GIG DS404 Operation Manual

Operations Manual

Docking Station DS404

2

GfG Products For Increased Safety

Congratulations!

You decided in favour of a high-technology product from GfG.

A good choice!

Our detectors are characterised by reliability, safety, best performance and

economic efficiency.

They comply with national and international directives.

This manual will help you to operate the detector quickly and safely.

Please take note of the operational hints before putting into operation!

For any questions please feel free to contact us.

Your

GfG Gesellschaft für Gerätebau mbH

Klönnestraße 99

44143 Dortmund, Germany

Tel.: +49(0)231 – 564 00-0

Fax: +49(0)231 – 564 00-895

E-mail: info@gfg-mbh.com

Internet: www.gasmessung.de

3

Table of Contents

Page

INTRODUCTION 4

For your Safety 4

Application and Purpose 4

Installing and Connecting the Docking Station 4

Connections and Control Elements of the DS404 5

Detector Adapter 6

CO2 Absorption Filter 6

HANDLING FEHLER! TEXTMARKE NICHT DEFINIERT.

Charging 7

Bump Test 7

Sensor Calibration 9

Data Storage/Data Transfer to a PC 11

SOFTWARE 12

Installation 12

Installation of the USB Driver 12

Configuration of the DS404 12

Connection 12

General 12

CO2 Filter 13

Gas Input 1 13

Test Times 13

Clock 14

Intervals 14

ANNEX 15

Care 15

Maintenance and Inspection 15

Troubleshooting 15

Accessories and Spare Parts 16

Technical Data 16

4

Introduction

For your Safety

In accordance with § 3 of the German Equipment and Product Safety Act (GPSG), this manual describ es the

intended use of the product and serves to avoid danger. It must be read and observed by all persons who

operate, servic e, maintain and inspect this product.

This detector can serve its intended purpose only if it is operated, serviced, maintained and inspected

according to the instructions given by GfG Gesellschaft für Gerätebau. The warranties given by GfG

Gesellschaft für Gerätebau mbH will be voided if the product is not operated, serviced, maintained and

inspected in accordance with GfG’s instructions.

The above does not alter statements regarding warranties and liabilities in the General Conditions of Sale

and Delivery of GfG mbH. Repairs may only be carried out by skilled or trained persons. Modifications and

changes to the product may only be carried out with the approval of GfG mbH. Unauthorised modifications

to the product result in the exclusion of any liability for possible damage. Only genuine GfG accessories may

be used together with the produc t. O nly spare parts approved by GfG mbH may be used for repa ir work.

Note: When using the docking station you have to remember that all gas detectors that are calibrated with

the station will be influenced. Incorrectly entered test gas concentrations will result in all gas detectors being

incorrectly cali b r a ted.

Application and Purpose

The Docking Station DS404 is an automatic test station with four test gas ports for carrying out function

tests ("bump tests") and for calibration of the zero point and sensitivity of the sensors of the Microtector II,

Microtector II I und Polytector III series gas detectors.

Installing and Connecting the Docking Station

During commissioning, the hoses and leads for fresh air supply, test gas

supply, gas discharge, pressure switch, mains power supply and PC

interface or interface to a further docking station must be connected to

the test station.

The docking station must be installed on a firm and even surface. The

gases must be supplied pressure-free. For direct gas tapping from test

gas cylinders, use the gas connection fittings listed in section

"Accessories and Spare Parts". During operatio n, the gas is drawn in by

the pump of the docking station. Ensure also that the test gas can leave

the docking station freely without pressure! If CO

tested or calibrated using the docking station, a CO

should be installed in the fresh air supply line (see chapter CO

absorption filte r ).

Ensure that the plug is installed on the T-piece of the fresh air supply

line or that it is conn ected to a further doc king station.

Up to two DS404 or three DS400 docking stations can be operated with

one DS400-PS1 power supply u nit. For this the DS404 or DS400 have to

be connected together using a double-sided jack plug.

During commissioning, the connections for gas supply, gas discharge,

pressure switch, mains power supply and PC interface or interface to a

further docking station must be made as shown in the figure in the

following chapter.

sensors are also to be

2

absorption filter

2

2

5

Zero gas/fresh air

Pressure switch –

Gas exhaust pipe

Pressure switch –

SD card

Red LED

Connection for

power

supply unit

Ports for RS485

Green LED

(on

the card slot)

Connection for

12

supply unit

1 2 3 4

Connections and Control Elements of the DS404

channel 4

Test gas supply –

channel 4

12 V DC

(on left side in the card slot)

