Giant Factories ANSI Z21.10.3, UGTC-152N, CSA 4.3, UGTC-152P, UGTC-199N Owner's Manual

...

DIRECT VENT TANKLESS WATER HEATERS

R

WARNING

CAUTION

OWNER’S MANUAL

INSTALLATION AND OPERATING INSTRUCTIONS

FOR INDOOR

APPLICATIONS ONLY

UGTC-199N

UGTC-199P

UGTC-152N

UGTC-152P

If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage,

personal injury, or death.

DO NOT

liquids in the vicinity of this or any other appliance.

store or use gasoline or other flammable vapors and

WHAT TO DO IF YOU SMELL GAS:

•

DO NOT

•

DO NOT

•

DO NOT

From a neighbor’s phone, immediately call your gas sup-

•

plier.

• If you cannot reach your gas supplier, call the fire department

Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

try to light any appliance.

touch any electrical switch.

use any phone in your building.

Follow the gas supplier’s instructions.

.

ANSI Z21.10.3 • CSA 4.3

READ ALL OF THE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR OPERATING THIS WATER HEATER.

THIS MANUAL PROVIDES INFORMATION ON THE INSTALLATION, OPERATION, AND MAINTENANCE OF THE

WATER HEATER. FOR PROPER OPERATION AND SAFETY IT IS IMPORTANT TO FOLLOW THE INSTRUCTIONS

AND ADHERE TO THE SAFETY PRECAUTIONS. A LICENSED PROFESSIONAL MUST INSTALL THE WATER

HEATER ACCORDING TO THE EXACT INSTRUCTIONS. THE CONSUMER MUST READ THE ENTIRE MANUAL

TO PROPERLY OPERATE THE WATER HEATER AND TO HAVE REGULAR MAINTENANCE PERFORMED.

For your records, write the model and serial number

here:

Model # _________________________________________

Serial # _________________________________________

© 2015 Giant Factories Inc. Printed in Canada

IMPORTANT

R

R

GI-IM045En-1015

TABLE OF CONTENTS

WARNING

CAUTION

DANGER

WARNING

CAUTION

CAUTION

Safety Information .................................2

Safety Behaviors ..................................3

Installation Instructions .............................4

Installer Qualifications ............................ 4

General Instructions .............................. 4

Determine Installation Location ..................... 5

Vent Termination Clearances ....................... 6

Additional clearances ............................. 7

Unit clearances .................................. 8

Freeze Protection ................................ 8

Maximum vent length ............................. 8

Checklist to Determine Installation Location ............ 9

Mount to Wall ................................... 9

Remove the Front Panel ........................... 9

Installation of Venting ............................ 10

Venting Guidelines .............................. 10

Flue Installation with Centrotherm Venting ............ 12

Condensate .................................... 12

Checklist for Venting and Condensate ............... 13

Twin Pipe Venting Guide ...........................13

Installation Instructions .......................... 14

Determine Installation Location .................... 15

Determining Vent Length ......................... 15

Adaptor Installation .............................. 19

Certified PVC/CPVC Vent Termination Options ......... 20

Acceptable Venting Clearances For IPEX Concentric

Vent Kit (CVK) Termination ........................ 22

Venting Installation Sequence ...................... 23

Twin Pipe (PVC/CPVC) Terminations ................ 24

PVC/CPVC Roof (Tee and upside down “U”)

Terminations ................................... 25

NOTE:

Giant sometimes shares customer contact information with businesses that we believe provide products or services that may be

useful to you. By providing this information, you agree that we can share your contact information for this purpose. If you prefer not to

have your information shared with these businesses, please contact customer service and ask not to have your information shared. We will

however, continue to contact you with information relevant to the product(s) you registered and/or you account with us. Should you have

any questions or feel that the manual is incomplete, please contact Giant at 1-800-363-9354.

Installation Instructions (continued) ..................28

Installation of Plumbing .......................... 29

Connect Water Heater to Water Supply ............... 29

Checklist for Plumbing ........................... 29

Installation of Gas Supply ......................... 31

General Instructions ............................. 31

Connect Electricity .............................. 32

Adjust for High Altitude (United States) .............. 32

Adjust for High Altitude (Canada) ................... 32

Adjust for Vent Length ........................... 33

Checklist for Gas and Electricity .................... 33

Installation of Temperature Controller ............... 33

Final Installation Checklist ........................ 34

Technical Data ...................................35

Specifications .................................. 35

Dimensions .................................... 36

Recirculation Mode .............................. 38

Wiring Diagram ................................. 40

Operating Instructions .............................41

Consumer Operation Guidelines for the

Safe Operation of your Water Heater ................ 41

How to Use the Temperature Controller .............. 42

How to Set the Temperature ....................... 42

Troubleshooting Guide ............................44

Diagnostic Codes and Remedies .................... 44

System Maintenance ..............................46

Flushing the Heat Exchanger ....................... 47

Manual Draining of the Water Heater ................ 48

Running a low volume of water through the water heater

to prevent freezing .............................. 48

When the water heater or external piping has frozen .... 48

Regulations ......................................49

Warranty ........................................50

SAFETY INFORMATION

Your safety and the safety of others is extremely important during the installation, operation, and servicing of this water heater. Many safety

related messages have been provided in this manual and on your water heater. Always read and obey all safety messages. These messages

will point out the potential hazard, tell you how to reduce the risk of injury, and tell you what will happen if the instructions are not followed.

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and others.

Indicates an imminently hazardous situation which, if not avoided, will result in serious injury

or death.

Indicates a potentially hazardous situation which, if not avoided, could result in serious injury

or death.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury. It may also be used to alert against unsafe practices.

2

SAFETY BEHAVIORS

CAUTION

WARNING

CAUTION

WARNING

CAUTION

• Before operating, smell all around the appliance area for gas.

Be sure to smell next to the floor because some gas is heavier

than air and will settle on the floor.

• Keep the area around the appliance clear and free from combustible materials, gasoline, and other flammable vapors and

liquids.

• Combustible construction refers to adjacent walls and ceiling

and should not be confused with combustible or flammable

products and materials. Combustible and/or flammable products and materials should never be stored in the vicinity of this

or any gas appliance.

• Always check the water temperature before entering a shower

or bath.

• To protect yourself from harm, before performing maintenance:

* Turn off the electrical power supply by unplugging the

power cord or by turning off the electricity at the circuit

breaker. (The temperature controller does not control

the electrical power.)

* Turn off the gas at the manual gas valve, usually located

immediately below the water heater.

* Turn off the incoming water supply. This can be done at

the isolation valve immediately below the water heater

or by turning off the water supply to the building.

• Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

do not try to repair it; call a licensed professional. Force or attempted repair may result in a fire or explosion.

• Do not use this appliance if any part has been under water.

Immediately call a licensed professional to inspect the appliance and to replace any part of the control system and any gas

control which has been under water.

• Do not use substitute materials. Use only parts certified with

the appliance.

• Should overheating occur or the gas supply fail to shut off, turn

off the manual gas control valve to the appliance.

• Do not adjust the DIP switch unless specifically instructed to

do so.

• Do not use an extension cord or an adapter plug with this appliance.

• Any alteration to the appliance or its controls can be dangerous

and will void the warranty.

• BURN HAZARD. Hot exhaust and vent may cause serious

burns. Keep away from the water heater unit. Keep children and

animals away from the unit.

California law requires this notice to be provided:

California Proposition 65

productive harm. This product may contain such substances, be their origin from fuel combustion (gas, oil), or components of the product

itself.

If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage, personal injury, or death.

lists chemical substances known to the state to cause cancer, birth defects, death, serious illness, or other re-

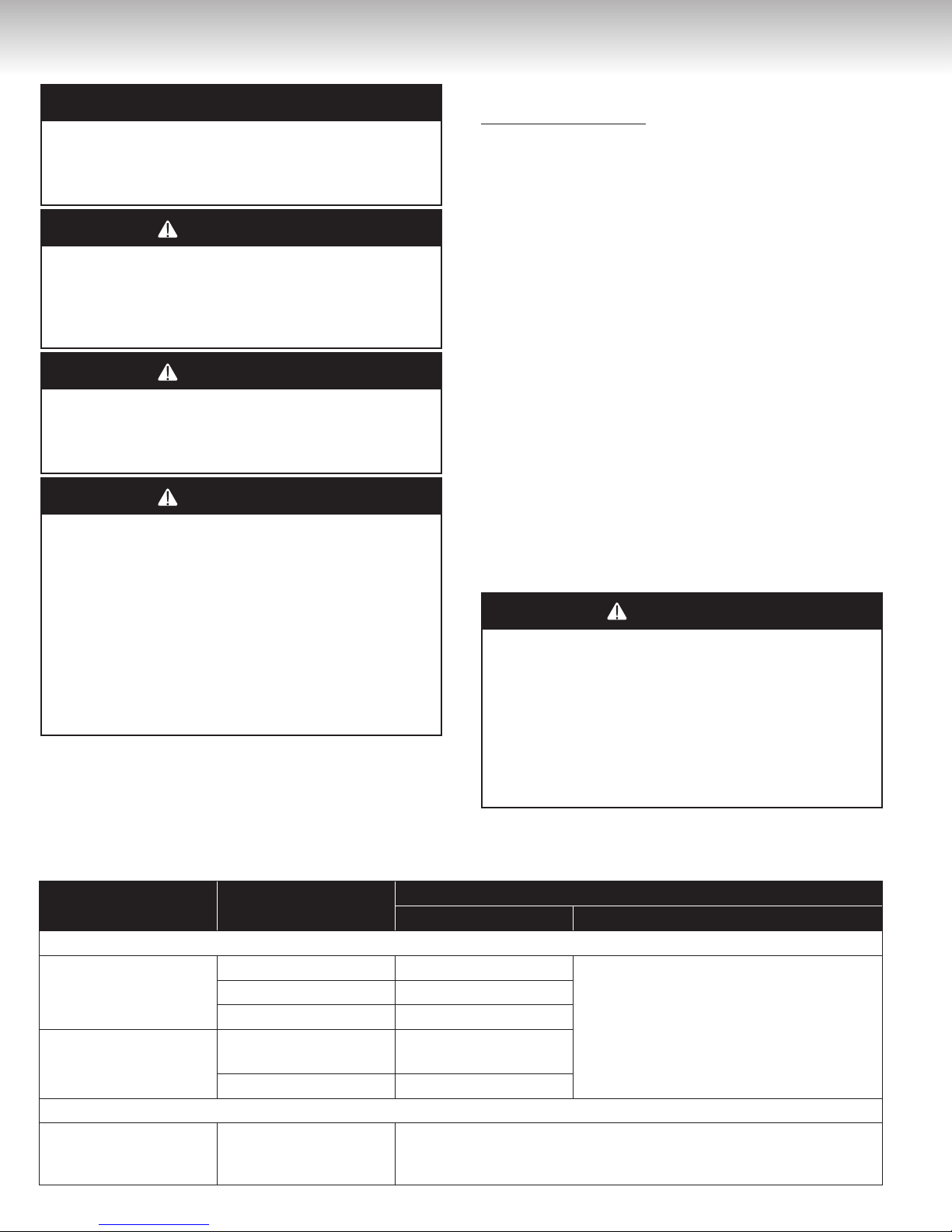

Hot water can be dangerous, especially for infants or children, seniors, or disabled people. There is hot

water scald potential if the thermostat is set too high.

