USE AND MAINTENANCE MANUAL

DECLARATION OF QUALITY

DECLARATION OF WARRANTY

DECLARATION OF PERFORMANCE DoP

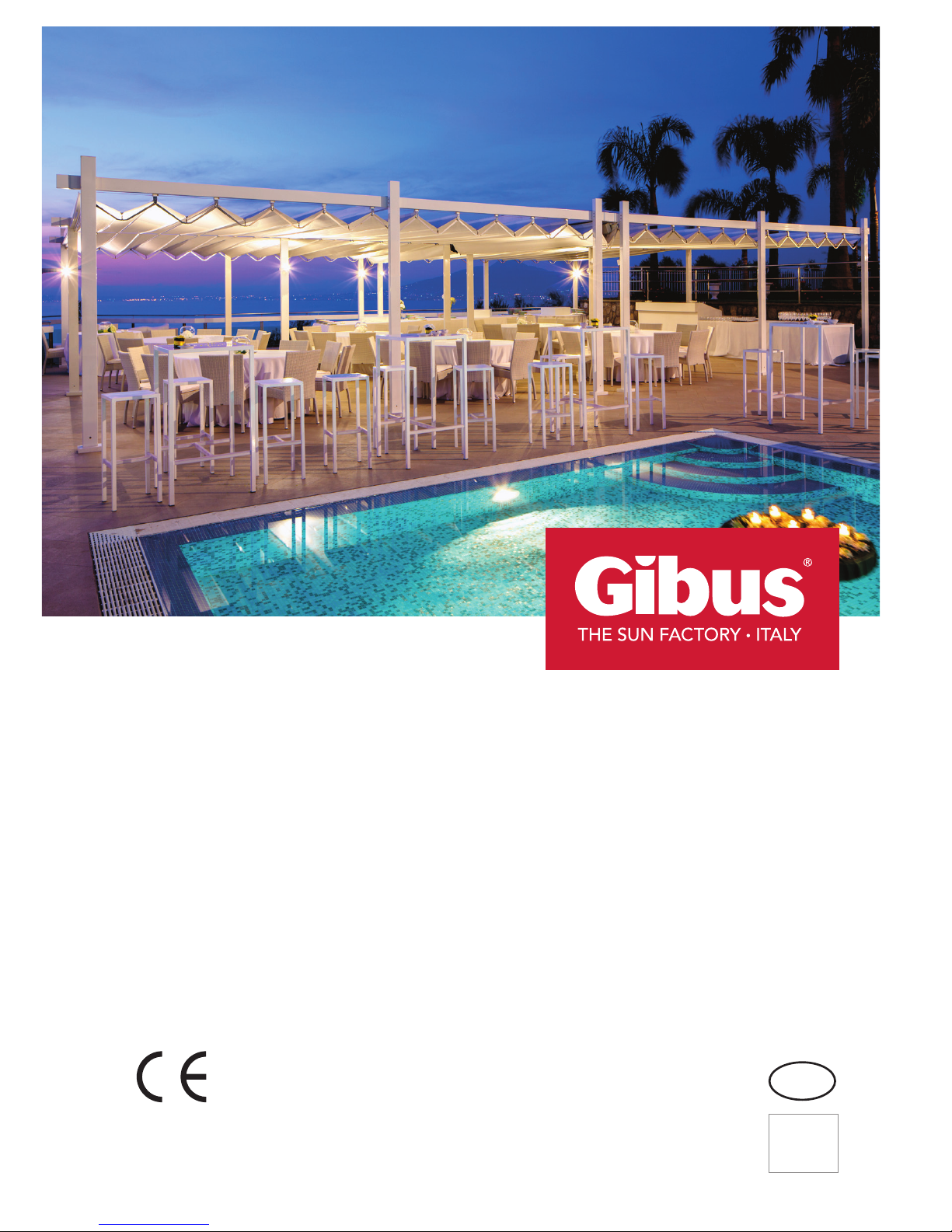

LINE MEDITERRANEA

MODEL

MEDISOLAFLY R

ISLAND, FRONTAL LEANING VERSION, LATERAL LEANING VERSION

SINGLE-MODULE, PLURI-MODULE, FLY FAbRIc cOVER

ENG

MUT 088

Rev. 1

01/03/2017

Gibus S.p.A. Via Luigi Einaudi, 35 35030 Saccolongo (PD) - ITALY www.gibus.it - gibus@gibus.it

Page 3 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

WARNING: CAREFULLY READ ALL WARNINGS AND INSTRUCTIONS IN THIS

MANUAL AND IN THE USE AND MAINTENANCE MANUAL BEFORE CARRYING

OUT ANY OPERATION WITH THE AWNING.

READ IN PARTICULAR THE CHAPTER ON SAFETY.

Dear Customer,

thank you for choosing an awning by "GIBUS", we are pleased to deliver this manual in order to

help you to use the product in the best possible way.

Please read carefully the recommendations described in the following pages and keep the manual

at hand for the Gibus specialist who will be responsible for management and maintenance of

the awning.

Gibus S.p.A.

via Luigi Einaudi, 35

35030 Saccolongo (PD) - ITALY

www.gibus.it - gibus@gibus.it

www.gibus.com

Page 4 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

Gibus S.p.A. reserves all rights to this manual, including the right, at any time, to make any

necessary changes aimed at improving its products and the manual itself without prior notice.

The reproduction, even partial, of this manual is strictly forbidden without the permission of

Gibus S.p.A.

