FR

MANUEL D’UTILISATION

EN

OPERATOR’S MANUAL

DE

GEBRAUCHSANWEISUNG

IT

MANUALE DI ISTRUZIONI

NL

GEBRUIKERSHANDLEIDING

ES

MANUAL DE INSTRUCCIONES

PT

MANUAL DE INSTRUÇÕES

EL

∂°Ã∂πƒπ¢π√ √¢∏°πø¡

TR

KULLANIM KILAVUZU

MK

УПАТСТВА ЗА УПОТРЕБА

NO

INSTRUKSJONSBOK

SV

BRUKSANVISNING

DA

BRUGSANVISNING

FI

KÄYTTÖOHJEET

CS

NÁVOD K POUŽITÍ

PL

INSTRUKCJE OBSŁUGI

HU

HASZNÁLATI UTASÍTÁS

RU

кмKйЗйСлнЗй ий щKлигмДнДсаа

HR

PRIRUČNIK ZA UPORABO

SL

PRIROČNIK ZA UPORABU

BS

UPUTSTVO ZA UPOTREBU

SK

NÁVOD NA POUŽITIE

RO

MANUAL DE INSTRUCŢIUNI

LT

INSTRUKCIJŲ VADOVAS

LV

OPERATORA ROKASGRĀMAT

SR

PRIRUČNIK SA UPUTSTVIMA

BG

мицнЗДзЦ бД мийнкЦЕД

ET

KASUTUSJUHEND

3.1

3 12

3.2

CHOKE

3

4

7

5.1.1 5.1.2

2

1

MAX

MIN

8

2

6

MAX

2

2

MIN

5.1.3 5.1.4

2

1

FAST

SLOW

STOP

5

1

2

3

3a

1

2

3

5.2.3 5.5-6

CHOKE

1

4

3

1

1

4

3

STOP

TABLE OF CONTENTS

1. General information ................................... 1

2. Safety regulations ..................................... 1

3. Components and controls ........................ 2

4. What you need to know ............................ 3

5. Standards of use ...................................... 4

6. Maintenance ............................................. 6

7. Troubleshooting ........................................ 8

8. Technical data ........................................... 8

EN

1

1. GENERAL INFORMATION

1.1

READING AND UNDERSTANDING

THE MANUAL

Some paragraphs in the manual containing information of particular importance for safety and

operation are highlighted at various levels of

emphasis, and signify the following:

These give details or further information on

what has already been said, and aim to prevent

damage either to the engine or other damages.

!

WARNING!

sult in the risk of injury to oneself or others.

!

DANGER!

sult in the risk of serious injury or death to

oneself or others.

NOTE

“front”, “rear”, “right” and “left”,

are to be taken as referring to the

engine positioned with the spark

plug facing forwards with respect

to the observer.

or

Non-observance will re-

Non-observance will re-

All indications,

IMPORTANTNOTE

2. GENERAL SAFETY STANDARDS

(To be strictly applied)

A) TRAINING

1 Carefully read the instructions contained in

this manual and the instructions of the

machine on which this engine is installed.

Learn how to stop the motor quickly.

2) Never allow people unfamiliar with these

instructions to use the engine.

3) Never use the engine while people, especially children, or pets are nearby.

4) Remember that the operator or user is

responsible for accidents or hazards occurring to other people or their property.

The number before the paragraph title refers to

the text references and their related figures

(shown inside front and back covers).

1.2

SAFETY SYMBOLS

Your engine should be used with due care and

attention. Symbols have therefore been placed

on the engine to remind you of the main precautions to be taken. Their full meaning is explained

later on.

You are also asked to carefully read the safety

regulations in the applicable chapter of this

handbook.

Warning! - Read and follow Operating Instructions before running engine.

Warning! - Keep away from hot surfaces.

Warning! - Petrol is flammable. Allow

engine to cool at least 2 minutes before

refuelling.

Warning! - Engines emit carbon

monoxide. DO NOT run in enclosed

area.

B) PREPARATION

1) Do not wear loose-fitting clothing, dangling drawstrings, jewels or items that could

become caught; tie up long hair and keep at

safe distance while starting the lawnmower.

2) Turn engine OFF and let it cool before

removing gas cap.

