Gianni Ferrari Turbo 1, Turbo 4, Turbo 2 User Manual

©GF Gianni Ferrari 10-2001

USER MANUAL

Turbo 1 - 2 - 4

Operator’s Manual Turbo 1 - 2 - 4

Page 1

©GF Gianni Ferrari 10-2001

INDEX

1 IDENTIFICATION DATA

2 TO OUR CUSTOMERS

3 OPERATOR’S RESPONSIBILITIES

4 SAFETY REGULATIONS

5 TECHNICAL FEATURES

6 DIMENSIONS

7 TRANSPORT

8 CONTROLS AND INSTRUMENTS

9 STARTING AND USING THE MACHINE

10 GRASS CUTTING AND PICK-UP

11 PRACTICAL SUGGESTIONS

12 INSPECTIONS AND MAINTENANCE

13 MOUNTING THE MOWER DECK

14 MOWER DECK VERTICAL SETTING

15 BLADES REPLACEMENT - SHARPENING

16 HYDRAULIC LIFT FOR FRONT ATTACHMENTS

17 HYDRAULIC COLLECTOR DUMPING

18 HYDRAULIC COLLECTOR ELEVATOR

19 ACOUSTIC LEVEL AND VIBRATIONS

20 MAIN MAINTENANCE OPERATIONS

21 SAFETY LABELS

Attached:

