Giant Factories UG50-65(-59), UG50-65, UG50-59 Owner's Manual Installation And Operating Instructions

RESIDENTIAL POWER VENT GAS-FIRED WATER HEATERS

ISO 9001

ENREGISTRÉ

ISO 9001

REGISTRED

(EQUIPPED WITH FVIR TECHNOLOGY)

OWNER’S MANUAL

INSTALLATION AND OPERATING INSTRUCTIONS

UG50-65(-59) Model

This water heater IS NOT design certified for

installation in a manufactured (mobile) home or

for installation outdoors.

If the information in these instructions is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury, or death.

DO NOT store or use gasoline or other

flammable vapours and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

•DO NOT try to light any appliance.

•DO NOT touch any electrical switch,

DO NOT use any phone in your building.

•From a neighbour’s phone, immediately

call your gas supplier. Follow the gas

supplier’s instructions.

•If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by

a qualified installer, service agency, or the gas

supplier.

IMPORTANT

READ THESE INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION. PROPER

INSTALLATION WILL PROVIDE SAFE AND EFFICIENT SERVICE, AND AVOID NEEDLESS EXPENSE NOT

COVERED BY THE WARRANTY. READ THE PRODUCT WARRANTY CONTAINED IN THIS MANUAL AND

REMEMBER TO FILL OUT AND RETURN TO THE MANUFACTURER ALL RELEVANT WARRANTY CARDS

AND CERTIFICATES. SHOULD YOU HAVE ANY QUESTIONS, PLEASE CONTACT YOUR LOCAL DEALER

OR REFER TO THE GETTING SERVICE FOR YOUR WATER HEATER SECTION OF THIS MANUAL.

SAVE THIS MANUAL FOR FUTURE REFERENCES.

For your records, write the model and serial number here:

