Page 1

CONTINUUM W

CYCLE COMPUTER

Press down on this lock lever

before removing the main unit.

1

2

3

4

5

15

12

11

6

SET

SW.

* Adjust the arm, elbow and bracket with the angle you

need, and then fasten it.

A

13

14

17

16

G

8

9

+

A <9015

10

Best direction

18

L

(

<

1

.

4

5

5

f

c

e

m

e

t

)

B

H

Lever

PRESS

Slide On

BRACKET

C

I

6

FORK

PULL

12

9

18

11

14

6

17

D

J

12

FORK

E F

K

13

Shorter screw

COIN

L

3

15

12

Magnet center aligns to

the marking line.

Gap < 5mm (0.2")

10

16

9

14

8

7

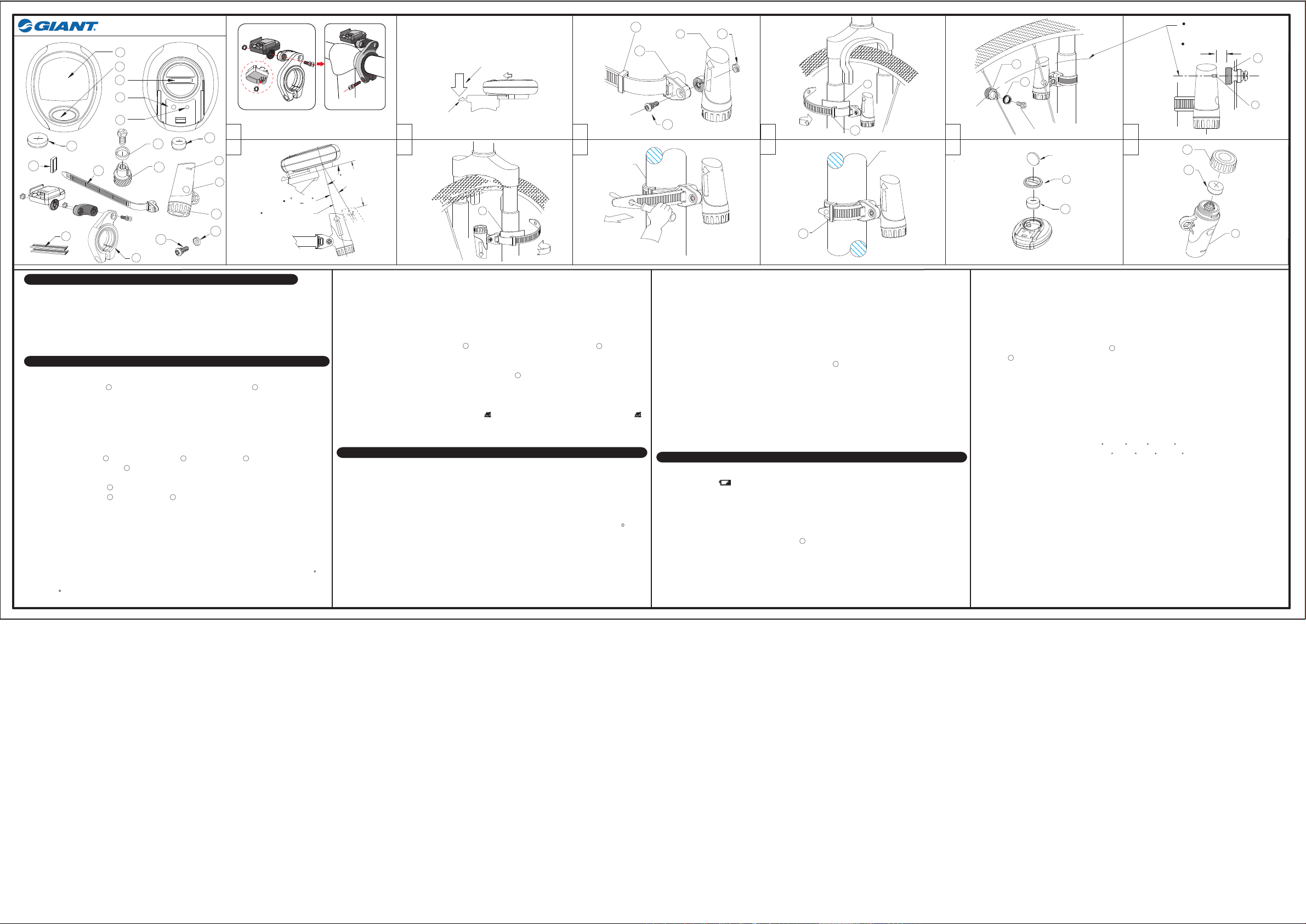

A. PHYSICAL DESCRIPTIONS

1. LCD DISPLAY

2. MODE BUTTON

3. MAIN BATTERY CAP

4. SET BUTTON

5. SLIDE ON/OFF SWITCH

6. RUBBER PAD x 2

7. BRACKET

8. SENSOR ZONE

9. SENSOR (TRANSMITTER)

10. SENSOR BATTERY CAP

11. SENSOR BAND

12. BAND CARRIER

13. RING

14. MAGNET

15. 3V BATTERY (CR2032)

16. 1.5V BATTERY

(LR44 IS TYPICAL)

17. SCREW

18. NUT

English

B. INSTALLATION

INSTALL THE BRACKET AND MAIN UNIT

1. Attach the bracket to the handlebar and fit the rubber pad between the

7

6

handlebar and the band of the bracket. Tighten the screw securely until the

bracket is secure. (Fig. A)

2. Slide the main unit onto the bracket from front to rear until it clicks into position.

To remove the main unit, press down on the bracket locking lever then push the

main unit forward and off. (Fig. B)

INSTALL SENSOR AND MAGNET

1. Attach the sensor to the sensor band with the screw .

Mount the band carrier onto sensor band. (Fig. C)

2. Mount the sensor unit on the right front fork with rubber pad. (Fig. D)

3. Mount the magnet on one spoke of the front wheel, The magnet should face the

sensor's mark line . Place the ring around the magnet to enhance the

9

12

14

8

11

13

17

reliability of the set screw. (Fig. E)

4. Adjust the relative position between the main unit and the sensor, according to the

following key points:

a. Adjust the magnet fixed position until the center of the magnet is aligned with

the line marked on the sensor. (Fig. E)

b. Adjust the sensor to set the gap between the magnet and the line marked on the

sensor at about 5mm (0.2"). (Fig. F)