- Wiring diagram

- Engine operator’s manual

Operator’s Manual Turbo 1 - 2 - 4

Page 2

©GF Gianni Ferrari 10-2001

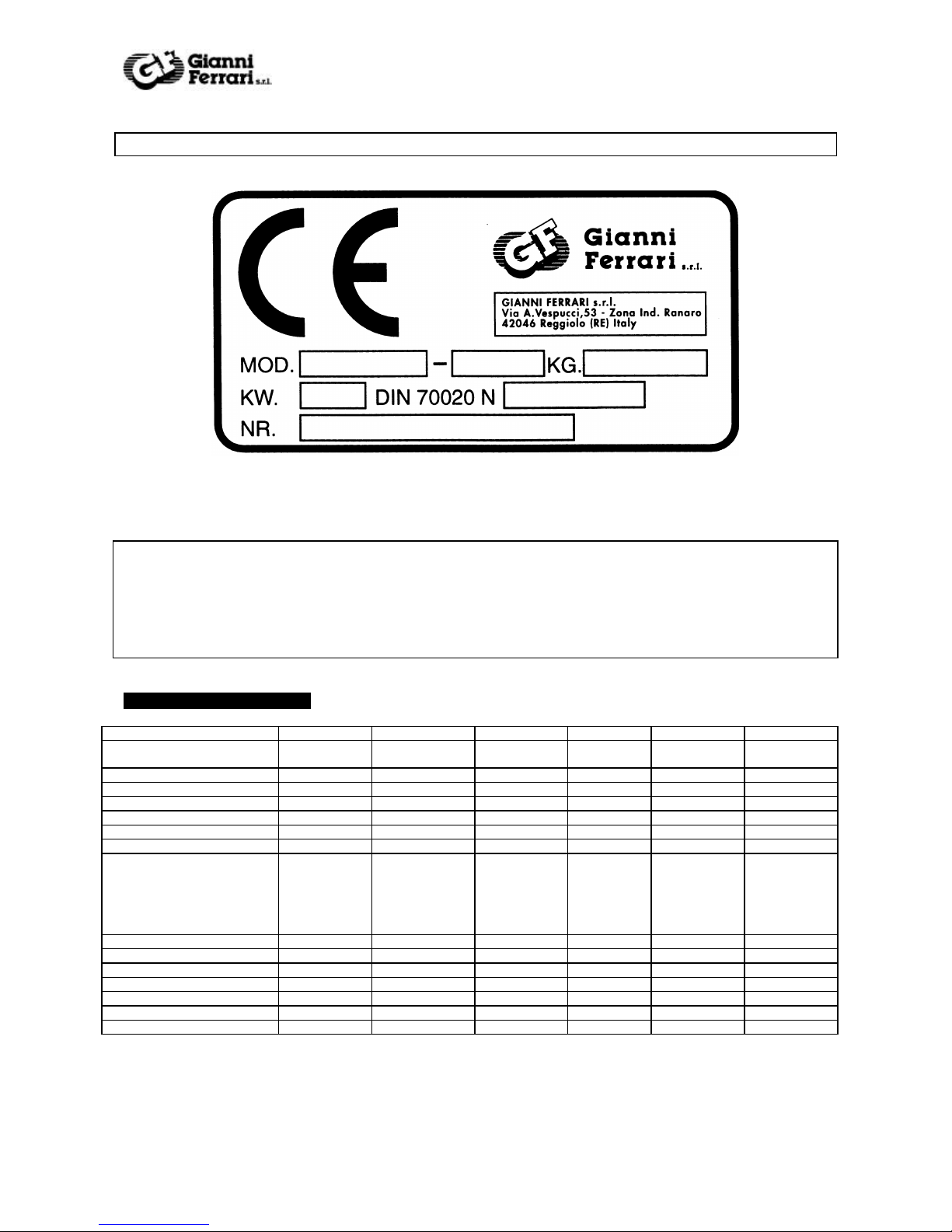

1 – IDENTIFICATION DATA

CE mark with the above data consists of an indelible label affixed on the rear right side of the body.

The serial number of the machine is stamped on the rear side of the right frame.

Please indicate this number when requesting technical assistance or ordering spare parts.

Serial number ………………………………………………..

TECHNICAL INFORMATION

MODEL Turbo 1 Turbo 1 Turbo 2 Turbo 2 Turbo 4 Turbo 4

ENGINE Lombardini Focs

1003

KUBOTA V 1105

Lombardini Focs

1404

KUBOTA V

1505

Lombardini Focs

1404

KUBOTA V

1505

DISPLACEMENT 1028 cc 1123 cc 1371 cc 1498 cc 1371 cc 1498 cc

KW 18.2 18.7 22.5 25 22.5 25

N° CYLINDER 3 3 4 4 4 4

RPM 3000 3000 3000 3000 3000 3000

TYPE 4 – DIESEL 4 – DIESEL 4 – DIESEL 4 – DIESEL 4 – DIESEL 4 – DIESEL

FUEL TANK CAPACITY 25 lt. 25 lt. 25 lt. 25 lt. 25 lt. 25 lt.

WEIGHT KG :BASE MACHINE

DECK 130 CM

DECK 150 CM

DECK 160 CM

COLLECTOR

ELEVATOR

KG. 690

130

150

160

100

110

KG. 700

130

150

160

100

110

KG. 780

130

150

160

110

115

KG. 800

130

150

160

110

115

KG. 840

130

150

160

110

115

KG. 860

130

150

160

110

115

GROUND CLEARENCE cm. 17 cm. 17 cm. 17 cm. 17 cm. 17 cm. 17

WHEEL DRIVE 2 2 2 2 4 4

FRONT WHEELS 23x10.50-12 23x10.50-12 23x10.50-12 23x10.50-12 23x10.50-12 23x10.50-12

REAR WHEELS 16x6.50-8 16x6.50-8 18x8.50-8 18x8.50-8 18x8.50-8 18x8.50-8

FORWARD SPEED 0-18 KM/H 0-18 KM/H 0-18 KM/H 0-18 KM/H

REVERSE SPEED 0-9 KM/H 0-9 KM/H 0-9 KM/H 0-9 KM/H

Operator’s Manual Turbo 1 - 2 - 4

Page 3

©GF Gianni Ferrari 10-2001

2 – TO OUR CUSTOMERS

- We are proud to welcome you amongst our customers.

- Before starting work, the operator should become thoroughly familiar with the instructions in this manual in order to

use and service the machine in the best possible way.

- The machine has been designed and built in order to offer the best service in the most varied conditions. As always,

the quality of the job will depend upon correct routine maintenance of the equipment.

- Contact the dealer for specific information and advice on matters not covered in this handbook. He will be more than

happy to offer assistance regarding use and maintenance of the machine.

