Page 1

CHAPTER

Installing and Starting Up

the Hub

This chapter provides installation warnings, guidelines, requirements, and package

contents and the following procedures:

• Unpacking the hub

• Powering up the hub and running the power-on self-test (POST)

• Installing the hub on a tabletop or shelf, in a standard or telco rack, and on a wall

• Connecting to the console port (FastHub 400M models)

• Assigning IP information to the hub and displaying the web and menu consoles

(FastHub 400M models)

• Connecting to the 10/100 ports on the hub

2

• Accessing the management interfaces (FastHub 400M models)

• Going to related procedures

Installing and Starting Up the Hub 2-1

Page 2

Warnings

Warnings

Translated versions of the following safety warnings are provided in Appendix E,

“Translated Safety Warnings.”

Warning Only trained and qualified personnel should be allowed to install or replace this

equipment.

Warning Do not work on the system or connect or disconnect cables during periods of

lightning activity.

Warning Unplugthepowercord before youworkon a system that doesnothavean on/off

switch.

Warning Do not touch the power supply when the power cord is connected. For systems

withapowerswitch, line voltages arepresentwithinthe power supply evenwhen the power

switch is off and the power cord is connected. For systems without a power switch, line

voltages are present within the power supply when the power cord is connected.

2-2

Warning Read the installation instructions before you connect the system to its power

source.

Warning This product relies on the building’s installation for short-circuit (overcurrent)

protection. Ensure that a fuse or circuit breaker no larger than 120 VAC, 15A U.S.

(240 VAC, 10A international) is used on the phase conductors (all current-carrying

conductors).

Warning To prevent the unit from overheating, do not operate it in an area that exceeds

the maximum recommended ambient temperature of 113°F (45°C). To prevent airflow

restriction, allow at least 3 inches (7.6 cm) of clearance around the ventilation openings.

Warning The device is designed to work with TN power systems.

FastHub 400 10/100 Series Installation and Configuration Guide

Page 3

EMC Regulatory Statements

Warning This equipment is intended to be grounded. Ensure that the host is connected to

earth ground during normal use.

Warning When installing the unit, the ground connection must always be made first and

disconnected last.

Warning Donot stack the chassis on any other equipment. If the chassis falls, it can cause

severe bodily injury and equipment damage.

Warning Caremust be given to connecting units to the supply circuit so that wiring is not

overloaded.

Warning Avoltagemismatchcan cause equipment damage and may pose a fire hazard. If

the voltage indicated on the label is different from the power outlet voltage, do not connect

the chassis to that receptacle.

Warning Ultimate disposal of this product should be handled according to all national

laws and regulations.

EMC Regulatory Statements

U.S.A.

U.S. regulatory information for this product is in the front matter and in Appendix E,

“Translated Safety Warnings,” of this manual.

Taiwan

15456

Installing and Starting Up the Hub 2-3

Page 4

Installation Guidelines and Requirements

Installation Guidelines and Requirements

When determining where to place the hub, ensure the following conditions are met:

• Cable distances from the hub to network equipment and workstations are within the

limits described in Appendix B, “Connector and Cable Specifications.”

• Operating environmentiswithinthe temperature, humidity,and altitude ranges listed in

Appendix A, “Technical Specifications.”

If the hub is installed in a closed or multirack assembly, the temperature might be

greater than normal room temperature.

• Clearance to front and rear panels is such that:

— Front-panel indicators can be easily read.

— Access to the rear-panel expansion slot is sufficient for inserting the optional

switched uplink module.

— Accessto the front- and rear-panel ports and connectors is sufficient for connecting

cables.

— Rear-panel power connectors are within reach of power sources.

• Airflow around the hub and through the vents is unrestricted.

• Cabling is away from sources of electrical noise, such as radios, power lines, and

fluorescent lighting fixtures.

Unpacking the Hub

Follow these steps to unpack the hub:

Step 1 Open the shipping container, and carefully remove the contents.

Step 2 Return all packing materials to the shipping container, and save it.

Step 3 Ensure that all items listed in the “Package Contents” section on page 2-5 are

included in the shipment.

2-4

FastHub 400 10/100 Series Installation and Configuration Guide

Page 5

Package Contents

Each hub is shipped with the following items:

• FastHub 400 10/100 Series Cabling and Start Up

• This FastHub 400 10/100 Series Installation and Configuration Guide

• Cisco Documentation CD-ROM

• AC power cord

• Mounting kit containing the following items:

— Four rubber feet for installing the hub on a table or shelf

— Two mounting brackets

— FourPhillips flat-head screws and four Phillips truss-head screws for attaching the

mounting brackets to the hub

— Four Phillips machine screws for attaching the mounting brackets to a rack

— Onecable guide and one black Phillips machine screw for attaching the cable guide

to one of the mounting brackets

• RJ-45-to-RJ-45 rollover console cable and an RJ-45-to-DB-9 female DTE adapter

(labeled Terminal) (FastHub 400M models only)

Package Contents

• Cisco Information Packet, containing warranty, safety, support information, and

Cisco Product Registration Card

Note If any item is damaged or missing, contact your Cisco representative or reseller for

support.

