Valid from firmware-version 7.02

As of 2017-02-06

ProfiLux 4

Programming Guide

ProfiLux 4 Programming Guide

Table of Contents

PREFACE .................................................................................................................................................................... 6

GET THE MOST OUT OF YOUR GHL PRODUCT .......................................................................................................................... 6

ABOUT THIS PROGRAMMING GUIDE ....................................................................................................................................... 6

SAFETY INSTRUCTIONS ......................................................................................................................................................... 7

INTENDED USE ................................................................................................................................................................... 7

1 FUNCTIONALITY AND OPERATING CONCEPT ..................................................................................................... 7

1.1 FUNCTIONALITY OF THE P4 ....................................................................................................................................... 7

1.2 OPERATING CONCEPT ........................................................................................................................................... 10

1.3 EXAMPLES OF SETTINGS ......................................................................................................................................... 10

1.3.1 How to setup Temperature control ......................................................................................................... 10

1.3.2 How to set the Illumination? ................................................................................................................... 10

1.3.3 How to set the Level control? .................................................................................................................. 11

1.3.4 How to set the Current pump control? .................................................................................................... 11

1.3.5 How to set Dosing or Timer activities? .................................................................................................... 11

1.4 FEATURES / RESOURCES ........................................................................................................................................ 11

1.5 NUMBERING AND DISPLAY OF RESOURCES ................................................................................................................ 11

2 CLOCK .............................................................................................................................................................. 12

2.1 TIME & DATE, DCF .............................................................................................................................................. 12

2.2 REMINDERS ......................................................................................................................................................... 13

2.3 TIMERS .............................................................................................................................................................. 14

2.4 DOSING PUMP ..................................................................................................................................................... 17

2.5 LOCATION ........................................................................................................................................................... 19

3 ILLUMINATION ................................................................................................................................................ 19

3.1 ILLUMINATION RUN .............................................................................................................................................. 20

3.2 COPY AN ILLUMINATION RUN USING GCC ................................................................................................................. 21

3.3 TIME SHIFT WITH GGC .......................................................................................................................................... 21

3.3.1 Time shift during clouds .......................................................................................................................... 21

3.3.2 Time shift for Illumination Run ................................................................................................................ 22

3.4 MANUAL ILLUMINATION ........................................................................................................................................ 23

3.5 CLOUDS .............................................................................................................................................................. 24

3.6 MOON ............................................................................................................................................................... 24

3.7 RAINY DAYS ........................................................................................................................................................ 25

3.8 BURNING-IN ........................................................................................................................................................ 25

3.9 OPERATING HOURS ............................................................................................................................................... 26

3.10 THUNDERSTORMS ................................................................................................................................................ 26

3.11 TEMPERATURE-DEPENDENT LIGHT REDUCTION ........................................................................................................... 27

3.12 VARIABLE ILLUMINATION ....................................................................................................................................... 29

3.13 MITRAS LIGHTBAR ................................................................................................................................................ 29

3.14 LIGHT DEMO ........................................................................................................................................................ 29

3.15 TIME LAPSE ......................................................................................................................................................... 30

3.16 ACCLIMATION ...................................................................................................................................................... 30

3.17 SHIFT CURVES ...................................................................................................................................................... 31

4 EXTRAS ............................................................................................................................................................ 31

4.1 MAINTENANCE .................................................................................................................................................... 31

4.2 FEEDING PAUSE ................................................................................................................................................... 33

4.3 INTERNAL TIME .................................................................................................................................................... 34

4.4 INFO & SUPPORT ................................................................................................................................................. 34

4.5 CURRENT ............................................................................................................................................................ 34

EN 2017-02-06 2

ProfiLux 4 Programming Guide

4.5.1 Nocturnal Change .................................................................................................................................... 35

4.5.2 Group Settings ......................................................................................................................................... 35

4.5.3 Pump Settings .......................................................................................................................................... 39

4.6 EHEIM ................................................................................................................................................................ 39

4.7 DISPLAY .............................................................................................................................................................. 40

4.8 MEASUREMENT DATA ........................................................................................................................................... 40

4.9 LANGUAGE .......................................................................................................................................................... 42

5 SENSOR SETTINGS ........................................................................................................................................... 42

5.1 ACTIVITY ............................................................................................................................................................. 43

5.2 NOMINAL VALUE.................................................................................................................................................. 43

5.3 OPERATION HOURS .............................................................................................................................................. 45

5.4 HYSTERESIS ......................................................................................................................................................... 45

5.5 ALARM ............................................................................................................................................................... 46

5.6 NOCTURNAL CHANGE............................................................................................................................................ 48

5.7 SUMMER SWITCHING ............................................................................................................................................ 49

5.8 THERAPY ............................................................................................................................................................ 50

5.9 CALIBRATION ....................................................................................................................................................... 50

5.9.1 General .................................................................................................................................................... 51

5.9.2 Calibration Tolerance .............................................................................................................................. 51

5.9.3 Overview of the Calibration values .......................................................................................................... 52

5.9.4 Temperature Sensor (Analog).................................................................................................................. 52

5.9.5 pH Sensor ................................................................................................................................................. 53

5.9.6 Redox-Sensor ........................................................................................................................................... 53

5.9.7 Conductivity ............................................................................................................................................. 54

5.9.8 Oxygen Sensor ......................................................................................................................................... 55

5.9.9 Control of Sensor calibration ................................................................................................................... 56

5.10 DISPLAY .............................................................................................................................................................. 57

5.11 COOLING DIFFERENCE ........................................................................................................................................... 58

5.12 EXTENSION.......................................................................................................................................................... 58

5.13 MEASUREMENT RANGE ......................................................................................................................................... 59

5.14 DENSITY OFFSET .................................................................................................................................................. 59

5.15 1-10 V MAX. AT… ................................................................................................................................................ 59

5.16 CURRENT ACTUAL VALUE ....................................................................................................................................... 60

5.17 OPERATION MODE CONTROLLER ............................................................................................................................. 60

5.18 SIGNAL FILTER ..................................................................................................................................................... 61

6 LEVEL ............................................................................................................................................................... 61

6.1 CONTROL ............................................................................................................................................................ 63

6.1.1 Operation Mode ...................................................................................................................................... 63

6.1.2 Maximum on-time ................................................................................................................................... 64

6.1.3 Automatic Error reset .............................................................................................................................. 65

6.1.4 Sensor select ............................................................................................................................................ 65

6.2 INPUT ................................................................................................................................................................ 65

6.2.1 Reaction Time .......................................................................................................................................... 65

6.2.2 Input Inverse ............................................................................................................................................ 65

6.3 ERROR RESET ...................................................................................................................................................... 66

6.4 DIAGNOSTIC ........................................................................................................................................................ 66

6.5 START WATER CHANGE ......................................................................................................................................... 66

7 FLOW ............................................................................................................................................................... 66

7.1 ALARM THRESHOLD .............................................................................................................................................. 67

7.2 CALIBRATION ....................................................................................................................................................... 67

7.3 NOMINAL VALUE.................................................................................................................................................. 67

7.4 CONNECTED AT LEVEL-SENSOR ................................................................................................................................ 67

EN 2017-02-06 3

ProfiLux 4 Programming Guide

8 SYSTEM ........................................................................................................................................................... 68

8.1 FACTORY SETTINGS ............................................................................................................................................... 68

8.2 PIN ................................................................................................................................................................... 68

8.3 SOCKET OUTLET FUNCTION .................................................................................................................................... 68

8.4 1-10 V INTERFACE ............................................................................................................................................... 71

8.5 PROGRAM LED .................................................................................................................................................... 73

8.6 COMMUNICATION ................................................................................................................................................ 74

8.7 ALARM ............................................................................................................................................................... 74

8.8 VIRTUAL PROBES .................................................................................................................................................. 75

8.9 DIGITAL POWERBARS ............................................................................................................................................ 76

8.10 CONFIGURE PTC .................................................................................................................................................. 78

8.11 DALI ................................................................................................................................................................. 78

8.12 DIGITAL INPUT ..................................................................................................................................................... 79

8.13 MYGHL .............................................................................................................................................................. 79

9 PROGRAMMABLE LOGIC .................................................................................................................................. 80