Turbo 1-2-4 is a professional self-propelled mower. This machine has been designed solely for grass cutting and

care in parks and gardens, in the specifications described in this Operator’s Manual.

The operator is responsible for any damage which may occur through improper use and operation outside the

bounds of any instructions given in this manual.

3 – OPERATOR’S RESPONSIBILITIES

- The operator must carefully read this manual and become familiar with the correct way in which to operate,

lubricate and service the machine.

- The operator is responsible for inspecting the machine and must replace or repair those parts subject to continuous

wear which could if neglected cause harm to others.

- The operator is responsible for any harm to third parties, to himself or to property resulting from improper use of

the machine or by failure to comply with the instructions given in this manual.

- The machine has been designed for professional users and should only be used after an adequate training period.

Never allow children or untrained personnel to use the machine. Never carry passengers.

- The operator must not tamper with the machine, or make modifications to it or to any accessories fitted, or fit any

parts or equipment which have not been supplied by our company.

- The machine must only be used for its intended purpose of grass cutting.

- Only use spare parts or accessories which have been designed and supplied by our company for the specific model

in your possession. Please contact your retailer for further information. It is absolutely forbidden to make changes

or to modify the machine other than in the ways expressly indicated in this manual.

The user and the operator are responsible for accidents and hazards caused to other people and to their

goods.

THIS SYMBOL IS USED TO DRAW YOUR ATTENTION TO THE SAFETY PRECAUTIONS

WHICH MUST BE TAKEN BY THE OPERATOR TO AVOID ACCIDENTOR INJURY.

PAY THE UTMOST ATTENTION WHEN YOU SEE THIS SYMBOL: YOUR SAFETY AND THOSE

OF OTHERS WILL BE AT STAKE.

THE OPERATOR MUST COMPLY WITH THE SAFETY INSTRUCTIONS GIVEN IN THIS

MANUAL WHEN USING THE MACHINE.

Operator’s Manual Turbo 1 - 2 - 4

Page 4

©GF Gianni Ferrari 10-2001

4 – SAFETY REGULATIONS

THE PRUDENT OPERATOR IS THE BEST OPERATOR.

Many accidents can be prevented by compliance with the instructions given in this manual. The machine must ONLY

be used by professionally trained operators.

GENERAL INSTRUCTIONS

1) Carefully read all parts of this manual.

2) Before starting work, always inspect all parts of the machine for any malfunction, loose bolts and screws, worn

belts, blades and any other damaged or badly fixed parts. It is absolutely forbidden to use the machine unless it is in a

perfect condition. Always carry out the recommended inspections and maintenance operations before use.

3) Become familiar with all parts and controls of the machine before starting up.

4) Never carry passengers on the machine and never allow children or untrained personnel to use it.

5) Ensure that the operating area of the machine clear of persons (other than the operator). Particularly check that there

are no children, animals or obstructions nearby.

Never allow anyone to stand near the machine while it is working or manoeuvering.

6) Only use genuine parts and accessories supplied by our company and never carry out or permit any modifications or

changes to the machine. Contact your Dealer for information.

7) Ensure that the work area is clear of any object which could damage the machine or cause injury to any person, such

as glass, metal, wood etc.

8) Replace all damaged, illegible or missing safety or warning decals and ensure that they are kept clean and legible.

Check the list of decals in the relative safety section.

9) Only engage the PTO when sitting on the seat having checked for enarby persons and objects.

10) The operator must ensure that his/her hands, feet, clothing and hair are kept away from all moving parts.

11) Never use the machine without first checking that all guards and covers are serviceable and in their correct

positions.

12) If the machine hits or drags up an object, immediately stop it, put on the parking brake, switch off the engine,

remove the key, disengage the PTO, rest the machine on the ground and check all parts. Before restarting check that

conditions have been reset for optimum machine operation.

13) When the machine is not in use, disengage the PTO, lower the attachment allowing it to rest on the ground, switch

off the engine, remove the key and set the parking brake.