Installing and Starting Up the Hub 2-5

Page 6

Powering Up the Hub and Running POST

Powering Up the Hub and Running POST

Before installing and cabling the hub, you might want power up the hub and verify that it

is operational.

To power up the hub, connect one end of the AC power cord to the AC powerconnector on

the hub and the other end of the cord to a power outlet. If your configuration has a Cisco

RPS, see the RPS documentation.

The hub begins the power-on self-test (POST) after power up. POST consists of the

ten individual tests listed in Table 4-2. The port LEDs showwhichtestthehubisexecuting.

At power up, all port LEDs are green. As each POST test executes, a port LED turns off.

For example, if the LED for port 12x is off, the boot code test (test 1) is being executed. On

the hub, the port LED for port 12x turns off first, followed by ports 11x, 10x, 9x, and so on.

The LEDs for ports 1x and 2x are not used during POST. The SYSTEM LED is blinking

green while POST is executing.

When POST completes, the following conditions can exist (if other devices are not

connected to the hub):

• All POST tests passed—If the SYSTEM LED is green and all of the port LEDs are off,

no problems were detected. The hub is fully operational.

• Nonfatal failure(s) detected—If the SYSTEM LED is amber and the hub is functional,

POST detected one or more nonfatal failures. Although the hub is still operational and

can forward packets, it might not operate optimally. Refer to the POST failure message

displayed on the diagnostic console screen, identifying the nonfatal failure(s) detected

(see the “Understanding POST Results” section on page 4-4).

2-6

• Fatal failure(s) detected—POST completes all tests, even after detecting a fatal failure.

If the SYSTEM LED is amber and one or more of the port LEDs are amber, POST

detected one or more fatal failures. The hub is not operational, but the amber port

LED(s) indicate which test(s) failed.

Youshould inform your system administrator if one or more nonfatal failures are detected.

Contact your Cisco representative or reseller for support if any fatal failures are detected.

The “Understanding POST Results” section on page 4-4 provides additional information,

including the possible causes of nonfatal and fatal failures.

FastHub 400 10/100 Series Installation and Configuration Guide

Page 7

Installing the Hub on a Table or Shelf

To install the hub on a table or shelf, follow these steps:

Step 1 Be sure the hub is powered off and is not connected to a power source.

Step 2 Locate the adhesive strip with the rubber feet that shipped with the hub.

Step 3 Attach the rubber feet to the round recesses on the bottom corners of the hub.

Step 4 Place the hub on a table or shelf close to an AC power receptacle.

Step 5 Connect one end of the AC power cord to the AC power connector on the hub

and the other end of the cord to a power outlet. If your configuration has a Cisco

RPS, see the RPS documentation.

After power is connected, the hub starts the series of self-tests described in the

“Powering Up the Hub and Running POST” section on page 2-6.

Installing the Hub on a Table or Shelf

Installing and Starting Up the Hub 2-7

Page 8

Installing the Hub in a Rack

Installing the Hub in a Rack

This section describes how to install the hub in 19- and 24-inch standard and telco racks.

Note Be sure the hub is powered off and is not connected to a power source before you

perform the steps in the sections that follow.

