Giatec Scientific iCOR User Manual

USER MANUAL

iCOR

®

C O N N E C T I O N L E S S C O R R O S I O N R A T E

M E A S U R E M E N T D E V I C E F O R

R E I N F O R C E D C O N C R E T E S T R U C T U R E S

Smart Concrete Testing Technologies

™

iCOR® User Manual

© Giatec Scientific Inc. i

TA BLE O F C ON T EN T S

TABLE OF CONTENTS .............................................................................. I

PACKAGE CONTENTS ............................................................................ III

WARRANTY ................................................................................................. V

SAFETY INSTRUCTIONS ........................................................................... 1

SAFETY SYMBOLS .............................................................................................................. 1

GENERAL GUIDELINES ................................................................................................... 1

DEVICE HANDLING ......................................................................................................... 2

DEVICE OPERATION ........................................................................................................ 2

DEVICE CLEANING .......................................................................................................... 3

OPERATION ENVIRONMENT .......................................................................................... 3

STORAGE ENVIRONMENT ............................................................................................... 3

INTRODUCTION TO GIATEC ICOR® ...................................................... 4

CORROSION OF STEEL IN CONCRETE ........................................................................... 5

CORROSION RATE MEASUREMENT ............................................................................... 5

POLARIZATION RESISTANCE OF REBAR (RP) ............................................................... 7

ELECTRICAL RESISTIVITY OF CONCRETE .................................................................... 8

HALF-CELL POTENTIAL MEASUREMENT ..................................................................... 8

APPLICATION ..................................................................................................................... 9

COMPLICATIONS/ LIMITATIONS .................................................................................. 10

ICOR® OVERVIEW ..................................................................................... 12

ICOR® MEASUREMENT UNIT OVERVIEW ................................................................. 12

ICOR® OPERATION .................................................................................. 15

PREPARATION OF ELECTRODES .................................................................................. 15

TURNING ON THE ICOR® ............................................................................................ 16

LED INDICATOR............................................................................................................. 16

iCOR® User Manual

© Giatec Scientific Inc. ii

CHARGING THE ICOR® ................................................................................................. 17

TURNING OFF AND ON THE DEVICE ....................................................................... 18

STORING THE DEVICE ................................................................................................... 18

DATA RECORDING AND PROCESSING SETUP .................................. 19

TABLET SOFTWARE ........................................................................................................ 19

ERRORS ............................................................................................................................. 33

CONTOUR PLOTS ............................................................................................................ 38

DATA EXPORTING AND SHARING .............................................................................. 40

VERIFICATION ......................................................................................... 44

DEVICE VERIFICATION .................................................................................................. 44

LOG FILE .......................................................................................................................... 48

PRACTICAL CONSIDERATIONS ............................................................ 48

MAINTENANCE ........................................................................................ 50

SERVICE ............................................................................................................................ 50

REPLACEMENTS............................................................................................................... 50

GIATEC ICOR® TECHNICAL SPECIFICATIONS ................................. 51

GENERAL.......................................................................................................................... 51

OPERATING CONDITIONS ............................................................................................. 51

REFERENCES ............................................................................................ 52

TERMS AND CONDITIONS OF SALE ("SALE AGREEMENT") ........ 53

EX HIB IT A: EN D U S ER S OF T WA R E L IC E NS E ...................... 60

iCOR® User Manual

© Giatec Scientific Inc. iii

PA CK A G E C O NT E NT S

Part

Qty

Photo

iCOR® Measuring Device

1X

Measurement Cable

(for half-cell test)

1X

Charging Cable

1X

Charger Cable for Tablet

1X

Contact Sponge

(for half-cell electrode)

3X

Alligator Test clip

1x

Contact Sponge

(for corrosion electrodes)

12X

Electrode Storage Solution

1X

iCOR® User Manual

© Giatec Scientific Inc. iv

Conductive gel

1X

Spray Bottle

1X

Carrying Case

1X

Data Recording App

-

Tablet with hands-free

carrying support

1X

Tablet Charger

1X

Verification Kit

(for half-cell potential)

1X

Verification Kit

(for corrosion rate/electrical

resistivity)

1X

* Please note that the images above are for illustration purpose only and might

not be to scale.

iCOR® User Manual

© Giatec Scientific Inc. v

WA RR A NT Y

LIMITED WARRANTIES

Giatec warrants the Product against defects in materials and workmanship

under normal use (the “Warranty”) for a period of 12 months from the

Delivery Date (the “Warranty Period”), on the condition that the Product

has been completely paid for. Unless as otherwise mandated by local law, the

Warranty Period does not restart if Customer receives a replacement

appliance and/or replacement Software. This Warranty does not apply: (a) to

consumable parts, such as batteries and cables unless damage has occurred

due to a defect in materials or workmanship; (b) to cosmetic damage,

including but not limited to scratches, dents and broken plastic on ports; (c)

to damage caused by accident, abuse, misuse, neglect or failure to properly

maintain (to include but not limited to water damage and/or condensation

or improper temperatures during storage), or improper installation; (d) to

damage caused by electrical disturbances or acts of God, to include but not

limited to civil disturbance, war, flood, fire, rodents or insects; (e) where

manufacturer’s serial numbers and security labels have been removed from

the Product; and (f) to damage caused during shipment (due to Customer’s

improper packaging) from Customer to Giatec in the case of Product returns

for repair.

Giatec disclaims all other warranties, express or implied, including without

limitation implied warranties of merchantability, fitness for a particular

purpose, or against hidden or latent defects. Giatec’s responsibility for

warranty claims is limited to repair or replacement. Giatec reserves the right

to modify this Warranty at any time, at its sole discretion, and with notice to

Customer.

Giatec does not warrant that the operation of the Product will be

uninterrupted or error-free. Giatec is not responsible for damage arising from

failure to follow instructions relating to the Product’s use. This Warranty is

voided immediately if repair, modification (to include upgrades, expansions

or usage or addition of non-manufacturer parts or accessories), alteration or

iCOR® User Manual

© Giatec Scientific Inc. vi

other service is attempted other than by Giatec. In this regard, the integrity

of the appliance casing (aka the box) should not be violated for any reason,

unless expressly authorized by Giatec in writing.

