Page 1

®

SERVICE MANUAL

PN: RCFM5535

A156/A212...SERIES

®

®

RICOH GROUP COMPANIES

Page 2

Page 3

SERVICE MANUAL

®

A156/A212...SERIES

RICOH GROUP COMPANIES

®

®

Page 4

Page 5

A156/A153

A160/A157

A162/A161

SERVICE TRAINING

MANUAL

Rev. 4/98

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

Page 8

Page 9

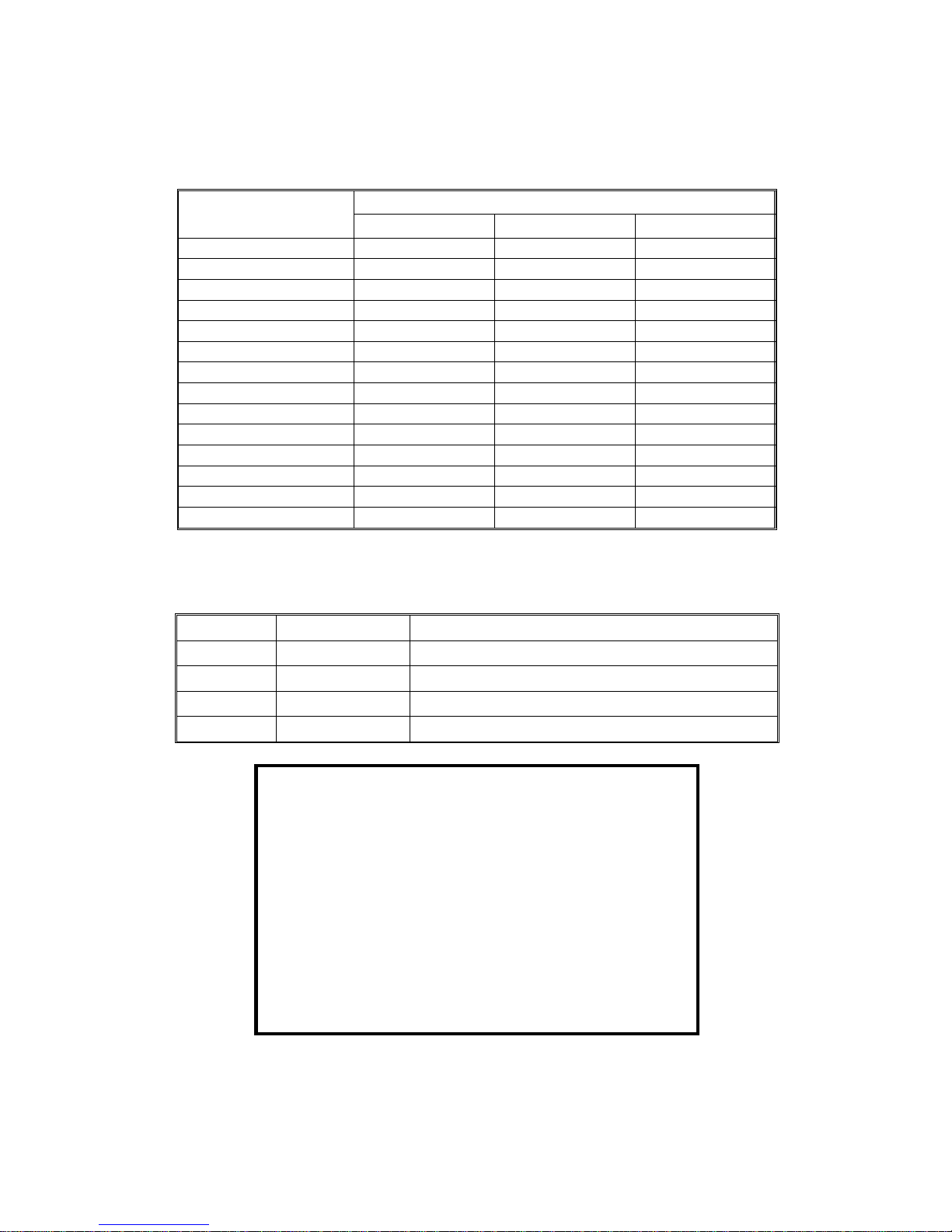

LEGEND

PRODUCT CODE COMPANY

GESTETNER

RICOH SAVIN

A156 2635TD FT5535 9035DL

A153 2635 FT5035 9035

A160 2627TD FT4527 9027DL

A157 2627 FT4027 9027

A162 2822TD FT4522 9220DL

A161 2822 FT4022 9220

A207 CMR402 FT5840 9400D

A208 CMR321 FT5632 9032

A211 CMR322 FT5832 9032D

A206 CMR401A FT5740 9400L

A204 CMR401 FT5640 9400

A210 CMR321A FT5732 9032L

A212 — FT4622 9122

A214 — FT4822 9122DL

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

13/95Original printing

27/95A162/A161 addition

35/97A207/A208/A211 Addition

4 12/97 A212/A214 Addition

The A204 copier is based on the A153 copier.

The A206 copier is based on the A155 copier.

The A207 copier is based on the A156 copier.

The A208 copier is based on the A157 copier.

The A210 copier is based on the A159 copier.

The A211 copier is based on the A160 copier.

The A212 copier is based on the A161 copier.

The A214 copier is based on the A162 copier.

Only the differences from the base copiers are described in the

following pages. Therefore, this documentation should be treated

as an insert version of the base copier’s service manual, although

it has a separate binder. It should always be utilized together with

the base copier’s service manual.

Rev. 4/98

Page 10

Page 11

The Service Training Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or certified

by successfully completing a Ricoh Technical

Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

WARNING

Page 12

Page 13

Table of Contents

1. OVERALL MACHINE INFORMATION

1. SPECIFICATIONS..............................................................1-1

2. MACHINE CONFIGURATION.......... .. .................. ..............1-5

2.1 COPIER ......................................................................................1-5

2.2 OPTIONAL EQUIPMENT ...........................................................1-6

3. MECHANICAL COMPONENT LAYOUT........................... 1-7

4. PAPER PATH ................................................................. 1-10

4.1 NORMAL COPYING..................................................................1-10

4.2 DUPLEX COPYING .................................................................1-11

5. ELECTRICAL COMPONENT DESCRIPTIONS ..............1-12