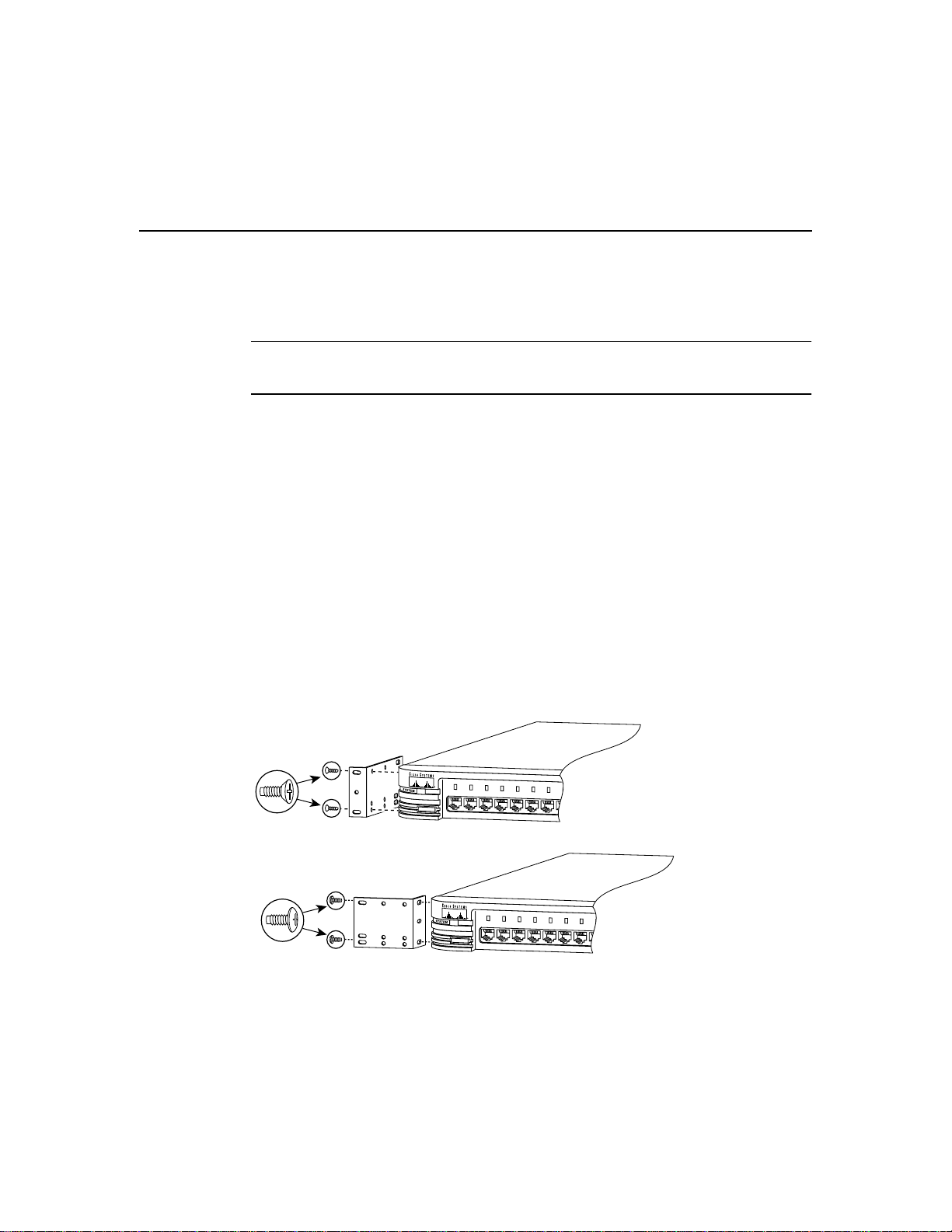

Attaching the Brackets to the Hub

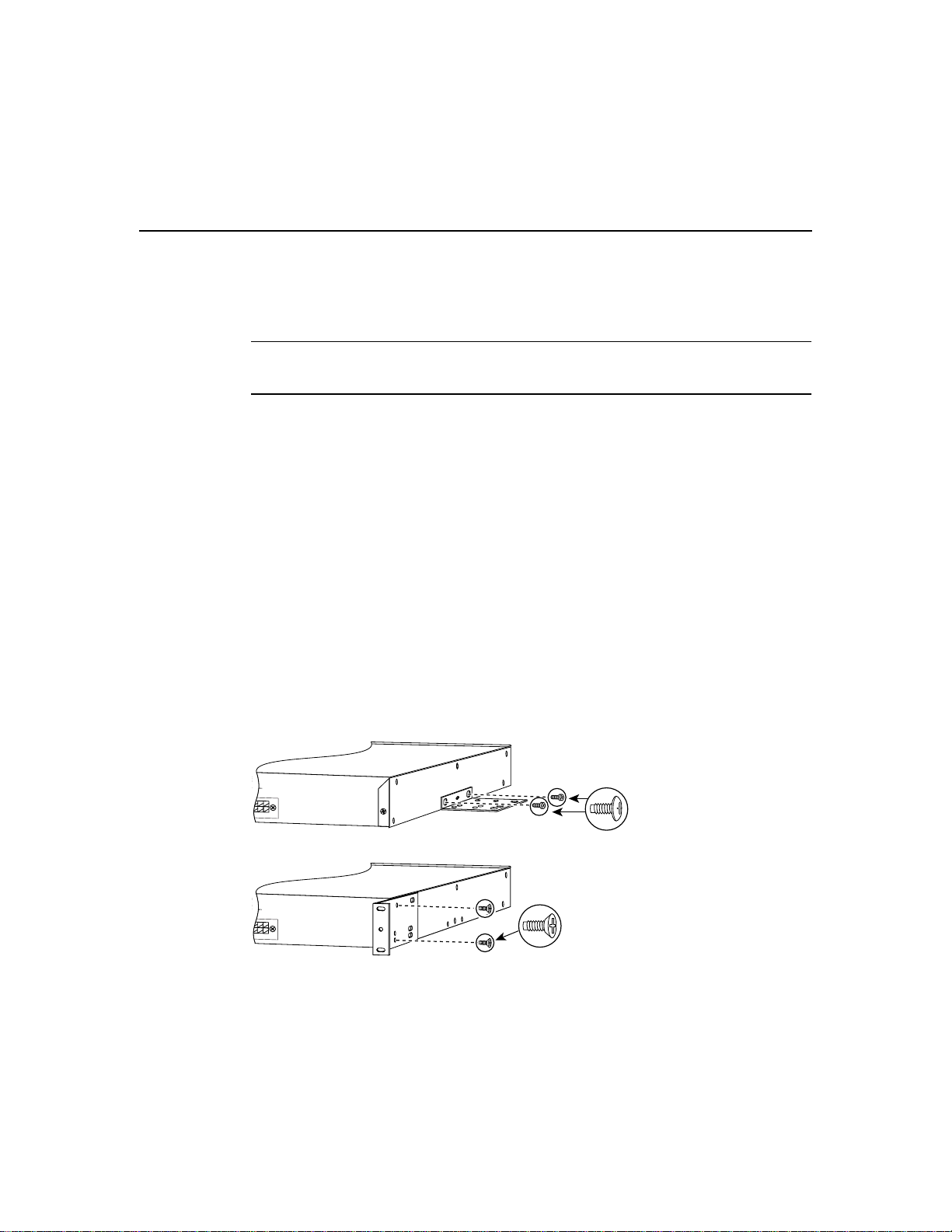

Thebracketorientation and the screws youusedependon whether you plan to use a19-inch

or a 24-inch rack:

• For a 19-inch rack-mount, use the Phillips flat-head screws to attach the long side of the

bracket to the hub.

• For a 24-inch rack-mount, use the Phillips truss-head screws to attach the short side of

the bracket to the hub.

Place the hub on a level surface, and use two of the supplied Phillips flat-head or truss-head

screws to attach a mounting bracket to each side of the hub.

Figure 2-1, Figure 2-2, and Figure 2-3 show how to attach one bracket to one side of the

hub. Follow the same steps for the opposite side of the hub.

2-8

Figure 2-1 Attaching Brackets for 19- and 24-inch Racks (Front Panel Forward)

Phillips

flat-head

screws

RPS

1x 2x 3x 4x 5x 6x 7x 8x

MODE

19" configuration

Phillips

truss-head

screws

RPS

1x 2x 3x 4x 5x 6x 7x 8x

MODE

24" configuration

FastHub 400 10/100 Series Installation and Configuration Guide

H10730

H10731

Page 9

Attaching the Brackets to the Hub

Figure 2-2 Attaching Brackets for 19- and 24-inch Racks (Rear Panel Forward)

R REMOTE

UPPLY

MANUAL

12V

@

R REMOTE

UPPLY

N MANUAL

12V

1A

@

1A

19" configuration

Phillips

flat-head

screws

H10186

Phillips

truss-head

screws

24" configuration

H10187

Figure 2-3 Attaching Brackets for 19- and 24-inch Racks (Mid-Mount)

R REMOTE

UPPLY

N MANUAL

12V

R REMOTE

UPPLY

N MANUAL

12V

@

1A

@

1A

19" configuration

24" configuration

Phillips

flat-head

screws

H10190

Phillips

truss-head

screws

H10191

Installing and Starting Up the Hub 2-9

Page 10

Installing the Hub in a Rack

Attaching the Hub to the Rack

After the brackets are attached, use two of the Phillips machine screws to securely attach

each bracket to the rack, as shown in Figure 2-4.

Figure 2-4 Attaching the Hub to a Rack (Front Panel Forward)

RPS

