Page 1

GESTRA

Issue Date: 11/04

GESTRA Steam Systems

Non-Return Valve

RK 86, 86A for Flanges PN 10/16/25/40

ASME Class 125/150/300

Description

Wafer-type non-return (check) valve for sandwiching between flanges. Valve with spring for installation in any

position. Without spring only for vertical lines with upward flow. Self-centering valve body. Application for liquids,

gases and vapours (observe classification according to PED).

Pressure/Temperature Rating for valves with metal-to-metal seat¹)

Service temp. °C 20 100 200 300 350 400 500 550 Min. temp.

)

2

pressure

Max. service

1

) For temperatures above 300 °C (572 °F) use a Nimonic spring.

Linear interpolation between pressure and temperature ratings possible.

According to AD 2000, W5 service pressure for 1.4408 must not exceed 300 °C.

2

) Sizing according to ASME 300.

Soft seats (Note pressure/temperature ratings in the above table for metal-to-metal seat.)

EPDM: – 40 to +150 °C for water, condensate and steam.

FPM: –25 to +200 °C for oils, gases and air.

Tightness with soft seats of EPDM and FPM in accordance with DIN 3230, part 3, leakage rates BN 1, BO 1.

Permissible leakage rates with metal-to-metal seat in accordance with DIN 3230, part 3, leakage rates BN 2, BO 3.

Chemical resistance see GESTRA Database “Chemical Resistance”

Connections of wafer-type valves

DIN3) BS 105) ASME JIS6)

EN 1092-1

PN 10/16/ 25/404) B 16.5 Class 150/300 RF 10K

3

) DN 125–200 mm (5–8"): On request form D or E acc. to EN 1092.

4

) DN 15–100 mm (½–4") also suitable for PN 6.

5

) For installation between flanges DN 15 mm (½"), BS 10, table H and J, please use RK 86/86A, DN 20 mm (¾").

6

) As standard for installation between Fl. JIS 10K (except DN 80 mm). When ordering please indicate nominal size (reworking required).

