Gibertini densimat Instruction Manual

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

DensiMat

Hydrostatic Balance

60.50.375 Ed. 2 - June 2009

All rights reserved.

Forbidden any form of print, duplication, reproduction and publication

of this instructions, or part of it, without the written agreement of

GIBERTINI ELETT R ONICA Srl

INDEX

1. IMPORTANT WARNINGS.................................................................................................3

2. GENERAL DESCRIPTION AND TECHNICAL CHARACTERISTICS................................4

3. INSTALLATION.................................................................................................................5

3.1 PROCEDURE INSTALLATION..........................................................................................5

3.2 DENSIMAT KE YBOARD....................................................................................................7

4. MEASUREMENTS WITH DENSIMAT...............................................................................7

4.1 DETERMINATION OF SPECIFIC GRAVITY D

20/20

OF A LIQUID...................................8

4.2 DETERMINATION OF THE DENSITY OF A LIQUID AT 20°C...........................................9

4.3 COMPENSATION OF FLOATER IN USE........................................................................10

5. BEHAVIOUR OF THE INSTRUMENT WHE N SWITCHING ON AND CONDITIONS FOR

OPTIMAL MEASUREMENTS.........................................................................................11

6. APPENDIX A: LIST OF PRINCIPAL MESSAGES DISPLAYED .....................................13

7. APPENDIX B: POSSIBLE OPTIONS FROM DENSIMAT KEYBOARD...........................14

8. APPENDIX C: USE OF THE CYLINDER FO R ME ASURE ME NTS IN CONTINUOUS ....15

8.1 INSTALLATION...............................................................................................................15

8.2 OPERATING INSTRUCTION...........................................................................................16

9. APPENDIX D: REFERENCE TO LEGAL METROLOGY.................................................17

9.1 METROLOGICAL CHECKING OF DENSIMAT................................................................17

10. DISPOSAL – INFORMATION FOR USERS....................................................................19

DensiMat

ENGLISH

- 3 -

- ATTENTION -

READ CAREFULLY THIS MANUAL, WHICH IS INTEGRAL PART OF THE

INSTRUMENT, BEFORE INSTALLING THE BALANCE

1. IMPORTANT WARNINGS

N.B. - These "WARNINGS" are integral part of the instrument

This instrument is to be used strictly for scientific purposes and/or for internal factory control only.

The use of our instruments is forbidden in the cases provided by art. 1, point 2, letter a) of directive

90/384, except for those models approved with CE mark (legal metrology).

THIS INSTRUMENT IS NOT T O BE USED IN AREAS EXISTING DANGER OF EXPLOSION.

It is important to note the following points for correct operation of the instrument:

1. Read the technical instructions given in the operating manual carefully. This manual contains information

about installation and use. If these instructions are not carried out precisely, the accuracy of results may be

affected. If in doubt, please consult the supplier’s engineers.

2. In common with any electrical equipment, installation should be carried out by a competent person. In

particular:

- ensure that the instrument is correctly earthed;

- do not install the instrument in areas of high fire risk, for example, in the presence of inflammable gases

and vapours;

- switch off and disconnect the power supply before removing any cover;

- do not touch the instrument with wet hands.

3. Install the instrument on a vibration free base and away from draughts or sources of heat. Check the

instrument with test weighing after installation or after repositioning.

4. Avoid connection to a power supply showing high voltage variations due to other loads. The instrument

should not be connected to the same electrical circuit as other high power consuming equipment as large

fluctuations may cause some inaccuracy.

5. The instrument should be checked every 6 months for correct functioning, calibration and accuracy of the

internal calibration mass by a suitable qualified person.

6. A routine calibration check should be carried out each day before use, using a standard mass. This mass

should be independently checked monthly.

7. Check the zero function before each weighing operation.

8. If in doubt about any function please call a qualified person. Avoid interference by non-qualified persons.

9. If the instrument is used for weighing food or drink, ensure that other substances are not weighed on the

unit which might cause contamination.

10. If the instrument is used for weighing chemicals and other similar substances ensure that it is cleaned and

any spillage removed to avoid potentially dangerous reactions.

