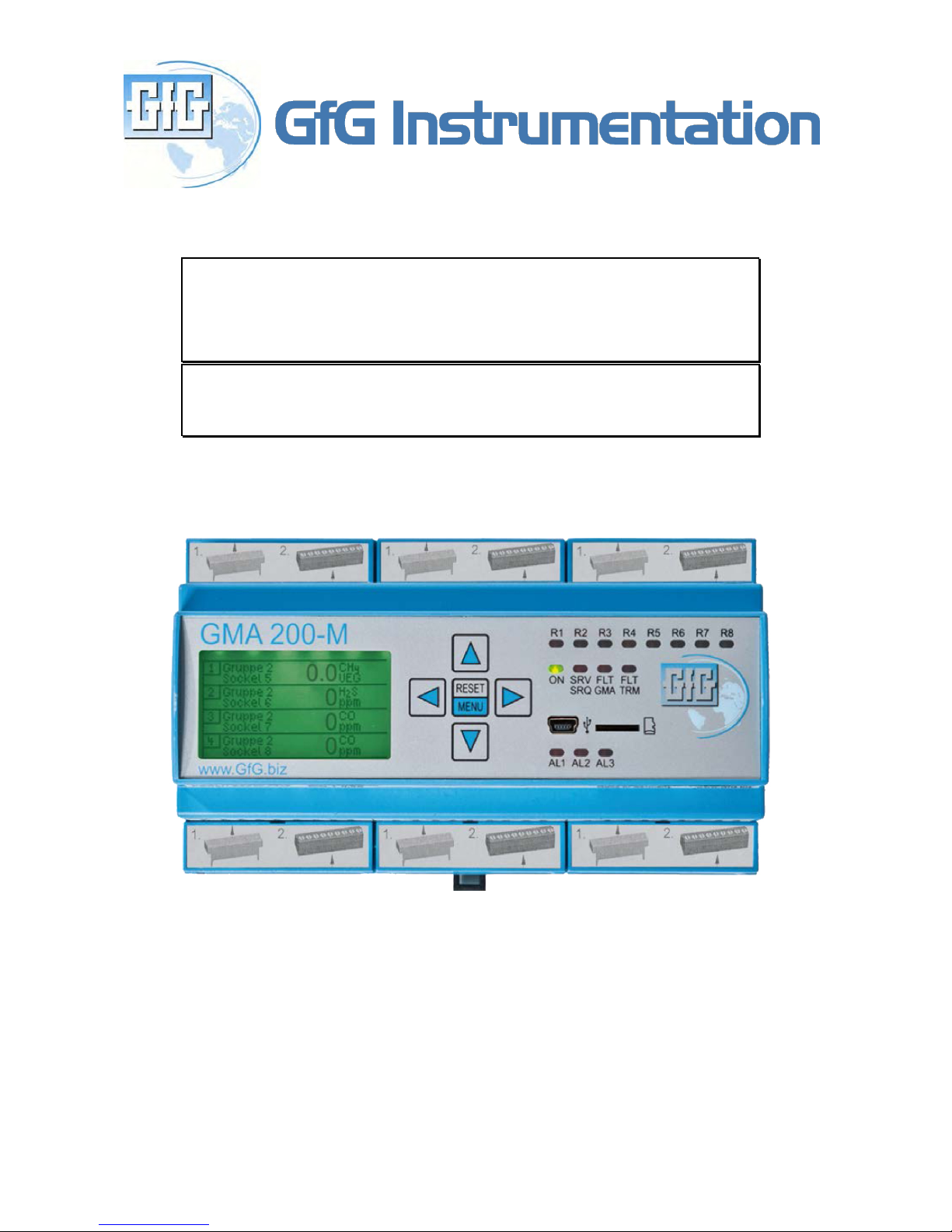

GIG GMA 200-MT series, GMA 200-MT6, GMA 200-MT16 Operation Manual

Worldwide Manufacturer of Gas Detection Solutions

GMA 200-MT

Operations Manual

1194 Oak Valley Dr, Ste 20, Ann Arbor MI 48108 USA

(800) 959-0329 • (734) 769-0573 • www.goodforgas.com

Table of Contents Page

INTRODUCTION 2

For your safety 2

Application 2

Special conditions for safe operation 2

GAS DETECTION CONTROLLER GMA 200-MT 3

General description 3

Device design 3

LED status displays 3

Graphical display 4

Internal relays of the GMA 200-MT 4

External relay with the relay module GMA 200-RT 4

Relay configuration 5

ASSEMBLY AND INSTALLATION INSTRUCTIONS 5

Site of installation 5

Electrical connections 5

Safety information 6

Floating relay contacts 6

24 V DC voltage supply 6

Connection of transmitters with an analog interface 6

Connection of transmitters with a digital interface (RS485) 7

Connection of further devices with a digital interface (RS485) 7

Using the alarm acknowledgement inputs 7

Using the 4-20 mA current outputs 7

Commissioning 8

OPERATING INSTRUCTIONS 8

Measuring mode 8

Alarms 8

Alarm configuration 9

Alarm acknowledgement (Reset) 9

Relays 9

Faults 10

Data logger function (configured using the “GMA200Config” software) 10

Analog outputs 11

KEYBOARD AND MENUS 12

Operation and menu navigation 12

Main menu 12

Service menu 13

APPENDIX 14

Cleaning and care 14

Maintenance and service 14

Visual inspection 14

Functional testing 14

System check 14

Repair 15

Parts and accessories 15

Technical data 16

EC declaration of conformity 17

Introduction

For your safety

As with any piece of complex equipment, the GMA 200-MT will do the job it is designed to do

only if it is used and serviced in accordance with the manufacturer's instructions. Please protect

yourself and your employees by following the instructions in this manual. All individuals who have

or will have the responsibility for using and servicing this product must carefully read this manual.

