Gigant Lift Column Series Installation Instructions Manual

Lift Column

Installation instructions

Description

Installation instructions

Areas of application

Gigant lift columns are supposed to be built in and used to

adjust the working position of workstations, f xtures or other

machines. Other areas of application can be dangerous, so

instructions from Gigant must be carefully studied and followed.

• Lift columns should not be used during hot work

such as welding without specif c precautions being

taken

• Lift columns must not be suspended from a

ceiling or walls

• Lift columns must not be used to lift people

!

Attention

Design

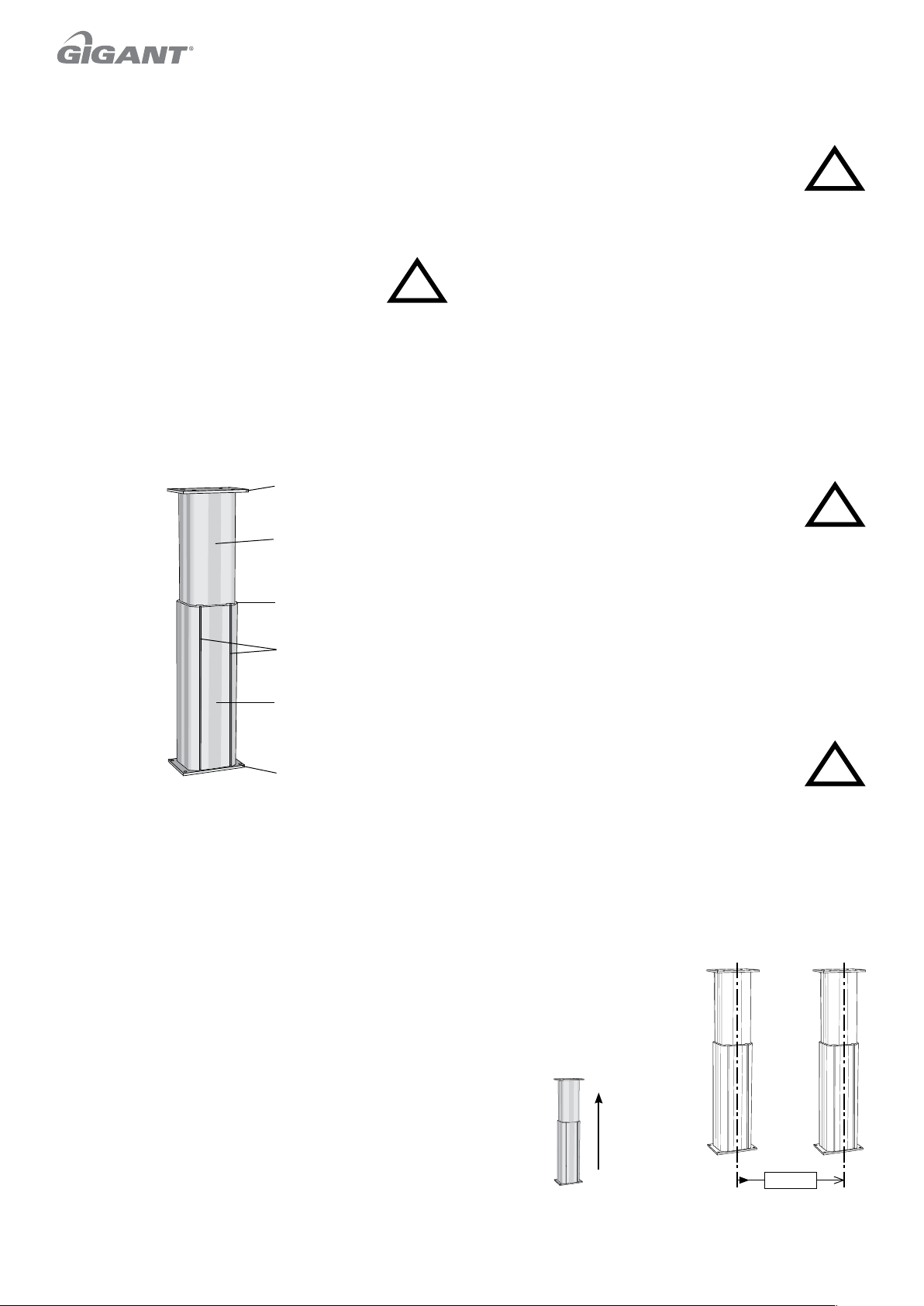

T e image to the right shows the lift column’s various

components.

Top plate

Inner tube

Inaccurate handling can cause malfunction. Please

make sure that all the steps in this assembly

instruction always are implemented in order to

ensure correct and safe function of the product.

• Compare the specif cations of the product with your current

application. Only when your specif cations are within the

products specif ed range can the product be used.

• Follow local laws and regulations

• Use the product in its original design without any changes.

!

Attention

Transport damage

Inspect the goods as soon as they arrive and report any transport

damage direct to the forwarder.

Transport/handling

Storage: time in original packaging should be kept short. Keep in

a cool dry place, protected from light and dust.

Transport: depending on design the lift columns can

weigh 30 kg or more. Crush hazard: should the

product tip over it can cause crush injuries. Suitable

lifting equipment should be used to ensure safe

handling of the product during transport and assembly.

!

Risk of

crushing

Cover strip

Nut slot

(LP192, LP200)

Outer tube

Base plate

Function

T e lift function of the lift column is driven by an electric

actuator housed inside the telescopic element. T e actuator is

powered by a low voltage transmitted via an external power

source/control unit and regulated by a controller. Integrated limit

switches stop the column at its top and bottom positions.

An integrated Hall ef ect sensor (all lift columns with an 8-pin

connector) measures and compares pulses between two lift

columns in order to synchronize them and achieve precise

parallel operation.

Accessories

Examples of accessories from the Gigant range:

• Control unit for single or parallel operation with one or more

motor groups

• Control unit bracket for attaching control units to the outer

tube’s nut slots (LP192, LP200)

• Controllers, such as table or hand control, foot pedal

• Reinforced base for f oor installation

• Base frames with adjustable feet for freestanding installation

Assembly

• Gigant lift columns must be installed indoors in well-lit

premises that are at room temperature.

• Ensure that the lift column is level by assembling it on a stable

surface. For freestanding applications, base frames are available

as an accessory. Control units and controllers must be

positioned to avoid damage during operation.

• Gigant lift columns must be positioned at least

120 mm from walls or surrounding objects to avoid

the risk of crushing. Ensure that there is no contact

with surrounding objects and no risk of crushing

as the lift column is raised and lowered.

• When installing mechanically-linked lift columns for parallel

operation, the columns must be assembled so that any

deviation in parallelism is less than 0.5 mm per 1,000 mm.

If this is not possible, one or more attachments must be

f exible enough to absorb deviations.

• All Gigant lift columns are to be assembled with the inner

tube positioned upwards as shown in the

accompanying illustration if not

otherwise specif ed.

Up

// Ø 0,5

!

Risk of

crushing

Loading...

Loading...