6. DRIVE LAYOUT ............................................................... 1-17

6.1 ALL MODELS ...........................................................................1-17

6.2 A153/A156 ...............................................................................1-18

6.3 A157/A160/A161/A162 ..............................................................1-18

2. DETAILED DESCRIPTIONS

1. PROCESS CONTROL .......................................................2-1

1.1 OVERVIEW..................................................................................2-1

1.1.1 Copy Process aro und the Drum.. ... ... ... ... ......................... ... .. ... ... ..............2-1

1.1.2 Factors Affecting Proce ss Con t ro l ...........................................................2-4

1.1.3 Process Control Pro ce du re s.............................. ......................... ... ... .. ... ...2- 5

1.1.3.1 Copy Image Contr o l............................... .......................... .. ... ... ... ...........2-5

1.1.3.2 Image Density Cont r ol................ ... ... ... .. .......................... .. ... ... ... ...........2-5

1.1.3.3 Drum Potential Control...........................................................................2-5

1.2 COPY IMAGE CONTROL............................................................2-8

1.2.1 Manual ID Correctio n.............................. .. ... ......................... ... ... ... ... ........2-8

1.2.2 Reproduction Ratio Cor rec tion........................ ... ... .. ... ...............................2-9

1.2.3 ADS Correction.............................. ... ... ......................... ... ... .. ... ...............2-10

Rev. 7/95

STM i A156/A160/A162

Page 14

1.3 IMAGE DENSITY CONTROL ....................................................2-10

1.3.1 Overview............... ... .................................................. ... ... ... .. ..................2-10

1.3.2 V

SP

and V

SG

Detection .........................................................................2-11

1.3.3 ID Correction for the V

SP

Pattern ...........................................................2-12

1.3.4 Toner Supply Control During Copying....................................................2-14

1.3.5 Toner Supply in Abnormal Sensor Conditions........................................2-16

1.4 DRUM POTENTIAL CONTROL.................................................2-18

1.4.1 VR Pattern Correction ...........................................................................2-18

1.4.2 V

L

Pattern Correction ...........................................................................2-20

