GIGA I6FZP, I2FZP, I4FZP Instructions For Installation, Use And Maintenance Manual

502_03

Instructions for installation,

use and maintenance

09/2015

© COPYRIGHT 2004 GIGA GRANDI CUCINE SRL

GAS KITCHENS

I2FZP

I4FZP

I6FZP

CHARACTERISTICS

502_03 - GAS KITCHENS

2 · 16

Supplied by:

Date:

Customer Service:

FAX

e-mail

INDEX

502_03 - GAS KITCHENS

3 · 16

1 Diagram 4

2 Features of the appliances 5

3 Technical data 5

4 Installation instructions 6

4.1 Safety rules 6

4.2 Structure, framework and safety devices of the appliances 6

4.2.1 Cooking zone 6

4.3 Assembly 6

4.3.1 Installation premises 6

4.3.2 Statutory regulations and technical requirements 6

4.3.3 Installation 6

4.3.4 Gas connection 6

4.3.5 Smoke extraction 6

4.3.6 Equipotential 6

4.4 Preparing for installation 7

5 Operation preparation 7

5.1 Preparation and Start-up 7

5.1.1 Start-up 7

5.1.2 Check of power 7

5.1.3 Checking the input pressure 11

5.1.4 Power check with volumetric method 11

5.1.5 Power check for operation with liquid gas 11

5.1.6 Check of pilot flame 11

5.1.7 Checking the primary air 11

