Page 1

Gigapack III Gold Packaging Extract, Gigapack III

Plus Packaging Extract, and Gigapack III XL

Packaging Extract

Instruction Manual

Catalog #200201 (Gigapack III Gold-4), #200202 (Gigapack III Gold-7),

and #200203 (Gigapack III Gold-11)

Catalog #200204 (Gigapack III Plus-4), #200205 (Gigapack III Plus-7),

and #200206 (Gigapack III Plus-11)

Catalog #200207 (Gigapack III XL-4), #200208 (Gigapack III XL-7),

and #200209 (Gigapack III XL-11)

Revision B

Research Use Only. Not for Use in Diagnostic Procedures.

200201-12

Page 2

LIMITED PRODUCT WARRANTY

This warranty limits our liability to replacement of this product. No other warranties of any kind, express

or implied, including without limitation, implied warranties of merchantability or fitness for a particular

purpose, are provided by Agilent. Agilent shall have no liability for any direct, indirect, consequential, or

incidental damages arising out of the use, the results of use, or the inability to use this product.

ORDERING INFORMATION AND TECHNICAL SERVICES

Email

techservices@agilent.com

World Wide Web

www.genomics.agilent.com

Telephone

Location Telephone

United States and Canada 800 227 9770

Austria 01 25125 6800

Benelux 02 404 92 22

Denmark 45 70 13 00 30

Finland 010 802 220

France 0810 446 446

Germany 0800 603 1000

Italy 800 012575

Netherlands 020 547 2600

Spain 901 11 68 90

Sweden 08 506 4 8960

Switzerland 0848 8035 60

UK/Ireland 0845 712 5292

All Other Countries Please visit www.genomics.agilent.com and click Contact Us

Page 3

Gigapack III Gold Packaging Extract, Gigapack III Plus

Packaging Extract, and Gigapack III XL Packaging Extract

CONTENTS

Materials Provided .............................................................................................................................. 1

Storage Conditions .............................................................................................................................. 1

Introduction ......................................................................................................................................... 2

Preparation of Host Strains ................................................................................................................ 3

Preparation of a –80°C Bacterial Glycerol Stock .................................................................. 3

Preparation of Host Bacteria ................................................................................................. 4

Packaging Protocol ............................................................................................................................. 4

Positive Wild-Type Lambda DNA Control for the Gigapack III Packaging Extract ............ 5

Titering the Packaging Reaction ........................................................................................................ 6

Titering the Cosmid Packaging Reaction.......................................................................................... 7

Appendix: Host Strain Preparation .................................................................................................. 8

Troubleshooting .................................................................................................................................. 9

Preparation of Media and Reagents .................................................................................................. 9

References .......................................................................................................................................... 11

Endnotes ............................................................................................................................................. 11

MSDS Information ............................................................................................................................ 11