The warranties made by GfG with respect to the product are void if functions or parameters are

changed without the permission of GfG. They are also void if the product is not used and serviced

in accordance with the instructions in this manual. Failures or false alarms caused by interfering

gases or electrical signals are not part of the warranty obligation. The above does not alter any

statements by GfG regarding warranties, conditions of sale and/or delivery.

Application

The GMA 200-MT6 and GMA 200-MT16 are gas detection controllers for mounting rail assembly.

Combined with connected transmitters, they form a fixed gas warning system for the continuous

measurement of gas concentrations and are used to issue a warning about combustible gases or

vapors in the range below the lower explosion limit and about toxic gases in the ambient air, as well

as to measure oxygen.

External relay modules GMA 200-RT are additionally available.

The “GMA200Config” software program is required to configure the controllers GMA 200-MT6

and GMA 200-MT16 and the relay module GMA 200-RT.

Special conditions for safe operation

According to the requirements stipulated, (e.g., by DIN EN 60079-29-1, DIN EN 45544 and DIN

EN 50104) at least one alarm threshold with self-locking must be configured for potentially

hazardous gas concentrations.

Gas detection controller GMA 200-MT

General Description

The fundamental configuration and design of the GMA 200-MT6 and GMA 200-MT16 gas

detection controllers ensure flexible, simple and clearly structured operation in industrial and

commercial applications for measuring combustible and toxic gases/vapors and oxygen

concentrations.

Using the "GMA200Config" software program, it is possible to quickly and easily configure

measuring points and relays even when extending already installed GMA200 gas warning systems.

Among other things, measuring point designation, transmitter type, gas type and measuring range,

as well as three individual or specified alarm thresholds, can be configured for each measuring

point.