THE WARRANTY SET FORTH IS EXCLUSIVE AND NO OTHER

WARRANTY, WHETHER WRITTEN OR ORAL, IS EXPRESSED OR

IMPLIED. GIATEC SCIENTIFIC INC. SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

* Please refer to the complete Terms and Conditions of Giatec’s products for

more details.

* The information contained in this document is subject to change without

notice.

iCOR® User Manual

© Giatec Scientific Inc. 1

SA FE T Y I N S TR U C T IO N S

This chapter contains important safety instructions that the user must follow

to operate and store the Giatec iCOR® device. Read the following safety

information before any operation to ensure your safety and to keep the device

in good working condition. Keep this user manual in a safe place for future

reference.

SAFETY SYMBOLS

In order to ensure the safety of the operator and increase the service life of

the instruments, pay attention to safety precautions described in this manual.

These messages are indicated by a symbol throughout this user manual.

WARNING: Identifies conditions or practices that could result

in injury or loss of life.

CAUTION: Identifies conditions or practices that could result

in damage to Giatec iCOR® or to other properties.

ATTENTION: Refer to the User Manual

NOTES: Identifies important points related to the operation

of the device

GENERAL GUIDELINES

1. Always follow basic safety precautions when using this product to

reduce risk of injury from fire or electric shock.

2. Read and understand all instructions in the documentation that

comes with Giatec iCOR®.

3. Observe all warnings and instructions marked on the product.

iCOR® User Manual

© Giatec Scientific Inc. 2

DEVICE HANDLING

CAUTION

• Giatec iCOR

®

is a non-destructive testing device. The electronic

parts, corrosion measurement electrodes, and half-cell potential

electrode are sensitive components. Please handle them with care.

• Do not place any heavy objects on the iCOR

®

device or the tablet.

• Avoid severe impact or rough handling that leads to damaging

iCOR® or the tablet.

• Do not disassemble iCOR

®

.

• Store the product in a protected location (e.g. carrying case) where

no one can step on or trip over the connection and USB-charging

cables, and in a location where these cables cannot be damaged.

DEVICE OPERATION

WARNING

• Power Input: USB only.

• Only use the provided USB charging cable for iCOR®, and the

provided power adapter for the tablet.

• Do not perform measurements at the circuits directly connected to

Mains (Live circuit).

• Do not place the instrument in a place where there is a chance of

spilling liquids on the device.

iCOR® User Manual

© Giatec Scientific Inc. 3

DEVICE CLEANING

ATTENTION

• Disconnect the device from the cable after testing (in case of half-

cell measurement).

• Do not use chemicals or cleaners containing harsh products such as

benzene, toluene, xylene, and acetone.

