Page 1

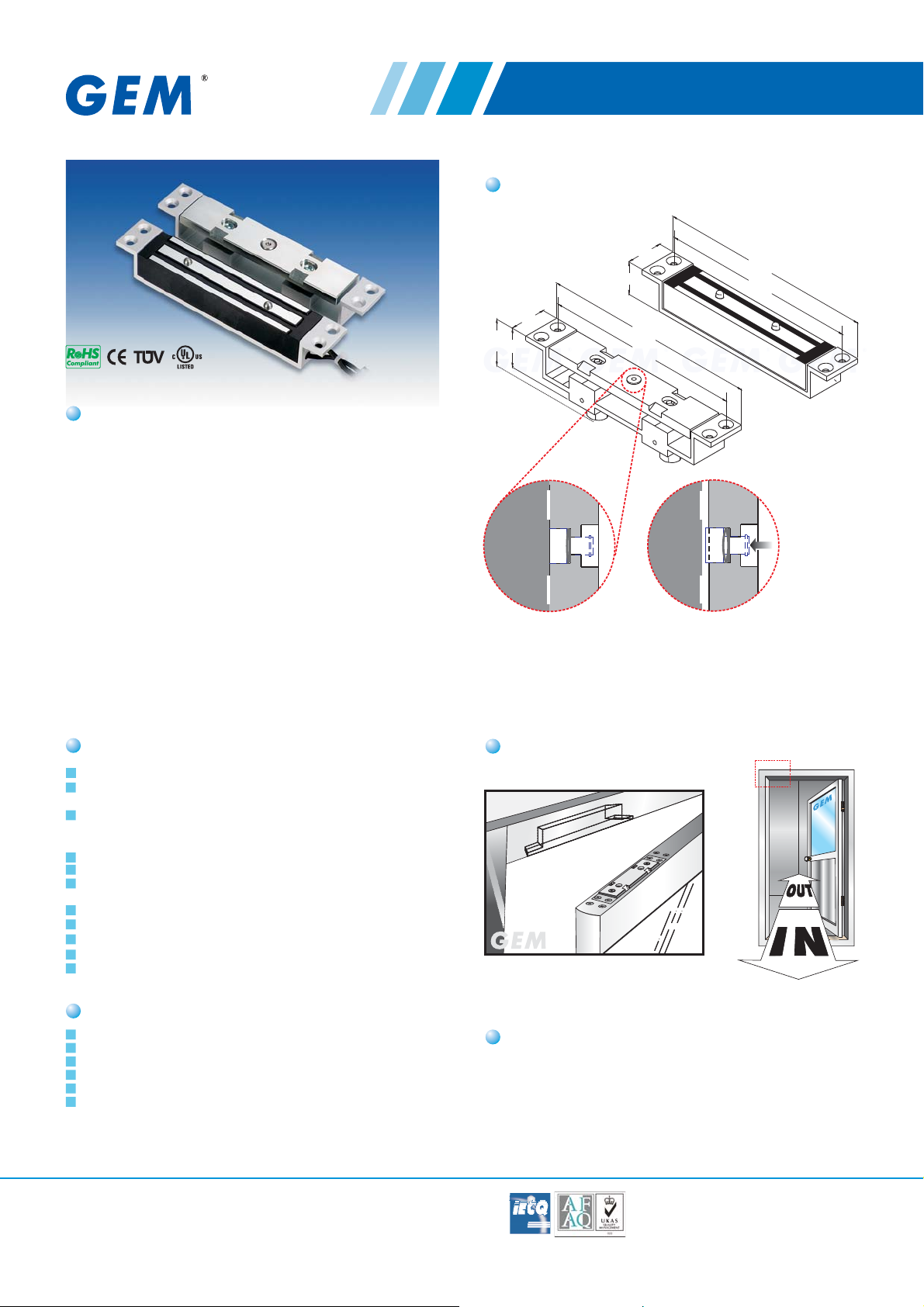

GS-200 MINI SHEAR LOCK

Magnet

Armature

(Power Off)

Magnet

Armature

(On Power)

Dimension

Statement

GEM Mini Shear Lock locks by seating two conical locking

bolts located on opposite corners of the Armature Plate into

matching keep holes on each end of the Electromagnet body.

