Page 1

GS-705N Shear Lock Installation Instruction

Unbalanced air conditioning (stack pressure) can hinder door alignment and must be corrected to help insure positive locking. It

is important to note that the Shear Locks need a regulated 12V DC (or 24VDC) at the lock, and use the highest quality door closer

only. Positive centering door closers are required for all double acting door applicators to help attain consistent dead center

alignment. Also the door latching problems must be corrected prior to installation.

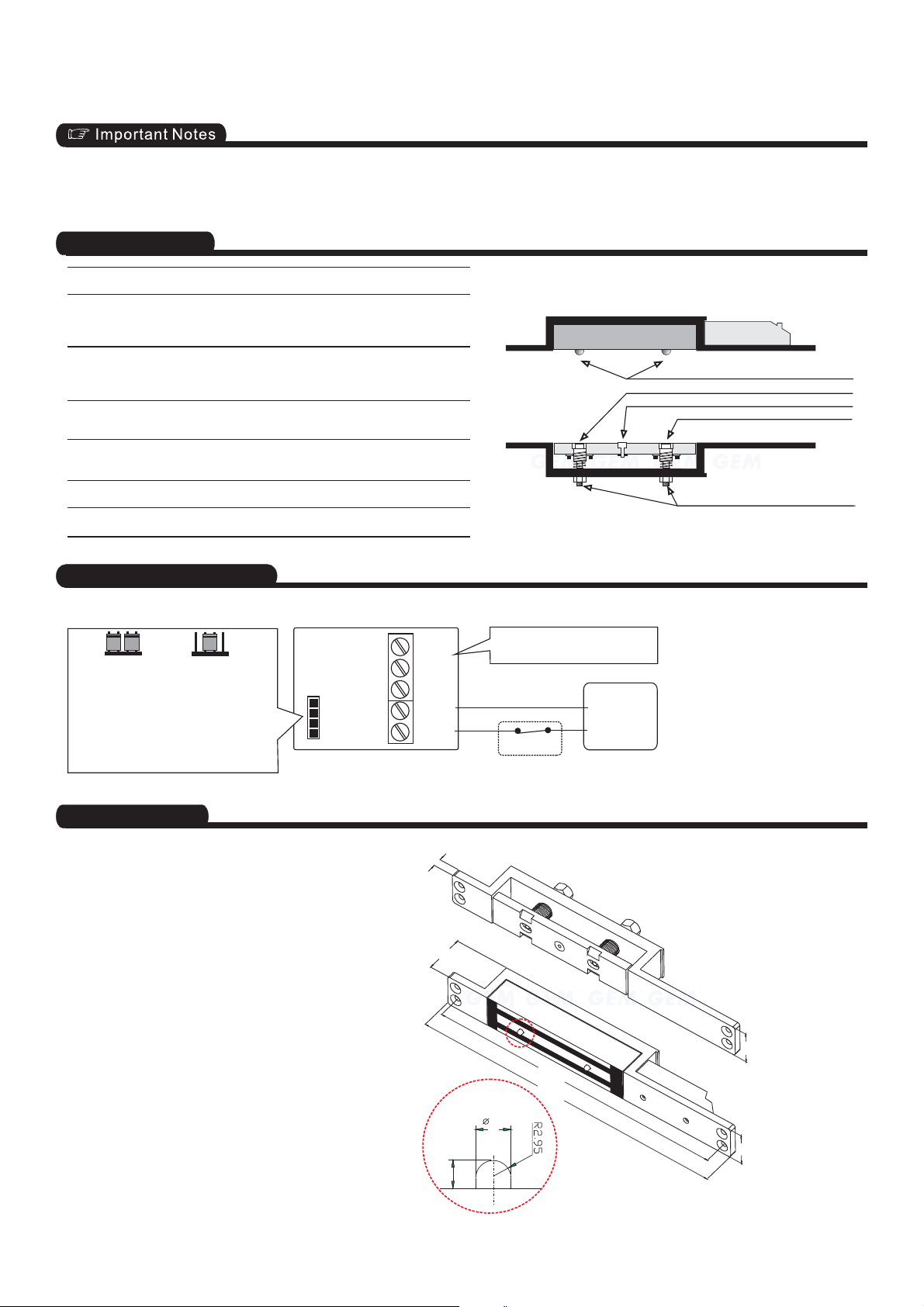

Specifications

Holding Force

Up to 2700 lbs (1226 Kg) in shear.

