Page 1

Air Interface

Protocol

EPCglobal UHF Class 1 Gen 2 / ISO 18000-63 (formerly 18000-6C)

Supports dense reader mode (DRM)

Tx Output Power

+10 to +23 dBm (Peak Power)

Operating

Frequencies

IPJ-RS500-GX (902-928MHz) supports all 900MHz bands worldwide

IPJ-RS500-EU (865-868MHz) supports current EU operating band

Package

29 mm by 32 mm by 3.8 mm

Package Type

32 pin surface mount package (SMT compatible)

Rx Sensitivity

-65 dBm (1% packet error rate). Assumes a 15 dB antenna return loss at 23 dBm

output power.

DC Power Supply

3.6 to 5.25 Volts

Supported

Regions

Worldwide regional support. All major regions supported. See section 5.6 for a

complete list.

Compliance

Certified: FCC and Canada modular operation, RoHS compliant

Indy

®

RS500 Datasheet

IPJ-RS500-GX, IPJ-RS500-EU

Electrical, Mechanical, & Thermal Specification

Indy® RS500 Overview

Indy RS500 is a completely integrated UHF reader SiP

(system-in-package). It can be easily added to an

embedded system, requiring only connections to a power

source, digital communication with a host, and an

antenna. The package design allows it to be attached to a

PCB using standard surface mount technology (SMT),

with no need for additional connectors or mounting

hardware. The Indy RS500 is the easiest way to embed

UHF RFID reader capability.

For technical support, visit the Impinj support portal at support.impinj.com

Revision 1.1

For more information, contact readerchips@impinj.com

Impinj and Indy are either registered

trademarks or trademarks of Impinj, Inc.

Copyright © 2014, Impinj, Inc.

www.impinj.com

Page 2

2 Revision 1.1, Copyright © 2014, Impinj, Inc.

1 Table of Contents

INDY® RS500 OVERVIEW .......................................................................................................................... 1

1

TABLE OF CONTENTS ......................................................................................................................... 2

1.1

FIGURES ............................................................................................................................................ 2

1.2

TABLES .............................................................................................................................................. 2

2

INTRODUCTION .................................................................................................................................... 3

2.1

KEY FEATURES OF THE INDY RS500 .................................................................................................... 4

3

SYSTEM BLOCK DIAGRAM ................................................................................................................. 4

4

PIN LISTING AND SIGNAL DEFINITIONS ........................................................................................... 7

5

ELECTRICAL SPECIFICATIONS ......................................................................................................... 8

5.1

ABSOLUTE MAXIMUM RATINGS ............................................................................................................ 8

5.2

OPERATING CONDITIONS ..................................................................................................................... 9

5.3

DEVICE FUNCTIONAL SPECIFICATIONS ................................................................................................. 9

5.4

UHF GEN 2 RFID RADIO SPECIFICATIONS ......................................................................................... 10

5.5

DEVICE INPUT AND OUTPUT SPECIFICATIONS ..................................................................................... 11

5.6

SUPPORTED REGIONS....................................................................................................................... 13

5.7

EPC CLASS-1 GENERATION-2 OPERATION ........................................................................................ 15

6

IMPINJ RADIO INTERFACE (IRI) ....................................................................................................... 16

7

REGULATORY INFORMATION .......................................................................................................... 17

8

PACKAGE AND ASSEMBLY INFORMATION ................................................................................... 17

8.1

PACKAGE MASS ................................................................................................................................ 17

8.2

PACKAGE DIMENSIONS ...................................................................................................................... 17

8.3

PCB FOOTPRINT .............................................................................................................................. 20

8.4

SMT REFLOW INFORMATION ............................................................................................................. 24

9

DOCUMENT CHANGE LOG ............................................................................................................... 25

10

NOTICES .......................................................................................................................................... 25

1.1 Figures

FIGURE 2-1: RS500 SYSTEM INTEGRATION ...................................................................................................... 4

FIGURE 3-1: EXAMPLE RS500 BLOCK DIAGRAM ............................................................................................... 5

FIGURE 4-1: INDY RS500 PIN LISTING .............................................................................................................. 7

FIGURE 6-1: HOST AND READER FIRMWARE STACK ........................................................................................ 16

FIGURE 8-1: RS500 PACKAGE DIMENSIONS, TOP, FRONT, AND SIDE VIEWS .................................................... 18

FIGURE 8-2: RS500 PIN DIMENSIONS (VIEWED FROM UNDERNEATH PACKAGE) ................................................. 19

FIGURE 8-3: RS500 RECOMMENDED ETCHED COPPER FOOTPRINT – ALL PADS .............................................. 20

FIGURE 8-4: RS500 RECOMMENDED ETCHED COPPER FOOTPRINT – SINGLE PAD ........................................... 21

FIGURE 8-5: RS500 RECOMMENDED PASTEMASK FOOTPRINT – ALL PADS ...................................................... 22

FIGURE 8-6: RS500 RECOMMENDED PASTEMASK FOOTPRINT – SINGLE PAD .................................................. 23

FIGURE 8-7: RECOMMENDED SOLDER STENCIL OPENING WITH ETCHED PAD FOR RS500 ................................. 23

FIGURE 8-8: RECOMMENDED SOLDER REFLOW PROFILE FOR THE INDY RS500 ............................................... 24

1.2 Tables

TABLE 4-1: INDY RS500 – PIN LISTING AND SIGNAL DEFINITIONS ...................................................................... 7

TABLE 5-1: INDY RS500 – ABSOLUTE MAXIMUM RATINGS ................................................................................. 8

TABLE 5-2: INDY RS500 – OPERATING CONDITIONS ......................................................................................... 9

TABLE 5-3: INDY RS500 – SUPPLY CURRENT SPECIFICATIONS ......................................................................... 9

TABLE 5-4: INDY RS500 – STARTUP AND WAKEUP TIME ................................................................................. 10

TABLE 5-5: INDY RS500 – RF RECEIVER SPECIFICATIONS .............................................................................. 10

Page 3

Revision 1.1, Copyright © 2014, Impinj, Inc.