1.4.3 T/H Correction ......................................................................................2-23

1.5 PROCESS CONTROL DURING ABNORMAL CONDITIONS ..2-25

1.6 SUMMARY.................................................................................2-26

1.6.1 Process Control and Sensor Detection Timing.......................................2-26

1.6.2 Process Control Checks During Machine Operation..............................2-27

2. DRUM .............................................................................2-32

2.1 DRUM UNIT...............................................................................2-32

2.2 DRIVE MECHANISM ...............................................................2-33

3. DRUM CHARGE .............................................................. 2-34

3.1 OVERVIEW ..............................................................................2-34

3.2 DRUM CHARGE ROLLER DRIVE MECHANISM ..................2-35

3.3 DRUM CHARGE ROLLER CLEANING ....................................2-37

3.4 TEMPERATURE COMPENSATION .....................................2-38

4. OPTICS............................................................................. 2-39

4.1 OVERVIEW .............................................................................2-39

4.2 SCANNER DRIVE ...................................................................2-41

4.3 LENS DRIVE..............................................................................2-41

4.4 HORIZONTAL LENS POSITIONING .......................................2-43

4.4.1 Original Alignment Position ....................................................................2-43

4.4.2 Paper Size ...................... ... ... ... .. .......................... .. ... ... ... .......................2-43