Water temperatures over 125ºF (52ºC) can cause severe burns or scalding resulting in death.

Hot water can cause first degree burns with exposure for as little as:

Three (3) seconds at 140ºF (60ºC)

Twenty (20) seconds at 130ºF (54ºC)

Eight (8) minutes at 120ºF (49ºC)

Test the temperature of the water before placing a child in the bath or shower.

• Hot water outlet pipes leaving the unit can be hot to touch. In

residential applications, insulation must be used for hot water

pipes below thirty-six (36) inches (91.4 cm) due to burn risk

to children.

3

Installer Qualifications

A licensed professional must install, inspect, and leak test the

appliance before use. The warranty will be voided due to improper

installation.

The installer should have skills such as:

• gas sizing

• connecting gas lines, water lines, valves, electricity

• knowledge of applicable national, provincial, and local codes

• installing venting through a wall or roof

If you lack these skills, contact a licensed professional.

Type of installation

• For installation in residential and commercial applications.

• You must follow the installation instructions for adequate combustion air intake and exhaust.

General Instructions

DO NOT

• Do not install the UGTC-152 or the UGTC-199 outdoors.

• Do not install the appliance in an area where water leakage of

the unit or connections will result in damage to the area adjacent

to the appliance or to lower floors of the structure. When such

locations cannot be avoided, it is recommended that a suitable

drain pan, adequately drained, be installed under the appliance.

The pan must not restrict combustion air flow.

• Do not obstruct the flow of combustion and ventilation air. Combustion air shall not be supplied from occupied spaces.

• Do not use this appliance in an application such as a pool or spa

heater that uses chemically treated water. (This appliance is suitable for filling large or whirlpool spa tubs with potable water.)

• Do not use substitute parts that are not authorized for this appliance.

MUST DO

• The installation must conform with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or the Natural Gas and Propane Installation

Code, CSA B149.1.

• When installed, the appliance must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.1.

• The appliance and its appliance main gas valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psi (3.5

kPa) (13.84 in W.C.).

• The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa) (13.84 in W.C.).

• You must follow the installation instructions for adequate combustion air intake and exhaust.

INFORMATION

• If a water heater is installed in a closed water supply system,

such as one having a backflow preventer in the cold water supply line, means shall be provided to control thermal expansion.

Contact the water supplier or local plumbing inspector on how

to control thermal expansion.

• Should overheating occur or the gas supply fail to shut off, turn

off the manual gas control valve to the appliance.

• Keep the air intake location free of chemicals such as chlorine

or bleach that produce fumes. These fumes can damage components and reduce the life of your appliance.

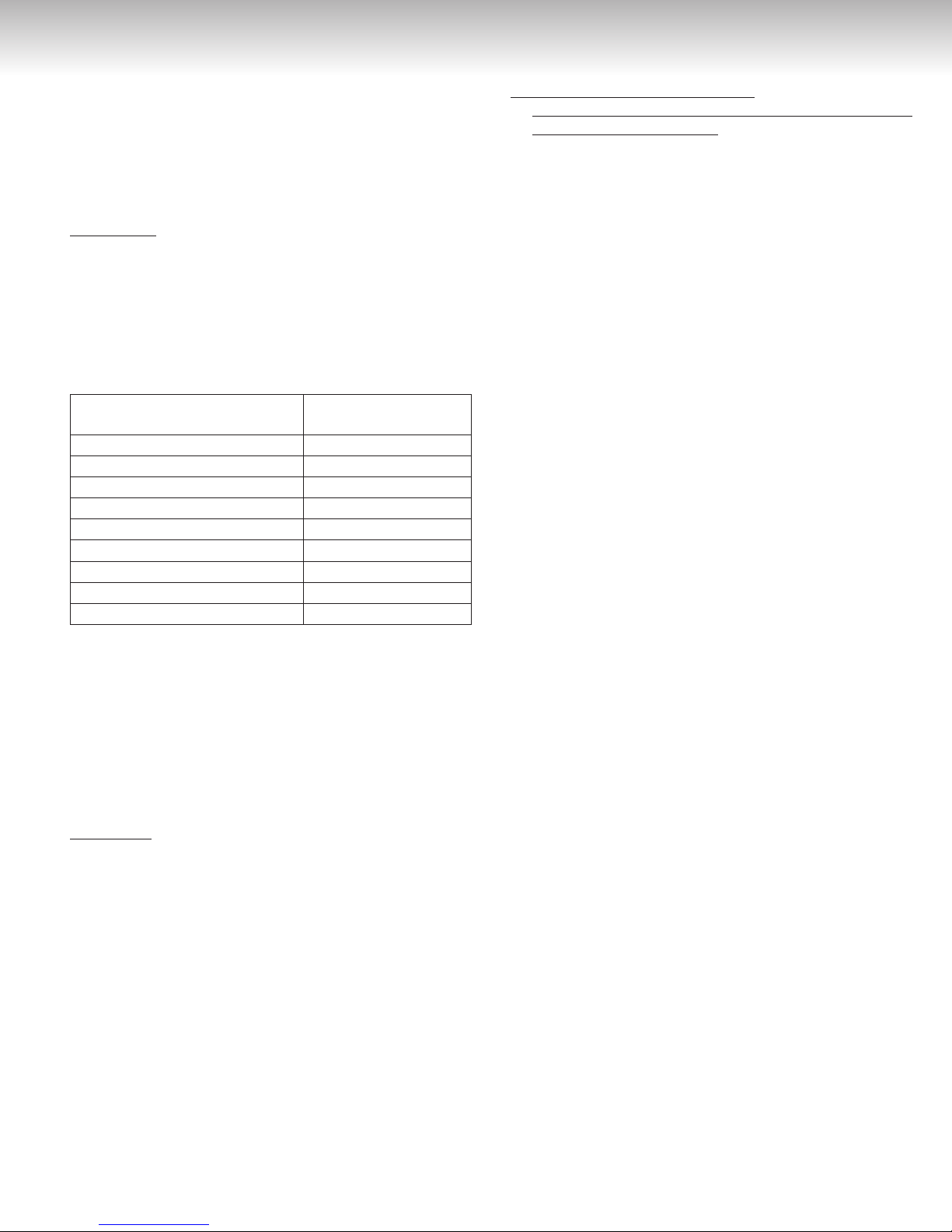

Table 1

Prepare for installation

Parts included

• Tankless water heater

Tools needed

• Pipe wrenches (2)

• Adjustable pliers

• Screwdrivers (2)

• Wire cutters

Tools that might be needed

• Hammer drill with

concrete bits

• Saw

• Threading machine with

heads and oiler

Materials needed

• Soap solution

• Approved venting

Materials that may be needed

• Heat tape

• Pipe insulation

• Electrical wire and conduit

per local code

• Concrete wall anchors

• Optional pipe cover

• Optional temperature

controller

• MC-91-2 temperature controller

(integrated into the front panel)

• Gloves

• Safety glasses

• Level

• Manometer

• Core drill with diamond head

• Torch set

• Copper tubing cutter

• Steel pipe cutter

• Teflon tape (recommended) or

pipe compound

• 5/8” ID PVC flexible tubing

• Two (2) conductor 22 AWG

wires for controller

• Single gang electrical box

• Wire nuts

• Unions and drain valves

4

INSTALLATION INSTRUCTIONS

Determine Installation Location

You must ensure that clearances will be met and that the vent

length will be within required limits. Consider the installation

environment, water quality, and need for freeze protection. Requirements for the gas line, water lines, electrical connection, and

condensate disposal can be found in their respective installation

sections of this manual.

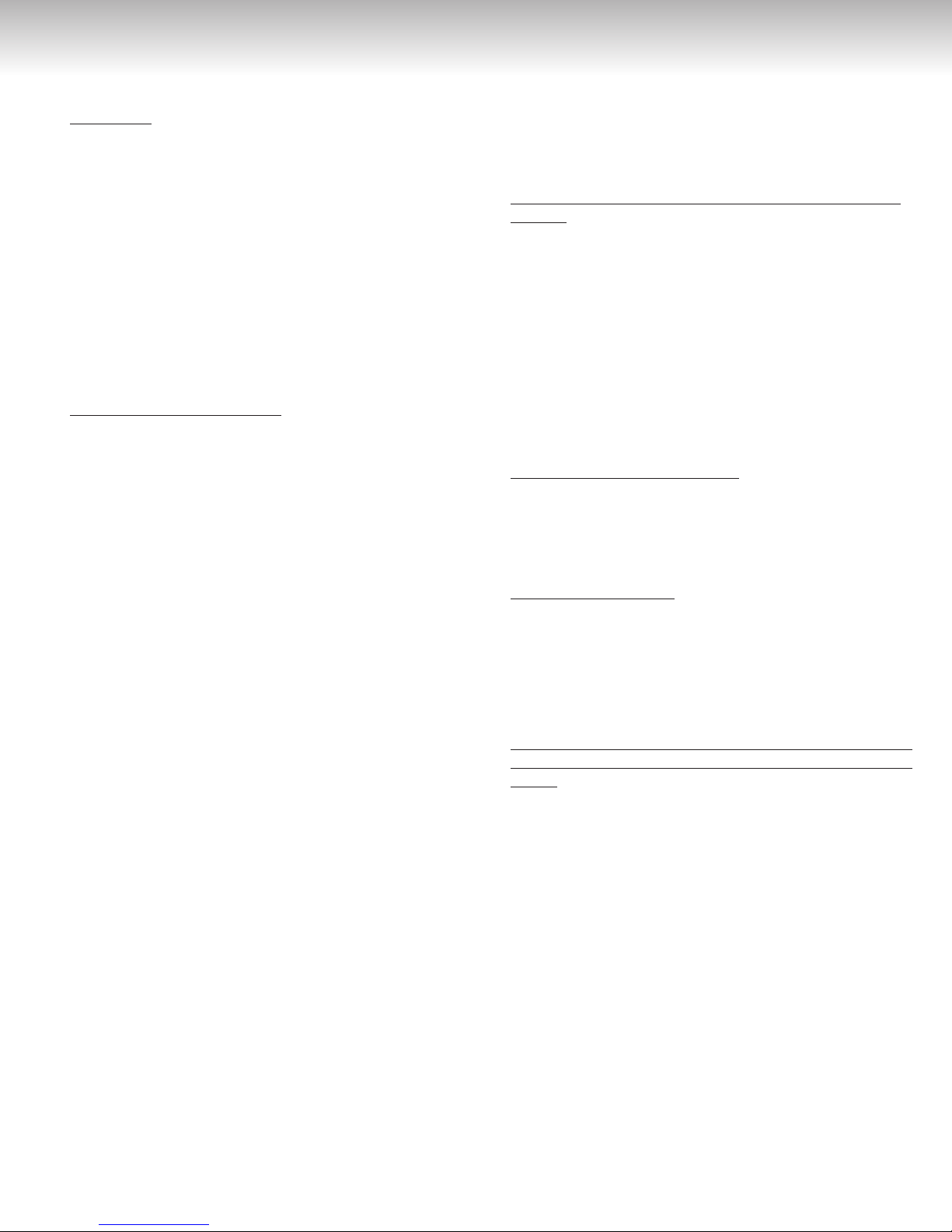

Water Quality

Consideration of care for your water heater should include evaluation of water quality.