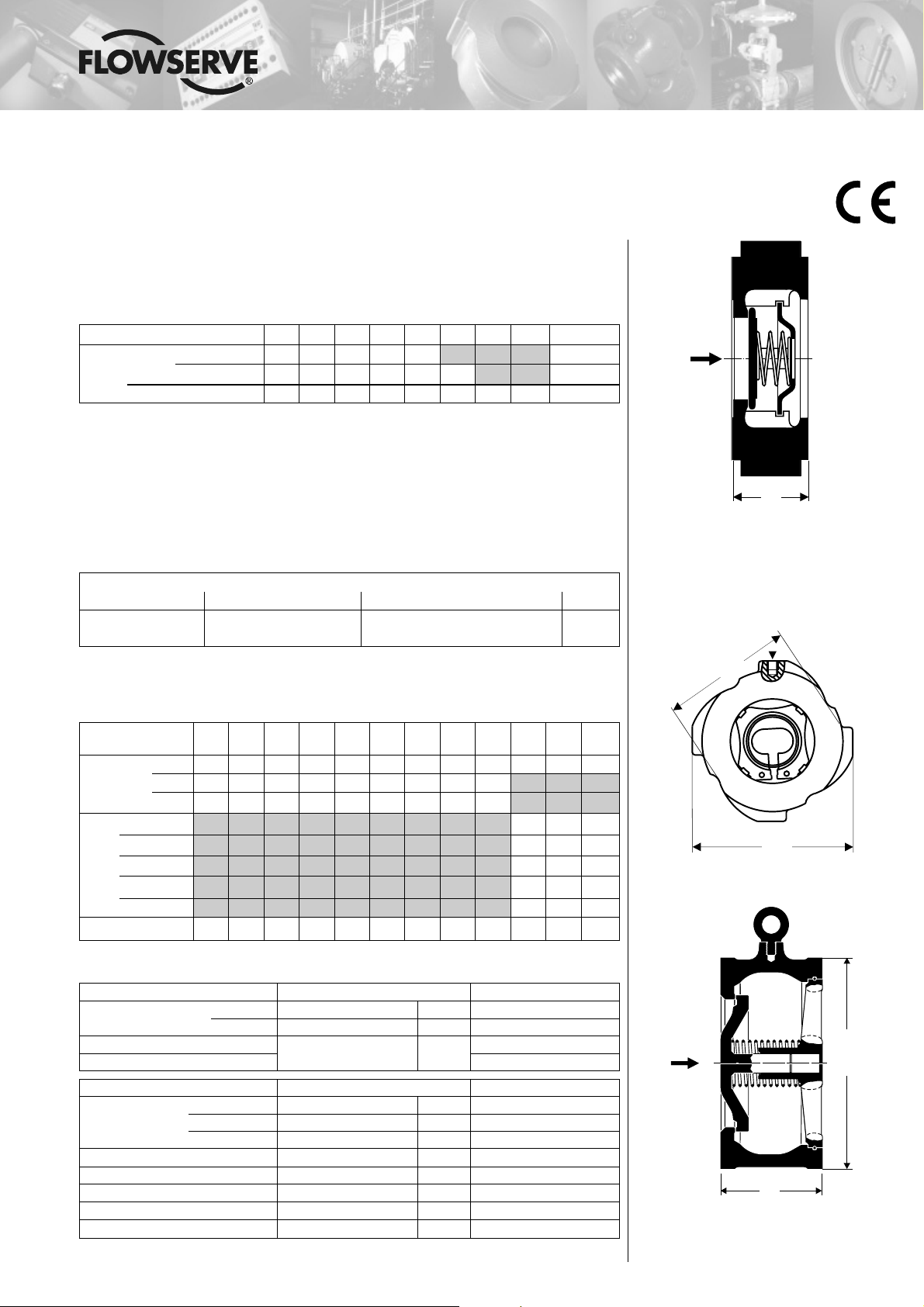

Dimensions

Nominal [mm] 15 20 25 32 40 50 65 80 100 125 150 200

sizes [inch] ½ ¾ 1 1¼ 1½ 2 2½ 3 4 5 6 8

Dimensions

[mm] ∅ D

Class 125/150 194 220 275

PN 10/16 194 220 275

∅ D PN 25 194 226 286

PN 40 194 226 293

Class 300 216 251 308

Weight [kg] 0.27 0.38 0.52 0.8 1.12 1.78 2.43 3.37 5.34 11 14 25

7

) Short overall length according to EN 558-1, series 49 (; DIN 3202, part 3, series K4)

Materials*)

DN 15–100 (¼ – 4") DIN reference ASTM equivalent

Body, seat and

guide ribs

Valve disc, spring retainer

Spring A 313 Type 316

DN 125–200 (5 – 8") DIN reference ASTM equivalent

Body hard faced seat X8CrTi18 1.4502 A 268

Valve cone RK 86 X12Cr13 1.4006 A 182 F6

Guide RK 86 GX8CrNi12 1.4107 A 217-CA15

Guide RK 86 A GX5CrNiMo19-11-2 1.4408 A 351 CF8M

Valve cone RK 86 A X6CrNiMoTi17-12-2 1.4571 A 182 F316

Spring

*) For the use in hygienic installations, foodstuff industry, pharmaceutical industry and similar applications please order RK 86 A

in pickled design.

DN 15 –100 51 46.4 43.9 38.9 36.9 –10°C

RK 86

DN 125 – 200 51 46.4 43.9 38.9 36.9 34.5 –10 °C

RK86A DN 15 –200 49.6 42.3 35.8 31.6 30.4 29.3 27.3 24 –200 °C

Standard valves for fitting between flanges to

Table D, E, F, H, J

B 16.1 Class 125 FF B2238

L7) 16 19 22 28 31.5 40 46 50 60 90 106 140

44 53 64 73 83 96 110 128 151

min

∅ D

67 76 82 93 104 118 136 158 186

max

RK 86 GX4CrNi13-4 1.4317 A 743-CA6-NM

RK 86A GX5CrNiMo19-11-2 1.4408 A 351 CF8M

X6CrNiMoTi17-12-2 1.4571

A182F316

RK 86 GP240GH 1.0619 A 216 WCB

RK 86 A GX5CrNiMo19-11-2 1.4408 A 351CF8M

RK 86 and 86 A

X6CrNiMoTi17-12 -2 1.4571 A313 Type 316

Product Range Group A2

RK 86, RK 86A

L

DN 15–100 mm (½–4")