www.gibus.com

Page 5 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

1 INTRODUCTION 7

1.1 Getting started 7

1.2 Warnings for use 7

1.3 Regulations and self-certification documentation 8

1.4 Liability 9

1.5 Product identification and technical nameplate 9

2 SAFETY PRECAUTIONS 10

2.1 Purpose and intended use of the awning 10

2.2 Use environment 10

2.3 Optional safety devices 11

2.4 Requirements of the user and installer 11

2.5 Recommendations 11

3 TECHNICAL DESCRIPTION 12

3.1 Structural and Mechanical Components 12

3.2 Electrical components 13

3.3 Electronic components of the awning (optional) 13

3.4 Fabric components 14

3.5 Supplementary materials 15

3.6 Biocidal products 15

3.7 Noise level 15

4 TECHNICAL DATA 16

4.1 TYPE 16

4.2 MEDISOLAFLY R - ISLAND 18

4.3 MEDISOLAFLY R - FRONTAL LEANING VERSION 20

4.4 MEDISOLAFLY R - LATERAL LEANING VERSION 22

5 PACKING, HANDLING AND TRANSPORTATION 24

6 SAFE INSTALLATION 25

6.1 Mechanical structure 25

6.2 Electrical connections 27

6.3 Radio control 29

7 INSTRUCTIONS FOR PROPER INSTALLATION 30

8 OPERATION AND USE OF THE AWNING 31

8.1 Important information on use 33

9 MAINTENANCE 34

9.1 Cleaning the fabric 34

9.2 Maintenance of mechanical and structural components 35

TABLE OF CONTENTS

www.gibus.com

Page 6 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

10 DISASSEMBLY AND DISPOSAL 35

10.1 Disposal of the awning 36

11 TROUBLESHOOTING 36

11.1 Faults and failures table 37

12 5-YEAR WARRANTY (Eu countries + Switzerland) 38

12.1 Object of the warranty 38

12.2 Duration 38

12.3 Remedies provided as per Art. 133 of consumption code Leg. Decree 206/2005 38

12.4 “Without charges” 38

12.5 Territorial extension 38

12.6 Standards for warranty validity 39

12.7 Exclusions 39

12.8 Liability of the manufacturer 39

12.9 Final indications 39

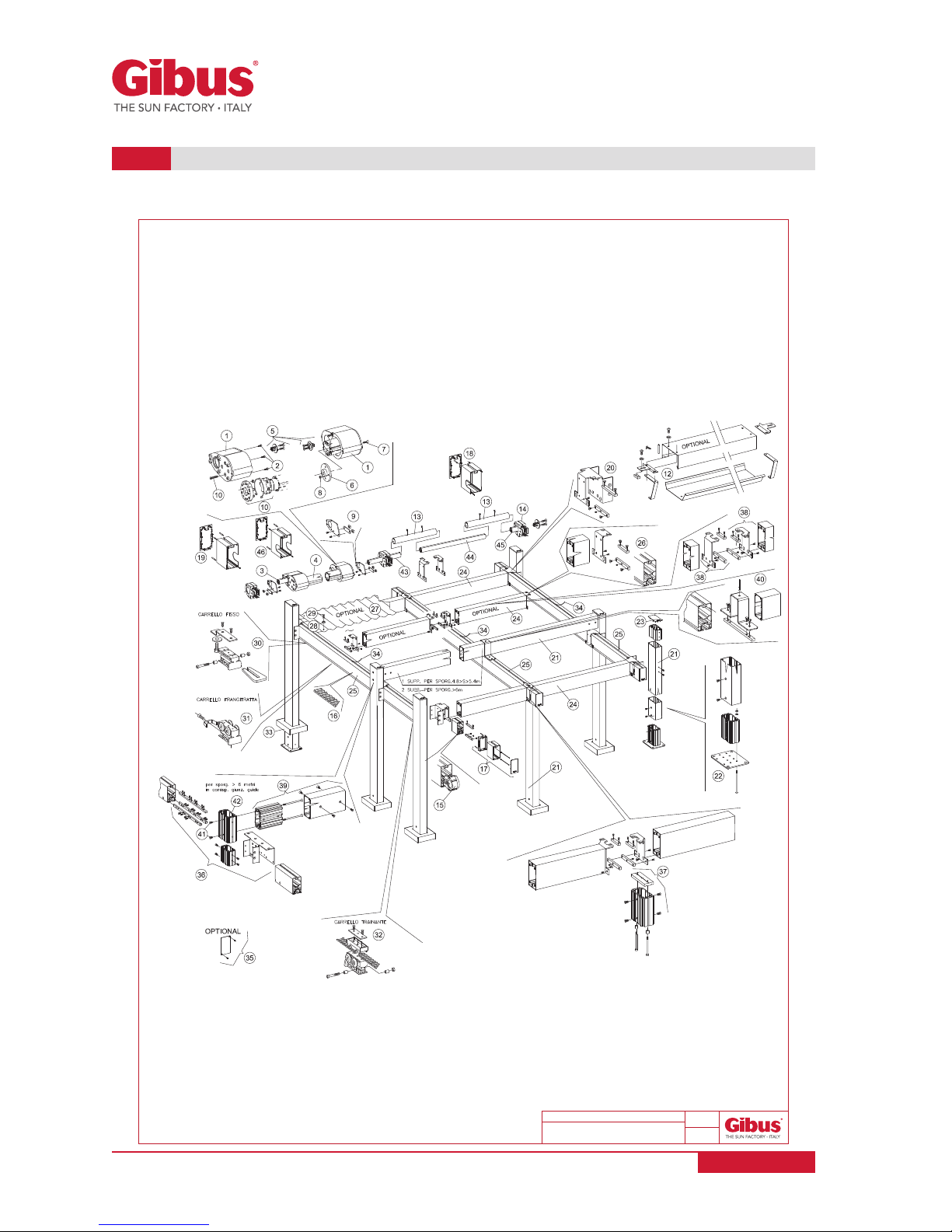

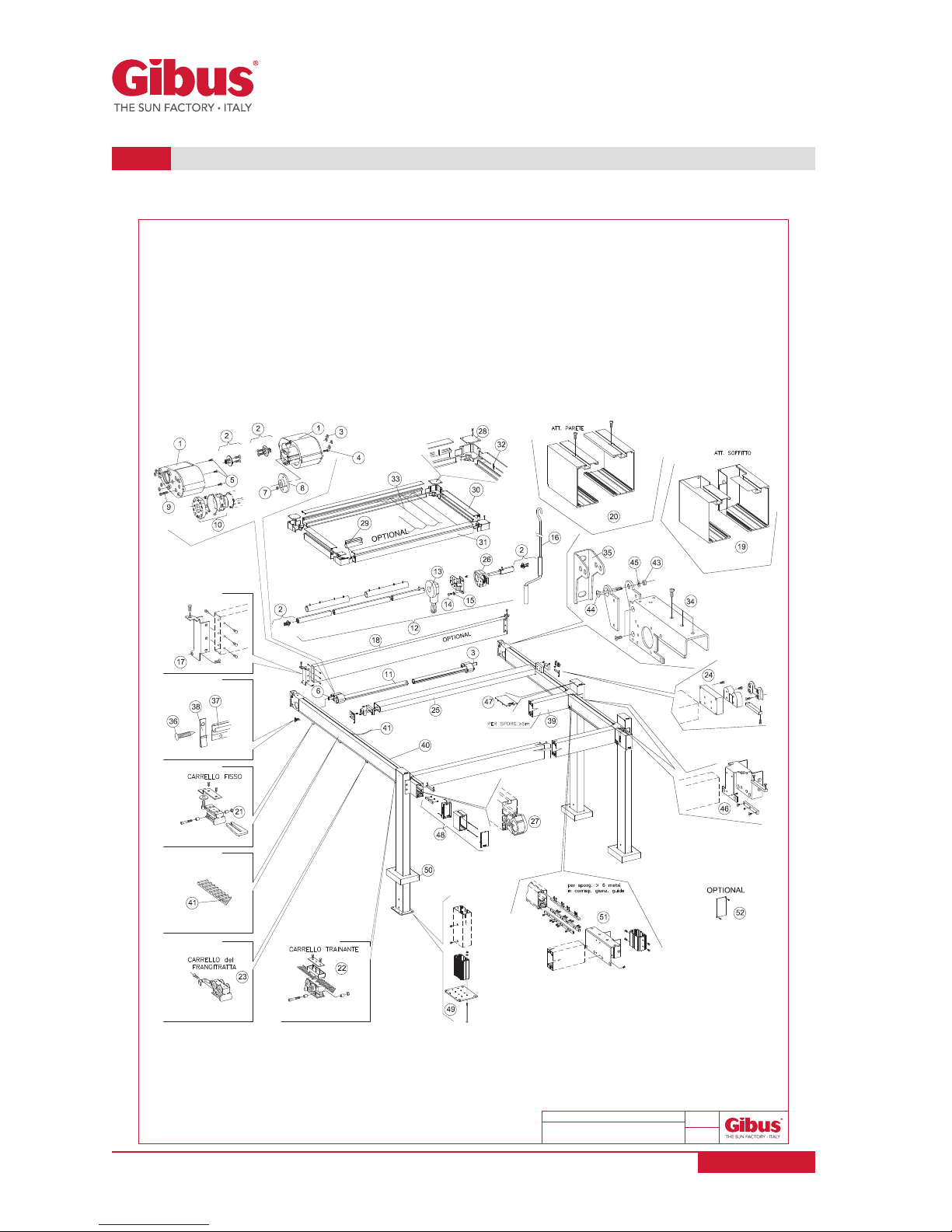

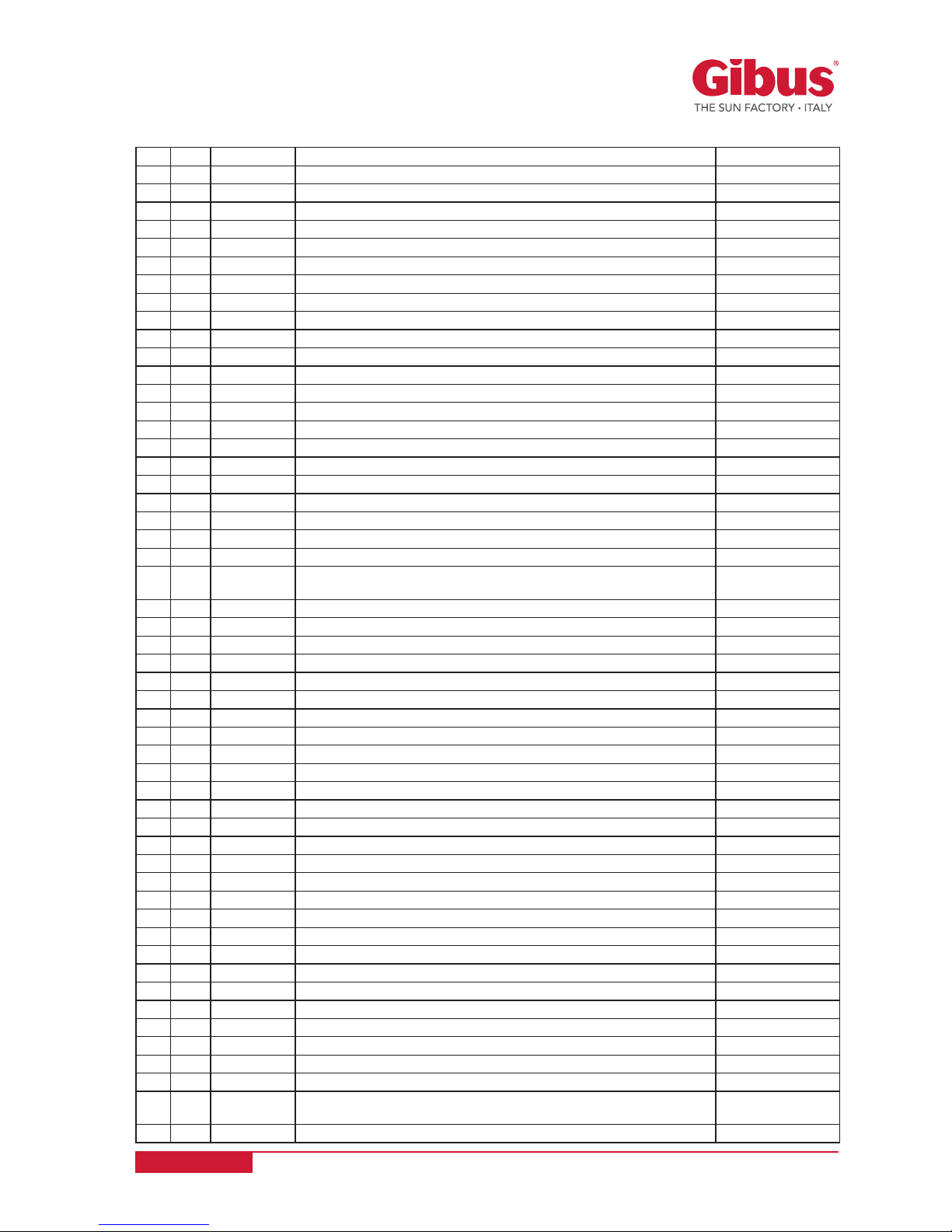

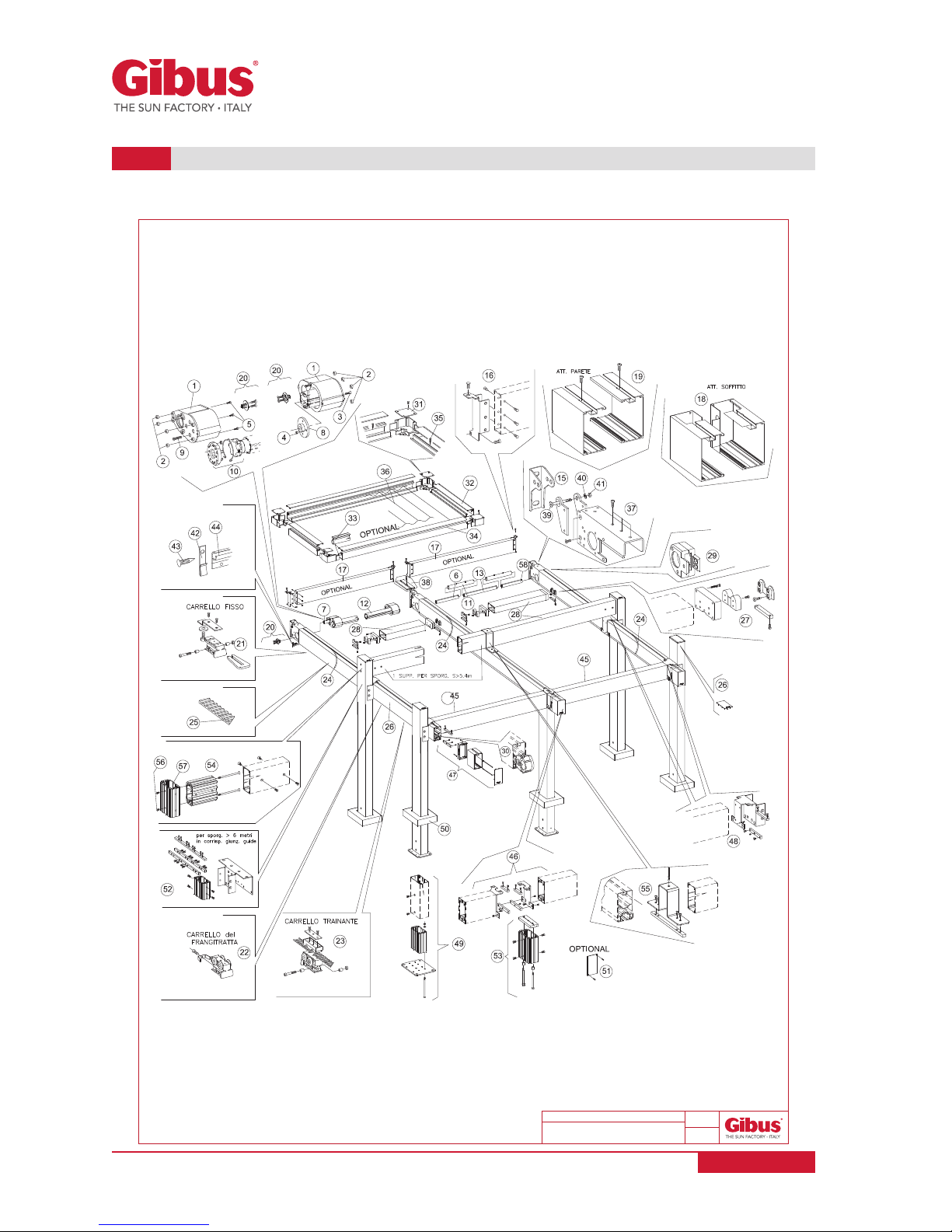

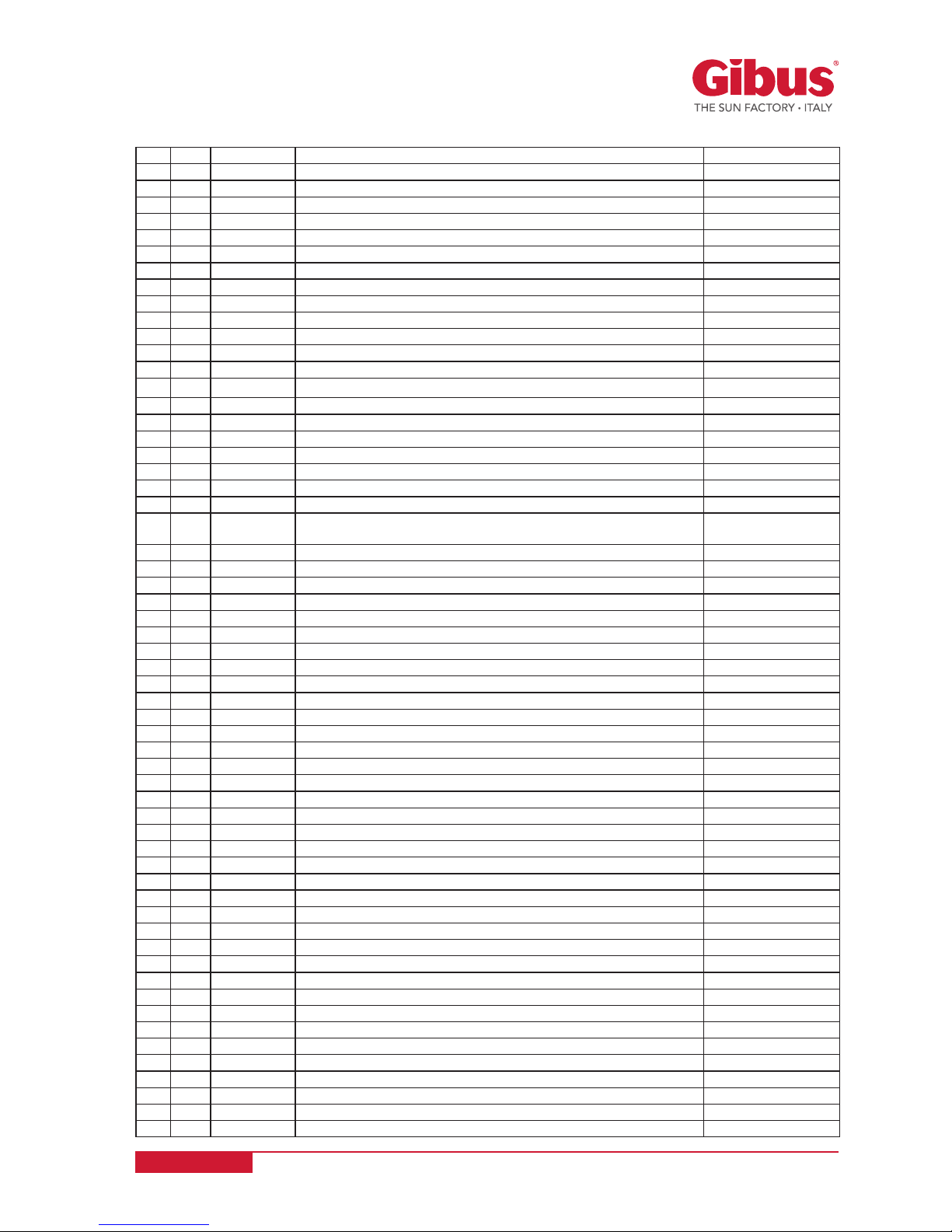

13 MED JEANS EXPLODED DRAWING 40

13.1 MEDISOLAFLY R - ISLAND SINGLE-MODULE 40

13.2 MEDISOLAFLY R - ISLAND DOUBLE MODULE 42

13.3 MEDISOLAFLY R - FRONTAL LEANING VERSION SINGLE-MODULE 44

13.4 MEDISOLAFLY R - FRONTAL LEANING VERSION DOUBLE MODULE 46

13.5 MEDISOLAFLY R - LATERAL LEANING VERSION SINGLE-MODULE 48

13.6 FLY fabric cover 50

14 DOCUMENTATION 52

14.1 Declaration for correct installation 52

14.2 Maintenance registry 53

14.3 Production notes 54

15 ANNEXES 55

TABLE OF CONTENTS

www.gibus.com

Page 7 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

CHAPTER 1: INTRODUCTION

Do not destroy and change, if needed just supplement with inserts published by the manufacturer.

This manual refers to the product:

Type of awning: “Pergola type” folding awning for outside use, free-standing or lean-to.

Single or two bay structure.

Line: MEDITERRANEA

Model: MEDISOLAFLY R

Revision No. 01

Published: 30/06/2016

Manufacturer's data:

GIBUS S.p.A. via L. Einaudi, 35 - 35030 SACCOLONGO (PD) - ITALY

http: www.gibus.it - e-mail: gibus@gibus.it

List of annexes:

- Installation instructions

- Instructions for awning motor drive

- Selection guide

- Delivery certificate

Each operator and personnel in charge of the installation, adjustments, operation and

maintenance of the awning, must read very carefully this manual and observe the instructions

given, the operator in charge of the installation and maintenance must also meet the qualification

requirements for the use and maintenance of the awning.

PRELIMINARY INFORMATION

1.1

IMPORTANT: The instruction manual is aimed at those who use the awning , such as an

installer, maintainer, owner or user and is the basis for the correct use and maintenance

of the product. Addressed to the installer are the instructions for handling, unpacking,

installation, adjustment and maintenance. Addressed to the owner are the instructions

for proper use, maintenance and disposal. This manual is an integral part of the

product. Keep it intact and in an easily accessible place for future reference and at hand

for further consultation until the disposal of the awning. In case of loss or destruction of

the manual, the customer must request a new copy to his Retailer, providing the main

data of the product and the destination of the new copy. When selling this manual must

follow the awning to its new destination. The manual must always be available to the

personnel involved in the installation, maintenance or adjustment of the product.

The Manufacturer reserves the right to update products and relevant manuals, with no

obligation to update previous manuals. This manual is the essential tool for maintaining

the validity of the guarantee.

INSTRUCTIONS FOR USE

1.2

The instructions contained in this manual are intended for awnings models:

- FREE-STANDING MEDISOLAFLY R: “pergola type” folding sun awning for outside use with

free-standing structure. Single or two bay structure. Retractable, Telo Fly.

- LEAN-TO MEDISOLAFLY R: “pergola type” folding sun awning for outside use with lean-to

structure. Single or two bay structure. Retractable, Fly awning.

Available with wall or ceiling attachments.

The instruction manual must be read and used in the following way:

- Read this manual carefully, and consider it an integral part of the awning;

www.gibus.com

Page 8 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

WARNING: DANGER TO THE OPERATOR/USER In reference to dangerous

situations that can occur with the use (including installation and maintenance) of

the awning. Failure to comply with these messages may endanger the safety of

persons.

WARNING: In reference to dangerous situations that may occur due to the

PRESENCE OF ELECTRICAL VOLTAGE. Failure to comply with these messages

may endanger the safety of persons and the integrity of the awning.

WARNING: In reference to dangerous situations that can occur with the use of the

awning to prevent damage to objects and the awning itself.

IMPORTANT: Useful information and tips to be observed to ensure proper use

and preservation of the awning. Failure to observe these messages can affect the

integrity and / or resistance of the product.

This User's Manual was prepared in accordance with as indicated in EN 13561 and section

1.7.4 of Annex 1 to Directive 2006/42/EC and taking into account the normal use of the awning

in order to inform, together with other instructions for use affixed to the awning itself, the

operators / users on residual risks that the products presents.

The awning complies with the “Construction products regulations - CPR 305/2011” and offers,

if properly installed, a resistance to wind load greater than those required by the Class 3 of the

UNI EN 13561 rule on "External awnings - Performance requirements including safety".

This Technical Classification ensures resistance to a wind that carries a maximum pressure

rating of 110 [N/m2] (Newton / sqm) similar to an wind insisting on the awning with a maximum

speed of 49 [km / h] corresponding to the 6th level of the Beaufort Scale.

The resistance to wind load was evaluated according to criteria related to those required by the

UNI EN 13561 and UNI EN 1932 rules, with the necessary safety margins.

The motorised version conforms as well as the relevant parts of the to the Machine Directive

2006/42/CE.

The CE Mark together with wind resistance characteristics according to UNI EN 13561 and

theself-certification document (Declaration of Performance DoP) are included in APPENDIX 0

and APPENDIX 1 on the last pages of this manual. The original Declaration of Performance DoP

issued by the manufacturer is kept by Gibus S.p.A.

Quick or careless preparation leads to improvisation, which is the cause of many accidents.

Before starting the installation work and before commissioning of the awning, carefully read

and strictly observe the following tips:

REGULATIONS AND SELF-CERTIFICATION DOCUMENTATION

1.3

- The instruction manual must be readily available for use by staff in charge of running and

maintenance;

- Keep the manual for the entire service life of the awning;

- In case of sale deliver the manual to the new owner of the awning;

- Use the manual in such a way not to damage all or any part of its content;

- In no case remove, tear or re-write any part of the manual;

- Keep the manual in a place protected from moisture and heat;

- If the manual is lost or partially damaged and then its complete content can no long be read, it

is advisable to request a new manual to the manufacturer.

In the following pages pay close attention to the following symbols and their meaning. Their

function is to highlight essential information such as:

www.gibus.com

Via Einaudi, 35 - 35030 Saccolongo (PD)

EN 13561

MODELLO: MED ISOLAFLY R- 230V/50Hz

MESE: 1 2 3 4 5 6 7 8 9 10 11 12 ANNO: 2016 - 17 - 18

D

A

E

B

C

Page 9 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

WARNING: For maintenance or repair to always use only original spare parts.

GIBUS SpA declines all responsibility for damages that may occur for noncompliance with the above instructions.

The awning is guaranteed according to the contractual arrangement prepared at

the time of sale.

The warranty is in any case deemed void if the rules and instructions for use

contained in this manual were not followed.

RESPONSIBILITY

1.4

GIBUS SpA is not liable and has no obligations for any accidents to persons or property, which

may occur due to:

- Failure to follow the instructions in this manual regarding the installation, use and maintenance

of the awning;

- Violent actions or mishandling in the installation, use and maintenance of the awning;

- Changes made to the awning without the prior written permission by GIBUS SpA;

- Incidents in any case arising beyond the normal and correct use of the awning.

In any case, if the user thinks the cause of the incident is a defect of the awning, he will have to

prove that the damage has been a major and direct consequence of such a "defect".

