GIG GMA200-MW4 Operation Manual

GfG GESELLSCHAFT FÜR GERÄTEBAU MBH▐ KLÖNNESTRASSE 99▐ 44143 DORTMUND, GERMANY▐ TEL. +49 / (0)231 / 564 00 –0 ▐ FAX +49 / (0)231 / 516 313

INFO@GFG-MBH.COM▐ WWW.GFG.BIZ▐ DORTMUND COUNTY COURT HR B 2742▐ CERTIFIED IN ACCORDANCE WITH DIN EN ISO 9001:2008▐ ATEX QM-CERTIFIED

Operation Manual

GMA200-MW4

Gas detection controller for wall mounting

2

Table of contents

Page

1. INTRODUCTION 3

1.1 For your safety 3

1.2 Application and purpose 3

1.3 Special conditions for safe application 3

2. GAS DETECTION CONTROLLER GMA200-MW4 4

2.1 General description 4

2.2 Device design 4

2.2.1 LED status displays 4

2.2.2 Graphical display 5

2.2.3 Visual and acoustic alarm 5

2.3 Internal relays of the GMA200-MW4 5

2.4 External relay with the relay module GMA200-RT 5

2.5 Relay configuration 5

3. ASSEMBLY AND INSTALLATION INSTRUCTIONS 6

3.1 Site of installation 6

3.2 Electrical connections 6

3.2.1 Safety information 6

3.2.2 Mains connection and separator 6

3.2.3 Floating relay contacts 6

3.2.4 External 24 V DC voltage supply 7

3.2.5 Connection of transmitters with an analogue interface 7

3.2.6 Connection of transmitters with a digital interface (RS485) 7

3.2.7 Connection of further devices with a digital interface (RS485) 7

3.2.8 Using the alarm acknowledgement inputs 7

3.2.9 Using the 4-20 mA current outputs 7

3.3 Commissioning 7

4. OPERATING INSTRUCTIONS 8

4.1 Measuring mode 8

4.2 Alarms 8

4.2.1 Alarm configuration 8

4.2.2 Alarm acknowledgement (Reset) 8

4.3 Relays 9

4.4 Faults 9

4.5 Data logger function (configured using the GMA200Config software) 9

4.6 Analogue outputs 10

5. KEYBOARD AND MENUS 10

5.1 Operation and menu navigation 10

5.2 Main menu 11

5.3 Service menu 11

6. ANNEX 11

6.1 Cleaning and care 11

6.2 Maintenance and service 11

6.2.1 Visual inspection 12

6.2.2 Functional testing 12

6.2.3 System check 12

6.2.4 Repair 12

6.3 Spare parts and accessories 12

6.4 Information on the environmentally sound disposal of used parts 12

6.5 Functional safety and parameters 13

6.6 Technical data 14

6.7 EC declaration of conformity 15

3

1. Introduction

1.1 For your safety

This user manual states the intended use of the product according to § 3 of the German Product

Safety Act (ProdSG) and helps to prevent hazards.

It must be read and observed by all persons who operate, service, maintain and inspect this

product. This product can serve its intended purpose only if it is operated, serviced, maintained

and inspected according to the instructions given by GfG Gesellschaft für Gerätebau mbH.

Otherwise, the warranty provided by GfG Gesellschaft für Gerätebau mbH becomes void. Settings

in service mode should only be carried out by experts.

1.2 Application and purpose

The GMA200-MW4 is a gas detection controller for wall mounting. Combined with connected

transmitters, it forms a fixed gas warning system for the continuous measurement of gas

concentrations and is used to issue a warning about combustible gases or vapours in the range

below the lower explosion limit and about toxic gases in the ambient air, as well as to measure

oxygen. External relay modules GMA200-RT are additionally available.

The GMA200Config software program is required to configure the controller GMA200-MW4 and the

relay module GMA200-RT.

The configuration software GMA200Config is not described in this user manual. (see UM 222-

000.30).

The relay module GMA200-RT/RTD is not described in this user manual. (see UM 222-000.24).