channel 1

Display of active input

supply

V DC power

the right in

6

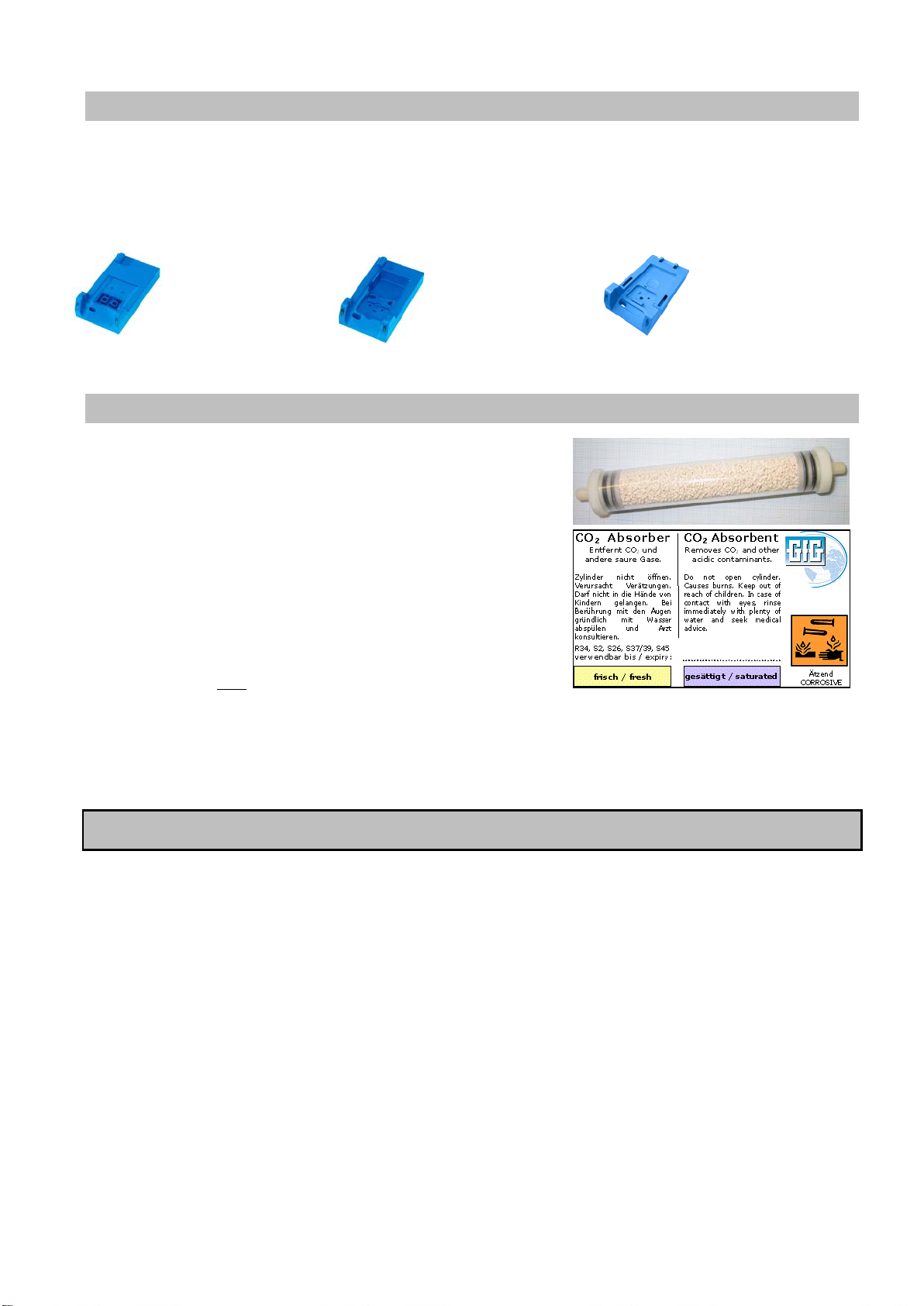

Three detector adapters are available for prepared docking stations. One version for devices without

Microtector III and Polytector III. The electric pump can remain on the

CO2-free zero gas is required particularly for the testing and

calibration of the CO

sensor zero point. As fresh air contains

approx. 500 ppm CO

can be removed using

a CO

is thereby absorbed by calcium

hydroxide (80

%) in the

follo

The absorber removes 1000 ppm

2,500 l of air.

This corresponds to a service life of approx.

minutes of

zero gas pump operation with one docking station. The DS404

calculates the service life on the basis of the flow rate and gives a

warning to replace the filter in good time. The filter gradually

changes colour to

G400-DIC1D for

Microtector II

without a pump

G400-DIC2D for

Microtector II with

attached pump

DIC888/999-B

for Microtector III

and Polytector II I

Detector Adapter

screwed on electric pump. A second version for devices with screwed on electric pump (G400-MP2) and a

third version for the detectors

device for all tests. All three device adapters can be used at the same time by the docking station as

charging cradle. To replace th e device adapter, the DS400 mus t be disc on nected from the power supply .

CO2 Absorption Filter

2

, the disturbing CO2

absorption filter. The CO2

2

wing reaction:

%) / sodium hydroxide (5 %) / H2O (15

2

CO2 + 2 NaOH Na2CO3 + H2O

Na2CO3 + Ca(OH)2 CaCO3 + 2NaOH

CO2 from appro x.

5,000

pale blue.

As water is also produced during the absorption process due to the chemical reaction, depending on the CO2

content of the air, this can have a min or influence on the setting of the sensor z e r o point.

Handling

The docking station is operated by means of the control ke ys of the gas detecto r . The status and tes t data

are output to the detector display . If a gas detector is inserted in to the docking station, the "Information",

"Function Test" or "AutoCal adjustment" options c a n be selected via softkeys on the gas detec tor.

Microtector II d evices can remain in the docking station for operation. De vices of the Microtector III and

Polytector II I s e r ies must be briefly rem oved from the ch a r g er to select the displayed operating opti ons, in

order to be able to operate the concealed keys. After pressing th e keys, the unit is placed back in the

charger. Under certain conditions, a "Firmware Update" can also be carried out using the docking station

when the gas detector is in the station . For this, there m ust be a newer version of a corresponding update

file on the SD card and the "Update" started by pressing the cor res ponding key.

In order to charg e a gas detector, it must be s witched off and placed in the docking s ta tion. If the detector is

placed into the docking station switched on, the necessary test or calibration will be started automatically

after 10 seconds. Within the 10 seconds you can override the automatic selection and start a function test or

calibration man ually.

Loading...

Loading...