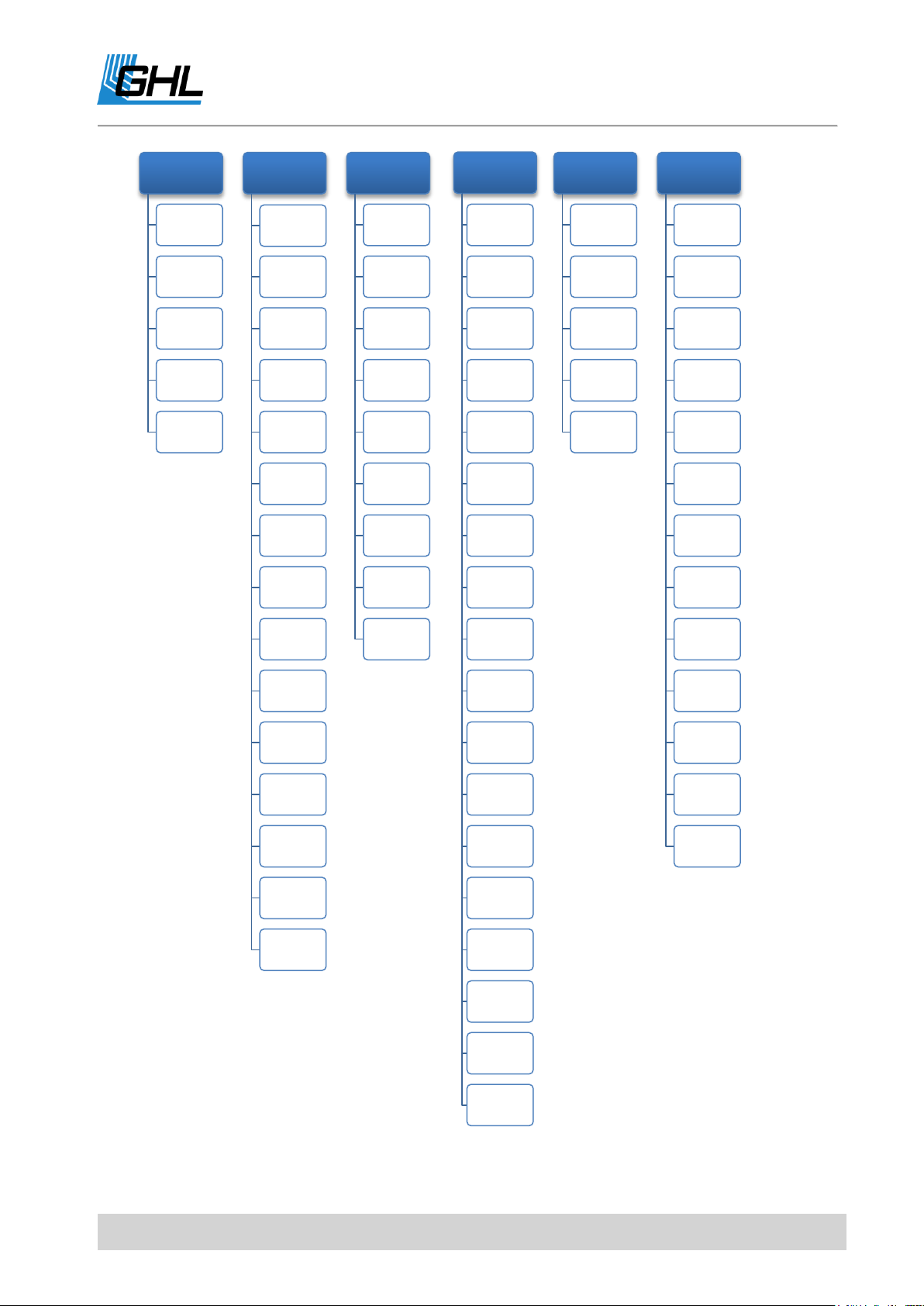

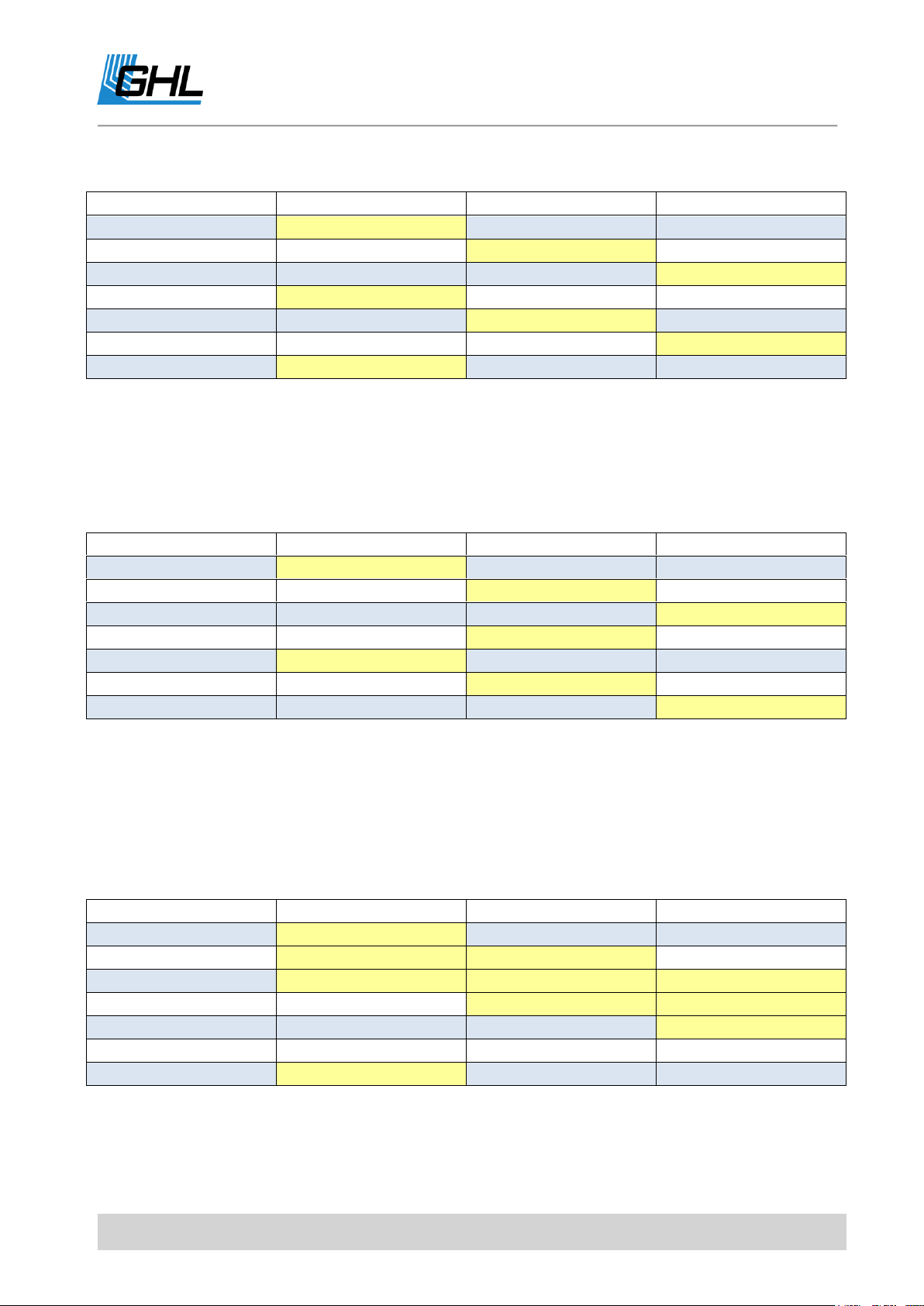

Below is the menu structure of the ProfiLux 4. These are the options available to you when

you operate the P4 through the device’s Control Pad. (This structure is also similar to the

layout seen in the PC-Software, GHL Control Center (GCC).

EN 2017-02-06 4

ProfiLux 4 Programming Guide

Clock

TIme & Date,

DCF

Reminders

Timers

Dosing

pump

Location

Illumination

Illumination

run

Manual

illumination

Clouds

Moon

Rainy days

Burning-in

Operating

hous

Storms

Temperature

-dependent

lightreductio

n

Variable

Illumination

Mitras

Lightbar

Lightdemo

Time lapse

Acclimation

Shift curves

Extras

Maintenance

Feeding

pause

Internal time

Info &

Support

Current

Eheim

Display

Measuremen

t data

Language

Sensor

settings

Activity

Nominal

value

Operation

hours

Hysteresis

Alarm

Nocturnal

change

Summer

switching

Therapy

Calibration

Display

Cooling

difference

Extension

Measuremen

t range

1-10 V maxi.

at

Density

offset

Current

actual value

Operation

mode control

Signalfilter

Level

Control

Input

Diagnostic

Start water

change

Error reset

System

Factory

settings

PIN

Socket outlet

function

1-10 V

interface

Program LED

Communikati

on

Alarm

Virtual

probes

Digital

powerbars

Configure

PTC

DALI

Digital inputs

myGHL

EN 2017-02-06 5

ProfiLux 4 Programming Guide

TIP

General note, tip or advice.

Preface

This manual is a supplement to the ProfiLux® 4 Instruction manual. This Programming

Guide is based on these operating instructions and cannot replace them in any

circumstances.