Water that contains chemicals exceeding the levels below

will affect and damage the heat exchanger. Replacement

of the heat exchanger due to water quality damage is not

covered by the warranty.

Table 2

Maximum Level

Total Hardness Up to 200 mg / L

Aluminum * Up to 0.2 mg / L

Chlorides * Up to 250 mg / L

Copper * Up to 1.0 mg / L

Iron * Up to 0.3 mg / L

Manganese * Up to 0.05 mg / L

pH * 6.5 to 8.5

TDS (Total Dissolved Solids) * Up to 500 mg / L

Zinc * Up to 5 mg / L

* Source: Part 143 National Secondary Drinking Water Regulations.

If you install this water heater in an area that is known to have hard

water or that causes scale build-up, the water must be treated and/

or the heat exchanger flushed regularly.

IMPORTANT CONSIDERATIONS FOR:

Indoor/Internal Water Heaters and Vent Terminations of

Indoor/Internal Water Heaters

•

DO NOT

contaminated with chemicals.

• Before installation, consider where air has the ability to travel

within the building to the water heater.

• Where possible, install the water heater in a sealed closet so

that it is protected from the potential of contaminated indoor

air.

• Chemicals that are corrosive in nature should not be stored

or used near the water heater.

• Install the water heater termination as far away as possible

from exhaust vent hoods.

• Install the water heater termination as far away as possible from air inlet vents. Corrosive fumes may be released

through these vents when air is not being brought in through

them.

• Chemicals that are corrosive in nature should not be stored

or used near the water heater or vent termination.

Damage and repair due to corrosive compounds in the air is not

covered by warranty.

install in areas where air for combustion can be

When scale build-up in the heat exchanger begins to affect the

performance of the water heater, the diagnostic code “LC #” will

display. Flush the heat exchanger to prevent damage to it. Scale

build-up is caused by hard water set at a high temperature.

Environment

Air surrounding the water heater, venting, and vent termination(s)

is used for combustion and must be free of any compounds that

cause corrosion of internal components. These include corrosive

compounds that are found in aerosol sprays, detergents, bleaches, cleaning solvents, oil based paints/varnishes, and refrigerants.

The air in beauty shops, dry cleaning stores, photo processing

labs, and storage areas for pool supplies often contains these

compounds.

The water heater, venting, and vent termination(s) should not be

installed in any areas where the air may contain these corrosive

compounds. If it is necessary for a water heater to be located in

areas which may contain corrosive compounds, the following instructions are strongly recommended.

54

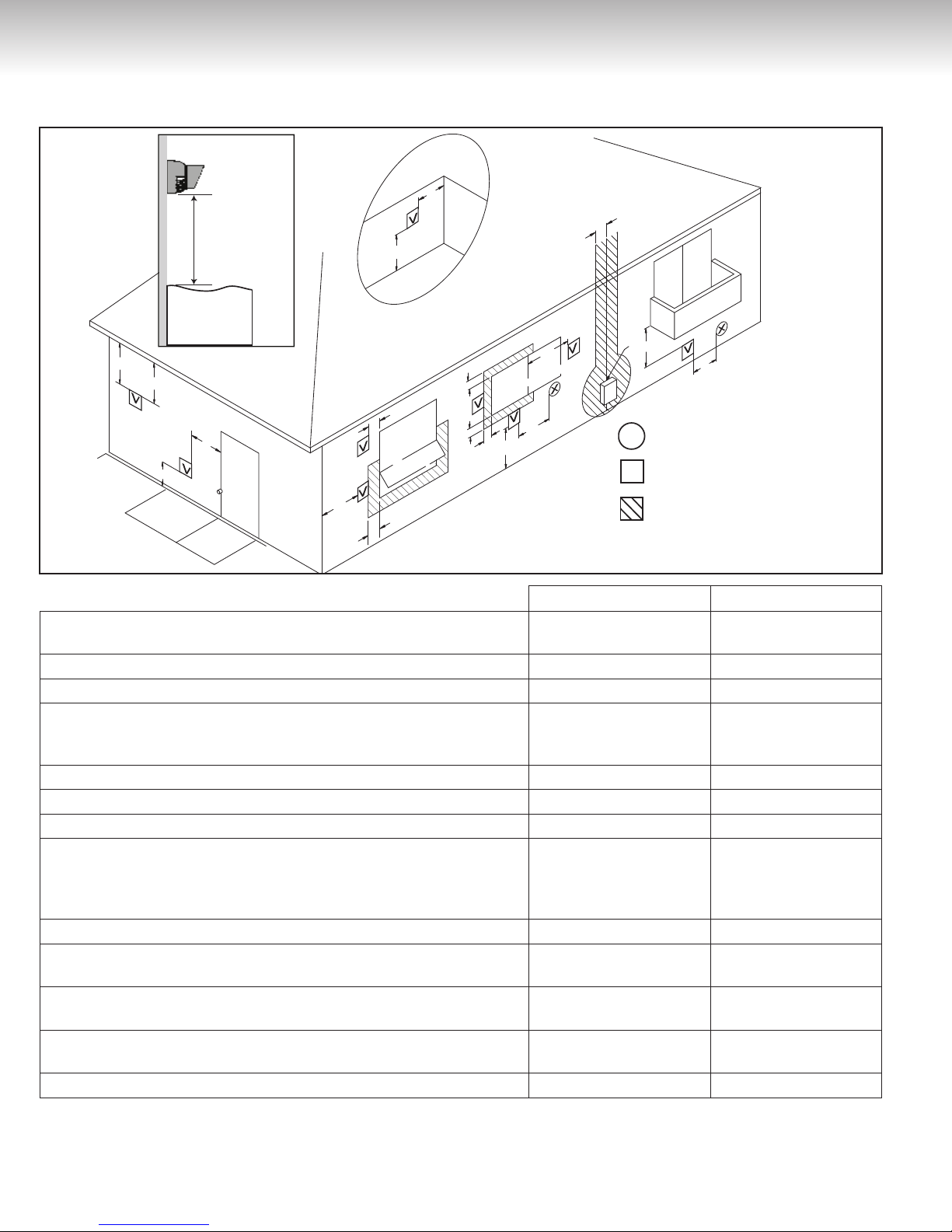

Vent Termination Clearances

X

You must install a vent termination to bring in combustion air and expel exhaust.

Figure 1

TERMINATION

INSIDE

CORNER DETAIL

G

Clearance in

Ref. A also

applies to

anticipated

A

H

snow line

SNOW

I

B

D

E

C

FIXED

B

L

F

CLOSED

OPERABLE

B

B

OPERABLE

B

B

FIXED

CLOSED

J

A

M

K

AIR SUPPLY INLET

VENT TERMINAL

V

AREA WHERE TERMINAL

IS NOT PERMITTTED

The Vent Termination must have a:

A) Clearance above grade, veranda, porch, deck, or balcony

1

Canadian Installations U.S. Installations

12 inches (30 cm) 12 inches (30 cm)

B) Clearance to window or door that may be opened 36 inches (91 cm) 12 inches (30 cm)

C) Clearance to permanently closed window * *

D) Vertical clearance to ventilated soffit, located above the terminal within

a horizontal distance of two (2) feet (61 cm) from the center line of the

* *

terminal

E) Clearance to unventilated soffit * *

F) Clearance to outside corner * *

G) Clearance to inside corner * *

H) Clearance to each side of center line extended above meter/regulator

assembly

3 feet (91 cm) within a

height of 15 feet (4.5 m)

above the meter/ regulator

*

assembly

I) Clearance to service regulator vent outlet 36 inches (91 cm) *

J) Clearance to non-mechanical air supply inlet to building or the combustion

air inlet to any other appliance

K) Clearance to a mechanical air supply inlet

L) Clearance above paved sidewalk or paved driveway located on public

property

M) Clearance under veranda, porch, deck, or balcony 12 inches (30 cm)

36 inches (91 cm) 12 inches (30 cm)

6 feet (1.83 m)

7 feet (2.13 m)

1

*

3 feet (91 cm) above

if within 10 feet (3 m)

*

*

1

A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves both dwellings.

* For clearances not specified in ANSI Z223.1/NFPA 54, clearances are in accordance with local installation codes and the requirements of the gas supplier. Clearance to opposite wall is twenty-four

(24) inches (61 cm).

6

INSTALLATION INSTRUCTIONS

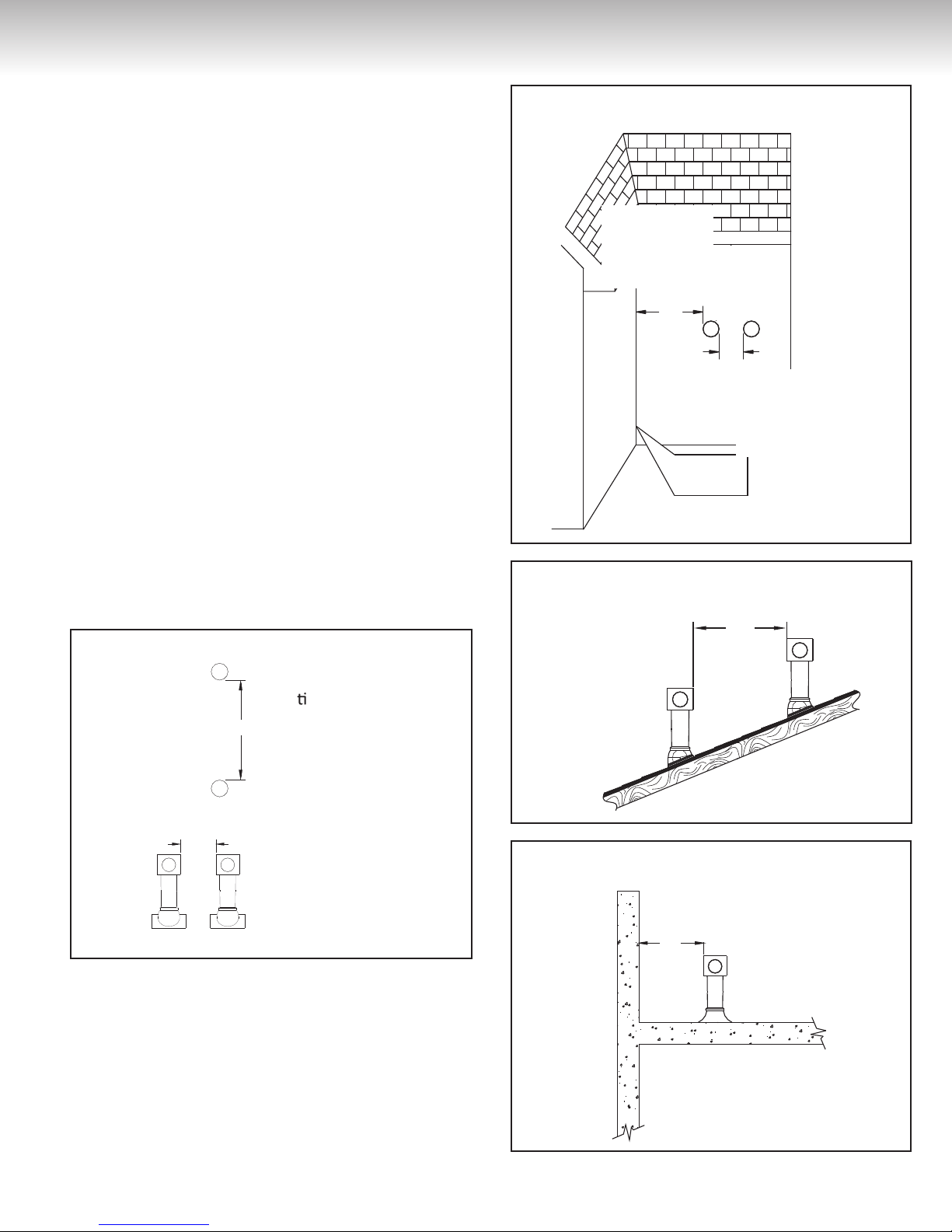

Additional clearances

Check on whether local codes supersede these clearances.