c. Adjust the angle of the sensor to aim in the direction of the main unit +/- 15 .

The best performance is acheived with the sensor arrow oriented perpendicular

(90 ) to the battery cap of the main unit. (Fig. G)

d. Install the sensor as close to the main unit as possible and no more than 45 cm

(1.5 feet) to improve wireless performance.

The computer will function with the sensor arrow pointed down (Fig. H), but by

pointing the arrow up the performance will be improved by reducing the

transmitting distance.

5. Refer to the TEST section to test the installation before tightening the sensor band

with a screwdriver. (Fig. I)

6. Secure the excess sensor band by inserting it into the band carrier . (Fig. J)

11

12

TEST

1. The main unit has a " On/Off Detecting Switch " (patents pending) to turn ON/OFF

5

the power of the wireless receiver. It can receive the wireless wheel signals only after

the main unit is installed onto the bracket.

2. Spin the front wheel to check if installation is correct. Correct installation is

confirmed if the main unit blinks the " " symbol. The installation is incorrect if " "

is not displayed. Please check the relative position of the main unit, the sensor and

the magnet, or refer to the trouble-shooting table.

C. WIRELESS SYSTEM PERFORMANCE

1. The sensor transmits the rotating wheel signal to the receiver in the main unit by

wireless transmission. To protect the receiver from interference from other wireless

noises - causing the main unit to display false data, install the transmitter

according to the following key points to improve performance.

a. The receiver is designed to receive a signal from only a certain direction and

angle to reduce the noise interference from other sources. Adjust the installation

angle of transmitter to aim in the direction of the main unit within a +/- 15 , The

best performance is with a vertical orientation.

b. The receiver will receive a stronger wireless signal if the transmitter is closer to

the receiver. A stronger sensing signal not only has better noise immunity, but

also increases the transmitter battery's operating life. For good wireless

performance, please install the transmitter as close to the main unit as possible

and within 45 cm (1.5 feet).