14) When moving to another location out of the operating area, disengage the PTO and keep the mower deck or other

attachment as indicated in the paragraph relating to the attachment itself. As for driving on roads, remember to comply

with the rules pertaining to the Country in which you are operating.

15) Never dismount from the machine whilst it is in motion or when the engine is running.

16) Never switch on the engine in a closed place or without adequate ventilation. Exhaust fumes are toxic.

17) Never allow work with flames or sparks to be carried out near the fuel tank or the battery. Leave the engine cooling

before parking the machine in closed places. If you have to empty the tank from fuel, execute this operation outdoor.

18) Never park the machine on a downward slope. If this is necessary for short periods and with the possibility of a

visual control, try to park transversally to the slope and check that the parking brake is engaged. However, follow the

limits that are specified in the next pages.

19) Always use the machine and attachments at a speed compatible with safety requirements.

20) ALWAYS TAKE GREAT CARE WHEN USING THE MACHINE ON SLOPES, ESPECIALLY WHEN

WORKING TRANSVERSALLY TO THE SLOPE.

TURBO 4: ON SLOPES USE THE TRANSMISSION SELCTOR IN «POSITION A» (PERMANENT 4

WHEEL DRIVE – SEE CONTROLS SECTION – TRANSMISSION SELECTOR), IN WHICH THE

MAXIMUM IS OBTAINED. AVOID POSITION C.

REDUCE FORWARD SPEED TO A MINIMUM AND REST THE MOWER DECK AND OTHER

ATTACHMENTS ON THE GROUND, EVEN WHEN TRANSPORTING THE MACHINE TO ANOTHER

LOCATION.

WHEN USING THE MACHINE A WARNING BUZZER WILL SOUND TO INDICATE WHEN THE

MACHINE IS REVERSING, COLLECTOR DUMPING, LIFTING AND DURING HOPPER RAISING

AND LOWERING OPERATIONS. A SAFETY DEVICE WILL PREVENT THE COLLECTOR FROM

BEING DUMPED, RAISED OR LOWERED WHILE THE PTO IS ENGAGED.

IT IS ESSENTIAL TO DISENGAGE THE PTO WHENEVER THE MOWER DECK OR OTHER

ATTACHMENT WITH SPINNING BLADES ARE RAISED.

Operator’s Manual Turbo 1 - 2 - 4

Page 5

©GF Gianni Ferrari 10-2001

THE MAXIMUM SLOPE ON WHICH THE MACHINE MAY BE USED SHALL NOT EXCEED

27% (15°).

AVOID OBSTRUCTIONS AND IRREGULAR GROUND WHICH COULD AFFECT THE STABILITY OF

THE MACHINE.

NEVER USE THE GRASSCATCHER HIGH DUMP ELEVATOR WHEN WORKING ON SLOPES.

21) Always wear suitable clothing when using and servicing the machine: goggles, gloves, shoes and other protective

garments.

22) In conclusion, pay attention to all hidden dangers not expressly mentioned in this manual in order to ensure

both your own safety and that of others.

Safety devices

The machine is equipped with the following safety devices:

The electric horn sounds:

1. when the hand brake is on and the unit is advancing

2. when the coolant temperature is too high

3. by manual operation with pushbutton

4. when the hydraulic oil temperature is too high

The buzzer sounds:

1. when the unit is going in reverse

2. during grasscatcher dumping

3. during grasscatcher lifting

The engine does not start when:

1. the hand brake is not on or when the operator is not seated on the seat

2. the PTO is engaged

3. forward and reverse pedals are not in neutral position

4. the body is open.

The engine turns off:

1. at any time when the operator stands up or takes his/her weight off the seat

2. during grasscatcher dumping or lifting when the PTO is engaged

3. if the body is open

In order to keep the engine running when the unit is stationary and in neutral the PTO must always be disengaged and:

a. either the hand brake shall be engaged,

b. or the operator is on the seat.

- Check the above described function of the electric horn and of the buzzer

- Check the non-starting of the engine in each of the 4 described conditions. It is important for safety that the

test with operator out of place and with absence of hand brake is executed on a level ground and with the

operator standing little up from the seat itself.