1x 2x 3x 4x 5x 6x 7x 8x 9x 10x 11x 12x 13x 14x 15x 16x 17x 18x 19x 20x 21x 22x 23x 24x

MODE

Phillips machine

screws

Ax Bx

SERIES

H10559

2-10

FastHub 400 10/100 Series Installation and Configuration Guide

Page 11

Attaching the Cable Guide to the Bracket

Attaching the Cable Guide to the Bracket

Attaching the cableguideandsecuringthecablesinthecableguide prevent the cables from

obscuring the hub and other devices in the rack. If the hub is in a 19- or 24-inch rack, you

can attach the cable guide to the left or right rack-mount bracket with the black screw, as

shown in Figure 2-5.

Figure 2-5 Attaching a Cable Guide

RPS

1x 2x 3x 4x 5x 6x 7x 8x 9x 10x 11x 12x 13x 14x 15x 16x 17x 18x 19x 20x 21x 22x 23x 24x

MODE

Ax Bx

SERIES

H10560

Black Philips machine screw

After the hub is in the rack, connect one end of the AC power cord to the AC power

connector on the hub and the other end of the cord to a power outlet. If your configuration

has a Cisco RPS, see the RPS documentation. After power is connected, the hub starts the

series of self-tests described in the “Powering Up the Hub and Running POST” section on

page 2-6.

Installing and Starting Up the Hub 2-11

Page 12

Installing the Hub on a Wall

Installing the Hub on a Wall

This section describes how to attach the hub in parallel and vertically to a wall.

Note Be sure the hub is powered off and is not connected to a power source before you

perform the steps in the sections that follow.

Attaching the Brackets to the Hub

The bracket orientation depends on whether you plan to parallel or vertical wall-mount the

hub:

• For a parallel wall-mount, use the Phillips truss-head screws to attach the short side of

the bracket to the hub.

• For a vertical wall-mount, use the Phillips flat-head screws to attach the long side of the

bracket to the hub.

Place the hub on a level surface, and use two of the Phillips truss-head or flat-head screws

to attach a mounting bracket to each side of the hub.

