Getemed VitaGuard 300, VitaGuard 310, VitaGuard 2000, VitaGuard 2100, VitaGuard 3000 Test procedure

...Page 1

Page 2

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

8 Equipment and Materials

The equipment listed below marked R is the equipment used by getemed AG. Similar

models from other manufacturers can be used as long as the performance is similar.

The model numbers of the equipment listed with getemed AG as manufacturer

correspond with the ordering (REF) numbers, should the distributor wish to purchase

the equipment from getemed.

Equipment Model / REF Manufacturer

Power adapter NA 3000-2 7344 1101 getemed AG

ECG patient cable 7341 1001 getemed AG

Masimo SpO2 cable PC08 70257 getemed AG, Masimo

Masimo SpO2 Sensor DC I 70254 getemed AG, Masimo

PC Interface cable (USB-Kabel) 7341 2001 getemed AG

VitaWin software VitaWin 3 getemed AG

R 1A / 3-6V power supply HM7042 Hameg

R Digital Multimeter Model 87 Fluke

R ECG/Respiration patient simulator 214B DNI Nevada Inc.

R SpO2 patient simulator Oxitest Plus DNI Nevada Inc.

R Stop watch - R Safety tester Unimet 1000 ST Bender

R Test PC with Windows 2000 or XP - -

0027-TD-0027-Rev C

9 Procedure

The procedure is divided into 4 sections:

· Visual inspection of the monitor

· Functional measurements

· Safety inspection

· Visual inspection of accessories

For easy reference, the numbers of this procedure correspond with the numbers in

the test report.

Before beginning the test procedure, the revision stand of the monitor should be

checked. The distributor should contact getemed on a regular basis at

service@getemed.de in order to determine if changes are necessary.

Should the monitor under test show any signs of malfunction, then it must be returned

immediately to getemed AG for inspection.

The test reports must be archived for at least 10 years and made available to

getemed AG on request.

The distributor shall maintain a database showing when a monitor was last tested and

by whom.

The remaining part of section 9 explains how to perform the test procedure. To

correspond with the test report, numbering will begin with 9.7.1.

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 2 of 11

Page 3

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

9.7.1 Visual inspection of the monitor

The first section of the test report is the visual inspection of the monitor.

9.7.1-1 Labels

All three labels listed in box 1 must be readable and free from damage. If this is the

case, then box 1 can be ticked-off with o.k.

The following labels are readable and not damaged:

· Top label with keys (key panel)

1

· Label on the back of the monitor with serial number and

safety warnings; warning label in battery compartment.

· Label stripe at the front marking all inputs

9.7.1-2 Connectors

The connectors listed in box 2 must be fitted tightly. The connector pins must be

visually inspected to ensure that none of them are damaged. If this is the case, then

box 2 can be ticked-off with o.k.

The following connectors are fitted tightly and not damaged:

· ECG input (VG 3100 and VG 2100 only)

· NA 3000-2 power supply input

2

· SpO2 input (VG 3100 and VG 310 only)

· USB input

· AUX input

9.7.1-3 Casing and LCD display

0027-TD-0027-Rev C

o.k.

o.k.

The monitor casing must not be cracked or have any significant scratches. The LCDdisplay must also be free from damage. If this is the case, then box 3 can be tickedoff with o.k.

3 The monitor casing and the LCD display are not damaged. o.k.

9.7.2 Functional measurements

The second section of the test report involves measuring parameters and performing

functional tests.

The external power adapter NA 3000-2 used must be modified to measure the current

flowing to the monitor. To do this, cut the positive wire going to the monitor and attach

two 4 mm connector jack plugs to the loose ends. These can then be inserted into a

multimeter.

It is assumed that the default settings are selected before beginning the test

procedure.

