Page 1

CONTINUUM 5/8

1

2

3

SET

4

5

8

S

12

11

CYCLE COMPUTER

6

Magnet center aligns to the

SENSING ZONES

S

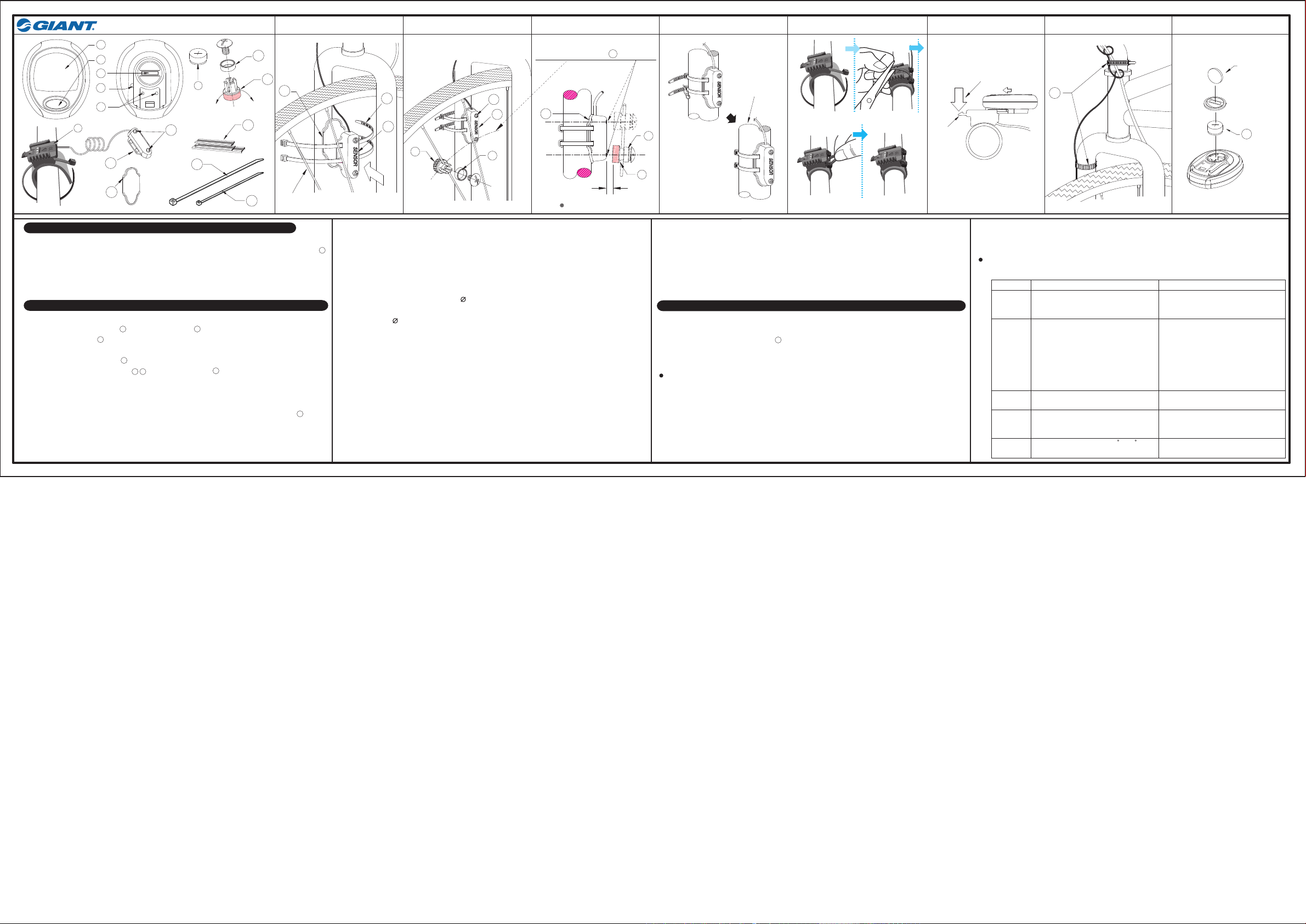

Fig. D Fig. E Fig. F Fig. G Fig. HFig. CFig. BFig. A

Press down on this lock lever

before removing the main unit.

COIN

For Flat

Spoke

10

7

11

14

12

7

13

12

6

11

SENSOR

6

FORK

1. 2.

Lever

PRESS

BRACKET

Slide On

14

Battery Cap

9

1/2

9

For Round

Spoke

13

E

N

S

O

R

15

7

Spoke

14

Gap < 4mm (1/6inch)

OK!

3. 4.