2. Precautions

a. This computer experiences almost no cross-talking interference when 2 bicycles

carrying the same or similar wireless cycle computers are ridden side by side, as

long as the cross-distance is over 40cm (15.8").

b. This computer has excellent noise immunity to some forms of electromagnetic

interference, but it may be effected by strong electromagnetic waves which will

cause the main unit to display erroneous data while it is near the source of strong

interference; such as TV transmission stations, radar stations, and some heavy

industrial machines.

3. This computer has a "On/Off Detecting Switch" to check that the main unit is

5

installed on the bracket.

a. To reduce the power consumption of the main unit and to increase the battery

operation life, but also to protect against all indoor electromagnetic interference

from electrical equipment (such as PC monitors, mobile-phones, etc.). It will turn

off the power supply of the receiver when the main unit is removed from the

bracket.

b. The main unit can only receive the wheel signals after it is installed onto the

bracket.

D. BATTERY CHANGE

1. MAIN UNIT BATTERY CHANGE

a. The symbol " " will appear to indicate the battery is nearly exhausted.

b. Replace the battery with a new battery within a few days after the symbol was

appeared.

c. All data will be cleared when battery is replaced, but this computer allows you to

re-key in ODO which you have ridden after replacing battery, record this data

before you remove the old battery.

d. Replace with a new CR2032 battery (Fig. K) and initiate the main unit.

15

2. CHANGING THE SENSOR (TRANSMITTER) BATTERY

a. The patent-pending transmitter circuit is designed to reduce power consumption;

a 1.5V battery (typically an LR44) can operate for over 24.000km (15.000miles)

riding distance or 2 years.

b. Replace a new battery when the transmitter's battery power is nearly exhausted,

otherwise the transmission power of the wheel signal will be weak, causing the

main unit to display unstable data.

c. Replace with a new LR44 battery with the positive (+) pole toward the sensor

cap . (Fig. L)

10

16

Sensor and Transmitter: No Contact Magnet sensor and Wireless Transmitter.

Suitable Fork Size: 12mm to 50mmo (0.5" to 2.0"o) Forks.

Wireless Transmition Distance: 55cm (1.8 feet) between the transmitter and the main

unit.

Cross-Talking Interference: Within 40 cm (15.8"), no interference by 2 bicycles

carrying similar cycle computers, even when ridden

side by side.

Wheel Circumference Setting: 1mm - 3999mm (1mm increment)

Operation Temperature: 0 C ~ 50 C (32 F ~ 122 F)

Storage Temperature: - 10 C ~ 60 C (14 F ~ 140 F)

Main Unit Battery Power: 3V battery x 1 (CR2032), battery operating life is about

2 years. (Based on an average of 1.5 hours use per

day)

Transmitter Battery Power: 1.5V battery x 1 (typical LR44). About 24.000km/15.000

miles riding distance or 2 years battery operating life.

(The original factory-attached battery life may be

shorter than this period due to shipping and storage

time).

Dimensions and Weight: Main Unit: 44.0 x 54.5 x 19.73mm/30.8g

Transmitter: 20.0mmo x 48.0mm/13.3g

* The specifications and designs may be changed without notice.

Page 2

INDEX:

a

2 SEC

Means press button more than 2 seconds.