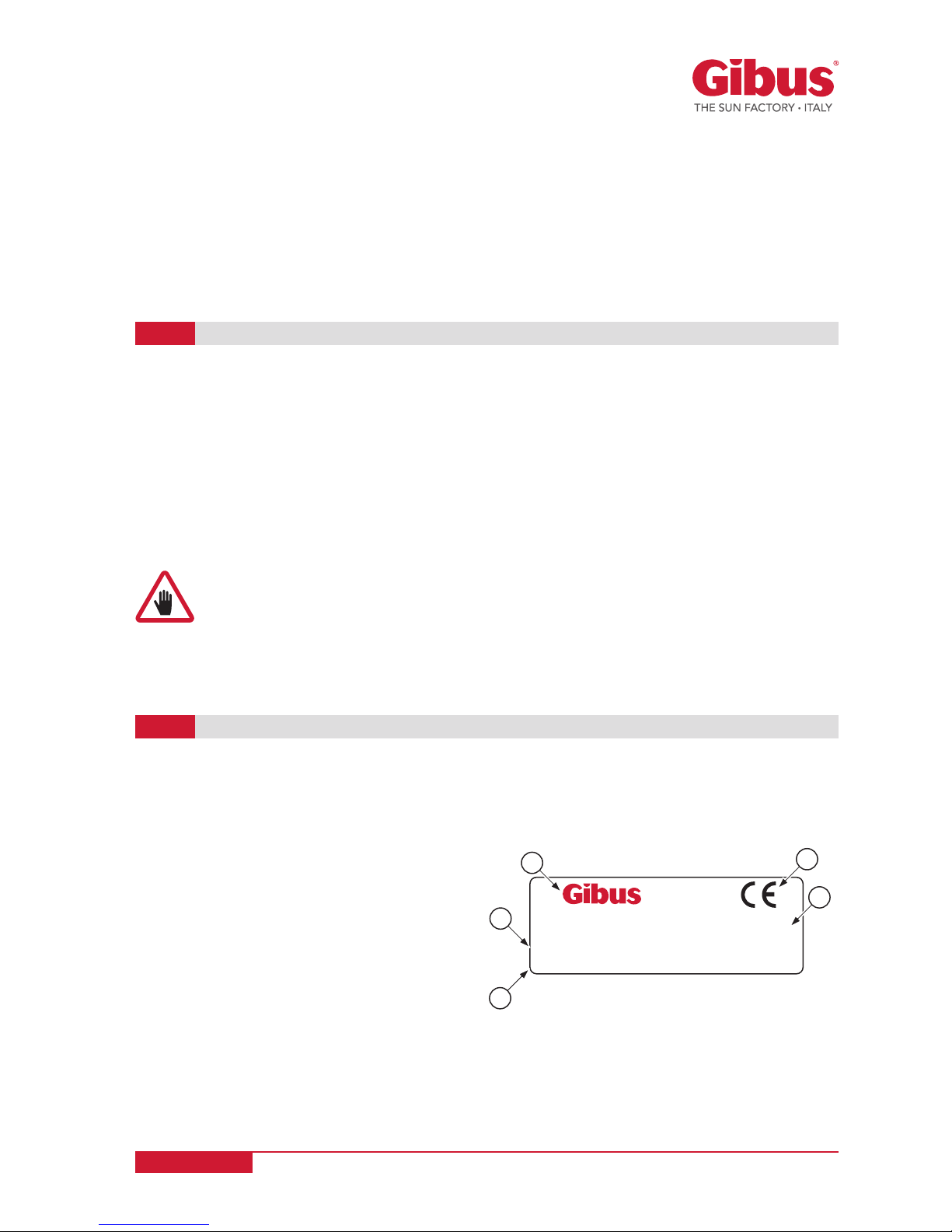

Each model is identified by the adhesive technical nameplate showing the CE marking (placed

on the profile breaker on the engine/winch drive) and contains the following data:

A

Name and address of the registered office of the

manufacturer.

B CE marking

C No of the European rule.

D Model of the awning and specifications (*).

E Year of manufacture.

IDENTIFICATION OF THE PRODUCT AND TECHNICAL NAMEPLATE

1.5

Each Gibus awning and pergola is unique, individually recognisable and traceable due to the

Gibus trademark 3D hologram with a unique alphanumeric serial number. All Gibus products

are supplied with the hologram (see back cover). The hologram is applied near the CE marking.

- The maintainer must always have at hand the instruction manual;

- Program all operation with the utmost care;

- Be well aware of where and how it is provided for the use and maintenance of the awning;

- Strictly follow all warnings relating to special dangers listed in this manual;

- A constant and careful preventive maintenance will always ensure a high level of operating

safety of the awning.

Never postpone needed repairs and have them carried out only by qualified personnel, and use

only original spare parts.

(*) The awning with manual start-up (version with winch) is

not fitted with the electrical characteristics „230V/50Hz.“

www.gibus.com

Page 10 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

The awning was designed and built exclusively as a sunscreen to be used in the context of

civil construction, residential, commercial and other services to the community. The awning

is designed solely for the use indicated above, even if packaged with plastic or PVC tarpaulins

provides some protection against the rain. Any other use is considered improper and

inadequate and release the manufacturer from all liability for any damage caused to

persons or property. The awning offers, if properly installed, a resistance to wind load greater

than those required by the Class 3 of UNI EN 13561. It is therefore recommended the exposure

to a wind exerting a maximum pressure of 110 Newton/sqm, corresponding to the load of a

continuous wind speed not exceeding 49 km/h. It is strictly required, for the sake of safety, to

pack the awning before exceeding such a limit.

CHAPTER 2: SAFETY REQUIREMENTS

PURPOSE AND INTENDED USES OF THE AWNING

2.1

CAUTION: for safety reasons the awning must be therefore packed in case of wind

exceeding the recommended maximum exposure, hard rain, hail and snow; it is

very dangerous to leave the awning open in these cases, it can cause injury to

persons and damage to property.

IMPORTANT: For any doubt or unintended use, consult the manufacturer before

installation.

The manufacturer is not liable for malfunctions and damage if the awning:

- Is used for purposes other than those for which it is intended to;

- Is not operated and maintained in accordance with the instructions specified in this manual;

- Is not subject to regular maintenance, as prescribed, or non-original spare parts are used for

replacement.

The awning was designed and built to operate outside. It offers adequate protection of electrical

parts to water infiltration. The motors provides a degree of protection against moisture equal to

IP44.

With proper protection of electrical parts against infiltration of water, such as a protective roof, the

awning can also be used outdoors or away from the wall of a building (intended use), provided

that the system is degree of protection IP 55.

The electrical switch should be placed in a protected position, at a minimum height of 1.50 [m]

from the ground (the remote control is recommended when used by disabled individuals) and

away from dangerous areas.

USE ENVIRONMENT

2.2

CAUTION: the engines cannot be used in atmospheres posing risk of explosion.

IMPORTANT: Failure to follow the conditions for proper use, automatically voids

any warranty given by the manufacturer.

IMPORTANT: In order to use the awning for purposes other than those described

above, a specific permission given by the manufacturer is required. Failure to follow the

conditions for proper use, automatically voids any warranty given by the manufacturer.

www.gibus.com

Page 11 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

CAUTION: No person shall install or place ladders or other fixed objects in such a

way as to obstruct the excursion path of the awning.

Anemometric sensor: In case of strong winds (greater than the set threshold), the closing of

the awning occurs automatically. The rate at which the wind sensor (anemometer) is recorded

during the initial start-up procedure, as described in the Use and Maintenance Manual (see

section 3.3 and instructions for the specific device).

Sun sensor: In case of sunshine the awning automatically opens The threshold at which the sun

sensor activates can be set (see section 3.3 and instructions for the specific device).

Rain sensor or pluviometric sensor: In case of prolonged rain, the awning automatically closes.

The activation level of the device for measuring the amount of rainfall in a given time interval (rain

gauge), is recorded during the initial start-up procedure (see section 3.3 and instructions for the

specific device).

OPTIONAL SAFETY DEVICES

2.3

The normal use of the awning is allowed to everyone, except those younger than 12 years.

The installation of the awning and of the electrical system, the adjustment of the awning

and the setting of the engine limit switch, as well as maintenance must be performed by

qualified personnel only. The installation of the awning must be carried out strictly in

accordance with the manufacturer's instructions provided in this manual and especially

following the attached INSTALLATION INSTRUCTIONS referred to in the pertinent sections

of this manual (Chap. 6 and Chap. 7).

USER AND INSTALLER REQUIREMENTS

2.4

In the manual and especially in the attached INSTALLATION INSTRUCTIONS referred to in the

pertinent sections of this manual (Chap. 6 and Chap. 7), are listed all instructions for proper

handling, storage, installation, use and maintenance of the awning, in compliance with the

"Machinery Directive" and product standards to avoid harm to people or damage to the awning

itself. Are also given instructions to perform properly both dismantling and disposal.

RECOMMENDATIONS

2.5

WARNING: The installation of the awning and its electrical connection,

are only to be carried out by specialized and authorized staff.

ANY OPERATION ON THE ELECTRICAL SYSTEM MUST BE CARRIED

OUT BY TRAINED PERSONNEL ONLY. IMPORTANT: For any doubt or

unintended use, consult the manufacturer before installation.

WARNING: The installation of the awning must be carried out strictly in accordance

with the instructions in this manual. A different installation could result in

hazardous situations.

IN THIS REGARD SEE THE SECTIONS "SAFE INSTALLATION" and "INSTRUCTIONS

FOR PROPER INSTALLATION" and the documents referred to in those sections

attached to this manual and inside the package.

ATTENTION!: Corrosion resistance is not guaranteed in the event of immersion or

sprays with salt water (sea storms, etc.). Also, with intense exposure to salty fog,

incrustations or bubbles could appear in the connections or aluminium profiles

and oxide or rust could appear on the stainless steel brackets. These conditions

are not covered by warranty.

www.gibus.com

Page 12 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

WARNING: You can not alter or modify the awning. Any changes or modifications

made without proper authorization by the manufacturer, relieves the latter from

any liability for any damage that may result and automatically void the warranty.

ATTENTION: it is strictly forbidden to carry out operations using open flames in

the vicinity of the awning.

The awning is prepared for the installation of a protection roof.

CHAPTER 3: TECHNICAL DESCRIPTION

STRUCTURAL AND MECHANICAL COMPONENTS

3.1

The awning of the MEDISOLAFLY R line were designed and built according to the principles

of constant innovation, impeccable workmanship and attention to the details of Gibus Total

Quality. A system of values designed to ensure complete customer satisfaction.

The FREESTANDING MEDISOLAFLY R is a pergola- style awning integrated into a special self-

supporting structure that is freestanding and detached from any building.

For the LEANING MEDISOLAFLY R the specific structure is leaned against the wall of a building.

A spring system means that the awning fabric is taut in all 3 positions, thanks to the lateral springoperated pantographs that give the fabric its curved shape. This ensures that the fabric is always

sloping (single or double slope) for water drainage and excellent resistance to wind.

The drive of the fabric cover is motorized or provided by a winch.

The awning is equipped with several patented systems to facilitate and speed up the installation

work and improve the performance of the product:

The “pergola type” awning is equipped with a bearing structure to be fixed to the floor or to

the wall and to the floor, made of painted aluminium with guides, transverse profiles and leg of

70x130 section.

Connections include stainless steel brackets, painted aluminium casts, stainless steel bolts and

nuts. Painted aluminium section break profiles measuring 40x50.

Transmission system on side guides and very strong toothed belt, moving on roller bearings.

Aluminium cast casing with belt tension regulation.

Slide carriages with wheels with stainless steel bearings and pins.

The guide profiles, section breaks and terminals, supporting structural beams are Anticorodal EN

AW 6060 UNI EN 573-03 UNI EN 755-2, and then treated with anticorrosion phosphochromatisation

and painted with thermosetting polyester powder paints.

Gibus Patent

®

Fast Coupling: Quick coupling system of the engine built into the gears.

Gibus Patent

®

Quick Block: Quick coupling system of the sliding trolley with the terminal

or the profile breaker.

Gibus Patent

®

Telo FLY: To tighten the arched cover fabric with pantograph system.

Registered design.

www.gibus.com

Page 13 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

The tubular motors are single-phase asynchronous irreversible equipped with thermal

protection at 140°C for safety devices against overheating. They are equipped with a

condenser, electromechanical brake assembly, two limit switches and mechanical scaler for the

reduction of primary turns at 12 or 17 [rev/min] ouputs.

The type of engine used on the awnings is indicated in the product sheet.

ELECTRICAL COMPONENTS

3.2

CAUTION: MOTOR REDUCERS have degree of protection IP 44, watertight and are

in insulation class 1 (compulsory grounding).

IMPORTANT: The instructions specific for engines are supplied upon delivery of

the awning. These instructions must be read carefully, annexed to this manual and

keep in good condition for any subsequent consultation by the customer.

Declarations of Conformity of the engine can be found in the restricted areas of

the sites supplying them.

ELECTRONIC COMPONENTS OF THE AWNING (OPTIONAL)

3.3

Upon optional request the awning can be managed electronically in its functions with control

of the weather conditions. In this case, the awning can be fitted with the following additional

electronic devices: automatic control unit for wing or automatic control unit of sun and wing or

rain gauge (see par. 2.3).

The type of electronic component used on the awning is indicated in the product sheet.

CAUTION: Never set the wind speed above the wind resistance of the awning itself

(maximum threshold recommended for MEDISOLAFLY R: 40 Km/h).

Response time:

• Detection of the wind : 3 seconds after up command.

• Presence of sun : 2 minutes after down command.

• Disappearance of the sun : 15 minutes after up command.

ATTENTION!: Corrosion resistance is not guaranteed in the event of immersion or

sprays with salt water (sea storms, etc.). Also, with intense exposure to salty fog,

incrustations or bubbles could appear in the connections or aluminium profiles

and oxide or rust could appear on the stainless steel brackets. These conditions

are not covered by warranty.

The aluminium casts are in EN AB 46100 and EN AB 44100 alloys.

The casted components for the sliding carriages, pulleys and other plastic components are

made from fiberglass reinforced nylon or Ryton® PPS. Toothed belt with steel strands. Stainless

steel screws.Stainless steel plates.

IMPORTANT: The specific installation, use and maintenance instructions of the

units are attached to the packaging of the units themselves, delivered with the

awning. These instructions must be read carefully, attached to this manual and

kept in good condition for future reference on part of the customer.

www.gibus.com

Page 14 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

The type of fabric used on the awning is indicated in the product sheet. For the type of

fabric recommended for each model, refer to current price list.

PACKAGING THE FABRIC COVERS

Seams: made with TENARA wire

®

by GORE in PTFE (polytetrafluoroethylene) unaffected by UV

rays and chemical agents; they are guaranteed for 10 years.

Seals of PVC tissue by fusion.

Trimming: 100% acrylic fibre.

The fabric can be of the following types:

PVC Precontraint 602 fabric - BLOCK-OUT

PVC polyester coated on 2 sides and glossy lacquered. Black coating on the inside. 730 g/mq.

Breaking load: warp 250 kg - weft 220 kg plot (DIN 53354). 100% Waterproof - Fireproof Class 2.

PVC Poly HR Opatex fabric

PVC coated polyester inner side, outside corrugated with dust-proof acrylic paint. Double inner

black coating. 850gr/mq. Tear strength: warp 250 Kg, weft 250 Kg (DIN 53354). Fireproof class 2

PVC Precontraint 302 fabric

PVC polyester coated on 2 sides and glossy lacquered. 480 g/mq. Breaking load: warp 140 kg weft 15 kg (DIN 53354). 100% Waterproof - Fireproof Class 2.

SOLTIS 86 fabric

1100 dtex polyester coated on 2 perforated PVC sides and glossy lacquered. 380 g/mq. Breaking

strength: warp 230 kg - weft 160 kg Fireproof class 1 UNI 9177-87.

SOLTIS 92 shading fabric

1100 dtex polyester coated on 2 perforated PVC sides and glossy lacquered. 420 g/mq. Breaking

strength: warp 310 kg - weft 210 kg Fireproof class 1 UNI 9177-87.

SOLTIS 96-W96 fabric

1100 dtex polyester coated on 2 perforated PVC sides and glossy lacquered. 400 g/mq. Breaking

strength: warp 220 kg - weft 220 kg Fireproof class 1 UNI 9177-87. Only W96 100% Waterproof

TS light polyester fabric

100% polyester mass dyed outdoor 300g/mq. Breaking load: warp 210kg - weft 140Kg (UNI EN

ISO 13934-1/2000). Water Column ≥ 300mm (UNI EN 20811). Waterproof (UNI EN 24920). Oil

resistance value 5 (AATCC118). Resistant to dirt, excellent dimensional stability.

