Page 1

Patent:

ZL 2006 2 0122522.X

Nr. 20 2006 012 052.1

M308308

GB 06 1 6099.8

Features

06 07229 (France)

Offers up to 800 LBS Holding Force.

Anodized aluminum housing.

Groove template & housing for easy installation.

Dual voltage 12 or 24 VDC selectable

)(.

Anti-Residual magnetism designed.

Complete mounting hardware included.

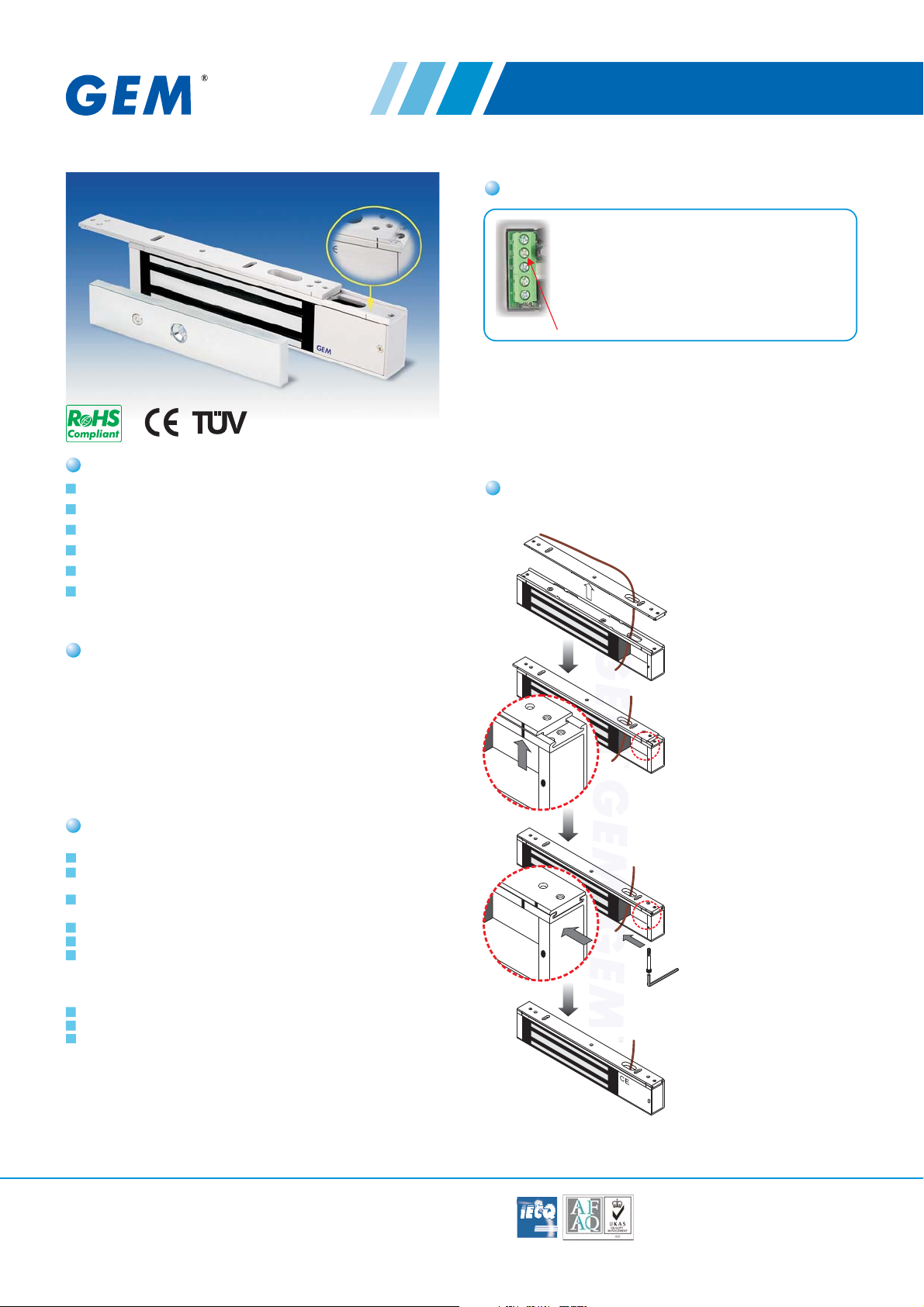

EM-NH350

Midi Electromagnetic Lock

Operating Features

EM-NH350M: Bond sensor output & Status LED

Bond sensor is used to indicate the door

status as in a locked or unlocked condition.

