Page 1

Triplex Ceramic

Plunger Pump Manual

Models

GP7150A, GP7155A, GP7255A

Updated 03/06

Contents:

Installation Instructions

GP7155A/GP7255A: page 2

Pump Specifications: page 3

Parts List/Exploded View: pages 4-5

Pump Specifications

GP7150A: page 6

Recommended Spare

Parts List: page 7

Repair Instructions: page 7

Dimensions: back page

Warranty Information back page

Page 2

INSTALLATION INSTRUCTIONS

Installation of the Giant Industries, Inc., pump is

not a complicated procedure, but there are some

basic steps common to all pumps. The following

information is to be considered as a general

outline for installation. If you have unique

requirements, please contact Giant Industries,

Inc. or your local distributor for assistance.

1. The pump should be installed flat on a base to a

maximum of a 15 degree angle of inclination to

ensure optimum lubrication.

2. The inlet to the pump should be sized for the

flow rate of the pump with no unnecessary restrictions that can cause cavitation. Teflon tape should

be used to seal all joints. If pumps are to be operated at temperatures in excess of 140

tant to insure a positive head to the pump to prevent

cavitation.

3. The discharge plumbing from the pump should be

properly sized to the flow rate to prevent line

pressure loss to the work area. It is essential to

provide a safety bypass valve between the pump and

the work area to protect the pump from pressure

spikes in the event of a blockage or the use of a shutoff gun.

4. Use of a dampener is necessary to minimize

pulsation at drive elements, plumbing, connections,

and other system areas. The use of a dampener with

Giant Industries, Inc. pumps is optional, although

recommended by Giant Industries, Inc. to further

o

F, it is impor-

reduce system pulsation. Dampeners can also

reduce the severity of pressure spikes that occur

in systems using a shut-off gun. A dampener

must be positioned downstream from the unloader.

5. Crankshaft rotation on Giant Industries, Inc.

pumps should be made in the direction designated by the arrows on the pump crankcase.

Reverse rotation may be safely achieved by

following a few guidelines available upon

request from Giant Industries, Inc. Required

horsepower for system

from the charts on pages 3 & 6.

6. Before beginning operation of your pumping

system, remember: Check that the crankcase

and seal areas have been properly lubricated per

recommended schedules. Do not run the pump

dry for extended periods of time. Cavitation

will result in severe damage. Always remember

to check that all plumbing valves are open and

that pumped media can flow freely to the inlet of

the pump.

Finally, remember that high pres

sure operation in a pump system has many

advantages. But, ifit is used carelessly

and without regard to its potential hazard,

it can cause serious injury.

operation can be obtained

IMPORTANT OPERATING CONDITIONS

Failure to comply with any of these conditions invalidates the warranty

1. Prior to initial operation, add oil to crankcase so

that oil level is between the two lines on the oil

dipstick. DO NOT OVERFILL. Use Giant

Recommended Oil (p/n 01154), which is equivalent to SAE 85-90W Industrial Grear Lube. Crankcase oil should be changed after the first 50 hours

of operation, then at regular intervals of 500 hours

or less depending on operating conditions.

2. Pump operation must not exceed rated

pressure, volume, or RPM.

device must be installed in the discharge of the

system.

3. Acids, alkalines, or abrasive fluids cannot be

pumped unless approval in writing is obtained

before operation from Giant Industries, Inc.

4. Run the pump dry approximately 10 seconds

to drain the water before exposure to freezing

temperatures.

A pressure relief

NOTE: Contact Giant Industries for Service School Information. Phone: (419)-531-4600.

