Page 1

AD-425S Automatic Door Operator

Instruction Manual

General Safety Precautions

z This instruction manual is intended solely for use by qualified professionals. All

installations, electrical connections and adjustments must follow the installation

instructions.

z Please read this manufacturer's instructions carefully before installing this unit. Incorrect

installation may result in severe personal injury and/or damage to property.

z Packaging materials (plastic and polystyrene, etc) should be disposed of without causing

environmental damage and should be kept out of reach of children.

z Do not install this unit in a chemical explosive environment or atmosphere to prevent a

risk of explosion. The location of this unit is important in achieving proper performance

and normal operating life. This unit should be installed in a safe operating condition

z Make sure the construction‘s strength and stability are up to standard. Manufacturer will

not be held responsible for any damage resulting from incorrect use of this unit.

z These safety devices (e.g. photocell and emergency stop) must follow the technical

safety regulations and current safety standards, including limiting of forces and speeds to

ensure the door operator works very well at all times.

Encoder

Photocell

z The safety devices must protect any areas where the risk exits of being crushed, cut or

gagged or where there are any other risks generated by the motorized door or gate.

Apply hazard areas notices required by applicable regulations.

z Each installation must clearly show the identification details of the motorized door/gate.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 1/ 20

Page 2

z Make sure the voltage specified as correct for the device.

z Must provide at least 10 seconds rest time between every restarting cycle to ensure

z Make sure to turn the power off before installing and checking this unit and to avoid the

adequate residual current can be returned to power system.

risk of fingers that are in contact with the electronic components. External

interconnection wiring should be performed wearing the antistatic glove.

Security S tatement

According to operating instructions, motorized door installer and the manufa cturer of

the machinery have the same obligations:

z The technical documents and the annex to the AD-4 25S Automatic Door Operator must

be kept and placed at the disposal of competent national authorities for at least 5 years

from the manufacturing dates. CE attestation of conformity should deliver it to the

customers.

z Should you have other queries, please refer to the http://gianni.tw

full details and other relevant documentations.

to download AD-425S

Manufacturer's Declaration

Gianni Industries, Inc.

Address: No. 306-1 Hsin Shu Road, Hsin Chuang, Taipei, Taiwan 242

E-mail:info@gianni.com.tw

http://gianni.tw

Herewith declares that AD-425S Automatic Door Operator for swing doors: (One way

direction only.)

z AD-425S Automatic Door Operator can not be installed with other mechanism except

electric door locks.

z Conformity with other CE directives: Electromagnetic Compatibility Directive

2004/108/EC(EN61000-6-1、 EN61000-6-3 、EN61000-3-2、 EN61000-3-3)

z Product life: 5 years

z Product should be operated under the recommended door weight. A reduction in

performance is to be expected when the access is made to operate at the maximum

permissible weight.

z Service class, product operation times and the number of consecutive cycles have been

statistically analyzed to determine under average operating conditions, and it does not

represent for use under a special condition. (See Figure 1)

z The characteristic performance of door operation may be affected by different

independent variables like friction, offset (balancing), environmental factors and so on.

These factors may change the performance of the door operator’s working life or parts.