Status LED

give the true status of the lock at any time.

Green light indicates the door is insecure

Bond sensor monitor output : SPDT rated: 3A@12VDC

Special Mounting Plate design

Cable

is a visual feedback for user to

Fasten the mounting plate on

the site then install

electromagnet lock with

power lead cable through

mountingplate slot hole.

Statement

EM-NH350

The electromagnet lock is an important mounting

plate design breakthrough. The mounting plate is designed

with a well engineered sliding mechanism that makes

electromagnet considerably easy to clasp the mounting plate

to allow security of use and maximize the ease of installation.

Therefore, even if used for longer periods, the tricky

innovation in its design will prevent the electromagnet of

being falling when the screw are loosening up .

Specifications

Voltage Tolerance: 15%

Current Draw: 500mA@12Vdc;250mA@24Vdc

)at 20 degree centigrade(

Operating Temperature from -10 to 55 degree

centigrade

Humidity: 0~95% non-condensing.

Holding Force: Up to 800 lbs (363 Kg)

Dimensions:

Magnet:(L) 265, (W) 52, (D) 29 mm

Armature Plate:(L) 185, (W) 45, (D) 14 mm

Mounting Plate:(L) 265, (W) 29, (D) 6.5 mm

Finishes for magnet and armature plate: Zinc

Epoxy Potting Compound: E87252 (S), UL94V-0

Weight (Approx.): 3.0 Kg

For assembling the mounting

plate and the electromagnet

lock into the groove, please

make the mark on the

mounting plate and the mark

on the electromagnet lock

itself to be a straight line for

alignment. Either aligning

from left side or from right

sideis feasible.

Slide the electromagnetic

lock to fit with the mounting

plate as the drawing. Once

the correct position is

encountered, use the Allen

Wrench to fasten the fixing

screws through the bottom of

the electromagnet lock into

themounting plate.

After the electromagnet

firmly assembled with the

mounting plate, use the

screws to fasten the lock on

thesite permanently.

GIANNI INDUSTRIES, INC.

No. 13, Zhong Sing Road, Tu-Cheng Industrial Zone,

Tu-Cheng City, Taipei, Taiwan 23678

Tel: 886-2 2267 7986 / Fax: 886-2 2267 9876

E-Mail: info@gianni.com.tw

Website: gianni.tw

Copyright 2008Gianni industries, inc. All rights reserved.

DM-CA-EM-NH350 Ver. D Published on 2008.08.18

The products are manufactured under an ISO

9001 QC 080000 Certified Quality

&

Management Program environment back its

product quality, performance and commitment

to customersatisfaction.