4.4.3 Reproduction Ratio ................................................................................2-43

4.5 3RD SCANNER DRIVE ...........................................................2-45

Rev. 7/95

A156/A160/A162 ii STM

Page 15

4.6 UNEVEN LIGHT INTENSITY CORRECTION ........................2-46

4.7 ORIGINAL SIZE DETECTION IN PLATEN MODE ................2-47

4.8 AUTOMATIC IMAGE DENSITY CONTROL

SYSTEM (ADS) .........................................................................2-49

5. ERASE.............................................................................. 2-51

5.1 OVERVIEW ...............................................................................2-51

5.2 LEADING EDGE AND TRAILING EDGE ERASE.....................2-52

5.3 SIDE ERASE..............................................................................2-52

6. DEVELOPMENT ..............................................................2-53

6.1 OVERVIEW ..............................................................................2-53

6.2 DRIVE MECHANISM ...............................................................2-54

6.3 CROSS-MIXING ....................................................................2-55

6.4 TONER DENSITY SENSOR ....................................................2-56

6.5 DEVELOPMENT BIAS CONTROL............................................2-57

6.6 TONER SUPPLY .......................................................................2-58

6.6.1 Toner Bottle Replenishment Mechanism ..............................................2-58

6.6.2 Toner Supply Mechanism ....................................................................2-59

6.6.3 Toner End Detection .............................................................................2-59

7. IMAGE TRANSFER AND PAPER SEPARATION ..........2-61

7.1 PRE-TRANSFER LAMP ...........................................................2-61

7.2 IMAGE TRANSFER AND PAPER SEPARATION ....................2-62

7.3 IMAGE TRANSFER AND PAPER SEPARATION

MECHANISM ..........................................................................2-63

7.4 TRANSFER BELT UNIT LIFT MECHANISM ............................2-65

7.5 PAPER TRANSP ORTATION AND BELT DRIVE

MECHANISM ...........................................................................2-66

7.6 TRANSFER BELT CLEANING MECHANISM ..........................2-67

7.7 TRANSFER BELT UNIT RELEASE MECHANISM ..................2-69

8. DRUM CLEANING ..........................................................2-70

8.1 OVERVIEW ..............................................................................2-70

8.2 DRIVE MECHANISM ................................................................2-71

Rev. 7/95

STM iii A156/A160/A162

Page 16

8.3 CLEANING BLADE PRESSURE MECHANISM AND

SIDE-TO-SIDE MOVEMENT ...................................................2-72

8.4 TONER COLLECTION MECHANISM ......................................2-73

9. TONER RECYCLING ......................................................2-74

9.1 OVERVIEW................................................................................2-74

9.2 NEW TONER AND RECYCLED TONER MIXTURE.................2-75

10. QUENCHING ................................................................. 2-76

11. PAPER FEED AND REGISTRATION ........................... 2-77

11.1 OVERVIEW ............................................................................2-77

11.2 PAPER FEED MECHANISM [A153/A156] ..............................2-78

11.2.1 Drive Mechanism ................................................................................2-78

11.2.2 Slip Clutch Mechanism .......................................................................2-79

11.2.3 Separation Roller Release Mechanism ................................................2-80

11.3 PAPER FEED DRIVE MECHANISM [A157/A160] ...............2-81

11.4 PAPER LIFT MECHANISM ....................................................2-82

11.5 PAPER END DETECTION .....................................................2-85

11.6 PAPER SIZE DETECTION .....................................................2-87

11.7 SIDE FENCE DOUBLE STOPPER

MECHANISM [A157/A160] ....................................................2-88

11.8 LARGE CAPACITY TRAY .......................................................2-89

11.8.1 Paper Lift Mechanism ..........................................................................2-89

11.8.2 Paper Feed Mechanism .......................................................................2-90

11.8.3 Paper End Detection ............................................................................2-90

11.9 BY-PASS FEED TABLE ..........................................................2-91

11.9.1 Table Open/Closed Detection ..............................................................2-91

11.9.2 Feed Mechanism/Paper End Detection ..............................................2-91

11.9.3 By-pass Feed Paper Width Detection .................................................2-92

11.10 PAPER REGISTRATION ......................................................2-93

11.11 PAPER FEED AND MISFEED DETECTION TIMING...........2-94

11.11.1 Paper Feed Tray.................................................................................2-94

11.11.2 By-pass Feed .....................................................................................2-96

Rev. 7/95

A156/A160/A162 iv STM

Page 17

11.11.3 (A160/A157)........................................................................................2-96

12. DUPLEX ......................................................................2-97

12.1 OVERVIEW..............................................................................2-97

12.2 DRIVE MECHANISM ............................................................2-98

12.3 TURN GUIDE SECTION .........................................................2-99

12.4 DUPLEX ENTRANCE TO DUPLEX TRAY ...........................2-100

12.5 DUPLEX STACKING .........................................................2-101

12.6 PAPER FEED FROM THE DUPLEX TRAY ........................2-102

12.6.1 Tray Lift Mechanism............................................................................2-102

12.6.2 Paper Feed System ...........................................................................2-103

13. IMAGE FUSING........................................................... 2-104

13.1 OVERVIEW ..........................................................................2-104

13.2 FUSING DRIVE AND RELEASE MECHANISM ..................2-105

13.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM .............2-106

13.4 PRESSURE ROLLER ...........................................................2-107

13.5 CLEANING MECHANISM .....................................................2-107

13.6 FUSING LAMP CONTROL ..................................................2-108

13.7 OVERHEAT PROTECTION...................................................2-111

13.8 ENERGY SAVER FUNCTIONS.............................................2-111

13.9 MAIN FUSING LAMP INTERCHANGEABILITY....................2-111

3. AUTO REVERSE DOCUMENT FEEDER A548