2

Page 3

Specifications

Model GP7155A, GP7255A

................................................................U.S. ........................ Metric

Volume.................................................... 65.8 GPM .............. 250 LPM

Discharge Pressure .................................1500 PSI ................. 100 Bar

Speed ......................................................2000 PSI ................. 138 Bar

Inlet Pressure ........................................................................... Up to 700 RPM

Plunger Diameter....................................2.17” ....................... 55mm

Plunger Stroke ........................................2.05”....................... 52mm

Crankshaft Diameter...............................1.89”....................... 48mm

Key Width...............................................0.55”....................... 14mm

Crankshaft Mounting............................................................... Either side

Shaft Rotation.......................................................................... Top of pulley towards manifold

Max.Temperature of Pumped Fluids ......140

Inlet Ports ................................................................................ (2) 2-1/2" NPT

Discharge Ports........................................................................ (2) 1-1/4" NPT

Weight.....................................................374 lbs. ................... 170 kg

Crankcase Oil Capacity ..........................1.6 Gal. ................... 6.0 liters

Fluid End Material GP7155A.................................................. Bronze

Fluid End Material GP7255A.................................................. Nickle Plated Spheroidical Cast Iron

Mechanical Effecency @ 700 RPM ........................................ 0.83

Volumetric Effecency @ 700 RPM ......................................... 0.96

o

F ..................... 60 oC

Consult the factory for special requirements that must be met if the pump is to

operate beyond one or more of the limits specified above.

PULLEY INFORMATION

Pulley selection and pump speed are based on a 1725

RPM motor and "B" section belts. When selecting

desired GPM, allow for a ±5% tolerance on pumps

output due to variations in pulleys, belts and motors

among manufacturers.

1. Select GPM required, then select appropriate

motor and pump pulley from the same line.

2. The desired pressure is achieved by selecting the

correct nozzle size that corresponds with the pump

GPM.

GP7155A, GP7255A PULLEY SELECTION & HORSEPOWER

REQUIREMENTS

PUMP

PULLEY

12.75 9.00

12.75 9.75

12.75 10.75

12.75 11.70

12.75 12.75

MOTOR

PULLEY

RPM GPM 800 PSI 1000 PSI 1300 PSI 1500 PSI 2000 PSI

479 45.0 25.7 32.1 41.8 48.2 64.3

531 49.9 28.5 35.6 46.3 53.5 71.3

585 55.0 31.4 39.3 51.1 58.9 78.6

638 60.0 34.3 42.9 55.7 64.3 85.7

700 65.8 37.6 47.0 61.1 70.5 94.0

HORSEPOWER INFORMATION

Horsepower ratings shown are the power requirements for the pump. Gas engine power outputs must

be approximately twice the pump power requirements shown above.

We recommend that a 1.1 service factor be specified

when selecting an electric motor as the power source.

To compute specific pump horsepower requirements,

use the following formula:

(GPH X PSI) / 1450 = HP

3

Page 4

Exploded View - GP7150A/GP7155A/GP7255A

4

Page 5

Spare Parts List - GP7150A/GP7155A/GP7255A

ITEM PART DESCRIPTION QTY.

1 07600 Crankcase 1

2 13000 Oil Filler Plug Assembly 1

4 076 01 Crankcase Cover 1

5 076 02 Gasket, Crankcase Cover 1

8 076 03 Oil Dip Stick 1

9 010 09 O-Ring, Dip Stick 1

10 13133 Hexagon Screw 12

11 13134 Spring Washer 12

12 07109 Drain Plug 3

13 07182 Gasket, Drain Plug 2

14 07607 Bearing Cover 2

15 07608 Radial Shaft Seal 2

16 07184 O-Ring 2

20 07610 Taper Roller Bearing 2

20A 07611 Fitting Disc (Shim) 1-5

21 07612 Shaft Protector 1

22 13405 Crankshaft 1

23 07614 Key 1

24 13182 Connecting Rod Assy. 3

25 13183 Crosshead Assy. 3

28 13184 Crosshead Pin 3

30 07619 Cover Plate 1

30A 07225-0100 Hexagon Screw 8

30B 13136 Grommet 4

30C 08280 Washer 8

30D 13154 Cover Plate 1

31 07623 Eye Bolt 1

32 07624 Radial Shaft Seal 3

32A 07625 Shaft Seal 3

33 07626 Seal Retainer 3

33A 07627 O-Ring 3

33B 07628 Circlip 3

33C 07 249 Fitting Disc 3

34 13137 Oil Scraper 3

36 07706 Plunger Pipe Assy.