3) WARNING: DANGER! Fuel is highly flammable:

– store the fuel in special containers;

– refuel only outdoors by using a funnel;

never smoke while refueling and/or handling fuel;

– add fuel before starting the engine. Never

remove the cap of the fuel tank or add fuel

while the engine is running or when the

2

EN

engine is hot;

– if you have spilt some fuel, do not attempt

to start the engine but move the machine

away from the area of spillage and avoid

creating any source of ignition until the fuel

has evaporated and fuel vapours have dissipated.

– always put the tank and fuel container caps

back on and tighten well.

4) Replace faulty silencers and the guard, if

damaged.

C) OPERATION

1) Do not operate the engine in a confined

space where dangerous carbon monoxide

fumes can collect.

2) Do not use starting fluids or similar products.

3) Do not change the engine governor settings or overspeed the engine.

4) Do not tilt the machine onto its side to prevent fuel leaks from the fuel tank cap.

5) Do not touch the cylinder fins and/or the

silencer guard until the engine has cooled

down.

6) Stop the engine and disconnect the spark

plug cable before checking, cleaning or servicing the machine or the engine.

7) Do not crank the engine with spark plug

removed.

8) Transport the machine with an empty fuel

tank.

3. COMPONENTS AND CONTROLS

3.1

ENGINE COMPONENTS

1. Rope handle

2. Fuel tank fillercap

3. Oil fillercap with dipstick

4. Air cleaner cover

5. Silencer

6. Silencer guard

7. Spark plug cap

8. Engine code

✍

Note your engine

serial number here

3.2

ACCELERATOR CONTROL

The throttle trigger (generally a lever), fitted to

the machine, is connected to the engine by a

cable (1).

Consult the machine’s Instructions Manual to

identify the throttle trigger and its positions, usually marked by symbols, corresponding to:

D) MAINTENANCE AND STORAGE

1) A routine maintenance is essential for

safety and for keeping a high performance

level.

2) Do not store the machine with fuel in the

tank in an area where the fuel vapours could

reach an open flame, a spark or a strong heat

source.

3) Allow the engine to cool before storing in

any enclosure.

4) To reduce fire hazards, keep the engine,

exhaust silencer, and fuel storage area free of

grass cuttings, leaves, excessive grease or

any other easily inflammable material.

5) If the fuel tank has to be drained, this

should be done outdoors once the engine has

cooled down.

6) On safety ground, never use the engine

with either worn or damaged parts. Parts are

to be replaced and not repaired. Use genuine

spare parts. Parts that are not of the same

quality can damage the engine and impair

your safety.

CHOKE = to be used for cold starting.

FAST = corresponds to maximum revs;

to be used when working.

SLOW = slowest speed.

STOP = engine stop (if fitted).

4. WHAT YOU NEED TO KNOW

The engine performance, reliability and life are

influenced by many factors, some external and

some strictly associated with the quality of the

products used and with the scheduled maintenance.

The following information allow a better understanding and use of your engine.

4.1

ENVIRONMENTAL CONDITIONS

The operation of a four-stroke endothermic

engine is affected by:

a) Temperature:

– Working in low temperatures could lead to a

difficult cold starting.

– Working in very high temperatures could lead

to a difficult hot starting due to the evaporation of the fuel either in the carburetor float

chamber or in the pump.

– In any case, the right kind of oil must be used,

according to the operating temperatures.

b) Altitude:

– The higher the altitude (above sea level), the

lower the max power developed by an

endothermic engine.

– When there is a considerable increase in alti-

tude, the load on the machine should be

reduced and particularly heavy work avoided.

4.2

FUEL

A good quality fuel is the major issue for the

engine reliability of operation.

a) Use unleaded gasoline, with a minimum of 90

octane.

b) Use clean, fresh fuel; purchase fuel in quanti-

ty that can be used within 30 days, to prevent

gum from forming inside the container or the

tank.

c) Do not use fuel which contains Methanol.

d) Do not add neither oil nor any kind of fuel

additive.

4.3

OIL

Use always high quality oils, choosing their viscosity grade according to the operating temperature.

EN

a) Use only detergent oil classified SF-SG.

b) Choose the SAE viscosity grade of oil from

this chart:

– from 5 to 35 °C = SAE 30

–

from -15 to + 5 °C =

– from -25 to + 35 °C = Synthetic oils

c) The use of multi-viscosity oils in hot temper-

atures will result in higher than normal oil consumption; therefore, check oil level more frequently.

d) Do not mix oils of different brands and fea-

tures.

e) SAE 30 oil, if used below +5°C, could result in

possible engine damage due to inadequate

lubrication.

f) Oil should be at «MAX» mark (see 5.1.1): do

not overfill. Overfilling with oil may cause:

– Smoking;

– Spark plug or air filter fouling, which will

cause hard starting.