12/24 VDC selectable via jumpers +10%

Power Input

over voltage is acceptable , under voltage

will reduce holding force.

Current Draw

0.35 A@12 VDC; 0.17A@24 VDC The unit

does not require initial voltage increase to

operate.

Finish

Magnet and Armature: Zinc plated

Housing: Black powder coated

Monitoring Output

Door Gap

Operating Temper.

Magnet bond sensor output,

1 AMP@30 VDC

2mm

-30C to +50C

Connecting Diagram

12Vdc

Voltage Selection jumpers

Check jumper settings before

connecting the lock to 24 VDC

input power. Damage to the

lock may result from incorrect

jumpersettings.

24Vdc

SPDT rating

Magnet bond

sensor output

Input

Power

N.C.

COM.

N.O.

-

+

Magnet Assembly

Armature Assembly

Magnet bond sensor output

SPDT relay : 1A@30 VDC

-

Power

+

supply

Control Device

N.C. contact orAccess Relay

Locking Bolt

Keep Hole

Push-off button

Keep Hole

Armature vertical

adjustment screws

Caution:

Make sure that the "+" and "-"

wire are connected correctly.

Failure to observe polarity will

result in a short circuit and is

not covered by products

warrant.

Dimensions

Install the magnet assembly into the door

frame before installation the armature assembly

into the door leaf. The magnet assembly requires

space to run wires, as wall as space for the

recesses portion of the unit. However, make sure

that the position selected for the magnet

assembly leaves enough room on the door to

install the armature assembly.

Copyright Gianni Industries, Inc. All Rights Reserved.