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 3 of 11

Page 4

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

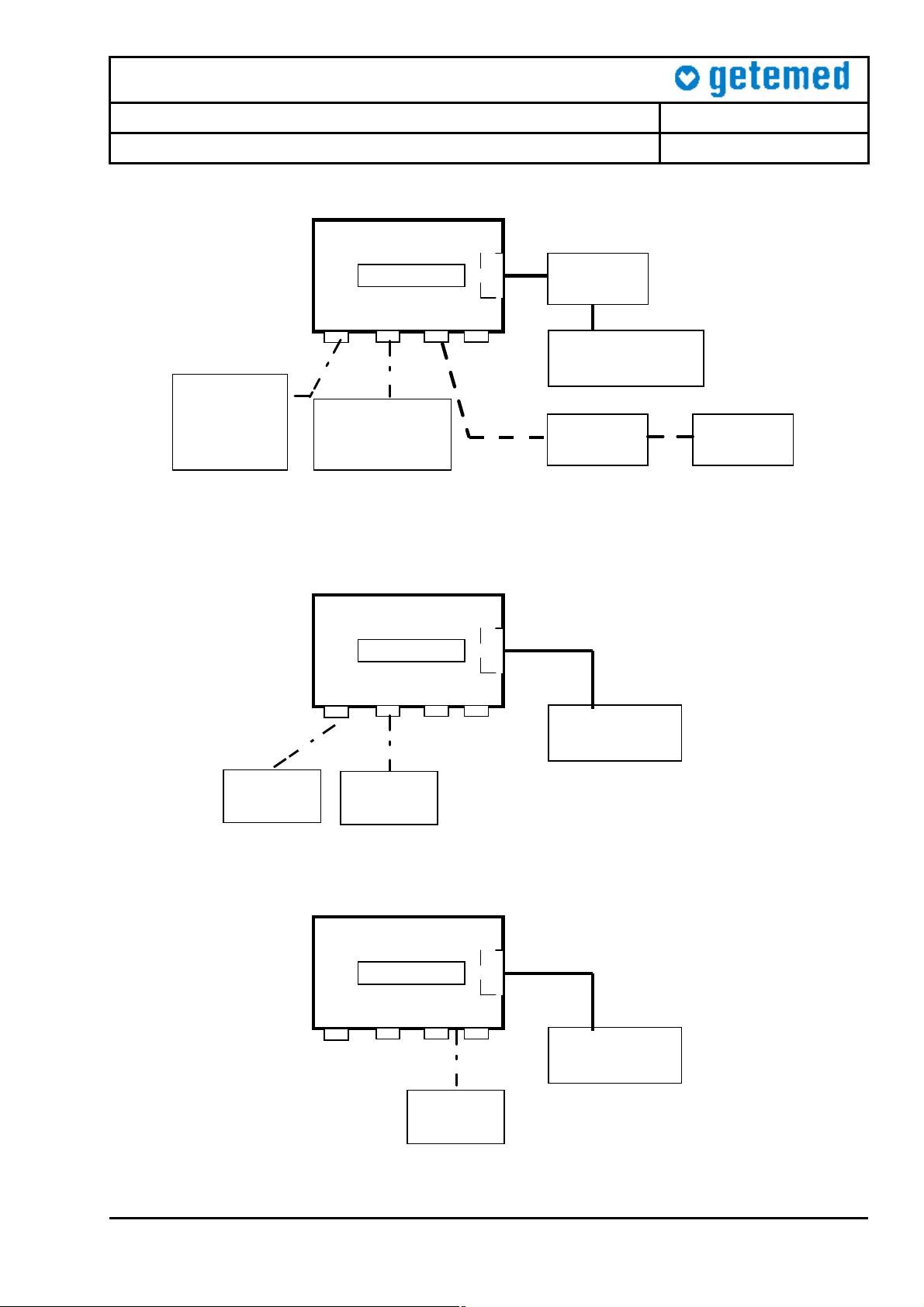

0027-TD-0027-Rev C

VitaGuard

Monitor

Comp.

Battery

Digital-

Multimeter

(1)

Power supply

3-6V / 2A

Digital-

Multimeter

NA 3000-2

SpO2Sensor

and

simulator

(3)

SpO2 ECG

Power

AUX

(4)

Patient

simulator

(2)

Figure 1 – Current Measurement Set-Up

VitaGuard

Monitor

Battery

Comp.

SpO2 ECG Power

AUX

Power supply

3-6V / 1A

SpO2

Simulator

PatientSimulator

Figure 2 – Alarm Measurement Set-Up

VitaGuard

Monitor

Battery

Comp.

SpO2 ECG

USB

Power AUX

Power supply

3-6V / 1A

PC

VitaWin

Figure 3 – PC Measurement Set-Up

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 4 of 11

Page 5

Service Manual - Test Procedure

B 3 2 1

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

Power

adapter

UNIMET 1000

VG2100/3100/310

0027-TD-0027-Rev C

LCD

Monitor

A

SpO2

ECG

Pwr

USB

AUX

Figure 4 – Patient Safety Tester

9.7.2-1 Current from batteries when monitor switched off

Connect the monitor as shown in Fig. 1 with NA 3000-2 disconnected. Set the output

voltage of the power supply to 6 V. Read the current flowing through the multimeter

(1) while the monitor is switched off. This value should be less than 200 µA. If this is

the case, then enter the value in the box provided.

