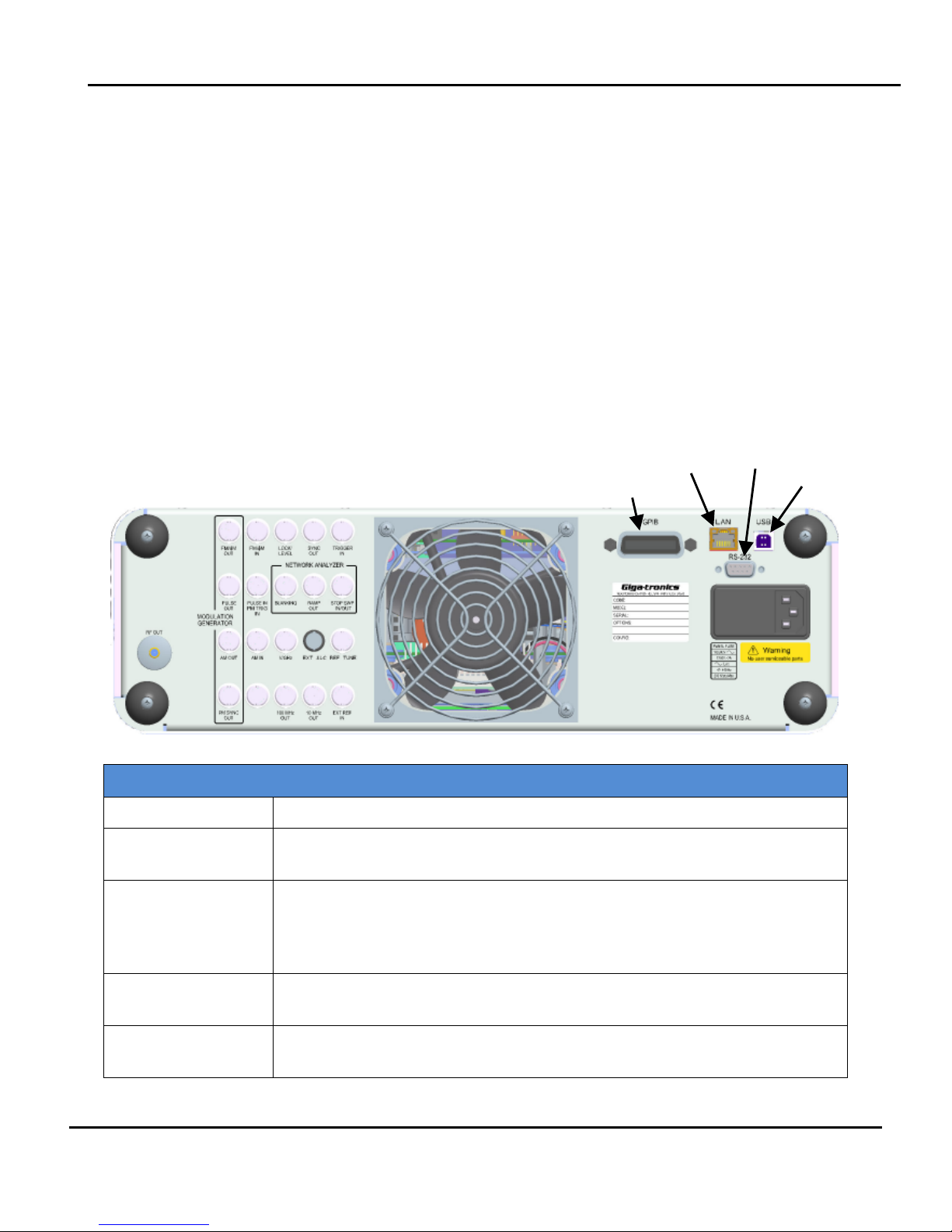

GPIB

RS-232

USB

LAN

Chapter 3. Hardware Interfaces

3.1 Introduction

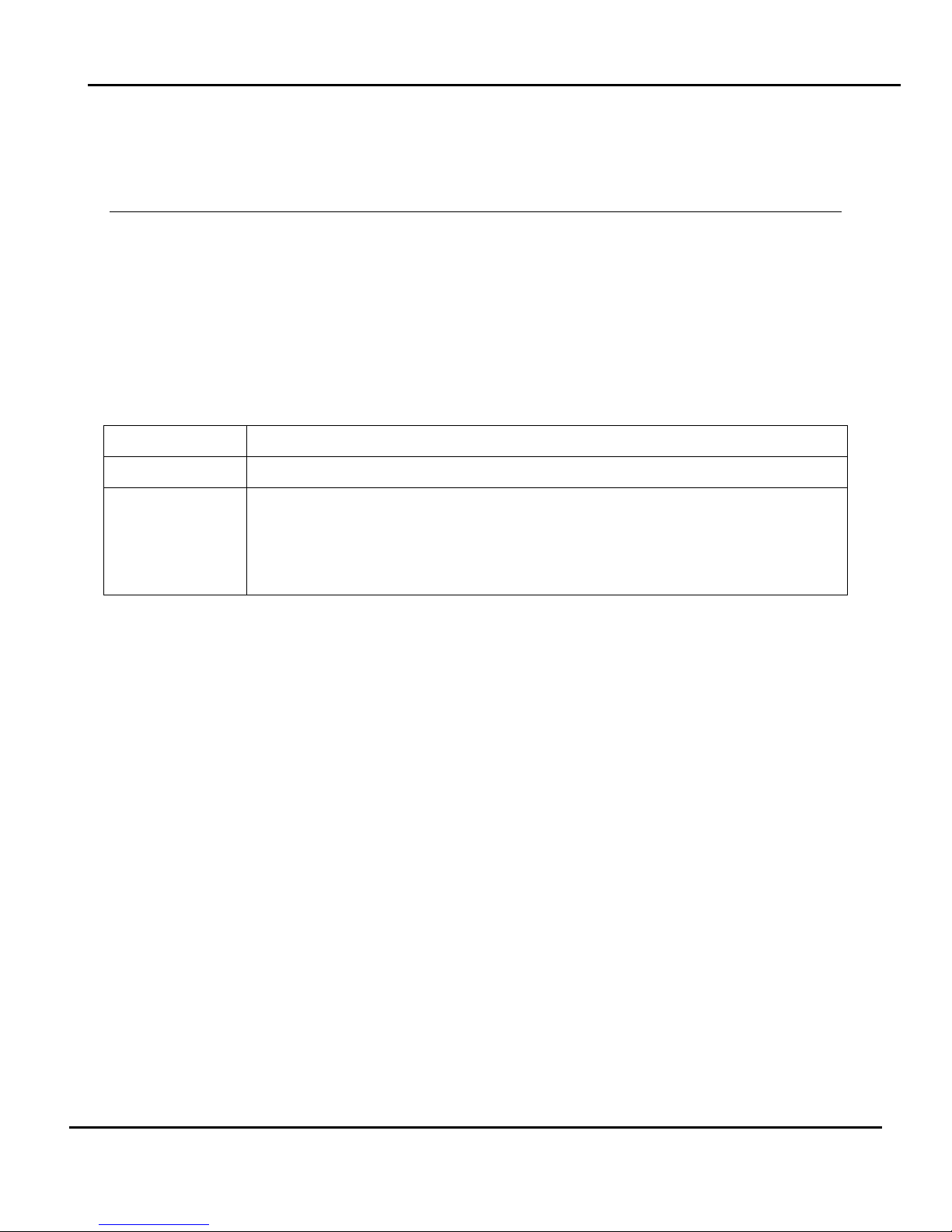

The 2400/2500 has four connectors to choose from for connecting to a computer:

• GPIB

• LAN (Ethernet)

• RS-232

• USB

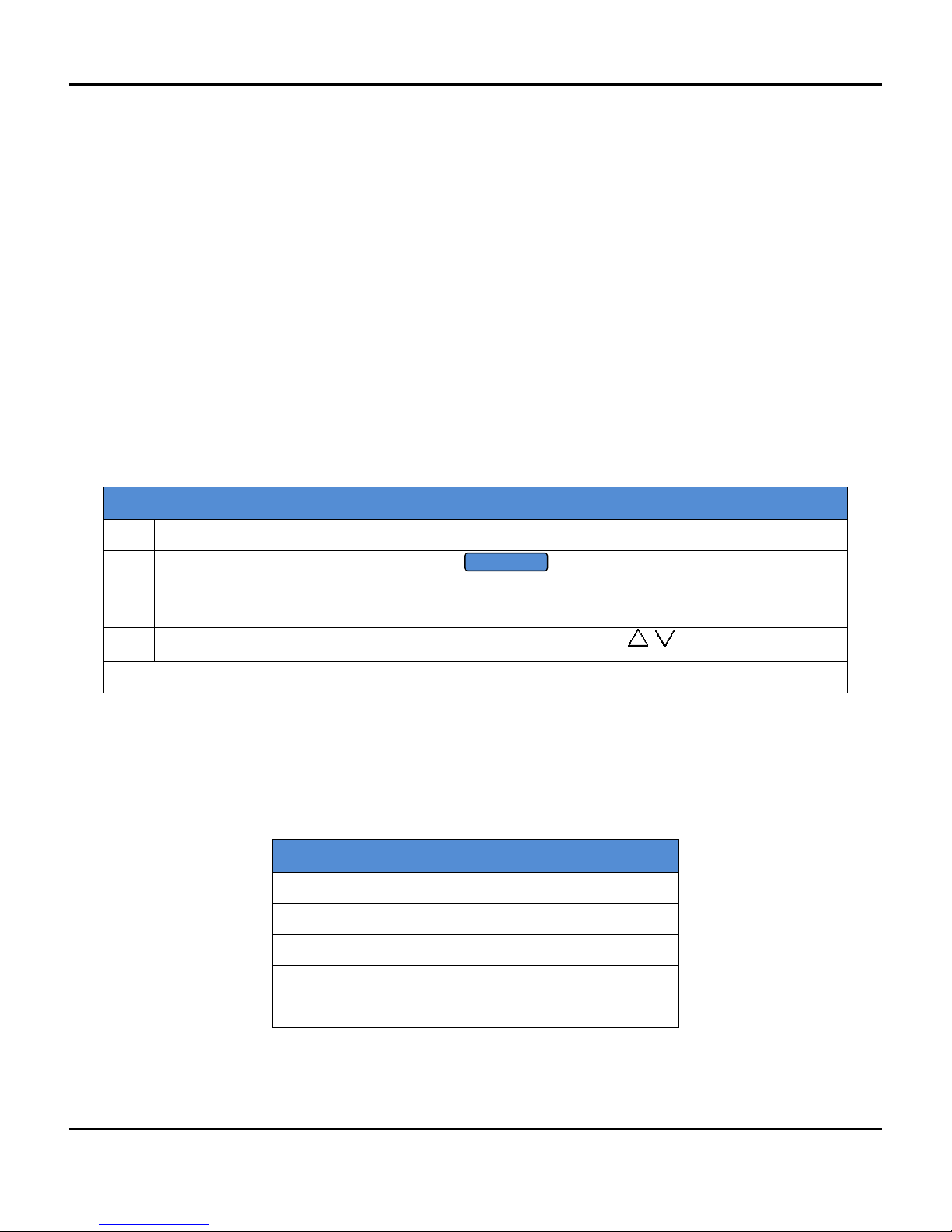

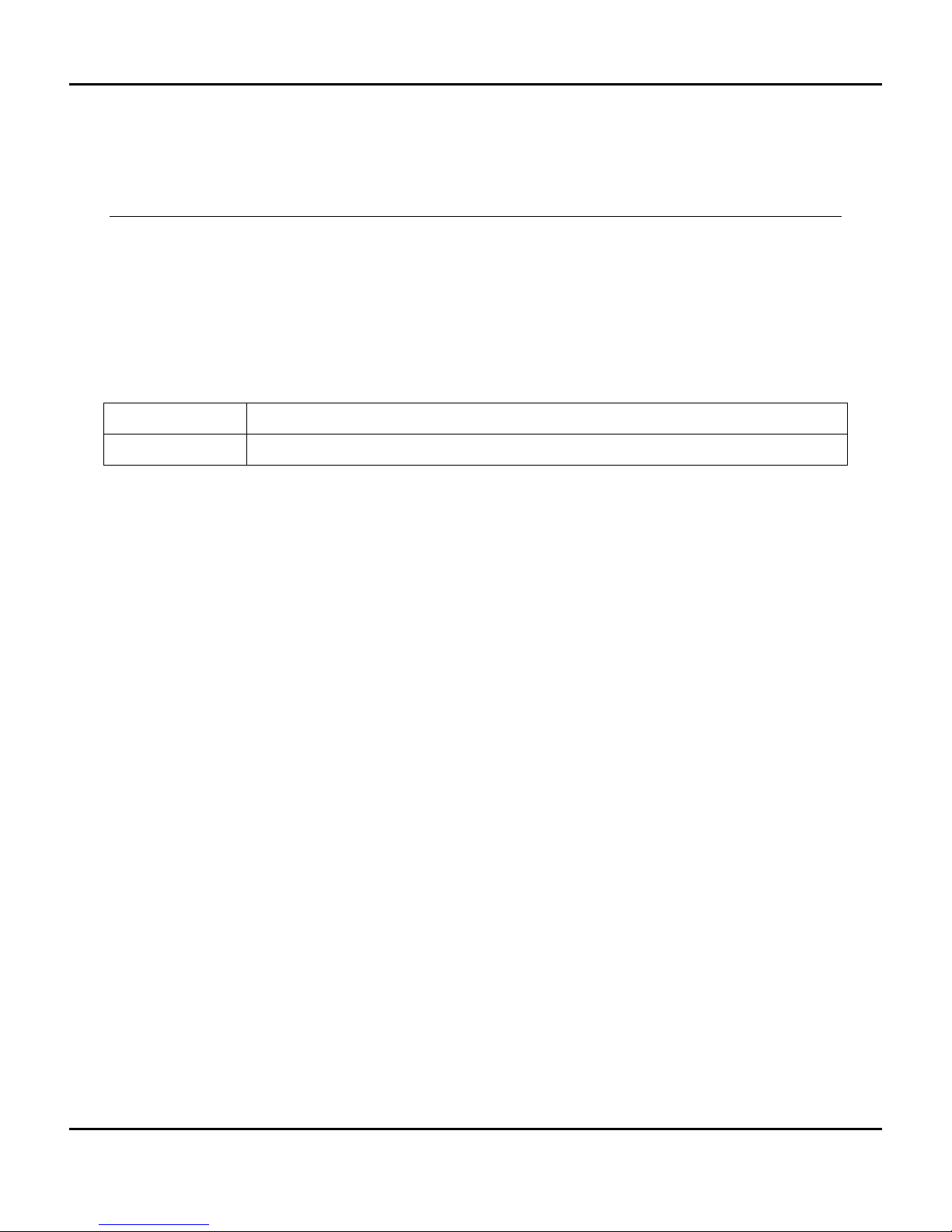

Figure 1 below shows the locations of the connectors on the 2400/2500 rear panel. Descriptions of the

connectors are given in Table 1 below.

NOTE: Your 2400/2500 may look slightly different, depending on series and model.