• Do not submerge the iCOR

®

device or the operating tablet

OPERATION ENVIRONMENT

ATTENTION

• Location: Indoor/outdoor

• Relative Humidity: 20% to 90%

• Temperature: 0°C to 45°C

• Avoid direct sunlight

• Do not submerge the device

STORAGE ENVIRONMENT

ATTENTION

• Location: Indoor

• Relative Humidity: 5% to 90%

• Temperature: 0°C to 50°C

iCOR® User Manual

© Giatec Scientific Inc. 4

IN T R OD U CT I ON T O G I A T E C i C O R®

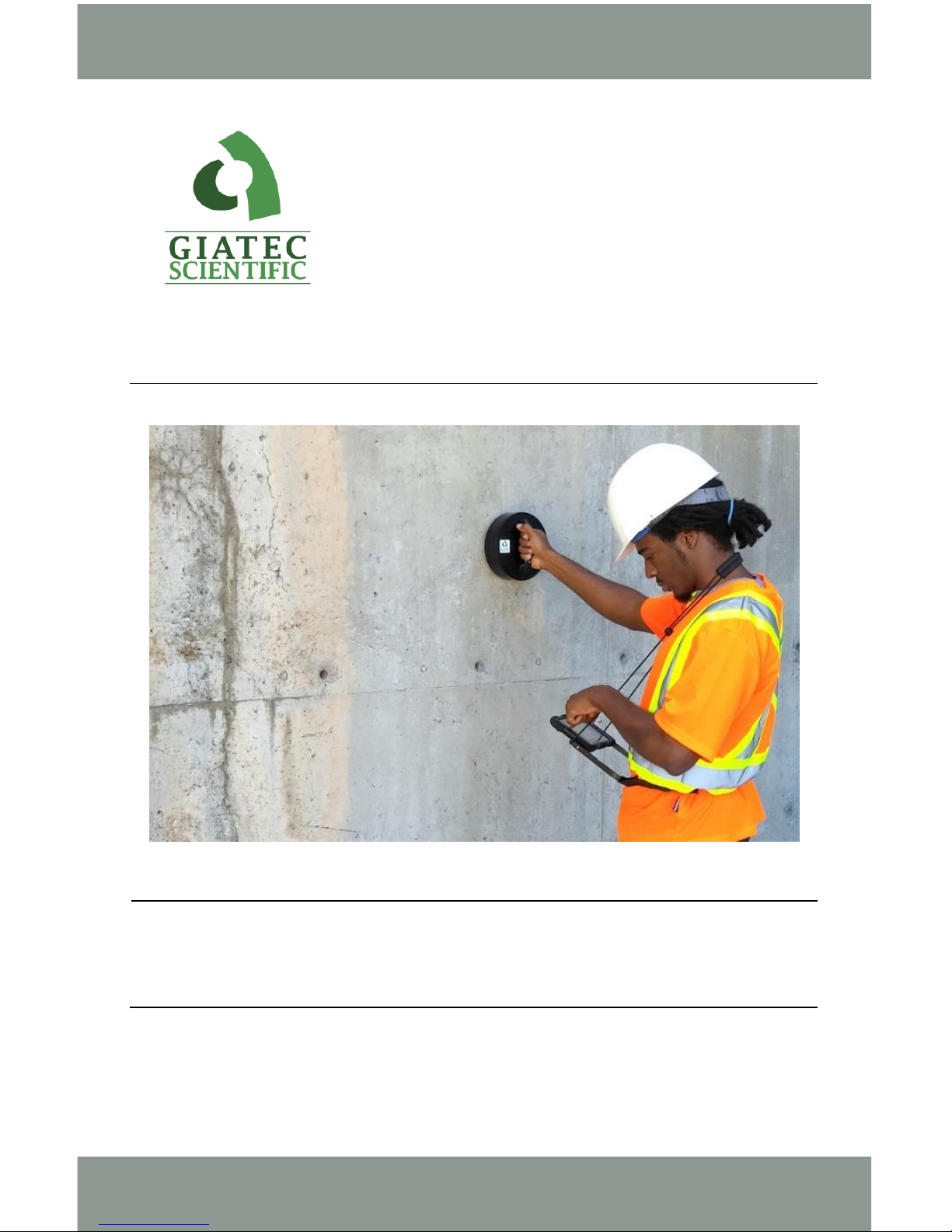

Giatec iCOR® is a compact and comprehensive non-destructive testing

(NDT) device for corrosion evaluation of reinforced concrete structures.

iCOR® can be used in field applications (i.e., condition assessment) as well as

laboratory testing.

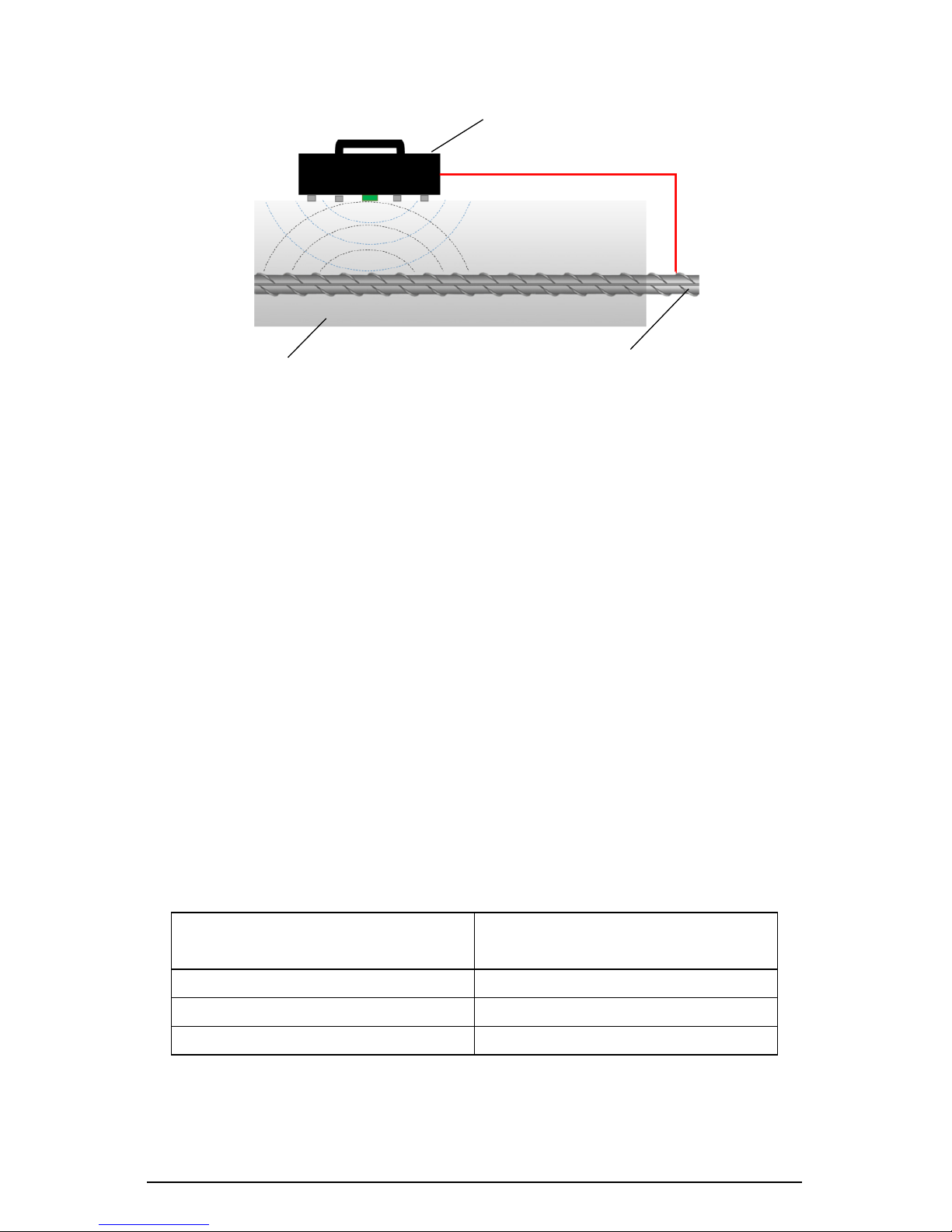

iCOR® benefits from a patented technology that makes it possible to estimate

the corrosion rate of rebar through a non-invasive approach. This means that

the need to connect the measuring unit to the rebar (which is the case for

other commercial devices) is eliminated in iCOR®. Fig. 1 schematically

illustrates the non-invasive feature of iCOR® compared to other

conventional corrosion testing devices.