5.1.8 Operation Control 12

5.1.9 Operator training 12

5.1.10 Conversion and adjustment 12

5.1.11 Replacement of burner nozzles 12

5.1.12 Setting reduced capacity power 12

5.1.13 Replacement of pilot nozzle (open flames) 12

5.2 Maintenance 12

5.3 Replacing parts 12

5.3.1 Gas valve (open flames) 12

5.3.2 Thermocouple (open flames) 12

6 Instructions for use 13

6.1 Safety, cleaning and repair rules 13

6.2 Start-up 13

6.2.1 Lighting and disconnecting open flame burner 13

Shutdown 13

6.3 Turning the appliance off in case of breakdown 13

6.3.1 What to do in case of failure or prolonged period of

disuse 13

6.4 Appliance care and frequency of maintenance 13

6.5 Recommendations for handling stainless steel industrial

kitchens 14

6.5.1 Useful information on stainless steel 14

6.5.2 Warnings and advice for maintenance of stainless steel

appliances 14

6.5.3 WEEE Directive 15

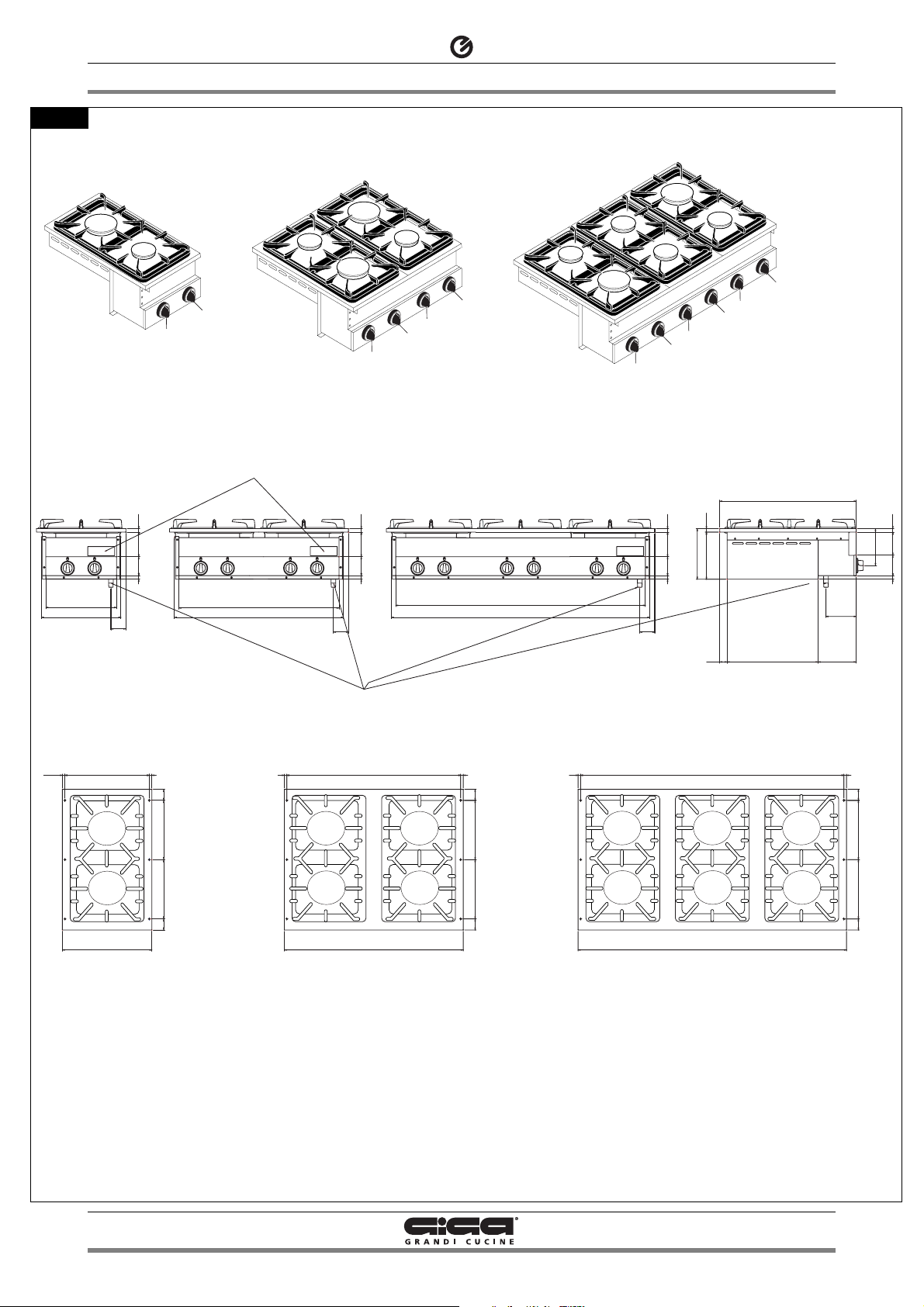

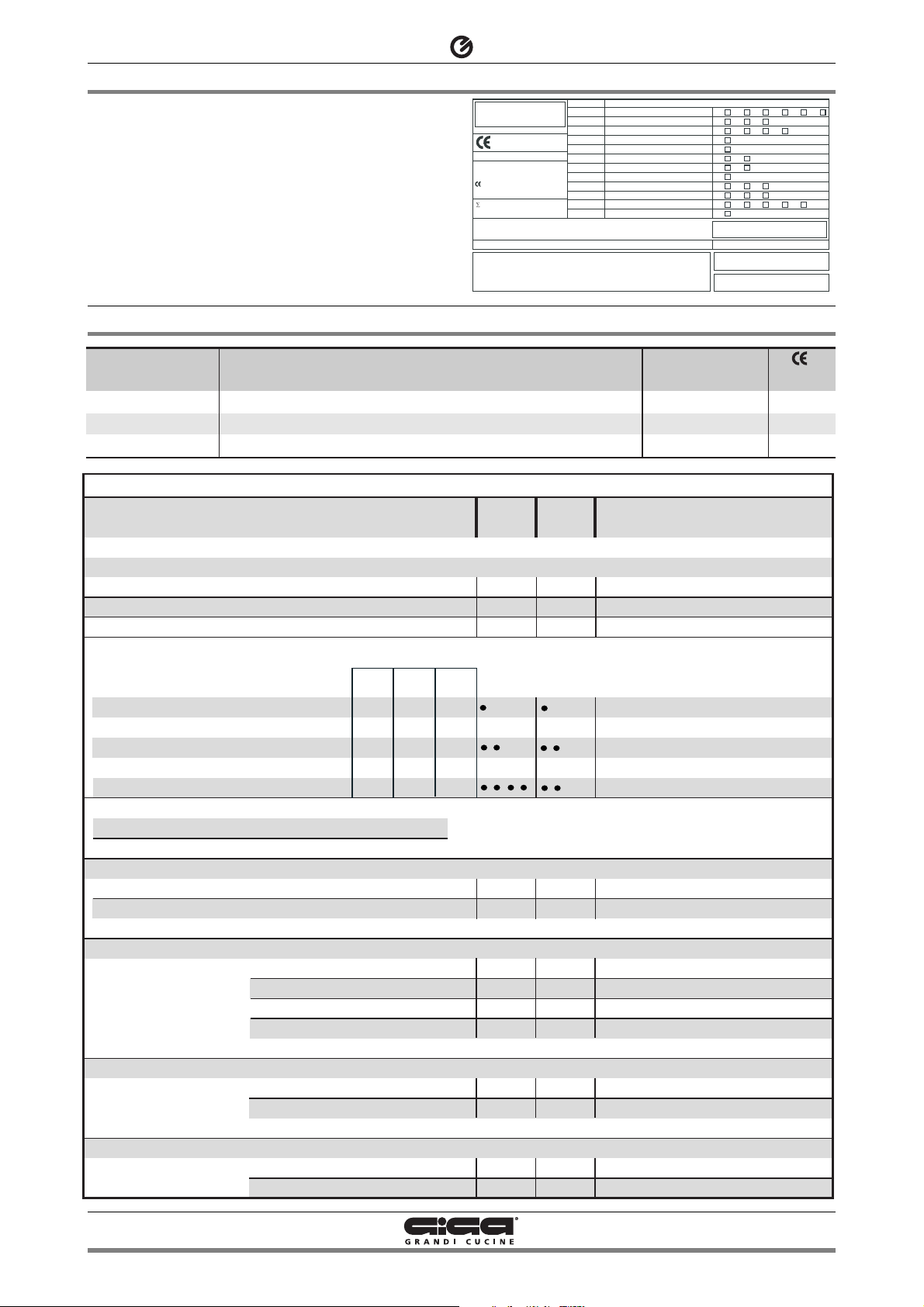

1 - DIAGRAM

502_03 - GAS KITCHENS

4 · 16

B

T

G

Knob

Data plate

Gas connection 1/2"