Page 4

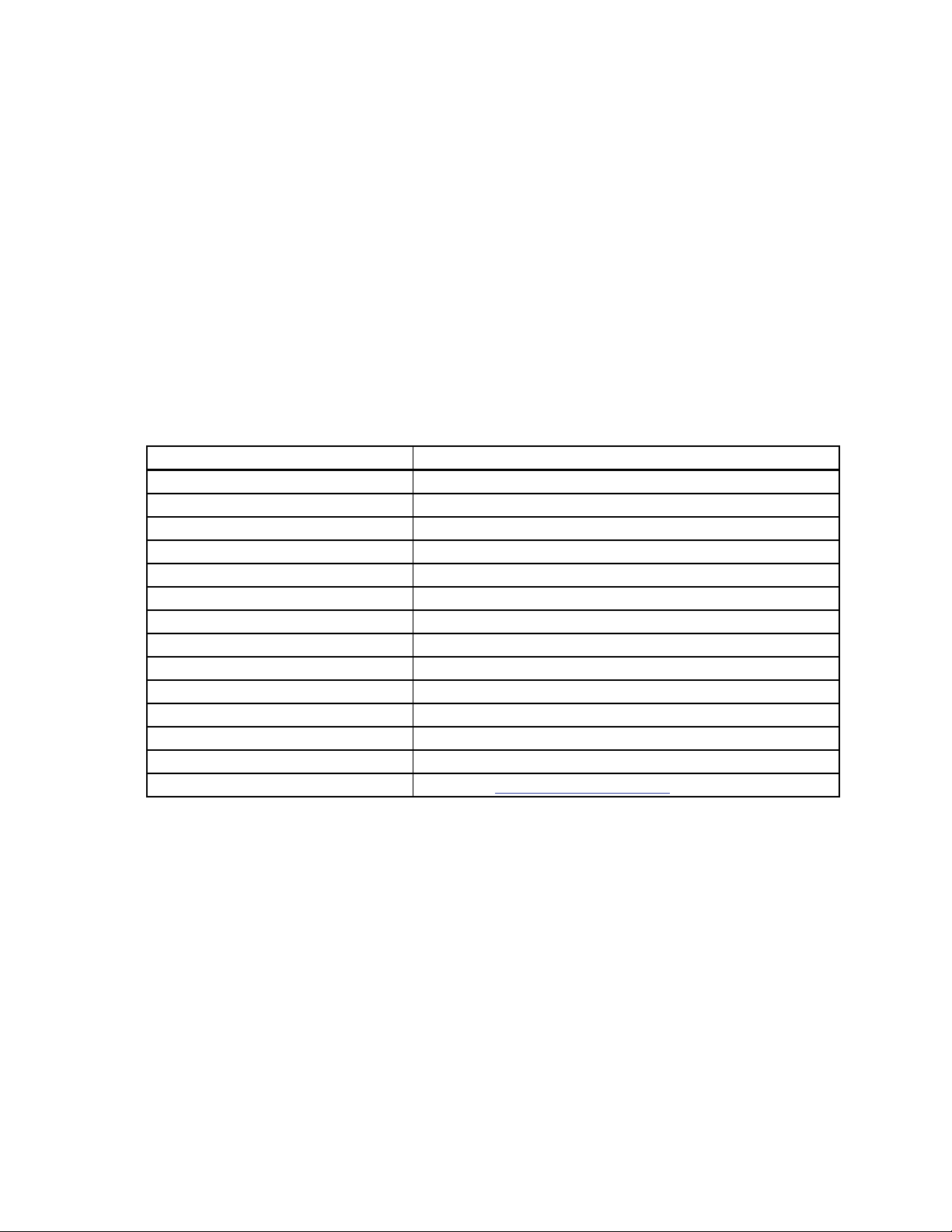

Gigapack III Gold Packaging Extract, Gigapack III Plus

Packaging Extract, and Gigapack III XL Packaging Extract

M

ATERIALS PROVIDED

Quantity

Catalog

Materials provided

Gigapack III Gold-4 packaging extract (blue tube)a 4 × 25 μl — —

Gigapack III Gold-7 packaging extract (blue tube)a — 7 × 25 μl —

Gigapack III Gold-11 packaging extract (blue tube)a — — 11 × 25 μl

λcI857 Sam7 wild-type lambda control DNAb 1.05 μg 1.05 μg 1.05 μg

VCS257 host strainc 1 ml 1 ml 1 ml

Catalog

Gigapack III Plus-4 packaging extract (blue tube)a 4 × 25 μl — —

Gigapack III Plus-7 packaging extract (blue tube)a — 7 × 25 μl —

Gigapack III Plus-11 packaging extract (blue tube)a — — 11 × 25 μl

λcI857 Sam7 wild-type lambda control DNAb 1.05 μg 1.05 μg 1.05 μg

VCS257 host strainc 1 ml 1 ml 1 ml

Catalog

Gigapack III XL-4 packaging extract (red-orange tube)a 4 × 25 μl — —

Gigapack III XL-7 packaging extract (red-orange tube)a — 7 × 25 μl —

Gigapack III XL-11 packaging extract (red-orange tube)a — — 11 × 25 μl

λcI857 Sam7 wild-type lambda control DNAb 1.05 μg 1.05 μg 1.05 μg

VCS257 host strainc 1 ml 1 ml 1 ml

a

Gigapack III packaging extract is very sensitive to slight variations in temperature. Storing the packaging extracts at the

bottom of a –80°C freezer directly from the dry ice shipping container is required in order to prevent a loss of packaging

efficiency. Transferring tubes from one freezer to another may also result in a loss of efficiency. Do not allow the

packaging extracts to thaw! Do not store the packaging extracts in liquid nitrogen as the tubes may explode.

b

The λcI857 Sam7 wild-type lambda control DNA is shipped frozen and should be stored at –80°C immediately on receipt.

c

The VCS257 host strain, included for plating the λcI857 Sam7 positive control, is shipped as a frozen bacterial glycerol

stock (see Preparation of Host Strains for additional storage instructions) and should also be stored at –80°C immediately

on receipt. This control host strain is a derivative of DP50 supF and should be used only when plating the packaged test

DNA. The control DNA used with Gigapack III Gold packaging extract requires a supF mutation in the bacterial host to

plate efficiently.