3

TABLE 5-6: INDY RS500 – RF TRANSMITTER SPECIFICATIONS ........................................................................ 10

TABLE 5-7: INDY RS500 – DIGITAL INTERFACE SPECIFICATION ........................................................................ 11

TABLE 5-8: INDY RS500 – ANALOG INTERFACE SPECIFICATION ....................................................................... 12

TABLE 5-9: INDY RS500 – REGIONAL SUPPORT.............................................................................................. 13

TABLE 5-10: INDY RS500 – LINK PROFILE ...................................................................................................... 15

TABLE 5-11: INDY RS500 – GEN 2 FUNCTIONALITY ........................................................................................ 15

TABLE 5-12: INDY RS500 – INVENTORY PERFORMANCE ................................................................................. 16

TABLE 8-1: RS500 SERIAL # MAKEUP ............................................................................................................ 19

TABLE 9-1: DOCUMENT CHANGE LOG ............................................................................................................. 25

2 Introduction

The Indy® RS500 reader SiP (system-in-package) is a completely integrated reader

solution for EPC Gen 2 / ISO18000-63 (formerly 18000-6C) applications. The Indy

RS500 was developed to make embedding UHF RFID reader capability easy. The Indy

RS500 builds on market-leading Indy reader chip technology and integrates all of the

necessary components into a small package. The Indy RS500 requires no external

components, is fully tested and meets regulatory requirements. The Indy RS500 comes

in a surface mount package designed to work as a SMT (surface mount technology)

compatible component in a standard PCB manufacturing process, which eliminates

costly mechanical hardware, RF cables and human assembly that are typically required

with embedded readers on the market today. The Indy RS500 is a turnkey solution that

will enable quick and easy embedding of RFID with low development risk and fast timeto-market.

Ideal for moderate read range of small tag populations, the Indy RS500’s small form

factor enables a diverse range of applications that need a low-cost embedded UHF

Gen 2 RFID reader capability, such as consumables authentication, access control,

process control, appliances, POS devices for retail, medical equipment, printers, and

low-duty handheld readers. The RS500 is capable of reading dozens of tags per second

at distances greater than 3 meters when using a 6 dBi reader antenna and far field

passive tags.

This document includes interface, functional, performance, mechanical and

environmental specifications. Host communication specifications (e.g. firmware upgrade

and host interface protocol) and Impinj Radio Interface (IRI) documentation is provided

in the latest RS500 Software release package. The Indy RS500 uses the IRI™ (Impinj

Radio Interface) to communicate with host systems. The IRI Tool Kit enables

developers to build on a variety of embedded host platforms by providing the following:

documentation, image loader, IRI library, sample C code and project files. The IRI Tool

Kit can be found in the latest Indy RS500 Software release package and can be

downloaded from the restricted documents and downloads section at

support.impinj.com. Please create an account and subscribe to receive automatic

updates to the latest documentation and releases. Contact your local Impinj

representative if you have trouble creating an account or accessing this site.

Page 4

4 Revision 1.1, Copyright © 2014, Impinj, Inc.

Figure 2-1: RS500 System Integration

Antenna

UART

Host

IRI

Library

DC Power

Three simple connections:

DC Power

UART Communication

RF Antenna

2.1 Key features of the Indy RS500

Fully tested turnkey solution

Partners build

API with IRI

Tool Kit

Maximum output power is 23 dBm

-65 dBm Rx sensitivity, assuming 15 dB antenna return loss

Inventory (FastID, Tag Population Estimate, Select, Session, Target)

Access (Read, Write, Lock, Kill, BlockPermalock, and QT)

Shielded to prevent unwanted radiation and provide noise immunity in embedded

environments

29 mm by 32 mm by 3.8 mm surface mount package with SMT compatibility

Single mono-static RF port

Field upgradability via firmware updates. Gen 2 v2 will be firmware upgradable.

Part of Impinj’s GrandPrix® platform, ensuring better performance when using

Impinj’s Monza® UHF RFID tag chips (enabling FastID, Tag Focus and QT)

UART serial interface using IRI (Impinj Radio Interface)

Test features (CW, PRBS, custom regions, channel lists, and fixed frequency)