Furthermore, the assembly must be considered and enables infinite durability and

continuous operation.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 2/ 20

Page 3

All Packing materials

1. Construction Name

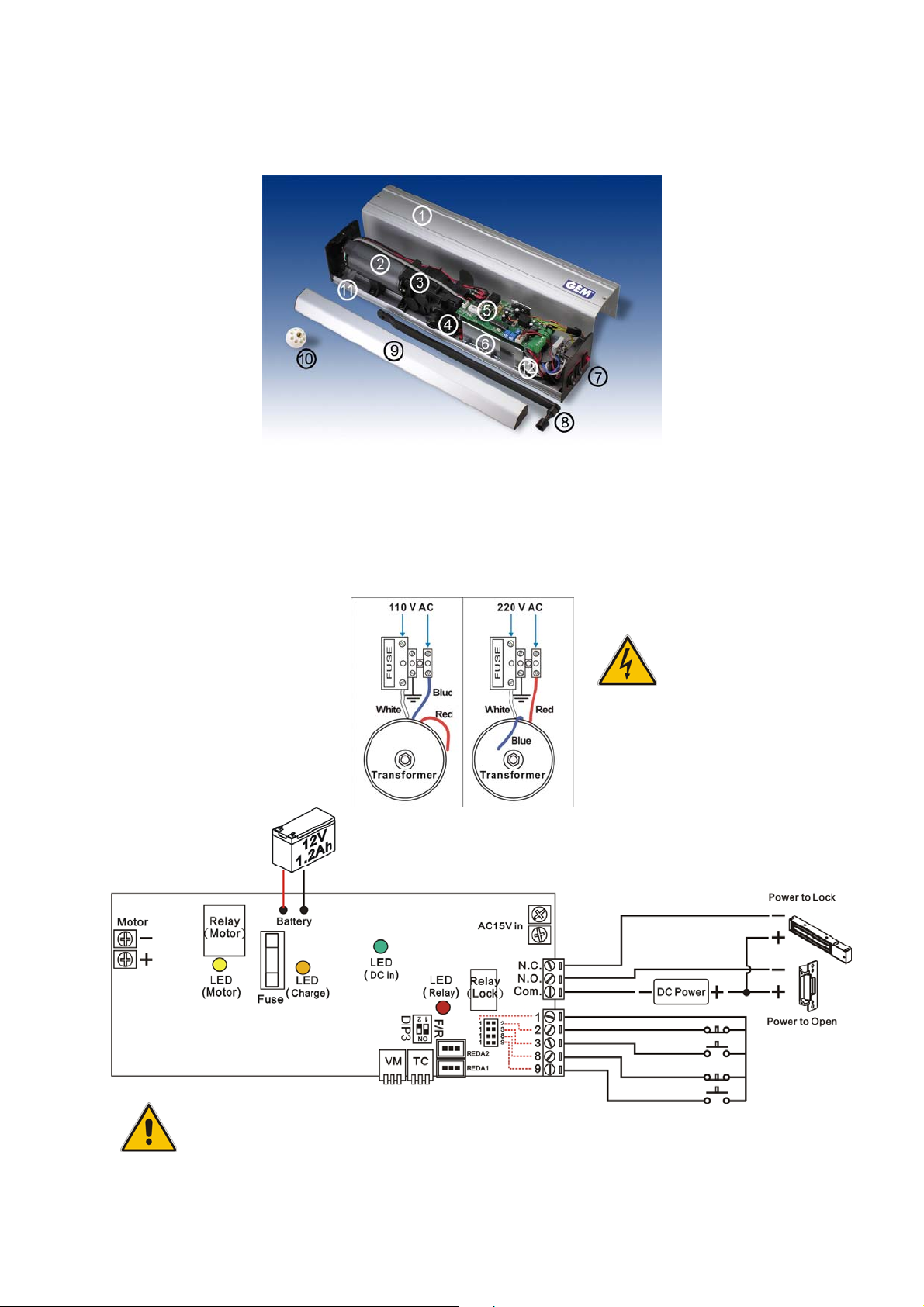

1 Cover ○2 Motor ○3 Reducer ○4 Square Couplings ○5 Control Board ○6 Battery

○

7 Power Switch ○8 Operating Arm ○9 Sliding Rail ○10 Stopper Ball ○11 Baseplate

○

12 Transformer

○

2. Control Board

Make sure the voltage

specified as correct for the device.

For safety reasons, we recommend user not to install this operator with a Fail-Secure

Electric Locks (Power to open) in case of emergencies or power interruption s.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 3/ 20