PN 6/10/16/25/40

Standard design fitted with M8 antistatic connection

Standard design fitted with M8 antistatic connection

ASME Class 125/150/ 300

min

D

D

max

L

DN 125 – 200 mm (5–8")

PN 10/16/25/40

ASME Class 125/150/ 300

∅ D

Page 2

Non-Return Valve

RK 86, 86A for Flanges

PN 10/16/25/40

ASME Class 125/150/300

Opening pressures

Differential pressures at zero volume flow

DN Opening pressures in mbar

Direction of flow

without with springs

[mm] [in]

15 ½ 2.5 25 22.5 20

20 ¾ 2.5 25 22.5 20

25 1 2.5 25 22.5 20

32 1¼ 3.5 27 23.5 20

40 1½ 4.0 28 24.0 20

50 2 4.5 29 24.5 20

65 2½ 5.0 30 25.0 20

80 3 5.5 31 25.5 20

100 4 6.5 33 26.5 20

125 5 12.0 34 22.0 10

150 6 13.5 37 23.5 10

200 8 16.0 42 26.0 10

1 mbar = 0.0145 psi = 100 mm w.g. = 0.4 in w.g.

On request at extra charge, special springs for opening

pressures:

Between 5 and 1000 mbar for DN 15– 50 mm (½ –2"),

between 5 and 700 mbar for DN 65 and 80 mm (2½, 3"),

between 5 and 500 mbar for DN 100–200 mm (4 –8").

springs

➝➝➝

Enquiry Specification

GESTRA DISCO non-return valve RK 86...

PN 10/16/ 25/40.

Wafer design with extremely short overall length to EN

558-1, series 49.

Suitable for fitting between flanges to DIN, BS or ASME.

Indications on pressure, nominal size (DN), body material.

Metal-to-metal seat or soft seat (EPDM or FPM).

Order Specification

Type RK 86..., DN. ..,

Metal-to-metal or soft seat, EPDM or FPM.

Fluid, flowrate, pressure and temperature. Type of pipe

flanges

Note

The valves should not be used on compressors or where

pulsating flow exists.

For these applications please consult us.