The GEM Shear Locks never bind under pressure, are not

sensitive to door alignment, and do not require door position

sensing or auxiliary timing circuitry. They are ideal for swingthrough doors and sliding doors as well. A unique benefit of

the GEM Shear Locks' physical design is that they function

equally well on doors that swing to close or doors that slide to

close.

The GS-200 series is available in two models, GS-200

Unmonitored or the GS-200M with hall effect monitoring. The

units are design for use with metal door frame, fitted to either,

wooden, aluminum, or glass doors with the assistance of

various housings. This manual gives a guide to all of the above

applications and other useful installation information.

The GS-200 provide up to 1200 pounds shearing force and

fully concealed mounting, combine the best in failsafe

performance with the most advanced features.

(43)

33

30

30

27

180

164

180

164

Unit: mm

When there is no power, there will be no holding force, and

the push-off button will pop out immediately, to release the

Electromagnetic Lock and the Armature Plate for no residual

magnetism.

Unique Anti-Residual design

Specifications

Voltage Tolerance: 10%

Current Draw: 420mA@12 VDC; 210mA@24 VDC

)at temperature 20C(

Magnetic bond sensor monitor output (GS-200M)

(SPDT rated 3A@30VDC), indicates the door locked

or unlocked status.

Operating Temperature: -30~+55C

Humidity: 0~95% non-condensing.

Lock's surface Temperature (when the power is on):

<current temperature +20C

Holding Force: Up to 1200 lbs (545 Kg) in shear.

The Gap between the Lock and Armature plate is 2 mm

Special Finishes for magnet and armature plate: Zinc

Epoxy Potting Compound: E87252 (S), UL94V-0

Weight )Approx.(: 1.2 Kg

±

Patent

GB 2400626 (Great Britain)

2854190 (France)

2003100306 (Australia)

219858 (Taiwan)

Nr.203 06 200 .0 (Germany)

ZL 03 2 45413.9(China)

GIANNI INDUSTRIES, INC.

No. 13, Zhong Sing Road, Tu-Cheng Industrial Zone,

Tu-Cheng City, Taipei, Taiwan 23678

Tel: 886-2 2267 7986 / Fax: 886-2 2267 9876

E-Mail: info@gianni.com.tw

Website: gianni.tw

Copyright 2008 Gianniindustries, inc. All rights reserved.

DM-CA-GS-200 Ver.C Published on 2008.05.14

Flush Installation

Horizontal Installation

Warranty

The product is warranted against defects in material and

workmanship while used in normal service for a period of 5

year from the date of sale to the original customer. The GEM

policy is one of continual development and improvement;

therefore GEM reserves the right to change specifications

without notice.

The products are manufactured under an ISO

9001 QC 080000 Certified Quality

&

Management Program environment back its

product quality, performance and commitment

to customersatisfaction.