Figure 1. Comparison of the iCOR

®

device vs other conventional

devices

Giatec iCOR® is also equipped with high precision sensors to measure the

electrical resistivity of concrete, the half-cell potential, ambient temperature

and relative humidity. iCOR® benefits from a wireless capability to transmit

data to a tablet, where data can be stored, analyzed and visualized. Moreover,

the tablet app offers a powerful post-processing tool and an easy way to share

the results with other team members. iCOR® can significantly save time,

human resources and cost.

iCOR® User Manual

© Giatec Scientific Inc. 5

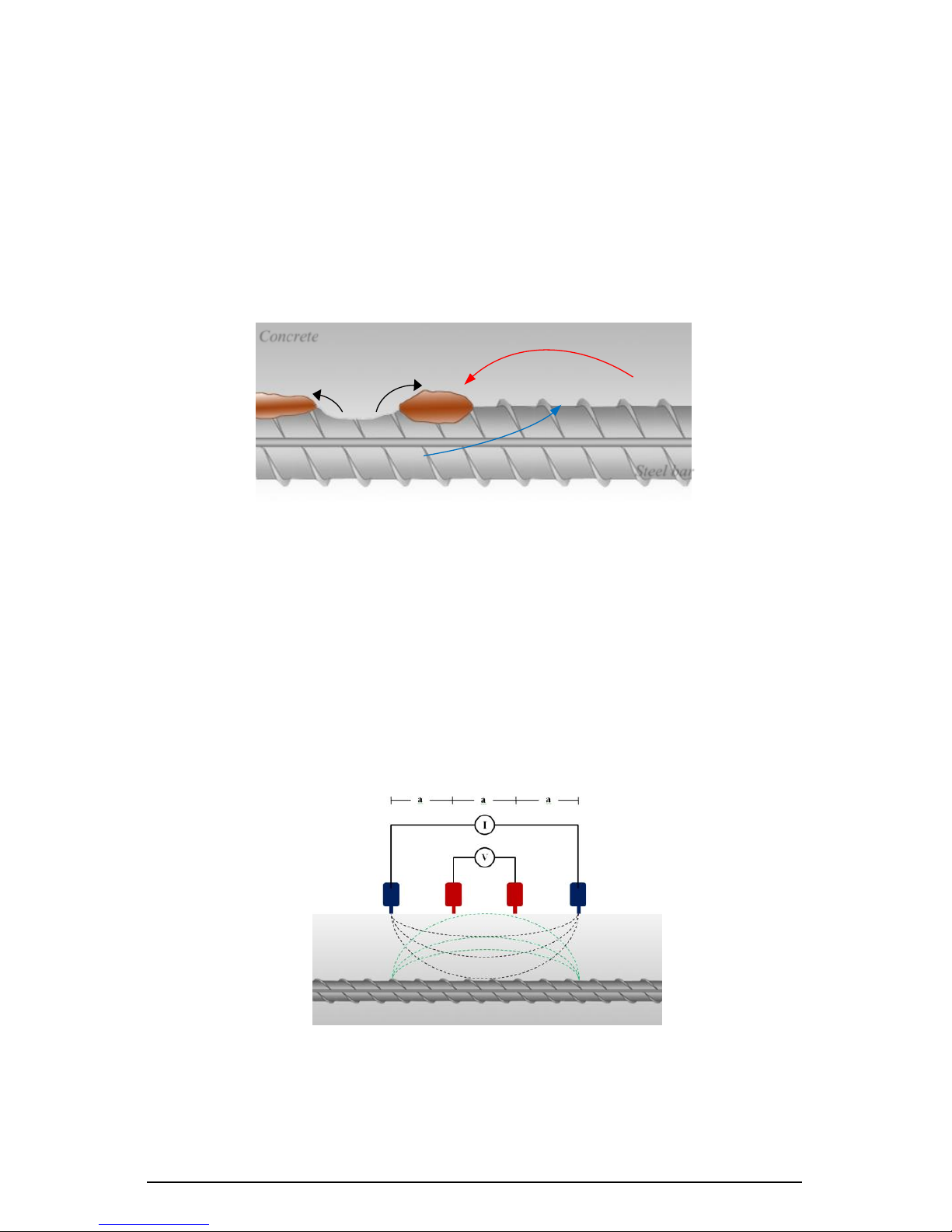

CORROSION OF STEEL IN CONCRETE

The corrosion of steel reinforcement inside concrete can be described as an

electrochemical reaction. In this reaction, electrons migrate from the anodic

zone to the cathodic zone, releasing ferrous ions at the anode and hydroxide

ions at the cathode (Fig. 2). This will eventually lead to a potential difference

between the anodic and cathodic areas at the surface of the steel

reinforcement.