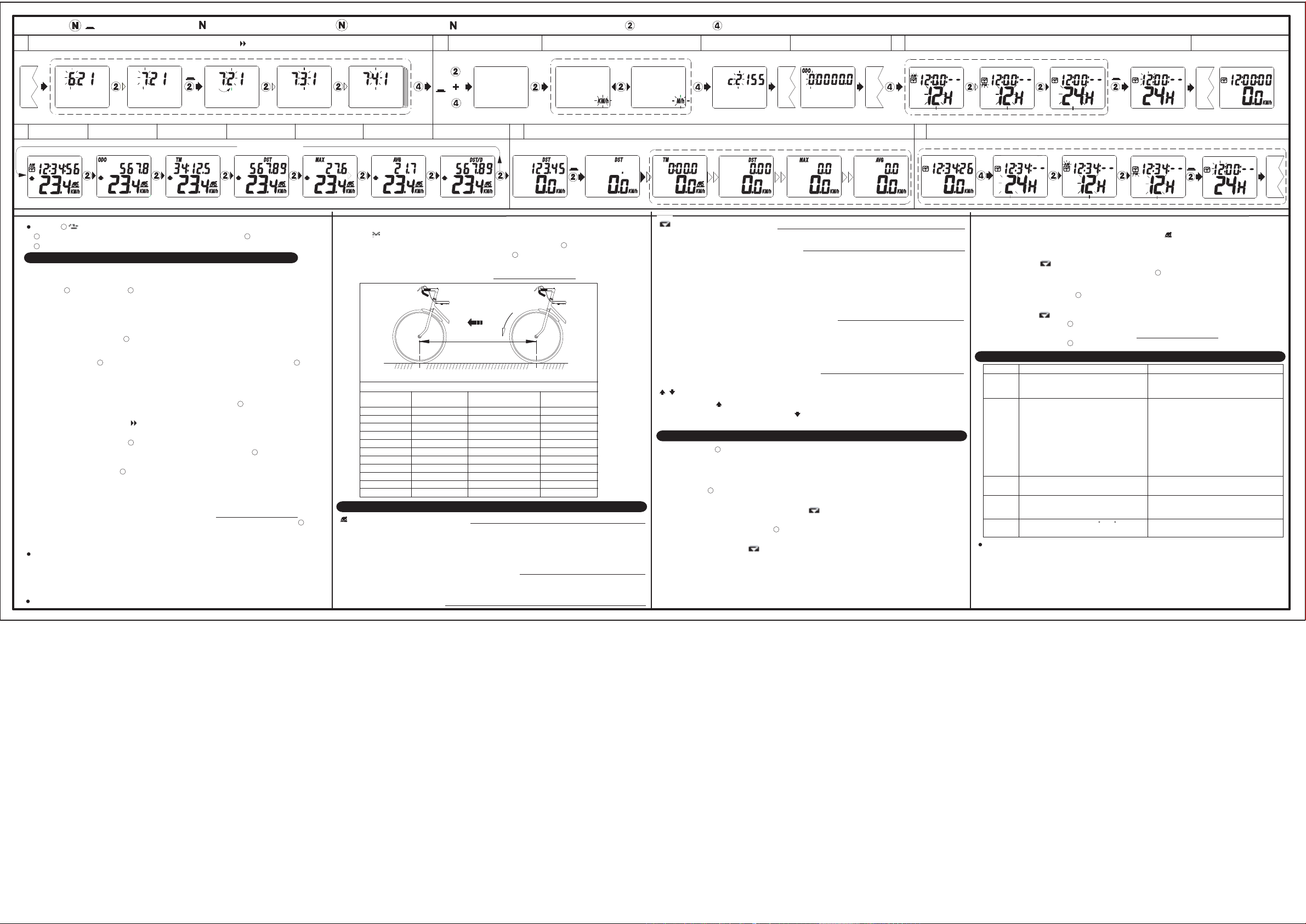

DATA SETTING PROCESSES (621 741)

Means press button quickly.

1

ALL CLEAR

N=KEY NUMBER: ( :Mode Button; :Set Button)

UNIT SELECTION

CIRCUMFERENCE SETTING

ODO SETTING

b

CLOCK SETTING

NORMAL OPERATION

EC2 S

2

D

Clock

Odometer

+1 +1 +1

Trip time

Distance

RIDING STATUS

N

INDEX: MEANS PRESS BUTTON N MORE THAN 2 SECONDS.

N

MEANS PRESS BUTTON N QUICKLY {N=KEYNUMBER: MODE Button.

4

SET Button. }

E. MAIN UNIT SETUP (Fig. 1)

COMPUTER SET-UP

1. A battery is already loaded in the main unit when purchased. Hold down the MODE

button and SET button simultaneously for more than 3 seconds to initiate the

computer and clear all data.

2

IMPORTANT: Be sure to initiate the computer before it is be used, otherwise the

4

computer may run errors.

2. The LCD segments will be tested automatically after the unit is initiated.

3. Press the MODE button to stop LCD test, then the flickering "KM/h".

2

UNIT SELECTION

Press MODE button to choose KM/h or M/h (Mile/h). Press the SET button to

2

select either as desired.