Page 2

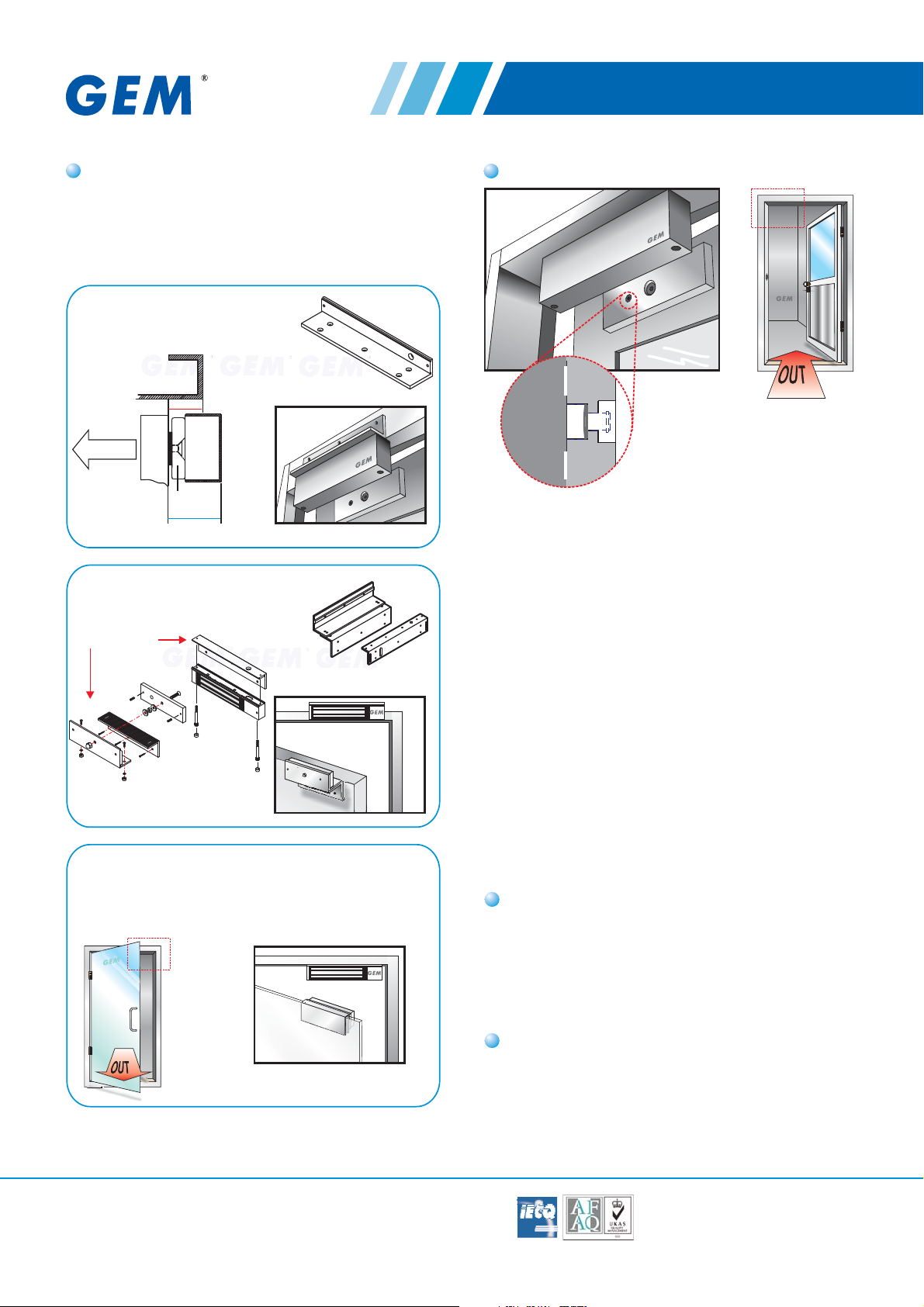

Magnet

Armature

(On Power)

EM-NH350

Midi Electromagnetic Lock

Optional Brackets

The door swinging direction and the door frame header are

used to determine whether the bracket is required and this

identify is a measure of which brackets is suitable. Our

optional brackets include L bracket LZ bracket and U

bracket

.

With L-bracket for narrow door frames

When <48mm,must

"A"

installed with "L" brackets.

Door

Frame

A

Out-swinging

Door

Leaf

Magnet

Armature

48 mm

With LZ-bracket for in-swinging doors

-,- -

L-NH350M

Regular Installation

Unique Anti-Residual design

When the power is switched off, the holding force will be

discontinuity and the bolt was installed in armature will pop

LZ-NH350M

With U-bracket for frameless glass doors

UBK-010

UBK-012

For 10mm thickness of glass door

For 12mm thickness of glass door

GIANNI INDUSTRIES, INC.

No. 13, Zhong Sing Road, Tu-Cheng Industrial Zone,

Tu-Cheng City, Taipei, Taiwan 23678

Tel: 886-2 2267 7986 / Fax: 886-2 2267 9876

E-Mail: info@gianni.com.tw

Website: gianni.tw

Copyright 2008 Gianniindustries, inc. All rights reserved.

DM-CA-EM-NH350 Ver. D Published on 2008.08.18

Patent

ZL 2006 2 0122522.X (China)

Nr. 20 2006 012 052.1(Germany)

M308308 (Taiwan)

GB 06 1 6099.8 (Great Britain)

06 07229 (France)

Warranty

The product is warranted against defects in material and

workmanship while used in normal service for a period of 5

year from the date of sale to the original customer. The GEM

policy is one of continual development and improvement;

therefore GEM reserves the right to change specifications

without notice.

The products are manufactured under an ISO

9001 QC 080000 Certified Quality

&

Management Program environment back its

product quality, performance and commitment

to customersatisfaction.

Loading...

Loading...