Figure 2. Corrosion of steel in concrete

CORROSION RATE MEASUREMENT

Measurement Concept

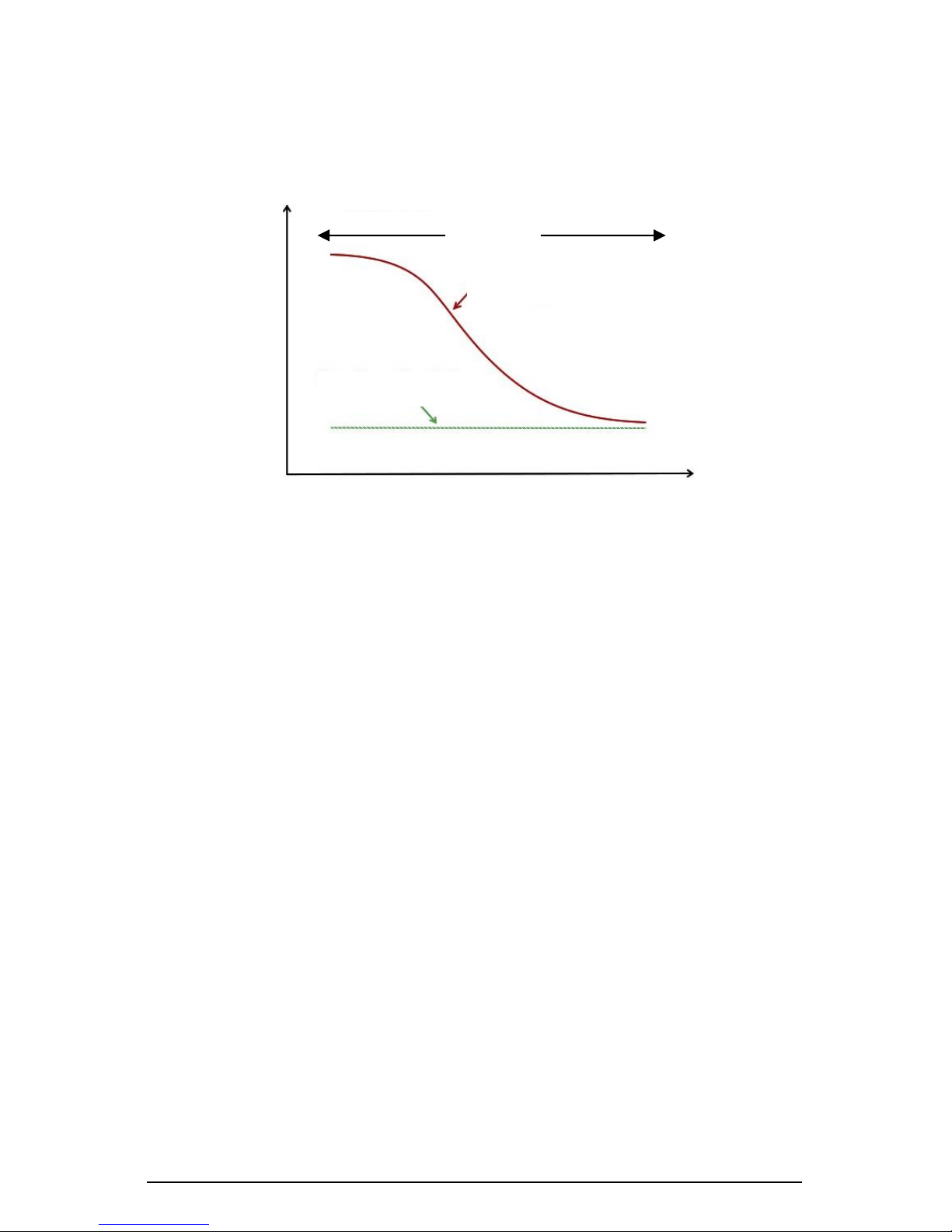

The electrical response of rebar inside the concrete can be determined from

the surface of concrete with four electrodes as shown in the Fig. 3. A constant

AC current is applied between the outer electrodes and the voltage between

the inner electrodes is measured.

Figure 3. The configuration of 4 electrodes on the surface of concrete

for corrosion detection of rebar inside the concrete

2Fe(OH)2

Steel bar

Concrete

4e-

O2 +2H2O +4e-→4OH-

Cathode

2Fe2+

2Fe→2Fe2+ + 4e-

Anode

4OH-

iCOR® User Manual

© Giatec Scientific Inc. 6

By sweeping the frequency of the AC current from a low frequency to a high

frequency, the voltage of the system is recorded as illustrated schematically

in Fig. 4.

Figure 4. The schematic illustration of the voltage-frequency response of

the corroding rebar compared to the non-corroding rebar

The voltage response of a corroding rebar is different from that of a noncorroding rebar. The voltage of a non-corroding rebar increases in the low

frequency zone of the plot, but it is almost invariable for a corroding rebar.

The basis of this concept has been utilized in iCOR® technology to detect

the corroding areas of reinforced concrete structures from the surface of

concrete. This technology eliminates the need to have an electrical

connection to the rebar inside the concrete unlike other existing nondestructive corrosion measurement techniques.

iCOR® Measurement Technique

As mentioned above, the low-frequency impedance response of rebar in

concrete can be correlated to the corrosion state of reinforcement in

concrete. However, direct measurement of the low-frequency impedance of

rebar in concrete is very time-consuming and vulnerable to noise

interruption; hence, it is not practical to use this technique in the field to

measure the corrosion rate of rebar inside the concrete. In Giatec iCOR®,

the low-frequency behavior of reinforced concrete system is determined by

applying a narrow DC/AC current pulse or a DC/AC step voltage for a short

Frequency (Hz)

Voltage (V)

Non-corroding bar

Corroding bar

High frequency

Low frequency

iCOR® User Manual

© Giatec Scientific Inc. 7

period of time and simultaneously recording the voltage of the system with a

relatively high sampling rate. Using the recorded voltage and the applied

current, the low-frequency impedance response of rebar in concrete can be

extracted which can be used to determine the state of corrosion in reinforced

concrete structures. This patented technology has been developed by Giatec

Scientific Inc. and is called Connectionless Electrical Pulse Response Analysis

(CEPRA).