Model # ________________________________

Serial # _________________________________

54000012

© 2012 Giant Factories Inc. Printed in Canada GI-IM015En-1112

TABLE OF CONTENTS

Safety Information ............. 3

Installation Instructions

Location ................ 4

Minimum Clearances .......... 4

Combustion and Ventilation Air Supply .. 4

Requirements for Unconfined Spaces ... 5

Requirements for Confined Spaces .... 5

Louvers and Grilles ........... 6

Corrosive Atmospheres ......... 6

Venting ................. 7

Through-the-Wall Venting Installation ... 7

Through-the-Roof Venting Installation ... 8

Condensation in the Venting System ... 8

Installation of the venting system ..... 8

Water Piping .............. 8

Temperature & Pressure-Relief Valve .. 10

Pressure Build-up in a Water System .. 11

Filling the Water Heater ........ 11

Gas Connections ........... 11

Installation Instructions for

Water Heaters Approved for Space

Heating and Potable Water Heating . 12

.......... 4

Wiring ................ 12

Installation Checklist .......... 14

Operating Instructions

Lighting the Water Heater ....... 15

Water Temperature Regulation ..... 16

Out of Fuel .............. 17

General Maintenance

Housekeeping ............. 17

Safety System ............. 17

Condensation ............. 17

Burner Ignitor Assembly ........ 18

Water Heater Tank ........... 18

Temperature and Pressure-Relief Valve . 18

Venting System Inspection ....... 18

Anode rods .............. 18

Draining the Water Heater ....... 18

Vacation ................ 19

Getting Service for your Water Heater .. 19

Replacement Parts

Troubleshooting Guide

Warranty

................. 24

.......... 15

........... 17

............ 20

.......... 21

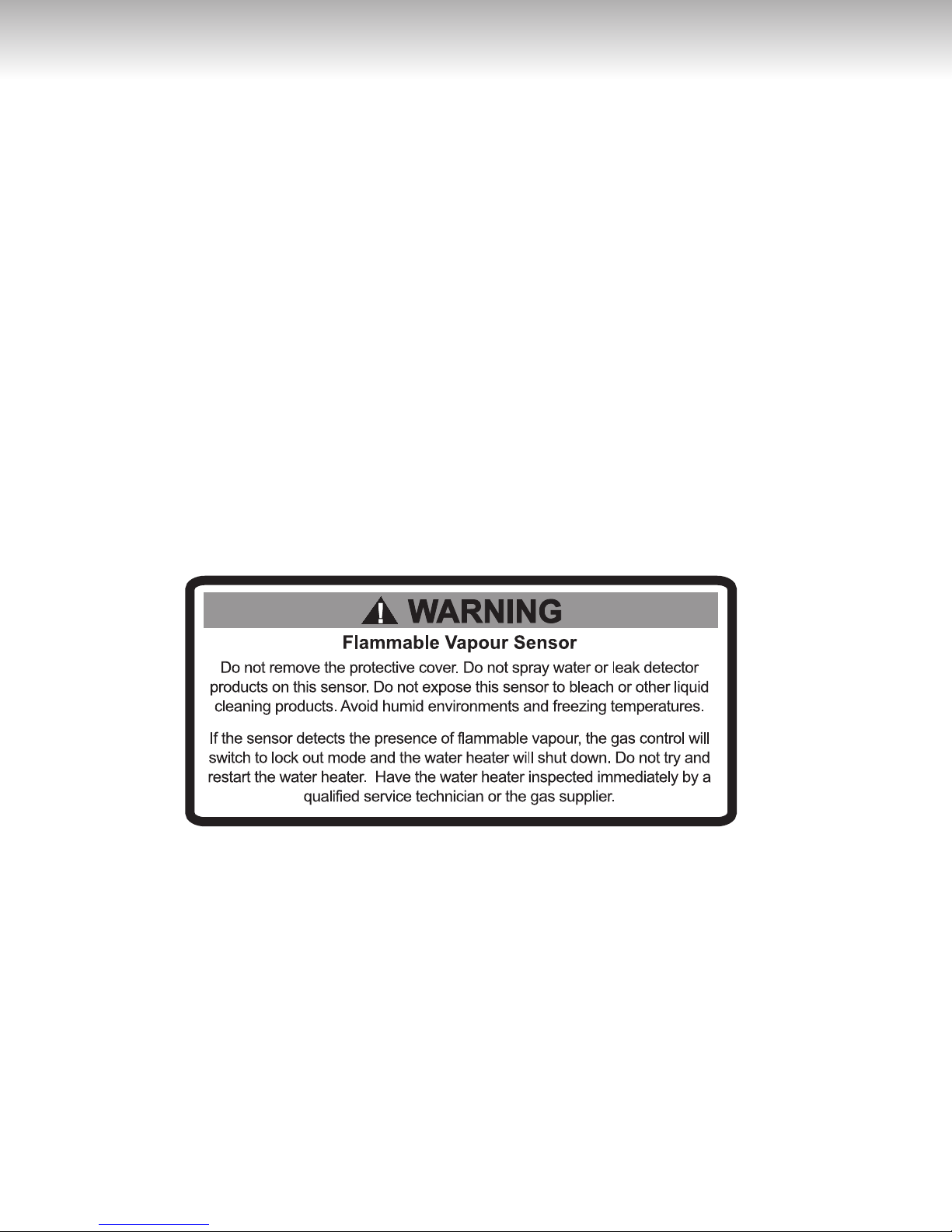

FVIR technology equipped with a flammable vapour sensor and the flame arrestor

This water heater is equipped with new FVIR technology. Activation of the FVIR technology occurs when

flammable vapours are drawn into the water heater. If the flammable vapour sensor detects the presence of

flammable vapours when the water heater is operating, the gas control will switch to lock out mode and the

water heater will shut down. If the water heater is not operating when the flammable vapours are detected, the

control will switch to lock out mode and prevent the water heater from lighting. If the flammable vapours enter the

combustion chamber and ignite, the flame arrestor will prevent these combustible vapours from igniting outside

of the water heater.

If flammable vapours are detected:

•DO NOT try to light any appliance.

• DO NOT touch any electrical switch, DO NOT use any phone in your building.

•From a neighbour’s phone, immediately call your gas supplier. Follow the gas supplier’s instructions.

•Ifyoucannotreachyourgassupplier,callthefiredepartment.

After the flammable vapours have been evacuated, contact a qualified service technician or the gas supplier to

have the water heater inspected immediately. Replacement of an FVIR technology equipped water

heater due to a flammable vapour shutdown is not covered under the terms of the Standard

Basic Limited Warranty.