Figure 2-6 shows how to attach one bracket to one side of the hub. Follow the same steps

for the opposite side of the hub.

2-12

Figure 2-6 Attaching Brackets for Parallel and Vertical Wall-Mounting

R REMOTE

UPPLY

N MANUAL

12V

@

1A

For parallel wall-mounting

R REMOTE

UPPLY

MANUAL

12V

@

1A

Phillips

flat-head

screws

For vertical wall-mounting

FastHub 400 10/100 Series Installation and Configuration Guide

Phillips

truss-head

screws

H10210

H10211

Page 13

Attaching the Hub to a Wall

For the best support of the hub and cables, make sure the hub is securely attached to a wall

stud or to a firmly attached plywood mounting backboard, as shown in Figure 2-7. You

must supply your own screws to attach the hub to the wall.

Note If you plan to use the optional switched uplink module, install it in the hub before

vertically attaching the hub to a wall.

Figure 2-7 Attaching the Hub to the Wall

User-supplied

screws

Parallel wall-mount

Attaching the Hub to a Wall

Vertical

wall stud

H10189

Bx

Ax

24x

23x

22x

21x

20x

19x

18x

17x

16 x

15x

14x

13x

12x

11x

10x

9x

8x

7x

6x

5x

4x

3x

2x

1x

MODE

RPS

H10188

Vertical wall-mount

SERIES

Ax Bx

1x 2x 3x 4x 5x 6x 7x 8x 9x 10x 11x 12x 13x 14x 15x 16x 17x 18x 19x 20x 21x 22x 23x 24x

RPS

MODE

User-supplied

screws

After the hubisattachedtothewall,connect one end of the AC powercord to the AC power

connector on the hub and the other end of the cord to a power outlet. If your configuration

has a Cisco RPS, see the RPS documentation. After power is connected, the hub starts the

series of self-tests described in the “Powering Up the Hub and Running POST” section on

page 2-6.

Installing and Starting Up the Hub 2-13

Page 14

Connecting to the Console Port (FastHub 400M Models)

Connecting to the Console Port (FastHub 400M Models)

To connect the RJ-45 console port of a FastHub 400M model to a management station or

modem, you must use the supplied RJ-45-to-RJ-45 rollover console cable and the

appropriate adapter and follow these steps.

Note The rollover console cable and a RJ-45-to-DB-9 female DTE adapter are supplied

with the hub. If your management station requires a different adapter—such as a

RJ-45-to-DB-25 female DTE or RJ-45-to-DB-25 male DCE adapter—you must provide it.

Step 1 Configure the hub console port settings to match the management station or

modem. These are the default settings of the console port:

• 9600 baud

• 8 data bits

• 1 stop bit

• No parity

• No flow control

2-14

You can change the console port characteristics of the hub from the web-based

System Configuration Page (see the “Changing the System Configuration”

section on page 3-40) or by using the terminal command from the CLI.

Note Make sure the settings of the console port and the management station or

the modem match.

FastHub 400 10/100 Series Installation and Configuration Guide

Page 15

Connecting to the Console Port (FastHub 400M Models)

Step 2 Connect one end of the supplied rollover console cable to the console port, as

shown in Figure 2-8.

Caution Do not connect an actual telephone line, an ISDN line, or an Ethernet cable to

this console port. Damage to the hub can result. Make sure you use the supplied

RJ-45-to-RJ-45 rollover cable and adapters to connect the console port to the management

station or modem.

Figure 2-8 Connecting to the Console Port

DC INPUTS FOR REMOTE

POWER SUPPLY

UP

RATING

100-127 / 200-240 V~

2A /1A 50 / 60 Hz

CONSOLE

Supplied RJ-45-to-RJ-45

rollover console cable

SPECIFIED IN MANUAL

+5V

@

6A, +12V

@

1A

DC INPUT

DOWN

MEDIA MODULE

14256

Step 3

Attach the appropriate adapter,such as the supplied RJ-45-to-DB-9 female DTE

adapter (labeled Terminal), to a management station or modem.

Note If you are connecting the hub to a Sun workstation (or to a management

station with a female DB-25 serial connector), use a male-to-male gender

changer to attach the supplied RJ-45-to-RJ-45 rollover cable and a

RJ-45-to-DB-25 female DTE adapter to the management station.

Step 4 Connect the other end of the supplied rollover cable to the adapter.

Connector and cabling specifications for the console port are in the Appendix B,

“Connector and Cable Specifications.”

Now that the hub is connected to a management station, you can assign IP information to

the hub (see the “AssigningIP Information to the Hub (FastHub400M Models)” section on

page 2-16).

Installing and Starting Up the Hub 2-15

Page 16

Assigning IP Information to the Hub (FastHub 400M Models)

Assigning IP Information to the Hub (FastHub 400M

Models)

After you install the hub and connect it to a management station, you can assign IP

information to the hub. IP information identifies the hub to the network and is required to

manage and monitor the hub through the FastHub 400 series Hub Manager, the CLI, or

SNMP.