Page 4

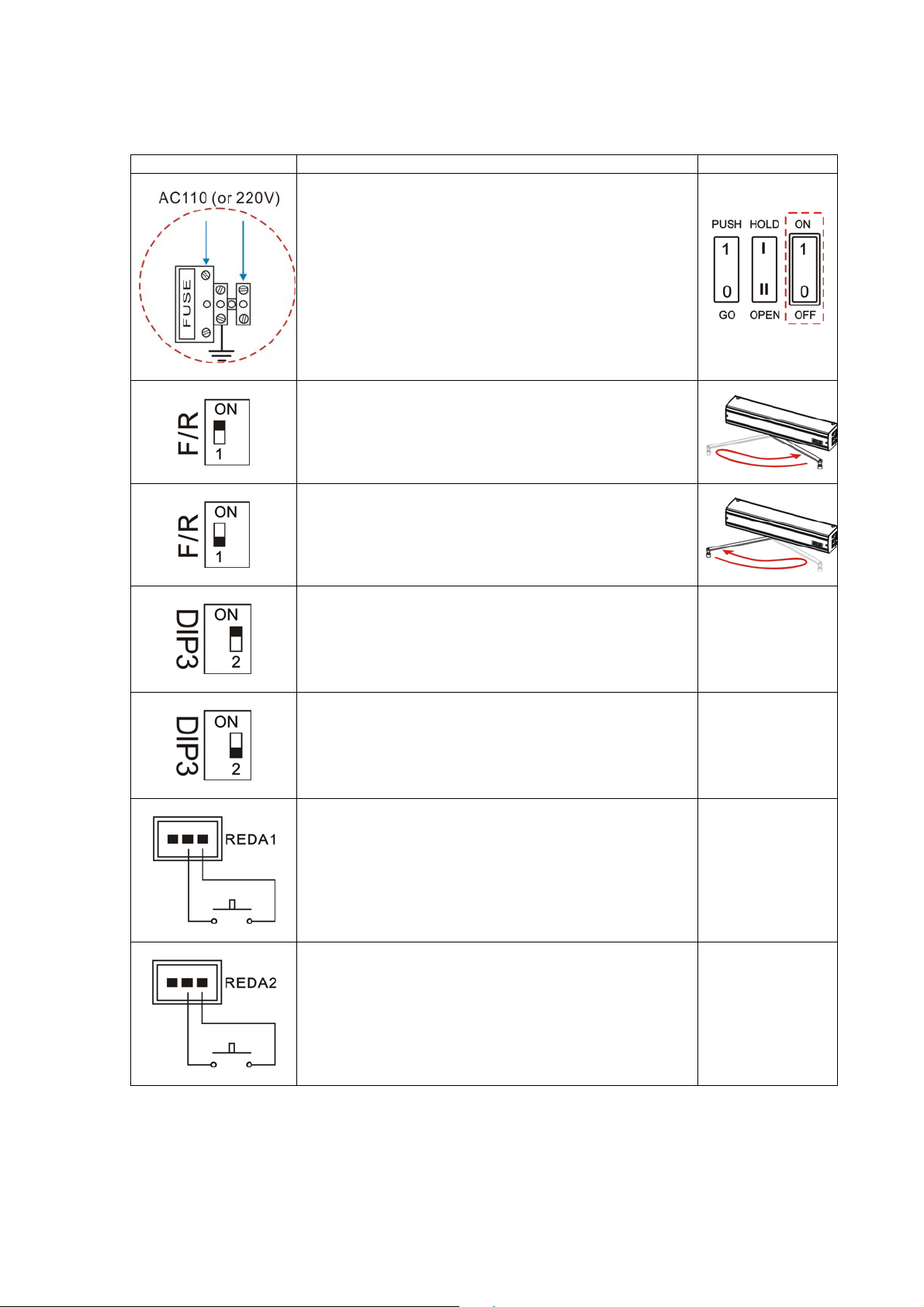

3. Control Board Guide

Input/Output Contact Explanation Remark

Make sure the input is used correctly (AC110 or 220V).

When turn on the power switch, it enters a learning

mode.

AD-425S Operating Arm turns clockwise. (See Figure

5~8)

AD-425S Operating Arm turns counter-clockwise. (See

Figure 5~8)

DIP3 switch ON, when the external pressure force either

“WIND” or “MAN MADE FORCE” occurs, AD-425S will

automatically open and close.

DIP3 switch “2”, when the external pressure force either

“WIND” or “MAN MADE FORCE” occurs, AD-425S can

be manually opened and closed.

REDA1 internal connector links up the control unit.

REDA2 external connector links up the control unit.

Power Switch

When Lock is

opened and wait

up to

0.7seconds, the

Motor will be

activated.