- Check the engine switching off in every of the 3 described conditions. It is important for safety that the test

with operator out of place is executed on a level ground and with the operator standing little up from the

seat itself.

THE MACHINE MUST BE REFUELLED IN THE OPEN OR IN A SUFFICIENTLY WELL

VENTILATED PLACE. THE ENGINE MUST BE SWITCHED OFF AND THE AREA MUST BE WELL

CLEAR OF NAKED FLAMES AND SPARKS.

ENSURE THAT DIESEL FUEL IS USED IF MACHINE IS POWERED BY A DIESEL ENGINE.

“The operator can work only if all these devices are operating. He must control their correct

operation at least once a week according to the under reported description”.

Operator’s Manual Turbo 1 - 2 - 4

Page 6

©GF Gianni Ferrari 10-2001

5 – TECHNICAL FEATURES

Hydrostatic transmission with variable displacement pump

- Front axle with piston hydraulic transmission fixed on the differential gear with final drives in oil bath; differential

lock; disc brakes

- Rear axle with piston hydraulic transmission (Turbo 4 only)fixed on the steering differential gear with cascade final

drives in oil bath

Steering and controls

- Steering wheel with hydraulic power steering;

- Forward and reverse with separate pedals;

- Service brake by means of hydraulic transmission; parking and emergency disc brake controlled by pedal.

- Turbo 4: service brake by means of hydraulic transmission; parking and emergency disc brake controlled by pedal.

- Turbo 2 and Turbo 1: service disc brake on the front wheels controlled by independent pedal.

PTO

- Manual engagement with belt tensioning system;

- Transmission with quick coupling telescopic cardan shaft;

- Automatic safety braking on shaft rotation on disengagement;

- Rotation speed: 2900 rpm.

Front attachment coupling

- 2 arms with 2 cylinder hydraulic lifting system.

Grass collection

- Central intake of cut grass by means of a turbine.

Electrical system

- 12 V 75 Amp battery.

- Electric starter, hour meter

- Safety microswitches

- Grass distributor control motor

- Warning buzzer to indicate full load, reverse motion, elevator operation and collector dumping

OPTIONS

- 1.000 litres capacity, hydraulically lifted grasscatcher (700 litres for Turbo1). Rear automatic opening during

grasscatcher dumping. Internal grass distributor, movable by electrical control. Full load warning buzzer.

- Hydraulic grasscatcher elevator discharging up to 210 cm.

- Lighting set

ACCESSORIES

- 130 or 150 cm. mower deck– Central discharge For grass collection.

Mechanical gear box in oil bath.

2 disks with 8 articulated impact-proof blades.

130 or 150 cm. cutting width.

Cutting height adjustable from 2 to 9 cm.

Dumping device for cleaning and maintenance operations.

- 130 cm. mower deck– Side discharge As above with cut grass side discharge.

-160 cm. mower deck-Rear discharge w/o pick-up As above with cut grass rear discharge, 3 disks with 12 articulated

impact-proof blades. 160cm cutting width

- 150 cm. snow blade 150 cm. working width with hydraulic positioning.

- 100 cm. aerator With bladed rotor. Working width 100 cm.