(GP7155A/GP7255A) (36 A-D) 3

36 07630 Plunger Pipe Assy. (36A-D) 3

36A 07667 Plunger Connection 3

36B 07 79 3 Plunger Pipe (50mm) 3

36B 07 66 6 Plunger Pipe (55mm)

(GP7155A/GP7255A) 3

36C 07664 Tension Screw 3

36D 07665 Copper Ring 3

38 13155 Seal Case (GP7155A/GP7255A) 3

ITEM PART DESCRIPTION QTY.

38 07794 Seal Case (GP7150A) 3

38A 13156 O-Ring 3

38B 07721 O-Ring (GP7155A/GP7255A) 3

38B 06258 O-Ring (GP7150A) 3

38C 07635 Support Ring (GP7150A Only) 3

39 13157 Seal Sleeve (GP7155A/GP7255A) 3

39 07795 Seal Sleeve (GP7150A) 3

39A 07723 Compact Ring (GP7155A/GP7255A) 3

39A 07796 Compact Ring (GP7150A) 3

40* 07797 Support Disc (GP7155A/GP7255A) 3

41 13158 O-Ring (GP7155A/GP7255A) 3

41 07636 Tension Spring (GP7150A) 3

42 07711 V-Sleeve (GP7155A/GP7255A) 6

42 07638 V-Sleeve (GP7150A) 6

43 07712 Pressure Ring (GP7155A/GP7255A) 3

43 07639 Pressure Ring (GP7150A) 3

44 07637 Support Ring (GP7150A only) 3

49 13159 Stud Bolt 8

49A 13160 Hex Nut 8

50 07790 Valve Casing (GP7155A) 1

50 07791 Valve Casing (GP7255A) 1

50 06628 Valve Casing (GP7150A) 1

50A 13162 Cylinder Stud 2

51 08288 Valve Assembly 6

51A 08281 Spring Tension Cap 6

51B 08282 Valve Spring Guide 6

51C 07732-0100 Valve Spring 6

51D 13164 Valve Plate 6

51E 08283 Valve Seat 6

51F 07653 O-Ring 6

51G 13166 Support Ring 6

51H 07266 O-Ring 6

56 13167 Valve Adaptor 3

56A 07658 O-Ring 6

56B 07635 Support Ring 6

56C 13166 Support Ring 3

56D 07653 O-Ring 3

57 13173 Tension Spring 6

58 13170 Plug 3

59A 07661 Copper Ring 1

60 12251 Plug, 1-1/4” NPT 1

61 12252 Plug, 2-1/2” NPT 1

66 13362 Disc For Crankshaft 1

67 13358 Hexagon Screw 1

* This item may be removed to add a third v-sleeve.

Plunger Packing Kit

# 09526 - GP7150A

Item Part # Description Qty.

38A 13156 O-Ring 3

38B 06258 O-Ring 3

39A 07796 Compact Ring 3

41 07636 O-Ring 3

42 07638 V-Sleeve 6

Plunger Packing Kit

# 9220 - GP7155A & GP7255A

Item Part # Description Qty.

38A 13156 O-Ring 3

38B 07721 O-Ring 3

39A 07223 Compact Ring 3

41 13158 O-Ring 3

42 07711 V-Sleeve 6

Oil Seal Kit - # 09221

Item Part # Description Qty.

32 07624 Radial Shaft Seal 3

32A 07625 Shaft Seal 3

33A 07627 O-Ring 3

Valve Kit

# 09606*

Item Part # Description Qty.

51B 08282 Valve Spring Guide 1

51C 07732-0100 Valve Spring 1

51D 13164 Valve Plate 1

51E 08283 Valve Seat 1

51F 07653 O-Ring 2

51G 13166 Support Ring 2

51H 07266 O-Ring 2

56A 07658 O-Ring 2

56B 07635 Support Ring 2

56C 13166 Support Ring 1

56D 07653 O-Ring 1

* Note: When ordering a valve kit for a pump produced

prior to 11/03, order kit #09222, which replaces part

08281 with p/n 13163. Kit 09222 does not require p/n

08282.