• Avoid termination locations near a dryer vent.

• Avoid termination locations near commercial cooking exhaust.

• You must install a vent termination at least twelve (12) inches

(30.5 cm) from the ground.

The vent for this appliance shall not terminate:

• Over public walkways; or

• Near soffit vents or crawl space vents or other area where condensate or vapor could create a nuisance or hazard or cause

property damage; or

• Where condensate or vapor could cause damage or could be

detrimental to the operation of regulators, relief valves, or other

equipment.

nation under a soffit (ventilated or unventilated or eave vent; or

to a deck or porch);

• Do not install vent termination under a soffit vent such that exhaust can enter the soffit vent;

• Install vent termination such that exhaust and rising moisture

will not collect under eaves. Discoloration to the exterior of the

building could occur, if installed too close;

• Do not install the vent termination too close under the soffit

where it could present recirculation of exhaust gases back into

the combustion air intake part of the termination.

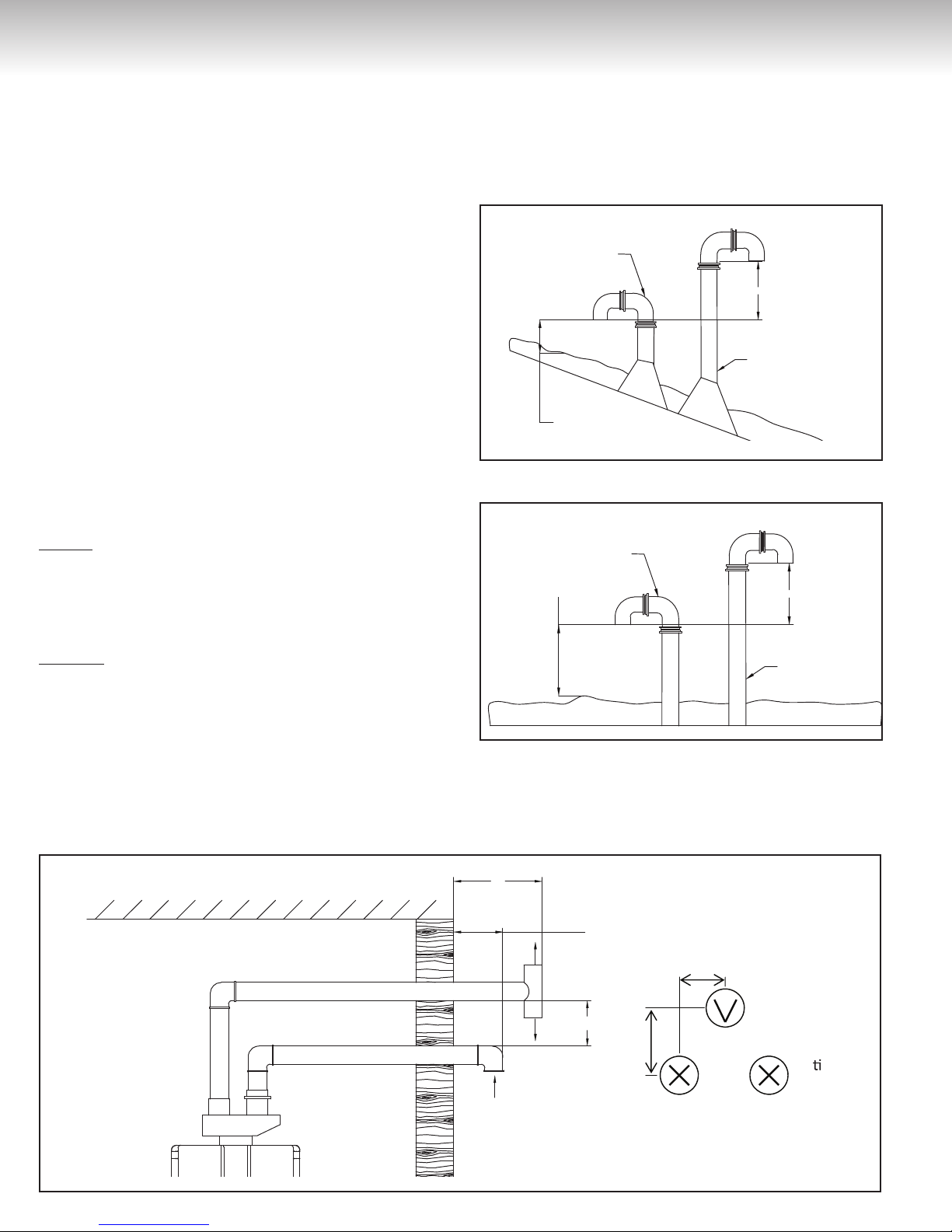

Figure 2

Important considerations

V

(1.5 m)

ver

between

60"

for locating vent termi-

cally

terminals

Figure 3

Figure 4

(30.5 cm) to

an inside

corner

12"

(1.5 m)

between

terminals at

different levels

V

36"

V V

12"

INSIDE

CORNER

60"

(30.5 cm) between

terminals at same

level

V

V

12"

V V

(30.5 cm) between

terminals at same

level

Figure 5

(61 cm) to wall or parapet

24"

V

76

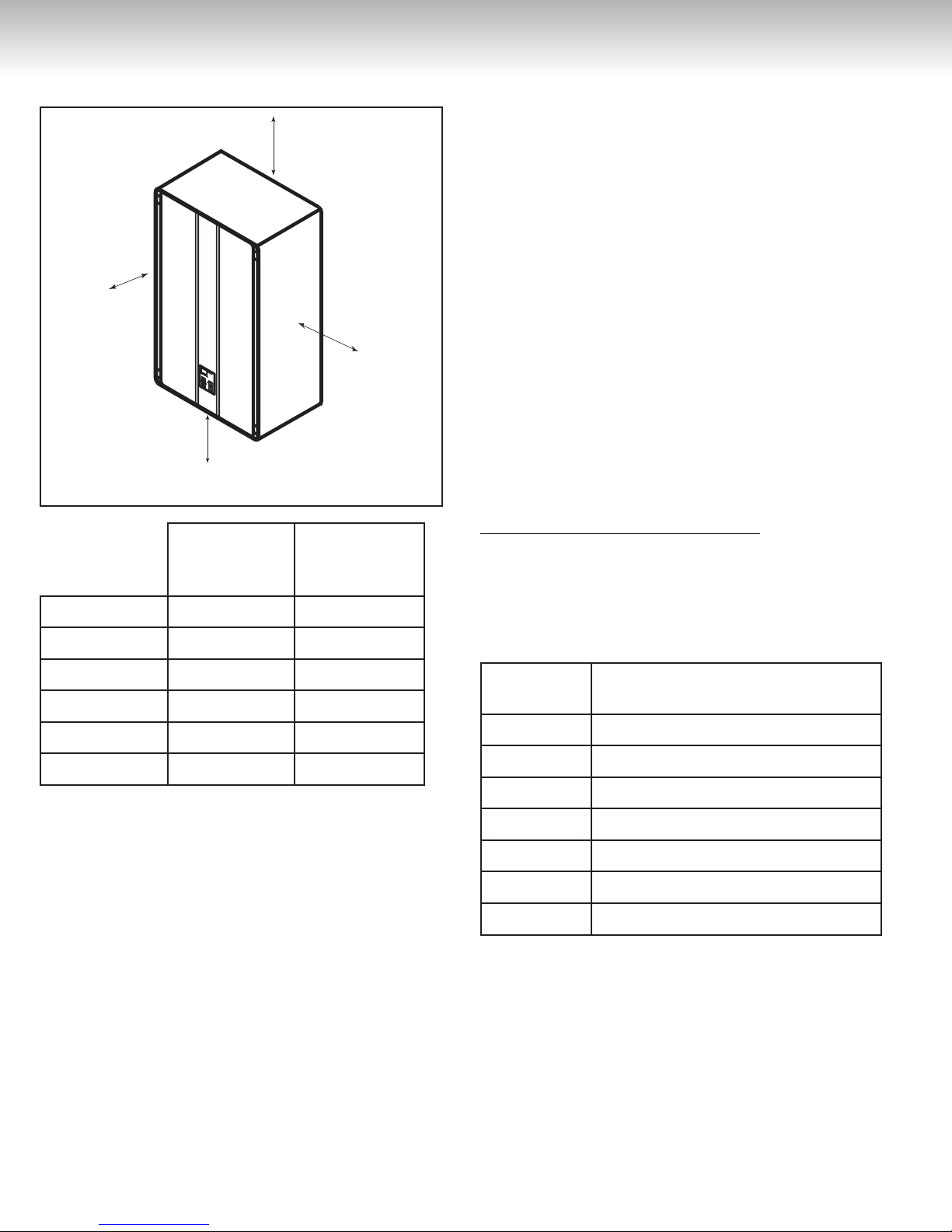

Unit clearances

Figure 6

to top

to front

to side

to floor/ground

Table 3

to Combustibles

inches (cm)

Top of Heater

Back of Heater

Front of Heater

Sides of Heater

Ground/Bottom

Vent

6 * (15.2) 2 *(5.1)

0 (zero) 0 (zero)

6 (15.2) 6 (15.2)

2 (5.1) 1/2 (1.3)

12 (30.5) 12 (30.5)

0 (zero) 0 (zero)

*0 inch from vent components and condensate drain line

The clearance for servicing is twenty-four (24) inches (61 cm) in

front of the water heater.

For closet installation, clearance is six (6) inches (15.2 cm) from

the front.

Freeze Protection

In case of freezing weather, make sure that the water heater and

its water lines are protected to prevent freezing. Damage due to

freezing is not covered by the warranty.

Loss of freeze protection may result in water damage from a burst

heat exchanger or water lines.

With electrical power supplied, the water heater will not freeze

when the outside air temperature is as cold as –22°F (-30°C) for

indoor models,

when protected from direct wind exposure

Because of the “wind-chill” effect, any wind or air circulation on

the unit will reduce its ability to freeze protect.

to Non

Combustibles

inches (cm)

The unit may be drained manually. However, it is highly recommended that drain down solenoid valves are installed that will automatically drain the unit if power is lost. These are available in a

kit, P/N 15000029-A. (The condensate trap drain plug and water

drain plug are not affected by the auto drain down solenoid valves

and will have to be manually opened.)