Operator’s Manual Turbo 1 - 2 - 4

Page 7

©GF Gianni Ferrari 10-2001

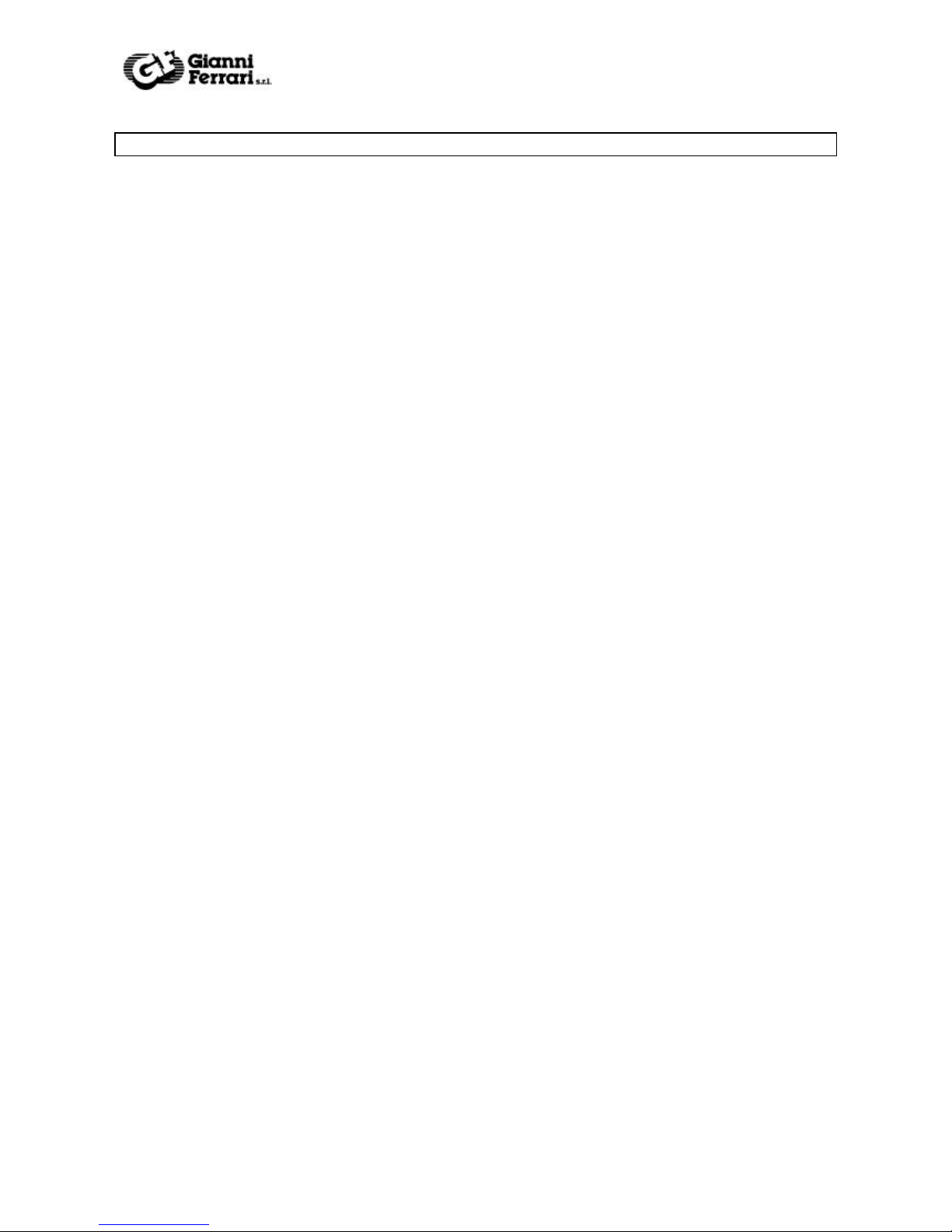

6 - DIMENSIONS

Operator’s Manual Turbo 1 -2 - 4

Page .