#200201

#200204

#200207

Catalog

#200202

Catalog

#200205

Catalog

#200208

Catalog

#200203

Catalog

#200206

Catalog

#200209

STORAGE CONDITIONS

Packaging Extracts: –80°C (Do not allow the packaging extracts thaw! Do not store the packaging

extracts in liquid nitrogen as the tubes may explode.)

Lambda Control DNA: –80°C (Store at 4°C after thawing.)

Bacterial Glycerol Stock: –80°C

Revision B © Agilent Technologies, Inc. 2010.

Gigapack

III Packaging Extract 1

Page 5

INTRODUCTION

Packaging extracts are used to package recombinant lambda phage with

high efficiency. The single-tube format of Gigapack III packaging extract

simplifies the packaging procedure and increases the efficiency and

representation of libraries constructed from highly methylated DNA. Each

packaging extract is restriction minus (HsdR

–

McrA– McrBC– McrF– Mrr–)

to optimize packaging efficiency and library representation. When used in

conjunction with restriction-deficient plating cultures, Gigapack III

packaging extract improves the quality of DNA libraries constructed from

methylated DNA.

1-4

Because choice of an in vitro packaging extract designed to achieve specific

experimental goals is important, we offers three different packaging

extracts: Gigapack III Gold packaging extract, Gigapack III Plus packaging

extract, and Gigapack III XL packaging extract. Gigapack III Gold

packaging extract produces the highest packaging efficiency commercially

9

available (2 × 10

pfu/μg) and is designed for use in cDNA and genomic

library construction. Gigapack III Plus packaging extract is an economical

alternative to Gigapack III Gold packaging extract when the highest

packaging efficiency is not required. Gigapack III XL packaging extract

preferentially packages large inserts (i.e., 47–51-kb recombinants), which

eliminates the need for time-consuming size fractionation steps and the loss

associated with sizing columns or sucrose gradients. This packaging extract

is designed for use in genomic lambda and cosmid library construction.

Optimal packaging efficiencies are obtained with lambda DNAs that are

concatemeric. Ligations should be carried out at DNA concentrations of

0.2 μg/μl or greater, which favors concatemers and not circular DNA

molecules that only contain one cos site. DNA to be packaged should be

relatively free from contaminants. Polyethylene glycol (PEG), which is

contained in some ligase buffers, can inhibit packaging. The volume of

DNA added to each extract should be between 1 and 4 μl. To obtain the

highest packaging efficiency [i.e., the number of plaque-forming units per

microgram (pfu/μg) of DNA], package 1 μl of the ligation reaction and

never more than 4 μl. Increased volume (i.e., >4 μl) yields more plaqueforming units per packaging reaction, but fewer plaque-forming units per

microgram of DNA.

DNA that is digested with restriction enzymes and religated packages less

efficiently (by a factor of 10–100) than uncut lambda DNA. For example,

uncut wild-type lambda DNA packages with efficiencies exceeding

9

1 × 10

pfu/μg of vector when using a Gigapack III packaging extract.

However, predigested arms, when ligated to a test insert, yield

6

~5 × 10

– 1 × 107 recombinant plaques/μg of vector.