2

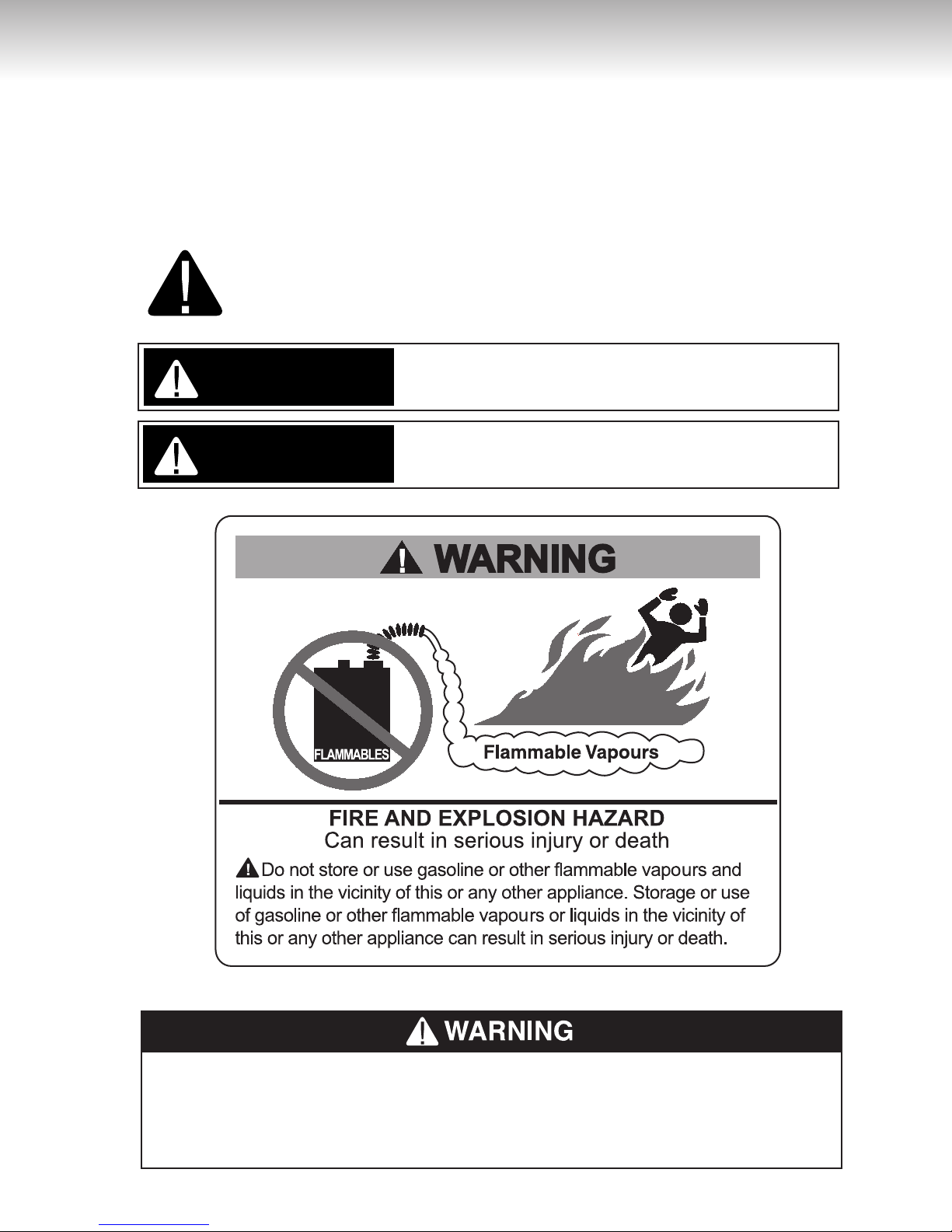

SAFETY INFORMATION

WARNING

Your safety and the safety of others is extremely important during the installation, operation, and servicing of this water heater. Many safety-related messages have been provided

in this manual and on your water heater. Always read and obey all safety messages. These

messages will point out the potential hazard, tell you how to reduce the risk of injury, and tell

you what will happen if the instructions are not followed.

This is the safety alert symbol. This symbol alerts you to potential hazards

that can kill or hurt you and others. All safety messages will follow the safety

alert symbol and either the word “DANGER” or “WARNING”.

Serious injury or death can occur if you do not

DANGER

WARNING

follow the instructions immediately.

Serious injury or death can occur if you do not

follow the instructions.

DO NOT use this water heater if any part has been under water. Immediately call a

qualified service technician to inspect the water heater and to replace any part of the

control system and any gas control which has been under water. Failure to follow this

instruction can result in property damage, personal injury, or death.

3

INSTALLATION INSTRUCTIONS

IMPORTANT

These instructions have been written as a guide for the proper installation and operation of your water heater,

and the manufacturer of this water heater will not accept any liability where these instructions have not been followed. However, for your safety and to avoid damage caused by improper installation, this water heater must be

installed by a Certified Licensed Professional, and meet all local codes or, in the absence of local codes, CAN/

CSA B149.1, Natural Gas and Propane Gas Installation Code, in Canada, and/or the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, in the United States.

Before proceeding with the installation instructions:

1)

Inspect the water heater and its component parts for possible damage. DO NOT install or attempt to

repair any damaged component parts. If you detect any damage, contact the dealer where the water

heater was purchased or the manufacturer listed on the warranty card.

Verify that the type of gas being supplied corresponds to that which is marked on the rating plate and gas

2)

control valve of the water heater.

Location

This water heater should be located close enough to the

outside wall so that it is within the venting requirements

listed in these installation instructions and as close as

possible to the main use of hot water. This location must

not be subject to freezing temperatures. The water

heater should be positioned, so that there is easy

access to the burner, gas control valve, and drain

valve. It must be located close to a suitable free-flowing floor drain. Where a floor drain is not adjacent to

the water heater, a suitable drain pan must be installed

under the water heater (see Figure 10). This drain pan

should be at least four (4) inches (10.2 cm) larger than

the diameter of the water heater, and at least one

(1) inch (2.5 cm) deep, providing access to the drain

valve. This pan must not restrict the flow of ventilation

and combustion air. This pan must be piped to a suitable drain to prevent damage to property in the event

of a water leak from the piping, the relief valve, or the

water heater.

Sooner or later, all water heaters leak. The

manufacturer, based on national building codes,

has given the necessary instructions to prevent

damage to the building. Under no circumstances

is the manufacturer to be held liable for any water

damage, in connection with this water heater.

This water heater is approved for installation on either a

combustible or non-combustible floor. However, should

this water heater be installed directly on carpeting, the

carpeting must be protected by a wood or metal panel

beneath the water heater. This panel must extend at

least three (3) inches (7.6 cm) beyond the width and

depth of the water heater. Should the water heater be

installed in an alcove or closet, the entire floor area

must be covered by the panel.