©GF Gianni Ferrari 10-2001

8

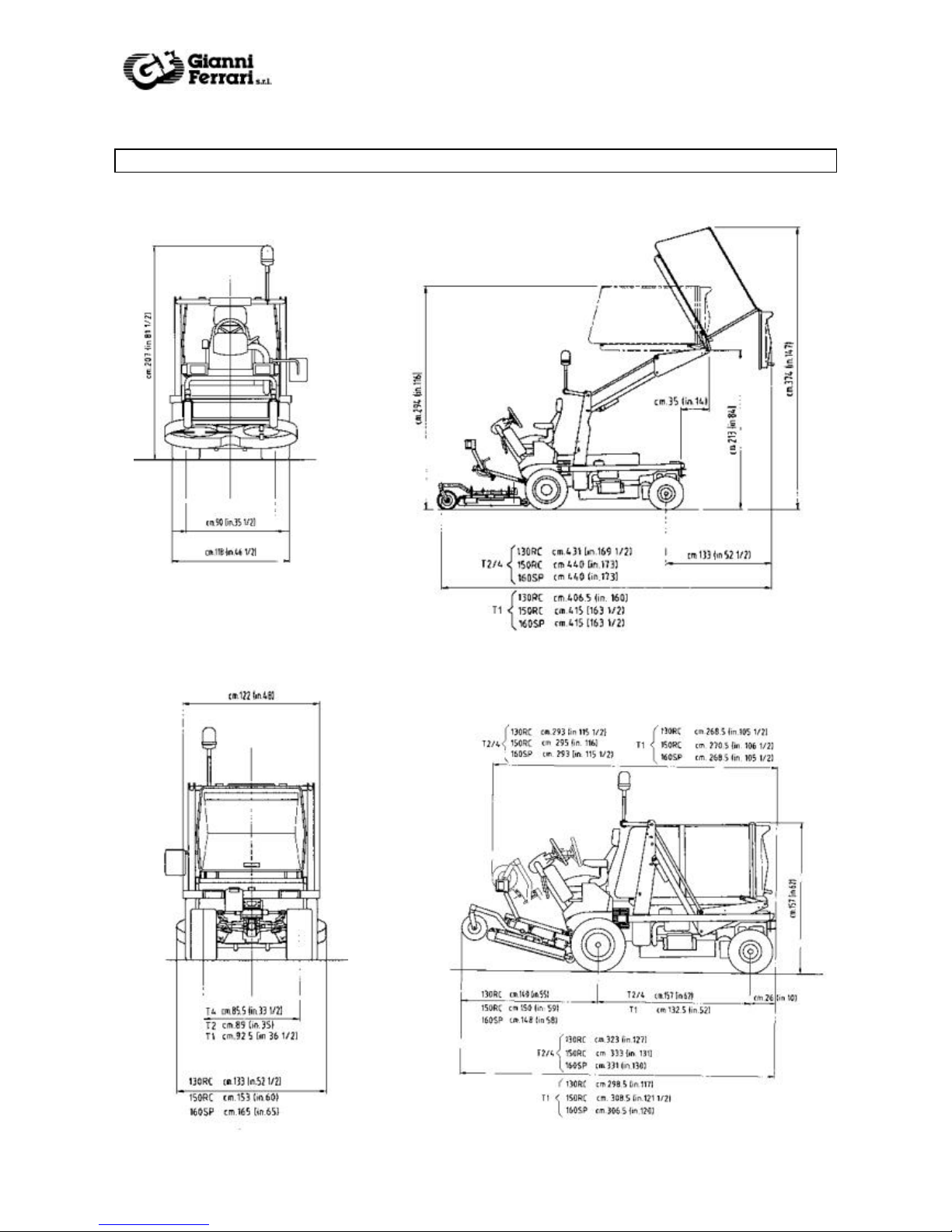

7 - TRANSPORT

The following operation must be executed with engine switched off.

Lifting must be carried out by fixing

suitable slings in three positions (2 in the

front side of the machine, see picture on the

left; 1 on the rear side, see picture on the

right).

The machine may be transported either

unpackaged or palletized and wrapped in

heat-shrunk polyethylene. It must be firmly

fixed and fastened to the transporter loading

platform.

It is also necessary to ensure that the parking brake is engaged and all wheels are chocked.

