+GF+ SIGNET 9030 Intelek-Pro Instruction Manual

+GF+

pH Controller

SIGNET 9030 Intelek-Pro

Instruction Manual

GEORGE FISCHER +GF

+

Important Safety Information!

CAUTION: Remove AC power to unit prior to

wiring input and output connections.

Remove AC power before opening unit. Electrical

shock hazard exists

Chapter Page

1 Introduction 1

1.1 Introduction 1

1.2 Front Panel Description 2

1.3 Rear Panel Description 3

2 Installation and Operation 4

2.1 Mounting Instructions 4

2.2 Power Connections 5

2.3 Input Connections 6

2.4 2-Relay Output Connections 7

2.5 Dual Proportional Relay Connections 8

2.6 Verifying Analog Outputs 9

2.7 Analog Output Connections 10

3 System Configuration 10

3.1 Introduction 10

3.2 Calibration Menu, pH Sensor Inputs 12

3.3 Calibration Menu, Analog Inputs 13

3.4 2-Relay Operation 15

3.5 Dual Proportional Relay Operation 15

3.6 Calibration Menu, Relay Outputs 17

3.7 Calibration Menu, Analog Outputs 19

3.8 View-Only Menus 20

Table of

Contents

4 Technical Support 21

4.1 Accessing Internal Options 21

4.2 AC Power Configurations 22

4.3 Security Code Function 22

4.4 Installing Input/Output Options 23

4.5 Input Card Introduction Mode 23

4.6 Option Cards and Accessories 28

4.7 Output Card Configurations 29

4.8 Troubleshooting 30

Specifications 31

Warranty Information 33

Unpacking and Inspection

Your pH controller package includes the following

items:

•+GF+ SIGNET 9030 Intelek-Pro pH Controller

• Two stainless steel mounting brackets

• Mounting Instructions w/self-adhesive template

• Panel gasket

• Instruction manual w/warranty card

Please fill out and return warranty card as soon as

possible.

Warranty Record

For your protection, record your unit's purchase

date and serial number for future reference. The

serial number decal is located on the instrument's

rear panel.

Model: +GF+ SIGNET 9030 Intelek-Pro

pH Controller

Purchase Date: _______________________

Serial Number: ________________________

Purchased From: _______________________

Purchase Order Number: _______________

1.1 Introduction

Your new +GF+ SIGNET 9030 Intelek-Pro pH

Controller has been specifically designed for pH

measurement process control applications. The

controller's compact 1/4 DIN enclosure (front) is

NEMA 4X/IP65 rated and ideal for installation

into instrumentation panels with limited space.

Modular "plug-in" input/output option cards allow

you to customize your pH controller to your

system's requirements. The controller's unique

"slide-out" chassis design makes option installation

fast and simple. Smart self-configuring

microprocessor based circuitry automatically

inventories installed options during power-up,

allowing you to upgrade your system in seconds

without the need for additional equipment.

The unit's front panel features a highly visible

4.5-digit (seven segment) and 8-digit (alphanumeric) liquid crystal display with adjustable contrast. Active pH, mV, temperature in °C, and

alarm relay status information is quickly accessed

at a glance. During calibration the user is

prompted with clear step-by-step instructions on the

unit's front panel display.

Chapter 1

Introduction

The +GF+ SIGNET 9030 Intelek-Pro pH Controller

is fully compatible with all +GF+ SIGNET pH

sensor products, yet also accepts other analog

inputs, such as 4 to 20 mA or 0 to 5 VDC etc.

The technical data given in

this publication is for general

information purposes only. It

implies no warranty of any

kind.