1 Current from batteries when monitor switched off < 200 µA

9.7.2-2 Current from batteries when monitor switched on

Connect the monitor as shown in Fig. 1 with NA 3000-2 disconnected. Set the output

voltage of the power supply to 6 V. Switch the monitor on and wait until the standard

display appears. Read the current flowing through the multimeter (1). When testing

VG 3100, read the values with the SpO2 module switched on. Enter the values in the

boxes provided.

2 Current from batteries, when monitor switched on

a VG 2100 40 ... 55 mA

b VG 3100, (SpO2 on) 60 ... 83 mA

c (from SN 80105050395) VG 310, (SpO2 on) 55 ... 63 mA

d (from SN 801040001 to SN 801050394) VG 310, (SpO2 on) 60 ... 75 mA

9.7.2-3 Current from batteries when NA 3000-2 connected

Connect the monitor as shown in Fig. 1. Connect the external power adapter NA

3000-2 to the monitor and read the current flow through multimeter (1). Enter the

value in the box provided.

3 Current from battery when NA 3000-2 connected < 5 µA

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 5 of 11

Page 6

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

0027-TD-0027-Rev C

9.7.2-4 Current from NA 3000-2 when monitor switched off

Connect the monitor as shown in Fig. 1. Switch the monitor off and read the current

flowing through multimeter (2). Enter the value in the box provided.

4 Current from NA 3000-2 when monitor switched off 4,5 ... 6 mA

9.7.2-5 Current from NA 3000-2 when monitor switched on

Connect the monitor as shown in Fig. 1. Switch the monitor on and wait until the

standard display appears. Read the current flowing through multimeter (2). When

testing VG 3100 ensure that the SpO2 module is switched on. Enter the values in the

boxes provided.

5 Current from NA2000-2, when monitor switched on

a VG 2100 107 ... 125 mA

b VG 3100, (SpO2 on) 125 ... 140 mA

c (from SN 80105050395) VG 310, (SpO2 on) 120 ... 128 mA

d (from SN 801040001 to SN 801050394) VG 310, (SpO2 on) 125 ... 135 mA

9.7.2-6 Green power LED

Connect the monitor as shown in Fig. 1. When the external adapter NA 3000-2 is

connected, the green power LED on the monitor front panel must illuminate. This

must happen when the monitor is switched on or off.

6 Green LED lights when NA 3000-2 connected o.k.

9.7.2-7 LCD backlight

Connect the monitor as shown in Fig. 1. When the external adapter NA 3000-2 is

connected and the monitor is switched on, the LCD backlight must illuminate. Ensure

that the brightness setting is > 70%

7 LCD backlight switches on when NA 3000-2 connected o.k.

9.7.2-8 Switch-over between NA 3000-2 and batteries

Connect the monitor as shown in Fig. 1. When the external adapter NA 3000-2 is

connected, the monitor switches automatically away from the batteries. When the

adapter is disconnected, the monitor switches back to battery mode. To perform the

test, remove and reconnect the adapter 3 times at the connector input in short

succession. The monitor must operate normally throughout the test. If this is the case,

enter o.k. in the box provided.

8 Automatic change-over between batteries and NA 3000-2 o.k.

9.7.2-9 Switch-over between NA 3000-2 and batteries

Connect the monitor as shown in Fig. 1. Repeat the test above. This time remove the

external adapter NA 3000-2 from the socket. The monitor must operate normally

throughout the test. If this is the case, enter o.k. in the box provided.

9 Automatic change-over when NA 3000-2 pulled from socket o.k.

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 6 of 11

Page 7

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

0027-TD-0027-Rev C

9.7.2-10 Battery symbol full

Remove the NA 3000-2 adapter and power the monitor from the Hameg power

supply, as shown in Fig. 1. Set the output voltage to 6 V. The battery symbol in the

status line must be full i.e. completely black. If this is the case, then enter o.k. in the

box provided.

10 Battery symbol full 6.0V

9.7.2-11 Battery symbol empty

Remove the NA 3000-2 adapter and power the monitor from the Hameg power

supply, as shown in Fig. 1. Set the output voltage to 4.1 V. The battery symbol in the

status line must be empty. If this is the case, then enter o.k. in the box provided.