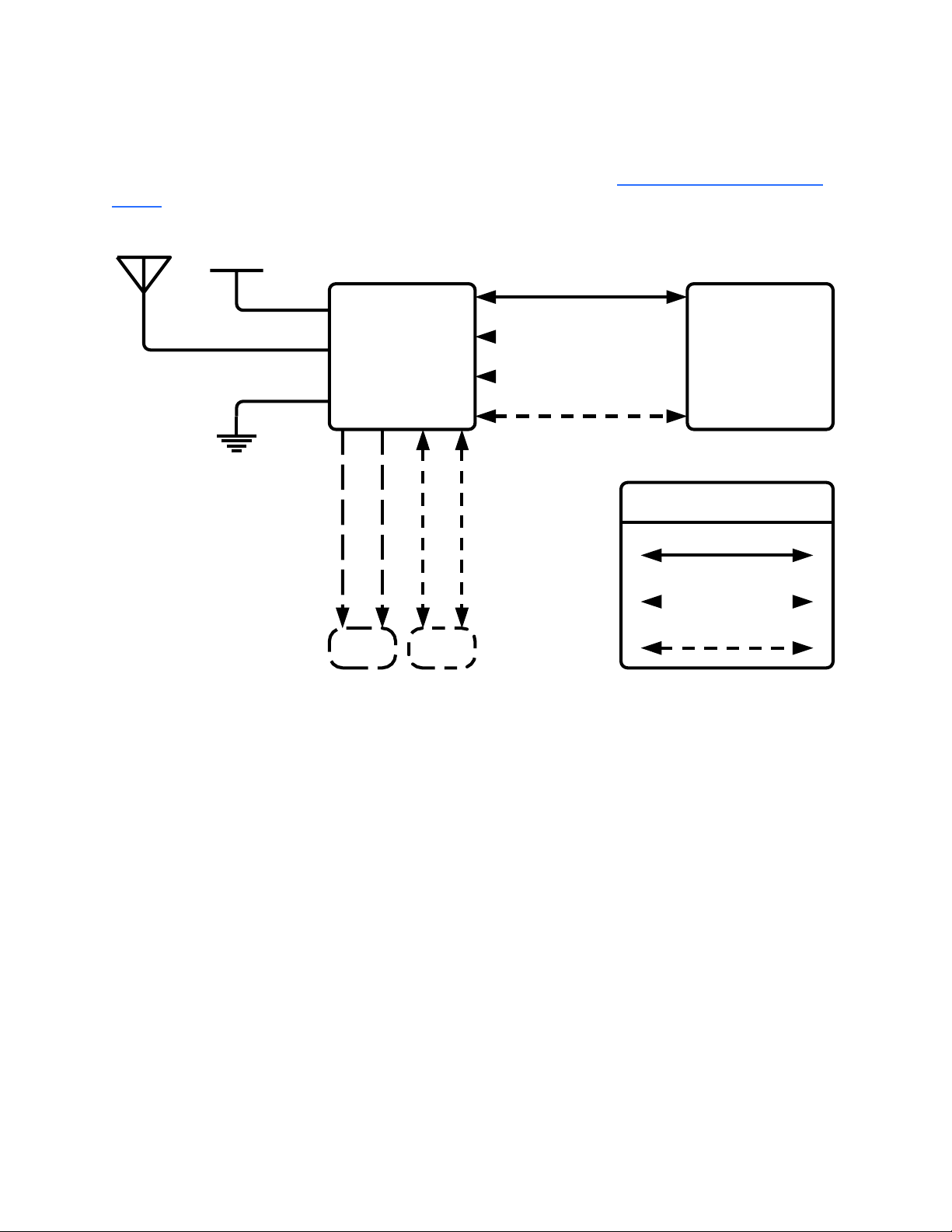

3 System Block Diagram

An example Indy RS500 system-level block diagram for an embedded application is

shown in Figure 3-1. This figure shows the electrical connections that may and must be

made to control the RS500. In the figure, the required connections are illustrated with

Page 5

Revision 1.1, Copyright © 2014, Impinj, Inc.

5

solid lines. Recommended and optional connections are illustrated with different dotted

3.6 - 5.25 V

VDC_IN

UART1 RX & TX

RF

GND

Indy

RS500

SiP

NRST

WKUP

Host

GPIOs

Key

Required

Recommended

Test

Points

User

Def.

Optional

STATUS

&

HEALTH

UART2

RX

&

TX

GPIOs UC_ADC

&

UC_DAC

and dashed line patterns. They are also listed below.

For more detail on pin characteristics and behaviors, see the RS500 Hardware User’s

Guide.

Figure 3-1: Example RS500 Block Diagram

Required connections:

VDC_IN and GND are required to power the RS500.

RF is required to connect to the UHF RFID antenna.

UART1 Tx and Rx are required to communicate with the system host.

Recommended connections:

nRST is used to reset the RS500 if UART communication is not available. This

connection is highly recommended. This pin internally driven strong low during

software resets, so it should only be driven externally by an open drain signal. It

must not be driven strong high.

UART2 Tx and Rx may be used to examine debug information.

HEALTH indicates successful operation of the RS500. Connection to an LED

provides a visual indication of whether or not an error condition exists.

STATUS provides an indication when the RS500 is in active mode (for example,

inventorying tags). Connection to an LED provides a visual indicator of the device’s

activity.

Optional connections:

Page 6

6 Revision 1.1, Copyright © 2014, Impinj, Inc.

GPIOs allow interaction with the RS500 as both digital inputs and outputs. They may

be used to trigger inventory, generate events based on inventory activity, or provide

general-purpose user-controlled digital I/O.

WKUP provides a mechanism to wake up the RS500 from the low power Sleep

mode. WKUP is also used to force entry into the Impinj firmware bootstrap. If

unused, this pin should be tied to logic low.

UC_ADC allows use of an ADC to convert an analog input voltage into a digital

value.

UC_DAC allows use of a DAC to generate an analog output voltage from a digital

value.

BOOT0 provides access to the built-in bootloader in case the Impinj firmware is

corrupted. For more details on the built-in bootloader, please contact Impinj support.

No connect:

SWCLK and SWD connections are reserved for Impinj use only.

