GIG CI21 Operation Manual

GfG GESELLSCHAFT FÜR GERÄTEBAU MBH▐ KLÖNNESTRASSE 99▐ D-44143 DORTMUND▐ TELEPHONE +49 / (0) 2 31 / 5 64 00 –0 ▐ FAX +49 / (0) 2 31 / 51 63 13

INFO@GFG-MBH.COM ▐ WWW.GASDETECTION.BIZ▐ AMTSGERICHT DORTMUND HR B 2742▐ CERTIFIED AS PER DIN EN ISO 9001:2000▐ ATEX QM CERTIFICATE

Operation Manual

CI21

Transmitter for NH3

Content

Page

For your Safety 3

General Description 3

Detection Principle 3

Operational Hints 4

Design 4

Mounting Position 5

Mounting 5

Installation of Electrical Connections 6

Putting into Operation 6

Check of Electrical Zeropoint 6

Check of Sensitivity 7

Service 8

Maintenance and Inspection 9

Trouble Shooting 9

Spare Parts 9

Accessories 9

Connection Diagram CI 21 Built-in Sensor 10

Connection Diagram CI 21 External Sensor 11

Technical Data 12

EC-Declaration of Conformity 13

-3-

For your Safety

According to § 3 of the law about technical working media, this manual points out the proper use of the

product and serves to prevent dangers. As any piece of complex equipment, the GfG transmitter CI 21

will do the job designed to do, only, if it is used and serviced in accordance with the manufacturer's

instructions. Please protect yourself and your employees by following them. This manual must be

carefully read by all individuals who have or will have the responsibility for using and servicing this

product. The warranties made by GfG Gesellschaft für Gerätebau with respect to the product are voided,

if the adjustment of functions or parameters is changed without GfG Gesellschaft für Gerätebau’s

permission. They are also voided, if the product is not used and serviced in accordance with the

instructions in this manual. Failures or false alarms caused by interfering gases or electrical signals, are

not part of the warranty obligation. The above does not alter statements regarding GfG Gesellschaft für

Gerätebau's warranties and conditions of sale and delivery.

General Description

A fixed gas monitoring system consists of the transmitter (MWG) and a controller (GMA), which are

connected by means of cable. The transmitter converts the unit for the gas concentration into an

electrical signal and transmits it over the cable to the controller.

Fixed Gas Detection System

A

1

F

A

U

L T

A3 A

2

4

0

O N

F A U L T

6

02010

080

%

C H A N N E L

T Y P E L A B E L I N S I D E

TEST

Q

UTA2A3A

1

MEN

U

MEN

U

U

n

M

U

ou

N

M E N U

Detection

Evaluation

Warning

Fig. 1

The CI 21 is an "intelligent" transmitter. The comprehensive electronics allows easy operation and

maintenance and also increases the operational safety and accuracy. The CI 21 is characterized by the

following features:

Easy calibration at site.

Compensation of temperature effects.

Long sensor life.

Detection Principle

The CI 21 is operated with a Charge Carrier Injection sensor. A s long as there is no gas in the ambient

air, the internal resistance of the sensor is rather high. As soon as NH

3

(Ammonia) is adsorbed at the

sensor surface, the internal resistance is reduced. The change in resistance is the measure for the gas

concentration and is converted into a standardized current signal (0.2 .. 1 mA or 4 .. 20 mA) by the

integrated electronics. The Charge Carrier Injection sensor has proven a good long-term stability and,

because of the sensor design, a good selectivity.

-4-

Operational Hints

According to national regulations gas warning devices have to be checked by a specialist for function

after installation but before being brought into service (putting into operati on). According to BGR 500,

Chapter 2.33, pt. 4.4 (testing of gas detection systems) as instructions of the BG-Chemie T021 (BGI

836).

Before shipment, the CI 21 passes a function and display test, being cal ibrated with suitable test gases.

This does not, however, overrule the obligation of putting into operation with test gas after

installation.