2 Gigapack III Packaging Extract

Page 6

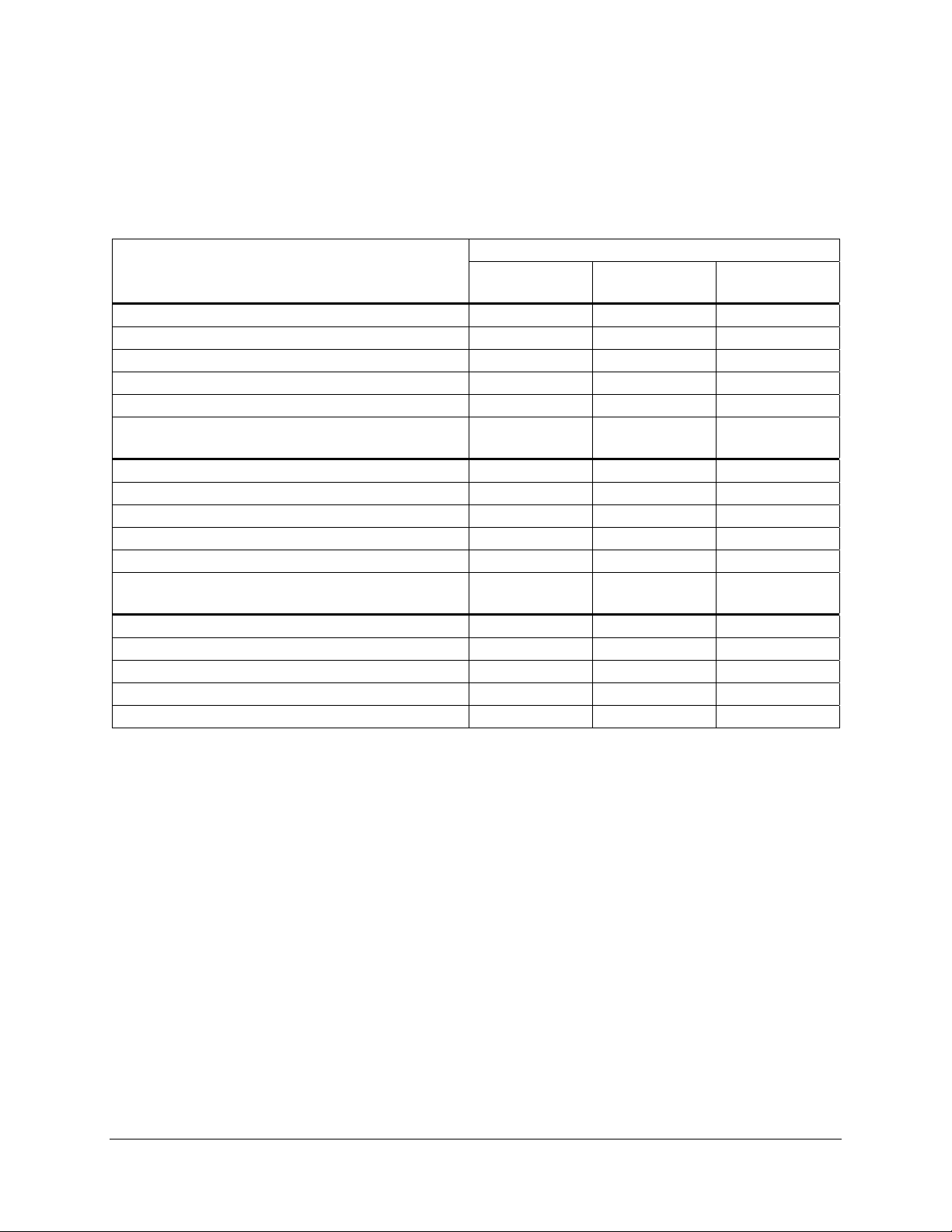

PREPARATION OF HOST STRAINS

Note The appendix is included as a convenient reference for preparing

host strains other than the VCS257 control host strain provided

with the packaging extracts (see Appendix: Host Strain

Preparation).

The host strain is shipped as a bacterial glycerol stock. For the appropriate

media, please refer to the following table:

Host strain

VCS257

strain

a

NZY medium (see Preparation of Media and Reagents) may be substituted for LB

medium in all cases.

b

See Preparation of Media and Reagents.

On arrival, prepare the following from the bacterial glycerol stock using the

appropriate media as indicated in the previous table:

Agar plates for

bacterial

streak

LBb LBb LB with 0.2% (w/v) maltose–

Medium for

a

bacterial

glycerol stock

Medium for bacterial

cultures for titering phage

a

(final concentration)

10 mM MgSO

4

a

1. Revive the stored cells by scraping off splinters of solid ice with a

sterile wire loop.

2. Streak the splinters onto an LB agar plate.

3. Incubate the plate overnight at 37°C.

®

4. Seal the plate with Parafilm

laboratory film and store the plate at 4°C

for up to 1 week.