Page 7

Revision 1.1, Copyright © 2014, Impinj, Inc.

7

Parameter

Min.

Max.

Unit

Conditions

Supply voltage

-0.3

5.5 V

VDC_IN pin relative to GND

IO voltage

-0.3

4.0 V

Non-VDC_IN pin voltages relative to GND

RF input power

- +23

dBm

Incident to pin 1 (RF)

Storage temperature

-30

+100

ºC

Humidity

- 95

% RH

Non-condensing

4 Electrical Specifications

4.1 Absolute Maximum Ratings

The absolute maximum ratings (see Table 5-1) define limitations for electrical and

thermal stresses. These limits prevent permanent damage to the Indy RS500.

Operation outside maximum ratings may result in permanent damage to the device.

Table 5-1: Indy RS500 – Absolute Maximum Ratings

Page 8

8 Revision 1.1, Copyright © 2014, Impinj, Inc.

Parameter

Min.

Max.

Unit

Conditions

ESD immunity

- 2 kV

Human-body model, all I/O pads

Package moisture

sensitivity level 3

-

-

-

Indy RS500 from open trays must be baked

before going through a standard solder

reflow process (48 hours at 125 ºC or 24hrs

at 150 ºC)

4.2 Operating Conditions

Parameter

Min.

Max.

Unit

Conditions

Supply

3.6

5.25 V

VDC_IN relative to GND

Temperature

-20

+70

ºC

Ambient Temperature

Frequency

902

928

MHz

IPJ-RS500-GX, See section 5.6 for regional support

Frequency

865

868

MHz

IPJ-RS500-EU, See section 5.6 for regional support

Parameter

Typ.

Unit

Description

Supply Current

Current consumed by RS500 via VDC_IN pin

Active mode - 5V

supply – GX

510

mA

+23 dBm transmit power

Inventorying tags

Active mode - 5V

supply - EU

580

mA

+23 dBm transmit power

Inventorying tags

Active mode -

3.6V supply

570

mA

+23 dBm transmit power

Inventorying tags

Idle mode –

low latency

50

mA

Ready to receive IRI packets. Lower latency to return

to Active mode.

Idle mode –

standard latency

15

mA

Ready to receive IRI packets.

Standby mode

1 mA

GPIO activity or WKUP rising edge required to wakeup

part.

Sleep mode

<100

µA

WKUP rising edge required to wakeup part.

This section describes operating voltage, frequency, and temperature specifications for

the Indy RS500 during operation.

Table 5-2: Indy RS500 – Operating Conditions

4.3 Device Functional Specifications

Table 5-3: Indy RS500 – Supply Current Specifications

Page 9

Revision 1.1, Copyright © 2014, Impinj, Inc.

11

Parameter

Min.

Typ.

Max.

Unit

Description

Startup Time

200 ms

Time to receive IRI packets after power supply or

nRST pin initiated startup

Wakeup Time

Time to receive IRI packets after wakeup event

Standby

50 ms

GPIO activity or WKUP rising edge required to wakeup

part.

Sleep

200 ms

WKUP rising edge required to wakeup part.

Parameter

Min.

Typ.

Max.

Unit

Conditions

Frequency

902 928

MHz

IPJ-RS500-GX, See section 5.6 for regional support

Frequency

865 868

MHz

IPJ-RS500-EU, See section 5.6 for regional support

Input impedance

50

Ω

Input match

-10 dB

S11

Rx sensitivity

-65 dBm

1% PER, assuming 15dB antenna RL at 23dBm

output

Parameter

Min.

Max.

Unit

Notes

Tx Power

10

23

dBm

Meets worldwide regulatory constraints (except

Japan)

Tx Power

10

20

dBm

Meets Japan regulatory constraints

Tx Power Error

18-23 dBm

-0.5

0.5

dB

Difference between desired Tx power and actual Tx

13-18 dBm

-1.0

1.0

dB

power.

10-13 dBm

-2.0

2.0

dB

Tx ACPR

1

st

Adjacent

-25

dBch

Refer to Gen 2 dense-interrogator transmit mask

1

st

Alternate

2

nd

Alternate

-55

-65

dBch

dBch

spec for definition of channel bandwidths and

measurement regions.

Return Loss

0

dB

No damage into open RF port at 23 dBm at any

phase angle

Frequency

902

928

MHz

IPJ-RS500-GX, See section 5.6 for regional support

Frequency

865

868

MHz

IPJ-RS500-EU, See section 5.6 for regional support

Table 5-4: Indy RS500 – Startup and Wakeup Time

4.4 UHF Gen 2 RFID Radio Specifications

Table 5-5: Indy RS500 – RF Receiver Specifications

Table 5-6: Indy RS500 – RF Transmitter Specifications

Page 10

10

Revision 1.1, Copyright © 2014, Impinj, Inc.

4.5 Device Input and Output Specifications

Parameter

Min.

Typ.

Max.

Unit

Conditions

nRST

V

IL

-0.3

0.8 V

V

IH

2

3.6 V

Hysteresis voltage

200 mV

Internal pull-up resistor

25

40

55

kΩ Reset pulse width

25

µs

BOOT0

V

IL

0.0 0.6 V V

IH

0.62

3.6 V

Hysteresis voltage

300 mV WKUP

V

IL

-0.3

1.0 V

V

IH

1.8 3.6 V Hysteresis voltage

200 mV

Internal pull-down resistor

25

40

55

kΩ

Digital inputs

V

IL

-0.3

1.0 V

V

IH

1.8 3.6 V Hysteresis voltage

200 mV Pull-up and pull-down resistor

25

40

55

kΩ

Digital outputs

V

OL

0.0 0.4 V V

OH

2.7 3.6 V

Drive current (sink or source)

8

mA

UART

Baud rate

115.2

kbaud

Parity

None

Table 5-7: Indy RS500 – Digital Interface Specification

Page 11

Page 12

12

Revision 1.1, Copyright © 2014, Impinj, Inc.