4.4

AIR FILTER

The air filter must always be in perfect working

order, to prevent debris, dirt or dust from getting

sucked into the engine, reducing the efficiency

and working life of the machine.

a) Always keep the filter element free of debris

and dirt in perfect working order (see 6.5).

b) If necessary, replace the filtering element with

an original spare part. Incompatible filtering

elements can impair the efficiency and life of

the engine.

c) Never start the engine without mounting the

filtering element properly.

4.5

SPARK PLUG

Not all the spark plugs for endothermic engines

are the same!

a) Use only spark plugs of the recommended

type, with the right heat range.

b) Check the length of the thread, because – if

too long – it will damage the engine beyond

repair.

c) Make sure that the electrodes are clean and

their gap is correct (see 6.6).

5W-30 or 10W-30

(Multi-viscosity)

5W-30 or 10W-30

(Multi-viscosity)

3

4

EN

5. STANDARDS OF USE

5.1

BEFORE EVERY USE

Before every use, perform the following checking

procedures in order to assure a regular operation.

5.1.1

Check oil level

See the specific chapter (see 8.1) for the oil to be

used.

a) Place engine level.

b) Clean around oil fill.

c) Unscrew the cap (1), clean the end of the dip-

stick (2) and insert it, as illustrated, without

screwing it down.

d) Remove the cap with the dipstick and check

the oil level that must be between the «MIN»

and «MAX» marks.

e) If oil is required, add oil of the same kind up

to the «MAX» mark, being careful not to spill

any outside the oil fill.

f) Fully tighten the fillercap (1) and wipe off any

spilled oil.

5.1.2

Check air cleaner

The efficacy of the air cleaner is crucial for the

good performance of the engine; never start the

engine if the filter element is missing, broken or

insufficiently saturated with oil.

a) Clean around the filter cover (1).

b) Remove the cover (1) by releasing the tabs

(2).

c) Check the condition of the filtering element

(3). It must be intact, clean and in perfect

working order; if not, either carry out maintenance or replace it (see 6.5).

d) Put the cover (1) back.

Add fuel only when the engine is cold.

a) Place the lawnmower level.

b) Clean around the fillercap (1).

c) Remove the fillercap (1).

d) Using a clean funnel (2), add fuel until it

reaches the internal lip (3) of the filler, taking

care not to spill any fuel.

e) Tighten the fillercap (1) back and clean any

spilled fuel.

5.1.4

Spark plug cap

Firmly connect the cable cap (1) to the spark

plug (2), making sure that there are no traces of

debris or dirt inside the cap or on the spark plug

terminal.

5.2

STARTING THE ENGINE (cold)

The engine must only be started when all the

accessory devices are disconnected (if fitted on

the machine) and when the gear (where fitted) is

in neutral.

– Move the throttle (1) to «CHOKE».

– Set the machine controls as indicated in the

machine’s Instructions Manual.

• Manual starting

a) Hold the starter rope grip (3) and pull it slow-

ly until you feel some resistance, then tug the

starter rope hard.

b) When the engine starts, let go of the rope.

NOTE

immediately, repeat the above steps.

If the engine fails to start

5.1.3

Adding fuel

IMPORTANT

plastic parts of the motor or the machine to

prevent damaging them and remove all traces

of spilt petrol immediately. The warranty does

not cover damage to plastic parts caused by

petrol.

See “Technical Data” chapter (see 8.1) for the

fuel characteristics.

Do not drip petrol onto the

• Electric starting (if provided)

a) Turn the starter key (4) as described in the

machine’s instruction manual.

After a few seconds, slowly move the throttle (1)

from «CHOKE» to either «FAST» or «SLOW».

NOTE

not keep running, repeat the above steps with

the throttle on «FAST».

If the engine starts but does

5.3

STARTING THE ENGINE (hot starting)

•) Follow the whole cold-starting procedure

with throttle control (1) in «FAST» position.

5.4

USE OF THE ENGINE IN OPERATION

When mowing, use the engine at its max rpm by

moving the throttle control to «FAST» position.

!

WARNING!

from the silencer and surrounding areas

that can become extremely hot. With the

engine running, do not get loose-fitting

clothing (ties, scarves, etc.) or hair closer to

the top part of the engine.