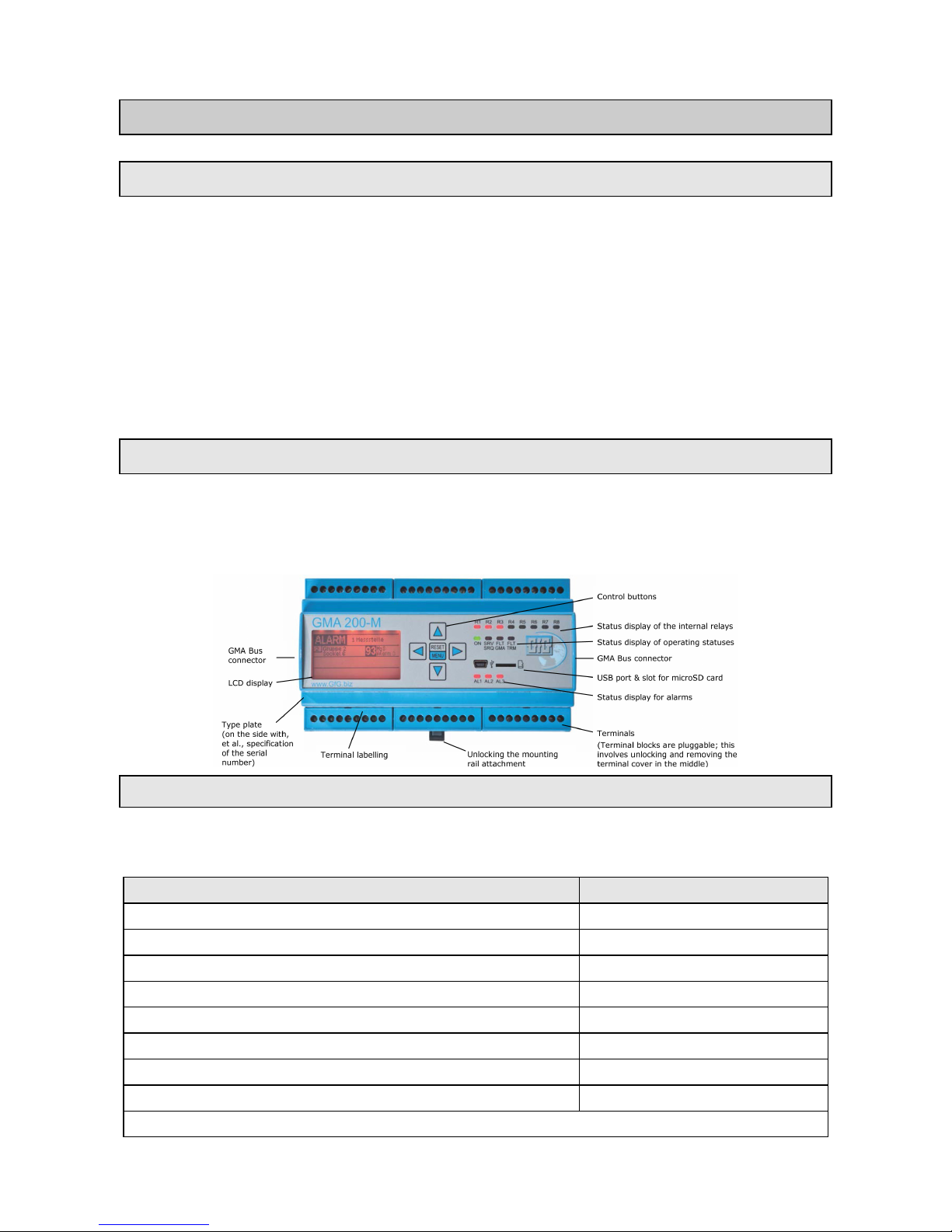

Device design

Up to 6 transmitters can be connected to the analog inputs of the GMA 200-MT6 and up to 16

transmitters with 4-20 mA or 0.2-1 mA output to the GMA 200-MT16. A microprocessor evaluates

the analog input signals of the connected transmitters, and a clearly structured display with LEDs

indicate the status of the gas detection controller, each measuring point and the relays.

LED status displays

During operation, the LED status displays at the GMA 200 controller indicating the following

statuses according to the event:

Event LED status display

Operating status (ON) green

Alarm 1 (AL1) red

Alarm 2 (AL2) red

Alarm 3 (AL3) red

Service (SRV/SRQ) required yellow

Fault (FLT) GMA yellow

Fault (FLT) TRM yellow

Relay 1 (R1) – Relay 8 (R8) red

(Relay activated in case of an alarm or fault)