11 Battery symbol empty

4.6 V ± 0.2V

9.7.2-12 Internal battery

Check the state of the internal battery by looking at Info window 2. The message must

read “very good”. If this is the case, then enter o.k. in the box provided.

12 Internal battery “very good” o.k.

9.7.2-13 Data retention

Connect the monitor as shown in Fig. 2. Set the apnea pause time to 12 s and the

lower heart rate to 60 /min. Switch the monitor off and back on again. These values

must reappear.

13 Parameters stay stored when monitor switched off o.k.

9.7.2-14 System LED’s

Connect the monitor as shown in Fig. 2. Switch the monitor off and back on again.

During the start-up phase, all LED’s must illuminate.

14 LED’s activated upon start-up, LCD display o.k. o.k.

9.7.2-15 System alarm buzzer

Connect the monitor as shown in Fig. 2. Switch the monitor off and back on again.

During the start-up phase, the system buzzer must sound loud and clear.

15 Buzzer sounds loud and clear o.k.

9.7.2-16 Apnea alarm

Set the apnea pause time to 12 s. Let the monitor run for 1 minute. Do not press any

keys during this time. Provoke an apnea alarm on the ECG patient simulation (4)

shown in Fig. 2. The monitor must respond with an apnea alarm within 12 s ± 2 s.

16 Apnea alarm after 12 s 10 … 14 s

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 7 of 11

Page 8

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

0027-TD-0027-Rev C

9.7.2-17 Apnea alarm

Connect the monitor as shown in Fig. 2. Let the apnea alarm continue for a further 15

seconds once the monitor has begun to alarm. The alarm must stay active for the

complete duration. Do not press any keys during this test.

17 Apnea alarm stays active for further 15 s o.k.

9.7.2-18 Basal impedance = 500 Ohm

Connect the monitor as shown in Fig. 2. Set the basal impedance on the patient

simulator to 500 W and, using the info windows, note the value for the basal

impedance measured. Ensure that lead YE-RD is selected.

18

Basal impedance = 500 W 400 ... 600 W

9.7.2-19 Basal impedance = 1000 Ohm

Connect the monitor as shown in Fig. 2. Set the basal impedance on the patient

simulator to 1000 W and, using the info windows, note the value for the basal

impedance measured.

19

Basal impedance = 1000 W 900 ... 1100 W

9.7.2-20 Open-Lead warnings

Connect the monitor as shown in Fig. 2. Disconnect the red electrode from the patient

cable. The corresponding open-lead warning message must appear on the LCD

display accompanied by a technical alarm. Do not press any keys during this test.

20 Warning when electrode removed o.k.

9.7.2-21 Heart rate display

Connect the monitor as shown in Fig. 2. Set the lower heart rate limit to 60 /min and

the upper limit to 200 /min. Using the patient simulator, increase the heart rate from

30 to 240 /min in appropriate steps. Ensure that the same heart rate is displayed on

the monitor.

21 Heart rate from 30 – 240 /min

HR ± 2 /min

9.7.2-22 Lower heart rate alarm

Connect the monitor as shown in Fig. 2. Using the patient simulator, set the heart rate

to 40 /min. Once the displayed HR falls below 60 /min, note the time for a bradycardia

alarm to appear. Do not press any keys during this test.

22 Bradycardia alarm when HR = 40 /min 4 ... 8 s

9.7.2-23 Upper heart rate alarm

Connect the monitor as shown in Fig. 2. Using the patient simulator, set the heart rate

to 240 /min. Once the displayed HR increases above 200 /min, note the time for a

tachycardia alarm to appear. Do not press any keys during this test.

23 Tachycardia alarm when HR = 240 /min 13 … 17 s

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 8 of 11

Page 9

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

0027-TD-0027-Rev C

9.7.2-24 ECG sensitivity

Connect the monitor as shown in Fig. 2. Using the patient simulator, set the ECG

amplitude to 0.5 mV. Ensure that 20 consecutive beats are registered by the monitor

by observing the heart rate LED.

24 Heart rate when signal amplitude = 0.5 mV o.k.

9.7.2-25 No ECG alarm

Connect the monitor as shown in Fig. 2. Switch the patient simulator off and note the

time for the monitor to produce a QRS! alarm. Do not press any keys during this test.

25 Alarm when no signal present 3 ... 5 s

9.7.2-26 SpO2 sensor off warning

Connect the monitor as shown in Fig. 2. Disconnect the SpO2 sensor from the SpO2

simulator. The monitor must display sensor off alarm and produce a technical alarm.