When Lock is

opened and wait

up to

0.7seconds, the

Motor will be

activated.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 4/ 20

Page 5

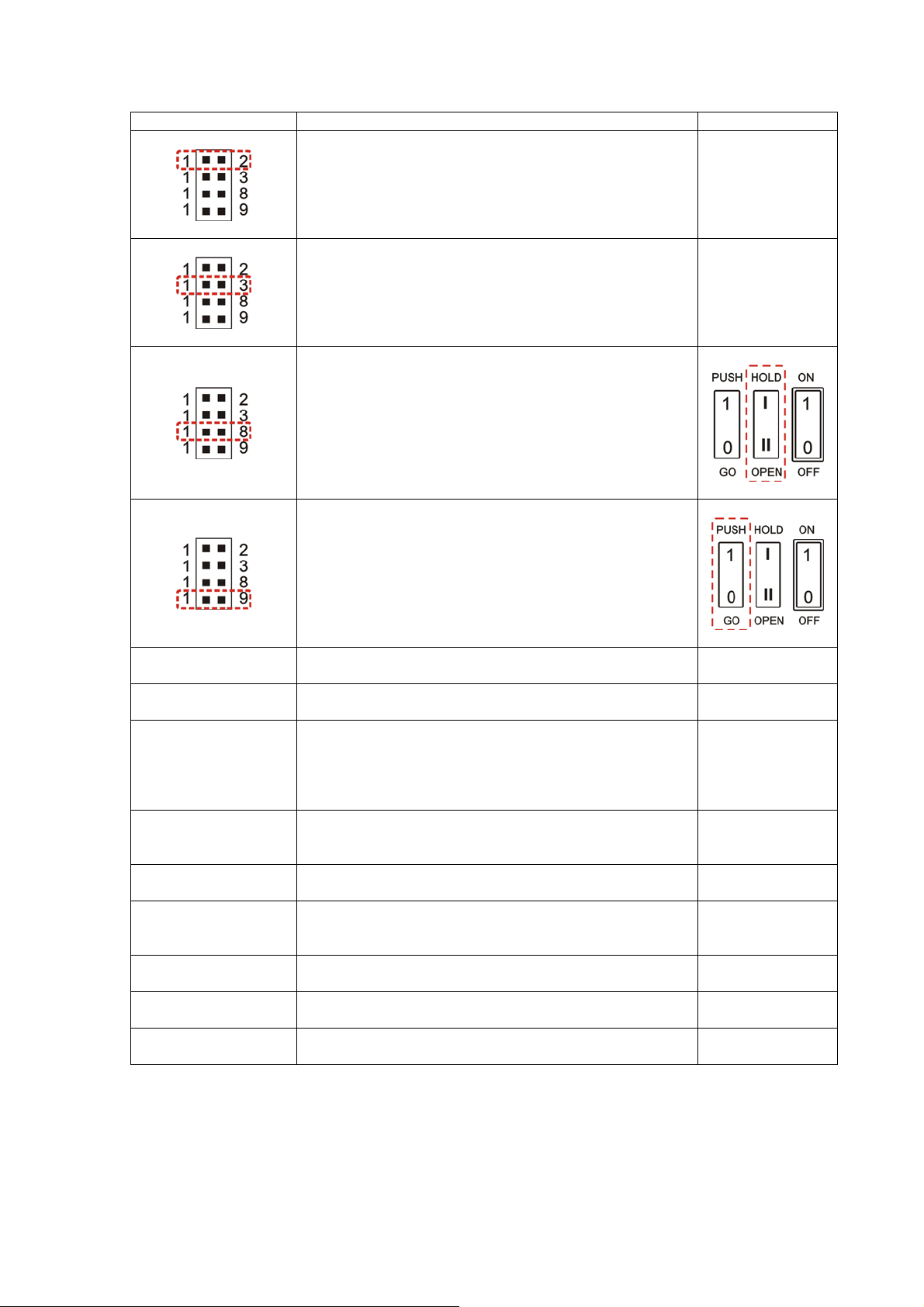

Input/Output Contact Explanation Remark

Jumper 1-2 is N.C. contact. N. C. (default)

Jumper 1-3 is N.O. contact. N. O. (default)

Jumper 1-8 is N.C., or using the “OPEN” switch.

AD-425S becomes automatic mode. When the

connector is N.O. or using the “HOLD” switch, and then

change to manual mode.

Jumper 1-9 is N.O., or using the “GO” switch.

AD-425S becomes manual mode. When the connector

is N.C. or using the “PUSH” switch, and then change to

automatic mode.

LED (Relay)

LED (DC in)

Relay(Lock) Action indicator. See page 3

PCB power status indicator. See page 3

This battery has

Battery Contact and

LED (Charge)

LED (Charge) indicates the battery charge is working

properly. The optimum operating temperature for the

rechargeable battery is 5℃ up to 40 ℃.

an expected life

of 250 recharge

cycles at full

charge.