You can assign IP information to the hub by following the hub start-up prompts displayed

from a terminal emulation program on your management station.

You should contact your system administrator for the following information:

• Hub IP address

• Subnet mask (netmask)

• Default gateway (router)

To assign IP information to the hub, follow these steps:

Step 1 From your management station, start the terminal emulation program.

After POST completes, the Continue with configuration dialog? prompt appears

on the management station, and you can then follow the prompts to assign IP

information to the hub.

2-16

Step 2 From the terminal or PC, enter Y:

Continue with configuration dialog? [yes/no]: Y

Step 3 Enter the IP address (for example: 10.1.105.20):

Enter IP address: 10.1.105.20

Step 4 Enter the subnet mask (IP netmask) (for example: 255.255.255.0):

Enter IP netmask: 255.255.255.0

FastHub 400 10/100 Series Installation and Configuration Guide

Page 17

Assigning IP Information to the Hub (FastHub 400M Models)

Step 5 Enter the IP address of the default gateway (for example: 10.1.105.254):

Enter IP default gateway: 10.1.105.254

Note If the management station from which the FastHub 400 series Hub

Manager is used is not on the same IP subnet as the hub, you must also assign a

default gateway (the router for the local subnet).

The following information is displayed:

The following configuration command script was created:

ip address 10.1.105.20 255.255.255.0

ip default-gateway 10.1.105.254

!

end

Step 6 Enter Y:

Use this configuration? [yes/no]: Y

The following information is displayed:

Building configuration...

Use the enabled mode ‘configuration’ command to modify this

configuration.

Press RETURN to get started.

Pressing Return opens a CLI session.

Step 7 Exit from the terminal session.

You can now use the hub with its default values or configure and monitor it by using the

FastHub 400 series Hub Manager, the CLI, or SNMP and the MIB files.

Installing and Starting Up the Hub 2-17

Page 18

Connecting to the 10/100 Network Ports and Uplink Port

Connecting to the 10/100 Network Ports and Uplink Port

You can connect the 10/100 network ports and the uplink port to the ports on any 10BaseT

or 100BaseTX network device, such as workstations, servers, switches, routers, and other

hubs.

The 10/100 network ports (ports 1x through 12x or 1x through 24x) are internally crossed.

These ports require a crossover cable to connect to another hub or switch (unless you are

connecting to the uplink port on another FastHub or device). When connecting to a

workstation, server, or router, these ports require a straight-through cable.

The 10/100 uplink port (port 12 or 24) is not internally crossed and requires a

straight-through cable to connect to a server, hub, switch, or router.

By default, each 10/100 port on the hub configures itself to operate at the speed of the port

to which it is connected. If the port on the attached devicedoesnotsupportautonegotiation,

you can explicitly set the 10/100 port to match the speed of the attached port by using one

of the management interfaces available to the FastHub 400M models.

When connecting other network devices to the 10/100 ports, keep the following guidelines

in mind:

• Use the following types of twisted-pair cables when connecting the 10/100 network

ports or the 10/100 uplink port to a network device:

2-18

— 10BaseT network devices—Category 3, 4, or 5

— 100BaseTX network devices—Category 5

Note Althoughyoucanuse Category 3 and 4 cablesfor10BaseTnetworks,these cable

types will not work for 100BaseTX network devices. When designing a network that

includes autosensing repeaters like the FastHub 400 models, keep in mind that

100BaseTX traffic cannot be sent over these cable types.

• Use a straight-through cable to connect two ports when one of the ports is designated

with an X. Use a crossover cable to connect two ports when both ports are designated

with an X.

FastHub 400 10/100 Series Installation and Configuration Guide

Page 19

Connecting to the 10/100 Network Ports and Uplink Port

• Connectingtodevicesthat do notautonegotiateor that havetheirspeed setting manually

set can reduce performance or result in no link. To maximize performance, choose one

of these methods for configuring the 10/100 ports:

— Let both ports autonegotiate port speed.

— Manually set the same speed setting for the ports on both ends of the connection.

• When a 10/100 device connected to the hub changes speeds (from 10 to 100 Mbps or

from 100 to 10 Mbps), the device must reboot. The device then drops the link to the hub

and recreates the link after rebooting. (If the device does not reboot after changing

speeds, the hub does not detect the change in speed.)

Caution If you connect to ports 12x and 12 (or ports 24x and 24), you will disable both

ports.

Follow these steps to connect to 10BaseT or 100BaseTX devices:

Step 1 Connect one end of the Ethernet cable to a 10/100 port on the hub, as shown in

Figure 2-9.

Note When connecting the hub to workstations, servers, and routers, ensure

that the cable is a straight-through, twisted-pair cable. When connecting the hub

to switches or repeaters, use a crossover cable.