IMPORTANT

inclines to prevent malfunctioning of the

engine.

5.5

STOPPING THE ENGINE DURING

MOWING

a) Move the throttle (1) to «SLOW».

b) Stop the engine as described in the ma-

chine’s instructions manual; in the case of

engines with electric ignition, move the throttle to «STOP», or turn the key (3) (if present)

to «OFF».

Keep your hands away

Do not operate on over 20°

EN

b) Preferably use a compressed air gun (max. 6

bars), to prevent debris, dirt or dust from penetrating inside the machine.

c) Store the lawnmower (and the engine) in a dry

place, sheltered from severe weather conditions and sufficiently ventilated.

5.8

LONG STORAGE (over 30 days)

In case the engine has to be stored for a long

time (for example at the end of the season), a

few precautions are needed to help the future

start-up.

a) Drain fuel from tank to prevent build-ups

inside the tank.

b) Remove the spark plug and pour inside the

spark plug hole about 3 cl of clean engine oil.

Close the hole with a cloth, then pull, slowly

and carefully, the starting rope so that, with a

few engine revolutions, the oil will be distributed on the cylinder inner walls. Reinstall the

spark plug without connecting the cable cap..

5

5.6

STOPPING THE ENGINE AFTER

MOWING

a) Move the throttle (1) to «SLOW».

b) Stop the engine as described in the ma-

chine’s instructions manual; in the case of

engines with electric ignition, move the throttle to «STOP», or turn the key (3) (if present)

to «OFF».

c) When the engine is cold, disconnect the

spark plug (4) and remove the key (3) (if present).

d) Remove all traces of debris or dirt from the

engine and especially around the exhaust

silencer to reduce the risk of fire

5.7

CLEANING AND STORAGE

a) Do not spray with water or use hydraulic

lances to clean the exterior of the engine.

6

EN

6. MAINTENANCE

6.1

SAFETY RECOMMENDATIONS

!

WARNING!

cap and read instructions before carrying

out any cleaning, repair or maintenance

operation. Wear proper clothing and working gloves whenever your hands are at risk.

Do not perform maintenance or repair operations without the necessary tools and

technical knowledge.

IMPORTANT

or other pollutants in unauthorised places.

IMPORTANT

the Machine’s Instruction Manual), the engine

can be laid down on its right side, or the front

part can be lifted, taking care not to allow oil or

fuel to leak out.

6.2

MAINTENANCE SCHEDULE

Follow the hourly or calendar – whichever occur

first – maintenance schedule shown in the following table.