Parameter

Min.

Typ.

Max.

Unit

Conditions

ADC (Pin 13)

Resolution

12 Bits Conversion voltage range

1

3.3 V Sampling rate

0.05

1 MSPs

Total conversion time

1

18

µsec

Power-up time

1 µsec

External input impedance

50

kΩ Sampling switch resistance

1 kΩ

Internal sample and hold

capacitance

8 pF

Total unadjusted error

±3.3 ±4

LSB

Offset error

±1.9

±2.8

LSB

Gain error

±2.8 ±3

LSB

DNL error

±0.7

±1.3

LSB

INL error

±1.2

±1.7

LSB

DAC (Pin 16)

Resolution

12 Bits Resistive load with buffer ON

5

kΩ

Impedance output with buffer OFF

15

kΩ

When the buffer is OFF, the

minimum resistive load

between DAC_OUT and V

SS

to

achieve 1% accuracy is

1.5 MΩ.

Capacitive load

50

pF

Maximum capacitive load at the

DAC_OUT pin when the buffer

is ON

Output voltage range

0.2 3.1 V

DNL

±2 LSB

INL

±4 LSB

Offset

±10

mV Gain error

±0.5 %

Settling time

3 4 µsec

C

LOAD

< 50 pF & R

LOAD

> 5 kΩ

Table 5-8: Indy RS500 – Analog Interface Specification

Page 13

Revision 1.1, Copyright © 2014, Impinj, Inc.

13

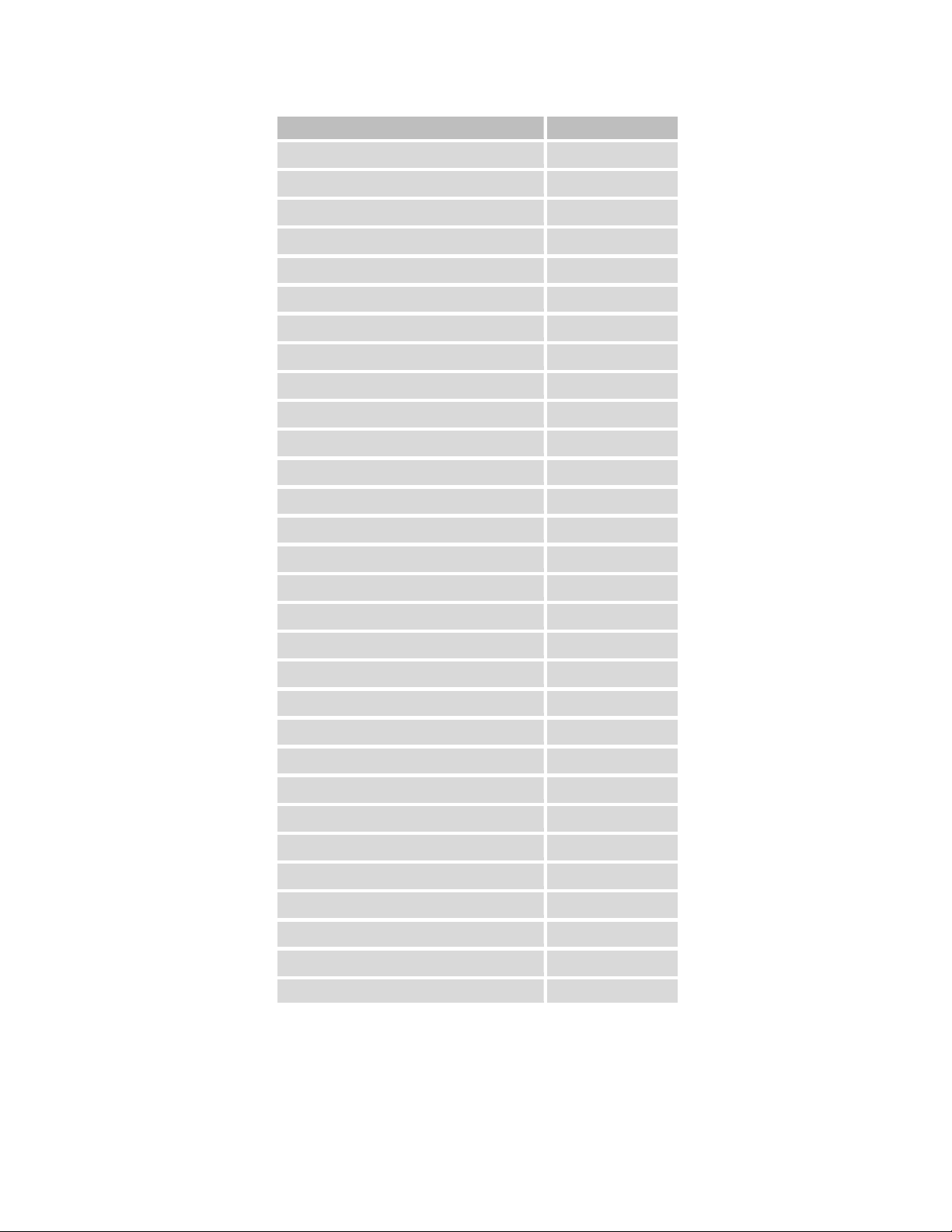

4.6 Supported Regions

Region

SKU

Argentina

IPJ-RS500-GX

Armenia

IPJ-RS500-EU

Australia (920-926 MHz)