TS heavy polyester fabric

100% polyester mass dyed outdoor 360g/mq. Breaking load: warp 210kg - weft 180Kg (UNI EN

ISO 13934-1/2000). Water Column ≥ 1000mm (UNI EN 20811). Waterproof (UNI EN 24920). Oil

resistance value 5/6 (AATCC118). Resistant to dirt, excellent dimensional stability.

TS polyester fabric, waterproof and resin treated

100% polyester mass dyed outdoor 360g/mq. Breaking load: warp 190 Kg - weft 120Kg (UNI EN ISO

13934-1/2000). Water Column ≥ 700mm (UNI EN 20811). Waterproof (UNI EN 24920). Oil resistance

value 5 (AATCC118). Resistant to dirt, excellent dimensional stability.TS FR fireproof polyester

fabric: Class 1 UNI EN 9177 - Class B1 DIN 4102

100% polyester mass-dyed outdoor 375g/mq. Breaking load: warp 210 kg - weft 180Kg (DIN EN ISO

13934-1/2000). Water Column ≥ 300mm (UNI EN 20811). Waterproof (UNI EN 24920). Oil resistance

value 5 (AATCC118). Resistant to dirt, excellent dimensional stability.

Acrylic Fabric

100% "outdoor" used acrylic fibre, mass-dyed 300 g/sqm. Stain-proof - anti-decay - water-proof

with Teflon treatment. Breaking load: warp 130 kg - weft 80 kg (UNI 8639). Water-proof (UNI EN

24920) Water column > 300 mm (UNI 5122).

FABRIC COMPONENTS

3.4

www.gibus.com

Page 15 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

The European Regulation EU 528/2012 regulates the marketing and use of biocidal

products: antifungal agents or aimed at making harmless other organisms.

Liberty Acrylic Fabric

100% "outdoor" used acrylic fibre, mass-dyed 350 g/sqm. Stain-proof - anti-decay - water-proof with

Teflon treatment. Breaking load: warp 160 kg - weft 115 kg (UNI 5122). Water-proof (UNI EN 24920)

Water column > 400 mm (UNI 8639).

Acrylic Printed Fabric

100% "outdoor" used acrylic fibre, mass-dyed 340 g/sqm. Stain-proof - anti-decay - water-proof with

Teflon treatment. Breaking load: warp 130 kg - weft 80 kg (UNI 8639). Water-proof (UNI EN 24920)

Water column > 1000 mm (UNI 5122).

Cristal PLUS 500 2S

PVC film stabilized for UV rays. 628 g / sqm, thickness 0.5 mm. 100% waterproof Tensile strength:

length 220 kg /cmq - height 210 kg /cmq (ASTM D882). On request: FR version with fire resistance

class 2.

Vinitex 3X3

Translucent laminated PVC with polyester support. 500 g/mq. 1100 Dtex polyester warp and weft,

100% waterproof. Tensile strength: warp 57 daN/5cm plot - weft 59 daN/5cm (EN ISO 1421).

BIOCIDALPRODUCTS

3.6

COMPLEMENTARY MATERIALS

3.5

IMPORTANT: the fabrics used are guaranteed for a period of 5 years, following a

normal exposure to the action of the sun and atmospheric agents in general, and

the action of moulds and micro-organisms.

ATTENTION: Some of the fabrics used by Gibus to package its products undergo

treatments with biocidal products. For more information and to know the type of

biocidal product possibly used in treating the fabric of your awning please visit

our website: www.gibus.com

IMPORTANT! THE CRISTAL IS GUARANTEED FOR 2 YEARS.

The measured noise (sound pressure level) was less than 70 dB (A).

NOISE LEVEL

3.7

www.gibus.com

Page 16 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

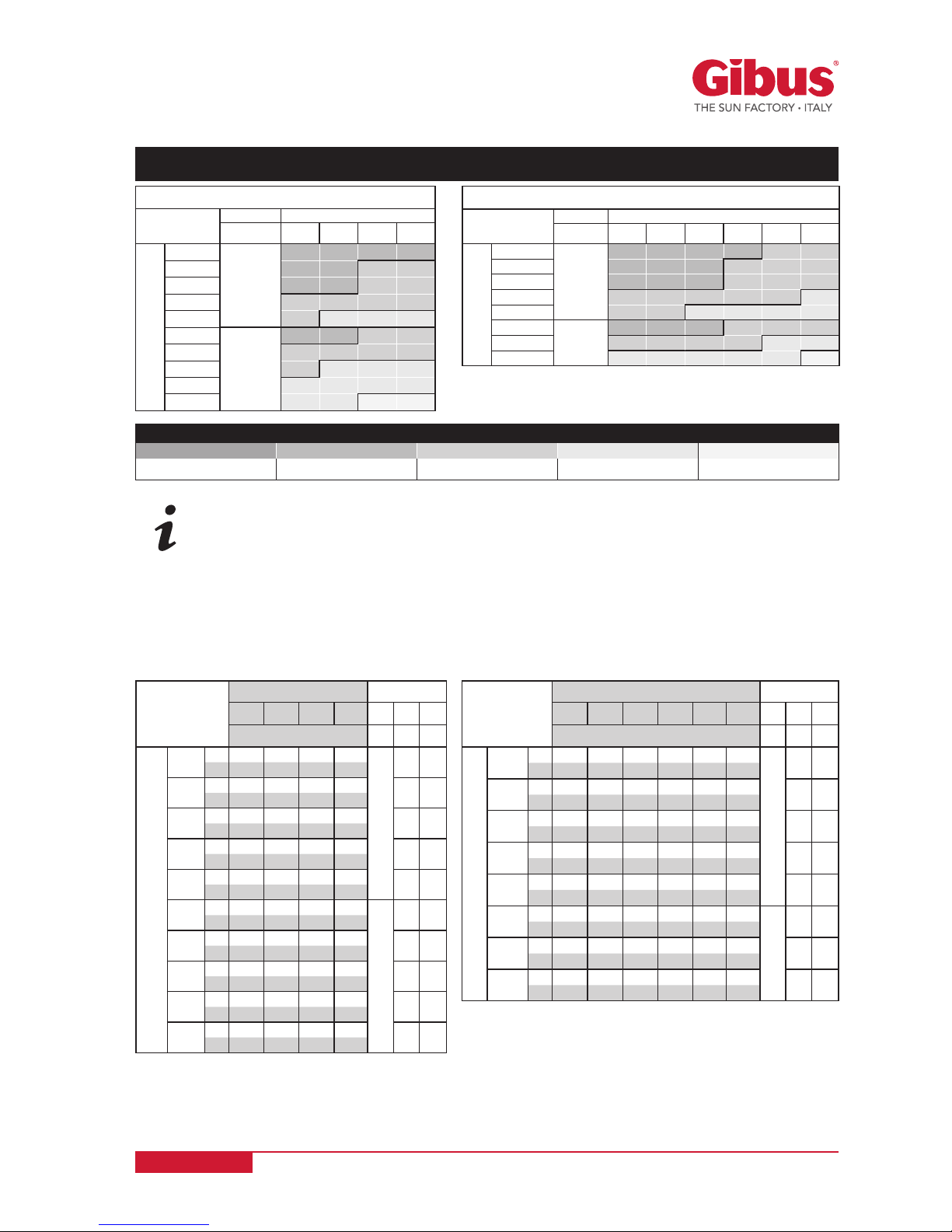

TYPE

4.1

CHAPTER 4: TECHNICAL DATA

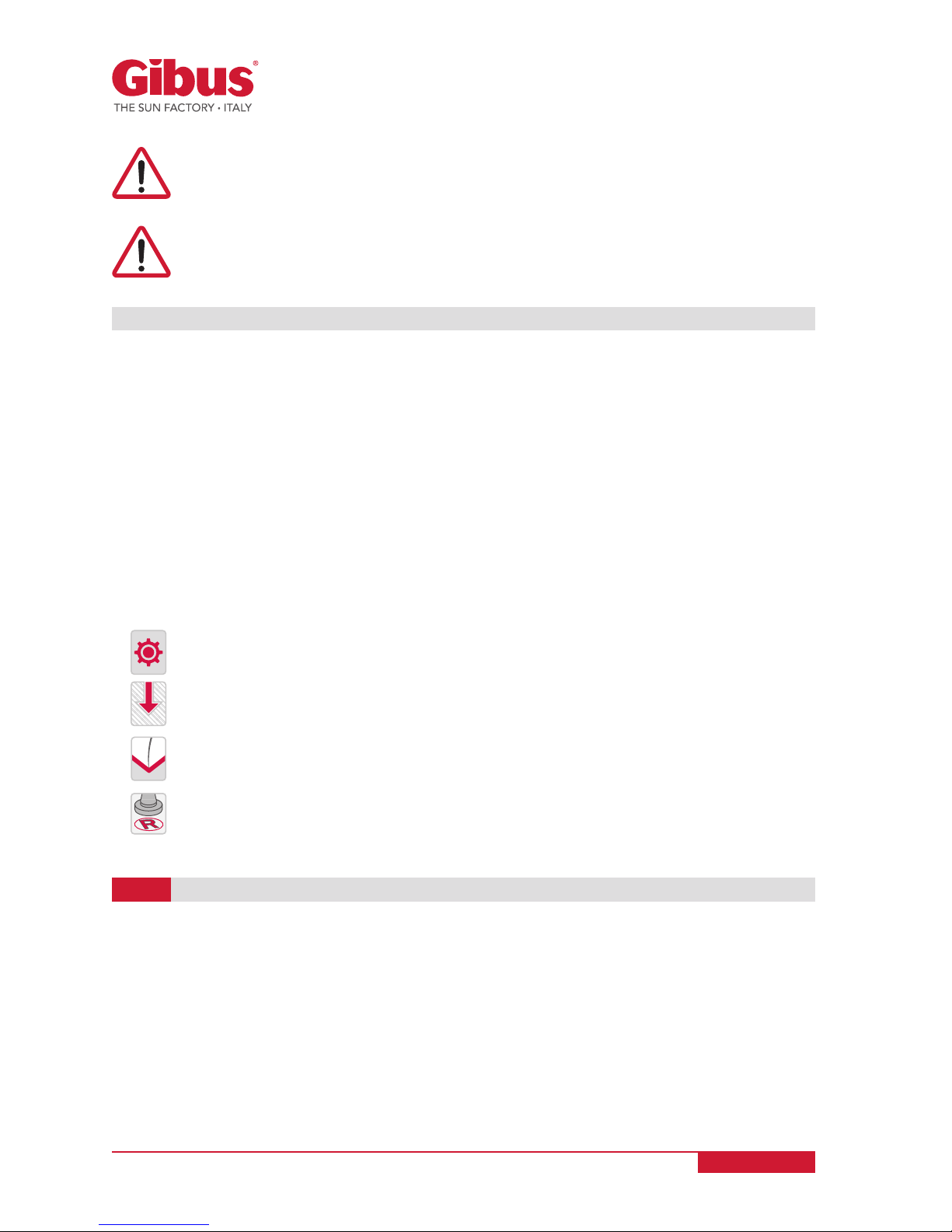

SINGLE MODULE FREESTANDING MEDISOLAFLY R:

DOUBLE MODULE FREESTANDING MEDISOLAFLY R:

With 4 posts:

Projection until 480 cm

With 6 posts:

Projection until 420+50 cm

With 6 posts:

Projection from 540 to 780 cm

With 8 posts:

Projection from 480+50 cm to 540+50 cm

With 10 posts:

Projection from 600+50 cm to 660+50 cm

Bilateral water

drainage

with double

pantograph

(standard)

Bilateral water

drainage

with double

pantograph

(standard)

Lateral water

drainage (left or

right) with single

pantograph

Lateral water

drainage (left or

right) with single

pantograph

www.gibus.com

CON SCARICO LATERALE

CON MONOPANTOGRAFO

Page 17 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

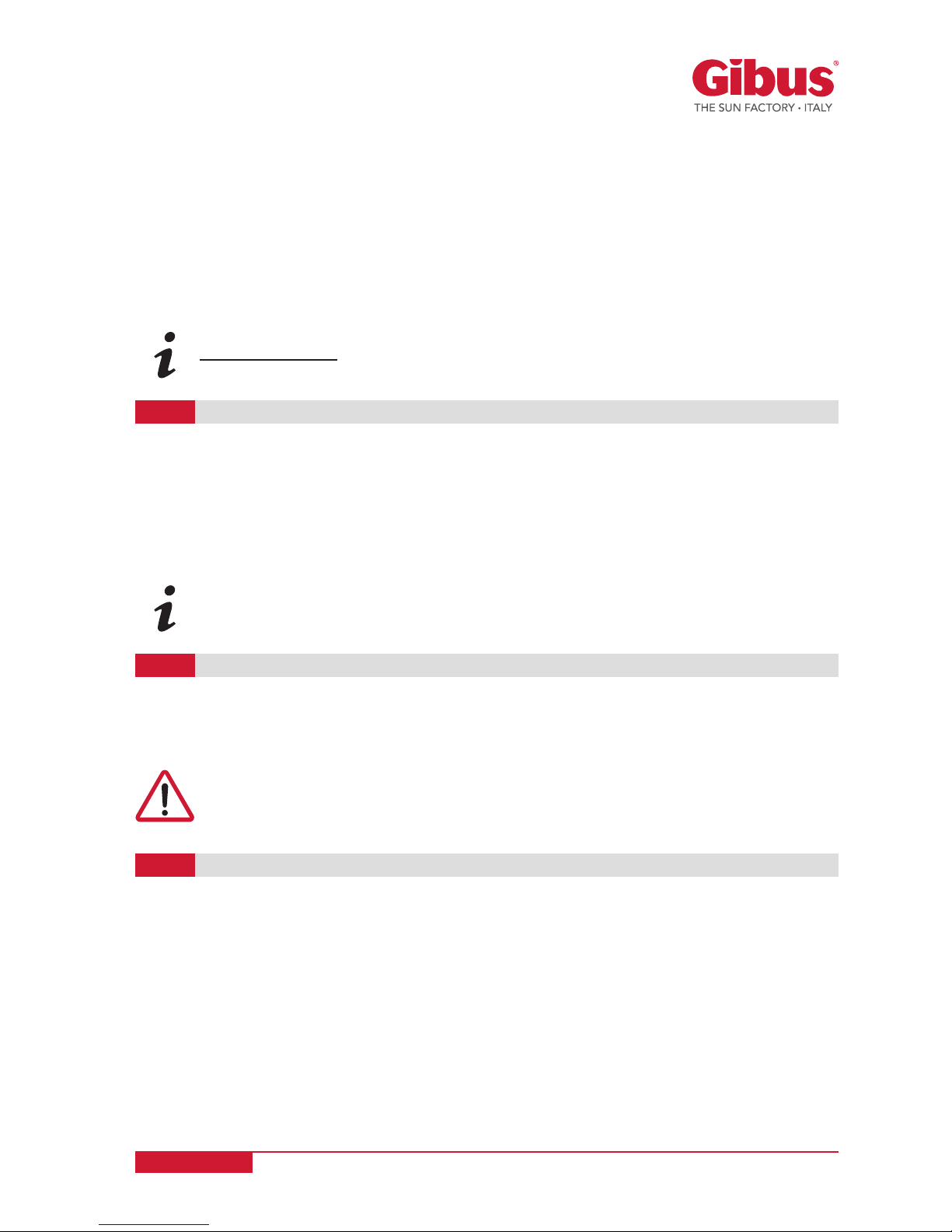

SINGLE MODULE FRONTAL LEANING VERSION MEDISOLAFLY R:

SINGLE MODULE LATERAL LEANING VERSION MEDISOLAFLY R:

DOUBLE MODULE FRONTAL LEANING VERSION MEDISOLAFLY R:

With 2 posts:

Projection until 480+30 cm

With 2 posts:

Width until 480 cm

With 3posts:

Width from 540 to 780 cm

With 3 posts:

Projection until 480+60 cm

With 4 posts:

Projection from 540+30 cm to 780+30 cm

With 5 posts:

Projection from 540+60 cm to 660+60 cm

Bilateral water

drainage

with double

pantograph

(standard)

Bilateral water

drainage

with double

pantograph

(standard)