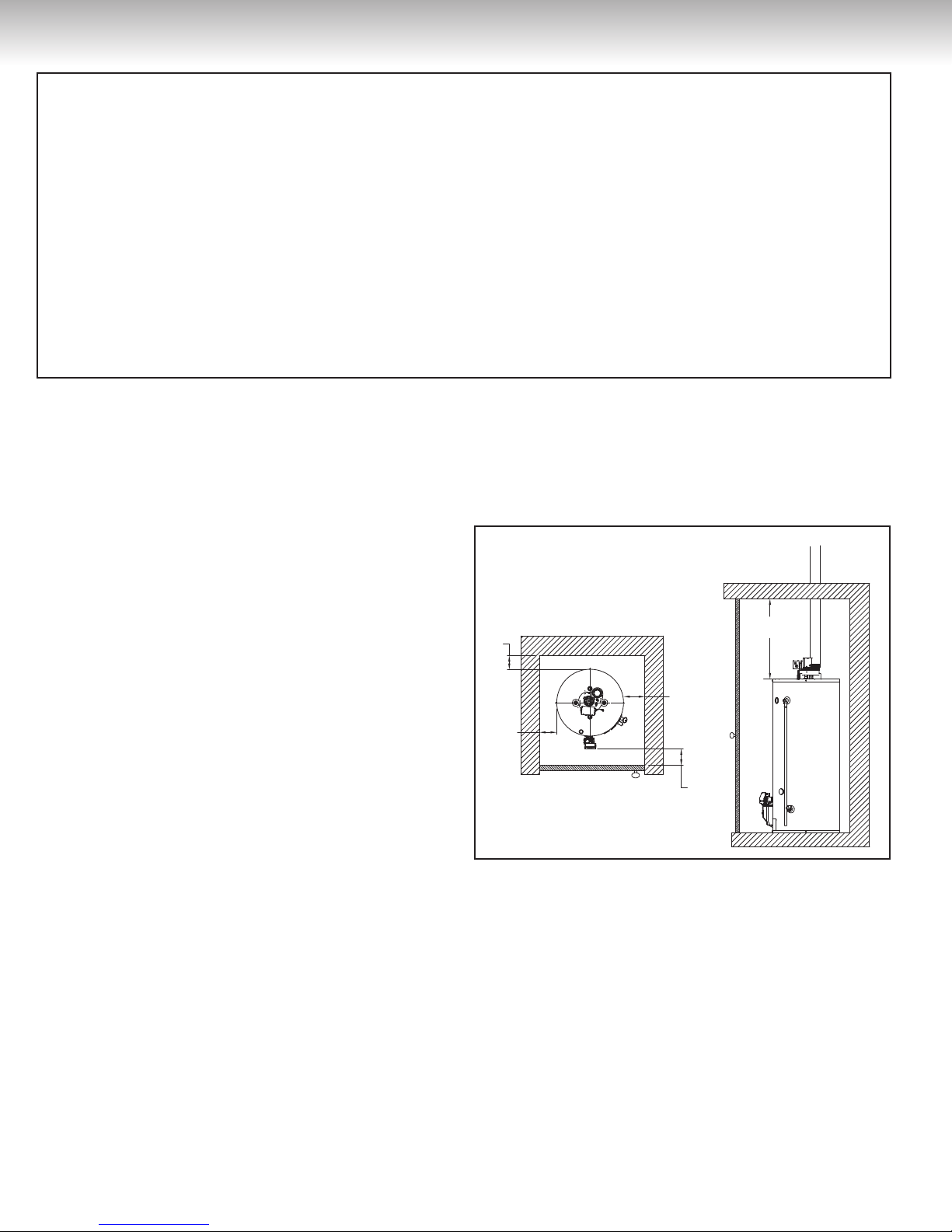

Minimum Clearances

The minimum clearances from combustible material

for this water heater are: Two (2) inches (5.1 cm) from

the sides and rear, four (4) inches (10.2 cm) from the

front, and eighteen (18) inches (45.7 cm) from the top

(see Figure 1).

Figure 1

18''

2''

min.

2''

min.

2''

min.

4''

min.

Combustion and Ventilation Air Supply

In order for the water heater to operate properly, it

must be supplied with an uninterrupted flow of clean

combustion and ventilation air. The area around the

water heater must always be kept clear and the combustion air intake holes at the bottom of the water

heater must never be blocked. An inadequate supply

of air to the water heater will produce a bright yellow

burner flame causing sooting in the combustion chamber, on the burner, and in the flue tube. This can result

in damage to the water heater and serious bodily

injury, if not corrected.

min.

4

INSTALLATION INSTRUCTIONS

Confined Space

Inlet air duct

18''

24''

Combustion and ventilation air requirements are determined by where the water heater is to be located.

Water heaters are installed in either open (unconfined)

spaces or smaller (confined) spaces, such as closets

or small rooms.

Requirements for Unconfined Spaces

An unconfined space is an area with at least 50 cubic

feet for each 1,000 BTUH (4.8 m

3

/kW) of the total

input rating for all gas appliances installed in that

space. Water heaters installed in unconfined spaces

do not usually require outdoor air to function properly.

However, in buildings with tight construction (heavy

insulation, vapour barriers, weather stripping, etc.),

and particularly in modern buildings, additional fresh

air may need to be provided. For instructions on

obtaining additional air supply, see the requirements

below for confined spaces.

Requirements for Confined Spaces

A confined space is an area where the volume is less

than 50 cubic feet for each 1,000 BTUH (4.8 m3/kW) of

the total input rating for all gas appliances installed in

that space. Water heaters installed in confined spaces

require additional air. This can be provided in two ways:

In Canada (refer to CAN/CSA B149.1)