In addition, the solenoid valves should be connected electrically to

a surge protector with terminals. This allows the solenoid valves

to operate if the water heater is disabled due to a diagnostic code.

The freeze protection features will not prevent the external piping

from freezing. It is recommended that hot and cold water pipes are

insulated. Pipe cover enclosures may be packed with insulation for

added freeze protection.

It is recommended that the condensate trap drain line be insulated.

A frozen condensate trap drain line results in diagnostic code #25.

In the event of a power failure at temperatures below freezing,

the water heater should be drained of all water to prevent freezing

damage. In addition, drain the condensate trap and drain line.

Maximum vent length

Maximum vent length with concentric venting

1) Determine the number of 90-degree elbows in the vent system. (Two (2) 45-degree elbows count as one (1) 90-degree

elbow.)

2) Refer to the table to find the maximum vent length based on

the number of elbows.

Table 4

Number of

900 Elbows

0

1

2

3

4

5

6

Maximum vent length

(concentric venting)

41 ft (12.5 m)

35 ft (10.7 m)

29 ft (8.8 m)

23 ft (7.0 m)

17 ft (5.2 m)

11 ft (3.4 m)

5 ft (1.5 m)

1

2

3

4

4

4

4

3) Adjust switch # 1 in the SW1 DIP switch (tan switches), if

required by the applicable note.

1. If the length is greater than twenty-one (21) feet (6.4 m),

then move switch # 1 (SW1) to OFF.

2. If the length is greater than fifteen (15) feet (4.5 m), then

move switch # 1 (SW1) to OFF.

3. If the length is greater than nine (9) feet (2.7 m), then

move switch # 1 (SW1) to OFF.

4. Move switch # 1 (SW1) to OFF.

.

Example: If you have one elbow, then your maximum

vent length is thirty-five (35) feet (10.7 m). If your actual

length is greater than fifteen (15) feet (4.5 m), then move

switch # 1 (SW1) to OFF.

8

Wall installaon

brackets

INSTALLATION INSTRUCTIONS

Checklist to Determine Installation Location

NOTICE

If you have a longer vent length (see above), switch # 1 is required to be in the OFF position. This ensures the water heater

will run properly. Blocked flue diagnostic codes and shutdowns

may result if switch # 1 is not in the correct position.

Maximum vent length for Centrotherm 2 Pipe InnoFlue Vent System

(single wall SW, 3-inch (7.6 cm) diameter)

Table 5: Vent length using short radius elbow

Number of

90° Short

Radius

Elbows

0

1

2

Maximum

Straight Vent

Length

42 feet

(12.8 m)

27 feet

(8.2 m)

12 feet

(3.7 m)

Switch #1 in the tan

DIP switches

(If length is greater)

18 feet (5.5 m) move

switch #1 to OFF

3 feet (91.4 cm) move

switch #1 to OFF

move switch #1 to OFF

□ The water heater is not exposed to corrosive compounds in

the air.

□ The water heater location complies with the clearances.

□ The planned venting will not exceed the maximum length for

the number of elbows used.

□ The planned venting termination/air intake location meets the

clearances.

□ The water supply does not contain chemicals or exceed total

hardness that will damage the heat exchanger.

□ A standard 3-prong 120 VAC, 60 Hz properly grounded wall

outlet or other 120 VAC, 60 Hz source is available.

□ The installation must conform with local codes or, in the ab-

sence of local codes, with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or the Natural Gas and Propane Installation

Code, CSA B149.1.

□

Leave the entire manual taped to the water heater or

give the entire manual directly to the consumer.

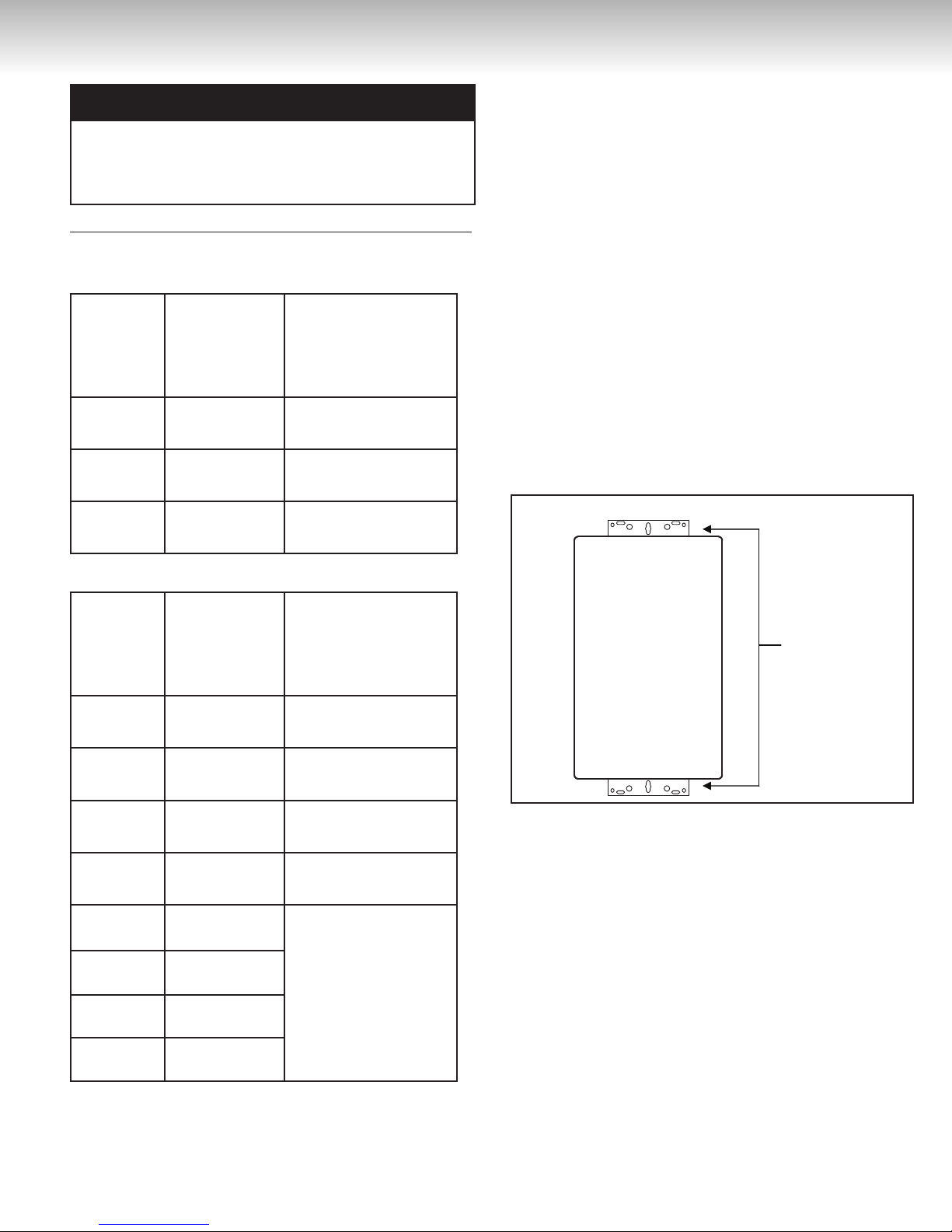

Mount to Wall

Figure 7

Table 6: Vent length using long radius elbow

Number of

90° Long

Radius

Elbows

0

1

2

3

4

5

6

7

Maximum

Straight Vent

Length

42 feet

(12.8 m)

27 feet

(8.2 m)

12 feet

(3.7 m)

27 feet

(8.2 m)

21 feet

(6.4 m)

15 feet

(4.5 m)

9 feet

(2.7 m)

3 feet

(91.4 cm)

Switch #1 in the tan

DIP switches

(

If length is greater)

21 feet (6.4 m) move

switch #1 to OFF

15 feet (4.5 m) move

switch #1 to OFF

9 feet (2.7 m) move

switch #1 to OFF

3 feet (91.4 cm) move

switch #1 to OFF

Move switch # 1 to OFF

for any length

1) Identify the installation location and confirm that the in-

stallation will meet all required clearances.

2) Securely attach the water heater to the wall using any

of the holes in the wall installation brackets which are at the

top and bottom of the water heater. Ensure that the attachment strength is sufficient to support the weight. Refer to the

weight of the water heater in the Specifications section. Use

a leveling tool to ensure that the water heater is level. Proper

operation requires that the water heater be level.

NOTE:

The water heater should be installed in an upright position.

Do not install upside down or on its side.

Remove the Front Panel

Slide the plastic trim pieces on each side of the water heater to

expose the screws. Remove the four (4) screws and pull off the

front panel.

98

Installation of venting

Install the correct venting for your model according to the venting

manufacturer’s instruction and the guidelines below (see Table 7

and Table 8). Refer to the manufacturer’s technical literature for

specific part numbers and instructions.

Venting Guidelines

DO NOT

• Do not use cellular core PVC/CPVC, Radel, or galvanized material to vent this appliance.

• Do not combine vent components from different manufacturers.

• Vent diameter must not be reduced.

• Do not connect the venting system with an existing vent or

chimney.

• Do not common vent with the vent pipe of any other manufacturer’s water heater or appliance. Giant water heaters can only

be common vented using a Giant certified common vent system. Common venting is approved for Canadian and U.S. installations.

MUST DO

• This water heater is a direct vent water heater and therefore is

certified and listed with the vent system. You must use vent

components that are certified and listed with the water heater

model.

• The vent system must vent directly to the outside of the building

and use outside air for combustion.

• Avoid dips or sags in horizontal vent runs by installing supports

per the vent manufacturer’s instructions.

• Support horizontal vent runs every four (4) feet (1.2 m) and all

vertical vents run every six (6) feet (1.8 m) or in accordance with

local codes.

• Venting should be as direct as possible with a minimum number

of pipe fittings.

• Vent connections must be firmly pressed together so that the

gaskets form an air tight seal.

• The vent piece connected to the water heater must be secured

with one self-tapping screw.

INFORMATION

• Refer to the instructions of the vent system manufacturer for

component assembly instructions.

• If the vent system is to be enclosed, it is suggested that the design of the enclosure shall permit inspection of the vent system.

The design of such enclosure shall be deemed acceptable by the

installer or the local inspector.

NOTICE

If it becomes necessary to access an enclosed vent system for

service or repairs, Giant is not responsible for any costs or

difficulties in accessing such vent system. The warranty does

not cover obtaining access to a vent system in an enclosed

environment.