5

Page 6

Specifications

Model GP7150A

................................................................U.S. ........................ Metric

Volume.................................................... 54.5 GPM.............. 206 LPM

Discharge Pressure .................................1900 PSI ................. 131 Bar

Speed ....................................................................................... 700 RPM

Inlet Pressure .......................................... 140 PSI .................. 10 Bar

Plunger Diameter.................................... 1.97” ...................... 50mm

Plunger Stroke ........................................ 1.89”...................... 48mm

Crankshaft Diameter............................... 1.89”...................... 48mm

Key Width............................................... 0.55”...................... 14mm

Crankshaft Mounting............................................................... Either side

Shaft Rotation.......................................................................... Top of pulley towards manifold

Max.Temperature of Pumped Fluids ...... 140

Inlet Ports ................................................................................ (2) 2-1/2" NPT

Discharge Ports........................................................................ (2) 1-1/4" NPT

Weight.....................................................374 lbs. ................... 170 kg

Crankcase Oil Capacity ..........................1.6 Gal. ................... 6.0 liters

Fluid End Material .................................................................. Bronze

Mechanical Effecency @ 700 RPM ........................................ 0.83

Volumetric Effecency @ 700 RPM ......................................... 0.96

o

F .................... 60 oC

Consult the factory for special requirements that must be met if the pump is to

operate beyond one or more of the limits specified above.

PULLEY INFORMATION

Pulley selection and pump speed are based on a 1725

RPM motor and "B" section belts. When selecting

desired GPM, allow for a ±5% tolerance on pumps

output due to variations in pulleys, belts and motors

among manufacturers.

1. Select GPM required, then select appropriate

motor and pump pulley from the same line.

2. The desired pressure is achieved by selecting the

correct nozzle size that corresponds with the pump

GPM.

GP7150A PULLEY SELECTION & HORSEPOWER REQUIREMENTS

PUMP

PULLEY

12.75 5.75

12.75 7.50

12.75 9.25

12.75 11.00

12.75 12.75

MOTOR

PULLEY

RPM GPM 800 PSI 1000 PSI 1300 PSI 1500 PSI 1900 PSI

300 23.4 13.4 16.7 21.7 25.1 31.8

400 31.2 17.8 22.3 29.0 33.4 42.3

500 38.9 22.2 27.8 36.1 41.7 52.8

600 46.7 26.7 33.4 43.4 50.0 63.4

700 54.5 31.1 38.9 50.6 58.4 74.0

HORSEPOWER INFORMATION

Horsepower ratings shown are the power requirements for the pump. Gas engine power outputs must

be approximately twice the pump power requirements shown above.

We recommend that a 1.1 service factor be specified

when selecting an electric motor as the power source.

To compute specific pump horsepower requirements,

use the following formula:

(GPH X PSI) / 1450 = HP

6

Page 7

GP7150A, GP7155A, GP7255A REPAIR INSTRUCTIONS

TO CHECK VALVES

Lossen plugs (58), take out tension spring (57) and then remove the complete valve (51) with either a valve tool or an

M16 hexagon screw. Remove valve adapter (56) and tension spring (57) with pull-out tool size 5. There is an O-ring

(51G) under both the suction and the discharge valve each of which can be removed with a bent piece of wire.To

disassemble valve hit the top of the valve plate (C) carefully with a bolt and press the valve seat (A) out of the spacer

pipe (E). Check sealing surfaces and replace worn parts. Check O-rings and support rings.Tighten plugs (58) to 107 ft.

lbs.

TO CHECK SEALS AND PLUNGER PIPE

Loosen nuts (49A) and remove pump head. Separate plunger connection (36A) from crosshead (25) by means of two

open-end wrenches (size 22 and 27). Pull seal sleeves (39) out of their fittings in the crankcase.

Take seal case (38) out of seal sleeve (39). Examine plunger parts (36A-36D), seals (42,39A) and O-rings.

When replacing plunger pipe (36B), tighten tension screws (36C) to 30 ft. lbs.

Replace worn parts; grease seals with Silicone before installing.

CAUTION: Don't loosen the 3 plunger connections (36A) before the valve casing has been removed otherwise the

tension screw (36C) could hit against the spacer pipe (51E) when the pump is being turned. Seal life

can be increased if the pretensioning allows for a little leakage. This assists lubrication and keeps the

seals cool. It is therefore not necessary to replace seals before the leakage becomes too heavy and

causes output and operating pressure to drop.