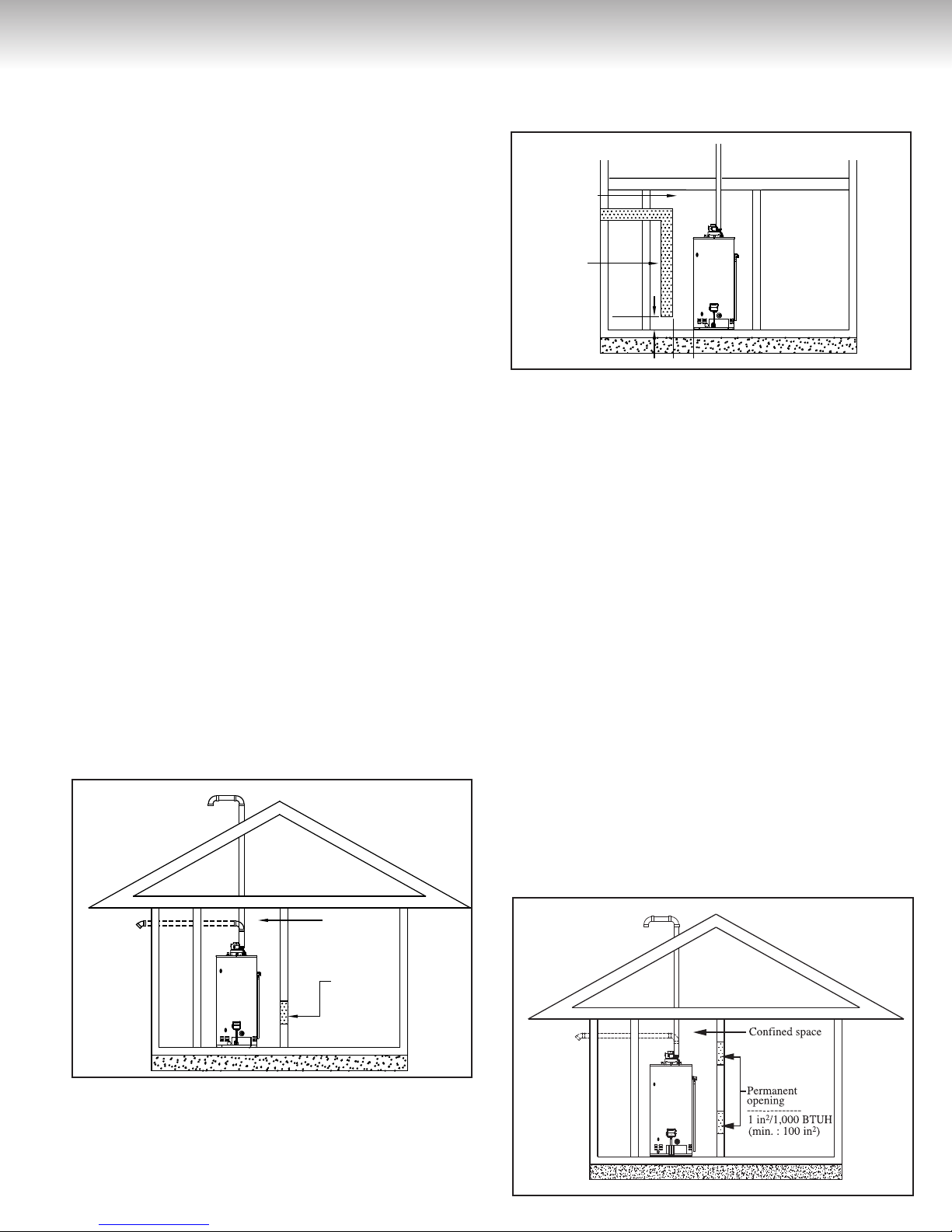

All Air From Inside the Building (see Figure 2):

1)

The confined space shall be provided with

one opening of one (1) square inch per 1,000 BTUH

(22.0 cm2/kW) communicating directly with one or

more rooms of sufficient volume, so that the combined volume of all spaces meets the criteria for an

unconfined space for all the appliances installed in

that confined space.

Figure 2

within two (2) feet horizontally from the burner level of

the appliance having the largest input.

Figure 3

Confined Space

Inlet air duct

18''

24''

In U.S.A. (refer to ANSI Z223.1/NFPA 54)

1) All Air From Inside the Building (see Figure 4):

The confined space shall be provided with two per-

manent openings communicating directly with one or

more rooms of sufficient volume, so that the combined

volume of all spaces meets the criteria for an unconfined space. The total input rating of all gas appliances

installed in the combined space shall be considered in

making this determination.

Each opening shall have a minimum free area of one

(1) square inch per 1,000 BTUH (22.0 cm2/kW)

total input rating of all gas appliances in the confined

space, but not less than 100 square inches (645,16

cm2). One opening shall commence within six (6) inches

(15.2 cm) of the top and one within six (6) inches (15.2

cm) of the bottom of the enclosure.

2) All Air From Outdoors:

The confined space shall be provided with two perma-

nent openings, one commencing within six (6) inches

(15.2 cm) of the top and one commencing within six (6)

inches (15.2 cm) from the bottom of the enclosure.

The openings shall communicate directly or by ducts,

with the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

of the

All Air From Outdoors: (see Figure 3):

2)