Battery

BATTERY Battery Contact.

Specification (12

V ,1.2 Ah)

LED (Motor)

N. C.

N. O.

Com.

AC 15V IN

Motor power status indicator. See page 3

N. C. is a normally closed contact, and it is for

fail-safe (Power to Lock) Electric Locks.

N. O. is a normally open contact, and it is for

fail-secure (Power to Open) Electric Locks.

Com. contact is a dry contact compatible with N. O. and

N. C. contacts.

The 15V AC power is transformed from 110 or 220 VAC

by the transformer to the Control Board.

All GEM electric

locks are

suitable.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 5/ 20

Page 6

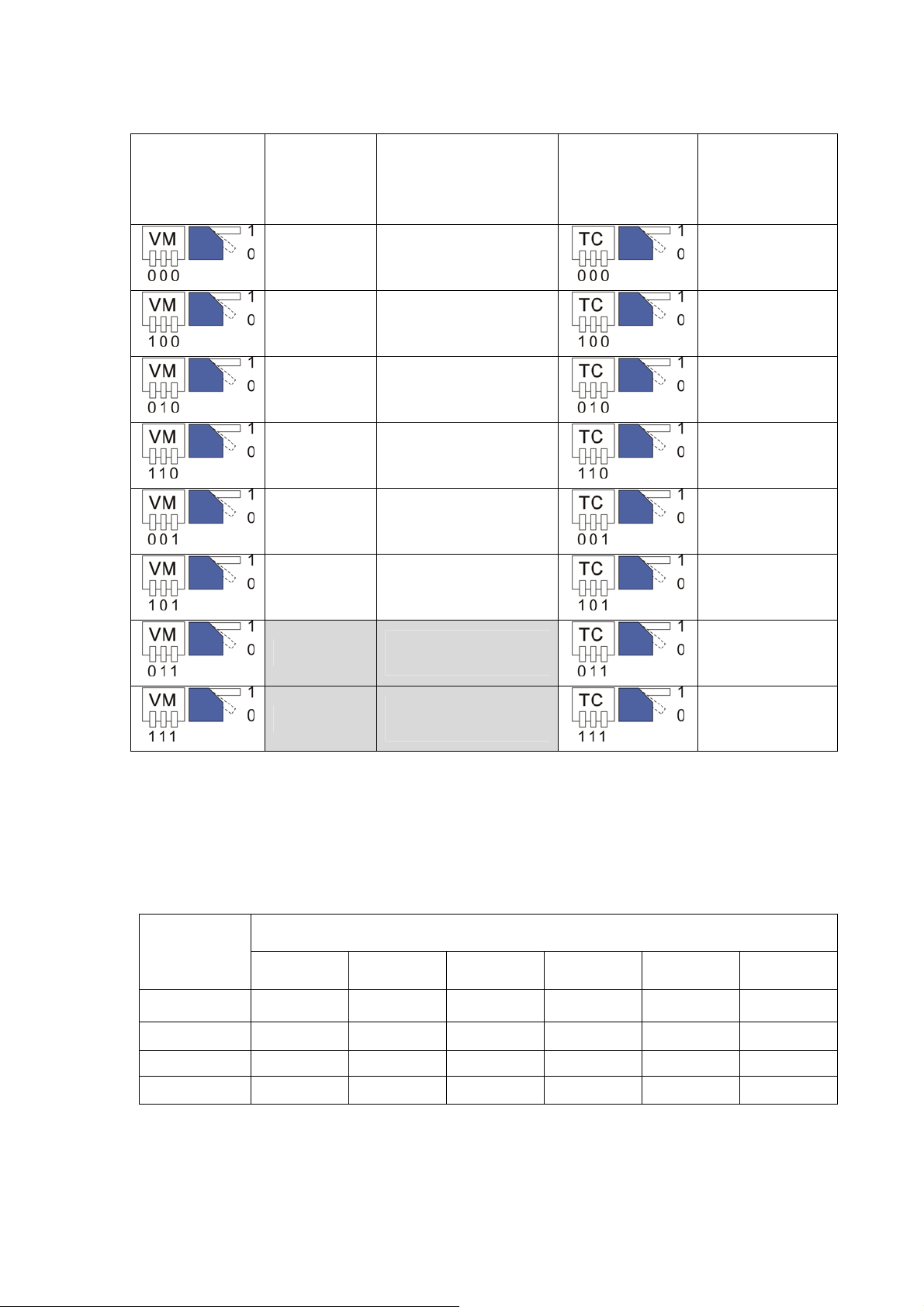

The opening, closing and maintain -open time illustration table.