5. Restreak the cells onto a fresh plate every week.

Preparation of a –80°C Bacterial Glycerol Stock

1. In a sterile 50-ml conical tube, inoculate 10 ml of appropriate liquid

medium containing the appropriate antibiotic, if one is necessary, with

one colony from the plate. Grow the cells to an OD

2.0.

2. Add 4.5 ml of a sterile glycerol–liquid medium solution (5 ml of

glycerol + 5 ml of appropriate medium) to the bacterial culture from

step 1. Mix well.

3. Aliquot into sterile centrifuge tubes (1 ml/tube).

This preparation may be stored at –20°C for 1–2 years or at –80°C for more

than 2 years.

between ~1.0 and

600

Gigapack

III Packaging Extract 3

Page 7

Preparation of Host Bacteria

Note Prepare an overnight culture of the VCS257 strain (see the table

in Preparation of Host Strains) prior to performing the protocol for

the positive wild-type lambda DNA control (see Positive Wild-

Type Lambda DNA Control for the Gigapack III Packaging

Extract).

1. Streak the bacterial glycerol stock onto the appropriate agar plates (see

Appendix: Host Strain Preparation). Incubate the plates overnight at

37°C.

Note Do not add antibiotic to the medium in the following step.

The antibiotic will bind to the bacterial cell wall and will

inhibit the ability of the phage to infect the cell.

2. Inoculate an appropriate medium, supplemented with 10 mM MgSO

and 0.2% (w/v) maltose (see Appendix: Host Strain Preparation), with

a single colony.

3. Grow at 37°C, shaking for 4–6 hours (do not grow past an OD

1.0). Alternatively, grow overnight at 30°C, shaking at 200 rpm.

Note The lower temperature keeps the bacteria from overgrowing,

4. Pellet the bacteria at 500 × g for 10 minutes.

5. Gently resuspend the cells in half the original volume with sterile

10 mM MgSO

6. Dilute the cells to an OD

Note The bacteria should be used immediately following dilution.

PACKAGING PROTOCOL

Note Polyethylene glycol, which is contained in some ligase buffers, can

thus reducing the number of nonviable cells. Phage can

adhere to nonviable cells resulting in a decreased titer.

.

4

of 0.5 with sterile 10 mM MgSO4.

600

inhibit packaging.

600

of

4

1. Remove the appropriate number of packaging extracts from a –80°C

freezer and place the extracts on dry ice.

2. Quickly thaw the packaging extract by holding the tube between your

fingers until the contents of the tube just begins to thaw.

3. Add the experimental DNA immediately (1–4 μl containing

0.1–1.0 μg of ligated DNA) to the packaging extract.

4 Gigapack III Packaging Extract

Page 8

4. Stir the tube with a pipet tip to mix well. Gentle pipetting is allowable

provided that air bubbles are not introduced.

5. Spin the tube quickly (for 3–5 seconds), if desired, to ensure that all

contents are at the bottom of the tube.

6. Incubate the tube at room temperature (22°C) for 2 hours.

7. Add 500 μl of SM buffer (see Preparation of Media and Reagents) to

the tube.

8. Add 20 μl of chloroform and mix the contents of the tube gently.

9. Spin the tube briefly to sediment the debris.

10. The supernatant containing the phage is ready for titering. The

supernatant may be stored at 4°C for up to 1 month.

Positive Wild-Type Lambda DNA Control for the Gigapack III Packaging

Extract

Use the following procedure to test the efficiency of the Gigapack III

packaging extract with the λcI857 Sam7 wild-type lambda control DNA.

1. Thaw the frozen wild-type lambda control DNA on ice and gently mix

the control after thawing.

2. Using 1 μl of the wild-type lambda control DNA (~0.2 μg), proceed

with steps 1–10 in the Packaging Protocol.

Note Because of the high titer achieved with the wild-type lambda

control DNA, stop the control packaging reaction with 1 ml

of SM buffer. This should make the plaques easier to count.

3. Prepare two consecutive 10

step 10 in the Packaging Protocol in SM buffer. (The final dilution is

–4

.)