26 Sensor off: Warning and technical alarm o.k.

9.7.2-27 SpO2 measurements

Connect the monitor as shown in Fig. 2. Set the monitor such that the heart rate is

determined from the Masimo SpO2 module (SpO2 menu). Set the pulse rate of the

SpO2 simulator to 100 /min. Select 4 SpO2 values from the simulator and verify that

these values are displayed by the monitor.

27 SpO2 set to 86%, 90%, 94%, 98% with HR = 100 /min o.k.

9.7.2-28 Pulse rate measurements

Connect the monitor as shown in Fig. 2. Set the SpO2 simulator to 96%. Select 4

pulse rate values from the simulator and verify that these values are displayed by the

monitor.

28 HR set to 70, 100, 150, 200 /min with SpO2 = 96% o.k.

9.7.2-29 SpO2 low alarm

Connect the monitor as shown in Fig. 2. Set the lower SpO2 limit to 88% and the

upper SpO2 limit to 98%. Let the monitor operate for 1 minute. Set the SpO2 simulator

to 70%. Verify that an SpO2 alarm occurs within 10s after the displayed value falls

below 88%. Do not press any keys during this test.

29 SpO2 alarm when SpO2 = 70% 8 ... 12 s

9.7.2-30 SpO2 high alarm

Connect the monitor as shown in Fig. 2. Set the lower SpO2 limit to 88% and the

upper SpO2 limit to 98%. Let the monitor operate for 1 minute. Set the SpO2 simulator

to 100%. Verify that an SpO2 alarm occurs within 10 s after the displayed value rises

above 98%. Do not press any keys during this test.

30 SpO2 alarm when SpO2 = 100% 8 ... 12 s

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 9 of 11

Page 10

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

9.7.2-31 Alarm episodes

Connect the monitor as shown in Fig. 3 and activate the VitaWin software on the PC.

Download the alarm episodes stored in the monitor during testing. Examine the data

to ensure that the signals have no interference. Also, check that the time stamp is

correct. If not, set the time/date on the device.

31 Read and analyse stored episodes o.k.

9.7.2-32 Compliance protocol

Connect the monitor as shown in Fig. 3 and activate the VitaWin software on the PC.

Download the compliance protocol and examine the data.

32 Read compliance protocol o.k.

9.7.2-33 Monitor reset

Reset the monitor by executing the “Admit New Patient” function

33 Reset monitor o.k.

9.7.3 Safety inspection

0027-TD-0027-Rev C

Connect the monitor to the patient safety tester as shown in Fig. 4. Most testers

perform the tests automatically and print out a protocol. This protocol can be attached

to the test report.

The tests performed should conform to EN 60601-1, class II, CF (cardiac floating).

9.7.4 Visual inspection of accessories

All the monitor accessories must be visually inspected before use. Special care must

be taken to ensure that all cables and connectors are clean and free from damage.

Any damaged accessories must be replaced. The user manual and the packaging

must also be clean.

Nr

Measurement / Action Range Value

1 Visual inspection of ECG cable o.k.

2 Visual inspection of power adapter NA 3000-2 o.k.

3 Visual inspection of SpO2 cable (PC08 or PC12) o.k.

4 Visual inspection of user manual o.k.

5 Visual inspection of packaging o.k.

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 10 of 11

Page 11

Service Manual - Test Procedure

VitaGuard®

Projekt ID: 0027

VG 3100 / VG 2100 / VG 310

9.8 Analysis and recommendations

Upon completing the tests, the results must be summarised in the table below. Any

comments or recommendations must be documented.

Part Result Recommendation

7.1

7.2

7.3

7.4

Finally, the test engineer must check the appropriate box below, declaring whether

the monitor is suitable for further use or not.

Monitor suitable for further use: yes o no o

10 Acceptance Criteria

0027-TD-0027-Rev C

The measured values must be documented in the test report provided and the results

analysed. Any results not meeting the requirements listed are to be assessed for their

potential effect. The monitor can only be accepted for further use if all the measured

values are within their allowed tolerances. If any deviations have been detected, the

distributor must inform getemed AG. It will then be decided if the monitor should be

returned to getemed AG for inspection.

0027-TD-0027-Rev C-B5.1-Service Manual 18 Month Regular Inspection Test Procedure English.doc

Page 11 of 11

Loading...

Loading...