Get the Most out of your GHL Product

GHL products are well-equipped with simple and intuitive features. In order to get the most

out of our products, we recommend you read our Programming Guide and Instruction

Manual together. Doing so will provide you with the most profound details for using our

product. These documents can be downloaded from our website’s download area (Support-

>Downloads). Visit our homepage at www.aquariumcomputer.com , our Support forum or

visit us on Facebook to become a GHL-Product expert and fully utilize the full range of

functions offered from your device!

About this Programming Guide

The information provided by this guide is primarily based on setup and configuration via the

ProfiLux 4 display. When you configure the ProfiLux 4 via GHL Control Center, setup will slightly

differ from the descriptions shown in this guide. Individual settings are however, identically

displayed on the device and GHL Control Center.

Please read these instructions carefully before operating the ProfiLux 4.

GHL products are built with maximum security and safety in mind. However, product safety

for this device can only be guaranteed if you follow these guidelines.

Anyone who uses this device must become familiar with the following safety instructions and

the operation of the device.

Failure to follow these instructions will void any warranty claims.

In this manual, the following symbols are used:

EN 2017-02-06 6

ProfiLux 4 Programming Guide

WARNING

Important note for operation, to avoid damage to the equipment, and for

your safety.

WARNING

This equipment must not be used:

By small children and vulnerable persons with limited physical,

sensory or mental capabilities.

By people who are unfamiliar with the functions of this product.

DANGER

Warning that non-compliance can result in injury or damage to the device.

Safety Instructions

Intended Use

The ProfiLux 4 is exclusively for use in the domestic area. Only GHL accessories may be

connected directly to the ProfiLux 4 controller.

Make sure to keep the device away from splashing water, moisture or other liquids.

This controller is for monitoring and controlling aquarium functions and is exclusively for

indoor usage. ProfiLux 4 must be kept dry at all times.

For your own safety, please read the hazard prevention and safety instructions in the

chapters that follow. These precautionary tips are also found in the ProfiLux 4 Instruction

Manual.

1 Functionality and Operating Concept

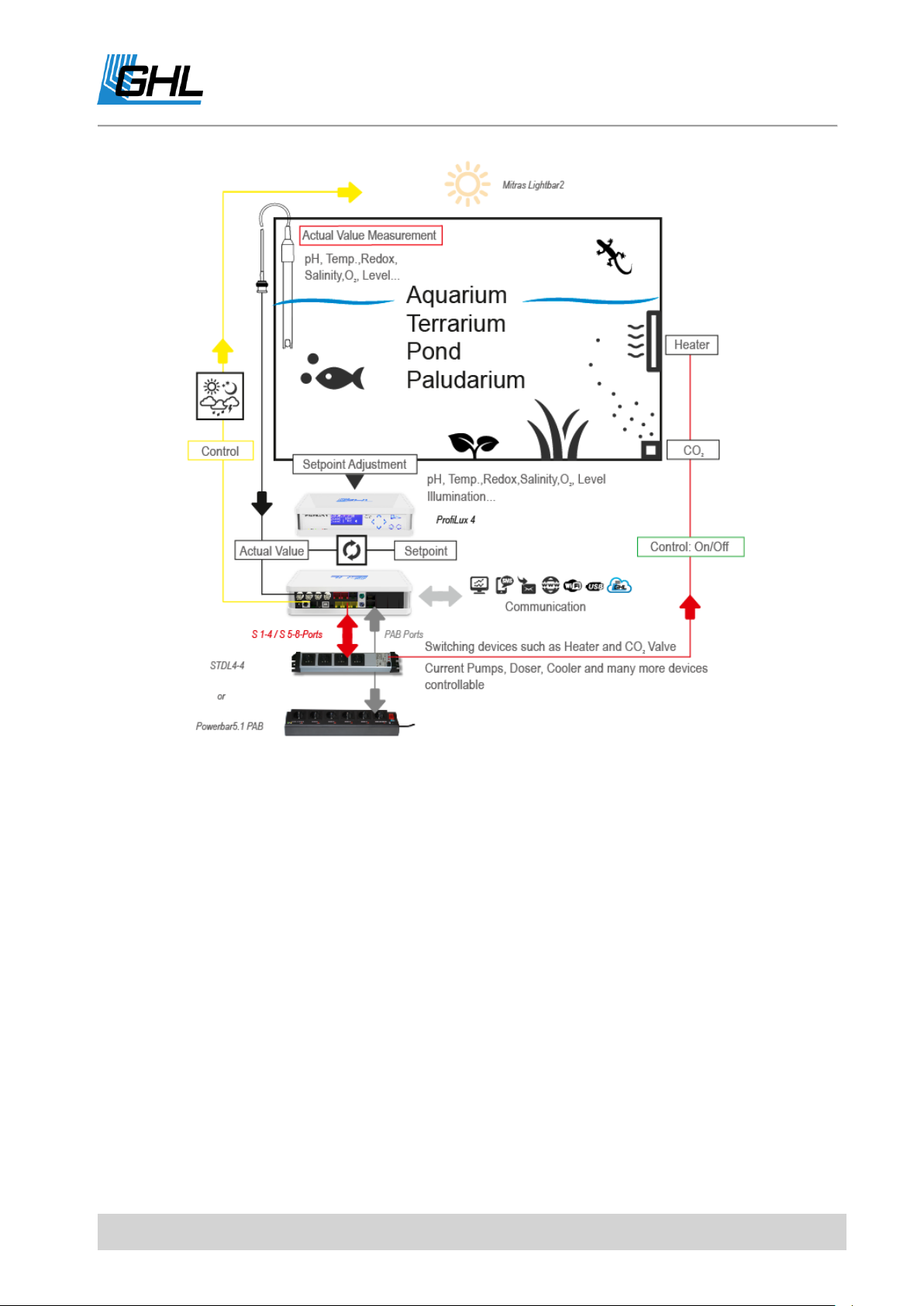

1.1 Functionality of the P4

The following graphic gives you a rough overview of the functionality of the ProfiLux 4

Aquarium Controller. It also shows the interaction of the different system components.

EN 2017-02-06 7

ProfiLux 4 Programming Guide

DANGER

Please note the following:

The ProfiLux 4 Controller and its components (ProfiLux 4 System)

perform measurement, control, and control tasks based on your

settings.

There is no plausibility check of the settings you have made.

The controller's factory settings must be adapted to the

requirements of your aquarium.

You are solely responsible for the plausibility of your computer

settings and its system components.

The ProfiLux 4 Controller cannot replace the lack of expertise

required for the maintenance and maintenance of an aquarium or

terrarium.

Never leave your aquarium unsupervised for an extended amount of

time.

The ProfiLux System can help you with a large number of tasks and

display error conditions - but it cannot replace regular personal

supervision and control.

The maximum period of time without personal supervision depends

on how long your aquarium / terrarium can survive even in the event

of a fault without significant damage.

Always remember that technologies can fail and therefore,

malfunctions can never be ruled out!

Power failures, incorrect settings, damage (For example, by water or

overvoltage) or simply an unexpected operating situation can lead to

fatal damage.

The manufacturer disclaims any liability for (consequential) damages

or losses which might arise in connection with the use of the ProfiLux

System as legally permissible.

EN 2017-02-06 8

ProfiLux 4 Programming Guide

The diagram shows an example of the functionality of the ProfiLux System.

Sensors that are used for measuring various values such as Temperature, humidity, etc., are

connected to either the ProfiLux 4 or to corresponding ProfiLux Expansion Cards. Each of these

sensors are assigned to a control circuit where parameters such as Set-point, hysteresis,

nocturnal change, etc., can be set.

With the desired values and settings set, each sensor can then be assigned to control a

powerbar socket. For example, assigning a temperature sensor to a powerbar socket will

result in that socket switching on/off based on the set probe conditions.

EN 2017-02-06 9

ProfiLux 4 Programming Guide

TIP

When creating a command, it is useful to set the function first.

1.2 Operating Concept

The operating concept of the ProfiLux computer strictly differs between two sets of settings:

Settings of functions such as e.g. pH set point, illumination run of a luminaire or

behavior of pumps

Settings of hardware such as the behavior of a switch socket (if this switching socket is

assigned to a lighting, a timer or a temperature sensor) or the behavior of a 1-10 V

interface (this interface should be assigned to a lighting or a pump)

This concept is extremely flexible because a function can be changed largely independently

of the hardware assigned to it and vice versa the hardware can be changed largely

independently of the function.

This concept allows you, e.g. to select a different socket for switching your tubular heater,

while the corresponding temperature settings can remain unchanged.

1.3 Examples of Settings

For a better understanding, take a look at some setting examples that are commonly used.

1.3.1 How to setup Temperature control

1. Setting the function: Set the desired set-point temperature, see also Sensor Settings->

Nominal value.