Remove the spark plug

Never get rid of used oil, fuel

If necessary (if foreseen in

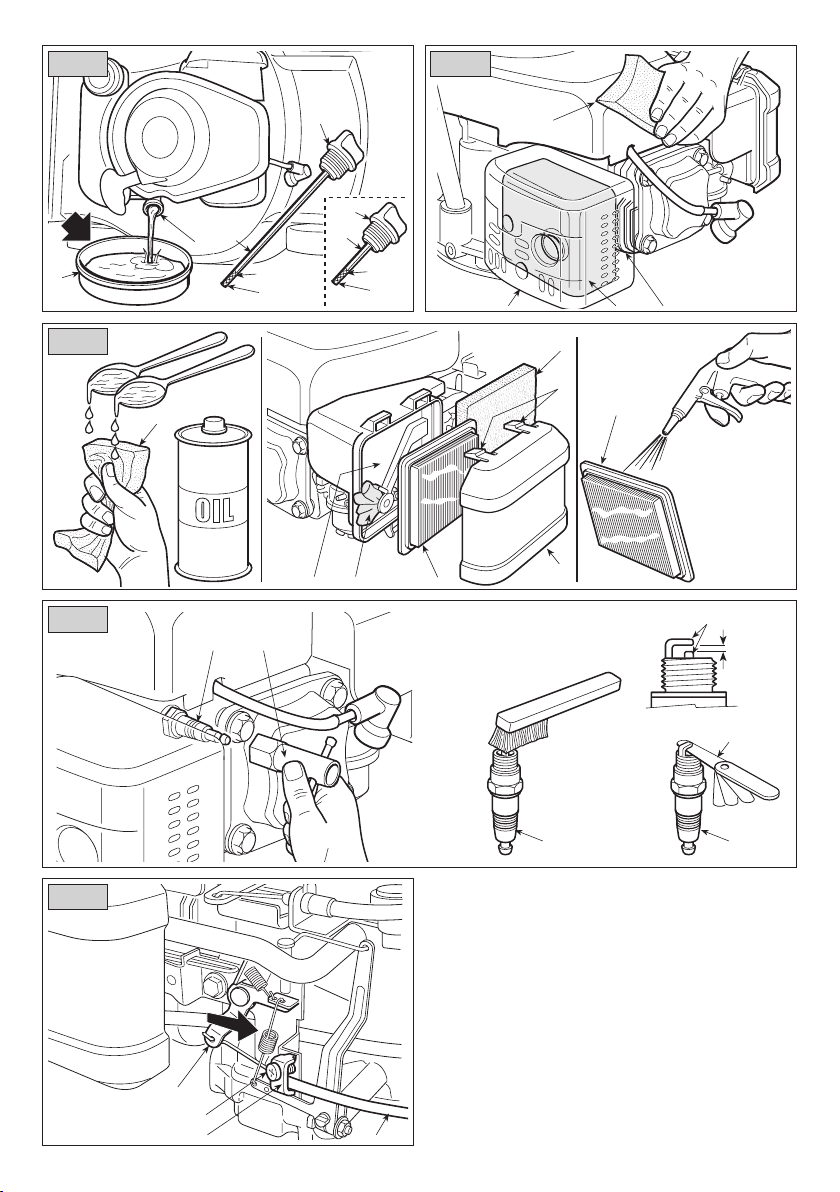

6.3

CHANGE OIL

See the specific chapter (see 8.1) for the oil to be

used.

!

WARNING!

Drain oil while the engine

is warm, being careful not to touch the hot

engine nor the drained oil.

a) Place engine level.

b) Make sure that the fuel tank is not full and

that the cap is properly closed.

c) Clean around oil fill (1).

d) Remove the fillercap (1).

e) Have a container ready (2) to collect the oil.

f) Tip the lawnmower on its right side so that

the oil will drain from the oil fill (3).

g) Place the lawnmower level and top up with

new oil (see 5.1.1).

h) Check the oil level on the dipstick (4). Oil

should be at «MAX» mark.

j) Close the fillercap and wipe off any spilled oil.

NOTE

The oil capacity is about

0.55 liter.

Operation

or daily

Every 5 hours

Every 25 hours or

After First 5 hours

Check oil level

(see 5.1.1)

Change oil

1)

(see 6.3)

Clean silencer and engine

see 6.4)

Check air cleaner

2)

(see 6.5)

Air filter replacement

(see 6.5)

Check spark plug

(see 6.6)

Replace spark plug

(see 6.6)

1)

Change oil every 25 hours if the engine is

operating under heavy load or in ht weather.

2)

Clean air cleaner more frequently if the

- ✔ --

✔ --✔

- ✔ --

- ✔ --

--✔ -

- ✔ --

---✔

machine is operating in dusty areas.

Silencer must be cleaned when the engine is

cold.

every season

a) Use a jet of compressed air or a brush to

every season

Every 50 hours or

b) Clean the cylinder and cylinder head fins (3)

c) Clean the plastic components with a sponge

The filtering element must be kept perfectly

clean and must be replaced if it is broken or

damaged.

a) Clean around the filter cover (1).

b) Remove the cover (1) by releasing the tabs

c) Remove the filtering element (3 or 3a).

6.4

CLEAN SILENCER AND ENGINE

remove any debris and dirt that could cause

a fire from the silencer (1) and its protective

cover (2).

to ease engine cooling and prevent overheating.

(4) soaked in water and detergent.

6.5

AIR FILTER CHECK AND MAINTENANCE

(2).

d) Block the inlet duct (5) with a rag to prevent

any dirt from entering.

e) Carry out maintenance on the filtering ele-

ment as described below for each type.

f) Clean inside the filter housing (4) to get rid of

any dust, debris or dirt, taking care not to

push anything into the induction pipe (5).

g) Put the filtering element (3 - 3a) back in place

and close the cover (1).

• Sponge filtering element (3)

Keep the filtering element clean and soaked in

oil. Replace it if it is disintegrating, cut or broken.

IMPORTANT

to clean the filtering element.

– Clean the sponge filtering element with water

and detergent and dry it with a clean cloth.

– Soak the filtering element in 2 tablespoonfuls

of clean engine oil and wring it well to distribute the oil evenly.