Figure 1. 2400/2500 Rear Panel

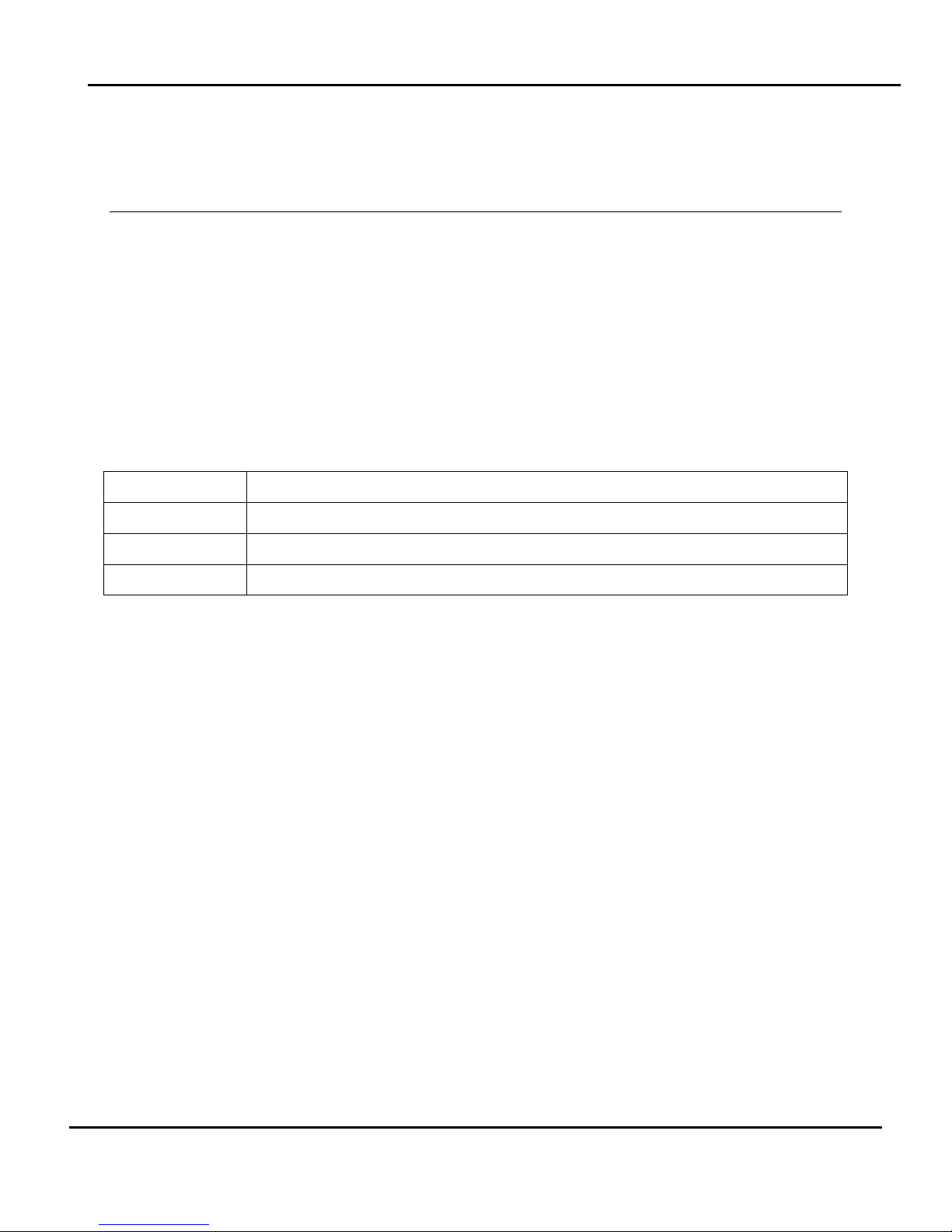

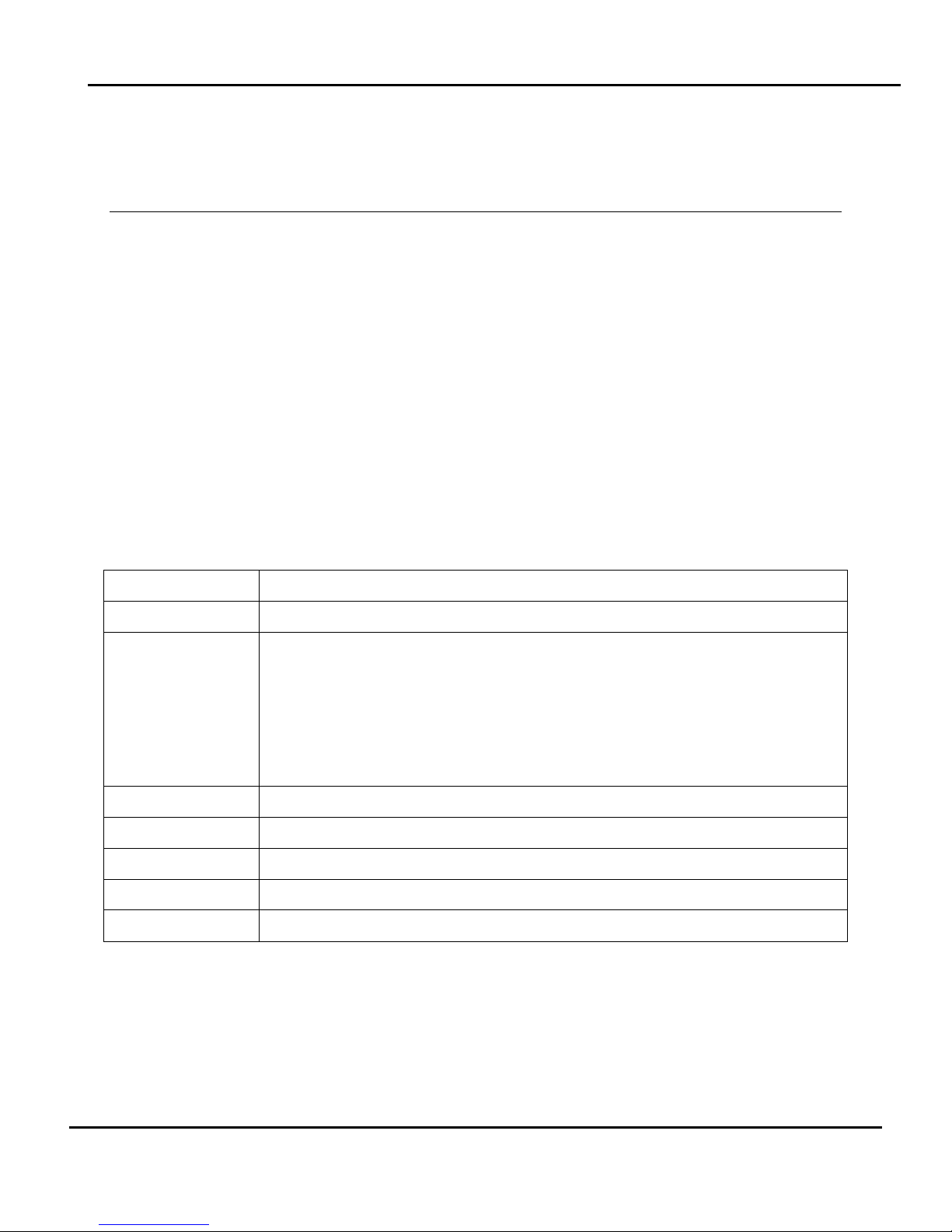

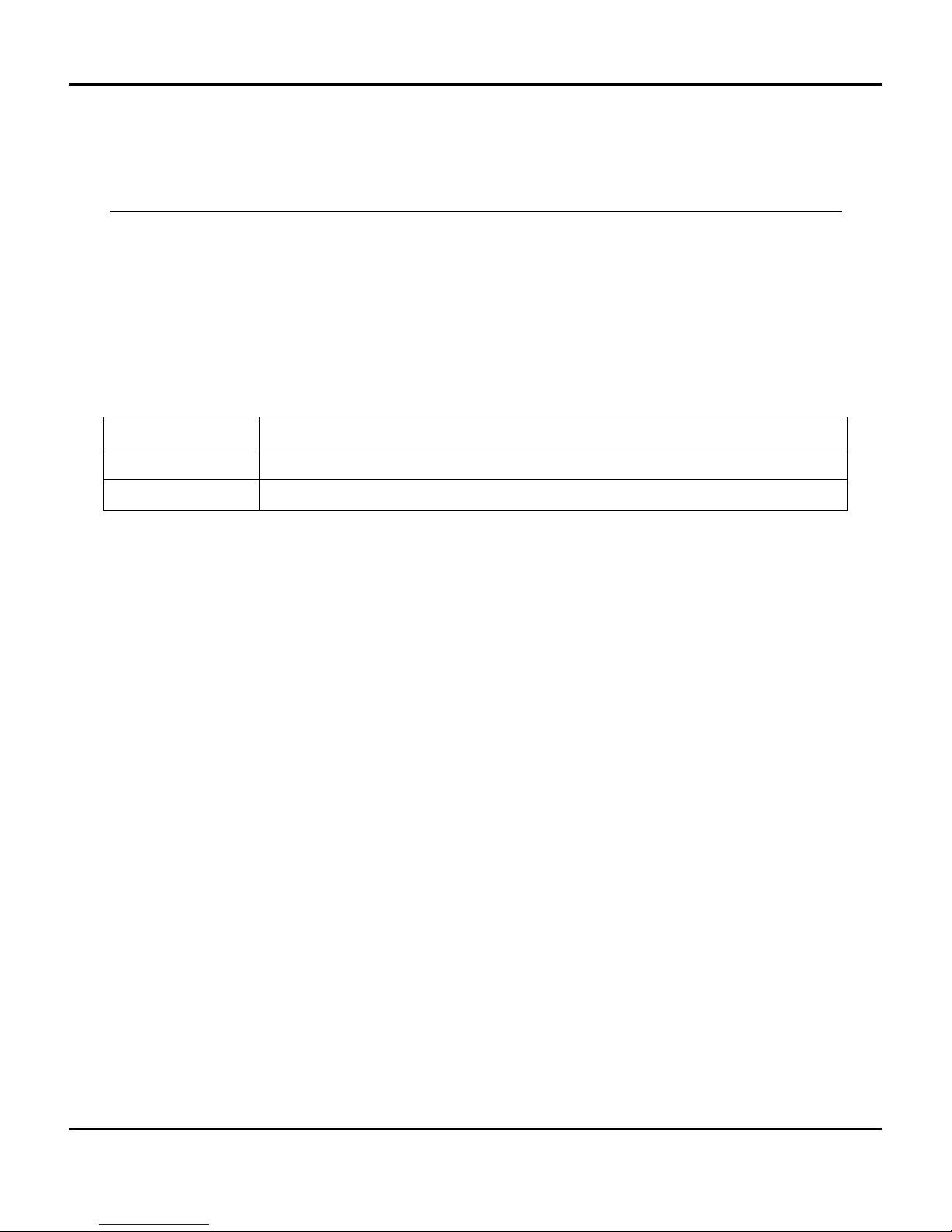

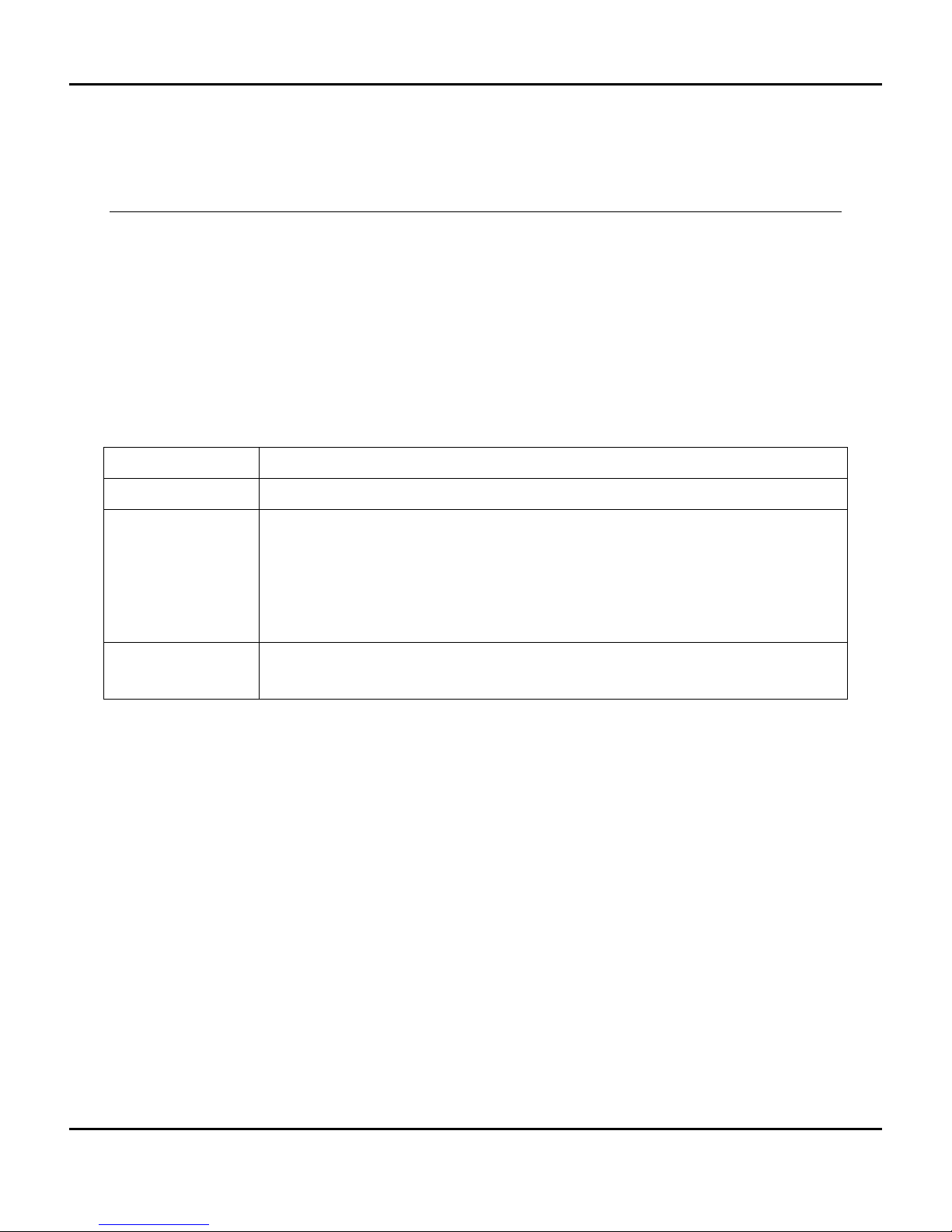

Table 1 2400/2500 Hardware Interfaces Description

Name Description

GPIB A 24-pin IEEE STD 488.2 connector for control of the instrument during remote

operation using GPIB.

RS-232 A DB-9 connector for control of the instrument during remote operation using

RS-232 serial communications. A USB to Serial Cable Port Adapter is included

with the 2400/2500 for controlling the instrument via the USB port on a host

computer.

USB A USB connector for control of the instrument during remote operation using

USB 2.0 (full speed) communications

Ethernet An Ethernet connector for control of the instrument during remote operation

using LAN interface communications.

Programming Manual, Part Number 34783, Rev A, July 2009 5

Page 12

3. Hardware Interfaces Giga-tronics 2400/2500 Series Microwave Signal Generators

SYSTEM

3.2 Configure the 2400/2500 Hardware Interface

3.2.1 Using the Included USB Cable

A USB 2.0 Type A Male to Type B Male cable shipped with the 2400/2500, and provides you with the

simplest way to connect a computer to the 2400/2500. The cable connects between a USB port on the

computer, and the USB port on the 2400/2500.

To use this cable, you must first install Automation Xpress and the USB driver on the computer. See

Table 40 on page 150.