An air-supply shall be provided with one opening that

communicates directly with the outdoors by means of

a duct. This duct shall be sized according to CAN/CSA

B149.1 and terminate within one (1) foot above and

Confined Space

Permanent

Opening

-------------1 square inches /

1,000 BTUH

Figure 4

5

INSTALLATION INSTRUCTIONS

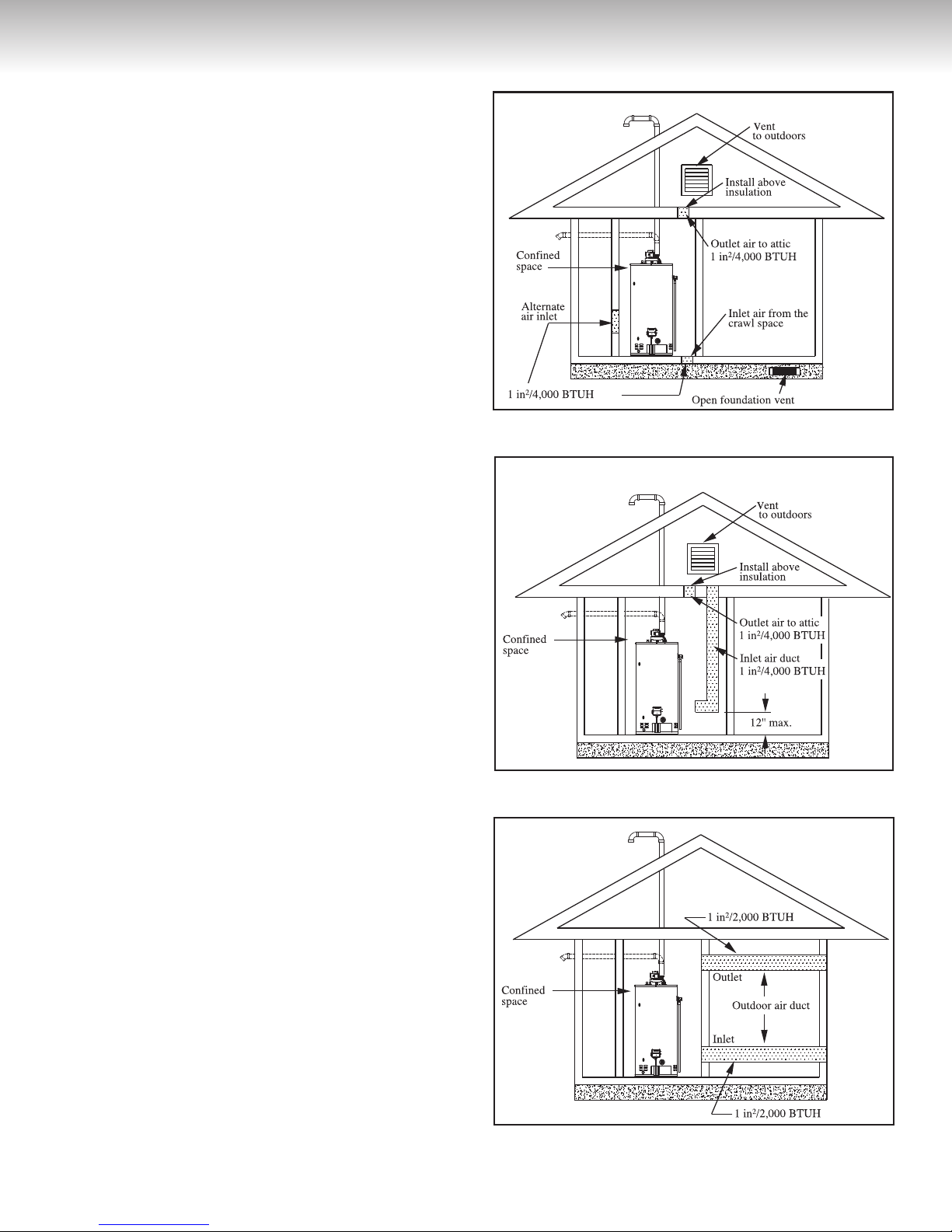

A) When communicating directly with the outdoors,

each opening shall have a minimum free area of one

(1) square inch per 4,000 BTUH (5.5 cm2/kW) of the

total input rating of all gas appliances in the enclosure

(see Figure 5).

B) When communicating with the outdoors through

vertical ducts, each opening shall have a minimum

free area of one (1) square inch per 4,000 BTUH

(5.5 cm2/kW) of the total input rating of all gas appliances in the enclosure (see Figure 6).

C) When communicating with the outdoors through

horizontal ducts, each opening shall have a minimum free area of one (1) square inch per 2,000

BTUH (11.0 cm2/kW) of the total input rating of

all gas appliances in the enclosure (see Figure 7).

When ducts are used, they shall be of the same

cross-sectional area as the free area of the openings to

which they connect. The minimum short side dimension

of rectangular air ducts shall not be less than three (3)

inches (7.62 cm).

Louvers and Grilles

In calculating free area for ventilation and combustion air supply openings, consideration must be

given to the blocking effect of louvers, grilles, or

screens protecting the openings. Screens must not

be smaller than 1/4 inch (6.4 mm) mesh. If the free

area through a particular design of louver or grille

is known, it should be used in calculating the size

of opening required to provide the free area specified. If the design and free area is not known, it may

be assumed that wood louvers and grilles will allow

20-25% free area and metal louvers and grilles will

allow 60-75% free area. Louvers and grilles must

be installed in the open position or interconnected with the water heater so that they are opened

automatically during water heater operation.

Figure 5

Figure 6

Figure 7

Corrosive Atmospheres

If this water heater is to be installed in a beauty shop,

barber shop, photo processing lab, dry cleaning

establishment, a building with an indoor pool, or

near a chemical storage area, it is imperative that

the combustion and ventilation air be drawn from

outside these areas. These particular environments

contain products such as aerosol sprays, detergents,

bleaches, cleaning solvents, refrige rants, and other

volatile compounds that, in addition to being highly

flammable, become highly corrosive acid compounds

when burned. Exposure to such compounds can be

hazardous and lead to premature product failure.

Should the water heater fail, due to exposure to

such a corrosive atmosphere, the warranty is void.

6

INSTALLATION INSTRUCTIONS

Venting

When installing the venting system, make sure to

follow all local codes or, in the absence of local

codes, CAN/CSA B149.1, Natural Gas and

Propane Gas Installation Code, in Canada, and/

or the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, in the United States. Never operate the

water heater unless it is properly ventilated to the

outdoors and has adequate air supply for proper

operation. Failure to properly install the venting

system could result in property damage, personal

injury, or death.