10

4. Add 10 μl of the 10

(This strain is recommended for plating the wild-type lambda control

DNA only.) Incubate at 37°C for 15 minutes. Add 3 ml of LB top agar

(see Preparation of Media and Reagents), melted and cooled to ~48°C,

and quickly pour the dilution onto dry, prewarmed LB agar plates.

–2

dilutions of the packaging reaction from

–4

dilution to 200 μl of the VCS257 host strain.

Gigapack

5. Incubate the plates for at least 12 hours at 37°C.

6. Count the plaques. Approximately 400 plaques should be obtained on

–4

the 10

dilution plate when the reaction is stopped with 1 ml of

SM buffer.

III Packaging Extract 5

Page 9

TITERING THE PACKAGING REACTION

Note For titering cosmid libraries, see Titering the Cosmid Packaging

Reaction.

1. Streak the bacterial glycerol stock onto the appropriate agar plates

(see Appendix: Host Strain Preparation). Incubate the plates overnight

at 37°C.

Note Do not add antibiotic to the medium in the following step.

The antibiotic will bind to the bacterial cell wall and will

inhibit the ability of the phage to infect the cell.

2. Inoculate an appropriate medium, supplemented with 10 mM MgSO

4

and 0.2% (w/v) maltose (see Appendix: Host Strain Preparation), with

a single colony.

3. Grow at 37°C, shaking for 4–6 hours (do not grow past an OD

600

of

1.0). Alternatively, grow overnight at 30°C, shaking at 200 rpm.

Note The lower temperature keeps the bacteria from overgrowing,

thus reducing the number of nonviable cells. Phage can

adhere to nonviable cells resulting in a decreased titer.

4. Pellet the bacteria at 500 × g for 10 minutes.

5. Gently resuspend the cells in half the original volume with sterile

10 mM MgSO

6. Dilute the cells to an OD

.

4

of 0.5 with sterile 10 mM MgSO4.

600

Note The bacteria should be used immediately following dilution.

7. Prepare dilutions of the final packaged reaction in SM buffer. Add 1 μl

of the final packaged reaction to 200 μl of host cells diluted in

10 mM MgSO

to an OD

4

of 0.5. If desired, also add 1 μl of a

600

1:10 dilution of the packaged reaction in SM buffer to 200 μl of host

cells.

8. Incubate the phage and the bacteria at 37°C for 15 minutes to allow the

phage to attach to the cells.

9. Add 3 ml of LB top agar (48°C) and plate immediately on prewarmed

LB agar plates.

10. Incubate the plates at 37°C for 12 hours.

11. Count the plaques and determine the titer in plaque-forming units per

milliliter (pfu/ml).

6 Gigapack III Packaging Extract

Page 10

TITERING THE COSMID PACKAGING REACTION

1. Streak the bacterial glycerol stock onto the appropriate agar plates

(see Appendix: Host Strain Preparation). Incubate the plates overnight

at 37°C.

Note Do not add antibiotic to the medium in the following step.

The antibiotic will bind to the bacterial cell wall and will

inhibit the ability of the phage to infect the cell.

2. Inoculate an appropriate medium, supplemented with 10 mM MgSO

4

and 0.2% (w/v) maltose (see Appendix: Host Strain Preparation), with

a single colony.

3. Grow at 37°C, shaking for 4–6 hours (do not grow past an OD

600

of

1.0). Alternatively, grow overnight at 30°C, shaking at 200 rpm.

Note The lower temperature keeps the bacteria from overgrowing,

thus reducing the number of nonviable cells. Phage can

adhere to nonviable cells resulting in a decreased titer.

4. Pellet the bacteria at 500 × g for 10 minutes.

5. Gently resuspend the cells in half the original volume with sterile

10 mM MgSO

6. Dilute the cells to an OD

.

4

of 0.5 with sterile 10 mM MgSO4.

600

Note The bacteria should be used immediately following dilution.

7. Prepare a 1:10 and a 1:50 dilution of the cosmid packaging reaction in

SM buffer.

8. Mix 25 μl of each dilution with 25 μl of the appropriate bacterial cells

at an OD

of 0.5 in a microcentrifuge tube and incubate the tube at

600

room temperature for 30 minutes.

Gigapack

9. Add 200 μl of LB broth to each sample and incubate for 1 hour at

37°C, shaking the tube gently once every 15 minutes. This incubation

will allow time for expression of the antibiotic resistance.