IPJ-RS500-GX

Austria

IPJ-RS500-EU

Azerbaijan

IPJ-RS500-EU

Belgium

IPJ-RS500-EU

Bosnia and Herzegovina

IPJ-RS500-EU

Brazil (902-907 MHz)

IPJ-RS500-GX

Brazil (915-928 MHz)

IPJ-RS500-GX

Bulgaria

IPJ-RS500-EU

Canada

IPJ-RS500-GX

Chile

IPJ-RS500-GX

China (920-925 MHz)

IPJ-RS500-GX

Colombia

IPJ-RS500-GX

Costa Rica

IPJ-RS500-GX

Croatia

IPJ-RS500-EU

Cyprus

IPJ-RS500-EU

Czech Republic

IPJ-RS500-EU

Denmark

IPJ-RS500-EU

Dominican Republic

IPJ-RS500-GX

Estonia

IPJ-RS500-EU

Finland

IPJ-RS500-EU

France

IPJ-RS500-EU

Germany

IPJ-RS500-EU

Greece

IPJ-RS500-EU

Hong Kong (920-925 MHz)

IPJ-RS500-GX

Hungary

IPJ-RS500-EU

Iceland

IPJ-RS500-EU

Table 5-9: Indy RS500 – Regional Support

Page 14

14

Revision 1.1, Copyright © 2014, Impinj, Inc.

Region

SKU

India

IPJ-RS500-EU

Indonesia

IPJ-RS500-GX

Ireland

IPJ-RS500-EU

Israel

IPJ-RS500-GX

Italy

IPJ-RS500-EU

Japan (916-921 MHz)

IPJ-RS500-GX

Korea (917-921 MHz)

IPJ-RS500-GX

Latvia

IPJ-RS500-EU

Lithuania

IPJ-RS500-EU

Luxembourg

IPJ-RS500-EU

Macedonia

IPJ-RS500-EU

Malaysia (919-923 MHz)

IPJ-RS500-GX

Malta

IPJ-RS500-EU

Mexico

IPJ-RS500-GX

Moldova

IPJ-RS500-EU

Netherlands

IPJ-RS500-EU

New Zealand (921-928 MHz)

IPJ-RS500-GX

Norway

IPJ-RS500-EU

Oman

IPJ-RS500-EU

Panama

IPJ-RS500-GX

Peru

IPJ-RS500-GX

Philippines

IPJ-RS500-GX

Poland

IPJ-RS500-EU

Portugal

IPJ-RS500-EU

Romania

IPJ-RS500-EU

Russian Federation (916-921 MHz)

IPJ-RS500-GX

Saudi Arabia

IPJ-RS500-EU

Serbia

IPJ-RS500-EU

Singapore (920-925 MHz)

IPJ-RS500-GX

Slovak Republic

IPJ-RS500-EU

Page 15

Revision 1.1, Copyright © 2014, Impinj, Inc.

15

Region

SKU

Slovenia

IPJ-RS500-EU

South Africa (915-919 MHz)

IPJ-RS500-GX

Spain

IPJ-RS500-EU

Sweden

IPJ-RS500-EU

Switzerland

IPJ-RS500-EU

Taiwan (922-928 MHz)

IPJ-RS500-GX

Thailand

IPJ-RS500-GX

Turkey

IPJ-RS500-EU

United Arab Emirates

IPJ-RS500-EU

United Kingdom

IPJ-RS500-EU

United Sates

IPJ-RS500-GX

Uruguay

IPJ-RS500-GX

Venezuela

IPJ-RS500-GX

Vietnam (920-925 MHz)

IPJ-RS500-GX

Parameter

Description

Forward Link

PR-ASK

25 µs Tari

Reverse Link

250 kHz link frequency

Miller, M=4

62.5 kbps data rate

Parameter

Description

Select

Support for 2 Select commands

Inventory

FastID, TagFocus, Tag Population Estimate, Select,

Session, and Target

Access

Read, Write, Lock, Kill, BlockPermalock, and QT

4.7 EPC Class-1 Generation-2 Operation

Table 5-10: Indy RS500 – Link Profile

Table 5-11: Indy RS500 – Gen 2 Functionality

Page 16

16

Revision 1.1, Copyright © 2014, Impinj, Inc.

RS500

Parameter

Min.

Typ.

Max.

Unit

Conditions

Inventory Rate

130 Tags/sec

1 Tag with tag population estimate = 1

35 Tags/sec

1 Tag with tag population estimate = 16

50 Tags/sec

16 Tags with tag population estimate = 16

Host

Customer Application

(main.c)

iri.h

IRI C Toolkit

(ITK_C/Library/*.h, *.c)

platform.h

Platform Interface

(platform_*.c)