Before installing the vent piping, make sure that the

vent system layout has been properly planned. Verify

that the location of the water heater respects all

clearances from combustible material, all venting

requirements (see Table 1), and that the vent terminal

will be installed as specified by all local codes or, in

the absence of local codes, CAN/CSA B149.1, Natural

Gas and Propane Installation Code, in Canada, and/or

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, in

the United States (see Figure 9).

According to the CAN/CSA-B149, Natural Gas and

Propane Installation Code, plastic vent systems installed

in Canada must be certified to the STANDARD FOR

TYPE BH GAS VENTING SYSTEMS, ULC S636.

Components of the certified vent system must not be

interchanged with other vent systems or unlisted pipe/

fittings. Plastic components and specified primers and

glues of the certified vent system must be from a single

vent system manufacturer and not intermixed with other

vent system manufacturer’s vent system parts unless

those are certified to be used with this system. Plastic

vent systems shall also be installed such that the first

three (3) feet (91 cm) of pipe from the water heater outlet

is readily accessible for visual inspection.

Through-the-Wall Venting Installation

Cut or drill a hole through the exterior wall, slightly

larger than the diameter of the vent pipe selected. The

larger hole will allow for final alignment with the water

heater. Extend a section of pipe through the hole to

the outside and attach the terminating elbow to the

exterior end of the pipe. Connect and secure all piping

and elbows from the power venter to the wall. Make

sure that all horizontal runs have a minimum rise of 1/4

inch per foot (21 mm/m) of run (see Figure 8).

This water heater is equipped with a power venter

that evacuates the products of combustion to the

outdoors. All models are shipped from the factory

with the power venter already installed.

Figure 8

3'' min.

18'' min.

2" min.

This water heater must be vented directly to the outdoors, either horizontally through the wall or vertically

through the roof. The venting must not be attached to

an existing chimney, or in common with any other appliance, and must not be insulated. Only three (3) inch (7.6

18'' min.

1/4"/foot

(21mm/m)

cm) schedule 40 PVC or CPVC, pipe and fittings may

be used to vent this water heater. The pipe and all the

fittings must be permanently joined using the appropriate primer and solvent-based cement. Horizontal

runs of vent pipe must be supported every three (3)

feet (91 cm) and vertical runs of vent pipe must be

supported every five (5) feet (1.5 m).

Table 1

UG50-65(-59)

PIPE VENT DIAMETER 3 inch

Maximum length plus one 45o or 90o termination elbow 50.0 feet (15.2 m)

Minimum length plus one 90o elbow and plus one 45o termination elbow 2.5 feet (0.8 m)

One 45o radius elbow is equivalent, in straight pipe, to 4.0 feet (1.2 m)

One 90o radius elbow is equivalent, in straight pipe, to 7.0 feet (2.1 m)

MAXIMUM EQUIVALENT LENGTH OF PIPE — DO NOT EXCEED MAXIMUM LENGTH OF PIPE

7

INSTALLATION INSTRUCTIONS

When the installation is completed, the vent terminal

must be a minimum of two (2) inches (5.1 cm) from the

exterior surface of the wall (see Figure 8). Make sure

that all piping is properly braced. If the venting will

pass through an enclosed area, make sure to leave

at least one (1) inch (2.5 cm) clearance around the

piping for air circulation.

Through-the-Roof Venting Installation

Cut or drill a hole through the roof and ceiling, slightly

larger than the diameter of the vent pipe selected.

The larger hole will allow for final alignment with the

water heater. Construct the vent terminal assembly.

Extend a section of pipe through the hole in the roof

to the outside and attach the terminal assembly to the

exterior end of the pipe. Connect and secure all piping

and elbows from the power venter to the roof. Make

1

sure that all horizontal runs have a minimum rise of

inch per foot (21 mm/m) of run (see Figure 8). When

the installation is completed, the vent terminal must

be a minimum of eighteen (18) inches (45.7 cm) from

the exterior surface of the roof (see Figure 8). Make

sure that all piping is properly braced. If the venting

will pass through an enclosed area, make sure to

leave at least one (1) inch (2.5 cm) clearance around

the piping for air circulation.

Condensation in the Venting System

In some installations, condensation will form in the

horizontal runs of vent piping. To prevent condensation from flowing back into the power venter, install a

condensate trap just past the first elbow of the vent

piping system. Make sure that the condensate removal tube flows to a suitable free-flowing drain.

Installation of the venting system

ALWAYS read and obey all safety messag-

es printed on the primer, cleaner, and cement

containers. Primer, cleaner, and cements are

extremely flammable. DO NOT store these products near heat, sparks, or flames. They are

harmful or fatal if swallowed. Their vapours are

also harmful. They may irritate eyes and can be

absorbed through the skin. Failure to follow these

instructions can result in property damage, personal injury, or death.

1) Adjust the vent pipe length to properly fit the vent system adaptor on the blower assembly outlet.

2) Cut pipe ends squarely, removing all burrs and dirt.

3) Dry fit the pipe/fitting to be connected to make sure

they fit properly.

4) Clean the pipe/fitting with the proper primer or cleaner.

/4

5) Apply a thin coat of cement to the fitting, avoiding puddling inside.

6) Apply a liberal coat of cement to the vent pipe, leaving

no voids.

7) QUICKLY assemble parts while cement is fluid! If you

wait too long, re-coat pipe/fitting.