2. Setting the hardware: Set the switch socket outlet (socket) to switch the heating

element, the substrate heater and the cooling system (if present). See also System->

Socket outlet function.

1.3.2 How to set the Illumination?

1. Setting the function: Set the illumination run as needed, see also Sensor Settings->

Nominal value.

2. Setting the hardware: Set which switch socket outlet (for non-dimmable luminaires),

also see under System-> Socket outlet function, or which 1 - 10 V interface (for

dimmable luminaires), also see under System-> 1- 10 V interface, or whether the Mitras

Lightbar interface (when controlling a Mitras Lightbar) shall respond to this

illumination run.

EN 2017-02-06 10

ProfiLux 4 Programming Guide

1.3.3 How to set the Level control?

1. Setting the function: Set the operating mode and the behavior of the level sensor, also

see under Level-> Control.

2. Setting the hardware: Set which switch socket outlet (socket) is to be switched from

the level control, see also under System-> Socket outlet function.

1.3.4 How to set the Current pump control?

1. Setting the function: Set the pump groups and the current pumps, see also under

Extras-> Current.

2. Setting the hardware: Set which switch socket outlet (for non-speed-variable pumps),

see also System-> Socket outlet function, or which 1-10 V interface (for speed-variable

pumps), and see also under System -> 1-10 V Interface should react to the Pump.

1.3.5 How to set Dosing or Timer activities?

1. Setting the function: First set the desired timer or dosing pump (note: only GHL Dosing

Pump Unit 1st generation, GHL Doser 2 is controlled via PAB!), see also under Clock->

Timers or under Clock-> Dosing pump.

2. Setting the hardware: Set which switch socket outlet (socket) is to be controlled by this

timer or dosing pump, see also under System-> Socket outlet function.

1.4 Features / Resources

The functional range of your ProfiLux 4 and, if applicable, your ProfiLux System is determined

by the available Expansion Cards, sensors, PAB devices and LED lights.

The total of all available inputs and outputs in the ProfiLux system is referred to as

resources.

1.5 Numbering and Display of Resources

All resources of the system are serially numbered by the ProfiLux Controller and this is always

carried out the same way.

The resources of the ProfiLux are numbered firstly, followed by the respective PAB devices in

order of their assignment such as Power Bars, Expansion Boxes, etc.

The numbering always starts with the internal resources of the ProfiLux, followed by the

resources of the module cards in the expansion slots according to their order in the slots of

the ProfiLux.

Then the resources of the first found and assigned PAB device will follow, after that the

resources of the second PAB device, etc.

EN 2017-02-06 11

ProfiLux 4 Programming Guide

2 Clock

Use the clock feature to make changes to all time-related settings. ProfiLux 4 uses the

astronomical hour count which divides the day into 24 h.

Two clocks are running the ProfiLux 4.

The first clock is a so-called real-time clock (RTC). It shows the actual ("our") time. This is also

the time normally seen on the display. In the event of a power failure, this clock runs on a

battery-backup.

The second clock runs in the device (internal). This internal clock controls the automatic

processes such as dimming, nocturnal decrease, timers, etc.

By default, both clocks run in sync with each other, except when the actual time (e.g.,

automatic or manual winter time / summer time) is adjusted. Then the internal clock is not

adjusted immediately, but within the set days. For example, a setting of 10 days results in

60:10 = 6 minutes daily.

2.1 Time & Date, DCF

First you will be asked if you want to use DCF (external radio clock receiver, available as an

accessory).

If you confirm with Yes, the time received by the radio receiver is used. If the reception is

sufficient, the setting of the date and time is superfluous, they are updated automatically.

If you are not using DCF, you can now optimize the clock accuracy by entering a correction per

day (from -59 s to 59 s). At 0 s (default setting) the clock runs without correction, otherwise

the adjusted second number is added (or subtracted) once per day.

Then you have the option to determine whether the ProfiLux clock should change between

the normal time (CET) and the summer time (CEST).

If this shall not be the case, then in your aquarium only the normal time will be valid (i.e. in

summer the clock will go wrong by one hour). This makes possibly sense if you would like to

avoid the clock change for your fishes and plants.

If you want a changeover, you can still adjust how many days the changeover is to be made.

If you use DCF, this smooth time adaptation starts beginning from the time of the CET-CEST-

change. If you don’t use DCF, then the time can be changed manually by one hour.

EN 2017-02-06 12

ProfiLux 4 Programming Guide

Note

The DCF signal for the radio clock is not always present.

Therefore it could happen that sometimes no reception is possible.

The internal clock continues to run and is synchronized again at the next

reception (possible minor deviations are corrected). Therefore DCF can also

be used with only occasional reception.

In this case also, the internal clock will be adjusted slowly within the set days. With this, you

are given the opportunity to spread this one hour over several days and you will have a

smooth time change.

After this you can then set the date and time manually.

When you save the time settings, you will be asked if you want to update the internal time

(see above).

If you confirm with Yes, the internal time is immediately set to the new time, otherwise the

internal time will be adjusted smoothly as explained above.

For initial time setting you should confirm with Yes. If you want to change clock due to

summer time, confirm with No.

2.2 Reminders

ProfiLux 4 can remind you of activities to be performed.

After a certain adjustable time (in days), the reminder text is displayed on the ProfiLux 4,

alternating with the standard display.

The reminder is displayed until you mark it as done. If you have set a repeated reminder, the

reminder will be displayed again after the new expiration time.

For example, a reminder can be set to be displayed every month to indicate a filter must be

replaced.

A single and repeating reminder can be set to display the desired text when requested.

After setting the reminder(s), ProfiLux 4 will display as a confirmation when the next reminder

will come about.

You can enter up to 16 reminder texts.

EN 2017-02-06 13

ProfiLux 4 Programming Guide

NOTE

You can use a timer for dosing purposes, but for more sophisticated

functions, we recommend using the dosing pump control, see

Clock ->Dosing pump.

Select the reminder (1 - 16) first.

Select whether the reminder should be enabled -> RETURN

If this reminder is currently up-to-date, you can mark it as done, it will not be

displayed any further.

If you have activated this reminder with Yes, you can set whether you want to be

reminded repeatedly.

You can then enter how many days you want to be reminded.

Then enter the reminder text.

Press the top arrow button on the control panel. The letter A appears. Press again to

display the letter B, press again to display C, and so on. The letters appear according

to their order in the alphabet. If you want to go back a letter (for example from C to B),

press the lower arrow key.

Press the left and right arrow keys to move the cursor to the right and left, and enter

additional characters or spaces.

When the text is finished, press RETURN and press YES. Safe with -> RETURN

After saving, ProfiLux 4 shows a confirmation when the next reminder is pending.

2.3 Timers

ProfiLux 4 has 32 freely programmable timers whose function you can adjust as described

below. The switch socket outlets (hardware), which are to react to the switching operations,

can be assigned as described under System-> Socket outlet function.

After selecting the timer that you want to program, the switching mode (function) needs to

be set. The following options can be selected:

Normal

This mode is used to program longer switching times (accuracy 1 minute).

The switching time (Duration) is set by entering the switch-on time and the switch-off time.

Short time

EN 2017-02-06 14

ProfiLux 4 Programming Guide

Min. wait time

Max. wait time

Result

Switch on 1

10s

20s

After 10 to 20 seconds is switched on

Switch off 1

60s

60s

After 60 seconds is switched off

Switch on 2

300s

1000s

After 300 to 1000 seconds is switched on

With this setting, short switching times (1s to 300s, accuracy 1s) can be realized. The

switching time is set by entering the switch-on time and duration.

Automatic dosing

As many Dosings per day will take place as it has been set before under Switching cycles per

day. The time points of the dosings are calculated automatically (they are spread evenly

throughout the day). The switching duration is calculated automatically on the basis of the

Flow rate of the pump and the Rate per dosing (see below).

Manual dosing

As many Dosings per day will take place as it has been set before under Switching cycles per

day. The time points of the dosings can be defined explicitly afterwards. The switching

duration is calculated automatically on the basis of the Flow rate of the pump and the Rate per

dosing (see below).

Event start

The timer initiates an operation such as e.g. A water change, see also under ->Level. Enter the

start time only.

Cyclic

This mode allows very special switching sequences. Please note that this mode can only be

selected and set via our PC program GCC (GHL Control Center)!

In this mode, the timer is switched on and off alternately, always after a certain waiting time

has elapsed.

The wait time after which is switched on is determined by random generator within the limits

of the minimum waiting time and maximum waiting time. If the waiting time should always be

the same, enter the same value for both times. The waiting time after which is switched off is

also determined by a minimum waiting time and a maximum waiting time.

One cycle consists of 1 to 4 pairs of switch-on and switch-off waiting times. After the last

switch-off of the cycle, the cycle starts from the beginning. All waiting times are adjustable in

the range from 1 s to 65535 s.