IRI over UART

Key

Provided by

Impinj

Provided by

customer

Table 5-12: Indy RS500 – Inventory Performance

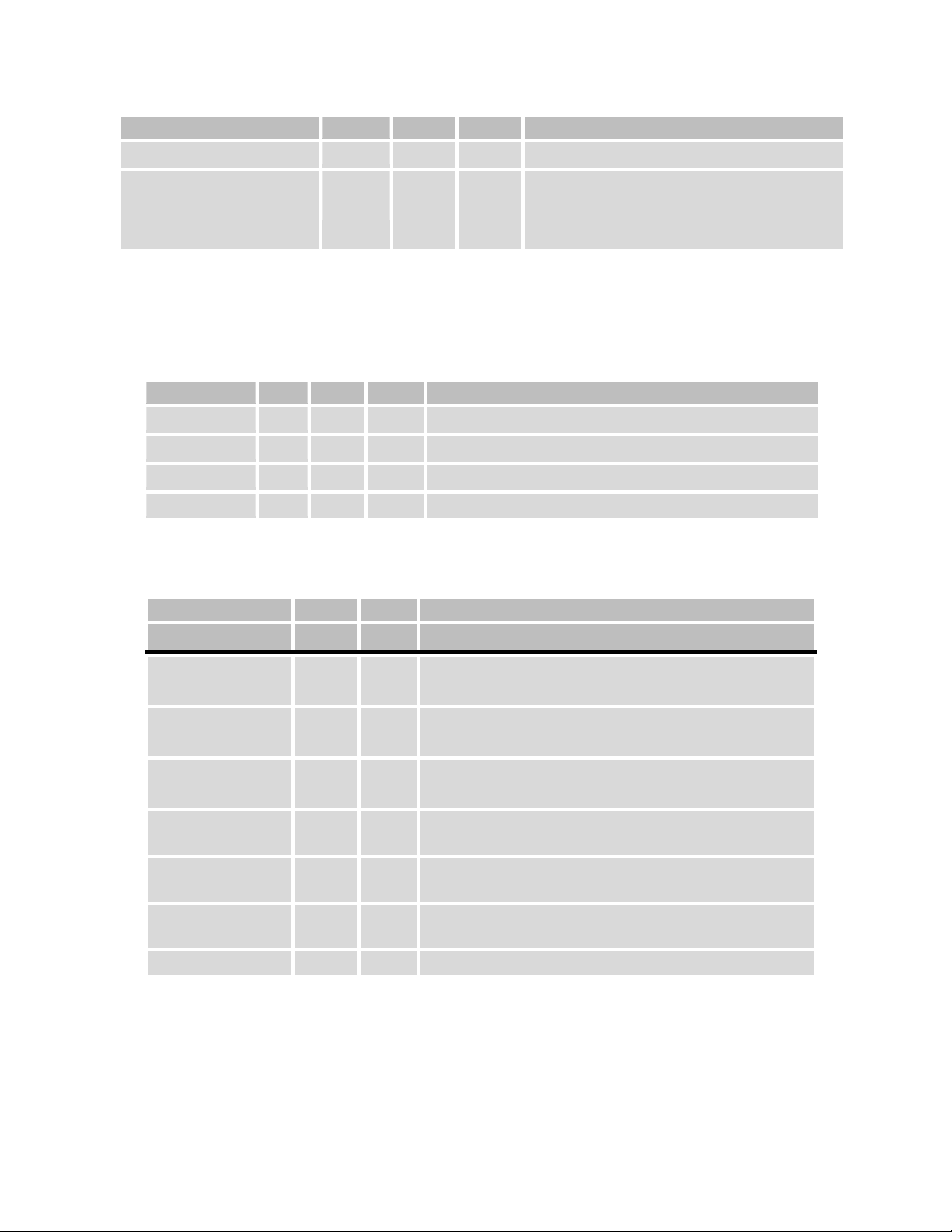

5 Impinj Radio Interface (IRI)

The Indy RS500 uses IRI to enable communications; this is enabled with the IRI Tool Kit.

The IRI Tool Kit includes documentation, IRI API, and sample C code. The IRI Tool Kit

is intended to enable a broad set of host platforms due to its ease of use and portability.

Communication with the RS500 via IRI occurs in two states:

1.

Configuration (synchronous)

a.

All communications are commands and responses

b.

Start and Stop commands cause transition to the Listen state

2.

Listen (asynchronous)

a.

Host is in a listening mode and polls to obtain tag reports

Customer applications can be enabled on a variety of embedded systems with hosts

ranging in size from small microcontrollers to large microprocessors. The IRI Tool Kit is

structured to ease portability by separating platform specific code from functional reader

operation; this is illustrated in Figure 6-1 below.

Figure 6-1: Host and Reader Firmware Stack

Page 17

Revision 1.1, Copyright © 2014, Impinj, Inc.

17

Please refer to the documentation included in the RS500 release package for complete

details on communicating with the Indy RS500 using IRI. The latest Indy RS500 release

package, which includes the IRI Tool Kit, can be downloaded at support.impinj.com.

6 Regulatory Information

The Indy RS500 (IPJ-RS500) has been certified for modular operation by FCC and

Industry Canada in certain specific configurations. Use of these IDs requires specific

text be added to product labeling and product Hardware User’s Guides. See the Indy

RS500 Hardware User’s Guide for more details on labeling specifics.

7 Package and Assembly Information

This section provides mechanical drawings and critical dimensions needed for PCB

layout and housing design, as well as SMT assembly information.

7.1 Package Mass

The mass of the RS500 SiP is 4.6 grams.

7.2 Package Dimensions

Package dimensions are shown in Figure 8-1 and Figure 8-2.

All dimensions are in millimeters.

Dimension tolerances (unless otherwise specified):

X = 1.0

X.X = 0.5

X.XX = 0.25

X.XXX = 0.125

Hole = 0.075

Angular: MACH 0.5

Bend: 1.0 Degree

Page 18

18

Revision 1.1, Copyright © 2014, Impinj, Inc.