ODO SETTING

1. This function is designed to re-enter ODO data when battery is replaced. New users

do not need to enter this setting. Pressing the SET button skips one step in the

set-up process.

2. Data Entry Processes (621 741): (Fig a)

A. The each digit is adjusted separately . The digit to be set blinks.

B. Press the MODE button to increase the value by 1.

2

C. Advance to the next digit by holding down the MODE button for more than 2

seconds.

D. Press the SET button to store the data and change to the next setting.

4

CIRCUMFERENCE DATA SETTING

1. "c2155"is displayed as the default value 2155mm. Measure the circumference of

your wheel or refer to the quick reference table provided in this manual.

2. Adjust the circumference data as described in the Data Setting Processes.

3. The display will change to the Clock setting screen after the "SET" button is

pressed to store the desired data.

WHEEL CIRCUMFERENCE

Precise Measurement (Fig. M)

Roll the wheel until the valve stem is at its lowest point close to the ground, then

mark this first point on the ground. Roll the bicycle forward in a straight line until the

valve stem returns to its lowest point. Mark the second point on the ground. Measure

the distance between the marks. Enter this value to set the wheel circumference.

Quick Reference Table (Fig. N): Select a suitable circumference value from the table.

2

English

4

4

2

4

Max speed

LCD

MODE

Average speed

EC3 S

Distance per day

SET

SEGMENTS

AUTO TEST

3

2 S CE

CLOCK SETTING (Fig. b)

1. The " " symbol is displayed in the clock mode.

2. 12H/AM, 12H/PM or 24H selection. Press the MODE button to select 12H/AM,

12H/PM or 24H. Hold down the MODE button for more than 2 second to change to

2

2

the clock setting screen.

3. Adjust the time setting according to the Data Setting Processes.

CIRCUMFERENCE

Tire Size

FIRST POINT

Number

2099

2117

2092

2124

2136

2155

2164

2174

2193

2234

2281

mm

SECOND POINT

Tire Size

18 Inch

20 x 1.75

20 Inch

22 Inch

ATB 24 x 1.75

24 Inch

24 x 13 / 8

ATB 26 x 1.40

ATB 26 x 1.50

ATB 26 x 1.75

26 Inch ( 650A )

POPULAR TIRES CIRCUMFERENCE REFERENCE TABLE

Circumference Circumference

Number

mm

1436

1564

1596

1759

1888

1916

1942

1995

2030

2045

2073

ATB 26 x 2.0 (650B )

700C TUBULAR

700 x 20C

700 x 25C

700 x 28C

27 Inch ( 700 x 32C )

700 x 35C

700 x 38C

27.5 Inch

28 Inch ( 700B )

28.6 Inch

F. FUNCTIONS and SPECIFICATIONS

: Current Speed

0.0 - 199.9 Km/h or 120.0 Mile/h +/- 1% (Typical)

1. The current speed is always displayed on the upper display when riding. It displays

current speed up to 199.9 KM/h or 120.0 M/h (for wheel diameters of over 24 inches).

2. When riding is stopped, the speed will continue to be calculated for 4 seconds to

confirm that the bicycle has come to a complete stop.

ODO: Odometer

0.0 - 99999.9 Km or Miles +/- 0.1%

1. The odometer accumulates the total distance the bike has traveled.

2. The ODO data can not be cleared to zero by the RESET operation.

TM: Riding Time

0M00.0S-59M59.9S, 1H00M00S-99H59M59S +/- 0.003%

RESET (TM=0, DST=0, MAX=0, AVG=0)

: 12HR AM/PM or 24HR Clock

D

0:00'00" - 12:59'59" AM/PM or 23:59'59" +/- 0.003%

D

4

Displays the current time in 12HR AM/PM or 24HR clock.

AVG: Average Speed

0.0 - 199.9 Km/h / 0.0 - 120.0Mile/h +/- 0.1%

1. Is calculated from the DST divided by the TM. The average speed data is calculated

from the last RESET to the current point.

2. "0.0" is displayed when TM is less than 4 sec., and is updated approximately every

second after the first 4 seconds.