Figure 2-9 Connecting to a 10/100 Port

RPS

1x 2x 3x 4x 5x 6x 7x 8x

MODE

Category 5 cable

(not supplied)

10BaseT/100BaseTx

9x 10x 11x 12x 13x 14x 15x 16x

17x 18x 19x 20x 22x 23x 24x

21x

24

14514

Installing and Starting Up the Hub 2-19

Page 20

Accessing the Management Interfaces (FastHub 400M Models)

Step 2 Connect the other end of the cable to the 10BaseT or 100BaseTX port of the

network device.

Step 3 Check to see that the port LED for the port that you connected in Step 1 comes

on.

If the port LED does not come on, check for the following problems:

• The network device is not turned on.

• The Ethernet adapter in the network device is not operating correctly.

• You are using the wrong type of Ethernet cable.

• The Ethernet cable is damaged or not connected correctly.

Step 4 If required, reconfigure and reboot the connected network device.

Step 5 Repeat Steps 1 through 3 for each device that you are connecting to the hub.

If you need more information about Ethernet cabling and 10/100 port pinouts, refer to

Appendix B, “Connector and Cable Specifications.”

Accessing the Management Interfaces (FastHub 400M

Models)

2-20

FastHub 400 10/100 Series Installation and Configuration Guide

After you assign IP information to the hub, you can access the hub management interfaces.

This section provides information for accessing the FastHub 400 series Hub Manager, the

CLI, and SNMP and MIB files.

Page 21

Accessing the FastHub 400 Series Hub Manager

Accessing the FastHub 400 Series Hub Manager

To access the hub manager, all you need is the IP information of the hub (and the password

if one has been assigned). IP information for the hub is usually assigned when the hub is

first started up after installation. (See the “Assigning IP Information to the Hub (FastHub

400M Models)” section on page 2-16.)

Note You can access the hub manager from a PC connected to one of the 10/100 ports.

Therefore, make sure that you do not disable or otherwise misconfigure the port through

which you are communicating with the hub. Youmightwanttowrite downtheport number

to which you are connected. Make changes to the hub IP information with care.

To access the hub manager, follow these steps:

Step 1 Start Netscape Communicator (4.03 or higher) or Microsoft Internet Explorer

(4.01 or higher).

Step 2 Ensure that the following browser features are enabled:

• Java

• JavaScript

• Set the caching of pages to Every time in Communicator or

Every visit to the page in Internet Explorer.

Step 3 Enter the IP address of the hub in the Location field if you are using

Communicator (the Address field if you are using Internet Explorer) to display

the hub manager Home Page (Figure 2-10).

Installing and Starting Up the Hub 2-21

11187

Page 22

Accessing the Management Interfaces (FastHub 400M Models)

Figure 2-10 Home Page

Click Apply after

making changes

on a page.

Click Revert

to discard

unapplied

changes on

a page.

Click Help for

procedures and

detailed field

descriptions.

Click the Mode

button to change

the mode that

the LEDs display

for the fixed

10/100 ports.

HOME PORT GROUP IP SNMP CDP SYSTEM

Click to display the settings, status, and

statistics of an installed 10BaseT/100BaseTX

or 100BaseFX switched uplink module.

Click these topics to move from page

to page. On Netscape Communicator

only, when the cursor is above a topic,

a pop-up briefly describes the options

on that particular page.

Click a port to display its

settings, status, and statistics.

Shows when another hub is connected to a

stacking connector on the hub rear panel.

Note You can bookmark the hub IP address to retrieve the hub manager for later use. If

you are using Communicator, choose the Communicator menu option, and select

Bookmarks > Add Bookmark. If you are using Internet Explorer, choose the Favorites

menu option, and select Add to Favorites.Do not use the right mouse button to bookmark

the hub IP address; doing so only saves the specific frame (image) of the hub manager page.

15529

2-22

FastHub 400 10/100 Series Installation and Configuration Guide

Page 23

Accessing the CLI

You can access the CLI

• From a console terminal connected to the hub console port. For more information, see

the “Connecting to the Console Port (FastHub 400M Models)” section on page 2-14.

• Through a Telnet session from a remote host by entering the telnet command and the

name or IP address of the hub.

• Through a Telnet session by clicking Telnet on the hub manager Home Page.

When you access the CLI and a password has been defined, the following prompt is

displayed:

Cisco Systems Console

Enter Password:

Enter the password. The hostname> prompt is displayed after you enter the correct

password.

For complete information about the CLI, refer to the FastHub 400 10/100 Series Command

Reference.

Accessing the CLI

Accessing the MIB Files through SNMP

Youcan access the hub MIBfilesthroughSNMP.The following MIBfilescontainvariables

that can be set or read to provide information about the hub and the traps generated by the

hub.

• RFC1213-MIB.my contains the MIB II (RFC 1213).

• ETHERLIKE-MIB.my contains the Ethernet Transmission MIB (RFC 1643).

• CISCO-CDP-MIB.my contains the CDP MIB.

• SNMP-REPEATER-MIB.my contains the standard MIB for managing the hub.

• RMON-MIB.my contains the RFC 1757 RMON (Groups 1, 2, 3, and 9). More

information about RMON and the RMON groups is provided in the “Remote

Monitoring” section on page 2-25.