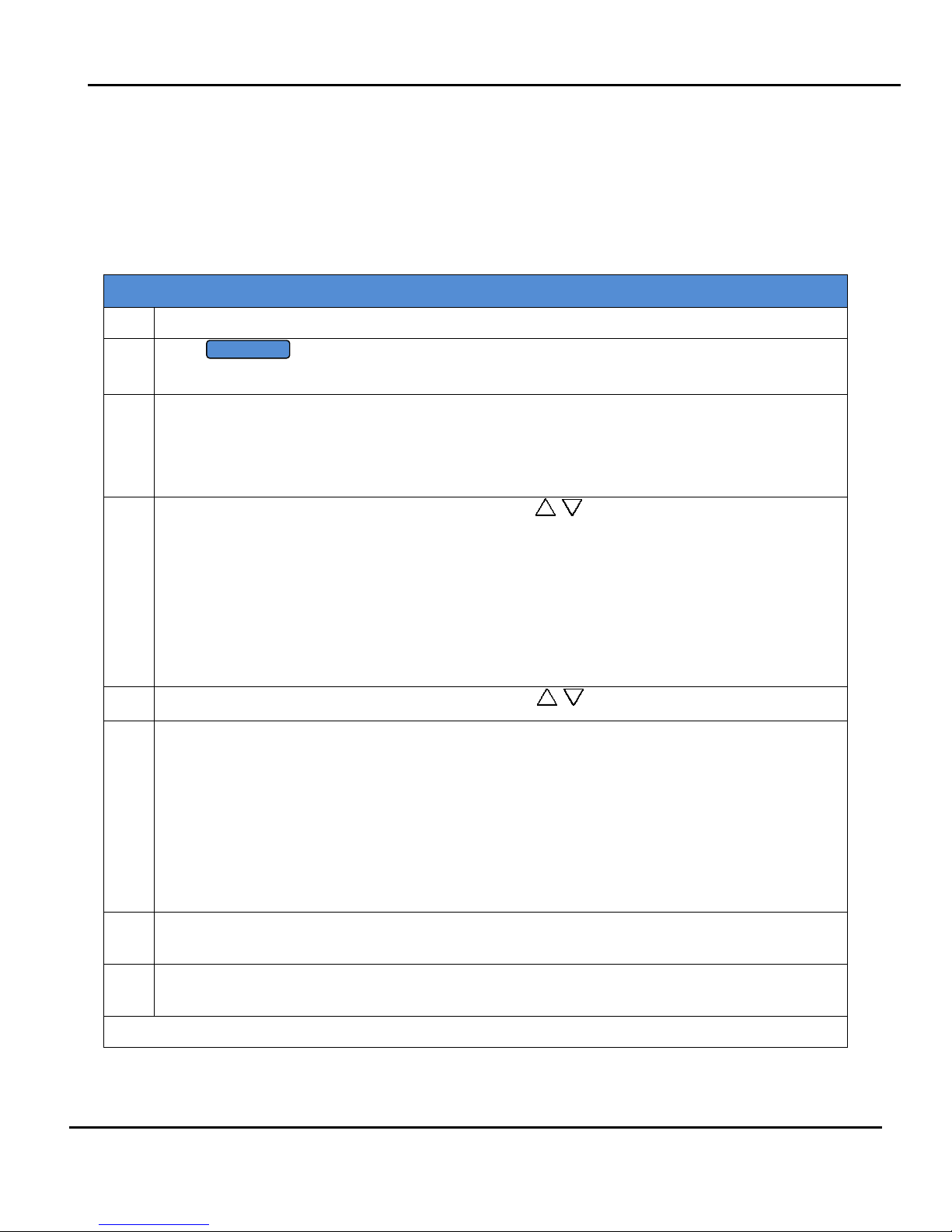

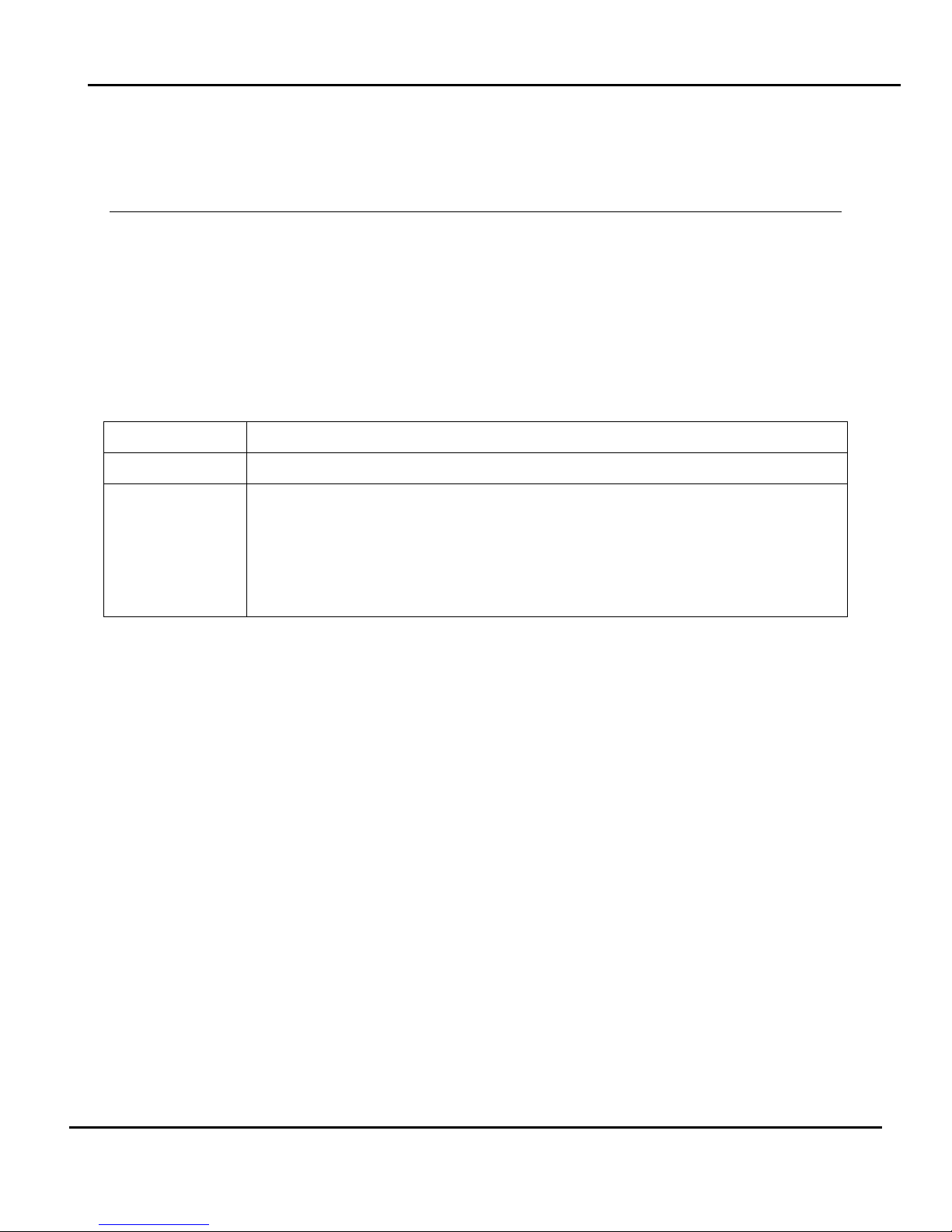

3.2.2 Assign a GPIB Address to the 2400/2500

To connect a computer to the 2400/2500 via GPIB, the 2400/2500 must be assigned a GPIB address. The

procedure below describes how to assign a GPIB address to a 2400/2500.

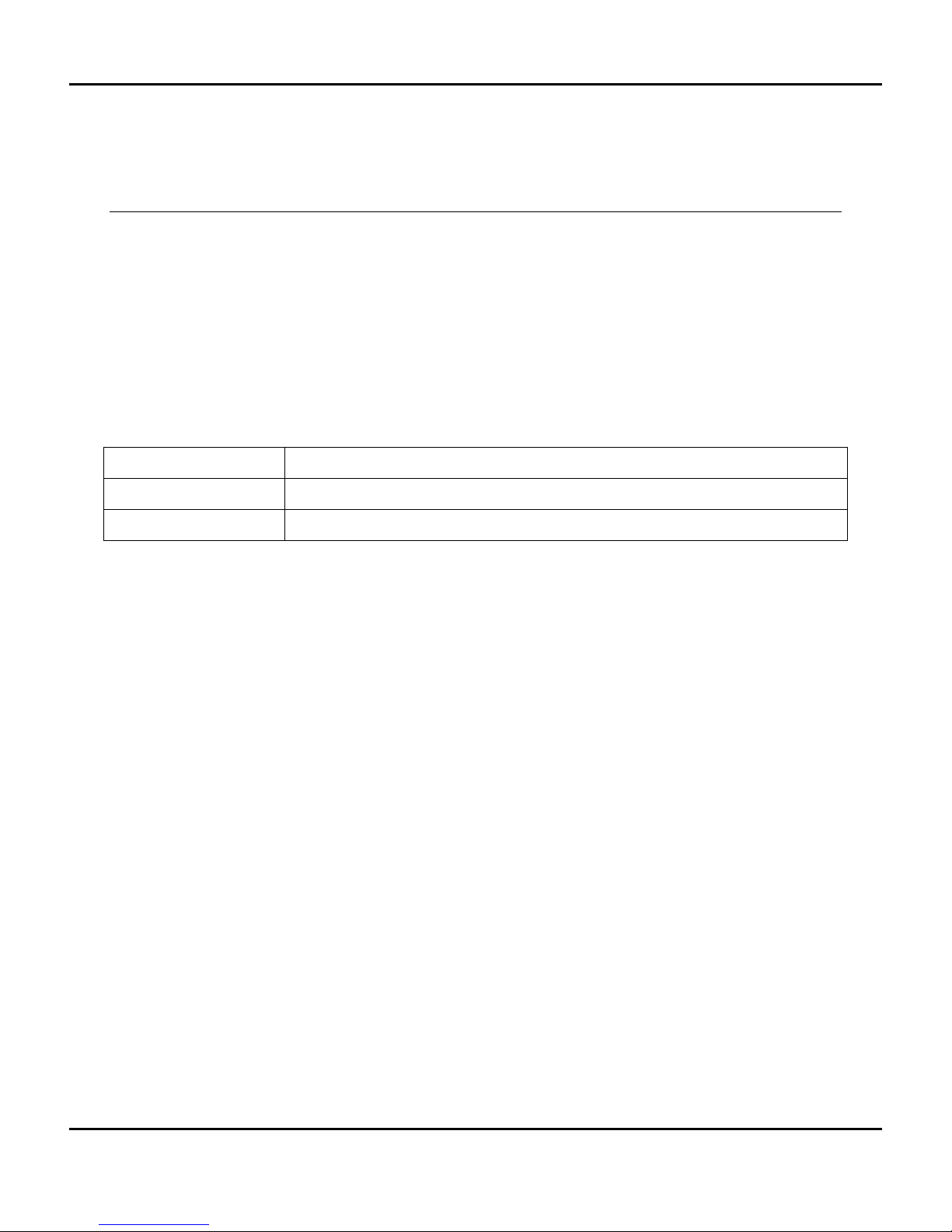

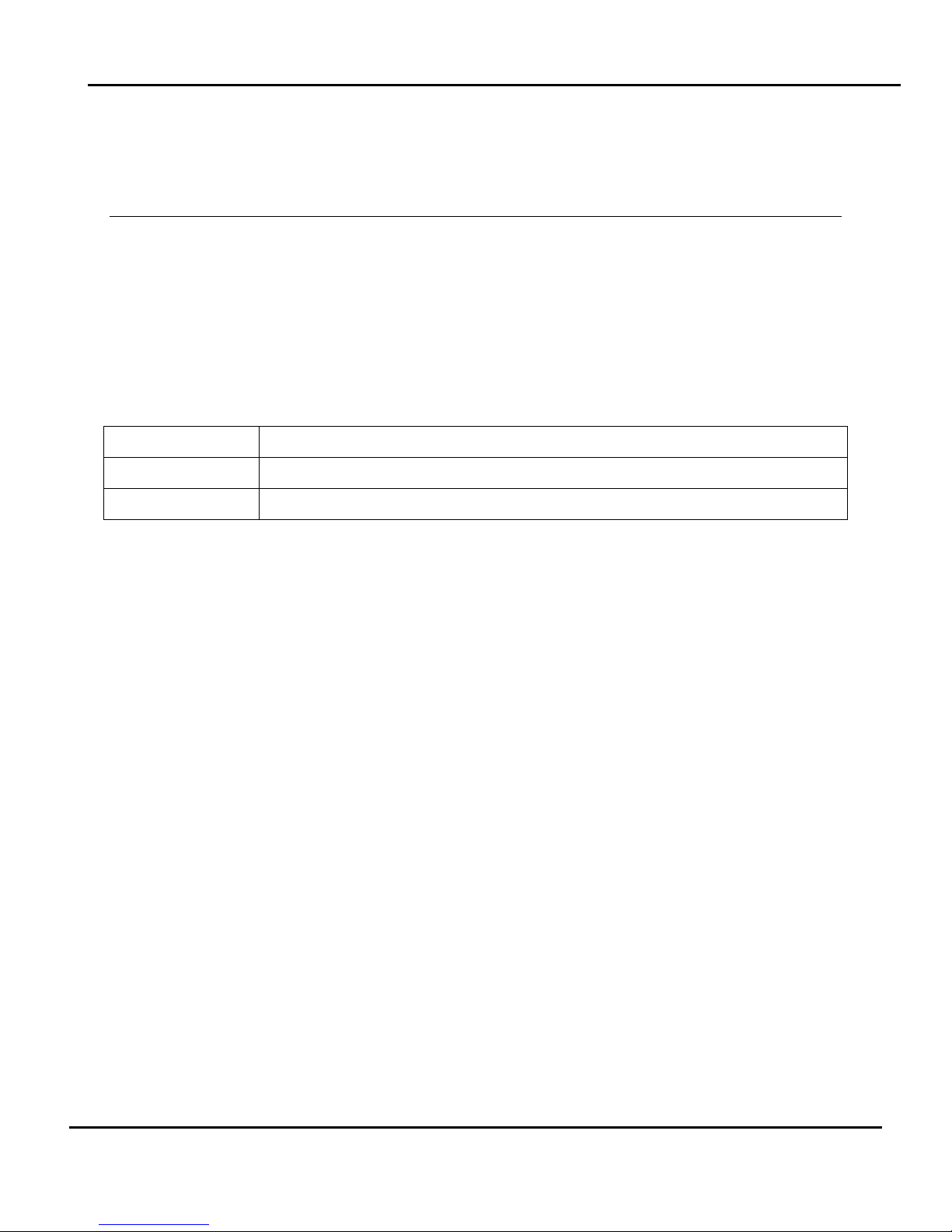

Table 2 Setup GPIB Address

Step Action

1.

On the front panel of the 2400/2500, press to display the System menus, and if the

SYSTEM 2 menu does not appear in the display, press the bottom-most interactive softkey until it

does.

2.

Enter the desired GPIB address using either the numeric keypad or .

