Page 1

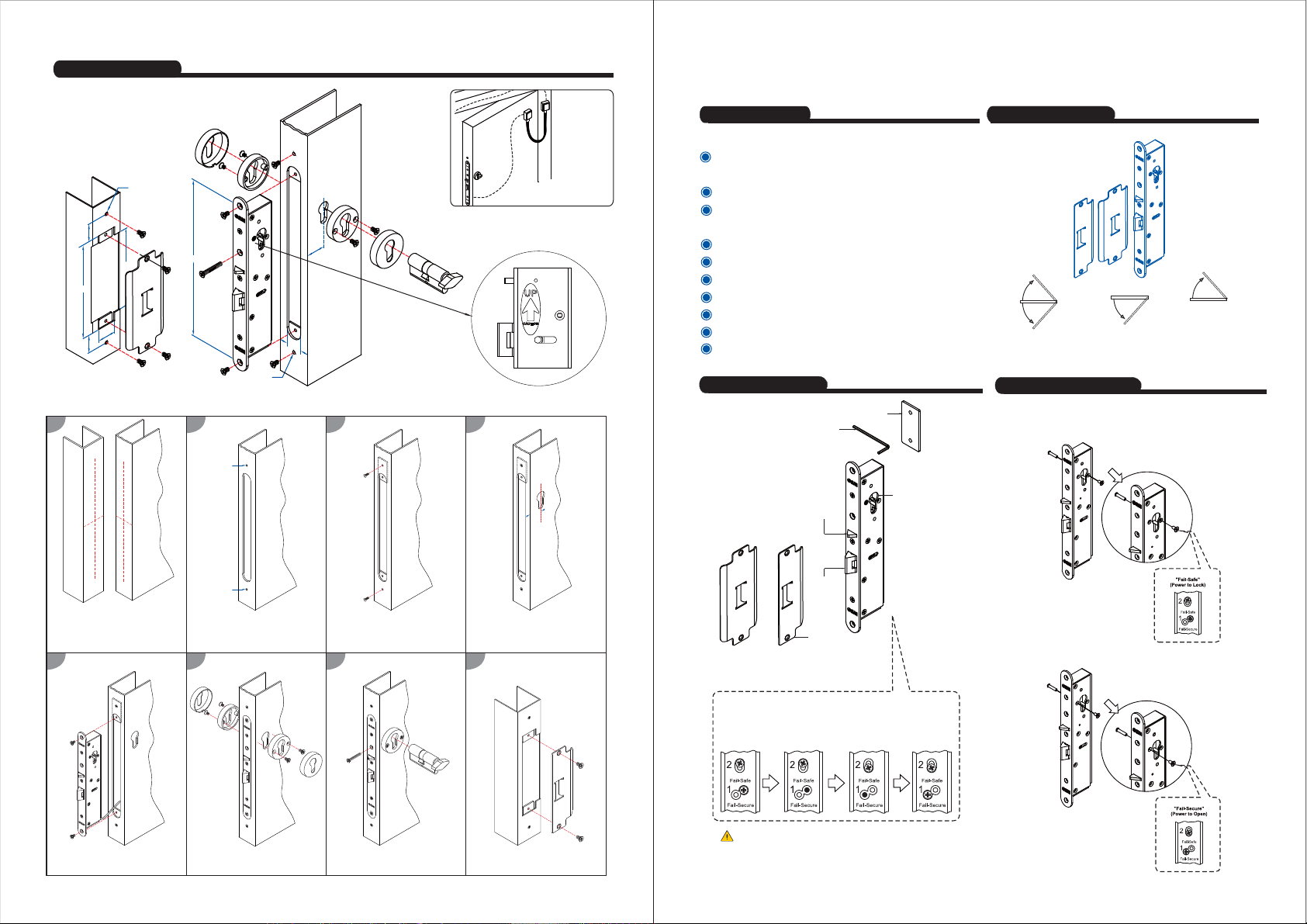

Installation Instructions

62mm cylinder for max •42mm door leaf

72mm cylinder for max •52mm door leaf

D

oo

r Frame

28

150

28

ø5.0

124

30

250

Unit:mm

Door Loop

(Optional)

or leaf

o

D

Specification Double Swing Doors

ML-300

ML-300-SW

Electromechanical Lock

Installation Instruction

Operating Voltage» ML-300: 12 or 24VDC

ML-300-SW: 12~24VDC/AC

Voltage Tolerance» ±10%

The door loop protects the wiring

from damage at the door hinge.