Example for a cycle with 2 switch-ons and switch-offs:

EN 2017-02-06 15

ProfiLux 4 Programming Guide

Switch off 2

1s

30s

After 1 to 30 seconds is switched off

Cycle starts from the beginning

Instructions for Dosing

The dosing amount per day corresponds to the Dosings/day and Rate/Dose.

For example, 4 doses per day with 10ml per dose will result in 40ml being

dosed per day.

Alternatively, you can also use a timer or a controller (e.g. pH-value or

conductivity) to control a dosing pump.

Due to tolerances, a pump’s flow rate on the data sheet can deviate from

the reality. To achieve the highest possible level of dosing accuracy, we

recommend you measure the actual flow rate of a pump (let pump run for 1

minute and measure the quantity of fluid pumped in this time) and set the

result of this measurement in Flow rate.

After that, you can enter the number of Switching cycles per day (0 up to 8; 0 means that this

timer is not active)

After setting the switching cycles, enter the Day mode:

Days of week

Here you can set the weekdays to be switched. A marked box means "Switching active on this

weekday", an empty box means "inactive ".

Interval of days

Here, the number of days after which the switching cycle is to be repeated is set, 1 day

means a daily switching cycle. After that you can set in how many days the switching shall be

started.

If you have selected a dosing switching mode, you must also enter the flow rate in ml /

minute.

Here, the actual pump power is needed. Based on this information, ProfiLux 4 calculates the

switch-on times of the dosing pump.

Changing this setting does not affect the pump performance - this is predefined by the pump

mechanism!

For an automatic dosing, you must also adjust the Rate per dosing.

A timer can activate a feeding pause, see at Extras-> Feeding pause.

EN 2017-02-06 16

ProfiLux 4 Programming Guide

2.4 Dosing Pump

ProfiLux 4 has 16 freely programmable dosing pump controllers, whose function you can

adjust as described below. The switching outputs (hardware) which shall react to the

switching processes can be assigned as described under System-> Socket outlet function.

Select the dosing pump you want to program and then set the Switching mode. Choose from

the following options:

1. Automatic dosing: This mode is suitable if you want to dose a certain amount of the

same quantity evenly over a certain time. A maximum of 150 doses per day are

possible

2. Manual dosing: This mode is suitable if you want to dose a certain amount at fixed

times during the day. For example, at 8:00 o'clock, dose 35 ml of XY. A maximum of 8

doses per day are possible.

Furthermore, you can determine whether you want to dose on specific weekdays or daily

intervals.

Day modes:

Days of week

Here, you can set the weekdays at which the switching should be carried out. Use the right

arrow key to select the checkboxes, to move on downwards press arrow down. A marked box

means "Switching on this day of week active", an empty box means "inactive". Confirm the

selection with ->RETURN.

Interval of days

Here, you can set the number of days by which the switching cycle/number of dosages are to

be repeated. 1 day means daily dosage. The maximum daily interval is 200 days. Be sure to

set the number of days until the switching/dosing shall start.

After that, enter the Flowrate of the Pump in ml/minute. Based on this information, ProfiLux 4

calculates the switch-on times of the dosing pump.

Changing this setting does not affect the pump performance - this is predefined by the pump

mechanism!

Automatic dosing

Set the number of doses per day. Use the arrow keys on the control panel to move the

cursor to the right or left. Enter numbers using the upper arrow key (counts up). Use

EN 2017-02-06 17

ProfiLux 4 Programming Guide

the lower arrow key to count back. Once you have entered the desired number,

confirm with ->RETURN. Up to 150 dosages are possible, 0 = No dosage.

Decide on which weekdays the dosages should take place or select the daily interval if

a dosing is to take place every day or every 2 days ... etc.

Enter the Flow rate of the dosing pump ->RETURN

Enter the dosing amount Rate per dosing ->RETURN

The dosing time points are calculated automatically (they are distributed evenly throughout

the day). The duration of the dosage is calculated automatically by means of the Flow rate of

the pump and the Rate per dosing (See below).

Manual dosing

Set the number of doses per day. A maximum of 8 dosings per day are possible -

>RETURN

Decide on which Days of week the dosages should take place or select the Interval of

days if a dosing is to take place every day or every 2 days ... etc. The maximum daily

interval is 200 days (see below).

Enter the flow rate of the dosing pump ->RETURN

Specify the time at which the first switching / dosing should take place

Enter the dosing amount Rate per dosing ->RETURN

Proceed with the further desired switching operations as with switching operation 1

There are as many switching cycles per day as was set at dosages per day before. The time

points of the dosage can be defined explicitly in the following. The switching time is

calculated automatically by means of the Flow rate of the pump and the Rate per dosing. (see

below).

If you have selected Automatic dosing, the first dosing of the day is usually made at 0:00. With

Always dose at (this time) you have the possibility to determine the time of the first dosing. All

other doses are distributed throughout the day

The following features are only available via GHL Control Center, Web Interface, App and cloud

service myGHL:

The dosing pump control has a level monitoring. When the pump is active ProfiLux 4

calculates the new filling level.

For this purpose, the Capacity of the container as well as the minimum amount must be

entered.

EN 2017-02-06 18

ProfiLux 4 Programming Guide

Instructions for Dosing

The dosing amount per day corresponds to the Dosings/day and Rate/Dose.

For example, 4 doses per day with 10ml per dose will result in 40ml being

dosed per day.

Alternatively, you can also use a timer or a controller (e.g. pH-value or

conductivity) to control a dosing pump.

Due to tolerances, a pump’s flow rate on the data sheet can deviate from

the reality. To achieve the highest possible level of dosing accuracy, we

recommend you measure the actual flow rate of a pump (let pump run for 1

minute and measure the quantity of fluid pumped in this time) and set the

result of this measurement in Flow rate.

If Alarm when below is activated ProfiLux 4 outputs an alarm. Before an alarm is issued

ProfiLux 4 will give a warning.

If the container is refilled, the replenished quantity can be entered, a possible alarm will be

reset if there is sufficient refilling.

2.5 Location

The coordinates (Longitude and Latitude) of your location can be entered here. This

information will be used for further simulations in the future.

From the factory, this is 49.4 ° N and 7.8 ° E - the coordinates of Kaiserslautern in Germany -

the production location of your ProfiLux 4.

3 Illumination

This menu contains all lighting-related settings and functions.

ProfiLux 4 can control 32 dimmable or non-dimmable lamps independently. Lighting units

can be switched via our powerbars. Dimmable lighting units can be also controlled via the 1-

10V interfaces. The dimmable LED Mitras Lightbar is controlled via its own digital interface.

Dimmable tubular lightbars are controlled by L1 (or L3, L5, etc.) as standard. It controls both

tubes of that lightbar.

You also have the option to simultaneously dim tubular lightbars.

EN 2017-02-06 19

ProfiLux 4 Programming Guide

TIP

If required, you can retrofit additional 1-10 V interfaces with ProfiLux

Expansion Cards, PLM-4L or PLM 2L4S.

NOTE

The brightness curve between the individual dim-points are calculated

automatically.

You can set the illumination run for each lighting individually. This makes it possible to

achieve effects like sunrise or moonlight.

3.1 Illumination Run

Please select which lighting is to be edited (Illumination to edit?). After selecting a lighting, you

can set the type of the luminaire, dimmable and non-dimmable.

It is also necessary to specify whether the automatic is to be switched on (Automatic on?). If

this is not the case, this lighting is in manual mode. Select whether you want a temperature-

dependent light reduction.

Enter the number of dim-points (for dimmable luminaires) or the switch-times (for non-

dimmable luminaires) for which you want to adjust the brightness (up to 24)

If you have selected a dimmable luminaire, please set the following for each dim-point:

Time – At this time, the luminaire shall have the brightness to be set subsequently

Light intensity (0% - 100%) – Brightness of the light at this time

If you have selected a non-dimmable luminaire, please set the following for each dimming

time:

Switch on – The light is switched on at this time

Switch off – The light is switched off at this time

Then select which simulations should affect this lighting process and save the settings with

Yes ->RETURN.

EN 2017-02-06 20

ProfiLux 4 Programming Guide

TIP

To create/edit your Illumination run, we recommend using GCC Light

Composer. Light Composer provides the quickest solution for creating your

own lighting schedule.

The Light Composer calculates the individual lighting channels by means of

the desired brightness and color sequence over the day.

You can download that free of charge software on our homepage (Support-

>Downloads) www.aquariumcomputer.com.

The following functions can only be set via GCC.

3.2 Copy an Illumination Run using GCC

With this function, you can spare yourself the time of having to enter the same illumination

run settings again and again, especially if several illumination channels shall do the same.