Lateral water

drainage (left or

right) with single

pantograph

Lateral water

drainage (left or

right) with single

pantograph

Lateral water

drainage (left or

right) with single

pantograph

www.gibus.com

13214

4.5

4

~ 208,5

285

I

254

F

TL

G

T

LI

HT

S

S

1

S L

Page 18 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

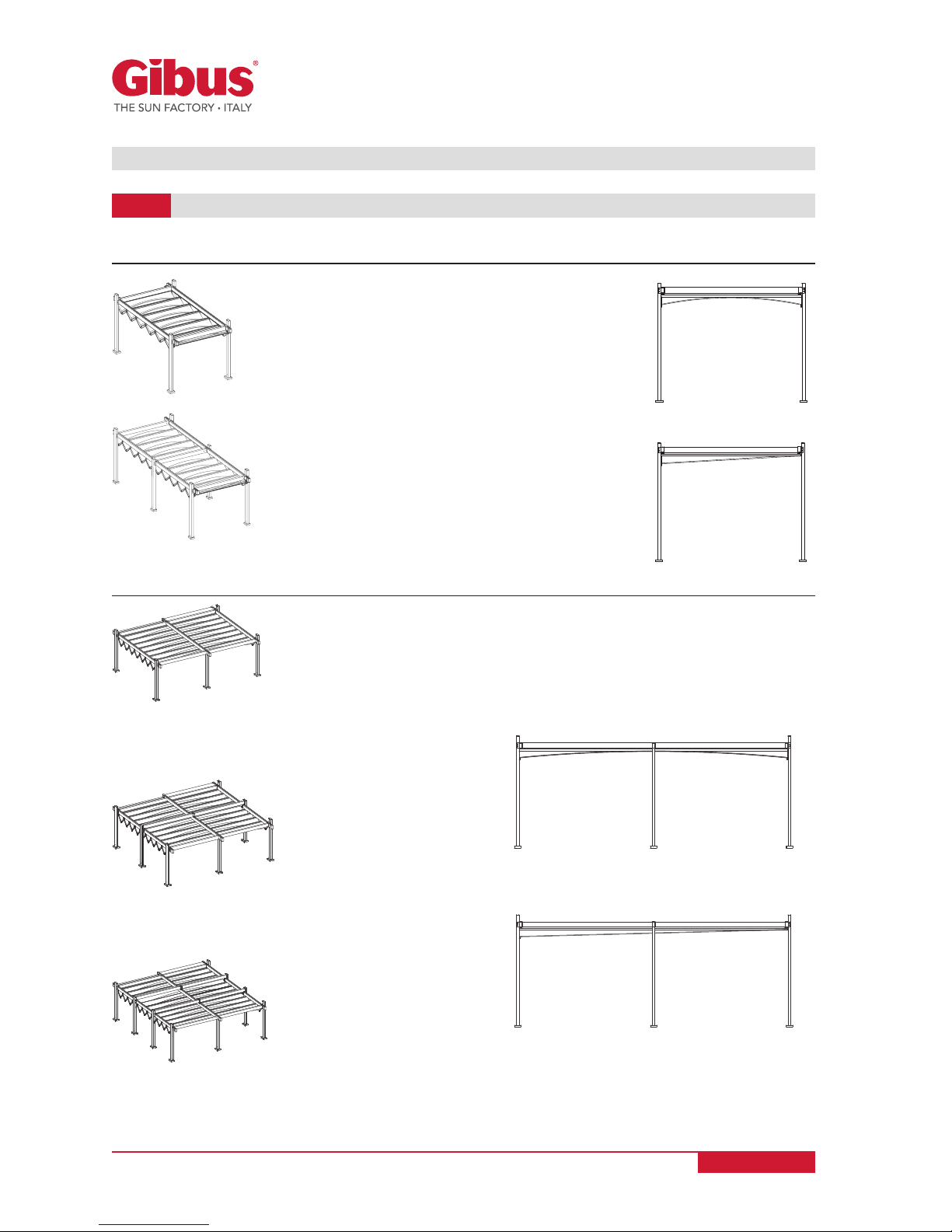

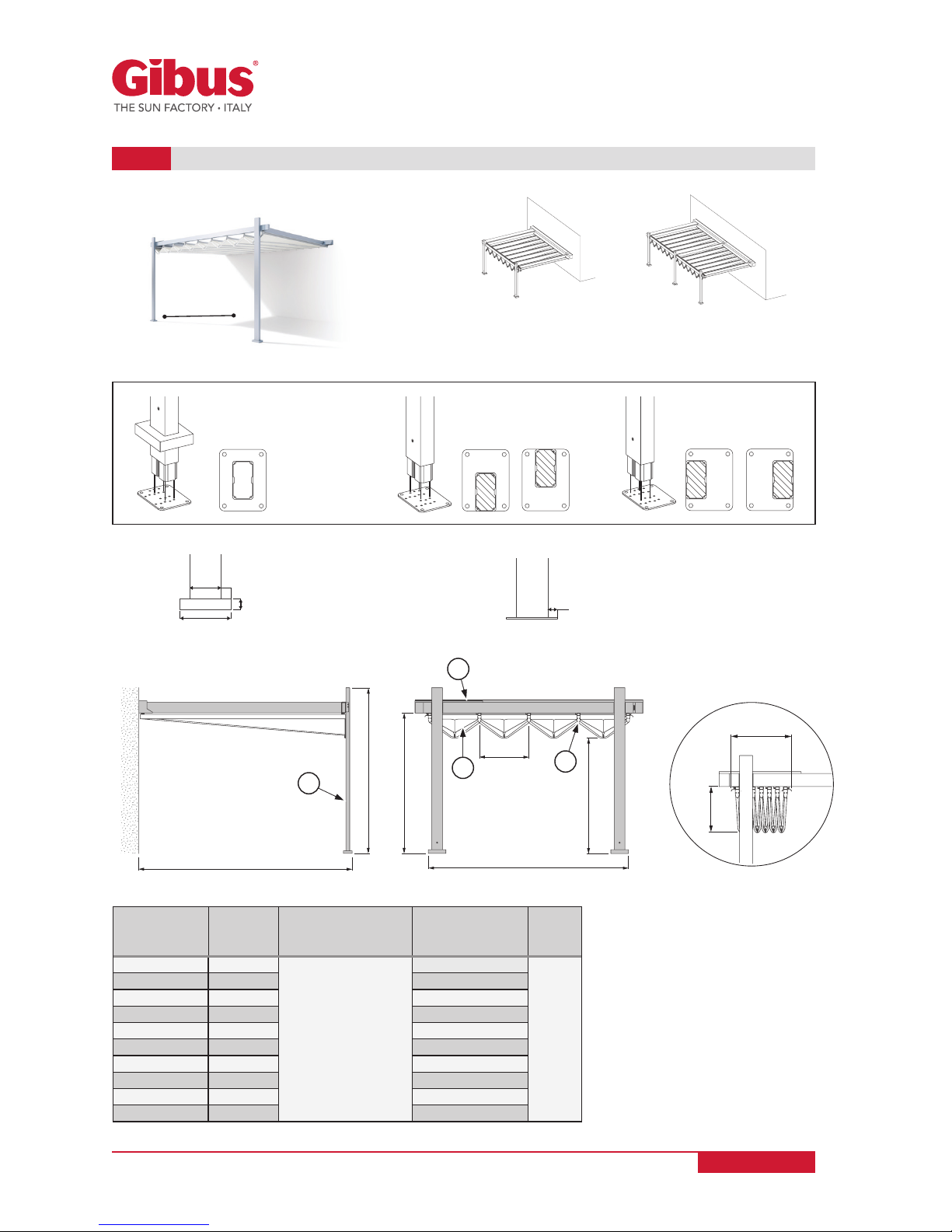

MEDISOLAFLY R - ISLAND

4.2

Central post base

with post base protective

cover

ISLAND

FREESTANDING

SINGLE MODULE

ISLAND

FREESTANDING

DOUBLE MODULE

Post base with

Cover

Standard (only on

central post base)

Post base without

Cover

on request

Aligned post base

Front Back

Aligned post base

Left and Right

4 posts 6 posts 6 posts 8 posts 10 posts

Freestanding

1 Module

Freestanding

2 Modules

S

projection

S

1

projection

F

profile

breaker

I

Wheelbase

section

breaking unit

LI

Packaging overall

dimensions

HT

height

240 290 (240+50) 5

60

43

45,5

300 350 (300+50) 6 49

360 410 (360+50) 7 55

420 470 (420+50) 8 61

480 530 (480+50) 9 67

540 590 (540+50) 10 73

600 650 (600+50) 11 79

660 710 (660+50) 12 85

720 - 13 91

780 - 14 97

www.gibus.com

Page 19 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

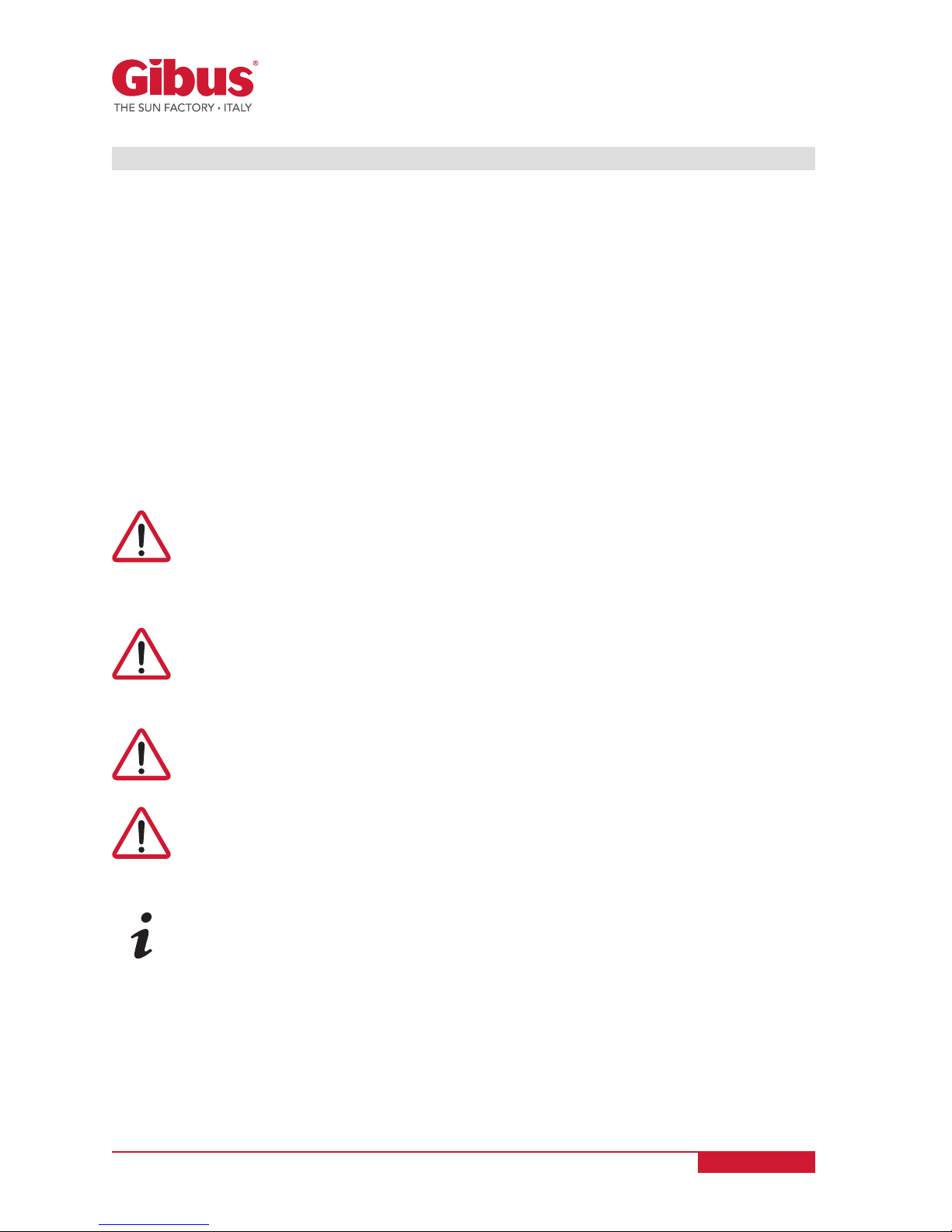

Legend:

A = Total weight of the awning: this refers to the total weight of the awning including bearing structure and fabric cover.

B = Weight of the fabric covers: this refers to the weight of just the fabric cover (including the opatex fabric).

T = Roof (optional) G = Legs

F = Profile breaker TL = Fabric covers

OPTIONAL

• Transparent PMMA canopy without edge profiles

• Guide metal sheet plugs

• Stainless steel ball bearings

ACCESSORIES

• Led Linear

IMPORTANT: For each size the load shown in the table is greater than the one provided

by Class 3 - UNI EN 13561 / UNI EN 1932 (safety load continuously distributed on the

extended surface equal to 13.5 [kg/m2] or 132 [N/m2 ]).

LEGEND - “BEAUFORT” WIND SCALE

GRADE 10 (10) GRADE 9 (9) GRADE 8 (8) GRADE 7 (7) GRADE 6 (6)

Storm Strong gale Gale Strong wind Wind

Table of maximum tolerable wind load values per square meter awning [kg/m2]

depending on the size of the awning:

Freestanding

single

module

WIDTH “L” (cm)

250 300 350 400 G F TL

Kg n° n° n°

PROJECTION “S” (cm)

240

A 192 203 218 229

4

5 4

B 36 41 45 50

300

A 203 215 231 243

6 5

B 42 47 53 58

360

A 214 228 244 258

7 6

B 47 54 60 66

420

A 228 242 261 275

8 7

B 53 60 67 74

480

A 240 255 274 289

9 8

B 58 66 74 82

540

A 279 297 319 336

6

10 9

B 64 73 82 90

600

A 290 309 332 351

11 10

B 70 79 89 98

660

A 304 324 349 368

12 11

B 75 86 96 106

720

A 316 336 362 383

13 12

B 81 92 103 115

780

A 327 349 375 397

14 13

B 86 98 110 123

Freestanding

double module

WIDTH “L” (cm)

450 500 550 600 650 700 G F TL

Kg n° n° n°

PROJECTION “S” (cm)

240

+50

A 328 341 359 372 390 404

6

5 4

B 69 74 79 84 89 94

300

+50

A 345 360 378 393 411 426

6 5

B 78 84 89 95 101 107

360

+50

A 363 379 398 413 433 448

7 6

B 87 93 100 107 114 121

420

+50

A 384 401 422 439 460 476

8 7

B 96 103 111 119 126 134

480

+50

A 402 420 441 459 481 498

8

9 8

B 105 113 122 130 139 147

540

+50

A 445 465 490 510 535 555

10 9

B 114 123 132 142 151 160

600

+50

A 463 484 509 530 556 577

10

11 10

B 123 133 143 153 164 174

660

+50

A 494 516 544 566 593 615

12 11

B 132 143 154 165 176 187

FREESTANDING SING LE M ODU LE

WIDTH (cm)

posts 250 300 350 400

PROJECTION (cm)

240

4

95

(9)

95

(9)

71

(9)

57

(9)

300 95

(9)

95

(9)

69

(8)

55

(8)

360 92

(9)

92

(9)

67

(8)

53

(8)

420 67

(8)

65

(8)

65

(8)

51

(8)

480 51

(7)

49

(7)

49

(7)

45

(7)

540

6

95

(9)

95

(9)

69

(8)

55

(8)

600 67

(8)

65

(8)

65

(8)

51

(8)

660 51

(7)

49

(7)

49

(7)

45

(7)

720 40

(7)

38

(7)

36

(7)

33

(7)

780 33

(7)

31

(7)

30

(6)

28

(6)

FREESTANDING DOUB LE M ODU LE

WIDTH (cm)

posts 450 500 550 600 650 700

PROJECTION (cm)

240+50

6

95

(9)

95

(9)

92

(9)

71

(9)

57

(8)

55

(8)

300+50 95

(9)

95

(9)

92

(9)

69

(8)

55

(8)

53

(8)

360+50 92

(9)

92

(9)

88

(9)

67

(8)

53

(8)

51

(8)

420+50 67

(8)

65

(8)

65

(8)

60

(8)

51

(8)

49

(6)

480+50

8

92

(9)

92

(9)

90

(9)

67

(8)

53

(8)

51

(8)

540+50 67

(8)

65

(8)

62

(8)

60

(8)

51

(8)

49

(8)

600+50

10

75

(9)

71

(9)

60

(8)

55

(8)

49

(7)

33

(7)

660+50 49

(7)

49

(7)

40

(7)

36

(7)

33

(7)