3. An "Error" symbol is displayed when either the TM is over 100 hours or the DST is

over 1.000km (or miles). Reset the unit in order to restart.

DST: Trip Distance

0.00 - 999.99 Km or Miles +/- 0.1%

The DST function accumulates the total distance traveled since the last RESET.

DST/D: Distance Today

The DST/D function calculates the distance traveled in a given day. The data is cleared

at 12:00:00 AM (0:00:00) automatically.

MAX: Maximum Speed

0.0 - 199.9 Km/h or 120.0 Mile/h +/- 1%

Displays the highest speed since the last RESET operation.

/

: Speed Pacer

It flashes the " " speed pacer arrow while the current speed is higher than the

average speed, and the down arrow " " flashes conversely.

* Remarks: All data functions are updated approximately once per second.

G. BUTTONS and NORMAL OPERATION

MODE BUTTON (Fig. 2)

2

1. Quickly press this button to move in a loop sequence from one function screen to

another.

2. The ODO function is skipped while riding.

SET BUTTON

4

Press this button to get in or out of the setting screens in order to re-set to wheel

circumference or the current time of the " ".

RESET OPERATION (Fig. 3)

1. Hold down the MODE button until the display goes blank, then release. The

2

computer will reset AVG, DST, TM and MAX data from stored values to zero.

2. ODO cannot be reset, .

MAIN UNIT ON/OFF DETECTION

The computer has a detecting switch (patents pending) to avoid noise interference

when the main unit is removed from the bracket. The main unit can receive the wheel

signal only when it is installed on the bracket.

AUTOMATIC START/STOP & AUTO SLEEP MODE

2 SEC

D

CLOCK RE-SETTING

CE2 S

The computer will automatically begin receiving data upon riding and stop receiving

data when riding is stopped. The flickering symbol " " indicates that the computer

is at start status.

To preserve the battery, this computer will automatically power down into a sleep

mode. Only the " " data will be displayed when it has not been used for about 30

minutes. Power up by pressing the MODE button .

CIRCUMFERENCE, CLOCK RE-SETTING (Fig. 4)

1. Press the MODE button to change to one of the following mode displays.

2

a. Change to ODO screen to set Circumference.

b. Change to " " screen to set Clock.

2. Press the SET button to enter to the relative setting screen.

4

3. Adjust the desired value according to the Data Setting Processes.

4. Press the SET button to store the desired data and complete the current setting.

4

H. TROUBLE SHOOTING

PROBLEM

Main Unit:

No display

No current

speed

orIncorrect

data

Irregular

display

LCD is

black

Display is

slow

CHECK ITEMS REMEDY

1. Is the battery dead?

2. Is there incorrect battery installation?

1. Is it at the MAIN UNIT SETUP or another

setting screen?

2. Are the relative positions and gap

between sensor and magnet correct?

3. Is the circumference correct?

4. Is the sensing distance too long or the

installation angle of the sensor incorrect?

5. Is the sensor battery nearly exhausted?

6. Is any strong interference source nearby?

Was the main unit under direct sunlight

when not riding the bike for a long time?

Is the temperature below 0 C (32 F)?

PRECAUTIONS

1. Don't leave the main unit exposed to direct sunlight when not riding the bike.

2. Don't disassemble the main unit or its accessories.

3. Check relative position and gap of sensor, magnet and main unit periodically.

4. Don't use thinner, alcohol or benzine to clean the main unit or its accessories when

they become dirty.

5. Remember to pay attention to the road while riding.

2

1. Replace the battery.

2. Be sure that the positive pole of the battery

is facing the battery cap.

1. Refer to the setting procedure and complete

the adjustment.

2. Refer to (Fig. G) and (Fig. H) and re-adjust

position and gap correctly.

3. Refer to "Circumference Setting" and enter

correct value.

4. Refer to (Fig. F) to adjust distance or angle

between the main unit and the sensor.

5. Replace with a new battery.

6. Move away from the source of interference.

Refer to the "MAIN UNIT SETUP" and initiate

the computer again.

Place main unit in the shade to return to

normal state.No adverse effect on data.

Unit will return to normal state when the

temperature rises.

OK

D

Loading...

Loading...