Getemed VitaGuard 300, VitaGuard 310, VitaGuard 2000, VitaGuard 2100, VitaGuard 3000 Replacement of internal battery

...Page 1

Technical Documentation

VitaGuard VG 3000 / VG 2000 / VG 300

Service Documentation - Replacement of Internal Battery

Project ID : 9204H1

Page 1 / 6

1 Purpose

This document describes how to replace the internal back-up battery.

2 Description

2.1 Devices

This section describes how to replace the internal back-up battery in the following devices.

Device types Serial number beginning from

VitaGuard

VG 300 SN > 251 99 0001

VG 2000 SN > 252 99 0001

VG 3000 SN > 253 99 0016

Werner & Müller RW 300 SN > 261 99 0001

RW 2000 SN > 262 99 0201

RW 3000 SN > 263 99 0001

Messer Medical / PX1 SN > 271 99 0001

Air Products SD1 SN > 272 99 0201

SD2 SN > 273 99 0001

Before replacing the internal back-up battery on a device from the above list, the

employee must check the current device status (firmware and hardware version).

Checking the current device status

To ensure the device status is up to date, the following needs to be checked:

Status Device version PC/ECG connector

EPROM V3.1.0 All Metal 8 pin or 14 pin

EPROM V3.3.0 All B678 plastic 14 pin

If the firmware is below V3.1.0, please contact getemed’s technical service to clarify the

current device status.

2.2 Required tools

The following tools are required:

§ Phillips screwdriver PZ1

§ Phillips screwdriver PH1

§ Hexagonal socket wrench SW 5,0

§ Soldering iron

§ Digital multimeter

9204-TD-0013-Rev B-Service-Replacement of Internal Battery.doc

CONFIDENTIAL AND PROPRIETY

Page 2

Technical Documentation

VitaGuard VG 3000 / VG 2000 / VG 300

Service Documentation - Replacement of Internal Battery

Project ID : 9204H1

Page 2 / 6

2.3 Required materials

The following materials are required:

• Tin solder

• Silicone adhesive

By a getemed Repair Kit

(look here: 9204-TD-0012-Rev A-Service-VitaGuard General equirements)

• 10 cm self-adhesive copper strips (5 x 2 cm each)

• rubber feet

• lithium battery 3V Varta CR2430 LF

3 Work Instructions

The maintenance work for each device must be documented in the protocol “9204-TD0013-A1-Service-Protocol for Replacement of Internal Battery”. A copy of the protocol

shall be sent to getemed AG.

3.1 Device type

The device type is read from the label. Tick the appropriate device type in the protocol.

3.2 Serial number

The serial number is read from the label and entered in the protocol.