30

(6)

www.gibus.com

S1

S

13214

4.5

4

~ 208,5

285

I

254

F

TL

G

T

LI25

HT

S L

Page 20 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

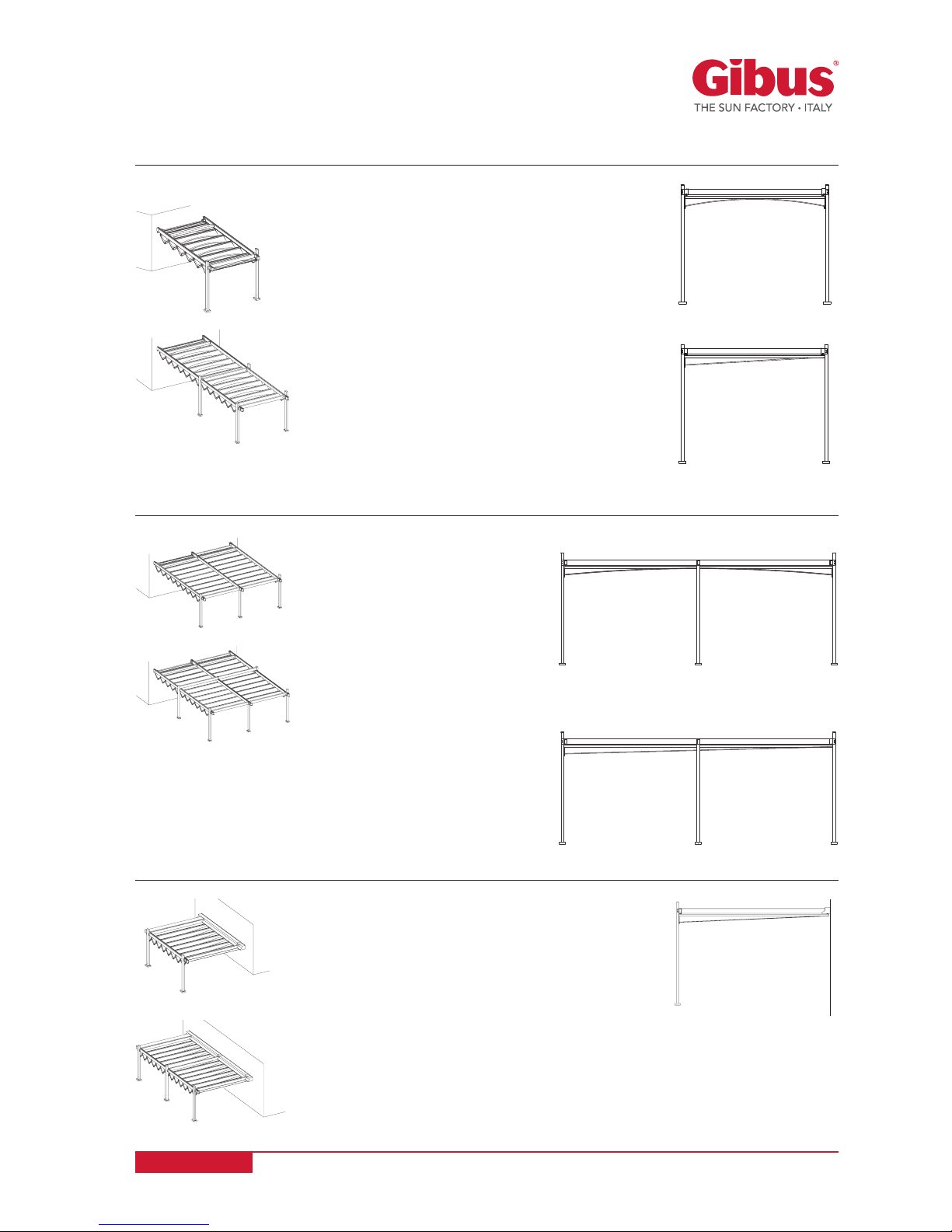

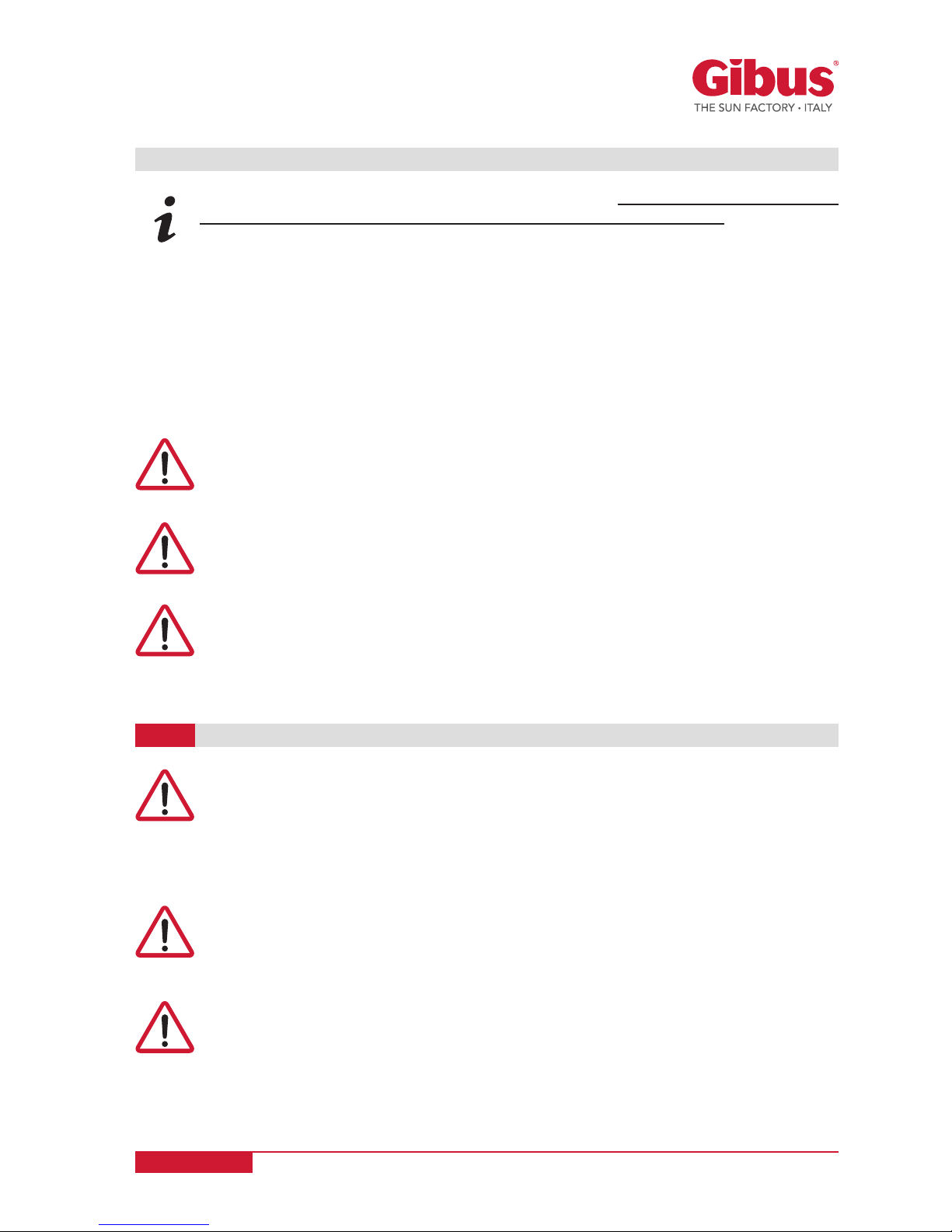

MEDISOLAFLY R - FRONTAL LEANING VERSION

4.3

Central post base

with post base protective

cover

FRONTAL

LEANING

VERSION

SINGLE MODULE

FRONTAL

LEANING

VERSION

DOUBLE MODULE

Post base with

Cover

Standard (only on

central post base)

Post base without

Cover

on request

Aligned post base

Front Back

Aligned post base

Left and Right

2 posts 4 posts 3 posts 5 posts

Frontal

leaning version

single module

Frontal

leaning version

double module

S

projectionS1projection

F

profile

breaker

I

Wheelbase

section

breaking unit

LI

Packaging

overall

dimensions

HT

height

270 (240+30) 300 (240+60) 5

60

43

45,5

330 (300+30) 360 (300+60) 6 49

390 (360+30) 420 (360+60) 7 55

450 (420+30) 480 (420+60) 8 61

510 (480+30) 540 (480+60) 9 67

570 (540+30) 600 (540+60) 10 73

630 (600+30) 660 (600+60) 11 79

690 (660+30) 720 (660+60) 12 85

750 (720+30) - 13 91

810 (780+30) - 14 97

www.gibus.com

Page 21 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

Legend:

A = Total weight of the awning: this refers to the total weight of the awning including bearing structure and fabric cover.

B = Weight of the fabric covers: this refers to the weight of just the fabric cover (including the opatex fabric).

T = Roof (optional) G = Legs

F = Profile breaker TL = Fabric covers

OPTIONAL

• Transparent PMMA canopy without edge profiles

• Guide metal sheet plugs

• Stainless steel ball bearings

ACCESSORIES

• Led Linear

IMPORTANT: For each size the load shown in the table is greater than the one provided

by Class 3 - UNI EN 13561 / UNI EN 1932 (safety load continuously distributed on the

extended surface equal to 13.5 [kg/m2] or 132 [N/m2 ]).

Table of maximum tolerable wind load values per square meter awning [kg/m2]

depending on the size of the awning:

LEGEND - “BEAUFORT” WIND SCALE

GRADE 10 (10) GRADE 9 (9) GRADE 8 (8) GRADE 7 (7) GRADE 6 (6)

Storm Strong gale Gale Strong wind Wind

Frontal

leaning version

single module

WIDTH “L” (cm)

250 300 350 400 G F TL

Kg n° n° n°

PROJECTION “S” (cm)

240

+30

A 166 177 192 203

2

5 4

B 36 41 45 50

300

+30

A 177 190 205 218

6 5

B 42 47 53 58

360

+30

A 189 202 218 232

7 6

B 47 54 60 66

420

+30

A 203 217 235 249

8 7

B 53 60 67 74

480

+30

A 214 229 249 264

9 8

B 58 66 74 82

540

+30

A 253 271 293 311

4

10 9

B 64 73 82 90

600

+30

A 264 283 306 325

11 10

B 70 79 89 98

660

+30

A 279 298 323 343

12 11

B 75 86 96 106

720

+30

A 290 310 336 357

13 12

B 81 92 103 115

780

+30

A 301 323 349 371

14 13

B 86 98 110 123

Frontal

leaning version

double module

WIDTH “L” (cm)

450 500 550 600 650 700 G F TL

Kg n° n° n°

PROJECTION “S” (cm)

240

+60

A 289 302 319 333 350 364

3

5 4

B 69 74 79 84 89 94

300

+60

A 307 321 339 354 372 386

6 5

B 78 84 89 95 101 107

360

+60

A 324 340 359 374 393 409

7 6

B 87 93 100 107 114 121

420

+60

A 347 363 384 400 421 437

8 7

B 96 103 111 119 126 134

480

+60

A 364 382 403 421 442 460

9 8

B 105 113 122 130 139 147

540

+60

A 382 400 423 441 464 482

5

10 9

B 114 123 132 142 151 160

600

+60

A 420 439 462 482 505 524

11 10

B 123 133 143 153 164 174

660

+60

A 443 463 488 508 533 554

12 11

B 132 143 154 165 176 187

FRONTAL LEANING VERSION SIN GLE MO DUL E

WIDTH (cm)

posts 250 300 350 400

PROJECTION (cm)

240+30

2

98

(9)

95

(9)

71

(9)

57

(9)

300+30 95

(9)

95

(9)

69

(8)

55

(8)

360+30 92

(9)

92

(9)

67

(8)

53

(8)

420+30 67

(8)

65

(8)

65

(8)

51

(8)

480+30 51

(8)

49

(7)

49

(7)

45

(7)

540+30

4

95

(9)

95

(9)

69

(8)

55

(8)

600+30 65

(8)

65

(8)

65

(8)

51

(8)

660+30 51

(8)

49

(7)

49

(7)

45

(7)

720+30 40

(7)

38

(7)

36

(7)

33

(7)

780+30 33

(7)

31

(7)

30

(6)

28

(6)

FRONTAL LEANING VERSION DOU BLE MO DUL E

WIDTH (cm)

posts 450 500 550 600 650 700

PROJECTION (cm)

240+30

3

98

(9)

95

(9)

95

(9)

71

(9)

57

(8)

55

(8)

300+30 95

(9)

95

(9)

92

(9)

69

(8)

55

(8)

53

(8)

360+30 92

(9)

92

(9)

90

(9)

67

(8)

53

(8)

51

(8)

420+30 67

(8)

65

(8)

65

(8)

60

(8)

51

(8)

49

(7)

480+30 51

(8)

51

(8)

49

(7)

49

(7)

40

(7)

36

(7)

540+30

5

80

(9)

75

(9)

71

(9)

65

(8)

55

(8)

51

(8)

600+30 65

(8)

62

(8)

60

(8)

55

(8)

49

(7)

33

(7)

660+30 49

(7)

49

(7)

40

(7)

36

(7)

33

(7)

30

(6)

www.gibus.com

S

285

~ 208,5

I

254

F

TL

G

T

13214

4.5

4

S

L

LI

HT

Page 22 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

MEDISOLAFLY R - LATERAL LEANING VERSION

4.4

Central post base

with post base protective

cover

LATERAL LEANING

VERSION

SINGLE MODULE

Post base with Cover

Standard

(only on central post base)

Post base without Cover

on request

Aligned post base

Front Back

Aligned post base

Left and Right

2 posts 3 posts

L

widht

F

profile

breaker

I

Wheelbase section

breaking unit

LI

Packaging overall

dimensions

HT

height

274 (240+34) 5

60

43

45,5

334 (300+34) 6 49

394 (360+34) 7 55

454 (420+34) 8 61

514 (480+34) 9 67

574 (540+34) 10 73

634 (600+34) 11 79

694 (660+34) 12 85

754 (720+34) 13 91

814 (780+34) 14 97

www.gibus.com

Page 23 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

Legend:

A = Total weight of the awning: this refers to the total weight of the awning including bearing structure and fabric cover.

B = Weight of the fabric covers: this refers to the weight of just the fabric cover (including the opatex fabric).

T = Roof (optional) G = Legs

F = Profile breaker TL = Fabric covers

OPTIONAL

• Transparent PMMA canopy without edge profiles

• Guide metal sheet plugs

• Stainless steel ball bearings

ACCESSORIES

• Led Linear

IMPORTANT: For each size the load shown in the table is greater than the one provided

by Class 3 - UNI EN 13561 / UNI EN 1932 (safety load continuously distributed on the

extended surface equal to 13.5 [kg/m2] or 132 [N/m2 ]).

LEGEND - “BEAUFORT” WIND SCALE

GRADE 10 GRADE 9 GRADE 8 GRADE 7 GRADE 6

Storm Strong gale Gale Strong wind Wind

Table of maximum tolerable wind load values per square meter awning [kg/m2]

depending on the size of the awning:

LATERAL LEANING VERSION SIN GLE MO DUL E

WIDTH (cm)

240+34 300+34 360+34 420+34 480+34 540+34 600+34 660+34 720+34 780+34

PROJECTION (cm)

250 100

(9)

100

(9)

95

(9)

92

(9)

65

(8)

100

(9)

95

(9)

65

(8)

49

(8)

40

(8)

300 95

(9)

95

(9)

92

(9)

70

(8)

55

(8)

95

(9)

65

(8)

49

(7)

40

(7)

33

(7)

350 95

(9)

95

(9)

92

(9)

65

(8)

49

(7)

92

(9)

62

(8)

49

(7)

38

(7)

31

(7)

400 71

(9)

69

(8)

67

(8)

60

(8)

47

(7)

69

(8)

58

(8)

49

(7)

36

(7)

30

(6)

450 57

(8)

55

(8)

53

(8)

51

(7)

45

(7)

55

(8)

51

(7)

49

(7)

33

(7)

28

(6)

posts 2 3

Lateral

leaning version

single module

WIDTH “L” (cm)

240+34 300+34 360+34 420+34 480+34 540+34 600+34 660+34 720+34 780+34

Kg

PROJECTION “S” (cm)

250

A 174 186 197 212 223 235 247 261 273 284

B 36 42 47 53 58 64 70 75 81 86

300

A 186 199 212 227 240 252 265 280 293 305

B 41 47 54 60 66 73 79 86 92 98

350

A 202 216 230 246 260 274 287 304 318 331

B 45 53 60 67 74 82 89 96 103 110

400

A 215 229 244 262 276 291 305 323 338 352

B 50 58 66 74 82 90 98 106 115 123

450

A 231 246 262 281 297 312 328 348 363 379

B 54 63 72 81 90 99 108 117 126 135

G n° 2 3

F n° 5 6 7 8 9 10 11 12 13 14

TL n° 4 5 6 7 8 9 10 11 12 13

www.gibus.com

Page 24 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

The awning is packed with Nylon film and polystyrene in double walled corrugated cardboard

boxes with reinforced corners to protect the product and lock the parts in place during transport.