10. Spin the microcentrifuge tube for 1 minute and resuspend the pellet in

50 μl of fresh LB broth.

11. Using a sterile spreader, plate the cells on LB agar plates with the

required amount of the appropriate antibiotic. Incubate the plates

overnight at 37°C.

III Packaging Extract 7

Page 11

APPENDIX: HOST STRAIN PREPARATION

Host strain

Agar plate for

bacterial streak

Medium for

glycerol stock

Medium for bacterial cultures for titering

phage (final concentration)

a

AG-1 strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

BB4 strain LB–tetracyclineb LB–tetracyclineb LB with 0.2% (w/v) maltose–10 mM MgSO4

C600 strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

JM101 strainc M9d M9b LB with 0.2% (w/v) maltose–10 mM MgSO4

JM109 strainc M9 M9 LB with 0.2% (w/v) maltose–10 mM MgSO4

JM110 straind M9 M9 LB with 0.2% (w/v) maltose–10 mM MgSO4

LE392 strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

NM514 strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

NM522 strainc M9 M9 LB with 0.2% (w/v) maltose–10 mM MgSO4

NM554 strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

P2392 strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

SCS110 straind M9 M9 LB with 0.2% (w/v) maltose–10 mM MgSO4

SURE straine LB–tetracycline LB–tetracycline LB with 0.2% (w/v) maltose–10 mM MgSO4

VCS257 strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

XL1-Blue strain LB–tetracycline LB–tetracycline LB with 0.2% (w/v) maltose–10 mM MgSO4

XL1-Blue MR strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

XL1-Blue MRF´ strain LB–tetracycline LB–tetracycline LB with 0.2% (w/v) maltose–10 mM MgSO4

XL1-Blue MRF´ Kan strain LB–kanamycin LB–kanamycin LB with 0.2% (w/v) maltose–10 mM MgSO4

XL1-Blue MRA strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

XL1-Blue MRA (P2) strain LB LB LB with 0.2% (w/v) maltose–10 mM MgSO4

Y1088 strain LB–ampicillinb LB–ampicillinb LB with 0.2% (w/v) maltose–10 mM MgSO4

Y1089r– strain LB–ampicillin LB–ampicillin LB with 0.2% (w/v) maltose–10 mM MgSO4

Y1090r– strain LB–ampicillin LB–ampicillin LB with 0.2% (w/v) maltose–10 mM MgSO4

a

NZY medium (see Preparation of Media and Reagents) may be substituted for LB medium in all cases.

b

See Preparation of Media and Reagents.

c

Will grow two times slower on M9 medium.

d

The amino acids—threonine, leucine, valine, and isoleucine—must be added to the M9 medium and plated at a

concentration of 50 mg/liter for proper growth. Filter-sterilize the amino acids with the glucose and add as instructed.

e

When growing lambda phage for plaque formation, incubate plates at 39°C.

8 Gigapack III Packaging Extract

Page 12

TROUBLESHOOTING

–

A

Observation Suggestion(s)

Packaging efficiency is too low Gigapack III packaging extract is very sensitive to slight variations in temperature;

therefore, store the packaging extracts at the bottom of a –80°C freezer and avoid

transferring tubes from one freezer to another

Do not allow the packaging extracts to thaw

Avoid use of ligase buffers containing PEG, which can inhibit packaging

Ligate at DNA concentrations of 0.2 μg/μl or greater and package between

1 and 4 μl of the ligation reaction

Never package >4 μl of the ligation reaction, which causes dilution of the

proteins contained within the packaging extract

Neither a bacterial lawn nor

plaques is observed on the plate

Be sure to spin down the chloroform completely prior to removing an aliquot for

titering

PREPARATION OF MEDIA AND REAGENTS

Note All media must be autoclaved before use.