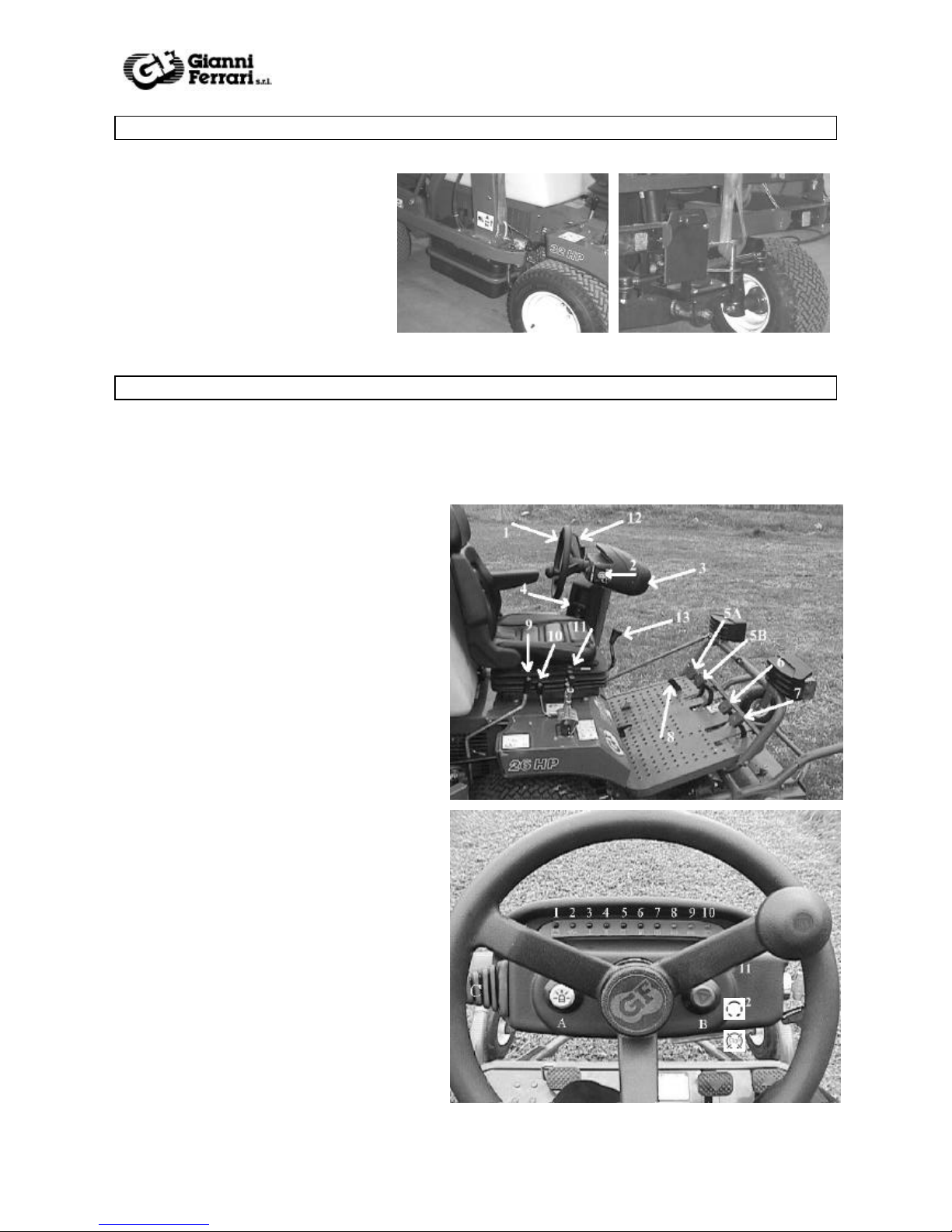

8 – CONTROLS AND INSTRUMENTS

IN EMERGENCY CONDITION:

To stop every movement turn the counter clockwise

For blades and turbine movements release the PTO lever.

To stop other movements it is enough leaving the driving control that will return to the neutral position.

As it concerns the emergency braking please see chapter 5.

1 Steering wheel

2 Starter key

3 Central control panel (see following pictures)

4 Side control panel (see following pictures)

5A Parking brake pedal

5B Brake pedal (Turbo 2 only – equipped with

lighting set)

6 Reverse pedal

7 Forward pedal

8 Differential lock

9 PTO engagement lever

10 Throttle lever

11 Hydraulic controls levers (see chapter 10).

12 Mirror (supplied only when the lighting set is

equipped)

13 Speed selection lever (Turbo2 only)

Central control panel

1 Battery alternator

2 Oil pressure

3 Coolant max temperature

4 Oil filter clogging

5 Glow plugs preheating

6 Fuel stock

7

8 Direction indicator

9 Side light (*)

10 Lower beams (*)

11 Start

12 Stop

Loading...

Loading...