Page 2

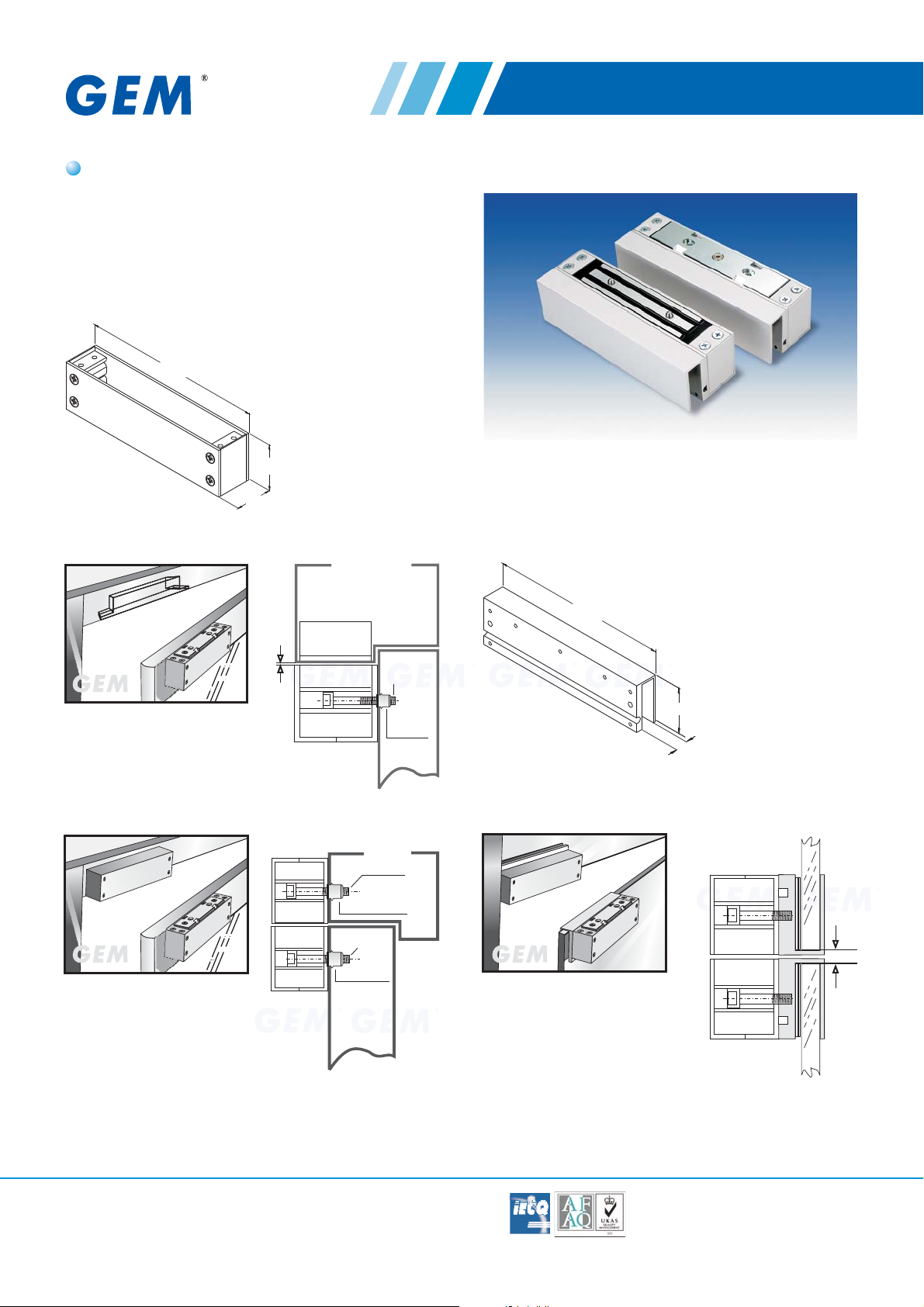

Optional Brackets

The unit may also be fitted semi-flush or sureface

installation with the use of the SMB-200 and UBK-182

Brackets. The magnet should be fitted to the door transom and

the housing holding the armature on to the door. It is vital that

a minimum gap of 2mm exists between the magnet and the

armature, to allow correct operation.

182

SMB-200 Bracket

48

35

GS-200 MINI SHEAR LOCK

GS-200VGL

Semi- Flush Installation

Surface Installation

Magnet Assembly

Mini clearance

2mmofgap

Surface Mount

Armature Assembly

Metal Door

Magnet

Assembly

Armature

Assembly

Metal Door

Header

Header

M6 x45 Screw

Blind Nut

M6 x45

Screw

Blind Nut

M6x45

Screw

Blind Nut

182

UBK-182 Bracket

48

14

Installation on Frameless Glass Door

Armature

Assembly

GS-200 using 2pcs of the

SMB-200 Bracket and 2pcs of

the UBK-182 mounting

brackets.(The thickness of

glass are 14 mm maximum.)

Magnet

Assembly

Mini clearance

=7mm

GIANNI INDUSTRIES, INC.

No. 13, Zhong Sing Road, Tu-Cheng Industrial Zone,

Tu-Cheng City, Taipei, Taiwan 23678

Tel: 886-2 2267 7986 / Fax: 886-2 2267 9876

E-Mail: info@gianni.com.tw

Website: gianni.tw

Copyright 2008 Gianniindustries, inc. All rights reserved.

DM-CA-GS-200 Ver.C Published on 2008.05.14

The products are manufactured under an ISO

9001 QC 080000 Certified Quality

&

Management Program environment back its

product quality, performance and commitment

to customersatisfaction.

Loading...

Loading...