11. Always clean the instrument after use to avoid subsequent inaccuracies and/or damage to the equipment.

12. Gibertini Elettronica s.r.l. does not accept any legal liability for damages or other consequences due to

mishandling of the instrument or its accessories.

ADDITIONAL PROCEDURES FOR WEIGHING SUBSTANCE WITH GREAT ACCURACY

Gibertini Instruments are manufactured to be reliable in use with high accuracy. However, reduced accuracy is

always possible due to ambient conditions, incorrect installation or improper use. Where greater accuracy is

required, the following procedures should be observed:

- use modern instruments (manufactured within three years) which are fully maintained;

- use certified calibration masses before each weighing operation;

- make at least two measurements;

- install the instrument in a draught-free, constant temperature cabinet: consider the use of two

instruments installed together and make weighings on both units, otherwise use calibrated masses with

a certificate of calibration from a recognised institute.

ALL ELECTRON IC BALANCES, WHICH ARE SENSITIVE TO CHANGES O F GRAVITY, MUST BE

CHECKED AND CALIBRATED IN THE PLACE WHERE THEY ARE TO BE USED (EEC 90/384).

ALL OUR INSTRUMENTS MEET INTERNATIONAL EMC-EMI-RFI STANDARDS ACCORDING TO 2004/108

EEC DIRECTIVE ON ELECTROMAGNETIC COMPATIBILITY.