Operation and maintenance of the various transmitters are described in separate user manuals.

1.3 Special conditions for safe application

According to the requirements stipulated, e.g., by DIN EN 60079-29-1 section 4.2.3.2,

DIN EN 45544 and DIN EN 50104 at least one alarm threshold with self-locking must be

configured for potentially hazardous gas concentrations.

At least one internal relay must also be configured as the collective message for all measuring

point faults (FLT-TRM) and for GMA faults (FLT-GMA).

4

2. Gas detection controller GMA200-MW4

2.1 General description

The design of the gas warning controller GMA200-MW4 ensures flexible, simple and clearly

structured operation in industrial and commercial applications for measuring combustible and

toxic gases/vapours, and for measuring oxygen concentrations.

Using the GMA200Config software program, it is possible to quickly and easily configure measuring

points and relays even when extending already installed GMA200-MW gas warning systems.

Measuring point designation, transmitter type, gas type and measuring range, as well as three

individual or specified alarm thresholds, can, e.g., be configured for each measuring point.

2.2 Device design

Up to 4 transmitters with 4-20 mA or 0.2-1 mA output can be connected to the analogue inputs of

the gas detection controller GMA200-MW4. A microprocessor evaluates the analogue input signals of

the connected transmitters, and a clearly structured display and LEDs indicate the status of the gas

detection controller, each measuring point and the relays.

2.2.1 LED status displays

During operation, LED status displays at the gas detection controller GMA200 indicate the following

statuses according to the event:

-

Operating status (ON)

→

green

-

Alarm 1 (AL1)

→

red

-

Alarm 2 (AL2)

→

red

-

Alarm 3 (AL3)

→

red

-

Service (SRV/SRQ) required

→

yellow

-

Fault (FLT) GMA

→

yellow

-

Fault (FLT) TRM

→

yellow

- Relay 1 (R1) – Relay 6 (R6)

→

red

(Relay activated in the case of an alarm or fault)