MOUNTING VALVE CASING

Check O-rings on seal case (38). Clean surfaces of seal sleeves in gear box and sealing surfaces of

valve casing. Push valve casing carefully on O-rings of seal case and centering studs (50A). Tighten nuts (49A) to 103

ft. lbs.

TO DISASSEMBLE GEAR

Take out plunger and seal sleeves as described above. Drain oil. After removing the circleclip ring (33B), lever out seal

retainer (33) with a screw driver. Check seals (32, 32A, 33A) and surfaces of crosshead. Remove crankcase cover (4).

Loosen inner hexagon screws on the connecting rods (24) and push con rod halves as far into the crosshead guide as

possible.

Note: Connecting rods are marked for identification. Do not twist con rod halves. Con rod is to be reinstalled

Note: Seal (32A) must always be installed so taht the seat up on the inside diameter faces the oil.

in the same position on shaft journals.Check surfaces of connecing rod and crankshaft (22) take out

bearing cover to one side and push out crankshaft taking particular care that the conrod doesn't gt bent.

Reassemble in revers order: Regulate axial bearing clearance minimum 0.1mm, maximum 0.15-by

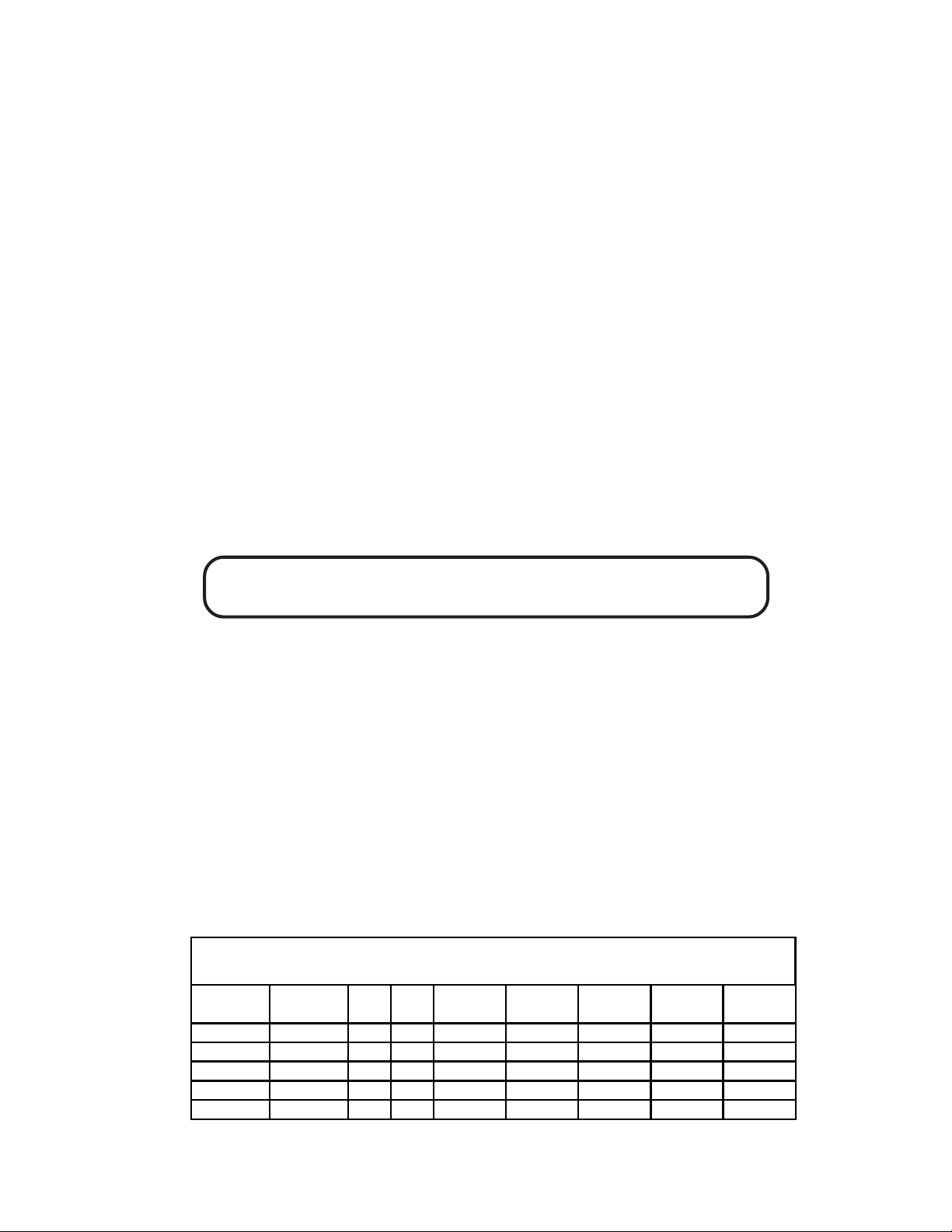

Preventative Maintenance Check-List & Recommended Spare Part List

Check Daily Weekly 50hr Every Every Every

500 hr 1500 hr 3000hrs

Oil Level / Quality X

Oil Leaks X

W ater Leaks X

Belts, Pulley X

Plumbing X

Recommended Spare Part

Oil Change (p/n 01154) X

X

Plunger Packing Kits(1 kit/Pump)

See page 5 for kit list

Oil Seal Kit ( 1 kit/Pump

See page 5 for kit list)

Valve Assembly Kit ( 1 kit/pump)

See page 5 for kit list

X

X

X

7

Page 8

GP7150A, GP7155A, GP7255A SERIES DIMENSIONS - INCHES (mm)

GIANT INDUSTRIES LIMITED WARRANTY

Giant Industries, Inc. pumps and accessories are warranted by the manufacturer to be free from defects in

workmanship and material as follows:

1. For portable pressure washers and self-service car wash applications, the discharge manifolds will never

fail, period. If they ever fail, we will replace them free of charge. Our other pump parts, used in portable

pressure washers and in car wash applications, are warranted for five years from the dateof shipment for

all pumps used in NON-SALINE, clean water applications.