ENGLISH

DensiMat

- 4 -

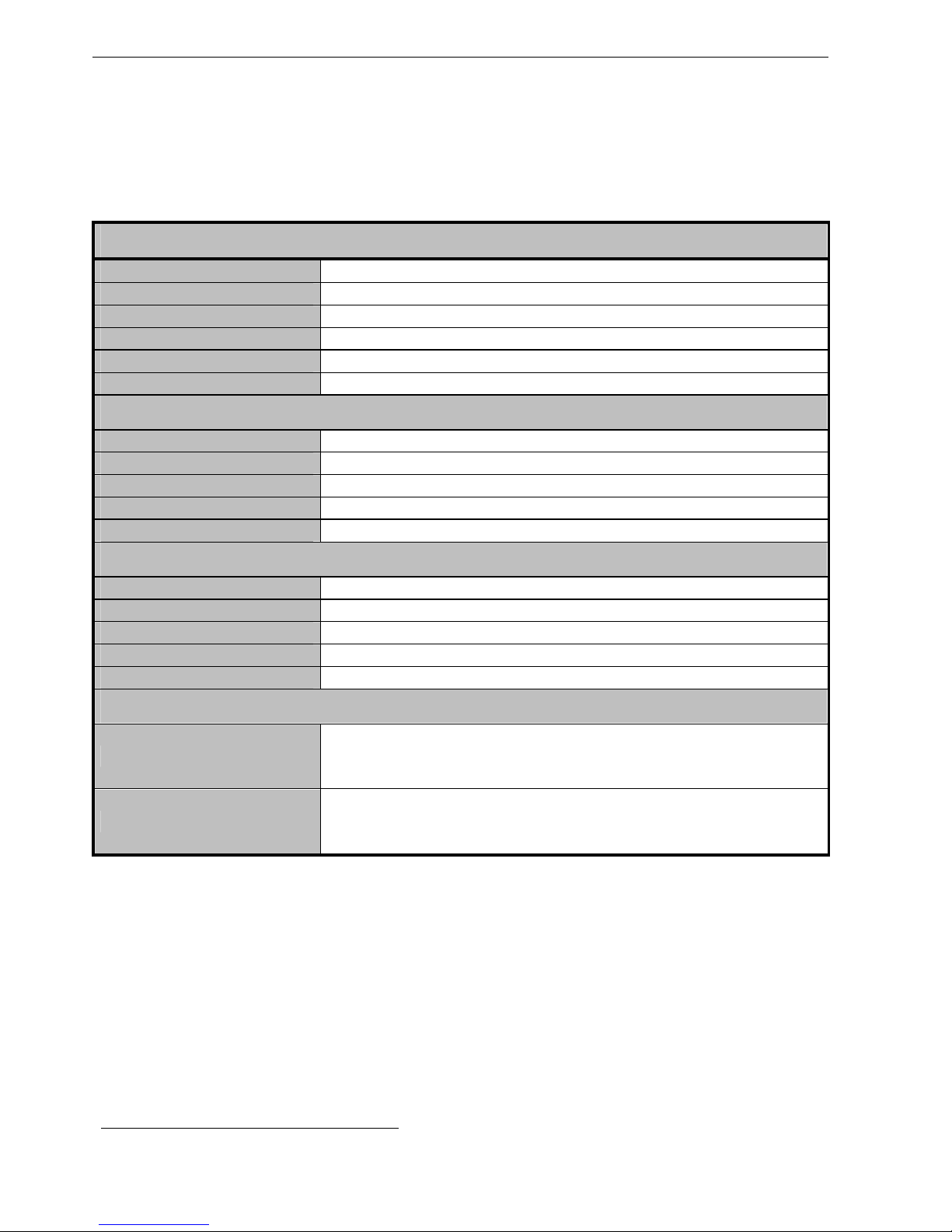

2. GENERAL DESCRIPTION AND TECHNICAL CHARACTERISTICS

The instrument consists of an electronic hydrostatic balance DENSIMAT, with a

sensitivity of fifth decimal points.

GENERAL SPECIFICATIONS

Warm-up time

≥ 15 minutes

Operating temperature

+15°C / +30°C

Data output

RS232 I/O

Operating voltage

220 V - 15% / + 10 % (110 V optional)

Power consumption

10 VA

Dimensions and weight

210x355x360 mm - 7,5 kg ~

HYDROSTATIC BALANCE SECTION

Relative density

Measuring range: 0.5 - 2.25

Readability

0.00005

Repeatability

+/- 0.00005

Auto-calibration

With internal mass

Response time

6 sec.

THERMOMETER SECTION

Measuring temperature

Range 8 ÷ 32 °C

Sensitivity

0.025 °C

Readability

0.1 °C

Repeatability

+/- 0.05 °C (range 10 ÷30 °C)

Thermometric probe

Pt 100 1/3 DIN

EQUIPMENT

Standard

2 floaters (plungers) calibrated

for weight (50 g) and volume (20 ml)

2 double wall 70 ml cylinders - Power supply

On request

Cylinder for measurements in continuous

Pan for metrological control

Certificated masses - Certificated floaters

FLOATERS INTERCHANGEABLE IN MASS AND VOLUME

Particular care must be paid in the construction and calibration of floaters.

They are all interchangeable in mass and in volume in order to facilitate utilization; for

example to determine the specific gravity of a must or a given wine and the relative

ASV, 2 separate floaters can be used without problem to avoid contamination

(preliminary check of the compensation factor; see chapter 4.3).

To obtain the above both the suspension

1

wire and the surface of the glass have been

subject of many studies in order to resolve the problems caused by surface tension,

from the volume of wire and from electrostatic charges.

1

Realized with an antimagnetic material, inoxidizable and a diameter lower or equal of 0,20 mm

DensiMat

ENGLISH

- 5 -

The wire is made with an antimagnetic material, inoxidizable and a diameter lower or

equal of to 0,20 mm.

The volume of floaters, on request, can be certified by the competent European

Institutes such as the L.N.E. of Paris, the I.M.G.C. of Turin, the PTB in Germany etc.

3. INSTALLATION

Densimat was designed and made to resist and to function even under difficult

conditions. However, it is advisable to install Densimat:

on a rigid support without vibrations

in a stable room temperature and without excessive ventilation

utilizing a separate electrical supply.

NOTE: if the Densimat stops working because of an incorrect operation on the

keyboard, the plug must be removed and connected again to the socket while

pressing the " + " key. When the instrument is switched on again the following

message appears

P n o r

which indicates the return to use of the parameters of standard functioning.