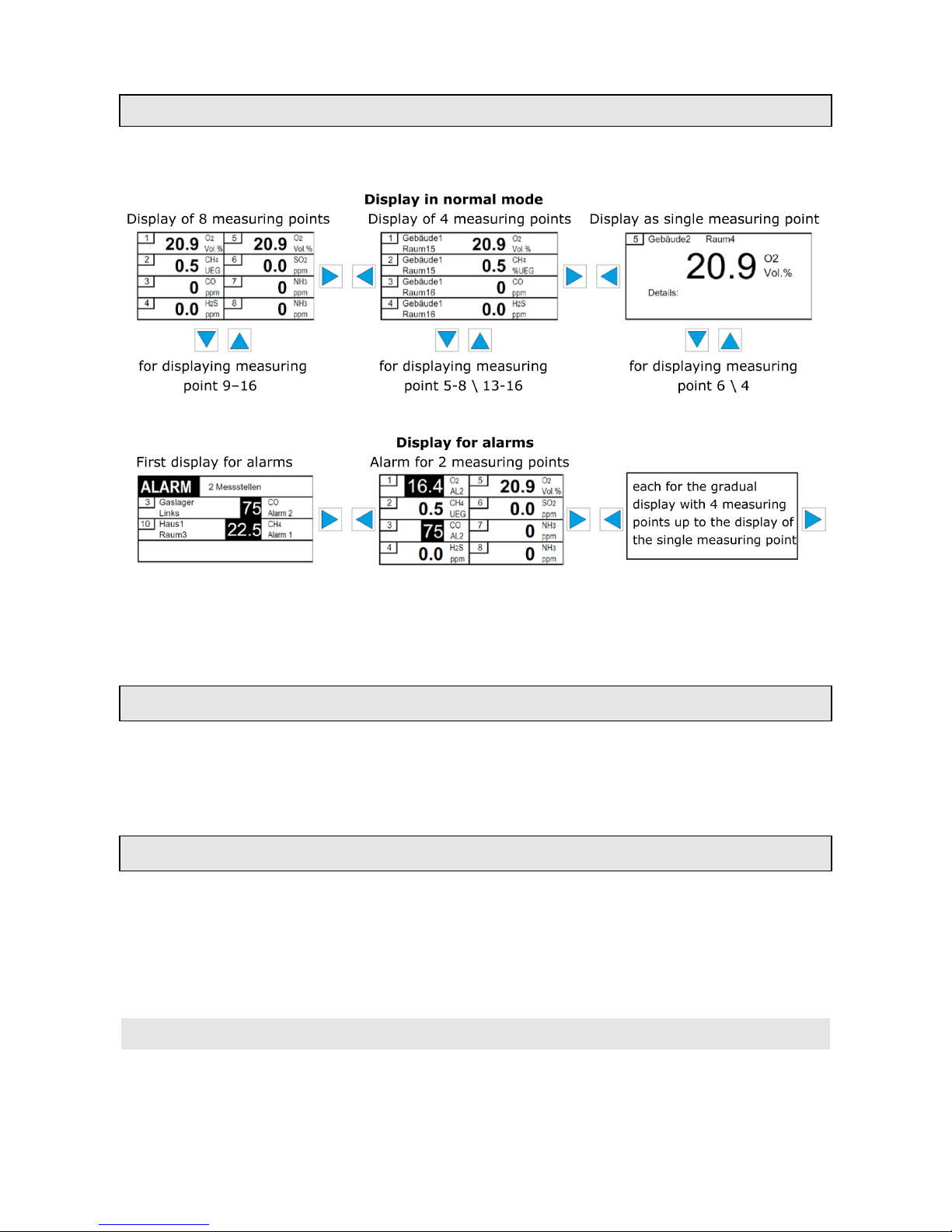

Graphical display

The display shows the currently measured values for each measuring point. The display for the

measuring points can be optionally set through the menu shown below.

The display is backlit; the light intensity can be increased using any control button.

In the event of a gas alarm or faults, the display lighting is automatically activated with a red

background.

Internal relays of the GMA 200- MT

The GMA 200-MT6/ GMA 200-MT16 controllers feature a total of 8 relays. In order to realize

specified safety measures and alarms, 6 relays can be configured using the “GMA200Config”

software program. An additional relay is available for each controller as a safety-related fault

message and maintenance relay.

External relay with the GMA 200-MT relay module

The GMA 200-RT relay module enables the addition of 16 more freely configurable relays. A total

of 4 relay modules with 64 additional relays can be managed via the GMA 200-MT controller. The

GMA 200-RT relay modules are connected to the GMA 200 controller using the RS-485 digital

interface, which also enables the spatial separation of the relay modules (max. 1,000 m).

The relay module is not described in this user manual.

Loading...

Loading...