Digits

Meaning

XX

SKU code:

01 = GX

02 = EU

ZZ

Lot number

WW

Workweek produced

YY

Year produced

AAAA

Serial number within

the lot

Table 8-1: RS500 Serial # Makeup

Figure 8-2: RS500 Pin Dimensions (viewed from underneath package)

Note. Callouts A and B show package markings that will vary depending on the

manufacturing lot of the RS500 unit.

Page 19

Revision 1.1, Copyright © 2014, Impinj, Inc.

21

7.3 PCB Footprint

Recommended footprint copper and pastemask dimensions are shown in Figure 8-3

and Figure 8-5. Dimensions for the individual pads are shown in Figure 8-4 and Figure

8-6.

Figure 8-3: RS500 Recommended Etched Copper Footprint – All Pads

Page 20

20

Revision 1.1, Copyright © 2014, Impinj, Inc.

Figure 8-4: RS500 Recommended Etched Copper Footprint – Single Pad

Page 21

22

Revision 1.1, Copyright © 2014, Impinj, Inc.

Figure 8-5: RS500 Recommended Pastemask Footprint – All Pads

Page 22

Revision 1.1, Copyright © 2014, Impinj, Inc.

23

Figure 8-6: RS500 Recommended Pastemask Footprint – Single Pad

It is important to note that the optimal pad and stencil design results in a stencil aperture

that is of a different shape than and that overhangs the etched pad. This design delivers

the optimum amount of solder to the castellation of the SiP pad. Figure 8-7 depicts the

pad/solder relationship.

Figure 8-7: Recommended Solder Stencil Opening with Etched Pad for RS500

Page 23

24

Revision 1.1, Copyright © 2014, Impinj, Inc.

7.4 SMT Reflow Information

No-clean Type 3 Sn3Ag0.5Cu Solder Paste (Koki S3X58- M650) was used during

Impinj’s testing of the Indy RS500. The solder manufacturer’s recommended reflow

profile is shown in Figure 8-8.

Figure 8-8: Recommended Solder Reflow Profile for the Indy RS500

Page 24

Revision 1.1, Copyright © 2014, Impinj, Inc.

25

8 Document Change Log

Version

Date

Description

1.0 Initial version

1.1

4/30/2014

Package drawings updated

Spec clarifications

Regulatory information moved to Hardware User’s Guide

Formatting updates

Change log added

Table 9-1: Document Change Log

9 Notices

Copyright © 2014, Impinj, Inc. All rights reserved.

Impinj gives no representation or warranty, express or implied, for accuracy or reliability

of information in this document. Impinj reserves the right to change its products and

services and this information at any time without notice.

EXCEPT AS PROVIDED IN IMPINJ’S TERMS AND CONDITIONS OF SALE (OR AS

OTHERWISE AGREED IN A VALID WRITTEN INDIVIDUAL AGREEMENT WITH

IMPINJ), IMPINJ ASSUMES NO LIABILITY WHATSOEVER AND IMPINJ DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY, RELATED TO SALE AND/OR USE OF

IMPINJ PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO

FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR

INFRINGEMENT.

NO LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY

PATENT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL

PROPERTY RIGHT IS GRANTED BY THIS DOCUMENT.

Impinj assumes no liability for applications assistance or customer product design.

Customers should provide adequate design and operating safeguards to minimize risks.

Impinj products are not designed, warranted or authorized for use in any product or

application where a malfunction may reasonably be expected to cause personal injury

or death or property or environmental damage (“hazardous uses”) or for use in

automotive environments. Customers must indemnify Impinj against any damages

arising out of the use of Impinj products in any hazardous or automotive uses.

Indy is a trademark of Impinj, Inc. All other product or service names are trademarks of

their respective companies.

www.impinj.com

Page 25

Federal Communication Commission Interference Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by

one of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC Caution:

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate this equipment.

This transmitter must not be co-located or operating in conjunction with any other

antenna or transmitter.

Page 26

Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This module can be used with T800 or similar platform with similar dimension,

antenna location and RF characteristic.

This device is intended only for OEM integrators under the following conditions:

1) The antenna must be installed at the same location as tested in the certification filing, and

the maximum antenna gain allowed for use with this device is 4.41 dBi.

2) The transmitter module may not be co-located with any other transmitter or antenna.

3) For portable usage condition, this module has been SAR evaluated in T800 host with

compliance result and can be used with this specific host as described in the certification

filing. Other host or platform needs separate approval.

As long as 3 conditions above are met, further transmitter test will not be required.

However, the OEM integrator is still responsible for testing their end-product for any

additional compliance requirements required with this module installed

IMPORTANT NOTE: In the event that these conditions can not be met (for example certain

laptop configurations or co-location with another transmitter), then the FCC authorization is

no longer considered valid and the FCC ID can not be used on the final product. In these

circumstances, the OEM integrator will be responsible for re-evaluating the end product

(including the transmitter) and obtaining a separate FCC authorization.

End Product Labeling

The final end product must be labeled in a visible area with the following: “Contains FCC

ID: QYLRS500”. The grantee's FCC ID can be used only when all FCC compliance

requirements are met.

Manual Information To the End User

The OEM integrator has to be aware not to provide information to the end user regarding how

to install or remove this RF module in the user’s manual of the end product which integrates

this module. The end user manual shall include all required regulatory information/warning as

show in this manual.

Loading...

Loading...