VM

(Opening and

Closing Time

Adjustment )

Opening and

Closing

Operating

Time

Total Opening and

Closing Time (VM+

Brake Time)

TC Time

(Maintain -open

time adjustment)

Maintain -open

time

(See Figure 4)

2 4.5

3 6.0

5 8.0

7 9.5

2

4.5 (With high torque

output)

3

6.0 (With high torque

output)

5

8.0 (With high torque

output)

1

5

10

15

20

25

30

7

9.5 (With high torque

output)

35

z For the wider door leaf, we suggest that you can extend the opening and closing time or

adjust the high torque output. For the 95cm~120cm door width, please refer the gray

region for setting. The high torque output enhanced the door stability.

z The opening operation based on 90° angle; however, there would be time dif ference from

the setting angles.

z Please refer to the below table for TC settings.

Door width

(cm)

50 kg 60 kg 70 kg 80 kg 90 kg 100 kg

Door weight (kg)

75 cm 20 s 20 s 22 s 22 s 25 s 28 s

85 cm 20 s 20 s 22 s 22 s 25 s 28 s

100 cm 22 s 22 s 24 s 24 s 27 s 30 s

120 cm 22 s 22 s 24 s 24 s 27 s 30 s

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 6/ 20

Page 7

5. Specification

Power Input

Current (See Figure 2) 3.5A max., 0.6A average

Torque 30Nm

Opening/Closing time (VM)

Maintain - Open time (TC) 1~35 seconds

Battery Specification 12V 1.2AH

Temperature -20 ~+55℃℃ (Battery 5 ~40℃℃)

Degree of Protection IP 12D

Product Weight 6.5 kg

Voltage: 8~24VDC

Motor specification

Battery charge 12V=0.15A (Normal); 0.3A (Peak)

Dimensions

Door Dimensions

(Figure 1)

Maximum current : 4A

Power consumption : 65W

Maximum rotation frequency: 2400 RPM

110V (or 220V) AC,50-60Hz

4.5~9.5 s (90°)

Operator: 526(L) x 100(W) x 96(D) mm

Arm: 375 mm

Door width : 75~120 cm

Door weight : 50~100 kg

Figure 1

Door Width(cm)

Door Weight(kg)

Service Class A: average of up to 600 cycles

per day

Service Class B: average of under 200 cycles

per day

This warranty is only for our specified door leaf

width and door leaf weight.

z Figure 2: Automatic door operator power consumption graph. Wh en activated the curre nt

will increase from 0 to 3.5A, and will decrease to 0.5~0.6A afterward. The deceleration

time will cause the current up to 1.8A.

Figure 2

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 7/ 20

Page 8

Installation instructions

z Refer to figure 3 for in-swing door (right-hand).

Figure 3

z Opening, Closing action time and Maintain time illustration. AD-425S will be

automatically counted the round trip distance and can be adjusted the opening, closing

and break time.

Figure 4

Opening angle: 90 degrees.

Beginning

Destination

Brake for wall blanking function.

VM action time is the opening and closing time.

TC Maintain time of 1-35 seconds

.

Prepare the installation

To mount the AD-425S depends on the direction way of the doors, out-swing, in-swing, rightopen and left-hand doors by adjusting the F/R switch and the direction of the Operating Arm.

For the safety reason, AD-425S must be installed indoor.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 8/ 20

Page 9

Figure 5: For right-hand and out-swing door. F/R switch set 「ON」. Operating Arm mounts to

left-side.

Figure 6: For left-hand and out-swing door. F/R switch set 「1」. Operating Arm mounts to

right-side.

Figure 7: For right-hand and in-swing door. F/R switch set 「1」. Operating Arm mounts to

left-side.

Figure 8: For left-hand and in-swing door. F/R switch set 「ON」. Operating Arm mounts to

right-side.