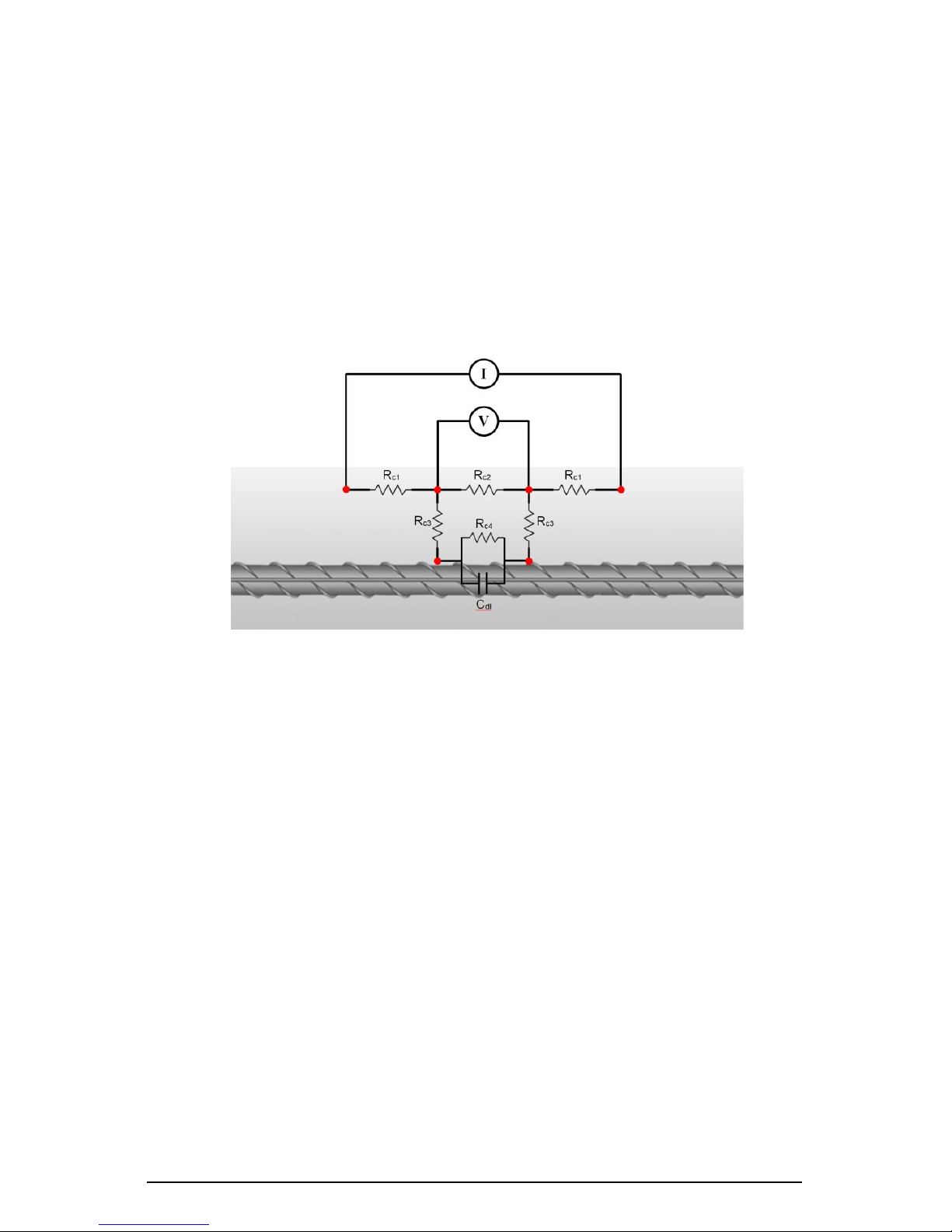

Figure 5. Electrical circuit of reinforced concrete system in

connectionless four-electrode measurement

Giatec iCOR® employs a complex electrical circuit model for predicting

different properties of concrete materials and steel reinforcement. This

electrical circuit is schematically represented in Fig 5. An advanced

mathematical algorithm is implemented in the core software of the device.

This core software processor is responsible for the analysis of certain

characteristics of concrete materials such as the polarization resistance,

electrical resistivity, and half-cell potential of embedded reinforcement.

POLARIZATION RESISTANCE OF REBAR (

R

P

)

This parameter is related to the corrosion rate of rebar in concrete. One can

calculate the corrosion rate from Rp using the following well-stablished

equation:

iCOR® User Manual

© Giatec Scientific Inc. 8

where Ap is the polarized area of rebar, R

c4

is the charge transfer resistance of

rebar defined in Fig. 5 and B is a constant parameter determined

experimentally.

ELECTRICAL RESISTIVITY OF CONCRETE

The intrinsic electrical resistivity of concrete can be calculated from ,

and defined in Fig. 5 using the following equation:

where a is a constant parameter determined from the geometry of the

measurement electrodes, R is the equivalent resistance of concrete calculated

from ,

and .

It is noted that the effect of rebar, unlike other concrete surface resistivity

measurement techniques, would be minimized using this approach. Other

AC techniques have inherent error in the measurement of concrete resistivity

due to the rebar effect.

HALF-CELL POTENTIAL MEASUREMENT

iCOR® is also equipped with a reference electrode for half-cell corrosion

measurement (Fig. 6). The purpose of the half-cell potential measurement

is to determine the electrical potential on the surface of concrete which is an

indication of corrosion potential of rebar in concrete.

The potential measurement is used to determine the state of rebar corrosion

in concrete. This technique allows for plotting of a potential contour map on

the concrete surface, which can be used to identify the corroding areas and

estimate the probability of corrosion (Elsener and Bohni, 1995, ASTM C876,

2009).

iCOR® User Manual

© Giatec Scientific Inc. 9

Figure 6. Half-cell potential measurement

APPLICATION

Giatec iCOR® can be used in either field or laboratory applications to

measure the corrosion rate and corrosion potential of steel reinforcement in

concrete structures. This technique can be utilized for various applications

such as:

• Estimation of the corrosion rate of steel reinforcement in concrete

• Measurement of corrosion potential of uncoated reinforcing steel

• Determination of corrosion activity of steel rebar

The measured corrosion potential values are indicative of corrosion

probability as presented in Table 1.

Table 1- Relationship between the potential values and corrosion probability

(adapted from ASTM C876)

Measured Potential (mV/CSE*)

Probability of

Steel Corrosion Activity

> -200

Less than 10%

-200 to -350

Uncertain

< -350

More than 90%

*

CSE= Copper Sulfate Electrode

Rebar

Concrete

Giatec iCOR®

iCOR® User Manual

© Giatec Scientific Inc. 10

It is noted that half-cell potential measurements can also be affected by

testing conditions. RILEM TC-154 (2003) reported the typical ranges for

half-cell potential measurements in different conditions (see Table 2).

Table 2- Typical ranges of half-cell potentials of rebar in concrete (adapted

from RILEM TC-154, 2003)

Condition

Potential values (mV/CSE*)

Humid, chloride free concrete

-200

to

+100

Wet, chloride contaminated concrete

-600

to

-400

Water saturated concrete without oxygen

-1000

to

-900

Humid, carbonated concrete

-400

to

+100

Dry, carbonated concrete

0

to

+200

Dry concrete

0

to

+200

*

CSE= Copper Sulfate Electrode

COMPLICATIONS/ LIMITATIONS

Half-cell potential measurement is a very useful technique in studying the

corrosion of existing structures (or elements). However, this test does not

provide any information on the kinetics of corrosion (i.e., corrosion rate of

steel reinforcement). It is always recommended to interpret corrosion

potential measurements with supplementary data from corrosion rate

measurements as well as other tests (concrete electrical resistivity, cover

thickness, and chloride profile). The presence of large cracks and

delamination can affect both corrosion rate and potential data. In the case of

pre-stressed post-tensioned steel tendons, these tests will not provide any

useful information if the tendons are placed in protective tubes. These tests

are also not applicable to concrete structures with epoxy-coated or galvanized

steel rebar.