• CISCO-SIBU-SIMPLE-UPGRADE-MIB.my contains the MIB module for upgrading

the firmware on Cisco low-end devices.

Installing and Starting Up the Hub 2-23

Page 24

Accessing the Management Interfaces (FastHub 400M Models)

• CISCO-SIBU-MANAGERS-MIB.my contains the MIB module for management

interfaces on the FastHub 400M models.

• CISCO-SIBU-STACKABLE-DUAL-SPEED-HUB-MIB.mycontains the MIB module

that extends the REPEATER-MIB to manage Cisco low-end stackable repeater

products.

If you are going to manage the hub by using SNMP and the MIB files, the Read and Write

community strings need to be set. To do this, you can either

• Use the default community strings

— Read community string. The default is public.

— Write community string. The default is private.

• Assign community strings by using the SNMP Management Page or by using the

snmp-server community command on the CLI.

Note Wait approximately 30 seconds for the changes to be saved to permanent storage

before turning off the hub, or the changes might not be saved.

You can obtain a copy of the MIB files in the following ways:

• Using File Transfer Protocol (FTP) to access the ftp.cisco.com server.

• Using Cisco Connection Online (CCO) to access the cisco.com server.

Using FTP to Access the MIB Files

To obtain a MIB file, follow these steps:

Step 1 Use FTP to access the server ftp.cisco.com.

Step 2 Log in with the username anonymous.

Step 3 Enter your e-mail name when prompted for the password.

Step 4 At the ftp> prompt, change directories to /pub/MIBs.

Step 5 Use the get README command to display the readme file listing available

files.

Step 6 Use the get MIB_filename command to get a copy of the MIB file.

2-24

FastHub 400 10/100 Series Installation and Configuration Guide

Page 25

Using CCO to Access the MIB Files

To access the MIB files from CCO, click Software & Support to display the Software

Center site.

CCO serves a wide variety of users through two interfaces that are updated and enhanced

simultaneously: a character-based version and a multimedia version that resides on the

World Wide Web (WWW). The character-based CCO supports Zmodem, Kermit,

Xmodem, FTP, and Internet e-mail, and it is excellent for quick access to information over

lower bandwidths. The WWW version of CCO provides richly formatted documents with

photographs, figures, graphics, and video, as well as hyperlinks to related information.

You can access CCO in the following ways:

• WWW: http://www.cisco.com

• WWW: http://www-europe.cisco.com

• WWW: http://www-china.cisco.com

• Telnet: cco.cisco.com

• Modem: From North America, 408 526-8070; from Europe, 33 1 64 46 40 82. Use the

following terminal settings: VT100 emulation; data bits: 8; parity: none; stop bits: 1;

and connection rates up to 28.8 kbps.

Accessing the MIB Files through SNMP

Foracopy of CCO’sFrequently Asked Questions (FAQ),contact cco-help@cisco.com. For

additional information, contact cco-team@cisco.com.

Remote Monitoring

The Remote Monitoring (RMON) MIB is used by network managers to monitor remote

devices. An RMON implementation consists of a software probe that continually collects

statistics about a LAN and a management station that communicates with the probe. The

probe transfers information to the management station on request or when a predefined

threshold is crossed.

The hub supports four RMON groups (Table 2-1) as defined in RFC 1757. Default statistic

rowsarecreated for each port when you start the hub. You can obtain information about the

four supported groups by using any SNMP management application.

Installing and Starting Up the Hub 2-25

Page 26

Where to Go Next

Table 2-1 RMON Groups and Their Functions

Group Name Description

Statistics This group collects traffic and error statistics for a specific interface. For

example, you could use this group to determine how many error packets have

been seen on a given port.

Statistics from this group can be used by the history group to record historical

views of network performance. A statistics row is established by default for

each hub port.

History This group periodically samples the counters generated by the statistics

group. This information can be used to establish baseline information

regarding network activity. You can define the intervals you want to record

information for, and you can define how many of the samples are to be stored.

Note RMON statistics gathering has a maximum limit of 50 history buckets

per historyControlTable entry.

Alarm This group generates alarms according to user-defined thresholds. You could,

for example, configure RMON to generate an alarm when alignment errors on

a port exceeded a predefined limit. Rising and falling thresholds can be

defined, and the events group can generate traps and automated responses

based on the alarms.

Event This group sends traps to the management station based on information

(alarms) received from the alarm group.

Where to Go Next

Now that you have installed the hub and, if you have a FastHub 400M models, assigned IP

information to the hub, you can continue to

• Chapter 3, “Configuring and Monitoring from the Hub Manager” for configuration and

monitoring information. (FastHub 400M models only).

• Appendix C, “FastHub Stacks” for interconnecting the hub to other FastHub 400M

models to form hub stacks.

• Appendix D, “Switched Uplink Modules” for descriptions of the optional switched

uplink modules and procedures for installing and connecting to them.

2-26

FastHub 400 10/100 Series Installation and Configuration Guide

Loading...

Loading...