LB Broth (per Liter)

10 g of NaCl

10 g of tryptone

5 g of yeast extract

Add deionized H

O to a final volume of

2

1 liter

Adjust to pH 7.0 with 5 N NaOH

Autoclave

LB–Ampicillin Broth (per Liter)

1 liter of LB broth, autoclaved

Cool to 55°C

Add 10 ml of 10-mg/ml filter-sterilized

ampicillin

LB–Kanamycin Broth (per Liter)

1 liter of LB broth

Autoclave

Cool to 55°C

Add 50 mg of filter-sterilized kanamycin

LB Agar (per Liter)

10 g of NaCl

10 g of tryptone

5 g of yeast extract

20 g of agar

Add deionized H

O to a final volume of

2

1 liter

Adjust pH to 7.0 with 5 N NaOH

Autoclave

Pour into petri dishes

(~25 ml/100-mm plate)

LB

mpicillin Agar (per Liter)

1 liter of LB agar, autoclaved

Cool to 55°C

Add 10 ml of 10-mg/ml filter-sterilized

ampicillin

Pour into petri dishes

(~25 ml/100-mm plate)

LB–Kanamycin Agar (per Liter)

1 liter of LB agar

Autoclave

Cool to 55°C

Add 50 mg of filter-sterilized kanamycin

Pour into petri dishes

(~25 ml/100-mm plate)

Gigapack

III Packaging Extract 9

Page 13

LB–Tetracycline Broth (per Liter)

1 liter of LB broth

Autoclave

Cool to 55°C

Add 12.5 mg of filter-sterilized tetracycline

Store broth in a dark, cool place as

tetracycline is light-sensitive

LB Top Agar (per Liter)

1 liter of LB broth

Add 0.7% (w/v) agarose

Autoclave

M9 Medium (per Liter)

6.0 g of dibasic sodium

phosphate (Na

3.0 g of monobasic potassium

phosphate (KH

1.0 g of ammonium chloride (NH

0.5 g of NaCl

Add deionized H

1 liter

Autoclave

While autoclaving, prepare the following

solution:

1.0 ml of 1 M MgSO

2.0 g of glucose

0.1 ml of 1 M CaCl

1.0 ml of 1 M thiamine-HCl

Add deionized H

of 10 ml and filter sterilize

Add the above solution to the cooled

M9 media

HPO4)

2

)

2PO4

Cl)

4

O to a final volume of

2

4

2

O to a final volume

2

LB–Tetracycline Agar (per Liter)

1 liter of LB agar

Autoclave

Cool to 55°C

Add 12.5 mg of filter-sterilized tetracycline

Pour into petri dishes

(~25 ml/100-mm plate)

Store plates in a dark, cool place or cover

plates with foil if left out at room

temperature for extended time periods

as tetracycline is light-sensitive

NZY Top Agar (per Liter)

1 liter of NZY broth

Add 0.7% (w/v) agarose

Autoclave

NZY Agar (per Liter)

5 g of NaCl

2 g of MgSO

. 7H2O

4

5 g of yeast extract

10 g of NZ amine (casein hydrolysate)

15 g of agar

Add deionized H

O to a final volume of

2

1 liter

Adjust the pH to 7.5 with NaOH

Autoclave

Pour into petri dishes

(~80 ml/150-mm plate)

NZY Broth (per Liter)

5 g of NaCl

2 g of MgSO

5 g of yeast extract

10 g of NZ amine (casein hydrolysate)

Add deionized H

1 liter

Adjust the pH to 7.5 with NaOH

Autoclave

. 7H2O

4

O to a final volume of

2

SM Buffer (per Liter)

5.8 g of NaCl

2.0 g of MgSO

50.0 ml of 1 M Tris-HCl (pH 7.5)

5.0 ml of 2% (w/v) gelatin

Add deionized H

1 liter

Autoclave

10 Gigapack III Packaging Extract

· 7H2O

4

O to a final volume of

2

Page 14

REFERENCES

1. Kretz, P. L., Reid, C. H., Greener, A. and Short, J. M. (1989) Nucleic Acids Res

17(13):5409.

2. Kretz, P. L. and Short, J. M. (1989) Strategies in Molecular Biology 2(2):25-26.

3. Kohler, S. W., Provost, G. S., Kretz, P. L., Dycaico, M. J., Sorge, J. A. et al. (1990)

Nucleic Acids Res 18(10):3007-13.

4. Kretz, P. L., Kohler, S. W. and Short, J. M. (1991) J Bacteriol 173(15):4707-16.

ENDNOTES

Parafilm® is a registered trademark of American Can Company.

MSDS INFORMATION

Material Safety Data Sheets (MSDSs) are provided online at http://www.genomics.agilent.com. MSDS

documents are not included with product shipments.

Gigapack

III Packaging Extract 11

Loading...

Loading...