While corrosion rate and corrosion potential measurements are quite simple,

the application of these techniques has several complications. For example,

ambient and measurement conditions can influence these measurements.

These complications can lead to misinterpretations of the collected data. The

most important parameters that can influence measurements are briefly

described below:

iCOR® User Manual

© Giatec Scientific Inc. 11

Temperature: The variation in ambient temperature would affect the

corrosion rate, corrosion potential and concrete resistivity measurements. In

a half-cell potential measurement the measured values should be corrected

for the temperature effects (CEFRACOR, 2007); but temperature correction

is not required for the corrosion rate measurement. It is recommended not

to perform the test below freezing point.

Moisture: Concrete moisture has a significant effect on the corrosion rate

and corrosion potential as well as the electrical resistivity of concrete. Since

the moisture of concrete changes from time to time, it can affect the

consistency of measurements (RILEM TC-154, 2003). The drier the concrete

is, the more positive the corrosion potential, the lower the corrosion rate and

the higher electrical resistivity values will be resulted performing the test.

Cover Thickness: The thickness of concrete cover would affect the

corrosion potential as well as the electrical resistivity of concrete. A lower

concrete cover leads to more negative values in half-cell potential

measurements and lower values in concrete electrical resistivity of concrete.

There is limited research on the effect of cover thickness on potential

measurements; hence there is no straightforward correction procedure

(SHRP, 2013). Therefore, it is recommended to verify the cover thickness for

the area being tested in order to avoid misinterpretation of the collected data.

Concrete Properties: Concrete properties such as density, permeability,

porosity, and electrical resistivity are factors that can affect the half-cell

potential measurements. A dense concrete cover reduces the permeability of

chloride and oxygen. This will reduce the oxygen concentration. As a result,

the half-cell potential values tend to be more negative (Gu and Beaudoin,

1998).

Availability of Oxygen: The availability of oxygen at the surface of steel

rebar can affect the corrosion rate and half-cell potential readings. Generally,

a lower concentration of oxygen at rebar level leads to lower corrosion rate

but more negative half-cell potential values (Gu and Beaudoin 1998, Elsener

et al. 2003), which can be misleading.

iCOR® User Manual

© Giatec Scientific Inc. 12

iC O R

®

OV E RV I E W

Giatec iCOR® has two main components: iCOR® Measurement device, and

Data Recording Unit (tablet).

This section describes how to setup and operate the iCOR® device for

measuring the corrosion rate and corrosion potential of steel reinforcement

in concrete structures. Before starting a test, please make sure that the iCOR®

device and your data recording unit are fully charged.

iCOR

®

MEASUREMENT UNIT OVERVIEW

Giatec iCOR® device provides an advanced multi-test platform to measure

the corrosion rate of steel reinforcement, rebar corrosion potential (Halfcell), concrete electrical resistivity, temperature and relative humidity (RH).

The device is equipped with wireless technology to transmit the test data to

the Data Recording Unit (Tablet) (Fig. 7).