End of Procedure

3.2.3 Configure the Computer’s RS-232 for Remote Operation

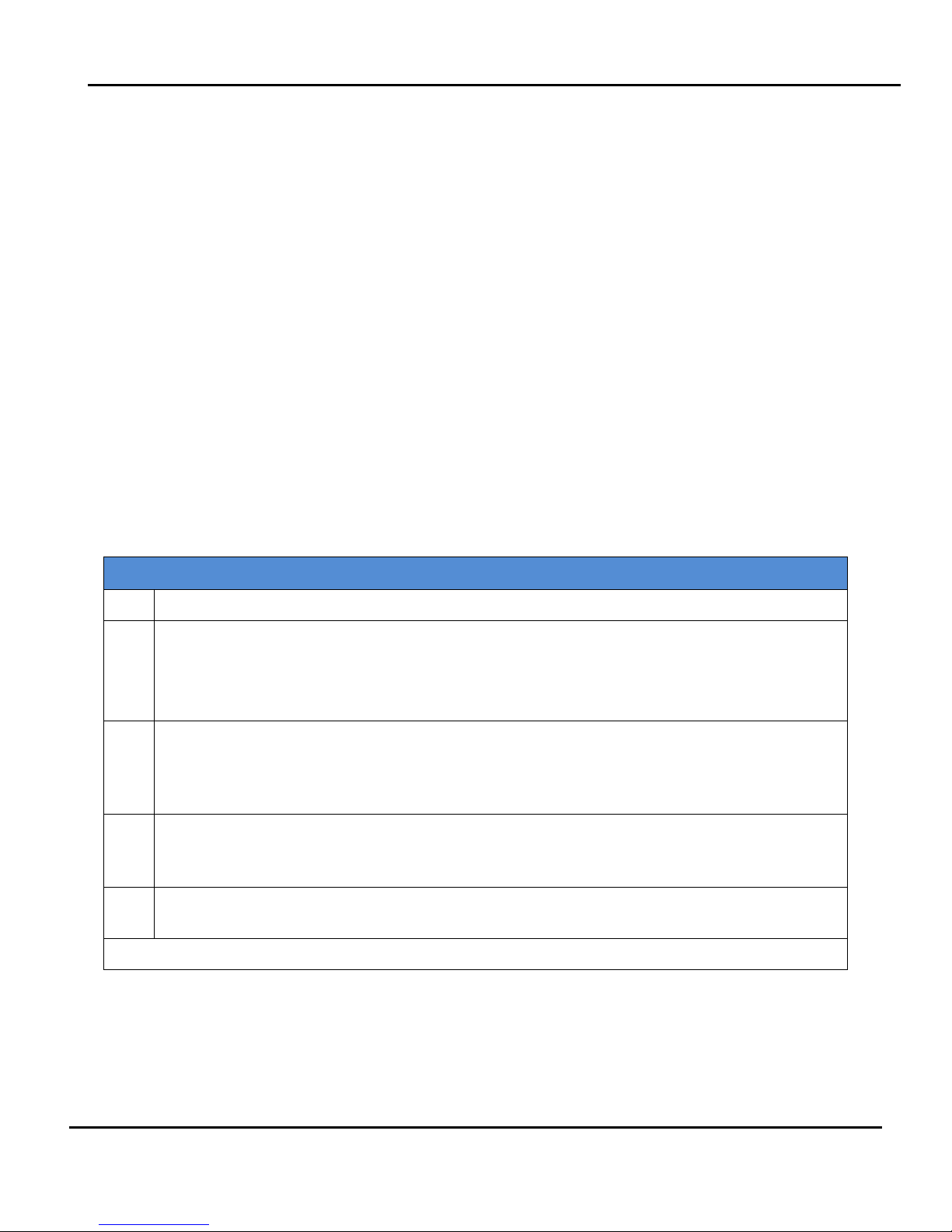

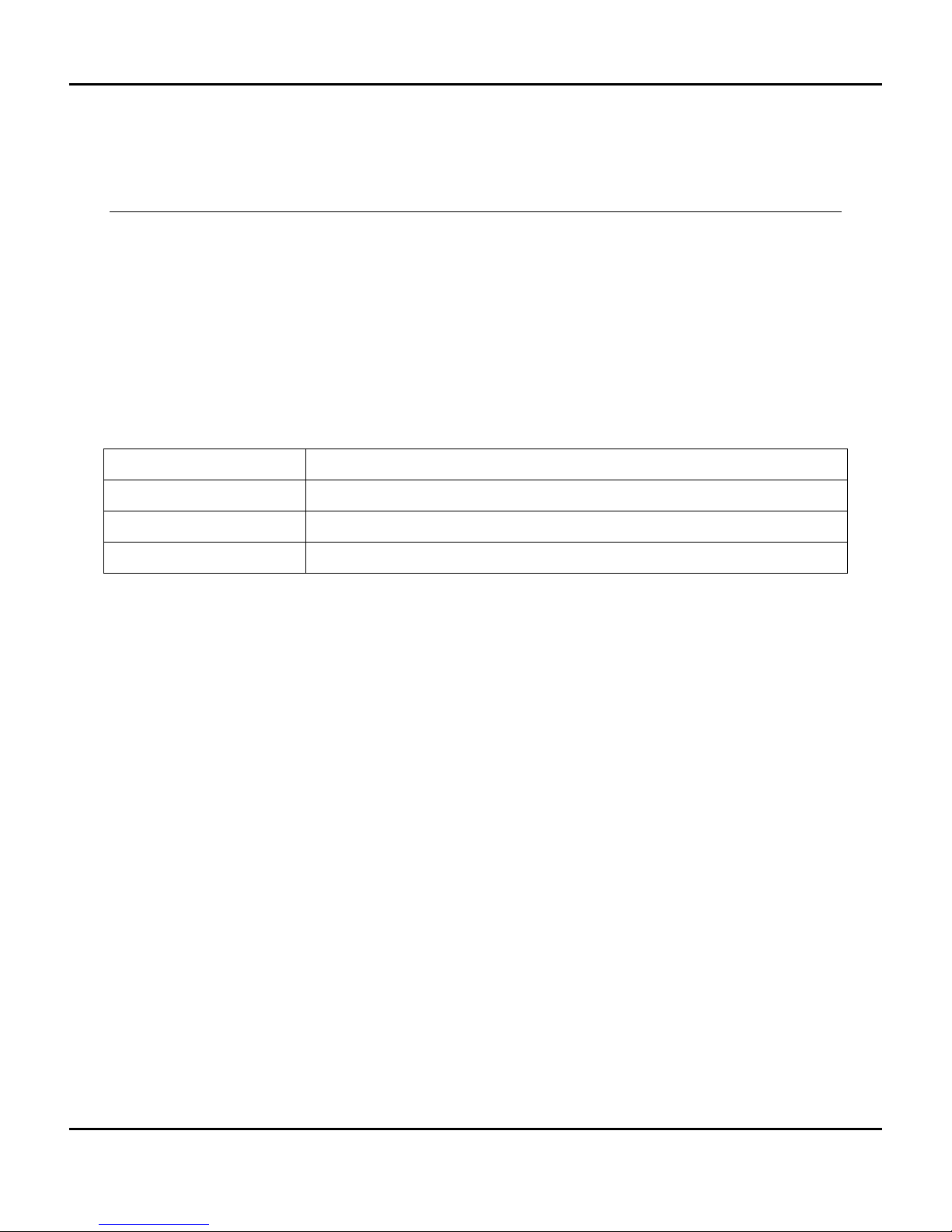

Table 3 below gives information for configuring an RS-232 port on a computer to communicate with the

2400/2500.