(

C

y

li

30

n

d

e

r

n

o

t

i

nc

l

u

d

ed

)

Current Draw» ML-300: 280mA/12VDC; 140mA/24VDC

ML-300-SW: 210mA/12VDC; 150mA/24VDC

Version Changeable» Fail-safe or Fail-secure

Operating Temperature» -10~45°C

Humidity» 0~95% non-condensing

Lock bolt sensor switch output» SPDT rated 3A/125VAC

Solenoid testing» Tested to 1,000,000! cycles

25

Net Weight» ML-300: 800g / ML-300-SW: 815g

Just applicable to vertical installation

Double swing door Outswing Inswing

ø5.0

1 2 3 4

f

a

e

L

F

r

a

m

e

r

o

o

D

ø5.0

f

a

e

L

r

o

o

D

Alignment CL

ø5.0

Align the center line (CL) of the

lock body template with the CL of

the door leaf. Ensure the CL of the

strike plate template matches the lock

body CL as closely as possible.

Cut out mortise holes for the lock

body and strike plate and drill holes

according to the templates.

Tighten the fixing lugs with

screws.

5 6 7 8

Attention! Please ensure that the

direction of the template is correct

30

Drill and cut the hole for the lock

cylinders as shown in the template.

D

o

o

r

F

r

am

e

Packing Contents

Allen wrench (1.6mm)

NIB

Lock bolt

Strike Plate

For double swing door

Version Changeable:

Take out the Screw 1 , release screw 2 , move the

position and then tighten both screws.

“Fail-Safe”

(Power to Lock)

For single swing door

Fixing Lug

Euro profile

key cylinder

“Fail-Secure”

(Power to Open)

Stud bolt Position

For fail-safe mode

For fail-secure mode

Connect power cable to the lock

and test before screwing to the

door leaf.

Attach the cover plates for the

cylinder lock

Copyright © All Rights Reserved. P-MU-ML-300 Ver. H Publish: 2010.12.24

Install the cylinder

Fix the strike plate.

4-4

Caution:

Do not completely remove screw 2 (as marked in the figure)

as the interior solenoid might fall off.