Fig. 1

B

B

B

B

B

B

B

B

B

B

B

B

I6FZPI6FZPI4FZPI4FZPI2FZPI2FZP

TT

610610

1515

1515

1515

1515

1515

11.511.5

316316

356356

377377

7.8

kW

4.0

kW

400400

100100

9090

14.514.5

6767

716716

755755

100100

9090

14.514.5

6767

755755

11161116

100100

219.5219.5

9090

204.5204.5

14.514.5

135135

6767

3333

407407

170170

160160

100100

9090

14.514.5

GG

48484848

257257

257257

11.511.5

4.0

kW

7.8

kW

777777

800800

7.8

kW

4.0

kW

4848

257257

257257

4848

11.511.5

4.0

kW

7.8

kW

11771177

4.0

kW

4.0

kW

12001200

7.8

kW

4.0

kW

4848

257257

257257

4848

I6FZPI6FZPI4FZPI4FZPI2FZPI2FZP

2 - CHARACTERISTICS OF THE APPLIANCES

3 - TECHNICAL DATA

502_03 - GAS KITCHENS

5 · 16

These appliances are used for professional purposes. Installation,

repair and use must be carried out by expert personnel.

These instructions for installation are for our gas kitchens set up for

the category in the table on page 5. The data plate is located on the

front part of the appliance (on the control panel).

Primary air distance “A”

Methane gas G20

Liquid gas G30/G31

TABLE 1

Category

Construction type

Air necessary for combustion

Nominal thermal power

Minimum thermal power

Overall thermal power (gas)

Connection pressure

Methane gas 2H

Liquid gas 3+

Nozzles Ø 1/100 mm

Main burner

G20

G30/G31

(HuB = 9.45 kWh/m3) in m3/h

(HuB = 12.87 kWh/kg) in kg/h

Nominal thermal power

Minimal thermal capacity

Nominal thermal power

Minimal thermal capacity

G20

G30/31

20 mbar

28/37 mbar

12.2

24.4

32.8

kW

kW

kW

II2H3+

A

m

3

/h

kW

kW

No. of nozzles, pilot burner

G20

G30/G31

7

Open

X

Ø 100

8

4.0

1.2

0.423

0.313

145

Adjustable

100

45

27

19

15

Open

Z

Ø 120

14

7.8

2.9

0.825

0.611

200

Adjustable

135

75

27

19

1,29

2,58

3,47

-

-

-

-

0,95

1,91

2,57

Hour consumption

G20

m3/h

G25

m3/h

G30/G31

kg/h

I2FZP

I4FZP

I6FZP

Model

Gas connection values

Methane gas 2H

Liquid gas 3+

Model

I2FZP

I4FZP

I6FZP

Description

2 burners with pilot flame

4 burners with pilot flame

6 burners with pilot flame

Dimensions in mm.

(LxPxH)

400 x 610 x 220

800 x 610 x 220

1200 x 610 x 220

N.

51BQ2896

51BQ2896

51BQ2896

TIPO/TYPE

MOD.

ART.

N.

MOD.

V AC kW Hz

THE APPLIANCE MUST BE CONNECTED IN COMPLIANCE WITH THE LAWS IN FORCE

AND INSTALLED IN A WELL-VENTILATED ROOM. READ THE INSTRUCTION MANUALS

BEFORE INSTALLING AND USING THE APPLIANCE.

THE APPLIANCE MUST BE INSTALLED BY QUALIFIED PERSONNEL.

N.

Qn kW

CAT/KAT GAS/GAZ G30 G31 G20 G25

II2H3B/P P mbar 30 30 20 II2H3+ P mbar 30 37 20-II2H3+ P mbar 28 37 20 -

0051

II2ELL3B/P P mbar 50 50 20 20

II2E+3+ P mbar 28 37 20 25

II2H3B/P P mbar 50 50 20 I2E P mbar - - 20 -

II2H3+ P mbar 28 37 20 -

m3/h

I3B/P P mbar 30 30

I3+ P mbar 28 37

Eingestelt für Gas: - Preparado para gas: -

25II2L3B/P P mbar 30 30

--II2H3B/P P mbar 30 30

--

Predisposto a gas: - Gas preset: - Prevu pour gaz:

--

Geschuckt voor:

SE FI DK CZ SK SI

IT CH PT

ES IE GB GR

NL

DE

FR BE

AT CH

LU

EE LV LT

EE LV LT

NO MT CY IS HU

CY

MADE IN ITALY

G30/G31 28/37 mbar

G20 20 mbar

Loading...

Loading...