Table 7

Manufacturer Listed and Tested Vent Products Telephone Fax Contact

Ubbink

IPEX Concentric/low profile termination kit 866-473-9462 514-769-1672

Centrotherm

Heat-Fab Saf-T Vent SC System 800-772-0739 413-863-4803

Metal-Fab Corr/Guard Vent/Air Intake System 800-835-2830 316-943-2717

Table 8

Manufacturer Product Vertical Termination Horizontal Termination

Ubbink

IPEX Concentric/low profile termination kit

Centrotherm InnoFlue ICRT3539 ISELL0387UV

Heat-Fab Saf-T Vent

Metal-Fab Corr/Guard 3CGRVDK 3CGRVT

Rolux Condensing Vent System

Concentric to Twin pipe adapter

InnoFlue Vent System

(single wall SW, 3-inch (7.6 cm) diameter)

Rolux

PVC/CPVC concentric to twin pipe adapter

800-363-9354 514-640-0969 www.giantinc.com

www.ipexinc.com

sales@ipexinc.com

877-434-3432 518-618-3166

96000050-A 96000051-A, 96000052-A

Saf-T Vent CI Plus

Wall Termination

info@centrotherm.us.com

www.centrotherm.us.com

custsvc@heat-fab.com

www.heatfab.com

info@mtlfab.com

www.metal-fabinc.com

Saf-T Vent CI Plus Rain Cap

10

INSTALLATION INSTRUCTIONS

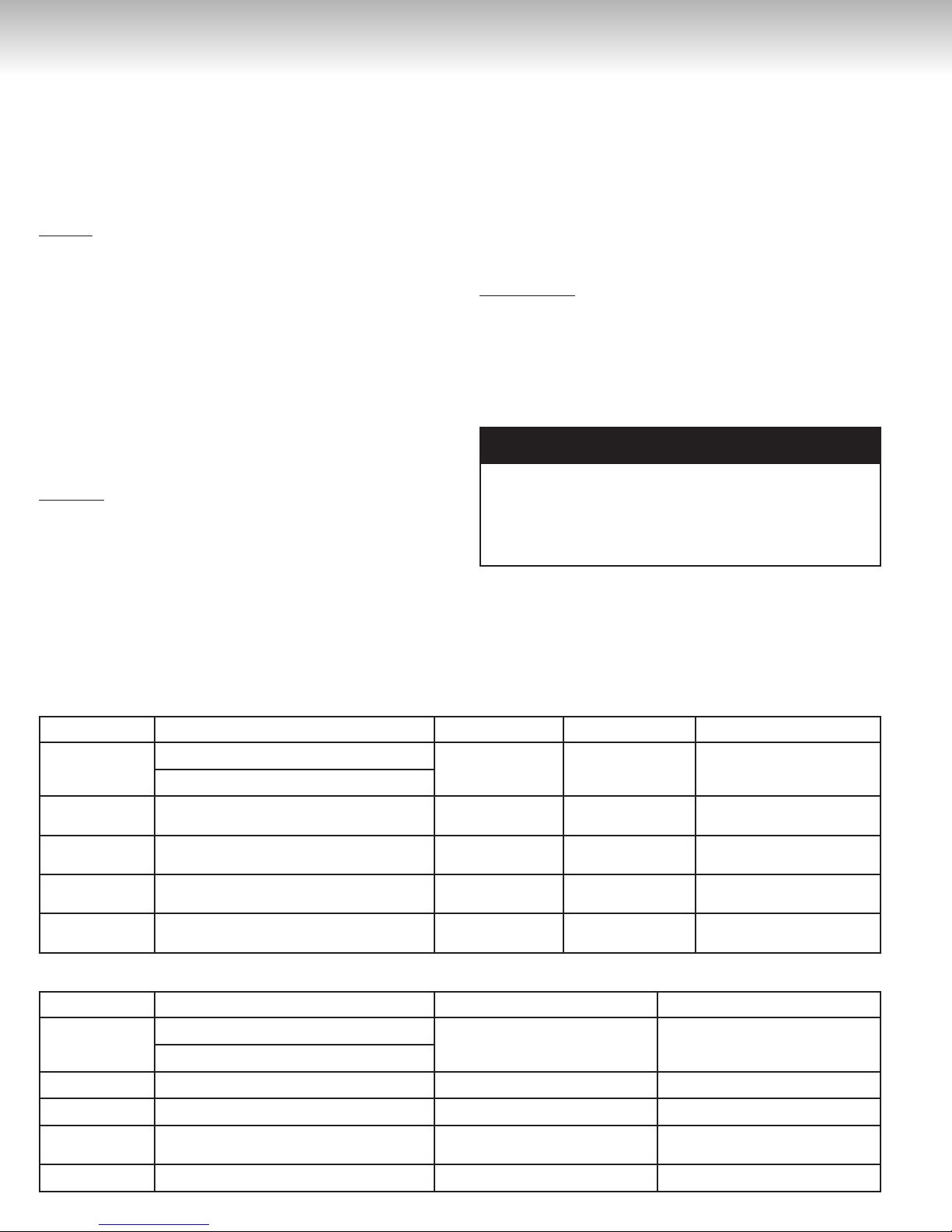

Figure 8

Slope the venting toward the appliance according to the vent

manufacturer’s installation instructions.

Dispose of condensate per local codes.

Horizontal Termination

Vertical Termination

Slope the venting toward the appliance according to the vent

manufacturer’s installation instructions.

Dispose of condensate per local codes.

Securing Screw

Secure the first vent component to the water heater with one selftapping screw at the hole.

1110

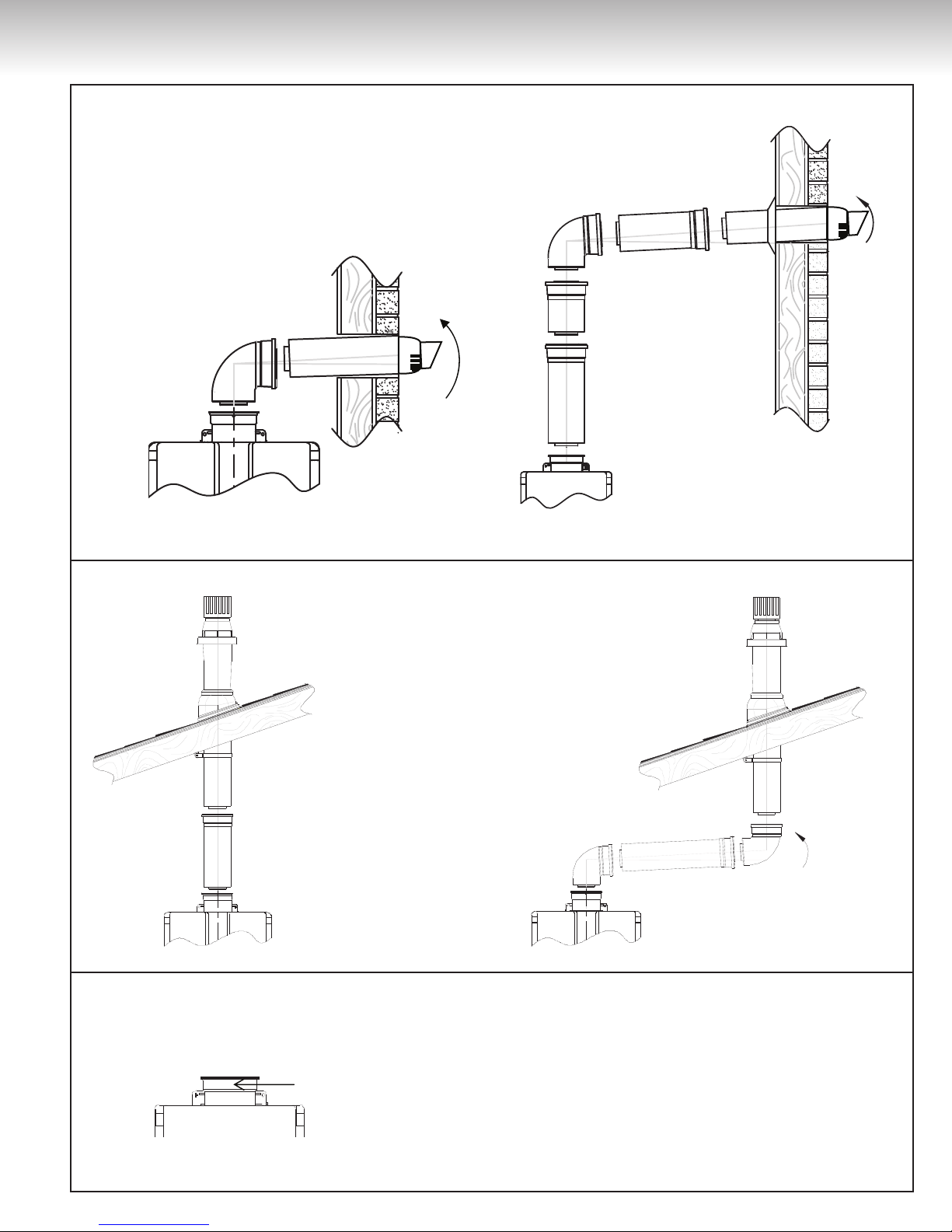

Flue Installation with Centrotherm Venting

Combustion Air pipe

12” (30.5 cm) Minimum

Exhaust Pipe

12” (30.5 cm) Minimum

above anticipated snow level

Exhaust Pipe

12” (30.5 cm) Minimum

Combustion Air Pipe

12” (30.5 cm) Minimum above

anticipated snow level

11”

5”

Admission

Op

onnel

Ven

la on

Échappement

Échappement

Entrée d’air de

combustion

(30,5 cm)

(10,2 cm)

(28 cm)

(12,7 cm)

(20,4 cm)

(30.5 cm)

(10.2 cm)

(20.4 cm)

(28 cm)

(12.7 cm)

11”

5”

Intake

Op

onal

Vent

12”

4”

Exhaust

Exhaust

8”

Install the venting termination according to the diagrams and instructions below.

• Comply with the exhaust clearances found in the Giant Installation and Operating Manual.

• Only one appliance can be attached to the vent system.

• Install the system according to the Centrotherm installation instructions.

• Use the 3”/5” (7.6/12.7 cm) concentric to twin pipe adaptor and

the 3-inch (7.6 cm) diameter venting.

• The vent termination and air intake must be in the same pressure

zone.

• Do not exceed maximum straight vent length with number of

elbows as shown in the following tables.

• Maintain the clearances shown in the following Figures.

Condensate

Condensate formation can occur in high efficiency direct vent

appliances. Without proper drainage condensate will damage the

heat exchanger.

• The condensate drain pipe (along its entire length) must be at

least the same diameter as the drain line, (1/2 inch NPT).

• The end of the condensate drain pipe should be open to the atmosphere. The end should not be under water or other substances.

Figure 10

To prevent condensate damage, follow these instructions.

DO NOT

• Do not connect the condensate drain pipe directly to the rain

sewer.

• Do not connect the condensate drain line with an air conditioning evaporator coil drain.

MUST DO

• Use only vent that is approved and identified as acceptable for

your particular model.

• Slope the venting toward the appliance according to the vent

manufacturer’s installation instructions.

• All condensate must drain and be disposed of according to local

codes.

• Use only corrosion resistant materials for the condensate drain

lines, such as PVC pipe or plastic hose.

Figure 9

Figure 11

12

WARNING

CAUTION

WARNING

CAUTION

TWIN PIPE VENTING GUIDE

INFORMATION

• Water heaters have an integrated condensate collector.

• Regions of cold climate will create more condensate in the vent

system. The condensate collector should be used in cold climates.

• The condensate drain pipe should be as short as possible and

have a downward pitch.

• If the condensate drain gets blocked, a diagnostic code will display on the controller. If this occurs, the condensate drain must

be cleaned.

• The condensate trap will automatically prime (self-prime) during

operation of the unit as condensate forms. Condensate draining

from the unit indicates that the trap is full and that there is no

blockage in the condensate drain. It is not necessary to add water to the condensate trap.