Figure 5 Figure 6 Figure 7 Figure 8

To mount the operator on a right-hand door, Operating Arm mounts to left-side. (See Figure 9)

To mount the operator on a left-hand doo r, Operating Arm mounts to right-side. (See Figure 10)

Mount the Operating A rm

Figure 9 Figure 10

z Required Tools

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 9/ 20

Page 10

z Figure 11~13 showing an operator installation of a minimum door leaf width and a

maximum opening angle. The opening angle is recommend ed not excess to 120∘.

Figure 11

Figure 12 Figure 13

z Figure 14: Automatic door operator dimension

Figure 14

z Install AD-425S on an out-swing door, make sure that the distance between the header

and leaf is not more than 60mm, and the space between the header and Sliding Rail

mounting hole must be 60mm. (See Figure 15)

z Install AD-425S on an in-swing door, make sure that the distance between Square

Couplings and hinge is not more than 74mm , the space between header and the bottom

of AD-425S must be 23mm, and the space between header and Sliding Rail mounting

hole must be 39mm (See Figure 16)

Figure 15 Figure 16

z All dimensions and units are in millimeters unless otherwise specified.

z Make sure AD-425S performance is effectively; no extra door closer required.

z Warning: The AD-425S installation should regard the external and internal pressure

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 10/ 20

conditions. To assure the pr oper operation and the finest performance, please make a

regular check for your operator.

Page 11

AD-425S Template Installation Instruction

Figure 17 Out-swing door (Right-Hand Open)

Figure 18 Out-swing door (Left-Hand Open)

Figure 19 In-swing door (Right-Hand Open)

Figure 20

In-swing door (Left-Hand Open)

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 11/ 20

Page 12

Installation Steps Out-swing door( Right-Hand Open )

Step Figures Explanation

Place the AD-425S template to the right position on

Step 1.

the door header. See the figure presented for an

out-swing door (Right-Hand Open), more details

shown in Figure 17.

Step 2.

Step 3.

Step 4.

Mark for pilot holes.

Mark six pilot holes, one cable hole and center line.

Drill a pilot hole.

(Use the center pointer)

Step 5.

Step 6.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 12/ 20

Drill six Ø 9.5mm pilot holes and one Ø 18mm cable

hole.

Tap and insert a Blind Nut.

Page 13

Steps Figures Explanation

Use Allen Wrench to tighten the Blind Nut. This will

Step 7.

Blind Nuts Installation illustration

compress the screw so that it remains permanently

fixed in the hole. Repeat these steps on other Blind

Nuts. (Do not over tighten the Blind Nut.)

Step 8.

Step 9.

Step 10.

Blind Nuts installation completed.

Place the sliding rail template to the right position on

the door. See the figure presented for an out-swing

door (Right-Hand Open), more details shown in Figure

17.

Mark for pilot holes.

(Use the center pointer)

Step 11.

Drill three Ø 9.5mm pilot holes.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 13/ 20

Page 14

Steps Figures Explanation

Use Allen Wrench to tighten the Blind Nut. This will

Step 12.

compress the screw so that it remains permanently

fixed in the hole. Repeat these steps on other Blind

Nuts. (Do not over tighten the Blind Nut.)

Step 13.

Step 14.

Step 15.

Blind Nuts installation completed.

Insert two mounting screws. (Screw specification: 6 X

20 mm)

This is the position of Mounting Hanger.

Step 16.

Mount the automatic door operator.

Step 17.

Tighten the other 4 screws. (Screw specification: 6 X

20 mm)

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 14/ 20

Page 15

Steps Figures Explanation

Step 18.

Step 19.

Step 20.

Tighten screws.

Insert screws (6 x 95 mm) to the Operating Arm on

Square See the figure presented for a out-swing door

(Right-Hand Open), more details shown in Figure 9.

Tighten nut at other end of screw.

Step 21.

Step 22.

Step 23.

Use the 10mm wrench to tighten nuts.

Insert pin to avoid the screws from loosing.

Slide the Operating Arm to Sliding Rail.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 15/ 20

Page 16

Steps Figures Explanation

Step 24.

Step 25.

Step 26.

Fix the Sliding Rail on the door leaf. (Screw

specification: 6 X 20 mm)

Slide in the Sliding Rail Cover.

Attach two Side Ends.

Step 27.

Step 28.

Step 29.