– Remove any excess oil with a clean cloth.

If you need to replace the filtering element, oil

the new filter as described above.

Do not use compressed air

EN

6.7

ADJUSTMENT OF THE

ACCELERATOR CABLE

If the engine does not reach its maximum rpm

with the throttle control in «FAST» position, this

is likely due to an out-of-phase connection

between the accelerator lever and the governor

lever.

To restore the correct phase:

a) Stop the engine, remove the spark plug cap

and wait until the engine has cooled.

b) Loosen the screw (1) of the clamp (2) so that

the cable casing (3) is free to move.

c) Move the throttle control to «CHOKE».

d) Move governor control lever (4) forward as far

as possible and, by keeping it in this position,

lock the casing (3) full tightening the screw (1)

of the clamp (2).

7

• Cartridge filtering element (3a)

– Blow compressed air from the inside to remo-

ve dust and debris.

6.6

SPARK PLUG SERVICE

a) Remove the spark plug (1) using a spark plug

socket wrench (2).

b) Clean the electrodes (3) with a metal brush

and remove any carbonaceous build-up.

c) Using a thickness gauge (4), check for the

right gap (0.6 - 0.8 mm) between the electrodes.

d) Install the spark plug (1) and tighten with a

socket wrench (2).

Replace the spark plug if the electrodes are

burnt or if the porcelain is broken or damaged.

!

WARNING!

the ignition system with spark plug removed.

IMPORTANT

recommended type (see 8.1).

Fire hazard! Do not check

Use only spark plugs of the

8

EN

7. TROUBLESHOOTING

PROBLEM LIKELY CAUSE SOLUTION

a) Hard starting

b) Inconsistent

working

– No fuel

– Stale fuel or build-ups in tank

– Incorrect starting procedure

– Spark plug disconnected

– The spark plug is wet or the spark

plug electrodes are dirty or placed

inadequately

– Air filter clogged

– Incorrect oil for the season

– Fuel evaporation in the carburetor

(vapor lock) due to high temperatures

– Fault in carburation

– Hard starting

– Dirty electrodes or incorrect gap

– The spark plug cap is inserted incor-

rectly

– Air filter clogged

– Throttle trigger in «CHOKE» position

– Fault in carburation

– Fault in ignition

– Check and top up (see 5.1.3)

–

Empty fuel tank and refill with fresh fuel

– Perform the starting procedure

correctly (see 5.2)

– Check that the spark plug cap fits well

over the plug terminals (see 5.1.4)

– Check (see 6.6)

– Check and clean (see 6.5)

– Replace with proper oil (see 6.3)

– Wait for a few minutes then start

again (see 5.3)

– Contact a Licensed Service Centre

– Contact a Licensed Service Centre

– Check (see 6.6)

– Check that the cap is fitted correctly

(see 5.1.4)

– Check and clean (see 6.5)

– Move the lever to the «FAST» position

– Contact a Licensed Service Centre

– Contact a Licensed Service Centre

c) Loss of power

whilst operating

– Air filter clogged

– Fault in carburation

– Governor out of phase with respect

to the accelerator

– Check and clean (see 6.5)

– Contact a Licensed Service Centre

– Adjust the cable (see 6.7)

8. TECHNICAL SPECIFICATIONS

8.1

REFILLING AND OPERATION MATERIALS

Fuel ........................................................................................ Unleaded gasoline, minimum 90 octane

Tank capacity ............................................................................................................................. 1.0 liter

Engine oil: from 5 to 35 °C ...................................................................................................... SAE 30

Oil capacity .............................................................................................................................. 0.55 liter

Spark plug ..........................................................................RC12YC/QC12YC (Champion) or equivalent

Spark plug gap ................................................................................................................. 0.6 - 0.8 mm

from -15 to +5 °C ............................................................................... 5W-30 or 10W-30

from -25 to +35 °C ............................................................. Synthetic 5W-30 or 10W-30

6.3 6.4

1

1

4

3

2

MAX

MIN

4

MAX

MIN

6.5

3

54

3a

6.6

1

2

4

2 1 3

3

2

3a

1

3

0,6-0,8

mm

6.7

4

1 1

4

1

2 3

© by GGP - ITALY

Realizzazione: EDIPROM / bergamo

GGP ITALY

Via del Lavoro, 6

I-31033 Castelfranco Veneto (TV) ITALY

SPA

171520152/1

Loading...

Loading...