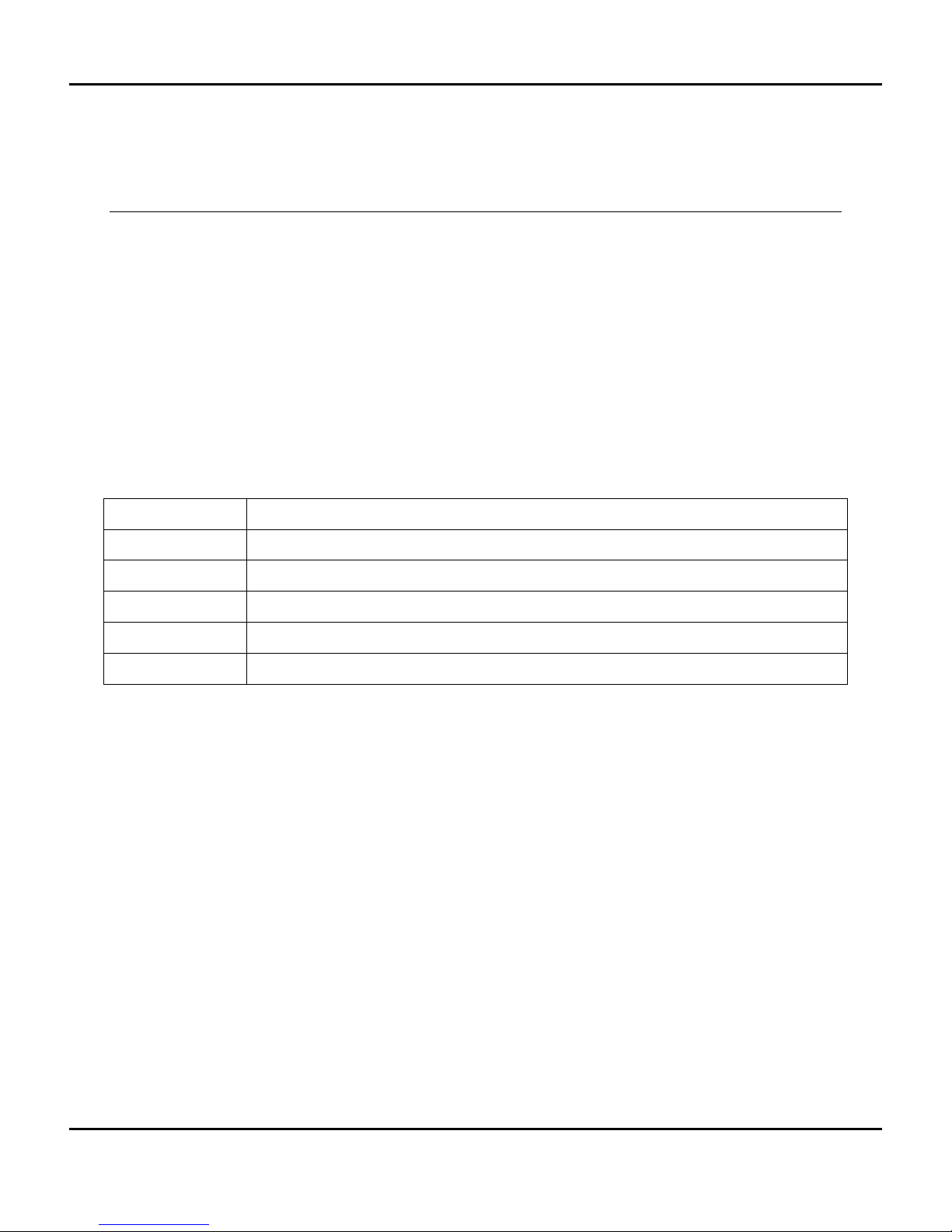

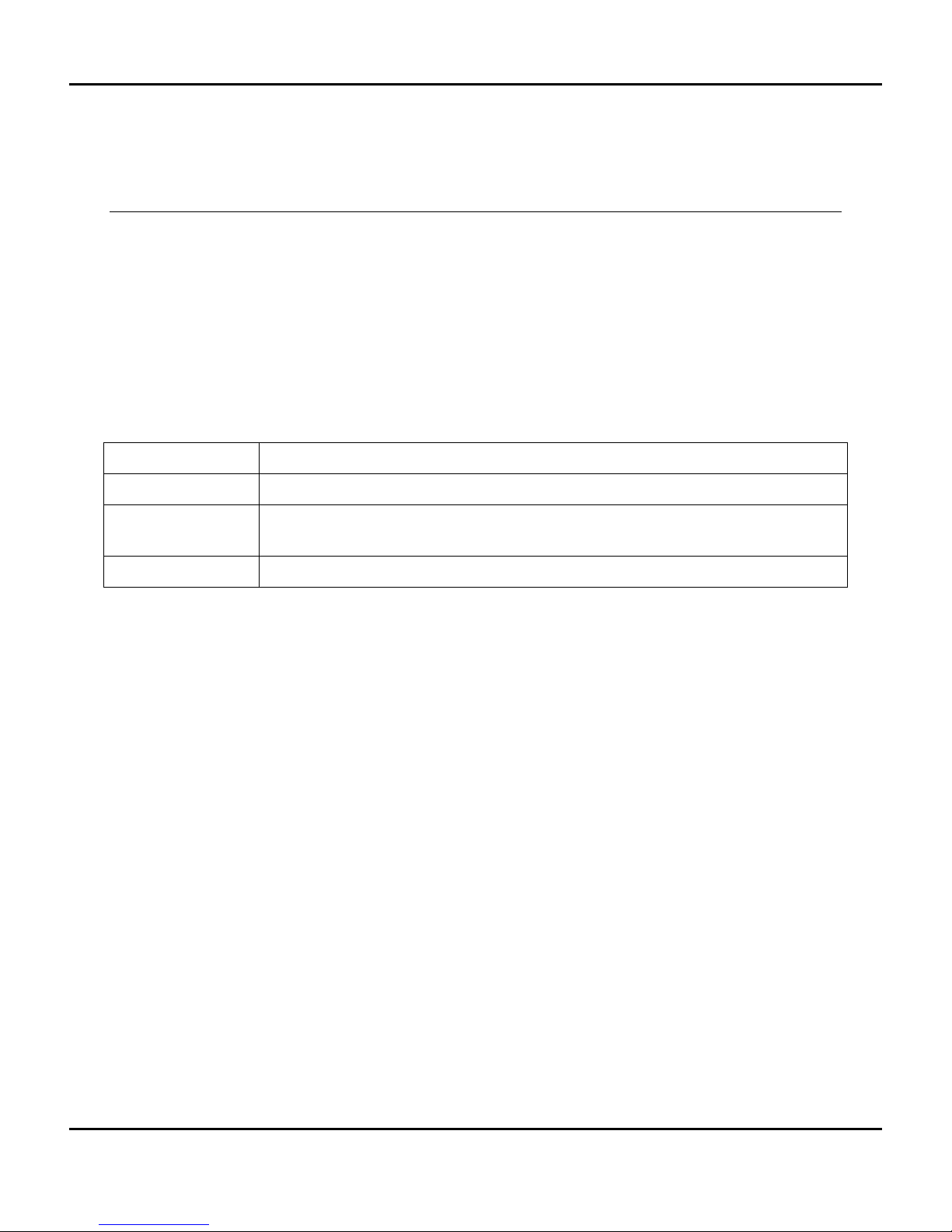

Table 3 RS-232 Communication Settings

Baud rate 115200

Data Bits 8

Parity None

Stop bits 1

Handshake None

6 Programming Manual, Part Number 34783, Rev A, July 2009

Page 13

Giga-tronics 2400/2500 Series Microwave Signal Generators 3. Hardware Interfaces

SYSTEM

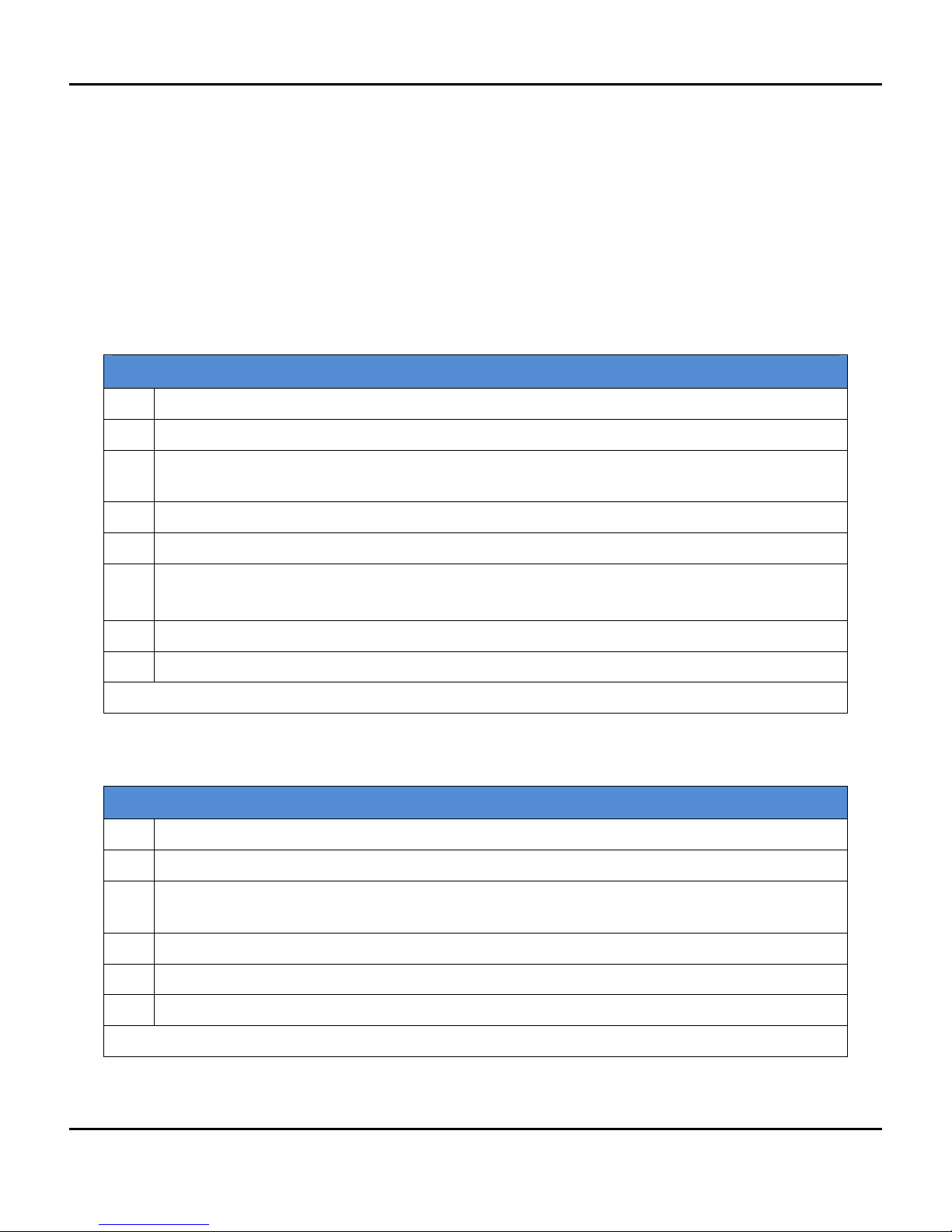

3.2.4 Configure the 2400/2500 Ethernet Connection

The following procedure explains how to set the DHCP, IP Address, and Subnet Mask of the 2400/2500

when using the Ethernet (LAN) connector on the rear of the 2400/2500. The instrument is identified via

Ethernet connection during remote operations using the IP address set in this procedure. Each unit on

the network must have a unique IP address.

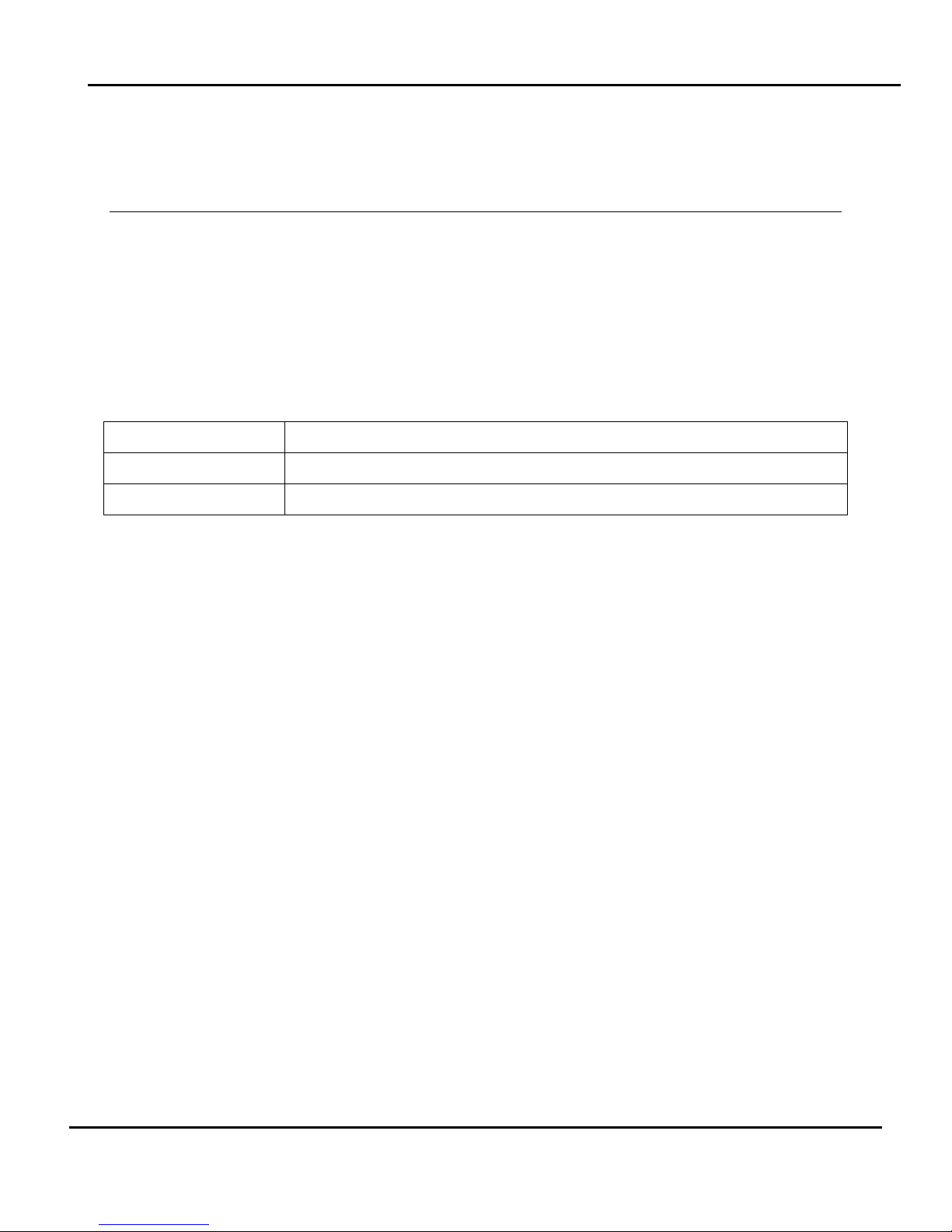

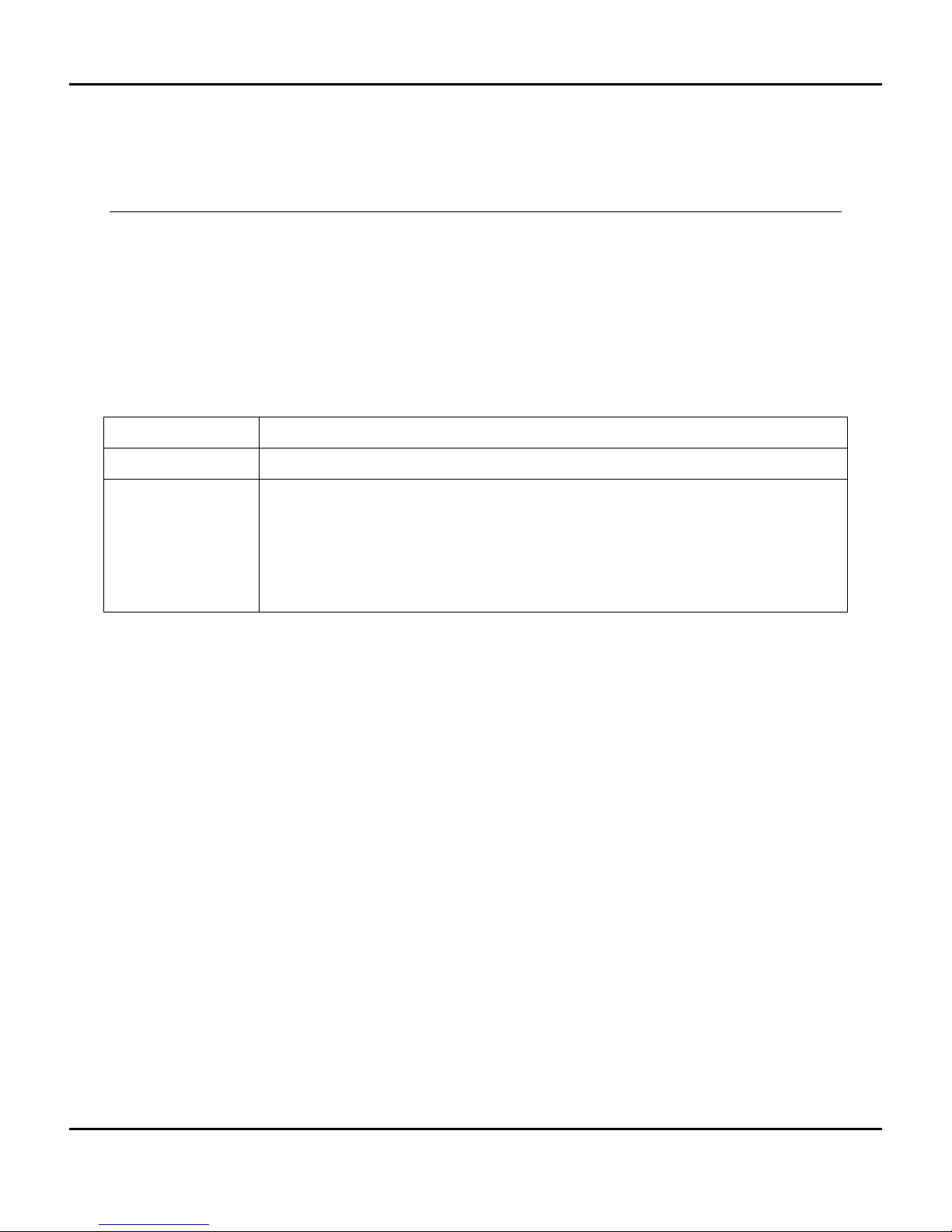

Table 4 Configure Remote Operation Using the LAN

Step Action

1.

Press to invoke the System menus, and if the SYSTEM 4 menu does not appear in

the display, press the bottom-most interactive softkey until it does.

2. Are you going to connect the LAN using Dynamic Host Configuration Protocol (DHCP), or

configure the LAN connection manually?

If the LAN connection will be done by DHCP: go to the next step.

If the LAN connection will be configured manually: go to Step 4.

3.

Press the DHCP softkey and set DCHP to On using the keys. The instrument will try to

connect to the DCHP server and the IP address and Subnet Mask will be set automatically from

the first server that establishes communication via the LAN connection.

Go to Step 7.

NOTE: If the 2400/2500 fails to connect to the DCHP server, the unit will attempt to reconnect

again. If it fails to connect to the DCHP server a second time, the 2400/2500 will attempt to

reconnect once every hour. During this period, the IP address and subnet mask values will be

zero.

4.

Press the DHCP softkey and set DCHP to Off using the keys.

5. Press the IP Address softkey to highlight the IP Address menu item. Enter the IP address using the

numeric keypad.

NOTE: An IP address consists of four sets of three-digit numbers, separated by decimal points.

The following example demonstrates how to properly enter an IP address:

190.165.001.034

An invalid IP entry will be displayed as Invalid IP Input in the Step Size/Error Message section of

the display. Examples of invalid addresses are values greater than 255, less than zero (negative

sign), values greater than three digits per set or more or less than 4 sets of three-digit values.

6. Press the Subnet Mask softkey to highlight the Subnet Mask menu item. Enter the subnet mask

number using the sequence defined in the previous step.

7. Confirm that the server has connected to 2400/2500 by observing the Link Status menu item.

This menu item is an indicator only. No entry key functions are processed.

End of Procedure

Programming Manual, Part Number 34783, Rev A, July 2009 7

Page 14

3. Hardware Interfaces Giga-tronics 2400/2500 Series Microwave Signal Generators

This page is intentionally blank

8 Programming Manual, Part Number 34783, Rev A, July 2009

Page 15

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

Chapter 4. Programming Interfaces

4.1 Introduction

This chapter describes the different programming interfaces and methods for remotely controlling a

2400/2500.

4.2 Select the Remote Programming Language

The 2400/2500 can communicate using a variety of languages. Every 2400/2500 is capable of

communications using the SCPI (Standard Commands for Programmable Instruments) language or any

Giga-tronics native command set. Optional Command Sets are available as well.