Depending on the door leaf opening angle, there may

need a Stopper Ball.

Optional electric lock, wireless push button, microwave

sensor, reader and other accessories ca n be used with

the AD-425S operator. See the Control Board guide

above on Page 3-5 to wire this application.

After the initial installation, please connect AC power

and turn the switch on.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 16/ 20

Page 17

Steps Figures Explanation

Step 30.

Step 31.

Step 32.

First opening movement, the AD-425S will be

automatically set the opening angle and distance.

Attach the cover.

Attach the Operating Arm cap.

Make final

settings and

adjustments

Change

battery

Please refer to page 4~6 for more details of the setting.

Battery is located on the back of Control Board.

Remove the Fixing Plug and old battery, replace the

new battery, then tighten the Fixing Plug.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 17/ 20

Page 18

Trouble shooting

Problem Possible Cause Solution

Make sure the Control Board and fuse are

working properly and connected properly.

No AC power

The door does not

respond.

Motor have no power

(LED motor light not on.)

Jumper 1-9, or PUSH Switch

setting is incorrect.

Door accidentally locked.

Safety contacts are open

Make sure all motor terminals are connected

properly.

Jumper 1-9 is N.O., or using the “GO” switch.

AD-425S becomes manual mode. When the

connector is N.C. or using the “PUSH” switch,

and then change to automatic mode.

Attach any flexible items (eg, rubber or others) to

the Door-stop for increasing damping capacity.

We recommend you to use the electromagnetic

lock.

Turn to “OPEN” Mode.

The door can

automatically open

but doesn’t close.

Check Jumper 1-2 (N. C.)

The automatic close function

does not respond.

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 18/ 20

Page 19

Problem Possible Cause Solution

Contact your local distributor to check the

The door

automatically

open but doesn’t

close.

Safety devices are on

“REDA 1”, “REDA 2” contacts

are on.

Photocell and Safety Device. (keep the device

clean)

Check the “REDA 1”, “REDA 2” contacts are

working properly. Remove the obstacles.

The door

automatically opens

and closes by itself.

The door

automatically stops

before reaching the

preset destination.

LED(Relay)

indicates in the

opposite status.

LED(Charge) not

working.

The sensor detects something

moving.

The Encoder may be

incorrect.

The AD-425S stops operating

automatically when the door

is interrupted for three times.

The input power is low . Make sure the Power input is working properly.

The direction of Operating

Arm is incorrect.

Fuse burn out.

Wires loose Check the wiring

Check the “REDA 1”, “REDA 2” contacts are

working properly. Remove the obstacles.

When the encoder is incorrect, please contact

your local distributor.

Make sure the door swing freely without any

obstruction.

Adjust the F/R. (Restart the power)

Replace fuse.(250V, 5A)

Maintenance ( every 6 months)

Turn the power off. Please ensure and switches are “OFF”

z Clean and lubricate all moving components.

z Check that all screws are well tightened.

z Check all wiring is working normally .

Turn the power on. Please ensure that switches are “ON”.

z Check the door movement stability.

z Check the condition of the hinges.

z Check all functions of the AD-425 are working normally. .

Normal Operation:

During maintenance, in case of malfunction or emergency, please ensure the power is “OFF”

and the operator is working manually . For the safety reason, we recommen d user do not install

this operator with a Fail-Secure Electric Locks (Power to open).

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 19/ 20

Page 20

General Safety Precautions

The following precautions are essential for the user.

z Read the precaution below carefully as it contains important

information about safe installation and maintenance.

z This instruction must be conducted to all potential users.

z The product must be used in visible place.

z The manufacturer will not be held responsible for any

damage caused by improper use of this unit.

z Do not use the door closer with the AD-425S.

z Do not put any obstacle in the door path when operating.

z Do not allow children to play or stay within the field of action

of the motorized door or gate. Keep remote control or any

other control devices out of the reach of children, in order to

avoid an unexpected accident happened. Do not attempt to

modify or fix this unit. Contact your local distributor when

any service is needed.

z To assure the finest performance, please follow the

operation instructions. Contact qualified personnel to make

regular maintenance checks. All installation, maintenance

and repair work must be documented and made available

to the user.

Distributor:

Copyright All Rights Reserved.

P-MU-AD425S Ver. A Publish:2008.07.11 Page: 20/ 20

Loading...

Loading...