The components are packed in several parcels given the size and weight of the product (see

TECHNICAL TABLE Chap. 4). The weight of each package can be high, the result is the need for

manual handling in two or more persons whenever the weight exceeds 25 kg.

In order to facilitate transport by operators, check the weight of the awning depending on

its size shown in the TEHCNICAL TABLE on Chapter 4.

For transportation to the customer’s premises by the Retailer and / or Manufacturer, it is required

to fill the support points on racks to prevent scratches to the structure or to the fabric cover.

Product integrity must be preserved until delivery to the customer. Damage to the product

caused by the dismantling of the awning and subsequent handling and / or transportation

performed after installation, are not covered by warranty. To avoid hazardous situations observe

the following safety requirements:

CHAPTER 5: PACKING, HANDLING AND TRANSPORTATION

ATTENTION: Due to the size and weight of the awning and of each individual

packaging, make sure that for handling a sufficient number of people is available,

so that the weight to be loaded by each person is not more than 25 kg in the case

of manual handling (in this regard, check the weight of the awning depending on

its size in the TECHNICAL TABLES on Chapter 4).

CAUTION: Do not store packages in an upright position, or leave them unattended

in the area of installation if the awning is not yet installed; avoid leaving them

unattended in the presence of children. Avoid storage the packed or unpacked

awning outdoor area when the weather conditions are adverse (rain).

ATTENTION: Keep out of reach of children packaging materials, they can be a

source of danger to them. In particular, the Nylon film with "bubble barrier effect"

could be used so as to cause suffocation.

WARNING: If the awning is to be mounted on a higher surface than the ground,

it is necessary to define and supervise the area during the ascent to the awning,

so that no one stands at any time under the suspended load. Securely fasten the

packages of the awning in order to prevent it from falling.

IMPORTANT: unpack using scissors with rounded tips in order not to damage

the fabric, do not use cutters. The packaging material should be disposed of or

recycled in accordance with the regulations in force in the Country of destination

of the product.

www.gibus.com

Page 25 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

The installation usually is not performed directly by staff from Gibus S.p.A. but by staff appointed

by the buyer or customer.

The client (user) is responsible under the law to entrust the installation to an expert staff, strictly

complying to the installation rules listed in this manual. In particular follow the "Instructions for

proper installation" in Chapter 7.

At the time of installation arrange all the tools mentioned on the first pages of the “Installation

Instructions - MEDISOLAFLY R line”.

If installers are more than one, it is necessary to appoint an operations co-ordinator.

CHAPTER 6: SAFE INSTALLATION

IMPORTANT: The installation must be performed in full compliance with the

installation instructions and safety rules in force in mobile sites. Be especially

careful when working at height.

MECHANICAL STRUCTURE

6.1

IMPORTANT: Before using the staging, scaffoldings, ladders, any lifting elements

and all personal protective device, especially when working at height (harnesses,

safety belts, etc..), make sure all comply with the requirements of the current law

on safety and are all in good conditions.

WARNING: If the awning is to be mounted on a higher surface than the ground,

it is necessary to define and supervise the area during the ascent to the awning,

so that no one stands at any time under the suspended load. Securely fasten the

packages of the awning in order to prevent it from falling.

WARNING: Operators must act in accordance with the safety instructions received.

USE SUITABLE SLING DEVICES AND PROVIDED PPE.

WARNING: Improper installation can result in bodily injury. Read and carefully

follow the installation instructions (provided with this manual) to properly secure

the structure and the fabric cover, so avoiding any risk of falls. At the time of

installation arrange all the tools mentioned on the first pages of the “Installation

Instructions - MEDISOLAFLY R line”.

ATTENTION!: the “ceiling supports” the dowels are not sheared but extracted

(the worst case condition). In this case therefore, dowels must be used able to

withstand a double load with respect to the wall supports.

ATTENTION!: The choice of dowels depends on the type and condition of the wall

(wall or ceiling) and floor. If the necessary requirements are satisfied, use alternative

technical solutions like internal counter brackets in the wall, chemical dowels or

other solutions.

www.gibus.com

Page 26 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

Each column/leg has a drilled foot for fixing it to the floor with dowels.

Fix the feet to the floor only after having completely assembled the structure and ensured

that the awning opens and closes correctly.

Ensure that each foot rests on a solid firm base (a concrete base is ideal). If the structure will be

standing on soft ground (a garden or similar), prepare suitable foundation plinths beforehand for

each column/leg. The foundation surface must be much larger than the foot to ensure that each

securing hole for the dowel is completely surrounded by the foundation.

ATTENTION!: THE CHOICE OF ANCHORING DOWELS DEPENDS ON THE TYPE

AND CONDITION OF THE SITE FOR HOUSING THE STRUCTURE.

ATTENTION! In the case the structures are not considered adequate for the

installation, the installers must notify the client and record the details of the

inadequate features in the “INSTALLATION NOTES” in the section 14 of this manual.

If the minimum requirements are not satisfied, use other technical solutions, such

as preparing a suitable foundation plinth for each foot.

WARNING: Check the status of the housing and fixing site of the structure before

installing and anchoring the anchor pins.

The instructions on the installation are described in Annex “INSTALLATION INSTRUCTIONS”.

IMPORTANT!: Before hooking the awning to the supports, check that it was not

damaged during handling and transport.

www.gibus.com

Page 27 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

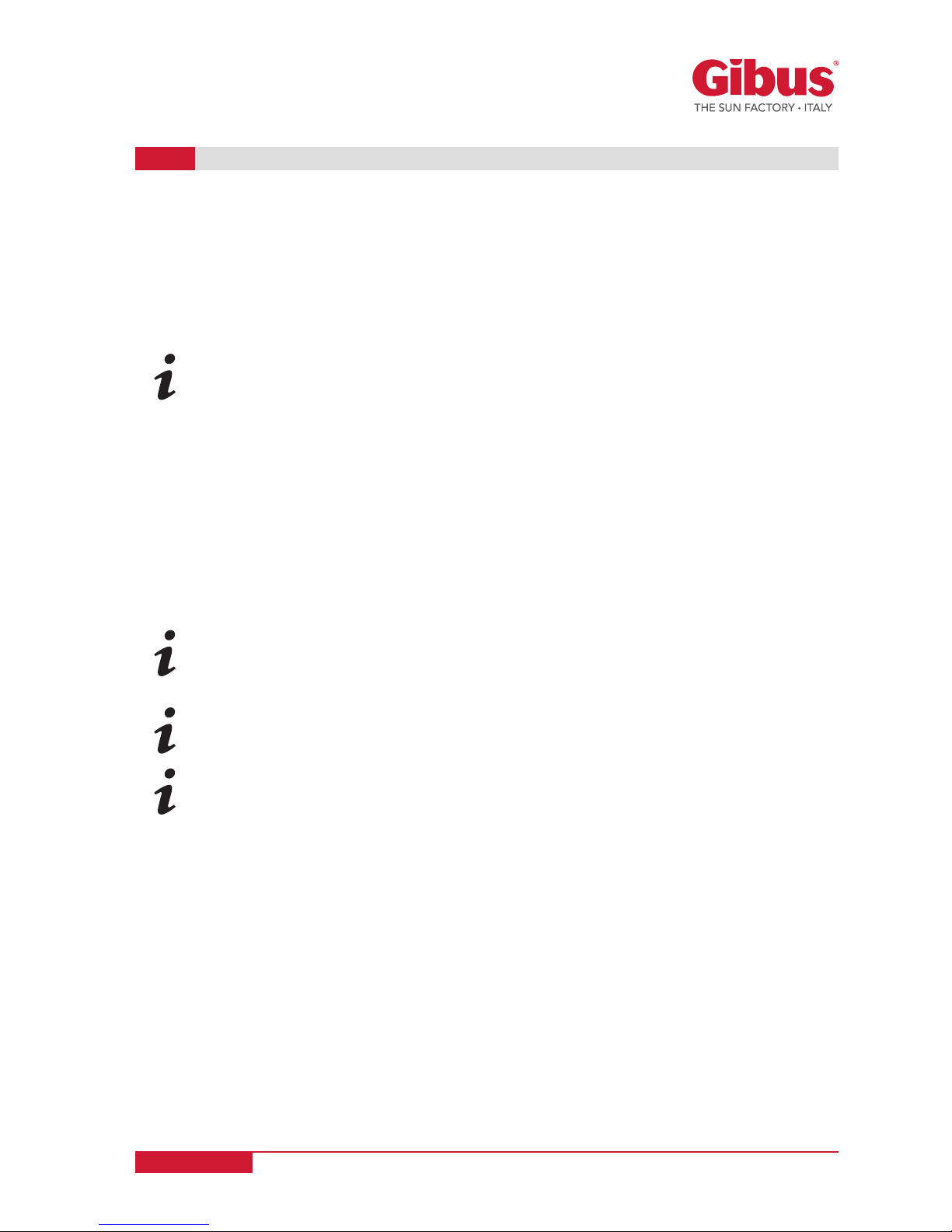

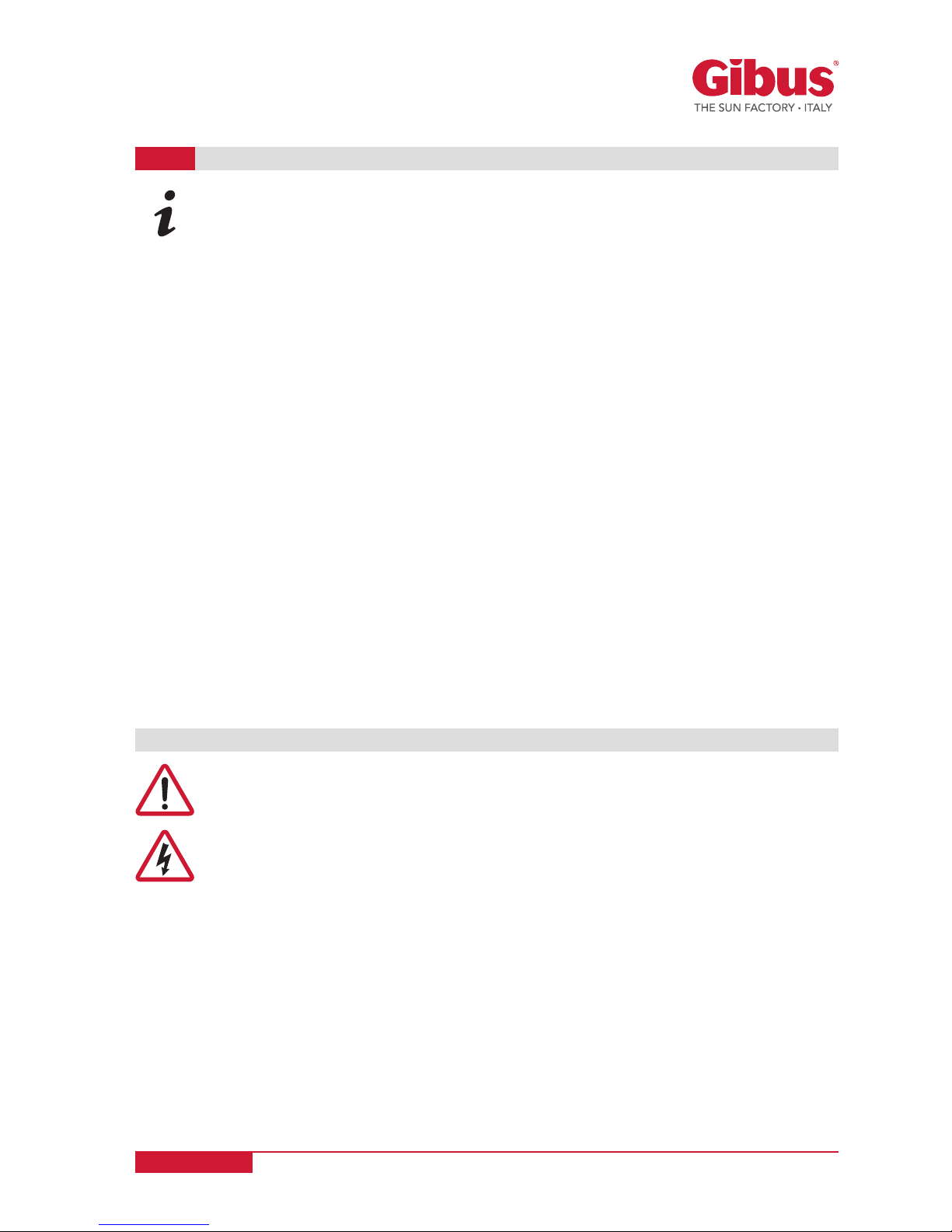

WARNING: ALL ELECTRICAL CONNECTIONS MUST BE MADE ONLY BY

PROFESSIONALLY QUALIFIED AND TRAINED STAFF, WITH THE POWER SUPPLY

CUT OFF AND IN ACCORDANCE WITH THE REGULATIONS IN FORCE.

The final implementation of the electrical system must be strictly carried out by a qualified

electrician. Also the technical choices carried out to implement the electrical connections fall

within his competence. Below are the guidelines that should be carefully considered by the

installer who will be charged with the costs of such operating decisions.

Instructions for qualified electrical installers:

ELECTRICAL CONNECTIONS

6.2

IMPORTANT: The electrical system must be carried out according to UNI EN 60335-1, or

subsequent, in force at the time of installation. The degree of protection of the electrical

must be at least IP55; and it must provide, upstream, a differential switch and a circuit

breaker. The metal parts must be grounded.

WARNING: The switch shall have degree of protection IP 44 if mounted outside the area

accessible to third parties and at a high from the ground lower than 1.80 [m], the degree

of protection can be IP40 if the switch is mounted inside or in areas not accessible to third

parties. The switch can be of the unstable position type, “man-controlled”, or stable position

type “not man controlled”. If the switch is the type without locking, it must be fixed in view of

the awning, out of danger areas (moving parts) and at a minimum height of 1.50 [m] from

the ground.

WARNING: if the awning is installed at a height from the walkable floor greater than 2,00

m in its lowest travel point, it is not necessary to install additional safety devices even in

the case of installation of electronic control automatic or semi-automatic units.

If its lowest point is less than 2,00 m from the walkable floor, it is required the

“man controlled” command. With the installation of electronic control units it is

necessary to install a buzzer or a warning light.

IMPORTANT! Never connect two or more engines to one single switch / inverter without

using a control unit. Do not connect the two switches / inverters to a single engine.

There is a risk of induced currents resulting in damage to the engines.

IMPORTANT! Check that the mains voltage is 230 V - 50 Hz. Standard equipment is

meant to be connected to 230v/50Hz electrical mains; for the installation in countries

with different features please specify the requirements when you place the order!