8) Push the vent pipe completely into the PVC coupling,

turning as it goes until it bottoms out.

9) Hold pipe and fitting together for 30 seconds. Then

carefully clean off any excess material with a cloth.

Allow connections a sufficient time to cure before disturbing.

10) Loosen the upper hose clamp on the rubber transition fitting and fully insert the CPVC pipe of the vent

system adaptor (1.25” deep). Do not apply cement to

the rubber transition fitting.

11) Tighten the upper hose clamp to ensure the vent pipe

is firmly secured and gas tight.

12) Make sure that the lower hose clamp is firmly seated,

secured and gas tight. Gently move the vent pipe side

to side and vertically to ensure that it is securely in

place and that there is no slippage.

When the installation is complete, visually inspect the

venting system to make sure that all joints are properly connected and all instructions have been followed.

Failure to properly install the venting system could

result in property damage, personal injury, or death.

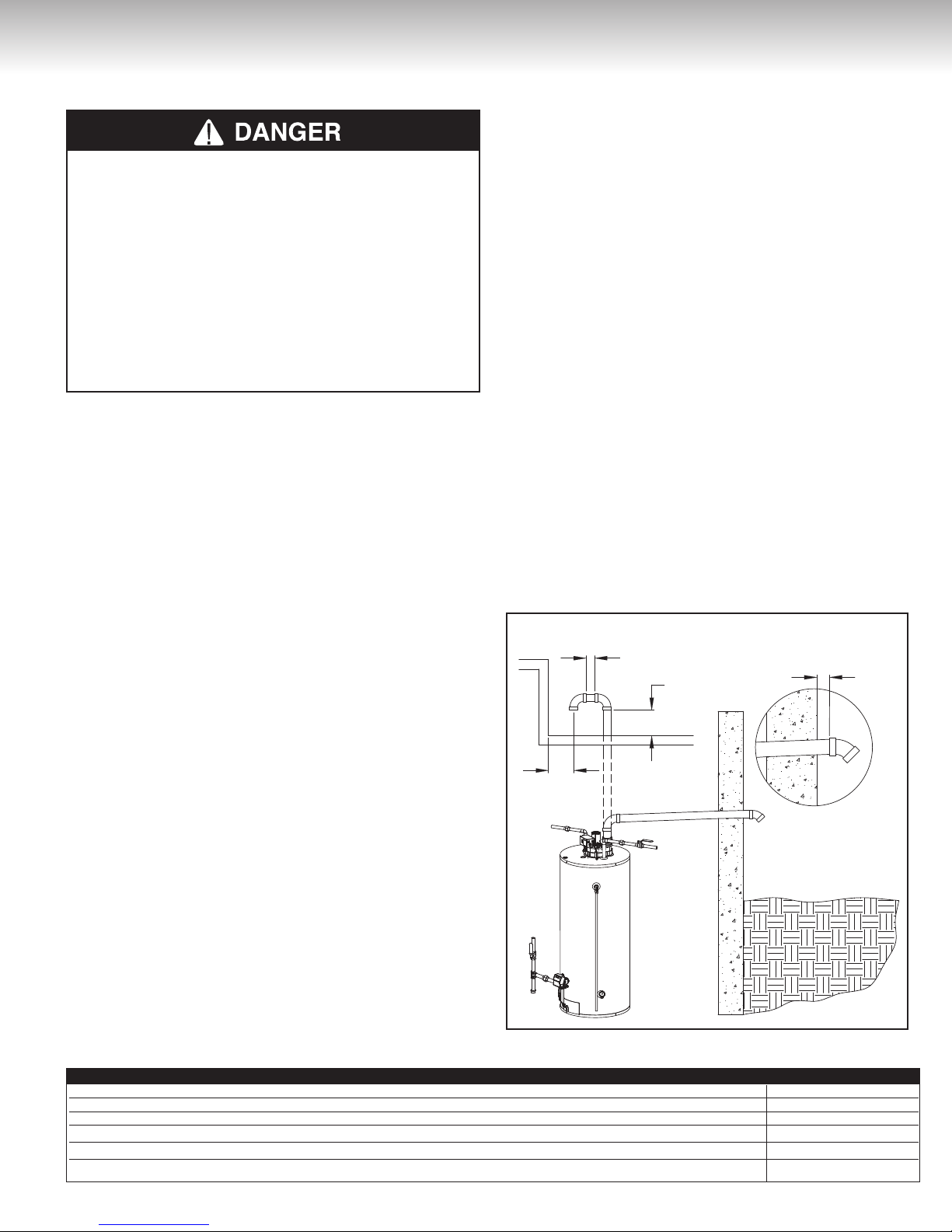

Water Piping

Refer to Figure 10 for a typical installation. Use of this

layout should provide a trouble-free installation for the

life of the water heater. Before making the plumbing

connections, locate the COLD water inlet and the

HOT water outlet. These fittings are both 3/4” N.P.T.

male thread. Make sure that the dip-tube is installed in

the cold water inlet. Install a shut-off valve close to the

water heater in the cold water line. It is recommended

that unions be installed in the cold and hot water lines

so that the water heater can be easily disconnected,

if servicing is required.

When assembling the hot and cold piping, use a

good food grade of pipe joint compound, and ensure

all fittings are tight. It is imperative that open flame is

not applied to the inlet and outlet fittings, as heat will

damage or destroy the plastic-lined fittings. This will

result in premature failure of the fittings, which is

not covered by the warranty.

8

Loading...

Loading...