PublishP-MU-GS705N-30 Ver.C :2007.07.17

6

32

3.5

GS-705N-30

30

251

267

Locking Bolt

5.9

30

Unit: mm

2-1

Page 2

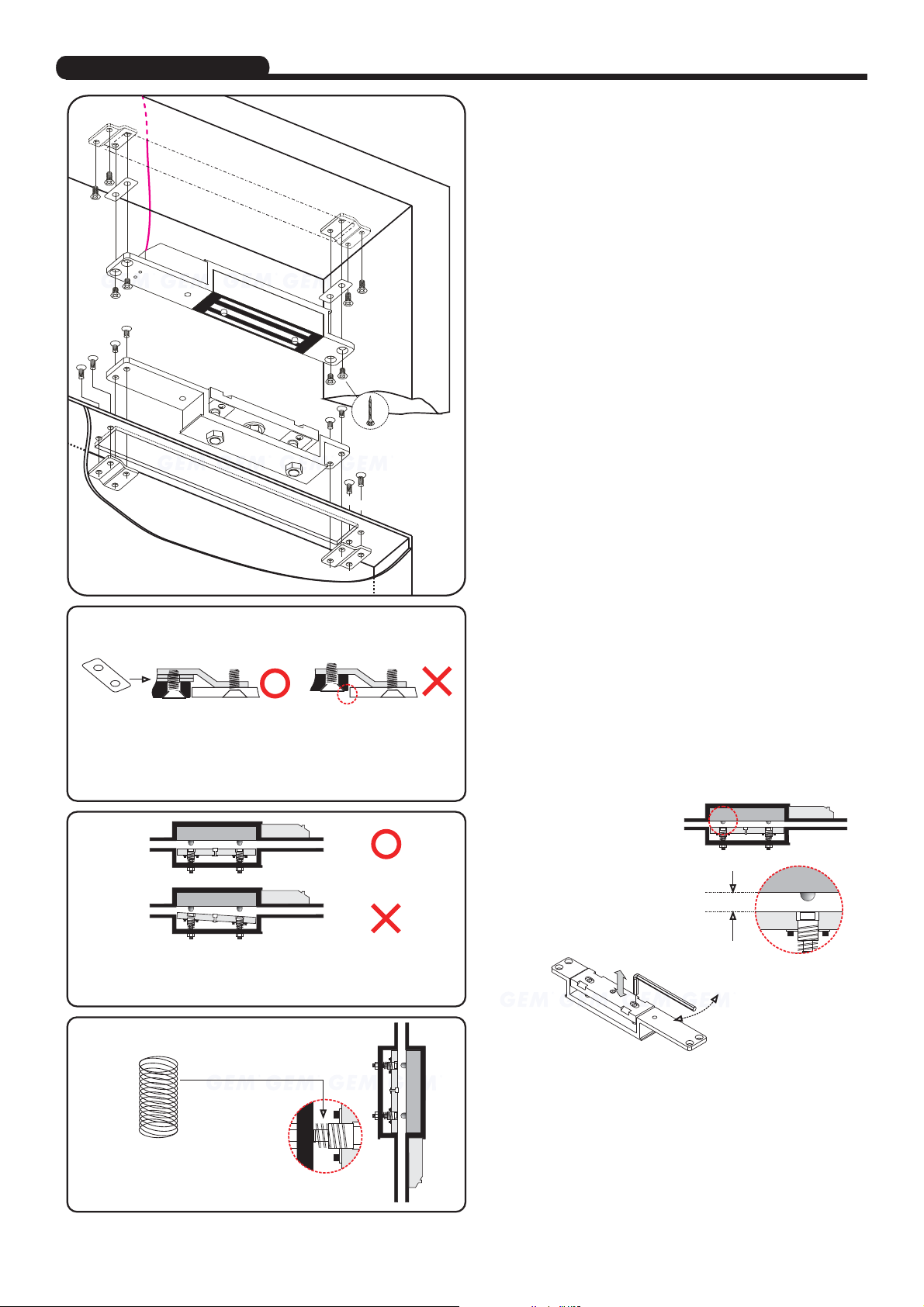

Flush Installation

Leading edge of door

Flat Lugs is used when the door frame is deep, and to prevent

the Electromagnetic Lock or the Armature Plate caved in, add

flat lugs to raise the plane (level) of the Electromagnetic Lock

face or theArmature Plate face to the door frame surface.

Use tapping

Screws for

wooden door

1. Make sure the gap between the door top rail and

frame header is 2mm. Make adjustments to the door

as required.

2. Adjust single acting door and door closer to insure

the door settles immediately and is fully closed .

(Adjust double acting door and POSITIVE

CENTERING DOOR CLOSER to insure the door

settles immediately and is fully closed and rest in the

dead center of the frame.

3. Locate the vertical centerline of the magnet and

armature as possible to the leading door edge.

4. Determine the horizontal centerline of the door

top rail thickness. The Armature centerline will be the

same. Mark the door per template.

5. Before determining the frame header centerline

single acting door must be fully closed. Double acting

doors must be fully closed and rest in the dead center

of the frame. Mark the frame header per the template.

Prepare the door and frame per the template.

6. Install the Shear lock and armature assembly

towards the leading edge of the door.

7. For proper operation the armature must be

adjusted upward as close as possible and parallel to

the Shear Lock without interfering with opening and

closing of the door.

8. Proper operation cannot be expected with more

than 2 mm gap between the armature and the magnet.

Use the key wrench provided to adjust the armature

vertical adjustment screws.

9 With the door closed turn the lock power on, check

the lateral alignment. The armature locking bolt

should be centered to magnet keep hole.

10. If the shear stops are too close or binding,

double check the templating and door alignment, and

make corrections as required.

11 Repeat steps 6~10 as necessary following shear

lock replacement. Cycle the door and Shear Lock

several times after the completion of the installation.

Make sure the gap between the Shear Lock and the

Armature Plate are the same while adjusting the gap.

For Vertical Installation

Change the spring which is provided

in the screw pack.

Copyright Gianni Industries, Inc. All Rights Reserved.

PublishP-MU-GS705N-30 Ver.C :2007.07.17

The Gap between the

Lock and Armature plate

is2mm

key wrench

Proper operation cannot be expected with

more than 2 mm gap between the armature

and the magnet. Use the key wrench

provided to adjust the armature vertical

adjustment screws.

2-2

Loading...

Loading...