If you activate Copy illumination run, you still have to enter the illumination channel from

which the run shall be copied. The entry of an illumination run on which you are just working

is then not necessary anymore (resp. also not possible anymore). This illumination channel

follows exactly the illumination run of the channel from which you would like to copy,

potentially time-shifted when you use the following functions.

3.3 Time shift with GGC

This function is used to allow an illumination channel to follow its set course or darkening

during clouds in a time-delayed manner. The time shift can be set separately for the

illumination run and for clouds. The time shift also has an effect when the illumination run

has been copied.

3.3.1 Time shift during clouds

With this function, sliding clouds that pull over several luminaires are possible.

This time, adjustable from 0 s to 3.1 s in steps of 0.1 s, determines with which delay the

illumination channel should be darkened during a cloud. The brightening at the end of a

cloud is delayed by the same time. If you have several dimmable luminaires that can be

separately controlled, you can use this function to create even more realistic clouds.

EN 2017-02-06 21

ProfiLux 4 Programming Guide

Illumination

channel

Time shift during

clouds

Effect

1

0s

Light is darkened immediately in case of a cloud

2

0.5s

Light is darkened after a delay of 0.5 s in case of a cloud

3

1s

Light is darkened after a delay of 1 s in case of a cloud

Before the cloud

Cloud starts

Cloud is fully there

Cloud fades away

After the cloud

Illumination

channel

Time shift for

illumination run

Illumination run

Effect

1

0

Channel has its own

illumination run

Follows directly illumination run 1

2

10 Minutes

Copy of 1

Follows illumination run 1 delayed by 10

minutes

3

20 Minutes

Copy of 1

Follows illumination run 1 delayed by 10

minutes

Example with 3 dimmable lights:

The following graphic illustrates the effect:

3.3.2 Time shift for Illumination Run

This time indicates the delay with which this lighting channel should follow its (or copied)

lighting curve (adjustable between 0s and 1h). With this function, it’s possible to distribute

switching on (or dimming up) and switching off (or dimming down) to several luminaires.

If you want your luminaires to have the same illumination run, only a little bit time-delayed,

the following procedure is recommended.

Example with 3 dimmable lights:

EN 2017-02-06 22

ProfiLux 4 Programming Guide

Before sunrise

Sunrise starts

Sunrise is advanced

Sunrise is complete

Sunset starts

Sunset is advanced

The sun has completely set

Symbol

Meaning

Dimmable only upwards (at 0%)

Dimmable only downwards (at 100%)

Dimmable in both directions

The following graphic illustrates the functional principle:

3.4 Manual Illumination

This menu is mainly used for testing and diagnostic purposes. With the arrow keys left right,

you can select the lighting channel whose brightness you want to adjust, 4 channels are

displayed simultaneously. Use the up and down arrows to make the channel brighter or

darker.

The symbols displayed to the left and right of the selected channel have the following

meanings:

Save your settings and exit the manual brightness setting by selecting Esc.

EN 2017-02-06 23

ProfiLux 4 Programming Guide

3.5 Clouds

ProfiLux 4 can simulate passing clouds by using a random generator. When a cloud passes, all

of the involved luminaires temporarily become darker as the simulation goes through its

effect.

The maximal waiting time (0s - 100s) determines how long the time intervals between two

clouds should be (with 0s the cloud simulation is switched off). The random number

generator waits between 1s and the maximal waiting time until a new cloud is generated.

Furthermore, the minimal and maximal cloud duration as well as the maximal darkening (10% -

95%) are to be set. The random generator generates new clouds, taking these values into

account.

The cloud simulation also works with simultaneous lunar phase simulations and during a

dimming process.

Note that the cloud simulation must be active for the desired illumination channels, see also

-> Illumination run.

3.6 Moon

ProfiLux 4 simulates the moon phases depending on the date.

In reality, the lunar cycle is a very complex matter:

Thus the distances vary from new moon to new moon. On average it is about 29.5

days.

Likewise, the moonrise time as well as the distance to the earth differ respectively.

It is not the fact that at half-moon the moon has 50% of its brightness. We consider on

average about 25%.

Our lunar phase simulation does not aim to replicate these complex sequences in every

detail. For us, it was important to produce a repeating moonlight sequence which would

illuminate the aquarium somewhat differently day-to-day. We’ve implemented such features

to provide a certain rhythm which would largely be in harmony with nature.

Lunar phases created by the ProfiLux 4 are based on the calendar date so that full moon and

new moon phases always correspond to the actual (real) lunar phase with a deviation of one

day or less.

You can set the time when the lunar phase simulation is active. In order for the lunar phase

simulation to function, it must first be activated in the desired lighting channels.

EN 2017-02-06 24

ProfiLux 4 Programming Guide

With the lunar phase simulation enabled on the selected lighting channels, the following

happens within the set time: The brightness (given by the set illumination run) is multiplied

by the calculated moon phase brightness. The illumination run is therefore still taken into

account.

The result is for example, at half-moon (= 50% lunar phase, 25% lunar brightness) and a

brightness of 30% (given by the illumination run). A luminaire brightness of 25% * 30% =

7.5%.

Illumination channels, without activated moon phase are not affected and follow their

lighting curves as normal.

Outside of the set simulation time, no illumination is influenced by the lunar phase

simulation.

With this method, it is possible to normally operate a lighting channel during the day (outside

the set simulation time/no influence of the lunar phase) and in the evening with the moon

phase (within the set simulation time).

The start and end-time of the lunar phase simulation should be created so that the night

illumination interval of the assigning lighting is included.

If the illumination of a luminaire is for example, programmed to illuminate as moonlight

from 19:00 (7:00pm) to 7:00 (7:00am), moon phase simulations should also be set from 19:00

(7:00pm) to 7:00 (7:00am).

The lunar phase simulation can also be tied-in with other simulations.

3.7 Rainy Days

ProfiLux 4 allows the programming of "Rainy days". On a rainy day, the lighting intensity is

reduced by an adjustable value.

With this feature, you have the option to set the weekdays for which Rainy Days should be

enabled. Once the days have been selected, the darkening of the day has to be set (0% -

100%).

The Rainy days simulation also takes other simulations into account.

3.8 Burning-in

Fluorescent tubes must be burned in before they can be used for dimming. ProfiLux 4

provides a convenient way to automate the burn-in process.

EN 2017-02-06 25

ProfiLux 4 Programming Guide

After selecting the Illumination to which the tube to be burnt-in is connected, the burning in

period can be set between 0h and 100h.

This lighting is then only operated with 0% or 100% until the operating hours meter (see also

-> Operating hours) has reached the burn-in period for this lighting (all dim-settings from 1%

are automatically output as 100%).

At 0% the lamp will be still switched off - the burn-in is done step by step.

By default, the burn-in time is set to 0 h, so the burn-in is deactivated.

3.9 Operating hours

Each lighting channel includes its own operating hours meter, which continues to run when

the corresponding lighting is active (brightness greater than 0%).

This feature continuously tracks the length of time a light is in operation so you always know

how when it should be exchanged. It is especially useful for preventing performance

decreases due to bulbs aging.

The operating hours counter is also used by the burn-in program. The operating hours are

written cyclically every 1h into the non-volatile memory. This ensures that the operating

hours are maintained even in the event of a power failure.

After selecting the menu item Operating hours, please select the Illumination option. The

operating hours for this Illumination are then displayed.

After a few seconds or by pressing a key, you will be asked if you want to “reset the operating

hours meter?” A confirmation with Yes resets the operating hours counter to 0 h. Of course,

this should only be done when changing the light source.

3.10 Thunderstorms

ProfiLux 4 can simulate an authentic thunderstorm.

When a thunderstorm simulation is in-effect, a slow reduction of all illumination channels will

occur. As these channels become darker, the number of flashes will increase. After the

thunderstorm has reached its climax, the lighting is slowly brought back to normal strength,

the flashes become less frequent until finally the thunderstorm is over.

A thunderstorm can be started manually any number of times or automatically up to 4 times

per day. There is also an option to start a thunderstorm at random.

Set the thunderstorm parameters in the Storm menu:

EN 2017-02-06 26

ProfiLux 4 Programming Guide

NOTE

The signals necessary for a thunderstorm can only be generated from the

onboard 1-10 V interfaces (L1 to L6) or from the Mitras Lightbar connector.

A "thunderstorm illumination" should therefore not be connected to

possibly existing additional 1-10 V interfaces (for example expansion card

PLM_2L4S)!

Darkening (0% - 100%) during a thunderstorm

Intensity (1 – 20) of the thunderstorm – Higher numbers, the more flashes are generated

Flash brightness (10% - 100%) – Determines the LED output power during a flash

Thunderstorm/Day – Number of automatically generated thunderstorms in a day (max. 4)

Weekdays – Only on these weekdays there is a thunderstorm

Start 1...4 – A thunderstorm begins at this time

Duration 1...4 – Duration of a thunderstorm (1 to 60 minutes)

Random thunderstorm duration – If you want random thunderstorms, enter a duration (max.