Control buttons

Status display of the

internal relays

Status display of

operating statuses

Status display for

alarms

Cable glands for

transmitter

connection cables

Alarm light

LCD display

Type plate with

date of production

Cable glands for

mains and relay

connection cables

Alarm horn

5

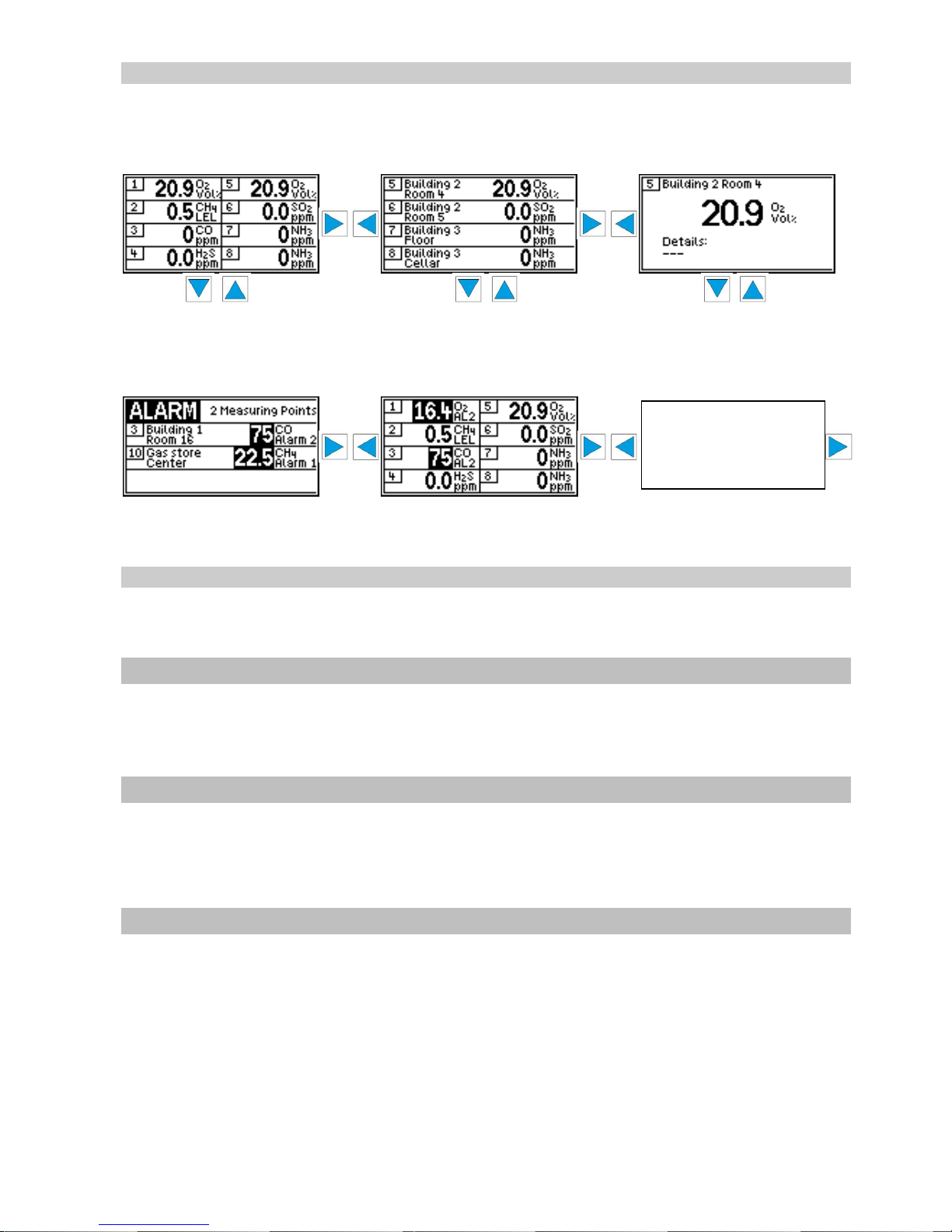

2.2.2 Graphical display

Currently measured values are shown on the display for each measuring point. The display for the

measuring points can be optionally set via the menu navigation (also see section 5.1), e.g.:

Display in normal mode

Display of 8 measuring points Display of 4 measuring points Display as single measuring point

for displaying for displaying for displaying

measuring point 9–16 measuring point 5-8 \ 13-16 measuring point 6 \ 4

Display for alarms

First display for alarms Alarm for 2 measuring points

The graphical display is backlit; the light intensity can be increased via any control button. In the

event of a gas alarm or faults, the display lighting is automatically activated with a red

background.

2.2.3 Visual and acoustic alarm

An alarm light and a horn for central visual and acoustic alarm are integrated in the wall

mounting housing GMA200-MW4 and triggered when the assigned alarm configuration for one or

several measuring points is exceeded or not achieved (for alarm configuration, see section 4.3).

2.3 Internal relays of the GMA200-MW4

The gas detection controller GMA200-MW4 features a total of 6 relays. In order to realise specified

safety measures and alarms, 4 relays can be freely configured using the GMA200Config software

program. An additional relay is available for each controller as a safety-related fault message and

maintenance relay.

2.4 External relay with the relay module GMA200-RT

The relay module GMA200-RT enables the addition of a further 16 freely configurable relays. A total

of 4 relay modules with 64 additional relays can be managed via the controller GMA200-MT. The

relay modules RT are connected to the controller GMA200 via the digital interface RS485 which also

enables the spatial separation of the relay modules (max. 1,000 m).

The relay module is not described in this user manual (see UM 222-000.24).

2.5 Relay configuration

Configuration of the relays using the GMA200Config software offers extensive options, e.g. the

allocation of individual or several measuring points to relays.

Configuration options:

- Single alarm per measuring point and alarm threshold

- Configuration of And/Or conjunctions

- Collective or group alarms

- Fault messages

- Voting functions

- Open-circuit principle / Closed-circuit principle

each for the gradual display

with 4 measuring points up

to the display of the single

measuring point

Loading...

Loading...