1

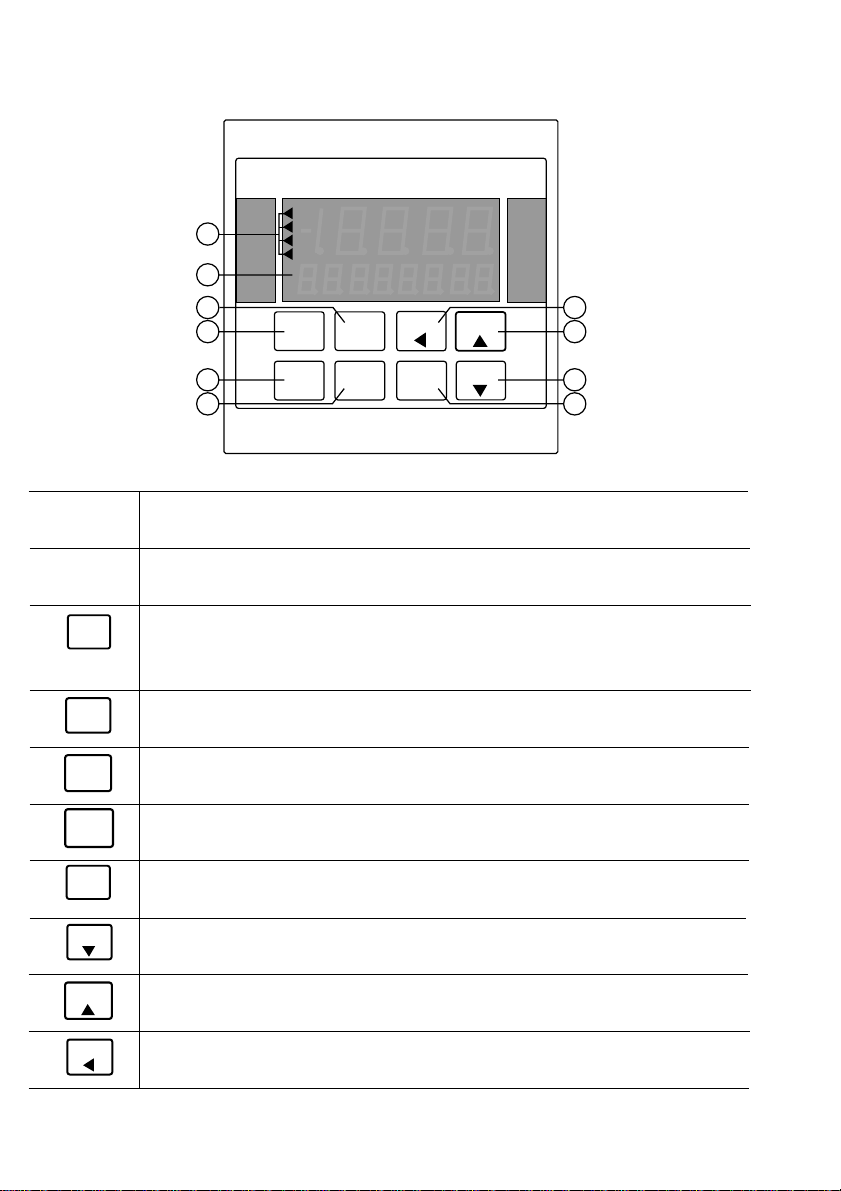

1.2 Front Panel Description

pH CONTROLLER

RLY 1

RLY 2

1

RLY 3

RLY 4

2

3

4

ENTER MOD

mV

pH

10

9

5

6

Item Function

1. Relay An-

nunciators:

Display:

3.

MOD

4

.

ENTER

5.

CAL

6.

RELAY

7.

OUTPUT

TEMP

8.

mV

9.

Indicate activation status of optional output "alarm" relays 1 & 2 and additional

relays 3 & 4 (proportional or on/off control)

Shows pH, mV, temperature in °C, and relay activation status information2. LCD

A) Accesses one of three calibration menus: CAL, RELAY, OUT B) Enables a

calibration parameter for modification C) Restores a calibration parameter to

it's original value during calibration.

A) Stores a calibration value into memory after modification B) Used to

display available input/output options during normal operation.

A) Accesses the CAL "view-only" menu B) Used in conjunction with MOD key to

access the main CAL menu

A) Accesses the RELAY "view-only" menu B) Used in conjunction with MOD key

to access the RELAY calibration menu

A) Accesses the OUTPUT "view-only" menu B) Used in conjunction with the

"MOD" key to access the OUTPUT calibration menu

A) Displays temperature in degrees Celsius during normal operation

B) Decreases the value of a selected calibration digit

A) Displays mV during normal operation B) Increases the value of a selected

calibration digit

CAL RELAY

+GF+

OUTPUT

SIGNET

TEMP

8

7

10.

2

pH

A) Returns the unit to normal operation mode B) Selects a digit for modification

during calibration.