3.3 Maintenance work

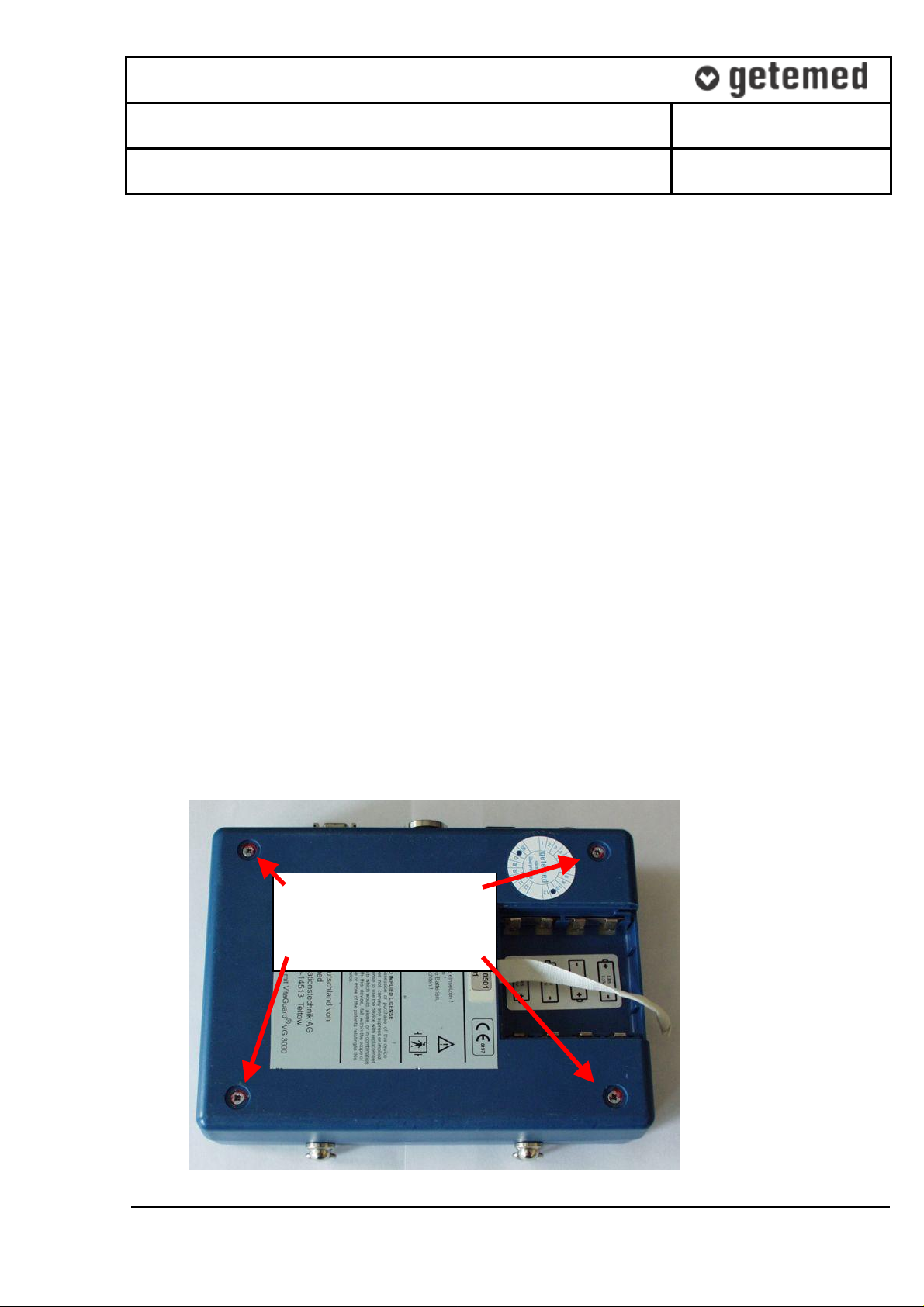

3.3.01

Remove housing screws

3.3.01 Remove the rubber feet and open the housing.

9204-TD-0013-Rev B-Service-Replacement of Internal Battery.doc

CONFIDENTIAL AND PROPRIETY

Page 3

Technical Documentation

VitaGuard VG 3000 / VG 2000 / VG 300

Service Documentation - Replacement of Internal Battery

Project ID : 9204H1

Page 3 / 6

3.3.02 When opening the housing, pay attention to the copper strips used to improve electrical

contact between the housing halves.

3.3.02

Pay attention to

the copper stripes

3.3.05

Loosen these 4 screws

3.3.03 To prevent other hardware failures, measure the voltage of the internal back-up battery.

The voltage PWR_BACKUP is measured from positive pole of CT13 against ground. If

the measured voltage is above 3.0V, the back-up battery is good.

3.3.04 Remove jumper JU4 to break the battery circuit.

3.3.05 Loosen the motherboard with a screw driver or socket wrench, depending on how the

main board is fixed to the casing.

3.3.05

Example:

Main board

mounted with

nuts

9204-TD-0013-Rev B-Service-Replacement of Internal Battery.doc

CONFIDENTIAL AND PROPRIETY

Page 4

Technical Documentation

VitaGuard VG 3000 / VG 2000 / VG 300

Service Documentation - Replacement of Internal Battery

Project ID : 9204H1

Page 4 / 6

3.3.06 The main board is connected to the housing with wires soldered to adhesive copper

strips. Remove the self adhesive copper strips from the housing in order to lift the main

board out of the housing.

3.3.06

Copper stripes

3.3.04

Jumper

3.3.07 The buzzer is connected to the motherboard with 2 wires. Unsolder the wires and

carefully raise the motherboard.

3.3.08 While raising the motherboard, pay attention to the keypad connector and remove the

connector.

3.3.07

Buzzer

3.3.08 Connector for

keypad

9204-TD-0013-Rev B-Service-Replacement of Internal Battery.doc

CONFIDENTIAL AND PROPRIETY

Page 5

Technical Documentation

VitaGuard VG 3000 / VG 2000 / VG 300

Service Documentation - Replacement of Internal Battery

Project ID : 9204H1

Page 5 / 6

3.3.09 Heat the outer ends of the solder tabs and lift off the sides. Remove the back-up battery.

3.3.09 Back-up battery with

solder tabs

3.3.10 Solder in a new back-up battery: The positive side of the battery points in the direction of

the keypad connector. Measure the battery to see if voltage is above 3.0 volts.

3.3.10 Measure voltage

3.3.11 Reconnect the keypad connector to the main board. Solder the buzzer wires back to the

solder pads on the main board.

3.3.12 Fit the main board back into the casing and solder the wires to new self adhesive copper

strips. Stick these onto the housing corners.

3.3.13 Prior to tightening the main board, align the display so that it is straight.

9204-TD-0013-Rev B-Service-Replacement of Internal Battery.doc

CONFIDENTIAL AND PROPRIETY

Page 6

Technical Documentation

consumption

VitaGuard VG 3000 / VG 2000 / VG 300

Service Documentation - Replacement of Internal Battery

Project ID : 9204H1

Page 6 / 6

3.3.14 Measure the current consumption at jumper JU 4. The measured value should be less

than 30 µA.

3.3.14 Measure current

3.3.15 Attach jumper JU 14 again and secure it with silicone adhesive.

3.3.16 Visually inspect soldered wires, mounting of the main board and, where appropriate, the

Masimo board. Check the position of wires and flat cables to other components and

housing. Make sure nothing is pinched or torn off.

3.3.17 The copper strips must be clamped securely before the housing is closed.

3.3.18 If both housing parts fit closely together, insert and tighten the housing screws.

3.3.19 Stick new rubber feet on the screws.

4 Functional check:

4.1 Remove the alkaline batteries from the battery compartment and then remove power

adapter during device operation. Ensure that the device outputs a permanent warning

tone. If the test is not passed, replace C7 according to “9204-TD-0014-Rev A-ServiceReplacement of Capacitor C7”.

4.2 Test the device according to work procedure AA30.

Please forward getemed a copy of the protocol together with the Maintenance Declaration so

that we can update our device database.

9204-TD-0013-Rev B-Service-Replacement of Internal Battery.doc

CONFIDENTIAL AND PROPRIETY

Loading...

Loading...