1- Floater knob

2- Cylinder and floater

3- Rubber mat

4- Keyboard

5- Transformer

6- Plug

7- Knob to adjust the

cylinder-balance

8- Centering plate

9- Knob for blocking

balance (to transport)

10- Thermo probe

11- Levelling feet

Figure 1

3.1 PROCEDURE INSTALLATION

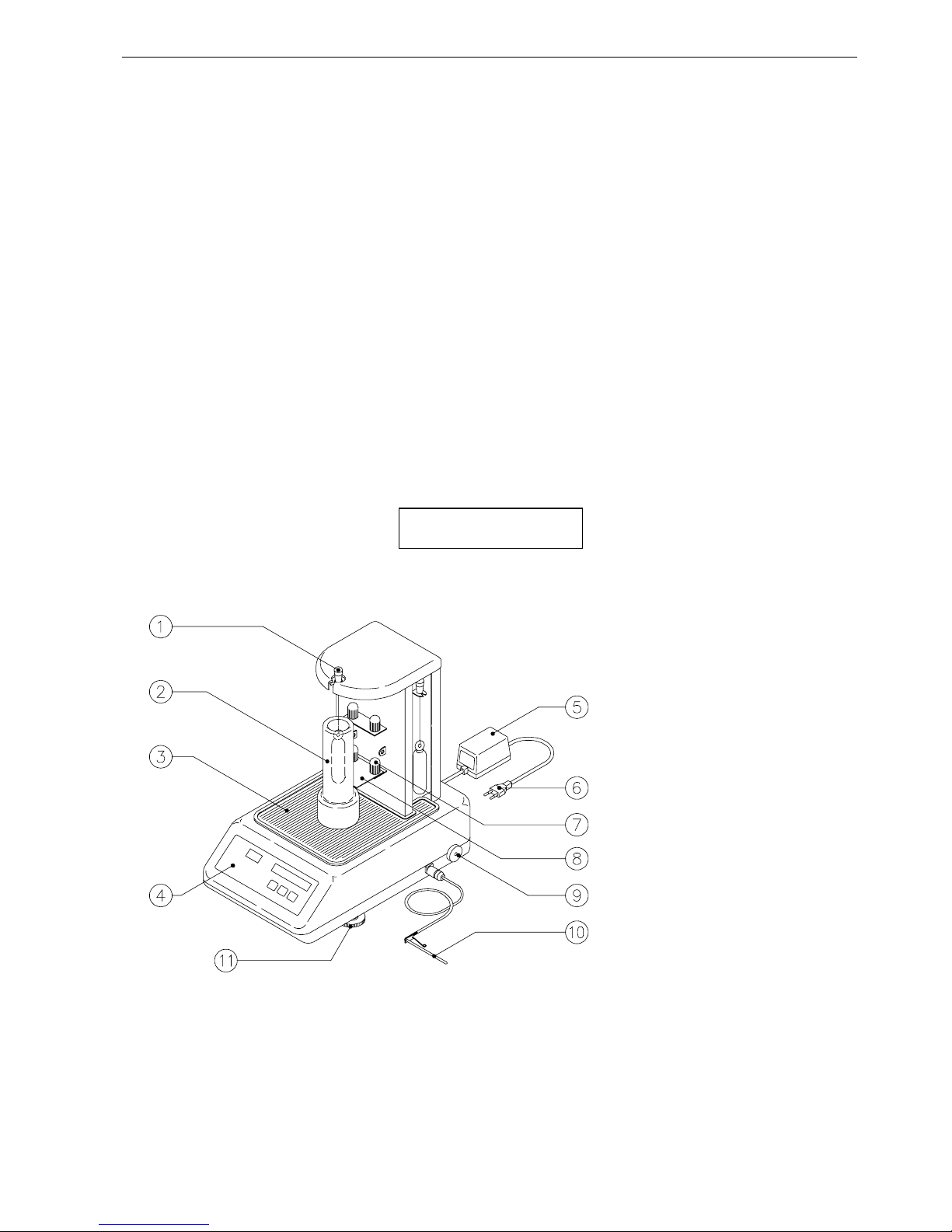

Level the balance by adjusting the back supports in order to centre the air bubble in

the middle of the circle.

unlock the balance by rotating the knob in an anticlockwise direction and when it

stops it comes to rest on the right side of the instrument (Fig. 1 n. 9 and Fig. 2).

ENGLISH

DensiMat

- 6 -

UNLOCKED LOCKED ( Only to transport )

Figure 2

Insert the connector of the thermo probe in the place indicated in figure 1 (n. 10),

keeping the locking pin in an upright position and pushing it till its complete

insertion: the connector is in the correct position if, trying to pull it out, it does not

come. To pull it out press the locking pin.