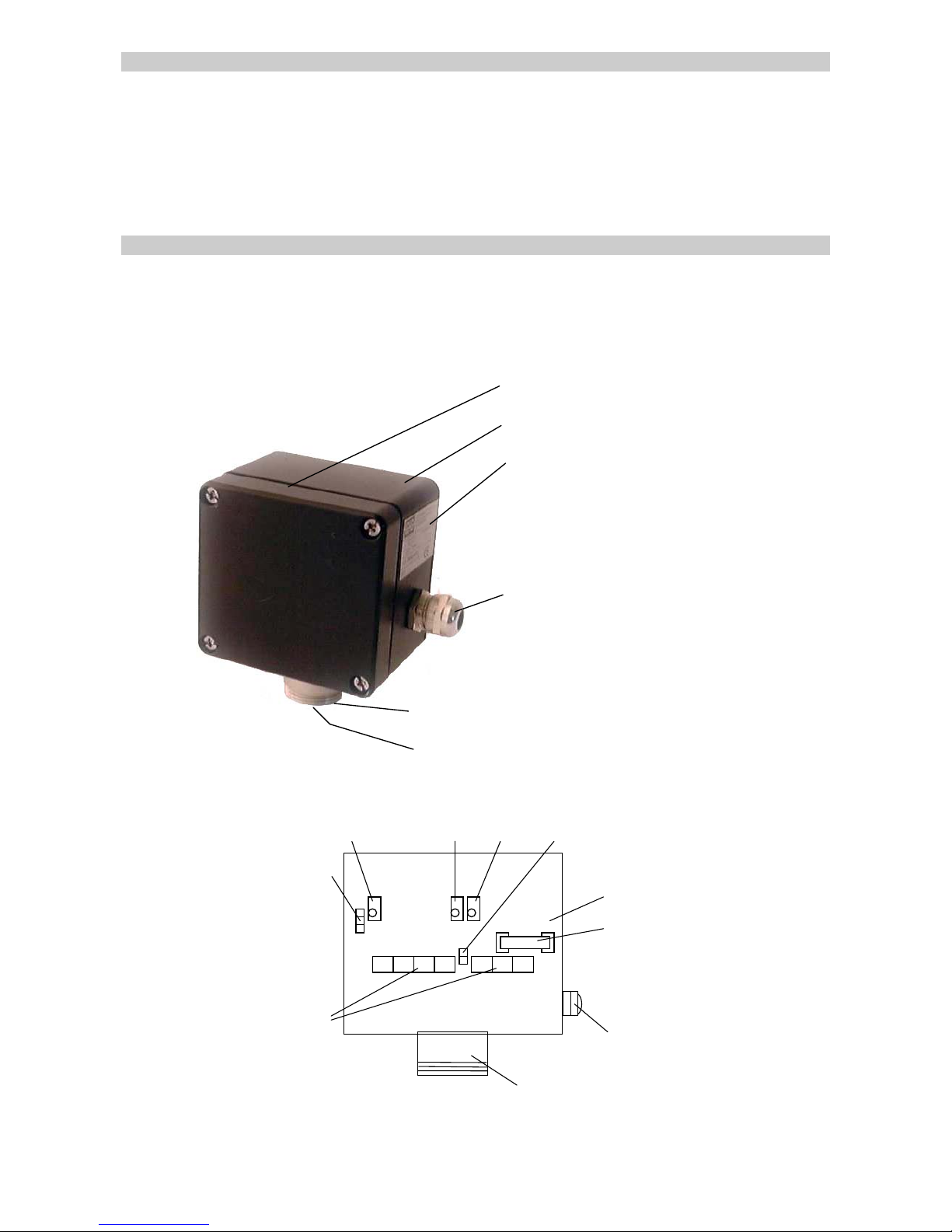

Design

The design of the CI 21 is shown in fig. 2. The sensor is mounted in the sensor support (pos. 5). The gas

enters the sensor chamber through the diffusion inlet (pos. 6). The casing (pos. 2) includes a resin

encapsulated p.c.board with electronic components. The electronics convert the measurement signal into

the output of 0.2 .. 1 mA or 4 .. 20 mA, which is supplied to the controller by means of cable.

CI21 – Design

1. Casing top

2. Casing bottom

3. Type label

4. EMC cable gland (PG 11)

5. Sensor support

6. Diffusion inlet

Fig. 2

Test Contacts

Terminals

Sensor

EMC - PG 11

0 1 3 6 5 4

Fuse

Epoxy Resin

2

Jumper

Poti A

Poti 0

(option)

Poti C

+

0

-

Fig. 3 / Schematic

Loading...

Loading...