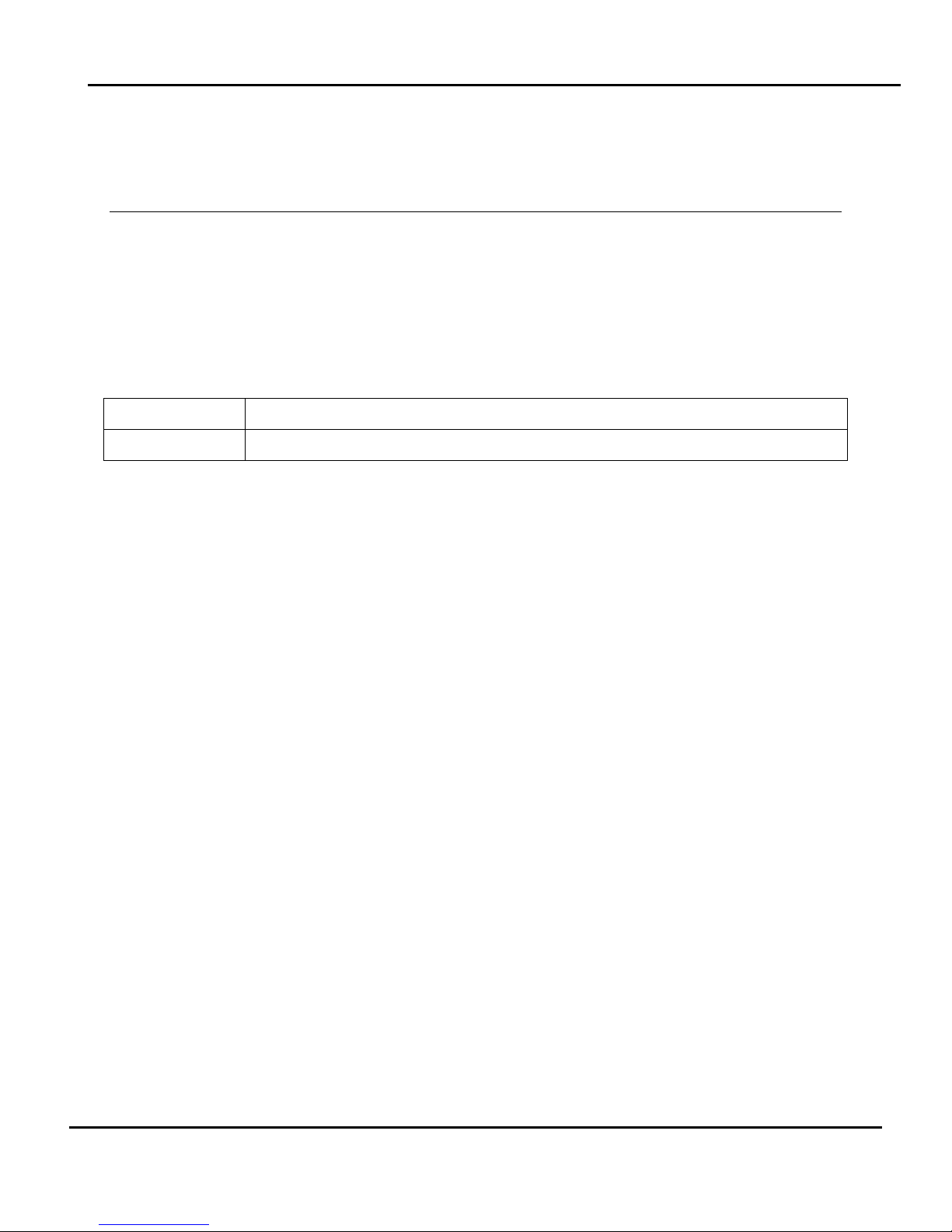

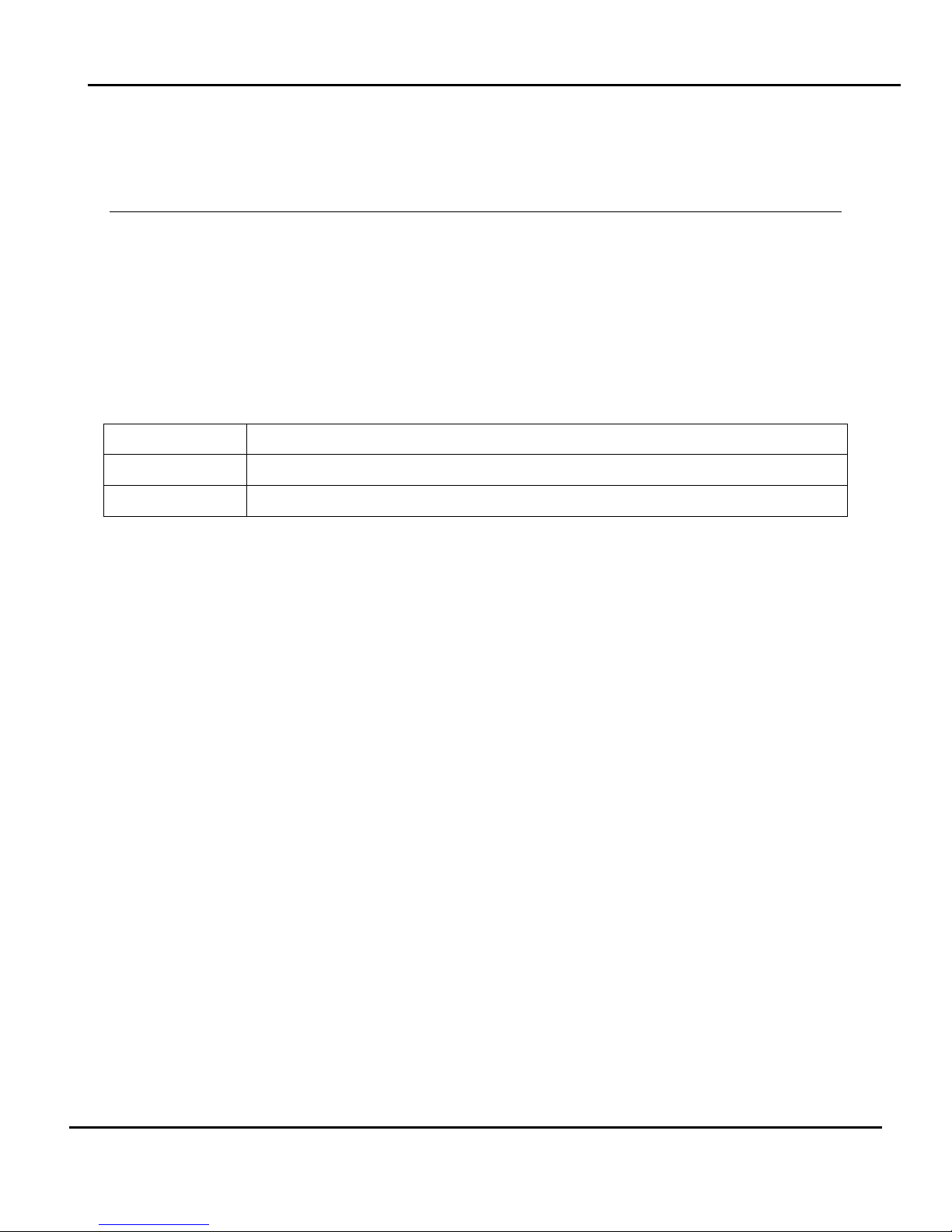

Table 5 below describes how to use the 2400/2500 front panel in local operating mode to select a

language from the Language Menu.

Table 5 Select the Remote Language

Step Action

1.

• If the instrument IS NOT in remote operating mode, press the LOCAL button once to invoke

the Language menus in the display.

• If the instrument IS IN remote operating mode, press the LOCAL button twice - once to take

it out of remote operating mode, then again to invoke the Language menus in the display.

2. If the desired language does not appear in the parameter area of the display, press the bottommost interactive softkey to go to the next menu. There are three screens for the Language

menus. Use the bottom softkey to go through the screens until you find the language you want

to use.

3. If the message “Option not installed” appears next to a given language in the menu area of the

display, that language is optional and not currently available in the instrument. Contact Gigatronics customer support to inquire about purchasing additional language options.

4. Once you have located the desired language, press the associated interactive softkey in the

display to select it.

End of Procedure

Programming Manual, Part Number 34783, Rev A, July 2009 9

Page 16

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3 Dynamic Link Library (DLL)

A DLL is a collection of routines that can be used by applications or other DLLs. A DLL is provided on the

CD-ROM that is included with the 2400/2500 Microwave Signal Generator. When you install Automation

Xpress from the CD-ROM onto your computer, the DLL is loaded onto your computer. The routines in

the DLL can be used in Visual C++, Visual Basic, and other applications.

4.3.1 Adding the DLL to Programming Projects

The following procedures describe how to include the DLL into Visual C++ and Visual Basic projects.

4.3.1.1 Add the DLL to a Visual C++ Project

Table 6 Add the DLL to a Visual C++ Project

Step Action

1. Create a Visual C++ project.

2. Copy GT2400.dll from C:\Program Files\Giga-tronics\AX\bin into your project’s executable folder

for run time calls. (e.g. folder named “Debug”)

3. Copy GT2400.lib from C:\Program Files\Giga-tronics\AX\lib into your project.

4. Copy all files from C:\Program Files\Giga-tronics\AX\include into your project.

5. Copy the following line into your application C/C++ files:

“#include “GT2400.h”

6. Make DLL function calls as needed from any .cpp files where GT2400.h file is included.

7. Build your application.

End of Procedure

4.3.1.2 Add the DLL to a Visual Basic Project

Table 7 Add the DLL to a Visual Basic Project

Step Action

1. Create a Visual Basic project.

2. Copy GT2400.dll from C:\Program Files\Giga-tronics\AX\bin into your project’s executable folder

for run time calls.

3. Copy DLLDeclare.bas from C:\Program Files\Giga-tronics\AX\VBModule to the project folder.

4. Make DLL function calls as needed from any files in the project.

5. Build the application.

10 Programming Manual, Part Number 34783, Rev A, July 2009

End of Procedure

Page 17

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.2 Programming Examples Using the DLL

4.3.2.1 CW Operation Using Visual C++

NOTE: Only bold faced code lines are unique to a specific operation mode. All other lines are supporting

lines shared by both CW and List modes.

Step Description

1.

Perform steps 1 through 5 in Table 6 on page 10 to add the DLL to a Visual C++ project.

2.

Write the following code:

#include "GT2400.h"

#include "stdio.h"

#define SUCCESS 0

//This routine sets CW frequency and power of a 2400/2500

synthesizer

//at your choice through GPIB at address 6.

void main(void)

{

STATUS status;

unsigned long instrumentHandle;

double Frequency = 1000;

double Power = 0;

status = GT2400_OpenConnection(0,6,0,&instrumentHandle);

if(status < SUCCESS )

{

char statusText[256];

GT2400_GetErrorMessage(status, statusText);

printf("Status Message %s\n",statusText);

}

status = GT2400_SetRF(instrumentHandle, 1);

printf("Frequency (MHz) =");

scanf("%lf",&Frequency);

printf("Power (dBm) =");

scanf("%lf",&Power);

status = GT2400_SetCW(instrumentHandle,Frequency,Power,0,0);

status = GT2400_CloseAllConnections();

}

3.

Build the project.

4.

Run the program.

Programming Manual, Part Number 34783, Rev A, July 2009 11

End of Example

Page 18

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.2.2 Programming Example; CW Operation Using Visual Basic

Step Description

1.

Perform steps 1 through 3 of Table 7 on page 10 to create a Visual Basic project.

2.

Write the following

‘This routine sets CW frequency and power of a 2400/2500

synthesizer

‘through GPIB at address 6.

Dim status As Long

Dim instrumentHandle As Long

Dim Frequency As Double

Dim Power As Double

Dim statusText As String

statusText = Space(100)

status = GT2400_OpenConnection(0,6,0,instrumentHandle)

If status < SUCCESS Then

GT2400_GetErrorMessage(status, statusText)

MsgBox statusText

End If

status = GT2400_SetRF(instrumentHandle, 1)

Frequency = 20000 ‘MHz

Power = 10

status = GT2400_SetCW(instrumentHandle,Frequency,Power,0,0)

status = GT2400_CloseAllConnections()

3.

Build the project.

4.

Run the program.

12 Programming Manual, Part Number 34783, Rev A, July 2009

End of example

Page 19

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.2.3 Programming Example; List Operation Using Visual C++

Step Description

1.

Perform steps 1 through 5 of Table 6 to create a Visual C++ project.

2. Write the following code:

#include <windows.h>

#include <stdio.h>

#include "gt2400.h"

#define SUCCESS 0

//This routine can load any list file to 2400/2500 synthesizer

//and set up repeat type and trigger type at user choice.

void main(void)

{

long status;

char listFileName[80];

char statusText[256];

unsigned long instrumentHandle;

short tmp;

status = GT2400_OpenConnection(0, 6, 0, &instrumentHandle);

if(status < SUCCESS )

{

GT2400_GetErrorMessage(status, statusText);

printf("Status Message %s\n",statusText);

}

printf("Please enter the file name to be loaded:\n ");

scanf("%s",&listFileName);

status = GT2400_LoadListFromFile(listFileName, statusText);

if ( status < SUCCESS ) //Error during loading

{

GT2400_GetErrorMessage(status, statusText);

printf("Status Message %s\n",statusText);

}

status = GT2400_DownloadList(instrumentHandle, listFileName);

printf("Enter Repeat Type (0 = single step; 1 = single sweep; 2 = continuous) =");

scanf("%d",&tmp);

status = GT2400_SetRepeatType(instrumentHandle, tmp);

printf("Enter Trigger Type (0 = External trigger; 1 = Software trigger or GET) =");

scanf("%d",&tmp);

status = GT2400_SetTriggerType(instrumentHandle, tmp);

status = GT2400_SetRF(instrumentHandle, 1);

status = GT2400_CloseAllConnections();

}

Continued next page

Programming Manual, Part Number 34783, Rev A, July 2009 13

Page 20

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

Step Description

3.

Build the project.

4.

Run the program.

5.

Send trigger.

End of example

14 Programming Manual, Part Number 34783, Rev A, July 2009

Page 21

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.2.4 Programming Example; Generate Two Frequencies

The following example shows how to write code for generating two CW frequencies, separated by a 40

second delay.

Step Description

//This example sets two CW frequencies in sequence, separated by a 40 second delay.

1.

#include "GT2400.h"

#include "stdio.h"

#include "winbase.h"

void main(void)

{

long STATUS;

unsigned long instrumentHandle;

printf("f= 23.456789 MHz, Power = 5 dBm\n");

STATUS = GT2400_OpenConnection(0, 6, 0, &instrumentHandle);

STATUS = GT2400_SetRF(instrumentHandle, 1);

STATUS = GT2400_SetCW(instrumentHandle, 23.456789, 5);

printf("Waiting for 40 seconds....\n");

//Reserve time for frequency counter to operate correctly

Sleep(40000);

printf("f= 33.4567891 MHz, Power = 0 dBm\n");

STATUS = GT2400_SetCW(instrumentHandle, 33.4567891, 0);

STATUS = GT2400_CloseAllConnections();

}

End of example

Programming Manual, Part Number 34783, Rev A, July 2009 15

Page 22

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.2.5 Programming Example: List Operation Using Visual Basic

Step Description

1. Perform step 1 through step 3 of Table 7 on page 10 to create a Visual Basic project.

2. Write following:

‘This routine can load any list file to 2400/2500 synthesizer

‘and set up repeat type and trigger type.

Dim status As Long

Dim listFileName As String

Dim statusText As String

Dim instrumentHandle As Long

statusText = Space(100)

status = GT2400_OpenConnection(0, 6, 0, instrumentHandle)

If status < SUCCESS Then

GT2400_GetErrorMessage(status, statusText)

MsgBox statusText

End If

‘Please replace C:\Temp\ListTest.txt with your list file name.

listFileName = “C:\Temp\ListTest.txt”

status = GT2400_LoadListFromFile(listFileName, listFileName)

If status < SUCCESS Then

‘Error during loading

GT2400_GetErrorMessage(status, statusText)

MsgBox statusText

End If

status = GT2400_DownloadList(instrumentHandle, listFileName)

‘Repeat Type (0 = single step; 1 = single sweep; 2 = continuous) =")

status = GT2400_SetRepeatType(instrumentHandle, 1)

‘ Trigger Type (0 = External trigger; 1 = Software trigger or GET) =")

status = GT2400_SetTriggerType(instrumentHandle, 0)

status = GT2400_SetRF(instrumentHandle, 1)

status = GT2400_CloseAllConnections()

3. Build the project.

4. Run the program.

5. Send trigger.

16 Programming Manual, Part Number 34783, Rev A, July 2009

End of example

Page 23

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3 DLL Functions

This section describes the DLL functions in detail.

Programming Manual, Part Number 34783, Rev A, July 2009 17

Page 24

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.1 DLL Function; GT2400_FindInstruments

GT2400_FindInstruments

Purpose

Find the addresses of instruments, either through GPIB or RS232, connected to PC.

Syntax

STATUS GT2400_FindInstruments( const short connectionType,

short addresses[],

short *pCount)

Parameter Description

connectionType Input: Connection type.

0 = GPIB,

1 = RS232

2,3 = SPECIAL (NOT FOR COMMON USE)

4 = GPIB Connection via remote SERVER PC (TCP/IP)

addresses Output: Array of GPIB addresses or COM port numbers of all the Giga-tronics

instruments connected.

(Note: In case the RS232 connection interface is selected, the first element returned

in this array is the first serial port that is connected to a Giga-tronics instrument

followed by the remaining serial port numbers on the PC.)

Example 1:

There are total of 4 COM ports on a PC, and only COM port 1 is connected to a Gigatronics instrument, the returned result will be

addresses[0] = 1

addresses[1] = 2

addresses[2] = 3

addresses[3] = 4

Example 2:

There are total of 4 COM ports on a PC, and only COM port 3 is connected to a Gigatronics instrument, the returned result will be

addresses[0] = 3

addresses[1] = 4

pCount Output: Total number of instruments connected to PC through the specified

interface.

18 Programming Manual, Part Number 34783, Rev A, July 2009

Page 25

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.2 DLL Function; GT2400_OpenConnection

GT2400_OpenConnection

Purpose

Establish the communication between the PC and the 2400/2500 with the specified connection interface

and address. For an Ethernet connection, call GT2400_SetIPAddress function first to establish the

TCP/IP address of the instrument.

Syntax

STATUS GT2400_OpenConnection( const short connectionType,

const short address,

const short resetDevice

unsigned long *instrumentHandle)

Parameter Description

connectionType Input: Connection interface:

0 = GPIB

1 = RS232

2,3 = SPECIAL (NOT FOR COMMON USE)

4 = GPIB Connection via remote SERVER PC (TCP/IP) (not supported after Revision

3.3)

5 = reserved

6 = Ethernet (TCP/IP) (supported from Rev 3.3)

address Input: GPIB address number if ConnectionType = 0

or COM port number if ConnectionType = 1

Note: GPIB communication board index can be set if GPIB interface is selected. The

2 byte (SHORT) “address” contains GPIB board index and address. The most

significant byte is used to set GPIB board index and the least significant byte is used

to set GPIB address. The default GPIB board index is 0.