The power cord should be protected by the sheath and provided by cable gland in

the cases of crossing of conductive materials.

www.gibus.com

Neutro

Blu

Fase

Marrone

Terra

Nero

Giallo/Verde

230 Vac – 50 Hz

OPTIONAL

Neutro

Azzurro

Fase

Marrone

Terra

Azzurro

Giallo/Verde

230 Vac – 50 Hz

N

L

1

1

2

2

3

3

4

4

Neutro

Blu

Fase

Marrone

Terra

Giallo/Verde

230 Vac – 50 Hz

N

L

1

2

3

1

2

3

1

2

3

OFF

230 V

~

50 Hz

3 x 1,5 mm

2

3 x 0,75 mm

2

Neutro

Blu

Fase

Marrone

Terra

Giallo/Verde

230 Vac – 50 Hz

N

L

1

2

3

Page 28 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

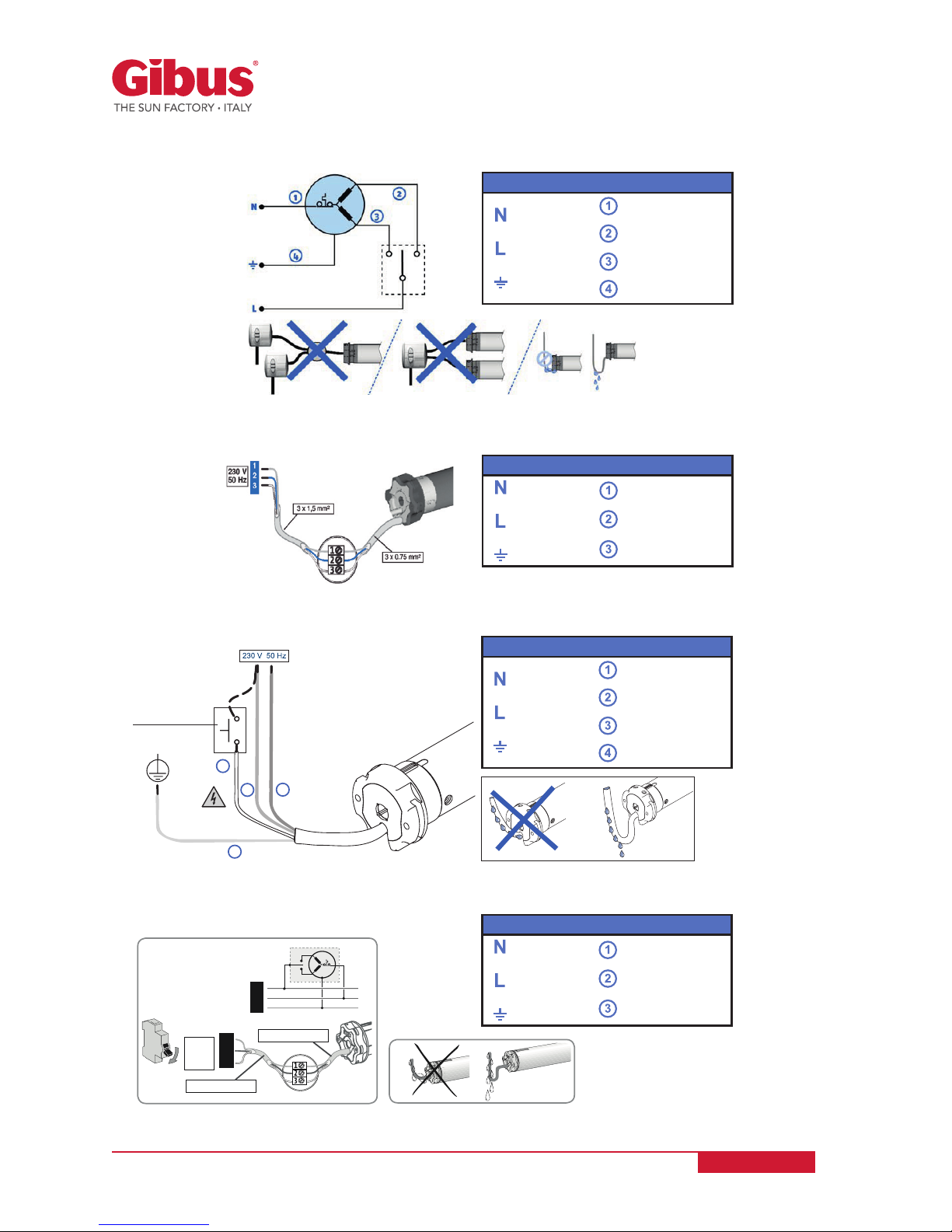

ELECTRICAL WIRING AND CONNECTIONS FOR SCS CABLATI ENGINES:

ELECTRICAL WIRING AND CONNECTIONS FOR RTS RADIO ENGINES:

ELECTRICAL WIRING AND CONNECTIONS FOR RX RADIO ENGINES:

230 Vac - 50 Hz

Neutral

Phase

Earth

Blue

Brown

Black

Yellow/Green

230 Vac - 50 Hz

Neutral

Phase

Earth

White

Brown

Blue

Yellow/Green

230 Vac - 50 Hz

Neutral

Phase

Earth

Blue

Brown

Yellow/Green

230 Vac - 50 Hz

Neutral

Phase

Earth

Blue

Brown

Yellow/Green

ELECTRICAL WIRING AND CONNECTIONS FOR IO RADIO ENGINES:

www.gibus.com

Page 29 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

The radio control is programmed/matched during the installation of the awning.

For more information on the procedure for programming and adjustment of the

limit switches, refer to the attached “INSTALLATION INSTRUCTIONS”.

IMPORTANT! The wiring diagrams and installation instructions for the use of

electronic control units or coupling modules for several motors, are annexed to

the control units themselves and should accompany this manual and carefully

stored for subsequent consultations. In the presence of these optional devices

check on the wiring diagrams attached the type of button or switch to be used. The

up and down indications depend on the mounting to the right or left of the awning.

RADIO CONTROL

6.3

The motorized running for radio engines of the awning involves the use of a radio control which

allows to control the movements of the fabric cover in a simple and intuitive way:

The button ▲ controls the packing of the fabric cover while the button ▼ controls the extension

of he fabric cover.

The button

stops the movement of the awning.

CONTROL FABRIC

COVER PACKING

CONTROL FABRIC

COVER EXTENSION

PROG

STOP

Use the channel selection control to change channel and enable the ▲ and

key to command:

light on and off and adjusting light intensity.

COMMANDS:

LIGHT ON

LIGHT OFF

LIGHT INTENSITY ADJUSTMENT

CHANNEL SELECTION CONTROL

www.gibus.com

OK! NO!

Page 30 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

WARNING: THE OPERATIONS FOR INSTALLATION MUST BE PERFORMED ONLY

BY PROFESSIONALLY QUALIFIED AND TRAINED STAFF, IN ACCORDANCE WITH

THE REGULATIONS IN FORCE.

WARNING: the adjustment must be made in safety conditions. With motorised

awnings there is a residual risk of crushing hands or head; therefore position

yourself on the outside of the awning, outside of the danger area (handling area).

In particular, to prevent risks of crushing/cutting, do not allow any parts of the

body to get between the mobile front of the awning and the fixed housings for the

structure. This is particularly important when the front is moving.

CHAPTER 7:

INSTRUCTIONS FOR PROPER INSTALLATION

IMPORTANT: To properly set up the awning strictly follow the "INSTALLATION

INSTRUCTIONS" attached to this manual and included in the accessory box or in

another part of the package.

IMPORTANT: Before starting the limit switch adjustment, it is necessary to identify

the type of engine installed on the awning. The up and down indications depend on

the mounting to the right or left of the awning. Check the enabling of the thermal

switch after about 4-5 minutes.

IMPORTANT: after installation the declaration for proper installation must be

compiled by the installer (Sec. 14 par. 1).

CAUTION: If the installation includes several motors with remote control it is

advisable to power one motor at a time to avoid interference between them all.

During programming then power the 1st motor and program its remote control,

then disconnect the power supply to the 1st engine and power up the 2nd, repeat

the programming and so on.

NOTE: the minimum distance between 2 operators must be at least 30 cm so there

is no interference between them.

www.gibus.com

OK! NO!

Page 31 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

CHAPTER 8: OPERATION AND USE OF THE AWNING

WARNING FOR THE USER: Pay the utmost attention to the signs placed in

dangerous areas. Before operating the awning carefully read the Chap. 2

concerning "SAFE" and "INTENDED USE AND USE ENVIRONMENT". Use the

awning only as a protection against the sun and for the purposes described in this

manual (see chap. 2.1 "Purpose and intended uses of the awning").

WARNING: Before operating the awning, check that there are no persons or

objects that hinder the opening and closing when the awning is positioned at a

height lower than 2.50 [m] from the walkable floor (especially if the lowest point in

the travel is at a height of less than 2,30 [m] from the walkable floor).

In particular, to prevent risks of crushing/cutting, do not allow any parts of the

body to get between the mobile front of the awning and the fixed housings for the

structure. This is particularly important when the front is moving.

The opening and closing of the MANUAL AWNING is performed through the operating rod and

a little winch. The opening and closing of the motorized awning can be performed thanks to a

SWITCH, installed in the vicinity of the awning and in a position such as to allow the user the

total visibility of its movements (if placed outdoor, the switch must be suitably protected) or, in

the case of RADIO engines, using a portable or wall mounted RADIO CONTROL (see sec. 6.3) or

wall (the awning must be operated from a site able to guarantee a good visibility of the excursion

of the fabric cover).

IMPORTANT! The characteristics and operation of the drive systems are described

in the manuals herein attached, related to the engine, to the automatisms and

commands required.

www.gibus.com

Page 32 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

(*) The awning is recommended to be exposed to a maximum wind load equal to 100 Newton/mq corresponding to a continuous

wind at a maximum speed of 49 Km/h according to the Beaufort scale. It is therefore strictly required, for the sake of safety,

to pack the awning before exceeding such a limit. In the absence of a sensor provide packing the awning in the presence of

strong wind.

The engines are equipped with electromagnetic brake and thermal protection. For its technical

characteristics, the motor provides a maximum time of continuous operation of about 4-5

minutes, after which the thermal protection device activated for cooling. The standard use of the

awning provides an opening and closing manoeuvre.

CAUTION: the awning must be packed in case of snow, hail and heavy rain;

(such as preventing the water from draining regularly), strong wind (*); it is very

dangerous to leave the awning open in these cases, it can cause injury to persons

and damage to property.

IMPORTANT!: in the awning with safety control engine, use the manual command only

in case of emergency due to power failure, do not operate the manual command on a

daily basis.

IMPORTANT!: in the case of failures, turn to you dealer and if required only ask for

Gibus original spare parts.

If the awning was inadvertently left opened and ice was formed or snow deposited on it, do not

pack after having previously removed the snow or melted the ice. Otherwise the movement could

be obstructed and the fabric cover damaged.

IMPORTANT! The operation with ice may damage the awning! Do not operate the

awning before having first removed the snow and the ice formed.

Additional safety devices can be added such as the sensor transmitter for the wind control or the

sensor transmitter for the management of the awning in the presence of the sun and wind. In the

event of malfunctioning, contact your retailer and ask for original spare parts only.

ATTENTION! In the case of fault or when searching for faults, respect the safety

measures. In particular when searching for or repairing any faults to the electric

components, THERE IS THE RISK OR FATAL ELECTRIC SHOCK. only qualified

electricians must carry out the maintenance to the electrical parts.

ATTENTION: NEVER PERFORM REPEATED OPENING AND CLOSING OPERATIONS

WITH THE ENGINE, this will activate the thermal switch, resulting in the shut-down

of the engine and without being able to perform any manoeuvres in case of need

(e.g. packing because of the presence of strong wind).

It is required, if the thermal switch is triggered, to let the engine cool before

performing new actions.

www.gibus.com

Page 33 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

• FOLDS - Spider Web Effect: May be formed in the packaging of the fabric cover; especially in

light colours these folds become darker marks on the fabric. In any case there is no degradation

of the quality of the awning.

• WAVES: May be formed next to the seams and to the side edges because of the double

thickness of fabric which, packed around the roller, creates different tensioning.

• FRAYING AND ABRASION: The valance, if exposed to strong wind and constant stress, may

show signs of wear, fraying and abrasions.

Regardless of the high standards of weaving, treatment of tissues and packaging techniques,

the fabric covers may be subject to the following problems:

• MOULD: The high concentration of harmful pollutants in the atmosphere resulting in acid

rain, the installation of the awning in the vicinity of roads, air conveyors, of tall trees, with the

consequent fall of resins and vegetable material, may cause the fabric covers, despite being

treated with anti-mould products and if constant maintenance cleaning is not carried out, be

attacked by micro-organisms, in such magnitude as to make it impossible the subsequent

cleaning.

IMPORTANT INFORMATION ON USE

8.1

IMPORTANT: water resistance on fabrics, Printed and Waterproof, is guaranteed

only on fabric not affected by mould.

BIOCIDES - Some fabrics are subjected to treatment that makes them hostile to

the formation of mould and mildew. Such treatments can contain biocidal products

(agents intended to destroy, intimidate or make harmless, in a biological or

chemical way, harmful organisms). See section 3.6.

Failure to follow the conditions for proper use, automatically voids any warranty given by

the manufacturer.

IMPORTANT! As highlighted in the preceding paragraphs does not constitute

product defect and therefore is not covered by warranty.

IMPORTANT! The fabric cover should always be packed when perfectly dry;

if packed when wet it is is more easily attacked by moulds and can cause the

phenomenon of waves close to the seams.

IMPORTANT! The extended fabric cover should always be tensioned, so you will

prevent the fabric from "banging" at every breath of wind.

www.gibus.com

Page 34 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

CHAPTER 9: MAINTENANCE

Operations of installation and initial start-up, adjustment and unscheduled maintenance

should be performed only by qualified technical personnel and specialized for such tasks.

Contact the Technical Service Department of your GIBUS dealer.

CAUTION: Cleaning with ladders, scaffolding or other is reserved for specialized

personnel who must carry out the operations in accordance with current directives

on safety and must use personal protective equipment such as safety harness with

sling.

ATTENTION: ALL THE OPERATIONS OF ROUTINE OR UNSCHEDULED

MAINTENANCE MUST BE CARRIED OUT SAFELY, AFTER CUTTING THE POWER

SUPPLY OFF. Before resume operating the awning carefully read the Chap. 2) on

"SAFETY".

The cleaning of the fabric cover is necessary to safeguard the fabric itself against the formation

of mould caused by dust or other material deposits, thus delaying as much as possible the

formation of permanent dirt. It is therefore advisable:

CLEANING THE FABRIC COVER

9.1

• at least twice a year (in spring before use during the summer season and in autumn before

winter closure) visually check the state of wear of the fabric cover; clear the upper part of the

fabric cover from leaves, branches, pine cones every time deemed necessary;

• if necessary clean the fabric covers by vacuuming the dust and using a damp sponge or cloth

with lukewarm water and non-aggressive products.

•Followtheinstructionsshownonthelabelofthefabriccover,donotdrywash,

do not wash in the washing machine;

•donotusesolvents-ammonia-hydrocarbons;

•leavethefabriccoverdryaftercleaning.

In case of doubt consult the dealer.

The compulsory maintenance required by the end of 2nd year and the following maintenance

operations for extending the warranty year after year must be carried out by a GIBUS technician

and must minimally include an inspection of the correct movement of the fabric, positioning

of the endstops in opening and closing, make sure that the wind sensor is working if

it is present. Also check the recommendations in paragraph 9.2 titled “MAINTENANCE OF

MECHANICAL AND STRUCTURAL COMPONENTS” (such as the belt tension, the conditions of

carriages and fabric). Also, the operations reported in the following paragraphs must be carried

out by the owner or by a specialist paying attention to the following warnings:

IMPORTANT: IT IS COMPULSORY to ask a GIBUS technician for an extraordinary

maintenance operation within the 2nd year from the installation of the awning so

that the warranty will also cover the 3rd year. A compulsory maintenance operation

within the end of the 3rd year will extend the warranty to the 4th year and a

compulsory maintenance in the 4th year will extend the warranty to the 5th year. If

the maintenance operations are not carried out, the GIBUS warranty will no longer

be valid. Use original Gibus spare parts; otherwise, the warranty will be voided.

www.gibus.com

Page 35 of 56

USE AND MAINTENANCE MANUAL

Code MUT 088

Rev. 1

CHAPTER 10: DISMANTLING AND DISPOSAL

CAUTION: dismantling of the awning must be carried out by qualified and trained

staff. Ask for a specialized GIBUS technician at the Service Department of the

vendor.

CAUTION: dismantling of the awning must be carried out applying all the safety

provisions as per installation: see chapter "SAFE INSTALLATION" and chapter

"INSTRUCTIONS FOR PROPER INSTALLATION".

MAINTENANCE OF STRUCTURAL AND MECHANICAL COMPONENTS

9.2

IMPORTANT: please open and close the awning periodically (open the fabric

completely and fold it up completely) and check periodically the correct operation

of the parts and their lubrication. Do not leave the product unused for long periods.

In order to keep the product in perfect operating conditions and safe proceed as follows:

• yearly check the tightening and the integrity of bolts and nuts, as well as screws. Check

that the floor attachments and wall/ceiling attachments are in perfect conditions. Check the

condition around the fixing devices (pay attention to cracks and that the screws are properly

tightened).

• yearly, before use during summer check the tensioning of the belts and the condition of the

trolleys (check that the slot of the guides housing the trolleys/belts is completely free from

leaves or other material). Lubricate with silicone lubricant the moving parts;

• yearly, or possibly more often, check that the gutters are free of leaves and debris. Remove

parts that block the movement or prevent water from flowing out;

• yearly, visually inspect the bearing structure. If necessary clean the surfaces of the aluminium