• A condensate neutralizer kit, P/N 50000100-A, is available from

Giant. The kit allows condensate to flow through neutralizing

media that raises the pH of the condensate to a level that will

help prevent corrosion of the drain and public sewer system.

Checklist for Venting and Condensate

□ Verify proper clearances around the vents and air intakes.

□ Ensure you have used the correct venting products for the

model installed and that you have completely followed the

venting manufacturer’s installation instructions as well as

these installation instructions.

□ Verify that the vent system does not exceed the maximum

length for the number of elbows used.

Twin Pipe Venting Guide

The purpose of this guide is to inform about changes with regard

to venting for the following tankless water heater products only:

NOTE

: The Ubbink Concentric to Twin Pipe Adaptor is ULC S636

approved and is listed by the applicable agencies having jurisdiction and is certified for use throughout the U.S. and Canada. The

Concentric to Twin Pipe Adaptor is supplied exclusively through

and/or its distributors.

The newly certified vent system is comprised of a Concentric to

Twin Pipe Adaptor (adaptable to three (3) (7.6 cm) to four (4)

(10.2 cm) sizes), PVC/CPVC pipes, fittings, and either the IPEX

Concentric Vent Kit (CVK) Assembly (System 636), snorkel termination, or tee termination.

NOTICE

PVC venting CANNOT be used with the condensing water

heater, under the following conditions:

• The water heater is installed in a recirculation system and the

thermostat setting is greater than 150˚F (65.5˚C).

• The water heater is used in a combination domestic water and

space heating application which requires a thermostat setting

greater than 150˚F (65.5˚C).

Tankless Water Heaters must be vented and furnished with intake air and exhaust vent using piping and methods described

in this guide and the appliance installation instructions. Each

water heater must have its own intake and vent.

mon vent with any other appliance using this method. Inspect

finished vent and intake air piping thoroughly to ensure all are

airtight and comply with the instructions provided and with all

requirements of applicable codes. Failure to provide a properly

installed vent and air system will cause severe personal injury

or death.

DO NOT

com-

UGTC-199N, UGTC-199P, UGTC-152N, and UGTC-152P

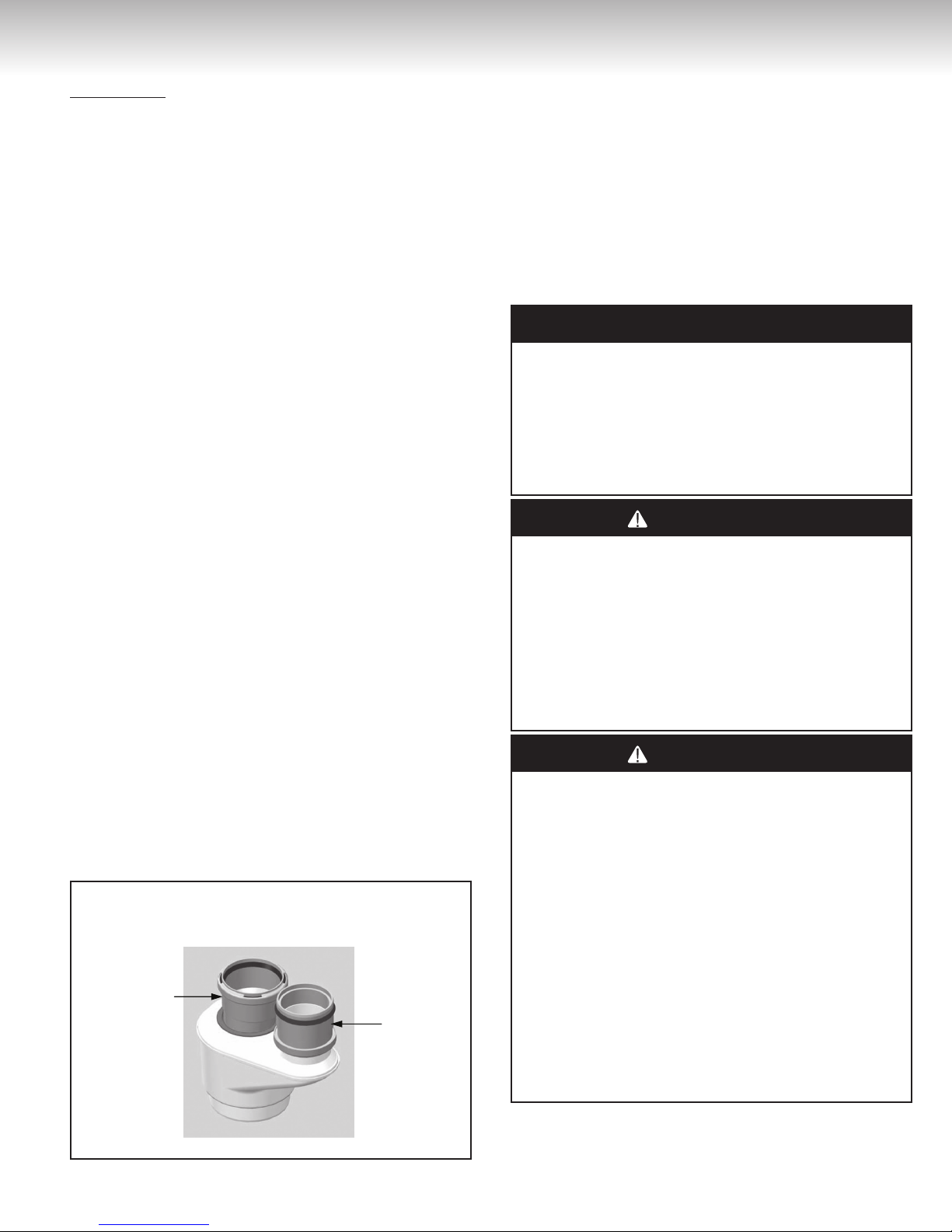

The Ubbink® 3’’/5’’ (7.6/12.7 cm) to 3’’/3’’ (7.6/7.6 cm) Concentric

to Twin Pipe Adaptor (

ment has been certified to be used with the optional PVC/CPVC

twin pipe venting system for both natural and propane units.

Figure 12: Ubbink® 3’’/5’’ (7.6/12.7 cm) to 3’’/3’’

(7.6/7.6 cm) Concentric to Twin Pipe Adaptor

Exhaust Vent

see Figure 12

) and other venting equip-

Combustion Air

Combustion Air Intake

for the condensing tankless water heaters as described in the

Water Heater Manual. The combustion air intake termination fitting must be installed with the clearances and geometry relative

to the exhaust (vent) depicted in this document to ensure that

flue products do not enter the combustion air intake. Ensure

that the intake air will not contain any of the contaminants as

outlined in the “

this document. Contaminated intake air will damage the water

heater, resulting in possible severe personal injury, death, or

substantial property damage.

Exhaust

specified in this guide and as required by all applicable codes.

The exhaust (vent) termination fitting must be installed with the

clearances and geometry relative to the combustion air pipe as

depicted in this document to ensure that flue products do not

enter the combustion air intake.

Determine Installation Location

- Provide exhaust (vent) piping to Water Heater as

- Install combustion air inlet piping

” section of

1312

NOTICE

WARNING

CAUTION

WARNING

CAUTION

WARNING

CAUTION

DANGER

WARNING

CAUTION

If the vent and/or combustion air intake piping configurations

covered in the Water Heater Manual cannot be applied to a specific installation, contact Giant for assistance. Other configurations may be available.

Installations must comply with local requirements and with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 for U.S. installations or CSA B149.1 for Canadian installations.

cellular core PVC, CPVC, or Radel based pipe materials for the

exhaust vent. Vents

Use only the materials listed in the Water Heater Manual for

vent, combustion air intake pipe, and fittings (see Table 9). Failure to comply with this warning could result in severe substantial property damage, personal injury, or death.

If used, a masonry chimney can ONLY be used as a PIPE CHASE

for the exhaust and combustion air intake pipes. The exhaust

and air piping must be installed as instructed in this guide and

applicable Water Heater Manual. The chimney must be used

only for Water Heater(s) vent chase. NO OTHER appliance or

fireplace can be connected to the chimney. Exhaust and air piping materials must comply with this instruction. The chimney

must be fitted with a sealed access opening to facilitate interior

inspection. The chimney chase (and liner, if installed) to be inspected annually for any degradation. Failure to comply could

result in substantial property damage, personal injury, or death.

MUST

be of solid core pipes ONLY.

DO NOT

use

Installation Instructions

Installation Requirements

• Installation should be performed by a licensed professional.

• All PVC/CPVC IPEX Concentric Vent Kit (CVK) assemblies are

certified to ULC S636. Where ULC S636 compliance is required,

use only System 636 pipe, fittings, and cement at terminal connection.

•

DO NOT

different vent manufacturers, this can result in unsafe conditions

and will void the certification.

•

DO NOT

DO NOT

•

•

DO NOT

solvents and glues have bonded.

• All PVC/CPVC exhaust vent material used in Canada must be

S636 certified.

If the preferred venting option is a twin pipe PVC/CPVC configuration, the approved twin pipe adaptor must be used.

For further details on listed PVC/CPVC venting material (see Table

9) refer to the installation manual of the PVC/CPVC manufacturer.

NOTE:

are all certified as part of the water heater vent system.

Failure to correctly install vent and combustion air intake pipes of

the water heater to atmosphere as outlined in the VENTING section of the Installation Instructions, will result in death from asphyxiation (from carbon monoxide), fire, or explosion.

operate the water heater without proper venting (exhaust and

combustion air intake). Always inspect the vent terminal unit,

combustion air intake pipe, and the entire vent system affixed to

the water heater for proper installation at equipment commissioning and at least annually thereafter.

mix pipe, fittings, cements, or joining methods from

use cellular core PVC, CPVC, nor Radel piping for vent.

use PVC/CPVC on Non-Condensing Units.

operate unit until venting is completely installed and all

The listed vent, vent fittings, termination, cleaner, and glue

NEVER

Table 9: Vent and Air Piping Materials

Item Material

Vent or combustion air

intake pipe & Fittings

PVC pipe cement &

primer

PVC schedule 40 ANSI/ASTM D1785

PVC-DWV ANSI/ASTM D2665

CPVC schedule 40 ANSI/ASTM F441

PVC ANSI/ASTM D2564

CPVC ANSI/ASTM F493

Termination Vent

Screens

Polyethylene

Standard for Installation in North America

United States Canada

Thermoplastic Piping Materials

Thermoplastic vent pipe must be certified to

ULC S636.

Intake pipe may be of any material listed (left).

IPEX bird screens (purchase separately)

Three (3) inch (7.6 cm) Vent screen: IPEX part # 196051;

Four (4) inch (10.2 cm) Vent screen: IPEX part # 196052

(Screens are friction fitted inside termination fitting bells.)

14

TWIN PIPE VENTING GUIDE

Determine Installation Location

Environment

Air surrounding the water heater, venting, and vent termination(s)

is used for combustion and must be free of any compounds that

cause corrosion of internal components. These include corrosive

compounds that are found in aerosol sprays, detergents, bleaches, cleaning solvents, oil based paints/varnishes, and refrigerants.

The air in beauty shops, dry cleaning stores, photo processing

labs, and storage areas for pool supplies often contains these

compounds. Therefore it is recommended that outdoor models be

used for these locations where possible.