A. PHYSICAL DESCRIPTIONS

1. LCD DISLPAY

2. MODE BUTTON

3. BATTERY CAP

4. ALL CLEAR (AC) KEY

5. CONTACTS

6. RING

B. INSTALLATION

7. MAGNET

8. BRACKET

9. 1.5V BATTERY

(LR44 IS TYPICAL)

10. BRACKET RUBBER PAD x 3

11. SENSOR RUBBER PAD

12. SENSOR

13. SENSING ZONES

14. CABLE TIES (S x 5)

15. CABLE TIES (L x 4)

English

SENSOR and MAGNET MOUNTING

1. Mount the SENSOR with 2 cable ties on the front fork with the

RUBBER PAD , and let the sensor face the spoke, do not tighten the

12

11

14

cable ties before the sensor is placed in the right position. (Fig. A)

2. Mount the MAGNET on one spoke of the front wheel and let the magnet

face the sensing zones . Place the RING around the nut to enhance

7

13

S

6

the reliability of the fixed screw. (Fig. B)

(New magnet with cross gap fit to all wheel spokes both aero and round).

3. Adjust the relative position between the sensor and the magnet. (Fig. C)

a. Align the center of the MAGNET to either of the sensing zones .

S

b. Make sure the GAP between the magnet and the sensor is within

4mm (1/6 inch). Adjust the desired gap by moving both the magnet

and the sensor up or down.

IMPORTANT: If either a) or b) is incorrect, poor signal input will result.

4. Be sure all relative positions are correct, tightening the cable ties so they

will not move.

5. Cut the excess strapping on the cable ties when the installation is finished.

S

(Fig. D)

MOUNTING BRACKET INSTALLATION (Fig. E)

1. Two rubber shims are included to attach the mounting bracket to your

handlebar securely. The thinner shim is to be used with large diameter

handlebars up to 31.8 mm . The thicker shim is to be used with 25.4 mm

or greater diameter bars. Both shims can be used for bars less than

25.4 mm .

2. To secure the bracket to the handlebar, place the mounting bracket in the

correct position, run cable ties through the passages in the bracket, wrap

around the bar and fit pad(s), insert into the cable tie closure, and pull tight.

Do not tighten cable ties before the bracket is in the proper position.

3. CAUTION! When trimming the cable ties, be sure not to leave any sharp

rough ends which could result in injury.

INSTALLING THE MAIN UNIT (Fig. F)

1. Mount the main unit onto the bracket by sliding it from front to rear until it

clicks into position.

2. This bracket is designed with a locking lever to secure the main unit and

prevent it from coming loose during use.

3. To remove the main unit, press down on the lock lever, then pull the main

unit forward and off.

SECURING THE SENSOR CABLE (Fig. G)

1. Select suitable positions to secure the sensor cable to the fork with CABLE

TIES.

2. Make sure the sensor cable is loose enough for the handlebar to turn

freely before tightening the cable ties.

3. Secure excess wire near the fork crown by wrapping it around the front

brake cable or by bending it back and forth and securing it with cable ties.

C. BATTERY REPLACEMENT

1. When the brightness of the LCD display begins to dim, this

indicates that the battery is nearly exhausted.

2. Replace with a new LR44 (Cross reference type A76, AG13 or

9

V13GA) battery in the compartment on the back of the computer

with the positive (+) pole toward the battery cap. (Fig. H)

PRECAUTIONS

1. This computer can be used in the rain but should not be used under water.

2. Don't leave the main unit exposed to direct sunlight when not riding the

bike.

3. Don't disassemble the main unit or it's accessories.

4. Check relative position and gap of sensor and magnet periodically.

5. Clean the contacts of the bracket and the bottom of the main unit

periodically.

6. Don't use thinner, alcohol or benzine to clean the main unit or its

accessories when they become dirty.

7. Remember to pay attention to the road while riding.

TROUBLE SHOOTING

Check the following before taking unit in for repairs.

PROBLEM

Main Unit:

No display

No current

Speed or

incorrect

data

Irregular

display

LCD is

black

Display is

slow

1.Is the battery dead?

2.Is there incorrect battery installation?

1. Is it at the recalibrating or 12HR

clock setting screen?

2. Are the contacts between the main

unit and the bracket poor?

3.Are the relative positions and gap of

sensor and magnet correct?

4.Is the wire broken?

5.Is the circumference correct?

Was the main unit under direct

sunlight when not riding the bike for a

long time?

Is the temperature below 0 C (32 F)?

CHECK ITEMS REMEDY

1.Replace the battery.

2.Be sure that the positive pole of the

battery is facing the battery cap.

1.Refer to the adjusting procedure and

complete the adjustment.

2. Wipe contacts clean.

3. Refer to (Fig.B) and (Fig.C) and

readjust data correctly.

4.Repair or replace wire.

5.Refer to "CALIBRATION" and enter

correct value.

Refer to the "MAIN UNIT SETUP" and

initiate the computer again.

Place main unit in the shade to return

to normal state.No adverse effect on

data.