1. SPECIFICATIONS..............................................................3-1

2. COMPONENT LAYOUT..................................................... 3-2

2.1 MECHANICAL COMPONENTS .................................................3-2

2.2 ELECTRICAL COMPONENTS ..................................................3-3

3. ELECTRICAL COMPONENT DESCRIPTION...................3-4

4. DETAILED DESCRIPTIONS ............................................. 3-5

4.1 ORIGINAL PICK-UP MECHANISM.............................................3-5

4.2 SEPARATION AND PAPER FEED MECHANISM ......................3-6

4.3 FRICTION BELT DRIVE MECHANISM.......................................3-7

Rev. 7/95

STM v A156/A160/A162

Page 18

4.4 ORIGINAL SIZE DETECTION ....................................................3-8

4.5 PAPER TRANSPORT MECHANISM ........................................3-9

4.6 THICK/THIN ORIGINAL MODES .............................................3-10

4.7 ORIGINAL FEED-OUT MECHANISM .....................................3-11

4.8 TWO-SIDED ORIGINAL FEED MECHANISM .........................3-12

5. TIMING CHARTS ............................................................3-13

5.1 A4 SIDEWAYS: 1 SIDED ORIGINAL ........................................3-13

5.2 COMBINE 2 ORIGINAL MODE ................................................3-14

5.3 A4 SIDEWAYS: DUPLEX ........................................................3-15

4. PAPER TRAY UNIT A550/A549

1. SPECIFICATIONS..............................................................4-1

2. COMPONENT LAYOUT..................................................... 4-2

2.1 MECHANICAL COMPONENT LAYOUT .....................................4-2

2.2 DRIVE LAYOUT...........................................................................4-3

2.3 ELECTRICAL COMPONENT DESCRIPTION.............................4-4

3. OVERVIEW......................................................................... 4-5

4. DRIVE MECHANISM..........................................................4-6

5. PAPER FEED AND MISFEED DETECTION TIMING .......4-7

5. PAPER TRAY UNIT A553

1. SPECIFICATIONS..............................................................5-1

2. COMPONENT LAYOUT..................................................... 5-2

2.1 MECHANICAL COMPONENT LAYOUT .....................................5-2

2.2 DRIVE LAYOUT...........................................................................5-2

2.3 ELECTRICAL COMPONENT DESCRIPTION.............................5-3

3. OVERVIEW......................................................................... 5-4

4. DRIVE MECHANISM..........................................................5-5

5. PAPER FEED AND MISFEED DETECTION TIMING .......5-6

Rev. 7/95

A156/A160/A162 vi STM

Page 19

6. SORTER STAPLER A554

1. SPECIFICATIONS..............................................................6-1

2. COMPONENT LAYOUT..................................................... 6-3

2.1 MECHANICAL COMPONENT LAYOUT .....................................6-3

2.2 DRIVE LAYOUT...........................................................................6-4

2.3 ELECTRICAL COMPONENT DESCRIPTION ............................6-5

3. BASIC OPERATION .......................................................... 6-7

3.1 NORMAL MODE AND SORT/STACK MODE ............................6-7

3.2 STAPLE MODE ........................................................................6-9

4. TURN GATE SECTION ................................................... 6-11

5. ROLLER DRIVE AND CONTROL...................................6-12

6. BIN DRIVE AND CONTROL............................................ 6-14

7. JOGGER SECTION ........................................................6-17

8. GRIP ASSEMBLY ......................................................... 6-19

9. STAPLER.........................................................................6-21

10. JAM DETECTION AND STAPLER ERROR.................. 6-24

10.1 SORTER JAMS .......................................................................6-24

10.2 STAPLER ERROR...................................................................6-25

11. TIMING CHARTS ........................................ ................... 6-26

7. SORTER STAPLER A555

1. SPECIFICATIONS .............................................................7-1

2. COMPONENT LAYOUT ................................................... 7-3

2.1 MECHANICAL COMPONENT LAYOUT ....................................7-3

2.2 DRIVE LAYOUT .........................................................................7-4

2.3 ELECTRICAL COMPONENT DESCRIPTION.............................7-5

3. BASIC OPERATION ......................................................... 7-6

Rev. 7/95

STM vii A156/A160/A162

Page 20

3.1 NORMAL MODE AND SORT/STACK MODE .............................7-6

3.2 STAPLE MODE ..........................................................................7-8

3.3 BIN DRIVE MECHANISM .........................................................7-10

3.4 BIN HOME POSITION ..............................................................7-11

3.5 JOGGER MECHANISM ............................................................7-12

3.6 GRIP ASSEMBLY ..................................................................7-13

3.7 STAPLER UNIT ........................................................................7-14

3.8 STAPLER SWITCH ..................................................................7-15

3.9 PAPER FEED AND MISFEED DETECTION TIMING ............7-16

3.10 JAM DETECTION ...................................................................7-18

8. SORTER A556

1. SPECIFICATIONS..............................................................8-1

2. MECHANICAL COMPONENT LAYOUT........................... 8-2

3. ELECTRICAL COMPONENT LAYOUT............................. 8-3

4. ELECTRICAL COMPONENT DESCRIPTIONS ................8-4

5. BASIC OPERATION .......................................................... 8-5

6. EXAMPLE OF SORT MODE OPERATION......... .. . . ..........8-6

7. BIN DRIVE MECHANISM .................................................. 8-8

8. BINS ................................................................................. 8-10

9. EXIT ROLLERS................................................................8-11

10. TIMING CHART..... ......................................................... 8-12

9. SORTER A557

1. SPECIFICATIONS..............................................................9-1

2. COMPONENT LAYOUT..................................................... 9-2

3. ELECTRICAL COMPONENT DESCRIPTIONS ................9-3

4. BASIC OPERATION .......................................................... 9-4

Rev. 7/95

A156/A160/A162 viii STM

Page 21

5. EXIT ROLLER DRIVE MECHANISM................................. 9-5

6. BIN DRIVE MECHANISM .................................................. 9-6

7. MISFEED DETECTION .....................................................9-8

Rev. 7/95

STM ix A156/A160/A162

Page 22

Page 23

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copi er po wer cord is un pl u gg ed.