60 minutes) for the random thunderstorm (If you enter 0, randomly generated

thunderstorms are disabled).

Waiting time minimal and maximal – the random generator determines a waiting time within

these limits (maximum 240 hours) until the next random storm is started.

In the Thunderstorm menu, a thunderstorm could be manually started by selecting Manual

Start. The duration (1 to 60 minutes) must then be entered here. When a manual

thunderstorm is triggered, the stored thunderstorm intensity and darkening Settings are

used.

3.11 Temperature-dependent light reduction

With this function, it is possible to gradually reduce the lighting (in the case of dimmable

luminaires) or switch it off (in the case of non-dimmable luminaires), depending on whether

the nominal temperature is exceeded.

When calculating the reduced light intensity of dimmable luminaires, the current illumination

run as well as possible simulations are included.

EN 2017-02-06 27

ProfiLux 4 Programming Guide

Actual temperature

Light reduction by

Actual temperature

Light reduction by

28.5 °C

25 %

29.5 °C

75 %

29.0 °C

50 %

29.0 °C

100 %(Off)

Example for Dimmable Lamps

Nominal temperature = 26.0 °C, min. temperature excess = 2.0 °C, max.

temperature excess = 4.0 °C, this results in the following table

With the temperature-dependent light reduction, it is possible to prevent your aquarium

from being further heated by the illumination on hot summer days. This feature is especially

useful when an existing cooling system cannot provide sufficient temperature reduction.

The following parameters can be set:

The determining Temperature sensor (for example, temperature 1 if you have

connected one temperature sensor. If you connected more than one, select the

sensor to be used for the measurement).

The Temperature excess minimal – If the nominal temperature is exceeded by this

value, then the reduction of the illumination intensity of the affected lamps begins,

adjustable from 1 °C up to 5 °C - this setting is only relevant for dimmable lamps!!

The Temperature excess maximal – If the nominal temperature is exceeded by this

amount, the lighting concerned is switched off completely, adjustable from 2 °C to 10

°C, must be at least 1 °C higher than the minimum temperature limit - this setting is

only relevant for dimmable luminaires!

The Shut off limit – If the nominal temperature is exceeded by this amount, non-

dimmable luminaires are switched off. A value between 1 °C and 10 °C is adjustable.

These lights are not switched on again until the programming of the corresponding

illumination run defines again a switch on (luminaire has been switched off according

to the programming, for example at night - and is switched on again, for example in

the morning). A drop in the temperature alone does not lead to a new switch-on,

which is particularly useful with gas discharge lamps, since these should not be

switched on and off continuously. This setting is only relevant for non-dimmable

luminaires!

EN 2017-02-06 28

ProfiLux 4 Programming Guide

Example

You would like to have for the illumination from Monday to Friday other

settings than for Saturday and Sunday, so you need 2 different illumination

runs.

First you set both illumination runs (e.g. illumination run 1 for Monday to

Friday and illumination run 5 for Saturday and Sunday) according to your

wishes.

Afterwards you set e.g. Variable Illumination 1 accordingly (Monday: 1,

Tuesday: 1, …, Friday: 1 and Saturday: 5 and Sunday: 5).

Finally you choose the function Variable Illumination 1 as function for the

corresponding 1-10 V-interface (see also System ->1-10 V interface) resp. for

the corresponding switchable socket (see also System ->Socket outlet

function.

3.12 Variable Illumination

This function allows you to use different illumination runs for a luminaire on different

weekdays.

Up to 16 variable lighting programs can be defined. After selecting the program (1 to 16), you

can set for Monday to Sunday, which lighting sequence (1 to 16, Illumination run) should be

used on the respective day.

3.13 Mitras Lightbar

Activate this setting when you have connected our Highpower LED Illumination Mitras®

Lightbar. You can also specify which of the available serial interfaces (usually COM1) are to be

used to control the Mitras Lightbar.

Here you can change the output power of the Mitras Lightbar.

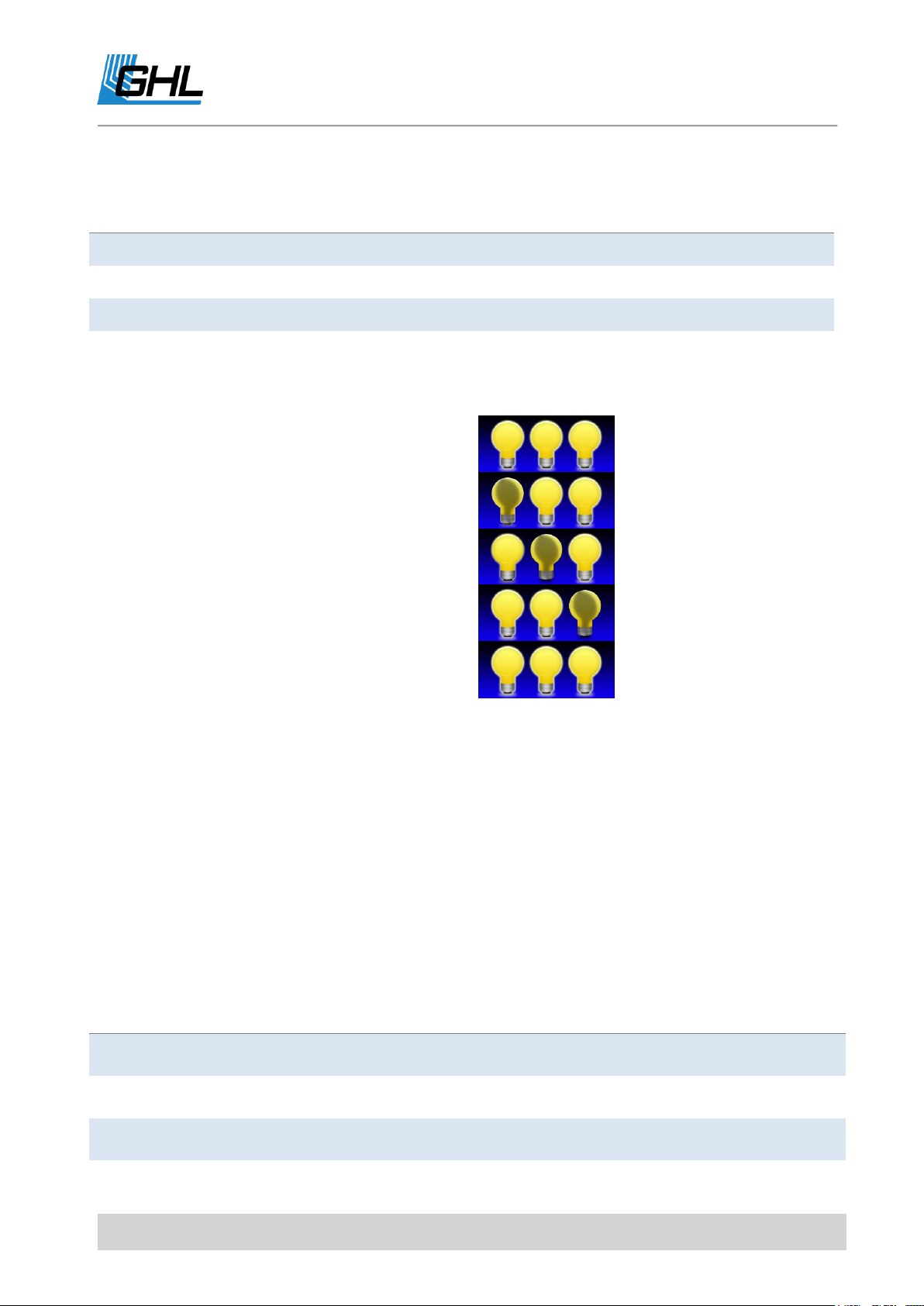

3.14 Light demo

The Lightdemo serves for demonstration purposes. After activation, the LEDs are alternately

dimmed up and down.

With the keyboard the Lightdemo can be varied:

Arrow up and down – Color change faster or slower

Arrows left and right - Change the color pattern

Return - Freeze the current color pattern, press Return again restarts the automatic

sequence

EN 2017-02-06 29

ProfiLux 4 Programming Guide

Esc finishes the light demo.

3.15 Time lapse

The Time lapse can be used for test and demonstration purposes. With this function you can

view the adjusted illumination run in time lapse.

There is a manual time lapse (indicated by an M in the upper right) and an automatic time

lapse (indicated by A). You switch between both modes by pressing Return.

In manual time-lapse, you can set the time to be simulated, at which the appropriate lighting

is to be displayed.