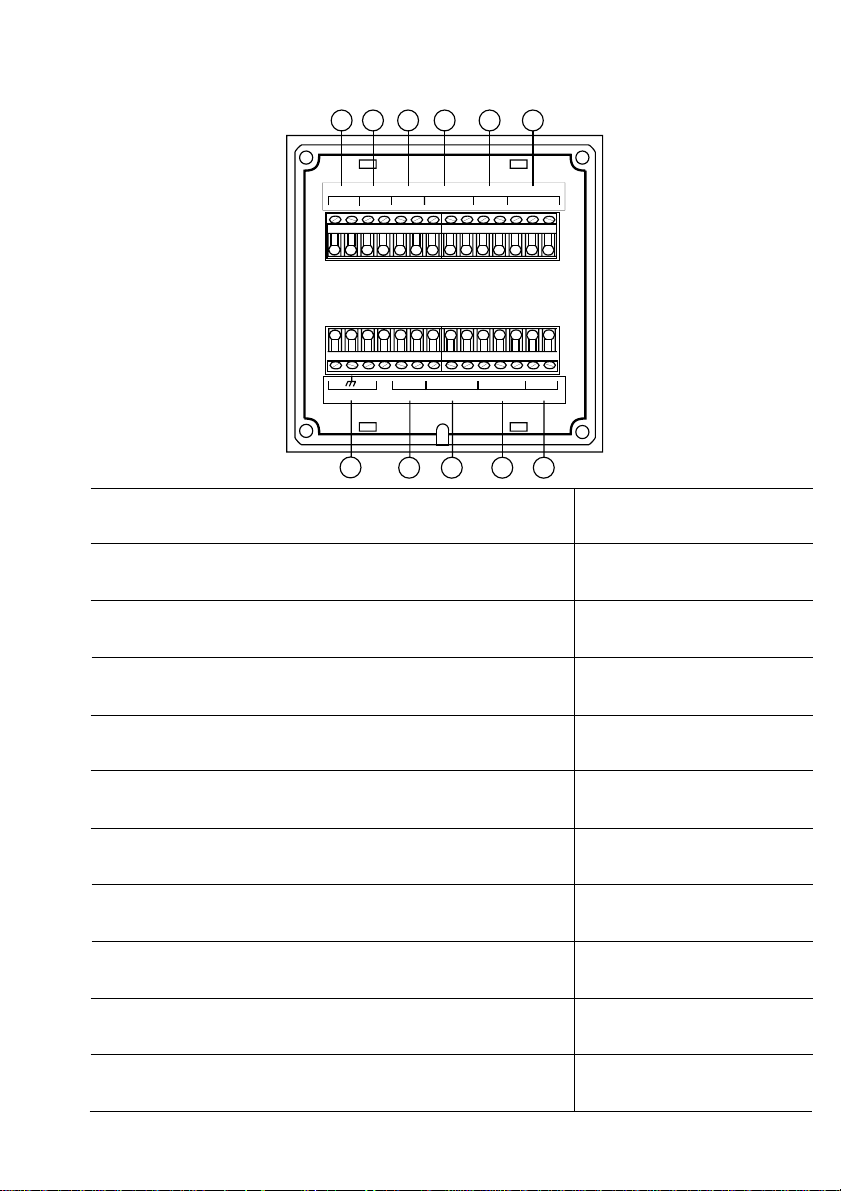

1.3 Rear Panel Description

10

11

8

9

6

7

RLY3

RLY4

CNO

CNO

1 2 3 4 5 6 7 8 9 10 11 12 13 14

ANL2

R+ R-

SERIAL

Tx GND Rx

PRE-AMP

V+ V-

INPUT

T+ Ain ISO

Note:

accept 18 to 22 AWG

15 16 17 18 19 20 21 22 23 24 25 26 27 28

L1

N

AC IN

1

+ GND

2

NO C NC

RLY1DC IN

3 4

90 to 132 VAC or 180 to 264 VAC system power

NO C NC

RLY2

R+ R-

ANL1

5

wire

ItemFunction

1. AC IN

connection

17 to 30 VDC system power connection

Alarm relay #1 (COM, NO, NC) contact set for external

2. DC IN

3. RLY1

device control (optional)

Alarm relay #2 (COM, NO, NC) contact set for external

4. RLY2

device control (optional)

Analog output #1 from option socket #1 (optional) 5. ANL1

Rear terminals

Sensor input connections

±5 VDC @ 1 mA power output for pH sensor pre-amp circuit

Serial outputs (future availability)

Analog output #2 from option socket #2 (optional)

Proportional control relay #4 (COM, NO) contact set for

external device control (optional)

Proportional control relay #3 (COM, NO) contact set for

external device control (optional)

6. INPUT

7.