Copyright © All Rights Reserved. P-MU-ML-300 Ver. H Publish: 2010.12.24

4-1

Page 2

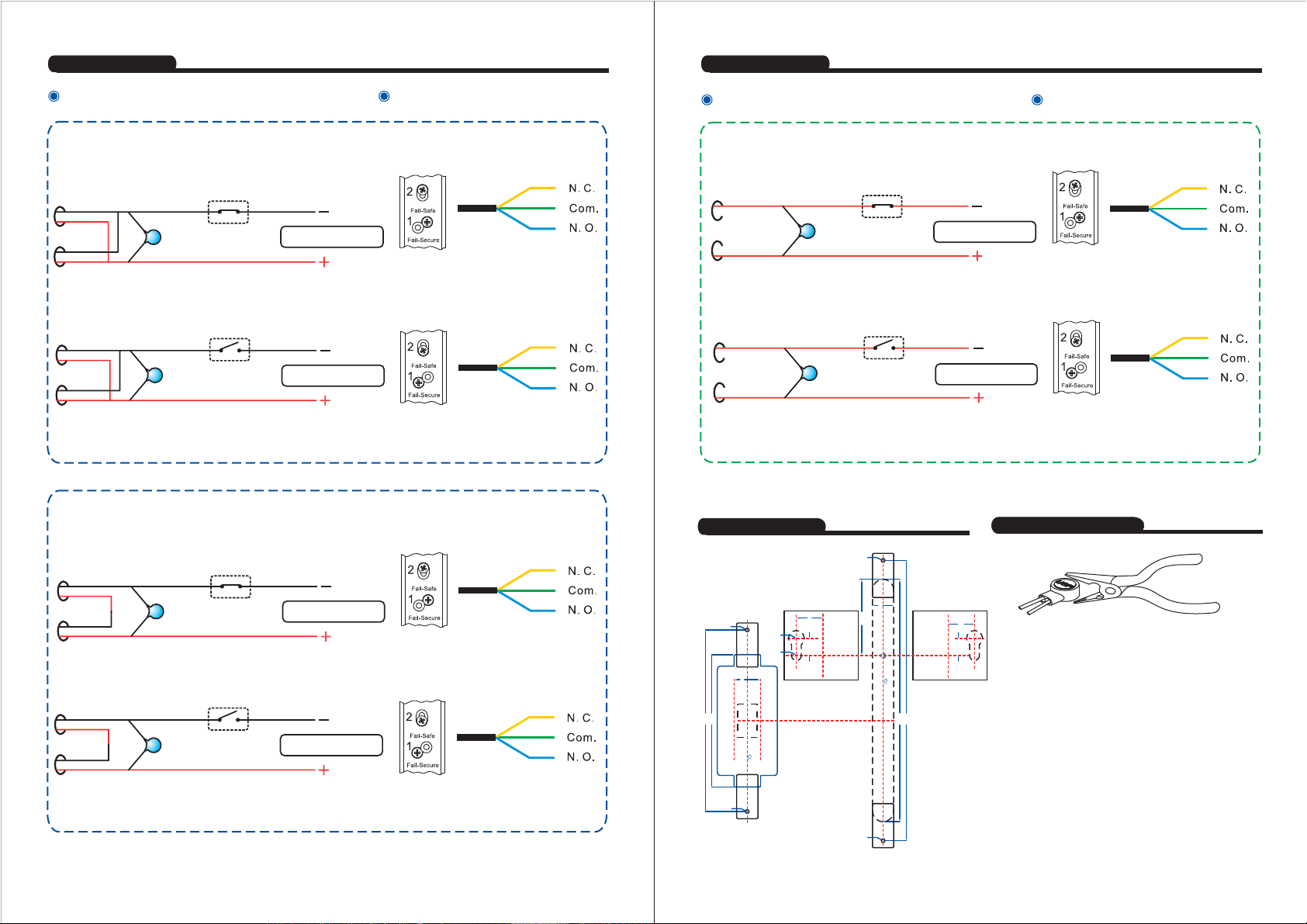

Wiring Diagram

Wiring Diagram

ML-300 Voltage Input: 12 or 24VDC Lock bolt sensor status output

For 12VDC operation, the solenoid input wires

should be connected in parallel as shown below.

Black

Red

Black

Red

Access Control Device

N.C. contact

Varistor

(Power input is polarity free)

12VDC Power supply12VDC Power supply

“Fail-Safe”

(Power to Lock)

Black

Red

Black

Red

For 24VDC operation, the solenoid input wires

should be connected in series as shown below.

Access Control Device

Varistor

N.O. contact

(Power input is polarity free)

12VDC Power supply

“Fail-Secure”

(Power to Open)

Yellow

Green

Blue

Yellow

Green

Blue

ML-300 Voltage Input: 12~24VDC/AC Lock bolt sensor status output

For the 12~24VDC/AC operation only

Yellow

Red

Red

Access Control Device

N.C. contact

Varistor

(Power input is polarity free)

12~24VDC/AC Power supply

“Fail-Safe”

(Power to Lock)

Red

Access Control Device

N.O. contact

Red

Varistor

(Power input is polarity free)

NOTE: The varistor (or diode) must be connected across the terminals as shown above. This protects the electromechanical

lock from spikes and surges.

Template

12~24VDC/AC Power supply

Unit:mm

“Fail-Secure”

(Power to Open)

Butt Splice (IDC) Connector

Green

Blue

Yellow

Green

Blue

Black

Red

Black

Red

Black

Red

Black

Red

Access Control Device

N.C. contact

Varistor

24VDC Power supply

(Power input is polarity free)

Access Control Device

N.O. contact

24VDC Power supply

Varistor

(Power input is polarity free)

Copyright © All Rights Reserved. P-MU-ML-300 Ver. H Publish: 2010.12.24

“Fail-Safe”

(Power to Lock)

“Fail-Secure”

(Power to Open)

Yellow

Green

Blue

Yellow

Green

Blue

4-2

ø5.0

25

86.5

Door leaf edge

Alignment CL

318

275

Cut on dotted line

ø5.0

Copyright © All Rights Reserved. P-MU-ML-300 Ver. H Publish: 2010.12.24

Alignment CL

30

19.5

Door leaf edge

Using crimper or pliers and pressing the header of

connector down to even position.

4-3

ø5.0

30

150

206

ø5.0

ø18.0

ø11.0

30

19.5

Alignment CL

Loading...

Loading...