During the automatic time-lapse, the time to be simulated is constantly incremented, you can

set the speed of the time-lapse. Set the duration, in seconds, to be used for 24-hour

simulation.

Esc finishes the time-lapse.

3.16 Acclimation

The acclimation function provides a simple and comfortable way to automatically change the

brightness of the light over a span of several days. We recommend using this simulation for

acclimating corals/plants to a new lighting program or when corals have been newly brought

in.

After activating, the following settings can be made:

Start date – The acclimation period begins on this day

Start percent- With this value, all dimmable lights are multiplied at the beginning of the

acclimation

End date - The acclimation period ends on this day

End percent - With this value, all dimmable lights are multiplied at the beginning of the

acclimation

During acclimatization, a dimming factor is calculated daily. The individual illumination runs

are converted according to this factor.

Example: Start on 01.12.2016 (12-01-2016) with 50%, end on 03.12.2016 (12-03-2016) with

100%

EN 2017-02-06 30

ProfiLux 4 Programming Guide

Note

In order to achieve maximum flexibility, the settings of the maintenance

function refer directly to the hardware (switch sockets and 1-10 V interfaces)

...

...and not on control and regulation functions (e.g., temperature control or

illumination channels).

Then the lighting channels are operated with 50% of the normally set brightness on the

01.12.2016 (and also before), on the second day with 75%, and on the last day with 100%

(and also thereafter).

Starting and ending percentages can be adjusted as needed; thus an increase as well as a

lowering over a certain period of time is possible..

3.17 Shift Curves

This function allows you to move complete illumination runs.

Select the illumination(s) whose illumination run(s) you want to move.

Then determine the time offset and confirm with ->RETURN

4 Extras

Special functions and settings are summarized here. The following submenus are provided.

4.1 Maintenance

During the maintenance and care of the aquarium, it can be helpful to set the switch state of

some switch sockets or the brightness of luminaires explicitly.

An example would be switching the heaters off, setting the flow to minimum and setting a

dimmable lightbar to 80%.

ProfiLux 4 offers 4 separately adjustable Maintenance programs.

In the Maintenance menu, you can set the maintenance parameters under Settings. For quick

access, the maintenance programs are positioned on top, one after the other. The menu

item Settings will show up afterwards. Scroll down the menu until you reach Settings. Then

select the Maintenance program you want to edit.

Set affected 1-10V interfaces

EN 2017-02-06 31

ProfiLux 4 Programming Guide

Here you can select the 1-10V interfaces to be affected during maintenance. All non-selected

interfaces continue to operate normally and program-controlled during maintenance.

Adjust affected 1-10V interfaces

For the previously selected 1-10V interfaces, you can set here which voltage in percentage

they shall output during the maintenance.

Select affected socket outlets

Here, you can set which sockets should be influenced during maintenance. All unselected

sockets continue to operate normally and program-controlled during maintenance.

Adjust affected socket outlets

The switch state (on or off) can be set for the previously selected sockets during

maintenance.

The following two settings are available only if a Mitras Lightbar is connected.

Select affected Mitras Lightbar LEDs

Here it is possible to adjust which LEDs of Mitras Lightbar are to be influenced during

maintenance. All non-selected LEDs continue to operate normally and as programmed

during maintenance.

Adjust affected Mitras Lightbar LEDs

For the previously selected LEDs, the brightness can be adjusted as a percentage during

maintenance.

Maximum length maintenance

This time (up to 240 minutes) determines the length of time the maintenance is

automatically switched off.

The automatic shutdown after a certain period of time prevents maintenance from

remaining permanently active if you forget to switch it off again. If maintenance is allowed

for an indefinite period, enter 0 here.

Activate the Maintenance program in the Maintenance menu with Start.

While the maintenance program is active, the selected sockets have the set switching states

and the selected 1-10 V interfaces output the set voltages.

ProfiLux 4 signals an active maintenance program with a blinking hammer symbol in the

display.

End the Maintenance program from the Maintenance menu by selecting Stop.

EN 2017-02-06 32

ProfiLux 4 Programming Guide

Note

During maintenance, the alarm monitoring of all sensors is switched off!

Note

To avoid damage to the microbiological climate of your filter, do not select

this time longer than absolutely necessary (approx. 5 to 10 minutes)!

4.2 Feeding Pause

ProfiLux 4 offers 4 independent feed pauses, which can be started and set in the feed pause

menu.

Scroll down in the Feed Pause menu until you get to Settings.

Select the feed pause (1 to 4) whose settings you want to adjust.

Set the duration of the feed pause (length feeding pause). This determines how long the

activated feed pause takes, which has been started manually with the Esc key or

automatically by a timer. It can be set between 0 and 120 minutes (0 means that this feed

pause is not used).

Furthermore you can set which effect the feeding pause shall have:

Stop filter? – with the selection of Yes the switchable socket with the function Filter (1 to 4,

depending on the feeding pause you are editing here) will be switched off during the feeding

pause.

Finally, you have to set whether a timer can activate the feed pause, if Yes is selected, choose

which timer should start this feeding pause.

If a timer should activate this feeding pause then the feeding pause is activated as long as

this timer is active. The feeding pause remains furthermore active for the time set under

Length feeding pause. This makes sense, if this timer controls an automatic feeder or a dosing

pump.

The behavior of the current pumps during the feeding pause can be defined in the settings

of the current pumps (Extras->Current->Pump settings).

EN 2017-02-06 33

ProfiLux 4 Programming Guide

You start a feed pause by pressing the Esc key. If more than one feed pause is used, then the

appropriate feed pause has to be selected. The food pause can be interrupted by pressing

Esc again.

4.3 Internal Time

This function is used to display the internal clock (see also ->Clock). This function is only for

diagnostic purposes, settings cannot be made here.

4.4 Info & Support

After selecting this menu item, information about the software version, model and our

homepage is displayed one after the other (automatically after the lapse of a certain time or

by pushing a key).

4.5 Current

ProfiLux can control (current) pumps in a variety of ways; subsequent pumps are suitable for

control:

• Pumps with an analog control signal input (mostly 1-10V-interface), such as those

from Tunze®, Royal Exclusiv® or Abyzz®, are connected to a 1-10V interface port of

the ProfiLux (for the connection to ProfiLux you need the corresponding accessory)

• Pumps whose speed is adjustable via phase controlled modulation (therefore our

dimmable powerbar Powerbar2Dim is necessary)

• EcoTech®-pumps of VorTech® (with our module VorTech-Controller)

• Electronical external filter Professionel 3e® from Eheim® (with our module Eheim-

Controller)

• Some low-voltage pumps, e.g. Koralia® from Hydor® (with our module PumpControl1)

Furthermore, non-controllable pumps can be switched via switchable sockets, see also

System-> Socket outlet function. These can then of course only be switched on or off but not

regulated.

The current control is organized in groups, one group consists of one or several pumps. The

settings can be made separately for each group and for each pump. The group settings

define the pumps belonging to the group, the operational mode and the time settings

(depending on the operational mode).

For each pump, settings such as wave duration, minimal or maximal speed or the behavior

during the feed pause can be set individually.

EN 2017-02-06 34

ProfiLux 4 Programming Guide

Note

"Pump active" means that the pump is running continuously between min.

and max. current speed and thus generates waves.

A socket assigned to the flow pump is then switched on.

"Pump inactive" does not necessarily mean that the pump is off, but that it

runs at its minimum power.

A socket assigned to the flow pump is then switched off.

The group settings determine when and for how long which pump is active

in this group, the pump settings determine the behavior of the pump during

activity and inactivity.

4 independent groups can be programmed. A group consists of up to 4 (or up to 16) pumps

which can be independently controlled.

4.5.1 Nocturnal Change

For the current simulation, a Nocturnal change of the pump power can be adjusted. If the

Nocturnal change is activated, the start and end times must also be entered. Within these

times, the pumps are operated with the power set for the night. The night change affects all

pumps in all groups.

4.5.2 Group Settings

The following parameters can be set for each group:

4.5.2.1 Operational Mode

Here you can set the operating mode for a group. The individual groups may have different

operating modes.

Off – The pumps of this group are permanently off.

Permanent – The pumps are permanently active and run synchronously.

Permanent alternating – The pumps are permanently active and operate alternating, i.e. if

pump 1 runs at maximum speed, pump 2 runs at minimum speed and vice versa.

Sequence 1 – Here, always exactly one current pump of this group is switched on alternating.

The duration for the change from one pump to the next one can be set, see below. When the

last pump of this group was active, the cycle starts again with the first pump of this group. If

this group consists of 2 pumps, then the ebb-tide-simulation is generated. If only one pump

belongs to this group, it is switched on and off alternating.

EN 2017-02-06 35

ProfiLux 4 Programming Guide

Step

Pump 1

Pump 2

Pump 3

1

on

off

off 2 off