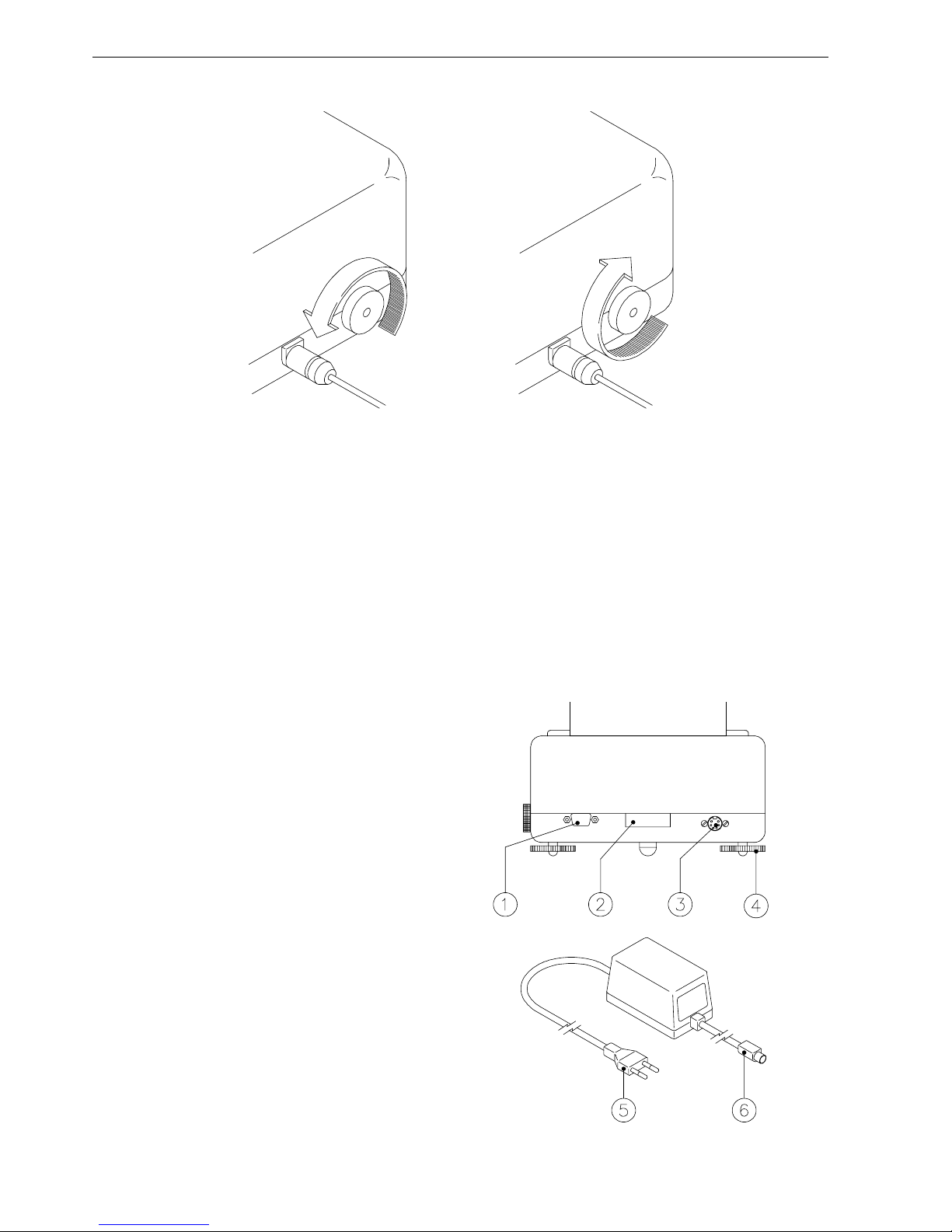

Connect the circular socket of the transformer (fig. 3 n. 6) to the connector of

Densimat (fig. 3 n. 3) keeping the flat side of pin upwards. Connect the transformer

to the socket (fig. 3 n. 5) of the electric mains.

Figure 3

Rear view of DENSIMAT

1- RS323 serial connection

2- Serial number

3- Transformer socket

4- Adjustable supports

5- Mains plug

6- Transformer plug

Loading...

Loading...