Example: GPIB board index = 1; GPIB address = 6

Parameter, address = 0x100 | 0x6 =

0x106 (in Hex.) or 262 (in Decimal)

resetDevice Input:

1 = Reset instrument in start up

0 = No reset

instrumentHandle Output: The unique identification of the connected instrument. This handle can be

used later to operate on multiple instruments.

Programming Manual, Part Number 34783, Rev A, July 2009 19

Page 26

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.3 DLL Function; GT2400_CloseGPIBConnection

GT2400_CloseGPIBConnection

Purpose

Close one specific GPIB connection.

Syntax

STATUS GT2400_CloseGPIBConnection( const unsigned long instrumentHandle)

Parameter Description

instrumentHandle Input: The unique identification of the connected instrument.

20 Programming Manual, Part Number 34783, Rev A, July 2009

Page 27

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.4 DLL Function; GT2400_CloseAllConnections

GT2400_CloseAllConnections

Purpose

Close all connection. You should always call this function before you close your application to avoid

memory leak.

Syntax

STATUS GT2400_CloseAllConnections(void)

Programming Manual, Part Number 34783, Rev A, July 2009 21

Page 28

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.5 DLL Function; GT2400_SetGPIBAddress

GT2400_SetGPIBAddress

Purpose

Set the GPIB address.

Syntax

STATUS GT2400_SetGPIBAddress( const unsigned long instrumentHandle,

const short address,

unsigned long *updatedInstrumentHandle)

Parameter Description

instrumentHandle Input: The unique identification of the instrument.

address Input: GPIB address.

updatedInstrumentHandle Output: Updated instrument handle after this function completes.

22 Programming Manual, Part Number 34783, Rev A, July 2009

Page 29

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.6 DLL Function; GT2400_SetServerIPAddr (for Rev 3.0 and above)

GT2400_SetServerIPAddr (for Rev 3.0 and above)

Purpose

Set the TCP/IP address of remote SERVER PC. (example: 194.177.0.482)

Syntax

STATUS GT2400_SetServerIPAddr( char ipAddr[])

Parameter Description

ipAddr Input: TCP/IP address of remote SERVER PC

Programming Manual, Part Number 34783, Rev A, July 2009 23

Page 30

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.7 DLL Function; GT2400_GetIPAddress (supported from Revision 3.3)

GT2400_GetIPAddress (supported from Revision 3.3)

Purpose

Get the TCP/IP address of the instrument. (example: 194.177.0.482).

Syntax

STATUS GT2400_GetIPAddress( char ipAddr[])

Parameter Description

ipAddr Output: TCP/IP address for the instrument

24 Programming Manual, Part Number 34783, Rev A, July 2009

Page 31

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.8 DLL Function; GT2400_SetIPAddress (supported from Revision 3.3)

GT2400_SetIPAddress (supported from Revision 3.3)

Purpose

Set the TCP/IP address for the instrument. (example: 194.177.0.482) For establishing Ethernet

connection with the instrument, this function needs to be called prior to calling

GT2400_OpenConnection function.

Syntax

STATUS GT2400_SetIPAddress( char ipAddr[])

Parameter Description

ipAddr Input: TCP/IP address for the instrument

Programming Manual, Part Number 34783, Rev A, July 2009 25

Page 32

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.9 DLL Function; GT2400_ResetInstrument

GT2400_ResetInstrument

Purpose

Reset the instrument to factory defaults.

Syntax

STATUS GT2400_ResetInstrument( const unsigned long instrumentHandle)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

26 Programming Manual, Part Number 34783, Rev A, July 2009

Page 33

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.10 DLL Function; GT2400_GetRF

GT2400_GetRF

Purpose

Get the state of RF output

Syntax

STATUS GT2400_GetRF( const unsigned long instrumentHandle,

short *RFState)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

RFState Output:

1 = RF is on

0 = RF is off

Programming Manual, Part Number 34783, Rev A, July 2009 27

Page 34

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.11 DLL Function; GT2400_SetRF

GT2400_SetRF

Purpose

Set the RF on or off.

Syntax

STATUS GT2400_SetRF( const unsigned long instrumentHandle,

const short RFState)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

RFState Input:

1 = Turn on

0 = Turn off RF output

28 Programming Manual, Part Number 34783, Rev A, July 2009

Page 35

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.12 DLL Function; GT2400_GetAttenuation

GT2400_GetAttenuation

Purpose

Get the attenuation value.

Syntax

STATUS GT2400_GetAttenuation( const unsigned long instrumentHandle,

short *pAttenuation)

Parameter Description

instrumentHandle Input: The unique identification of the instrument.

pAttenuation Output: current attenuation in the instrument.

If returned value = -10, it is in AUTO attenuation mode;

Else If returned value = -99, there is no attenuator option installed;

Else attenuation is in MANUAL mode with value = *pAttenuation

Programming Manual, Part Number 34783, Rev A, July 2009 29

Page 36

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.13 DLL Function; GT2400_SetAttenuation

GT2400_SetAttenuation

Purpose

Set the attenuation of the output power of the 2400/2500.

Syntax

STATUS GT2400_SetAttenuation( const unsigned long instrumentHandle,

const short attenuation)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

attenuation Input: attenuation value, e.g.

If attenuation = -10, set to auto attenuation;

Else If attenuation >= 0, set to manual attenuation with value = attenuation.

attenuation = [0, 10,20,30,40,50,60,70,80,90]

30 Programming Manual, Part Number 34783, Rev A, July 2009

Page 37

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.14 DLL Function; GT2400_GetALCLeveling

GT2400_GetALCLeveling

Purpose

Get the current ALC leveling source of the instrument.

Syntax

STATUS GT2400_GetALCLeveling( const unsigned long instrumentHandle,

short *alcLeveling)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

alcLeveling Output: Current ALC leveling source of the instrument

= 0: Internal

= 1: Power Meter

= 2: Positive Diode

= 3: Negative

Programming Manual, Part Number 34783, Rev A, July 2009 31

Page 38

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.15 DLL Function; GT2400_SetALCLeveling

GT2400_SetALCLeveling

Purpose

Set the ALC leveling source to the instrument.

Syntax

STATUS GT2400_SetALCLeveling( const unsigned long instrumentHandle,

const short alcLeveling)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

alcLeveling Input: ALC leveling source set to the instrument

= 0: Internal

= 1: Power Meter

= 2: Positive Diode

= 3: Negative

32 Programming Manual, Part Number 34783, Rev A, July 2009

Page 39

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.16 DLL Function; GT2400_GetErrorMessage

GT2400_GetErrorMessage

Purpose

Convert STATUS code to the corresponding description.

Syntax

STATUS GT2400_GetErrorMessage( const long errorID,

char statusText[])

Parameter Description

errorID STATUS of any DLL function

statusText Text description of the STATUS

Programming Manual, Part Number 34783, Rev A, July 2009 33

Page 40

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.17 DLL Function; GT2400_GetDLLVersion

GT2400_GetDLLVersion

Purpose

Return the DLL version.

Syntax

STATUS GT2400_GetDLLVersion( char version[])

Parameter Description

version DLL version

34 Programming Manual, Part Number 34783, Rev A, July 2009

Page 41

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.18 DLL Function; GT2400_GetCW

GT2400_GetCW

Purpose

Read the current CW setting (data) from the instrument.

Syntax

STATUS GT2400_GetCW( const unsigned long instrumentHandle,

double *frequency,

double *power)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

frequency Output: CW frequency (in MHz)

power Output: CW power (in dBm)

Programming Manual, Part Number 34783, Rev A, July 2009 35

Page 42

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.19 DLL Function; GT2400_GetCWDataLimit

GT2400_GetCWDataLimit

Purpose

Get the CW data limits of the instrument.

Syntax

STATUS GT2400_GetCWDataLimit( const unsigned long instrumentHandle,

double *pMinFrequency,

double *pMaxFrequency,

double *pMinPower,

double *pMaxPower)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

pMinFrequency Output: Minimum frequency allowed (in MHz)

pMaxFrequency Output: Maximum frequency allowed (in MHz)

pMinPower Output: Minimum power allowed (in dBm)

pMaxPower Output: Maximum power allowed (in dBm)

36 Programming Manual, Part Number 34783, Rev A, July 2009

Page 43

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.20 DLL Function; GT2400_SetCW

GT2400_SetCW

Purpose

Set CW.

Syntax

STATUS GT2400_SetCW( const unsigned long instrumentHandle,

const double frequency,

const double power)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

frequency Input: CW frequency (in MHz)

power Input: CW power (in dBm)

Programming Manual, Part Number 34783, Rev A, July 2009 37

Page 44

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.21 DLL Function; GT2400_GetPowerOffset

GT2400_GetPowerOffset

Purpose

Get the current power offset value of the instrument.

Syntax

STATUS GT2400_GetPowerOffset( const unsigned long instrumentHandle,

double *powerOffset)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

powerOffset Output: Current power offset value of the instrument

38 Programming Manual, Part Number 34783, Rev A, July 2009

Page 45

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.22 DLL Function; GT2400_SetPowerOffset

GT2400_SetPowerOffset

Purpose

Set the power offset value to the instrument.

Syntax

STATUS GT2400_SetPowerOffset( const unsigned long instrumentHandle,

const double powerOffset)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

powerOffset Input: Power offset value set to the instrument

Programming Manual, Part Number 34783, Rev A, July 2009 39

Page 46

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.23 DLL Function; GT2400_GetPowerSlope

GT2400_GetPowerSlope

Purpose

Get the current power slope value of the instrument.

Syntax

STATUS GT2400_GetPowerSlope( const unsigned long instrumentHandle,

double *powerSlope)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

powerSlope Output: Current power slope value of the instrument

40 Programming Manual, Part Number 34783, Rev A, July 2009

Page 47

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.24 DLL Function; GT2400_SetPowerSlope

GT2400_SetPowerSlope

Purpose

Set the power slope value to the instrument.

Syntax

STATUS GT2400_SetPowerSlope( const unsigned long instrumentHandle,

const double powerSlope)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

powerSlope Input: Power slope value set to the instrument

Programming Manual, Part Number 34783, Rev A, July 2009 41

Page 48

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.25 DLL Function; GT2400_DownloadList

GT2400_DownloadList

Purpose

Download a list to the GT2400 synthesizer. The file can be prepared beforehand by either MS Excel, or

any text editor or AutomationXpress GUI or AutomationXpress DLL list editing functions.

Syntax

STATUS GT2400_DownloadList( const unsigned long instrumentHandle,

const char listPath[])

Parameter Description

instrumentHandle Input: The unique identification of the instrument

listPath Input: Complete path (path + list name) of the list being downloaded to the unit

42 Programming Manual, Part Number 34783, Rev A, July 2009

Page 49

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.26 DLL Function; GT2400_GetRepeatType

GT2400_GetRepeatType

Purpose

Get the repeat type of the list to be triggered.

Syntax

STATUS GT2400_GetRepeatType( const unsigned long instrumentHandle,

short *repeatType)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

repeatType Output:

0 = single step;

1 = single sweep;

2 = continuous

Programming Manual, Part Number 34783, Rev A, July 2009 43

Page 50

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.27 DLL Function; GT2400_SetRepeatType

GT2400_SetRepeatType

Purpose

Set the repeat type of the list to be triggered.

Syntax

STATUS GT2400_SetRepeatType( const unsigned long instrumentHandle,

const short repeatType)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

repeatType Input:

0 = single step;

1 = single sweep;

2 = continuous

44 Programming Manual, Part Number 34783, Rev A, July 2009

Page 51

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.28 DLL Function; GT2400_GetTriggerType

GT2400_GetTriggerType

Purpose

Get the trigger type to trigger the list.

Syntax

STATUS GT2400_GetTriggerType( const unsigned long instrumentHandle,

short *triggerType)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

triggerType Output:

0 = External trigger;

1 = GET;

2 = Software trigger

Programming Manual, Part Number 34783, Rev A, July 2009 45

Page 52

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.29 DLL Function; GT2400_SetTriggerType

GT2400_SetTriggerType

Purpose

Set the trigger type to trigger the list.

Syntax

STATUS GT2400_SetTriggerType( const unsigned long instrumentHandle,

const short triggerType)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

triggerType Input:

0 = External trigger;

1 = GET;

2 = Software trigger

46 Programming Manual, Part Number 34783, Rev A, July 2009

Page 53

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.30 DLL Function; GT2400_SetListScanDirection

GT2400_SetListScanDirection

Purpose

Set the list scan direction.

Syntax

STATUS GT2400_SetListScanDirection( const unsigned long instrumentHandle,

const short direction)

Parameter Description

instrumentHandle Input: The unique identification of the instrument.

direction Input:

0 = scan from first point to last point;

1 = scan from last to first.

Programming Manual, Part Number 34783, Rev A, July 2009 47

Page 54

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.31 DLL Function; GT2400_SoftwareTrigger

GT2400_SoftwareTrigger

Purpose

Use the software to trigger the current list.

Syntax

STATUS GT2400_SoftwareTrigger( const unsigned long instrumentHandle)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

48 Programming Manual, Part Number 34783, Rev A, July 2009

Page 55

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.32 DLL Function; GT2400_GroupExecutionTrigger

GT2400_GroupExecutionTrigger

Purpose

Send a Group Execution Trigger (G.E.T. is defined in IEEE 488) to all the instruments connected to PC via

GPIB.

Syntax

STATUS GT2400_GroupExecutionTrigger( void)

Programming Manual, Part Number 34783, Rev A, July 2009 49

Page 56

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.33 DLL Function; GT2400_GetListDataLimit

GT2400_GetListDataLimit

Purpose

Get the list data limits of the instrument.

Syntax

STATUS GT2400_GetListDataLimit( const unsigned long instrumentHandle,

short *pMaxListPts,

double *pMinStepTime,

double *pMaxStepTime,

double *pMinRFOffTime,

double *pMaxRFOffTime,

double *pMinSyncOutDelay,

double *pMaxSyncOutDelay)

Parameter Description

instrumentHandle Input: The unique identification of the instrument.

pMaxListPts Output: Maximum number of list points

pMinStepTime Output: Minimum list step time (in ms)

pMaxStepTime Output: Maximum list step time (in ms)

pMinRFOffTime Output: Minimum list RF off time (in ms)

pMaxRFOffTime Output: Maximum list RF off time (in ms)

pMinSyncOutDelay Output: Minimum list sync out delay (in ms)

pMaxSyncOutDelay Output: Maximum list sync out delay (in ms)

50 Programming Manual, Part Number 34783, Rev A, July 2009

Page 57

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.34 DLL Function; GT2400_LoadListFromFile

GT2400_LoadListFromFile

Purpose

Load a list from a disk file to PC RAM.

Syntax

STATUS GT2400_LoadListFromFile( const char filename[],

char errText[])

Parameter Description

filename Input: Name of the file being loaded.

errText Output: If there is an error detected by STATUS, errText will hold the description

of the problems.

Programming Manual, Part Number 34783, Rev A, July 2009 51

Page 58

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.35 DLL Function; GT2400_CreateNewList

GT2400_CreateNewList

Purpose

Create a new list in PC RAM.

Syntax

STATUS GT2400_CreateNewList( const char listPath[])

Parameter Description

listPath Input: Complete path (path + list name) of the list whose content is requested

52 Programming Manual, Part Number 34783, Rev A, July 2009

Page 59

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.36 DLL Function; GT2400_SaveListToFile

GT2400_SaveListToFile

Purpose

Save a currently active list from RAM to a disk file.