2. The wall outle t sho ul d be near th e cop i er an d ea si ly accessib l e.

3. Note that the drum heater and the optional anti-condensation heaters are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or m ech an i cal ly dri ven components.

5. The inside and th e m et al pa r ts of the fusing unit become extre mel y ho t

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1 . Toner and developer are non-toxic , but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush wit h wat er as fi r st aid. If unsuccessful, get medical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

CAUTION

2. The RAM board has a lithium battery which can explode if handled

incorrectly. Replace only with the same type of RAM board. Do not

recharge or burn this battery. Used RAM boards must be handled

in accordance with local regulations.

STM a A156/A160/A162

Page 24

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1 . Do not incinerate toner cartridges or us ed toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used to ne r , de vel o pe r , an d or g an i c pho to con du ctors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4 . When keeping used lithium batteries (from the main control boards) in

order to dispose of th em lat er , do no t sto r e m or e tha n 10 0 ba tt er i e s (f rom

the main control boa r ds) pe r seale d bo x. Storing larger numbers or not

sealing them apart may lead to chemical reactions an d heat build-up.

A156/A160/A162 b STM

Page 25

TAB INDEX

TAB POSITION 1

TAB POSITION 2TAB POSITION 3TAB POSITION 4

TAB POSITION 5TAB POSITION 6

TAB POSITION 7TAB POSITION 8

OVERALL MACHINE INFORMATION

SORTER A557

Rev. 1/98

DETAILED SECTION DESCRIPTION

AUTO REVERSE DOCUMENT FEEDER A548

PAPER TRAY UNIT A550/A549

PAPER TRAY UNIT A553

SORTER STAPLER A554

SORTER STAPLER A555

SORTER A556

Page 26

Page 27

OVERALL MACHINE

INFORMATION

Page 28

Page 29

1. SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x17" (Paper trays)

Minimum

A5/8

1/2

" x 5

1/2

" sideways (Paper trays)

A4/11" x 8

1/2

" sideways (LCT)

A6/5

1/2

" x 8

1/2

" lengthwise (By-pass)

Duplex Copying: Maximum

A3/11" x 17"

Minimum

A5/8

1/2

" x 5

1/2

" (sideways)

Copy Paper Weight: Paper tray:

52 ~ 128 g/m2, 14 ~34 lb

(A153, A155, and A1 56 copie r s)

64 ~ 90 g/m2, 17 ~ 24 lb

(A157, A159, and A1 60 copie r s)

By-pass:

52 ~ 157 g/m2, 14 ~42 lb

LCT:

52 ~ 128 g/m2, 14 ~ 34 lb

Duplex copying:

64 ~ 105 g/m2, 17 ~ 24 lb

Reproduction Ratios: 4 Enlargement an d 6 Red uct i on

A4/A3 Version LT/DLT Version

Enlargement

200%

141%

122%

115%

200%

155%

129%

121%

Full size 100% 100%

Reduction

93%

82%

75%

71%

65%

50%

93%

85%

77%

74%

65%

50%

Power Source: 120V/60Hz:

More than 12 A (for North America)