Unit will return to normal state when

the temperature rises.

Page 2

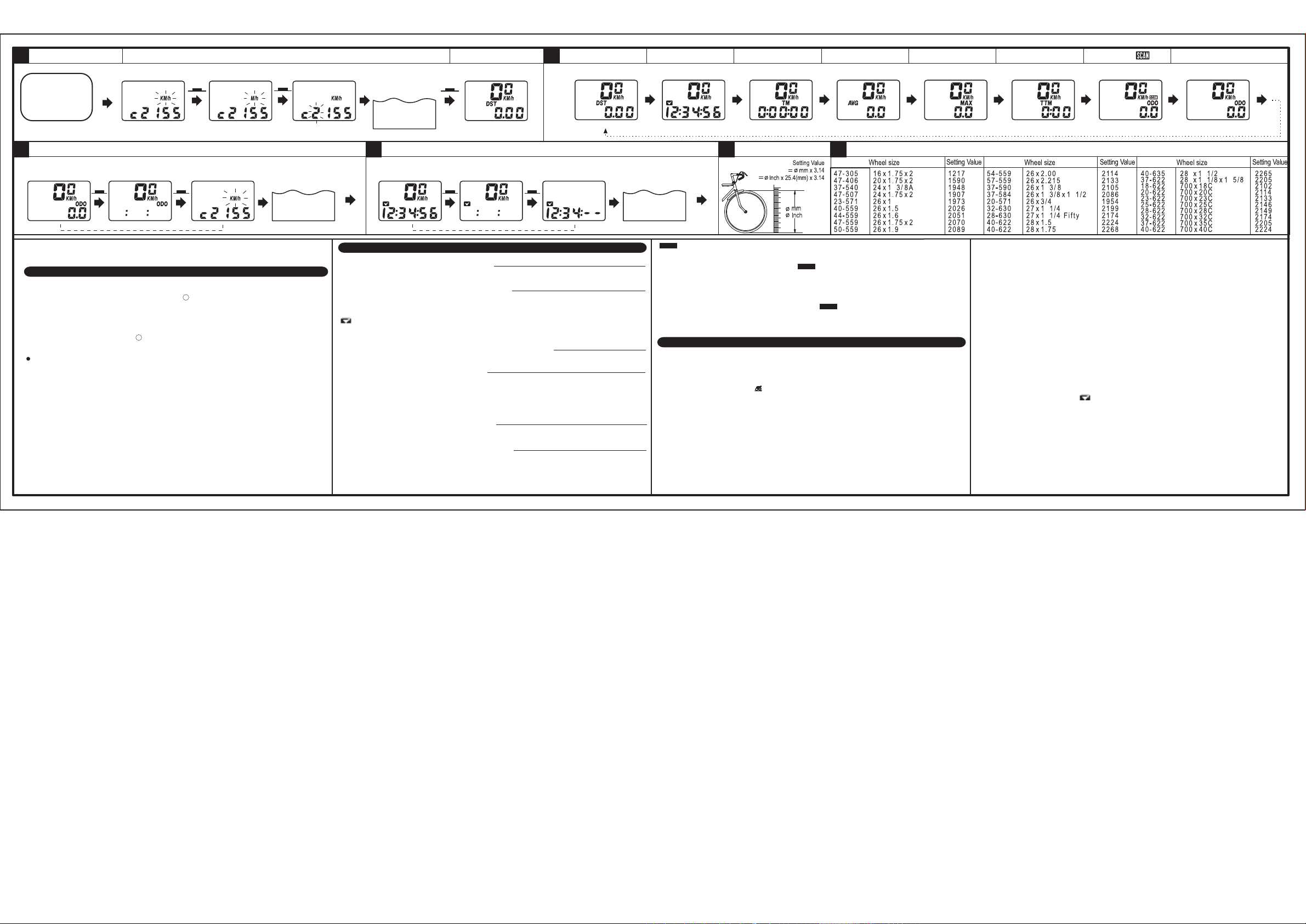

MAIN UNIT SETUP

CALIBRATION (UNIT SELECTION & CIRCUMFERENCE SETTING) END SETTING DST2 CLK TM AVG MAX T_TM ODO / ODO1

LCD

SEGMENTS

MODE

2 SEC

C mm

Setting

6 SEC

MODE MODE

AUTO TEST

3 4 5 6RECALIBRATIONS CLOCK SETTING WHEEL SIZE CHART

2 SEC 4 SEC 2 SEC 4 SEC

TOTAL 6 SEC

Calibration

Continuum 5 has 5 FUNCTIONS: SPD, DST, ODO, CLK, SCAN.