The water heater, venting, and vent termination(s) should not be

installed in any areas where the air may contain these corrosive

compounds. If it is necessary for a water heater to be located in

areas which may contain corrosive compounds, the following instructions are strongly recommended.

IMPORTANT CONSIDERATIONS:

•

DO NOT

taminated with chemicals.

• Before installation, consider where air has the ability to travel

within the building to the water heater.

• Where possible, install the water heater in a sealed closet so

that it is protected from the potential of contaminated indoor air.

• Chemicals that are corrosive in nature should not be stored or

used near the water heater.

• Locate the vent outlet where flue gases will not harm surrounding plants and/or cooling equipment. All vent locations must adhere to the recommended vent/combustion air intake terminal

position as outlined in Table 3.

• Avoid locating vent where prevailing winds could affect the performance of the water heater or cause recirculation of the flue gases.

•

DO NOT

an area where condensate or vapor can create a nuisance / hazard or where condensate can be detrimental to the operation of

equipment such as regulators or relief valves.

• Water Heater flue gases must be piped from the appliance to

the outside, installer MUST adhere to the instructions provided

herein and the most recent Water Heater Manual and all applicable codes.

• The exhaust and combustion air must terminate through the

same sidewall or roof as the terminations must be in the same

pressure zone and face the same direction.

• The vent pipe must terminate either through the sidewall or

through the roof, exhaust/vent termination and/or intake air

openings shall adhere to clearances as set forth in the Direct

Vent Termination Clearances diagram.

• Each Condensing Tankless Water Heater requires a separate

vent system.

• If common venting is required, refer to common Vent Installation Manual (latest revision) for instructions on optional venting

method as well as to verify which tankless models may be common vented.

• Use only PVC/CPVC three (3) inch (7.6 cm) and four (4) inch

(10.2 cm) Venting.

install in areas where air for combustion can be con-

terminate the venting over a public walkway or over

Damage and repair due to corrosive compounds in the air is not

covered by warranty.

For PVC/CPVC vent systems reduce the maximum allowable length

for each elbow and termination type as follows and as referenced

in

Tables 11-14

Exhaust and Combustion Air Intake Pipe Diameters and Max

Lengths:

• For PVC/CPVC vent systems reduce the maximum allowable

length for each elbow and termination type as follows:

* 2.5 feet (76.2 cm) for every 45° elbow.

* 5 feet (1.5 m) for every 90° elbow.

* Termination.

• Exhaust and combustion air intake pipe diameters to be as specified in

• Do not exceed exhaust and combustion air intake pipe MAXIMUM lengths as outlined in

(Lengths are specific to models and fuel type).

Additional Clearance Requirements:

• Avoid termination locations near a dryer vent.

• Avoid termination locations near commercial cooking exhaust.

• Install vent termination at least twelve (12) inches (30.5 cm)

above grade or anticipated snow level.

Vents shall not terminate:

• Over public walkways; or near soffit vents or crawl space vents

or other area where condensate or vapor could create a nuisance

or hazard or cause property damage.

• Where condensate or vapor could cause damage or could be

detrimental to the operation of regulators, relief valves, or other

equipment.

Important considerations for locating vent termination under a

soffit (ventilated or unventilated or eave vent; or to a deck or

porch):

•

DO NOT

exhaust can enter the soffit vent.

• Install vent termination such that exhaust and rising moisture

will not collect under eaves. Discoloration to the exterior of the

building could occur if installed too close.

•

DO NOT

where it could present recirculation of exhaust gases back into

the combustion air intake part of the termination.

Determining Vent Length

There are two options for determining the vent lengths/components necessary for the installation.

Option 1:

Option 2:

of this document:

Tables 11-14

install vent termination under a soffit vent such that

install the vent termination too close under the soffit

The installer can use the vent length calculation sheet,

filling in the quantity of the vent components in order

to calculate the total equivalent vent lengths.

The installer can use the maximum vent length tables

on the next pages to determine the amount of straight

pipe that can be used with a specific termination type

and quantity of elbows.

of this document.

Tables 11-14

of this document.

1514

OPTION 1:

CAUTION

Calculation of equivalent piping lengths for venting system:

Choose the vent type and fill out the following table. When determining equivalent combustion air and vent length, add five (5) feet

(1.5 m) for each 90° elbow, 2.5 feet (76 cm) for each 45° elbow.

Example of calculation

(assume three (3) inch (7.6 cm) diameter pipes for natural gas

unit):

• Twin pipe (parallel) with snorkel terminal

• Combustion air pipe length: forty (40) feet (12.2 m) straight pipe

with three (3) x 90° elbows

• Exhaust pipe length: forty (40) feet (12.2 m) straight pipe with

three (3) x 90° elbows (include all interior and exterior elbows)

• Snorkel Termination: ten (10) equivalent feet

Calculation:

• Equivalent Combustion air pipe length: [40+(3 X 5)+10] = 65

feet (19.8 m)

• Equivalent Vent Length: [40+(3 X 5)+10] = 65 feet (19.8 m)

• Total = 65 feet (19.8 m) for both exhaust and combustion air

pipes, which is the maximum allowable vent length for three (3)

inch (7.6 cm) PVC/CPVC on a natural gas unit. If longer lengths

are required, go to the four (4) inch (10.2 cm) diameter pipe

configuration which is certified for up to one hundred (100)

equivalent feet.

(see Table 11)

Maximum equivalent vent lengths are specific to the fuel type

of the tankless water heater. It is imperative when performing

equivalent vent length calculations, that the following be taken

in consideration:

Natural Gas Units

Vent Type

3” (7.6 cm)

PVC/CPVC

Concentric PP 65 Feet (19.8 m) 41 Feet (12.5 m)

4’’ (10.2 cm)

PVC/CPVC

Twin Pipe PP

(Centrotherm)

OPTION 2:

Maximum Equivalent Vent Length Tables:

1) Determine the number of 90-degree elbows in the vent system. (Two (2) 45-degree elbows count as one (1) 90-degree

elbow.)

2) Refer to Tables 11-14 to find the maximum vent length based

on the number of elbows and termination style.

Maximum Equiva-

lent Vent Length

65 Feet (19.8 m) 41 Feet (12.5 m)

100 Feet (30.5 m) 65 Feet (19.8 m)

41 Feet (12.5 m) 41 Feet (12.5 m)

Propane Units

Maximum Equiva-

lent Vent Length

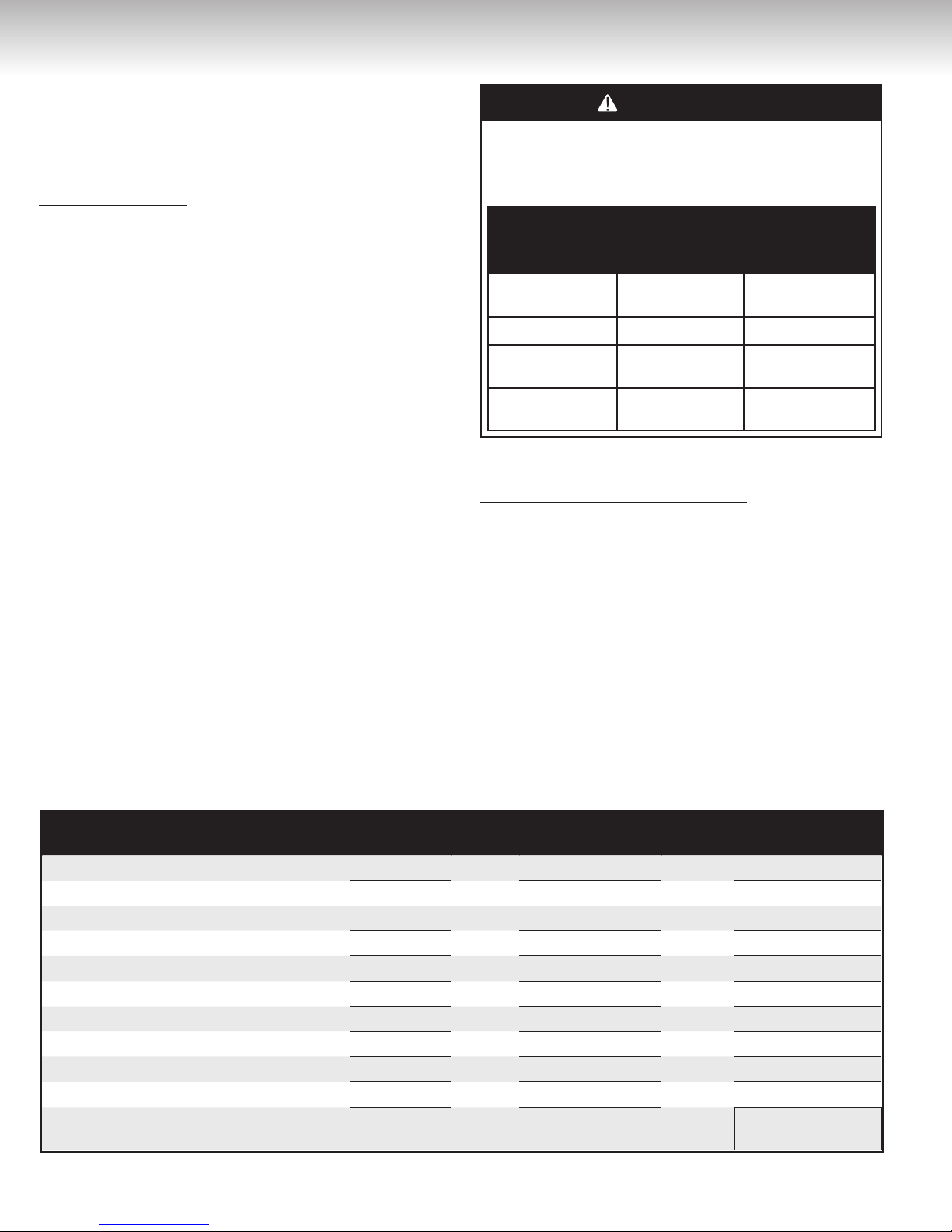

Table 10: Equivalent Vent Length Calculation Sheet

Fitting / Termination Type

1) 900 elbow 3

0

2) 45

elbow

3) IPEX Low Profile Termination

4) IPEX 4’’ (10.2 cm) Concentric Termination

5) IPEX 3’’ (7.6 cm) Concentric Termination

6) 3’’ (7.6 cm) Tee Termination

7) 4’’ (10.2 cm) Tee Termination

8) 3’’ (7.6 cm) Snorkel Termination 1

9) 4’’ (10.2 cm) Snorkel Termination

10) Length of Straight Section in feet NA

(A blank copy of the Vent Length Calculation Sheet is located at the end of this section)

Ensure switch #1 in the bank of eight (8) tan dip switches is in OFF position if vent length is greater than twenty-one (21) feet (6.4 m).

Number of

fittings

x

x

x

x

x

x

x

x

x

x

16

Equivalent Vent

Length

5

2.5

5

20

20

5

5

10

10

40

Total (add up

lines 1 through 10)

=

=

=

=

=

=

=

=

=

=

Total Equivalent

Length

15

0

0

0

0

0

0

10

0

40

65

Loading...

Loading...