PRE-AMP

. SERIAL

8

. ANL2

9

10

. RLY4

11. RLY3

3

Chapter 2

Installation

and

Operation

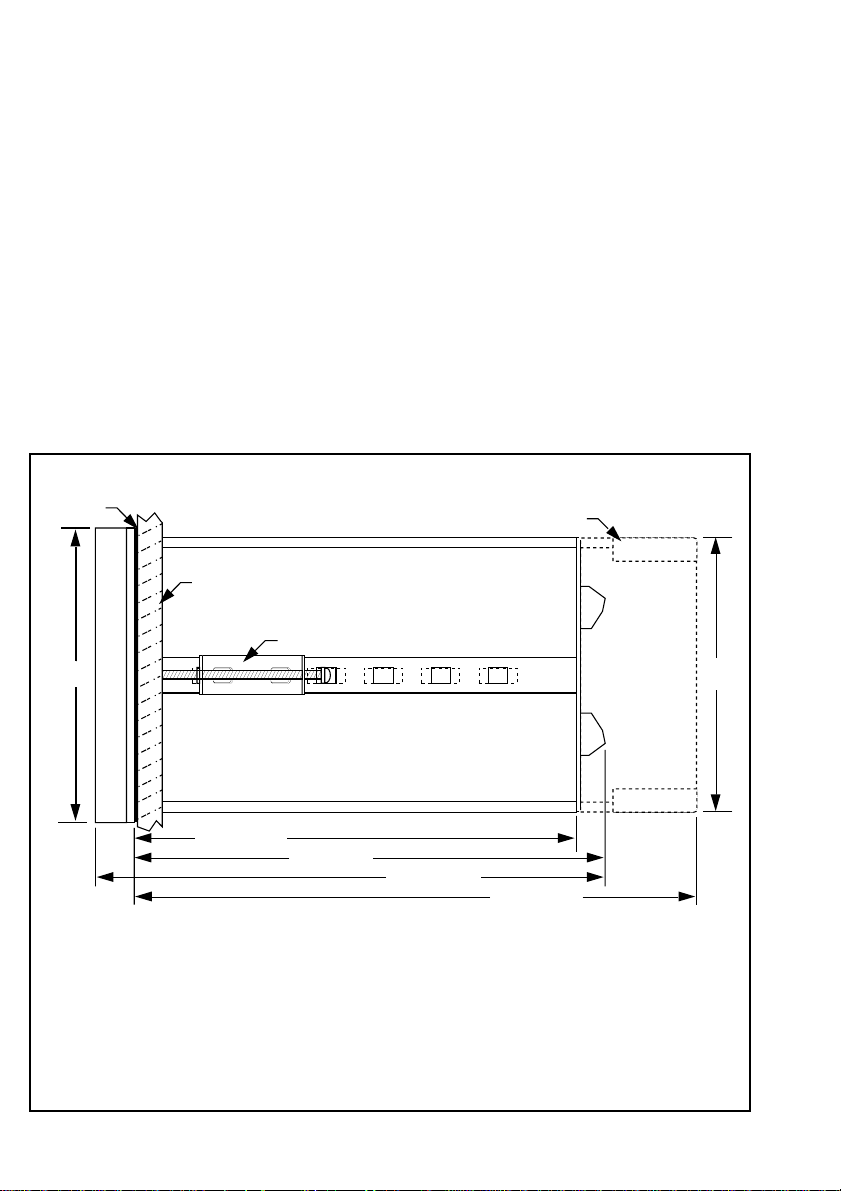

Figure 1

External dimensions

2.1 Mounting Instructions

The +GF+ SIGNET Intelek-Pro pH Controller's 1/4

DIN enclosure is specifically designed for panel

mounting. Adjustable mounting brackets allow

mounting in panels up to one inch (25 mm) thick.

An adhesive template and instructions are included

to insure proper installation.

For outdoor and/or stand alone installations the

splash-proof NEMA 4X/IP65 back cover kit is

recommended (ordered separately).

Panel

Gasket

3.8 in. sq.

96 mm

Mounting Panel

Max. panel thickness = 1 in./25 mm

Mounting Clamp (included, 2 ea.)

SIDE VIEW

5.7 in./145 mm

6 in./152 mm

*Optional NEMA 4X/IP65 Rear Cover

6.5 in./165 mm

7.2 in./183 mm

3.5 in.

88 mm

Panel Cutout Instructions

Recommended panel cutout 3.54 inch (90 mm) square. Maximum panel cutout 3.62 inch

(92 mm) square, DO NOT exceed. Use adhesive backed template (included)