Figure 7. Giatec iCOR

®

Measurement Unit

iCOR® User Manual

© Giatec Scientific Inc. 13

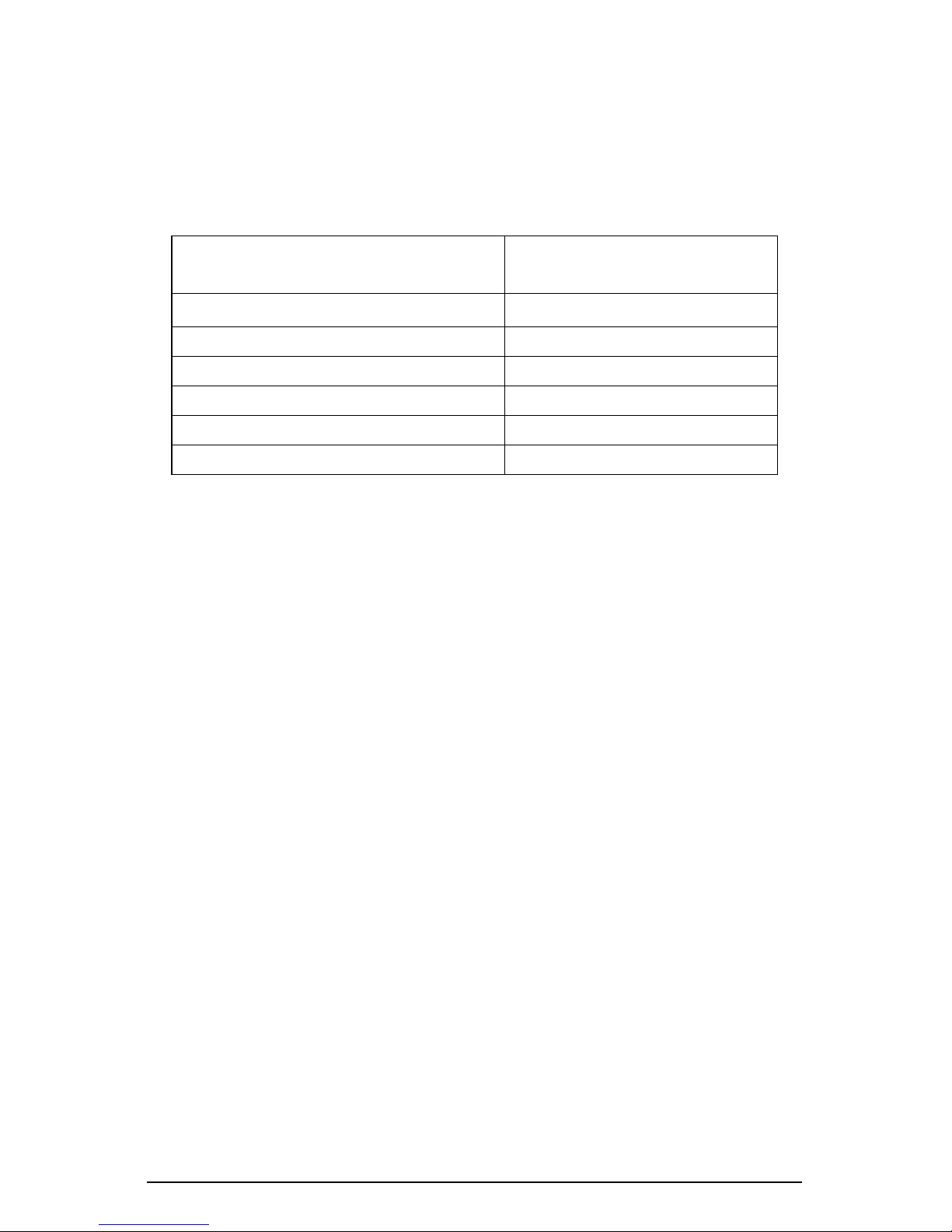

Figures 8 to 10 show the components of the Giatec iCOR® measurement

device.

Figure 8. Giatec iCOR

®

- Top view

1. Notification LED

2. ON/OFF button

3. Handle

Figure 9. Giatec iCOR

®

- Side view

1. Charging/Half-Cell connection terminal

2. Corrosion measurement electrodes

3. Half-cell potential measurement electrode

1

1

2

3

2

3

iCOR® User Manual

© Giatec Scientific Inc. 14

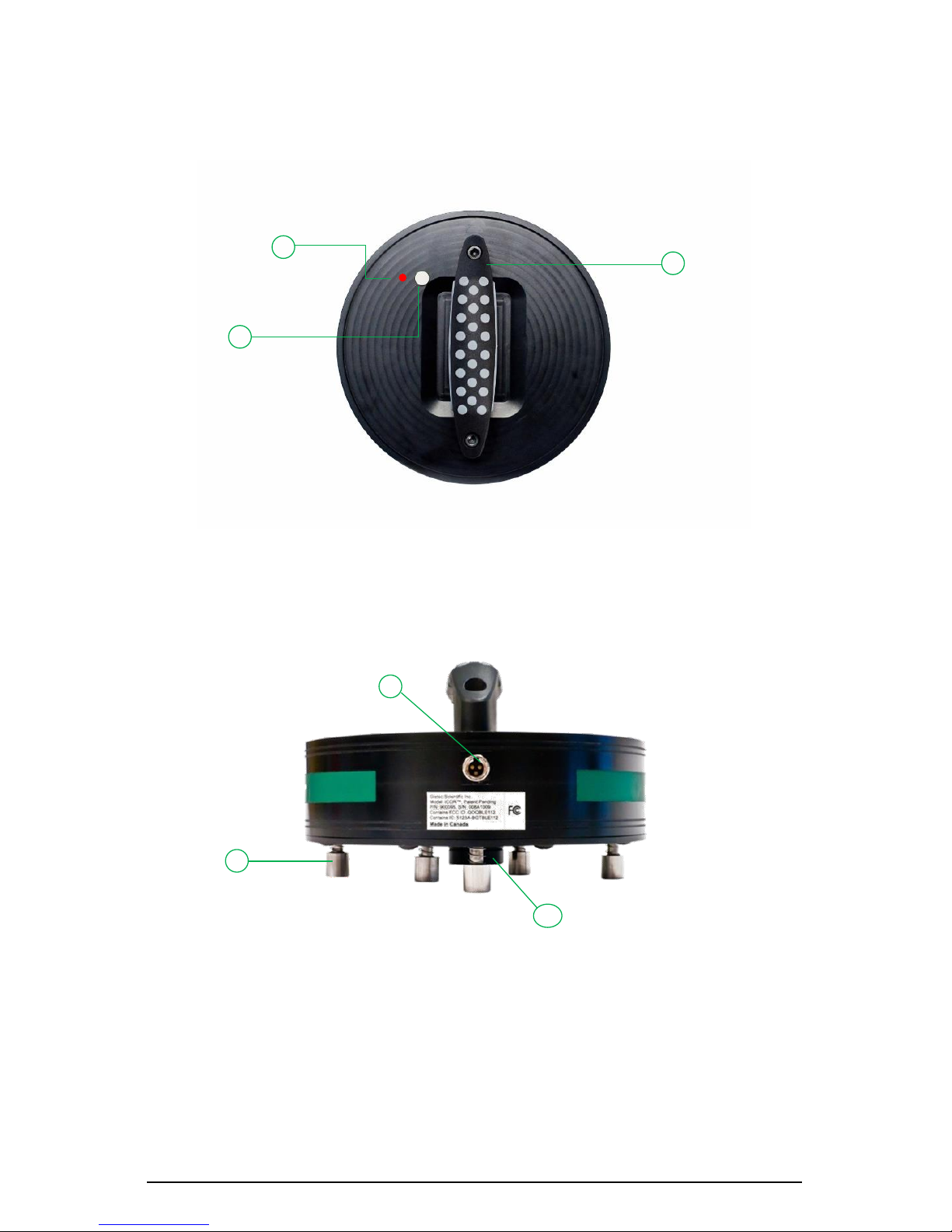

Figure 10. Giatec iCOR – Bottom view

1. Corrosion measurement electrodes

2. Half-cell potential measurement electrode

3. RH/ Temperature sensor inlet

NOTES

• There is a fixed electrochemical potential difference between the

Ag/AgCl electrode (that is used in iCOR®) and the Cu/CuSO4

electrode. The iCOR® software accounts for this difference and

presents the results in mV/CSE (i.e., Cu/CuSO4 Electrode, CSE) as

per ASTM C876.

• The reference electrode used in the measuring device has a

temperature coefficient of -0.65 mV per °C for the temperature

range between 0 to 50 °C. If the temperature compensation mode is

selected in the Giatec iCOR® software, the results are modified and

presented for 25°C.

The Giatec iCOR® half-cell potential measurement unit is equipped

with a maintenance-free electrode. It is not required to refill or

refresh the electrolyte of the electrode.

1

2

3

Loading...

Loading...