➝

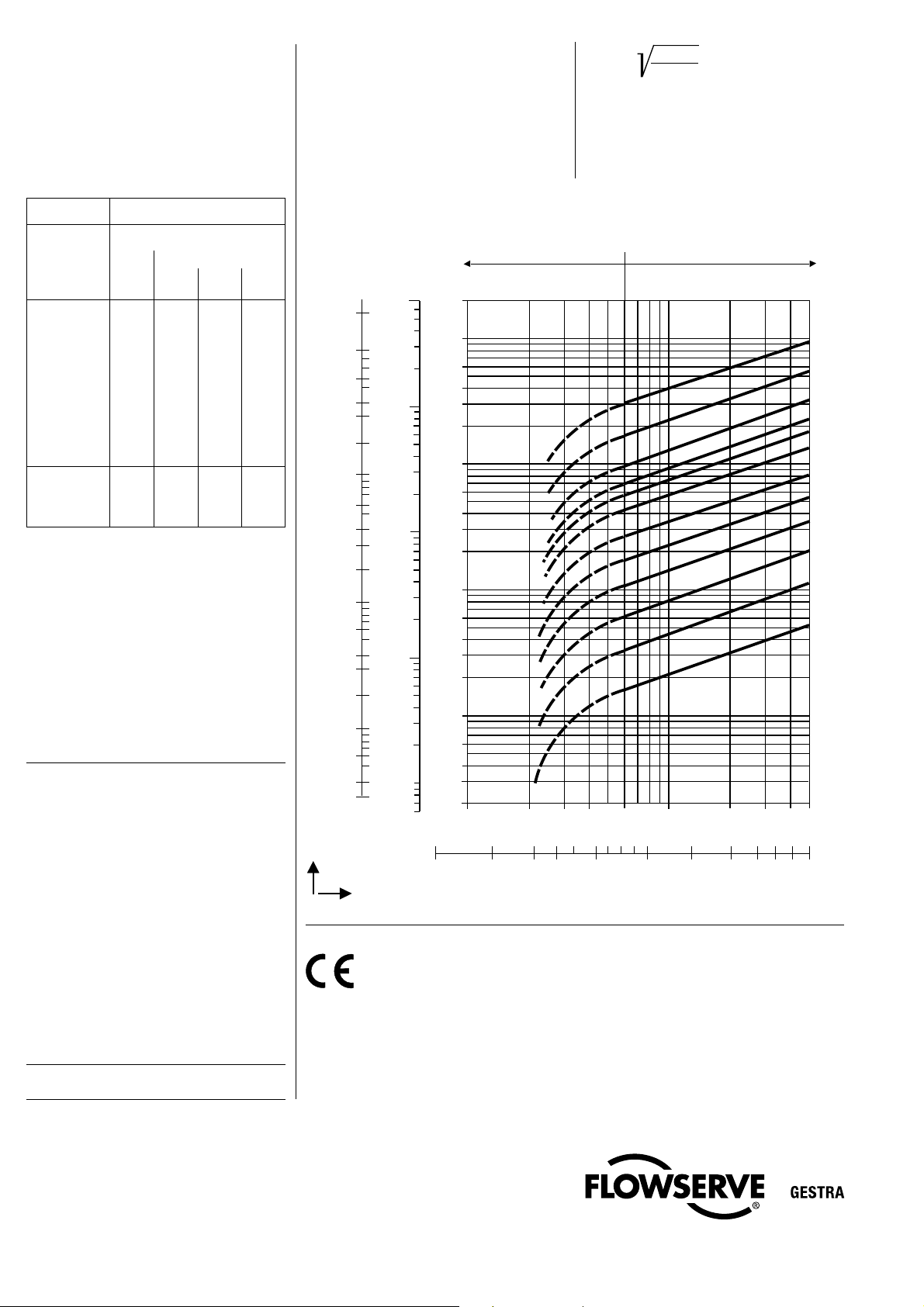

Pressure Drop Chart

The curves given in the chart are valid for water at 20 °C.

To read the pressure drop for other fluids the equivalent

water volume flowrate must be calculated and used in the

graph.

The values indicated in the chart are applicable to springassisted valves with horizontal flow. With vertical flow

insignificant deviations occur only within the range of

partial opening.

When selecting valve please consider:

Partial opening = instable range Full opening = stable range

lmp.

gal/min.

2000

1000

w

˙

Volume flow V

[m³/h]

600

400

300

200

100

60

40

30

20

10

6

4

3

2

1

0.6

0.4

0.3

Pressure drop ∆p

[l/s]

700

100

10

0.2

0.1

0.6

200

100

60

40

30

20

10

6

4

3

2

1

0.4

0.3

1

0.2

0.1

0.06

0.04

0.03

0.02

0.01 0.02 0.03 0.04 0.06 0.1 0.2 0.3 0.4 0.5 bar

0.1 0.2 0.3 0.4 0.6 1 2 3 4 5 6 7 psi

˙

= V˙ ·

V

w

˙

= Equivalent water volume flow

V

w

in l/s or m³/h

ρ = Density of fluid

(operating condition) in kg/m³

V˙= Volume of fluid

(operating condition) in l/s or m³/h

ρ

1000

1 US gallon ; 0.833 Imp. gallon

DN

200

150

125

100

80

65

50

40

32

25

20

15

Supply in accordance with our general terms

of business.

These products comply with the requirements of the EC

Pressure Equipment Directive (PED) 97/23/EC. Classified

for application with fluids of group 1 and 2 (hazardous

and non-hazardous substances). DN 32 – 200 mm with

CE marking. DN 15 – 25 mm are excluded from the

scope of this Directive and not entitled to bear the CE

marking.

ATEX

RK 86, 86A are excluded from the scope of the Directive

94/9/EC (ATEX) and can be used in the potentially

explosive zones (1999/92/EC) 0, 1, 2, 20, 21 and 22.

Loading...

Loading...