4

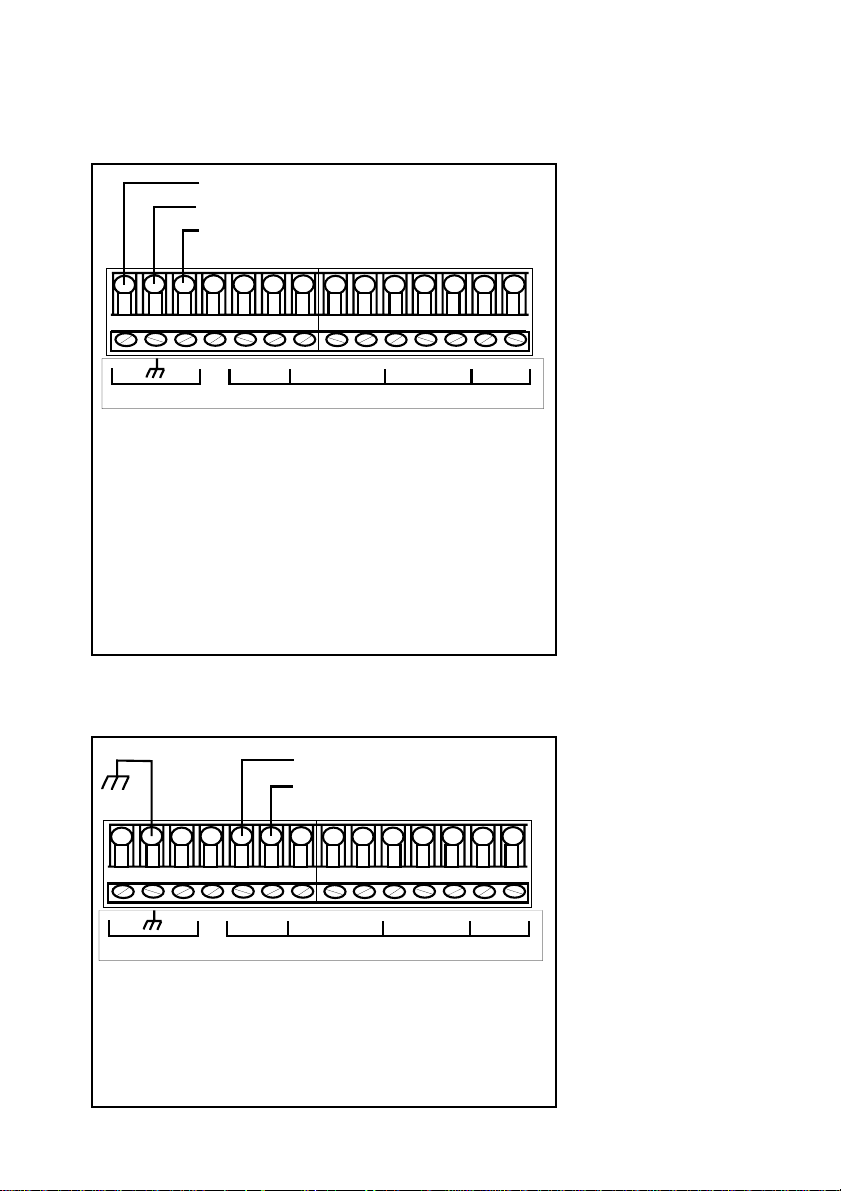

2.2 Power Connections

AC Power Connections

AC Hot

AC Ground*

AC Neutral

15 16 17 18 19 20 21 22 23 24 25 26 27 28

90 to 132 VAC

OR

180 to 264 VAC

Figure 2

AC power wiring

Note: DC power

recommended when ground

fault interruption devices

(GFI's) are used.

L

1

N

AC IN

+ GND

NO C NC

RLY1DC IN

NO C NC

RLY2

R+ R-

Instructions

1. Jumper selectable for 90 to 132 OR 180 to 264

VAC operation. Confirm AC power configuration before

applying power. See section 4.2

2. *A direct or low impedance AC ground (earth

ground) MUST be used for proper operation.

3. To reduce the possibility of noise interference, AC

power lines must be isolated from signal lines.

DC Power Connections

*

15 16 17 18 19 20 21 22 23 24 25 26 27 28

L

1

N

AC IN

17 to 30 VDC @ 0.5 A

GND

NO C NC

+ GND

RLY1DC IN

NO C NC

RLY2

R+ R-

ANL1

Figure 3

DC power wiring

ANL1

Note: AC/DC power can be connected simultaneously,

using DC power as an uninterrupted power source.

*A direct or low impedance earth ground must be used

for optimum performance

5

Note:

See section 4.6 for a

listing of available input cards

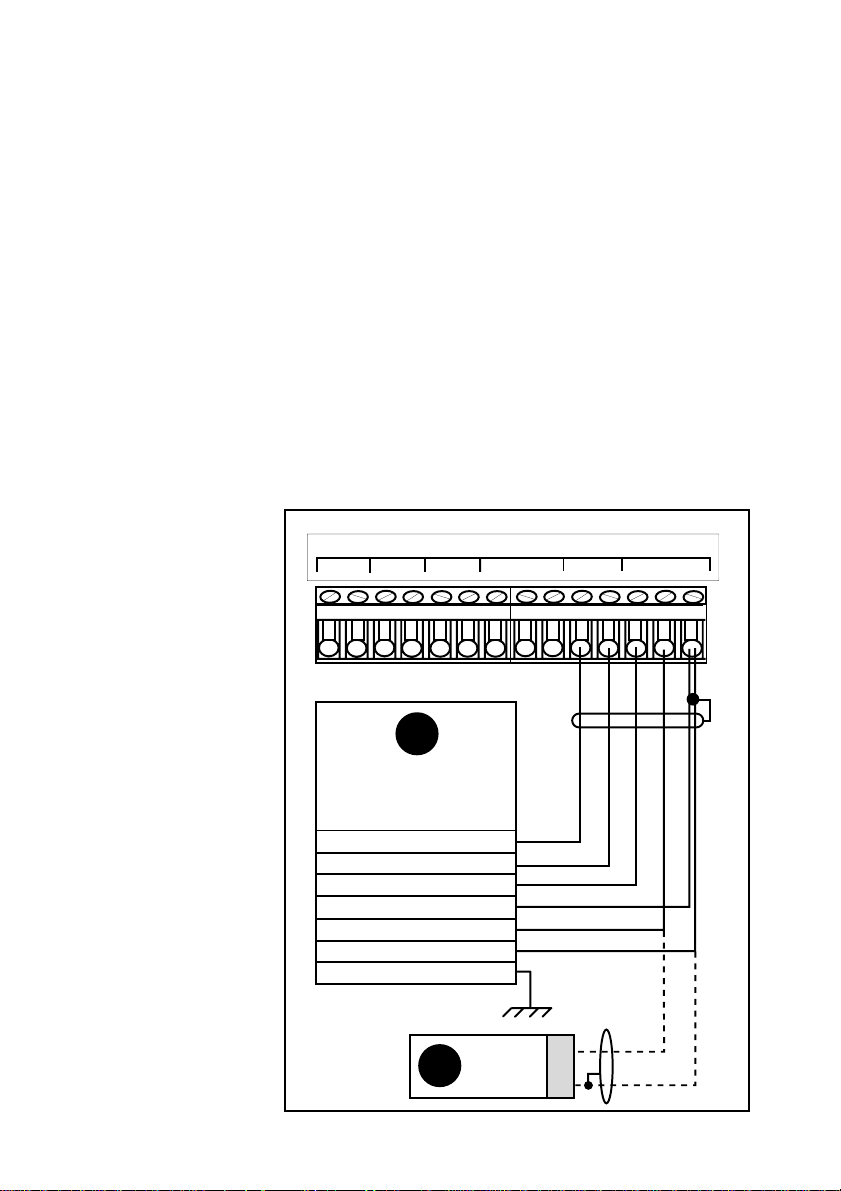

Figure 4A

Input Wiring

2.3 Input Connections

Three input options are available, providing a

wide range of compatibility for most applications.

pH Input Card

Provides isolated pH sensor input capability,

requiring no internal configuration.

Analog Input Cards

Two analog input options available:

• Analog (iso) current, 4 to 20/0 to 20 mA

• Analog (iso) voltage, 0 to 5/0 to 10 VDC

Input ranges are software selectable, requiring no

internal configuration.

RLY3

CNO

RLY4

CNO

R+ R-

ANL2

SERIAL

Tx GND Rx

PRE-AMP

V+ V-

INPUT

T+ Ain ISO

To reduce the possibility of

noise interference, separate

input lines from AC power

lines.

6

1 2 3 4 5 6 7 8 9 10 11 12 13 14

A

+GF+

SIGNET 3-2720

pH/ORP Pre-amplifier/

Sensor System

RED

BLACK

GREEN

WHITE

BROWN

BLUE

SILVER

B

Analog

Inputs

earth

ground

R+

R-

OR

RLY3

CNO

CNO

1 2 3 4 5 6 7 8 9 10 11 12 13 14

External

RLY4

ANL2

R+ R-

+

DC Power

Supply

-

SERIAL

Tx GND Rx

+-

+GF+

SIGNET

pH/ORP Transmitter

PRE-AMP

V+ V-

+GF+

SIGNET

8710

INPUT

T+ Ain ISO

2.4 2-Relay Output Connections

The 2-Relay option provides two relays for external

device control. Each relay's contacts are rated for

5 A maximum. Both NO and NC contacts may

be used simultaneously or individually as shown.

Figure 4B

2-Wire Transmitter Wiring

To reduce the possibility of

noise interference, separate

input lines from AC power

lines.

Figure 5

2-Relay wiring

-

Device A

+

-

External

+

AC/DC

Power

Source

NO C NC

RLY2

R+ R-

+ GND

+

NO C NC

RLY1DC IN

-

Device B

15 16 17 18 19 20 21 22 23 24 25 26 27 28

L1

N

AC IN

Note:

Relay contacts are rated as 5 A @ 250 VAC or

5 A @ 30 VDC maximum resistive load.

Device A is powered during

normal operation. Power is

discontinued when relay is

energized. Device B is not

powered during normal

operation. Power is applied

after relay is energized.