2. One (1) year from the date of shipment for all other Giant industrial and consumer pumps.

3. Six (6) months from the date of shipment for all rebuilt pumps.

4. Ninety (90) days from the date of shipment for all Giant accessories.

This warranty is limited to repair or replacement of pumps and accessories of which the manufacturer’s evaluation

shows were defective at the time of shipment by the manufacturer. The following items are NOT covered or will void

the warranty:

1. Defects caused by negligence or fault of the buyer or third party.

2. Normal wear and tear to standard wear parts.

3. Use of repair parts other than those manufactured or authorized by Giant.

4. Improper use of the product as a component part.

5. Changes or modifications made by the customer or third party.

6. The operation of pumps and or accessories exceeding the specifications set forth in the Operations

Manuals provided by Giant Industries, Inc.

Liability under this warranty is on all non-wear parts and limited to the replacement or repair of those products returned

freight prepaid to Giant Industries which are deemed to be defective due to workmanship or failure of material. A

Returned Goods Authorization (R.G.A.) number and completed warranty evaluation form is required

prior to the

return to Giant Industries of all products under warranty consideration. Call (419)-531-4600 or fax (419)-531-6836

to obtain an R.G.A. number.

Repair or replacement of defective products as provided is the sole and exclusive remedy provided hereunder and

the MANUFACTURER SHALL NOT BE LIABLE FOR FURTHER LOSS, DAMAGES, OR EXPENSES, INCLUDING

INCIDENTAL AND CONSEQUENTIAL DAMAGES DIRECTLY OR INDIRECTLY ARISING FROM THE SALE OR

USE OF THIS PRODUCT.

THE LIMITED WARRANTY SET FORTH HEREIN IS IN LIEU OF ALL OTHER WARRANTIES OR REPRESENTATION, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OR MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE AND ALL SUCH WARRANTIES ARE HEREBY DISCLAIMED AND

EXCLUDED BY THE MANUFACTURER.

GIANT INDUSTRIES, INC.

900 N. Westwood Ave.

P.O. Box 3187

Toledo, Ohio 43607

(419) 531-4600

FAX (419) 531-6836

Copyright 2006 Giant Industries, Inc.

03/06 GP7150A, GP7155A, GP7255A.PM6

Loading...

Loading...