Syntax

STATUS SaveListToFile ( const char filename[],

char errText[])

Parameter Description

filename Input: File name of list to be saved in.

errText Output: If there is an error detected by STATUS, errText will hold the description

of the problems.

Programming Manual, Part Number 34783, Rev A, July 2009 53

Page 60

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.37 DLL Function; GT2400_ActivateAList

GT2400_ActivateAList

Purpose

Activate the selected list so that the list is ready to respond to a trigger.

Syntax

STATUS GT2400_ActivateAList( const char listPath[])

Parameter Description

listPath Input: Complete path (path + list name) of the list to be activated

54 Programming Manual, Part Number 34783, Rev A, July 2009

Page 61

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.38 DLL Function; GT2400_GetListData

GT2400_GetListData

Purpose

Get the contents of the selected list from DLL allocated RAM into user application.

Syntax

STATUS GT2400_GetListData( const char listPath[],

double *stepTime,

double *rfOffTime,

double *syncOutDelay,

unsigned char *syncInfo,

short *attenSetting

double *frequency,

double *power,

short *pListLen)

Parameter Description

listPath Input: Complete path (path + list name) of the list whose content is requested.

stepTime Output: Step time of all list points (in ms)

rfOffTime Output: RF off time of all list points (in ms)

syncOutDelay Output: Sync out delay (in ms)

syncInfo Output: Sync out pulse information for every list pt

attenSetting Output: The attenuation setting for the current list

frequency Output: Array of frequencies in the list (in MHz)

power Output: Array of power in the list (in dBm)

pListLen Output: Number of points in the list

Programming Manual, Part Number 34783, Rev A, July 2009 55

Page 62

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.39 DLL Function; GT2400_GetListDataWithCorrection

GT2400_GetListDataWithCorrection

Purpose

Get the contents of the selected list from DLL allocated RAM into user application.

Syntax

STATUS GT2400_GetListDataWithCorrection ( const char listPath[],

double *stepTime,

double *rfOffTime,

double *syncOutDelay,

unsigned char *syncInfo,

short *attenSetting

double *frequency,

double *power,

double *correction,

short *pListLen)

Parameter Description

listPath Input: Complete path (path + list name) of the list whose content is requested.

stepTime Output: Step time of all list points (in ms)

rfOffTime Output: RF off time of all list points (in ms)

syncOutDelay Output: Sync out delay (in ms)

syncInfo Output: Sync out pulse information for every list pt

attenSetting Output: The attenuation setting for the current list

frequency Output: Array of frequencies in the list (in MHz)

power Output: Array of power in the list (in dBm)

correction Output: Array of correction in the list (in dBm)

pListLen Output: Number of points in the list

56 Programming Manual, Part Number 34783, Rev A, July 2009

Page 63

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.40 DLL Function; GT2400_SetCorrection

GT2400_SetCorrection

Purpose

Edit the correction of the selected list.

Syntax

STATUS GT2400_SetCorrection ( double *correction)

Parameter Description

correction Input: Array of correction

Programming Manual, Part Number 34783, Rev A, July 2009 57

Page 64

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.41 DLL Function; GT2400_GetCorrection

GT2400_GetCorrection

Purpose

Get the correction of the selected list.

Syntax

STATUS GT2400_GetCorrection ( double *correction)

Parameter Description

correction Output: Array of correction

58 Programming Manual, Part Number 34783, Rev A, July 2009

Page 65

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.42 DLL Function; GT2400_EditApplyCorrection

GT2400_EditApplyCorrection

Purpose

Set flag if correction should apply.

Syntax

STATUS GT2400_EditApplyCorrection ( bool correctionOn)

Parameter Description

correctionOn Input:

1 to turn on correction

0 to turn off

Programming Manual, Part Number 34783, Rev A, July 2009 59

Page 66

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.43 DLL Function; GT2400_EditAListPoint

GT2400_EditAListPoint

Purpose

Edit a selected point in a list.

Syntax

STATUS GT2400_EditAListPoint( const short position

const short insertType,

const char listPath[],

const unsigned char syncOutEnable,

const double frequency,

const double power)

Parameter Description

position Input: position in the list being edited. 0 < position ≤ current list length

insertType Input: Insert Type:

0 = REPLACE

1 = INSERT BEFORE

2 = INSERT AFTER

listPath Input: Complete path (path + list name) of the list

syncOutEnable Input: Enable/disable sync out pulse generated in the editing point

frequency Input: Frequency of the point being updated (in MHz)

power Input: Power of the pt being updated (in dBm)

60 Programming Manual, Part Number 34783, Rev A, July 2009

Page 67

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.44 DLL Function; GT2400_EditListPoints

GT2400_EditListPoints

Purpose

Edit multiple selected list points in a list with one function call.

Syntax

STATUS GT2400_ EditListPoints ( const short position,

const short insertType,

const char listPath[],

const unsigned char *syncOutEnable,

const double *frequency,

const double *power,

const short listLen,

char errorTxt[])

Parameter Description

position Input: position in the list being edited. 0 < position ≤ current list length

insertType Input: Insert Type:

0 = REPLACE,

1 = INSERT BEFORE

2 = INSERT AFTER

(Note: if insertType = REPLACE, the existing list will be replaced with the newly

created list.)

listPath Input: Complete path (path + list name) of the list

syncOutEnable Input: Byte array that enables or disables sync out pulse generated in list.

frequency Input: Array of frequency for list points (in MHz)

power Input: Array of power for list points (in dBm)

listLen Input: Number of list points being edited

errText Output: If there is an error detected by STATUS, errText will hold the description

of the problem.

Programming Manual, Part Number 34783, Rev A, July 2009 61

Page 68

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.45 DLL Function; GT2400_EditFreqRangeByStepFreq

GT2400_EditFreqRangeByStepFreq

Purpose

Establish a list or insert a sub-list to an existing list by inputting start frequency, stop frequency, step

frequency, and power.

Syntax

STATUS GT2400_ EditFreqRangeByStepFreq( const short position,

const short insertType,

const char listPath[],

const double startFrequency,

const double stopFrequency,

const double stepFrequency,

const double power)

Parameter Description

position Input: position in the list being edited, 0 < position ≤ current list length

insertType Input: Insert Type:

0 = REPLACE

1 = INSERT BEFORE

2 = INSERT AFTER

(Note: if insertType = REPLACE, the existing list will be replaced with the newly

created list.)

listPath Input: Complete path (path + list name) of the list

startFrequency Input: Start frequency (in MHz)

stopFrequency Input: Stop frequency (in MHz)

stepFrequency Input: Frequency step (in MHz)

power Input: Power for all list points (in dBm)

62 Programming Manual, Part Number 34783, Rev A, July 2009

Page 69

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.46 DLL Function; GT2400_EditPowerRangeByStepPower

GT2400_EditPowerRangeByStepPower

Purpose

Establish a list or insert a sub-list to an existing list by inputting start power, stop power, step

power, and frequency.

Syntax

STATUS GT2400_ EditPowerRangeByStepPower( const short position,

const short insertType,

const char listPath[],

const double startPower,

const double stopPower,

const double stepPower,

const double frequency)

Parameter Description

position Input: position in the list being edited, 0 < position ≤ current list length

insertType Input: Insert Type:

0 = REPLACE

1 = INSERT BEFORE

2 = INSERT AFTER

(Note: if insertType = REPLACE, the existing list will be replaced with the newly

created list.)

listPath Input: Complete path (path + list name) of the list

startPower Input: Start power (in dBm)

stopPower Input: Stop power (in dBm)

stepPower Input: Step power (in dBm)

frequency Input: Frequency for all list points (in MHz)

Programming Manual, Part Number 34783, Rev A, July 2009 63

Page 70

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.47 DLL Function; GT2400_EditFreqRangeByNumOfPts

GT2400_EditFreqRangeByNumOfPts

Purpose

Establish a long list or insert a sub-list to an existing list by inputting start frequency, stop frequency,

power, and number of list points.

Syntax

STATUS GT2400_EditFreqRangeByNumOfPts( const short position,

const short insertType,

const char listPath[],

const double startFrequency,

const double stopFrequency,

const double power,

const short numOfPts)

Parameter Description

position Input: position in the list being edited, 0 < position ≤ current list length

insertType Input: Insert Type:

0 = REPLACE

1 = INSERT BEFORE

2 = INSERT AFTER

(Note: if insertType = REPLACE, the existing list will be replaced with the newly

created list.)

listPath Input: Complete path (path + list name) of the list

startFrequency Input: Start frequency for range insertion (in MHz)

stopFrequency Input: Stop frequency for range insertion (in MHz)

power Input: Power for all list points (in dBm)

numOfPts Input: Number of list points being created

64 Programming Manual, Part Number 34783, Rev A, July 2009

Page 71

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.48 DLL Function; GT2400_EditPowerRangeByNumOfPts

GT2400_EditPowerRangeByNumOfPts

Purpose

Establish a long list or insert a sub-list to an existing list by inputting start power, stop power, frequency,

and number of list points.

Syntax

STATUS GT2400_EditPowerRangeByNumOfPts( const short position,

const short insertType,

const char listPath[],

const double startPower,

const double stopPower,

const double frequency,

const short numOfPts)

Parameter Description

position Input: position in the list being edited, 0 < position ≤ current list length

insertType Input: Insert Type:

0 = REPLACE

1 = INSERT BEFORE

2 = INSERT AFTER

(Note: if insertType = REPLACE, the existing list will be replaced with the newly

created list.)

listPath Input: Complete path (path + list name) of the list

startPower Input: Start power (in dBm)

stopPower Input: Stop power (in dBm)

frequency Input: Frequency for all list points (in MHz)

numOfPts Input: Number of list points being created

Programming Manual, Part Number 34783, Rev A, July 2009 65

Page 72

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.49 DLL Function; GT2400_EditListSyncOutOption

GT2400_EditListSyncOutOption

Purpose

Edit the sync out option for the current list.

Syntax

STATUS GT2400_EditListSyncOutOption( const char listPath[],

const short syncOutOption)

Parameter Description

listPath Input: Complete path (path + list name) of the list being edited

syncOutOption Input: Sync out option:

0 = No sync out

1 = Sync out at first list pt

2 = Sync out at last list pt

3 = Sync out at every list pt

66 Programming Manual, Part Number 34783, Rev A, July 2009

Page 73

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.50 DLL Function; GT2400_EditRFOffTime

GT2400_EditRFOffTime

Purpose

Set the RF off time of a current list in PC RAM.

Syntax

STATUS GT2400_EditRFOffTime( const double RFOffTime)

Parameter Description

RFOffTime Input: RF off time for all list points (in ms) 0.1ms ≤RFOffTime ≤ 1000ms

Programming Manual, Part Number 34783, Rev A, July 2009 67

Page 74

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.51 DLL Function; GT2400_EditStepTime

GT2400_EditStepTime

Purpose

Set the step time of a current list in PC RAM.

Syntax

STATUS GT2400_EditStepTime( const double stepTime)

Parameter Description

stepTime Input: Step time of the active list (in ms) 0.15ms ≤ stepTime ≤ 1000ms

68 Programming Manual, Part Number 34783, Rev A, July 2009

Page 75

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.52 DLL Function; GT2400_EditSyncOutDelay

GT2400_EditSyncOutDelay

Purpose

Set the delay time for the sync out pulse generated.

Syntax

STATUS GT2400_EditSyncOutDelay( const double syncOutDelay)

Parameter Description

syncOutDelay Input: Delay time of sync out pulse (in ms) 0.1ms ≤ syncOutDelay ≤ 1000ms

Programming Manual, Part Number 34783, Rev A, July 2009 69

Page 76

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.53 DLL Function; GT2400_CloseAllLists

GT2400_CloseAllLists

Purpose

Remove all existing lists from PC RAM.

Syntax

STATUS GT2400_CloseAllLists( void)

70 Programming Manual, Part Number 34783, Rev A, July 2009

Page 77

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.54 DLL Function; GT2400_CloseAList

GT2400_CloseAList

Purpose

Remove the selected list from PC RAM.

Syntax

STATUS GT2400_CloseAList( const char listPath[])

Parameter Description

listPath Input: Complete path (path + list name) of the list being removed

Programming Manual, Part Number 34783, Rev A, July 2009 71

Page 78

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.55 DLL Function; GT2400_DeleteAllListPoints

GT2400_DeleteAllListPoints

Purpose

Delete all points of a selected list. The contents of the memory are cleared but the memory is still

reserved for this list until the list is closed.

Syntax

STATUS GT2400_DeleteAllListPoints( const char listPath[])

Parameter Description

listPath Input: Complete path (path + list name) of a list

72 Programming Manual, Part Number 34783, Rev A, July 2009

Page 79

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.56 DLL Function; GT2400_DeleteAListPoint

GT2400_DeleteAListPoint

Purpose

Delete a point of a selected list from PC RAM.

Syntax

STATUS GT2400_ DeleteAListPoint( const char listPath[],

const short listPointIndex)

Parameter Description

listPath Input: Complete path (path + list name) of the list whose point is deleted

listPointIndex Input: Index of the list point being deleted

Programming Manual, Part Number 34783, Rev A, July 2009 73

Page 80

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.57 DLL Function; GT2400_SetAMState

GT2400_SetAMState

Purpose

Set AM on/off.

Syntax

STATUS GT2400_SetAMState( const unsigned long instrumentHandle,

const unsigned short AMState)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

AMState Input:

1 = AM is on

0 = AM is off

74 Programming Manual, Part Number 34783, Rev A, July 2009

Page 81

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.58 DLL Function; GT2400_SetAMSource

GT2400_SetAMSource

Purpose

Set AM source to external/internal.

Syntax

STATUS GT2400_SetAMSource( const unsigned long instrumentHandle,

const short AMSource)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

AMSource Output:

1= External source

0 = Internal source

Programming Manual, Part Number 34783, Rev A, July 2009 75

Page 82

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.59 DLL Function; GT2400_SetAMExtSensitivity

GT2400_SetAMExtSensitivity

Purpose

Set AM sensitivity when AM source is external.

Syntax

STATUS GT2400_SetAMExtSensitivity( const unsigned long instrumentHandle,

double AMExtSensitivity)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

AMExtSensitivity Input: AM sensitivity 0.0 < AMExtSensitivity < 95.0 (%/V)

76 Programming Manual, Part Number 34783, Rev A, July 2009

Page 83

Giga-tronics 2400/2500 Microwave Synthesizer Series 4. Programming Interfaces

4.3.3.60 DLL Function; GT2400_SetAMIntWavefrm

GT2400_SetAMIntWavefrm

Purpose

Set the AM internal waveform.

Syntax

STATUS GT2400_SetAMIntWavefrm( const unsigned long instrumentHandle,

const short AMIntWaveform)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

AMIntWaveform Input: AM internal waveform

1 = SINE

2 = SQUARE

3 = TRIANGLE

4 = RAMP

5 = NOISE

Programming Manual, Part Number 34783, Rev A, July 2009 77

Page 84

4. Programming Interfaces Giga-tronics 2400/2500 Microwave Synthesizer Series

4.3.3.61 DLL Function; GT2400_SetAMIntRate

GT2400_SetAMIntRate

Purpose

Set the AM internal rate.

Syntax

STATUS GT2400_SetAMIntRate( const unsigned long instrumentHandle,

const double AMIntRate)

Parameter Description

instrumentHandle Input: The unique identification of the instrument

AMIntRate Input: AM internal rate (in Hz) 0.01 Hz <= AMIntRate <= 1 MHz

78 Programming Manual, Part Number 34783, Rev A, July 2009

Page 85