ANL1

To reduce the possibility of

noise interference, separate

AC relay lines from input/

output lines.

7

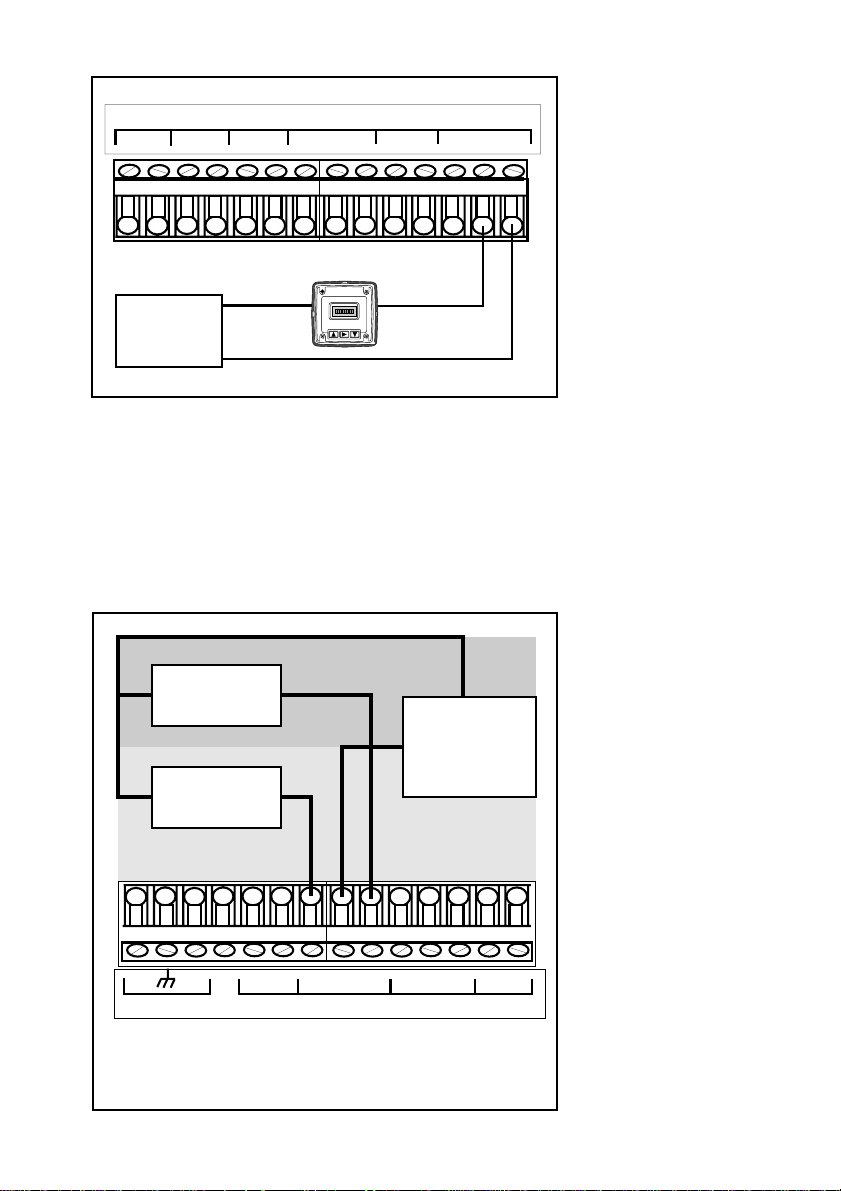

Figure 6

1 2 3 4 5 6 7 8 9 10 11 12 13 14

CNO

RLY3

RLY4

SERIAL

Tx GND Rx

PRE-AMP

V+ V-

T+ Ain ISO

INPUT

CNO

ANL2

R+ R-

Trig. A

Trig. A

-

+

+

-

Metering

Pump A

Trig. B

Trig. B

-

+

+

-

Metering

Pump B

External

AC/DC

Power

Source

External

AC/DC

Power

Source

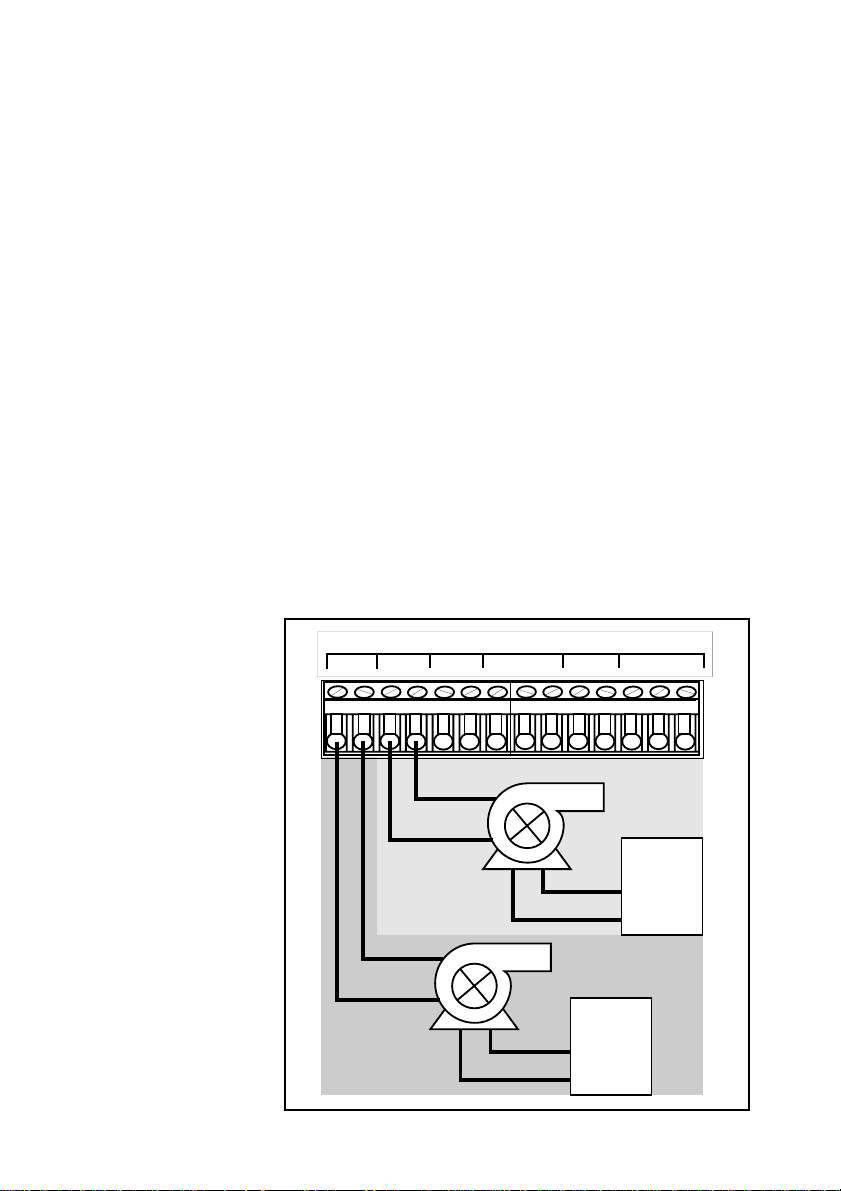

Proportional Control Wiring

2.5 Dual Proportional Relay Connections

The Dual Proportional Relay Card provides two

relays (3 and 4) for external device control.

Proportional or alarm operation is selectable

during calibration. Both relays MUST be like

configured, meaning one relay cannot be selected

for proportional operation while the other is

selected for alarm operation.

If alarm operation is selected, relays 3 and 4

operate as on/off controls similar to relays 1 and

2. The main distinction is the lack of the normally

closed (NC) contact. Refer to Figure 5 pg# 7 for

further instructions.

If proportional operation is selected, relays 3 and

4 are configured to provide a varying pulse rate to

control metering pumps. Relay 3 is dedicated to

low range control and relay 4 to high range

control.

Note:

rated as 5A @ 250 VAC or

5A @ 30 VDC maximum

resistive load.

Relay contacts are

To reduce the possibility of

noise interference, separate

AC relay lines from input/

output lines.

8

2.6 Verifying Analog Outputs

Installed output options can be configured to either

of the unit's rear analog output terminals: ANL1 or

ANL2. Configuration is determined by which

sockets the options are installed. Options installed

in option socket #1 are configured to the rear

ANL1 terminals, options installed in socket #2 are

config-ured to the rear ANL2 terminals, see

section 4.4.

Prior to connection, determine which options are

configured to terminals ANL1 and ANL2 as

follows:

1. Apply power to unit.

2. Press:

ENTER

Available input/output options are

individually prompted on the display.

3. Record option configurations for ANL1 and

ANL2 in the spaces provided. This information is

necessary for wiring analog outputs in the next

section.

ANL1=

(i.e. 4 to 20 mA)

ANL2=

(i.e. N/A)

Option Record

Note:

The unit display's

N/A for unavailable options

9

Loading...

Loading...