Contimuum 8 has 8 FUNCTIONS: SPD, DST, ODO, CLK, AVG, MAX, TM, SCAN

D. MAIN UNIT SETUP (Fig.1)

COMPUTER SET-UP

1. Be sure to press the All Clear (AC) key to clear all stored data and initiate

4

the computer before using it or when replacing battery otherwise the unit may

malfunction.

2. The LCD display will be tested automatically after the All Clear key is pressed.

3. Press the "MODE" button to stop the LCD test, then the flicking "KM/h" and

2

"c2155" will be displayed.

CALIBRATION

1. UNIT SELECTION

1. Press the "MODE" button to select "KM/h" or "M/h"(Mile/h).

2. Hold the "MODE" button until the blinking digit is changed to the digit "2" of

the c2155 to recognize either KM/h or Mile/h as desired.

2. CIRCUMFERENCE DATA SETTING

1. The default is set at 2155mm. Measure the value for your wheel (Fig. 5) or

refer to the quick reference table provided in the manual for your bicycle.

(Fig. 6)

2. A quick press of the "MODE" button advances the flickering digit by 1.

3. To change the blinking digit, hold down the "MODE" button until the blinking

digit moves to the next digit.

4. Hold down the "MODE" button until (about 6 seconds) it exits the set-up

mode to store the data entered and complete setup.

6 SEC

Complete

Setting

TOTAL 6 SEC

E. FUNCTIONS (Fig. 2)

SPD: Current Speed

0.0 - 199.9 Km/h or 120.0 Mile/h +/- 1%

The current speed is always displayed while riding.

DST: Trip Distance

0.00 - 999.99 Km or Miles +/- 0.1%

The DST function accumulates the distance data from the last RESET operation

as long as the bicycle is being ridden.

CLK: 12HR Clock

It displays the current time on a 12HR clock.

TM: Riding Time

0H00M00S - 19H59M59S

The TM totals the riding time from the last RESET operation.

AVG: Average Speed

0.0 - 199.9 Km/h or 120.0 Mile/h +/- 0.1%

1. Is calculated from the DST divided by the TM; the average data is calculated

from the last RESET to the current point.

2. An "Error" symbol is displayed when either the TM is over 100 hours or the DST

is over 1,000 km (or miles). Reset the unit in order to restart.

MAX: Maximum Speed

0.0 - 199.9 Km/h or 120.0 Mile/h +/- 1%

Displays the highest speed since the last RESET operation.

ODO: Odometer

0.0 - 19999.9 Km or Miles +/- 0.1%

The ODO accumulates the total distance the bike has traveled.

The ODO data can be cleared by the ALL CLEAR operation only.

CLOCK

SETTING

SCAN

6 SEC

Complete

Setting

: SCAN

1. Auto-Scanning Display Mode

Press the MODE button until the" " symbol is displayed. The computer will

SCAN

change the DST, CLK, TM, AVG, MAX, TTM and ODO display modes in a loop

sequence automatically every 6 seconds.

2. Fixed Display Mode

Press the MODE button to turn off the " " symbol and select a desired

SCAN

display mode; the computer will stop the auto-scanning display operation and

the display mode is set.

F. BUTTON and NORMAL OPERATIONS

AUTOMATIC START/STOP

1. The computer will automatically begin calculating SPD, ODO, DST, MAX, TTM,

TM and AVG data while riding and stop when you stop riding.

2. The blinking symbol " " indicates that the computer is at START status.

AUTO SLEEP MODE

To preserve battery, this computer will automatically power down when it has not

been used for about 10 minutes. The computer will power up automatically by

riding the bicycle or by pressing the button.

MODE BUTTON

Quickly press this button to advance in a loop sequence from one basic function

screen to another.

ALL CLEAR OPERATIONS (Initiate the Computer)

Press the ALL CLEAR (AC) key to initiate the computer or use ALL CLEAR if any

irregular data appears. It will clear all stored data.

RESET OPERATION

1. Hold down the "MODE" button until the LCD display goes blank, then release it.

The computer will RESET the DST, TM, AVG, MAX.

2. It cannot reset CLK, TTM and ODO data.

RECALIBRATIONS (Fig. 3)

1. Change the display to ODO screen, hold down the "MODE" button until (about 6

seconds) it jumps to the set-up screen.

2. Refer to the main unit setup process to adjust the circumference.

3. Hold down the "MODE" button until (about 6 seconds) it exits the set-up mode to

store the desired data and complete recalibrations.

12HR CLOCK SETTING (Fig. 4)

1. Change the display to " " screen.

2. Press the "MODE" button until (about 6 seconds) it jumps into the clock adjusting

screen to set the clock.

3. A quick press of the "MODE" button advances the blinking digit by 1.

4. To change the blinking digit, hold down the "MODE" button until the blinking

digit moves to the next digit.

5. Hold down the "MODE" button until (about 6 seconds) it exits out of the setting to

store the desired data and complete clock setting.

Loading...

Loading...