Rev. 7/95

Overall Machine

Information

STM 1-1 A156/A160/A162

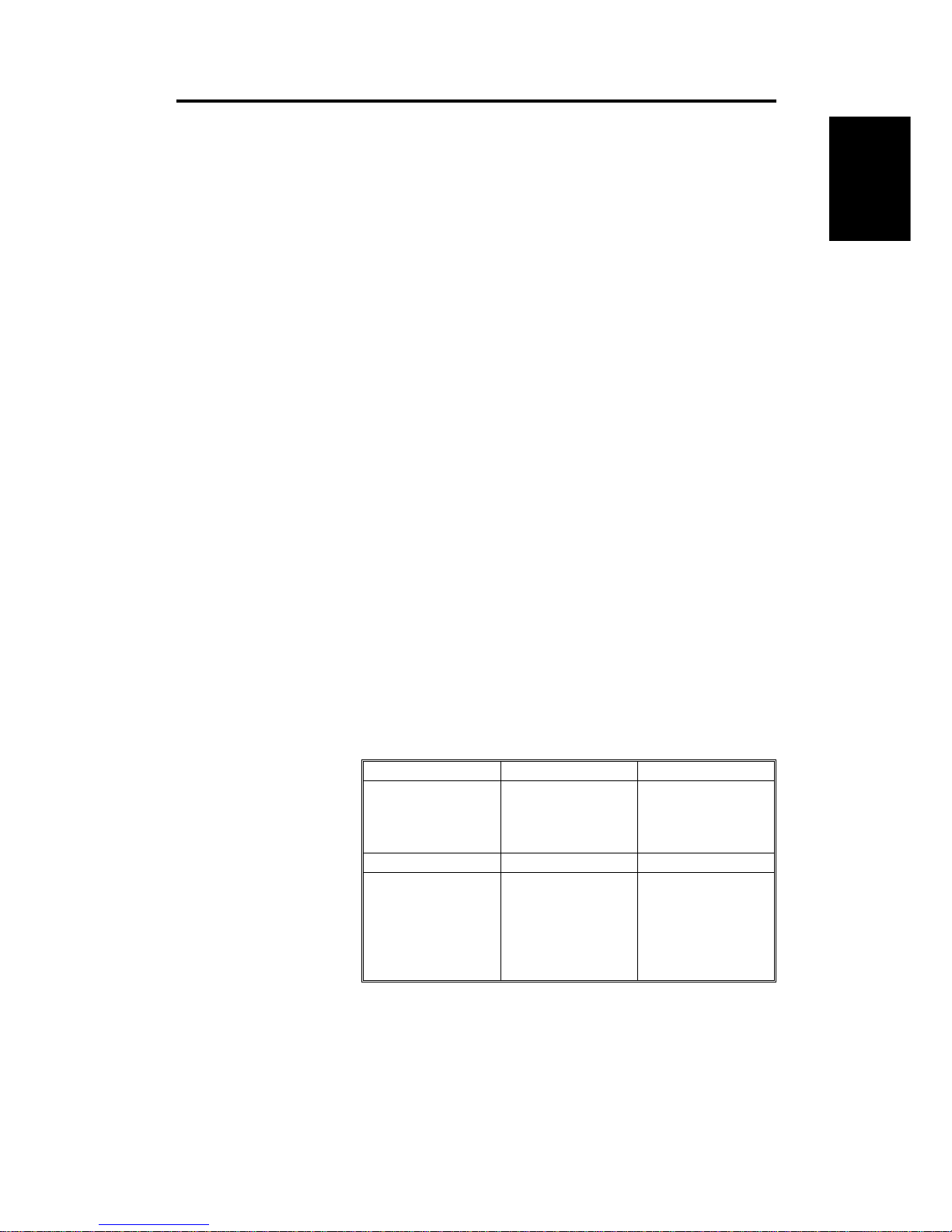

Page 30

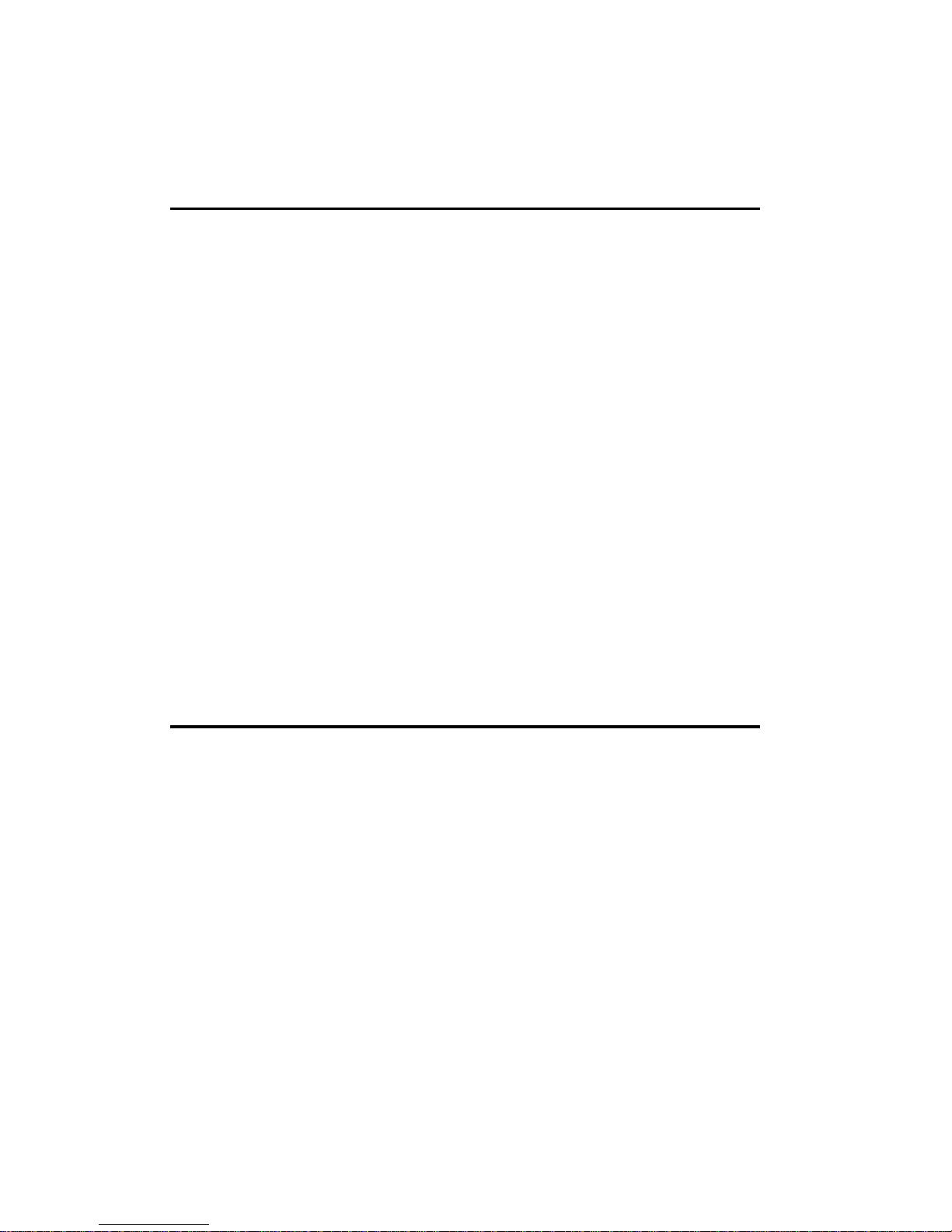

Power Consumption:

A153, and A156 copiers A157, and A160 copiers

Copier Only Full System Copier Only Full System

Maximum 1.45 KW 1.50 KW 1.45 KW 1.50 KW

Copying 1.00 KW 1.00 KW 0.80 KW 0.80 KW

Warm-up 0.90 KW 0.92 KW 0.90 KW 0.92 KW

Stand-by 0.16 KW 0.19 KW 0.15 KW 0.17 KW

Energy

Saver

1 0.15 KW 0.17 KW 0.14 KW 0.16 KW

2 0.13 KW 0.15 KW 0.12 KW 0.13 KW

3 0.12 KW 0.14 KW 0.09 KW 0.10 KW

4 0.11 KW 0.12 KW 0.07 KW 0.08 KW

5 0.09 KW 0.11 KW 0.05 KW 0.06 KW

6 0.07 KW 0.09 KW – –

Auto Off 0.02 KW 0.04 KW 0.02 KW 0.04 KW

NOTE:

1) Full System: Copier + ADF + Pap er Tr ay Unit + 20 Bin S/S

2) Energy Saver: See SP 1- 1 05 - 00 2

3) Auto Off: See SP5-305

A161 and A162 Copiers

Copier Only Full System

Maximum 1.45 KW 1.50 KW

Copying 0.64 KW 0.72 KW

Warm-up 0.95 KW 0.97 KW

Stand-by 0.15 KW 0.17 KW

Energy Saver

1 0.14 KW 0.16 KW

2 0.12 KW 0.13 KW

3 0.09 KW 0.10 KW

4 0.07 KW 0.08 KW

5 0.05 KW 0.06 KW

Auto Off 0.02 KW 0.04 KW

NOTE:

1) Full System: Copier + ADF + Pap er Tr ay Unit + 10 Bin S/S

2) Energy Saver: See SP 1- 1 05 - 00 2

3) Auto Off: See SP5-305

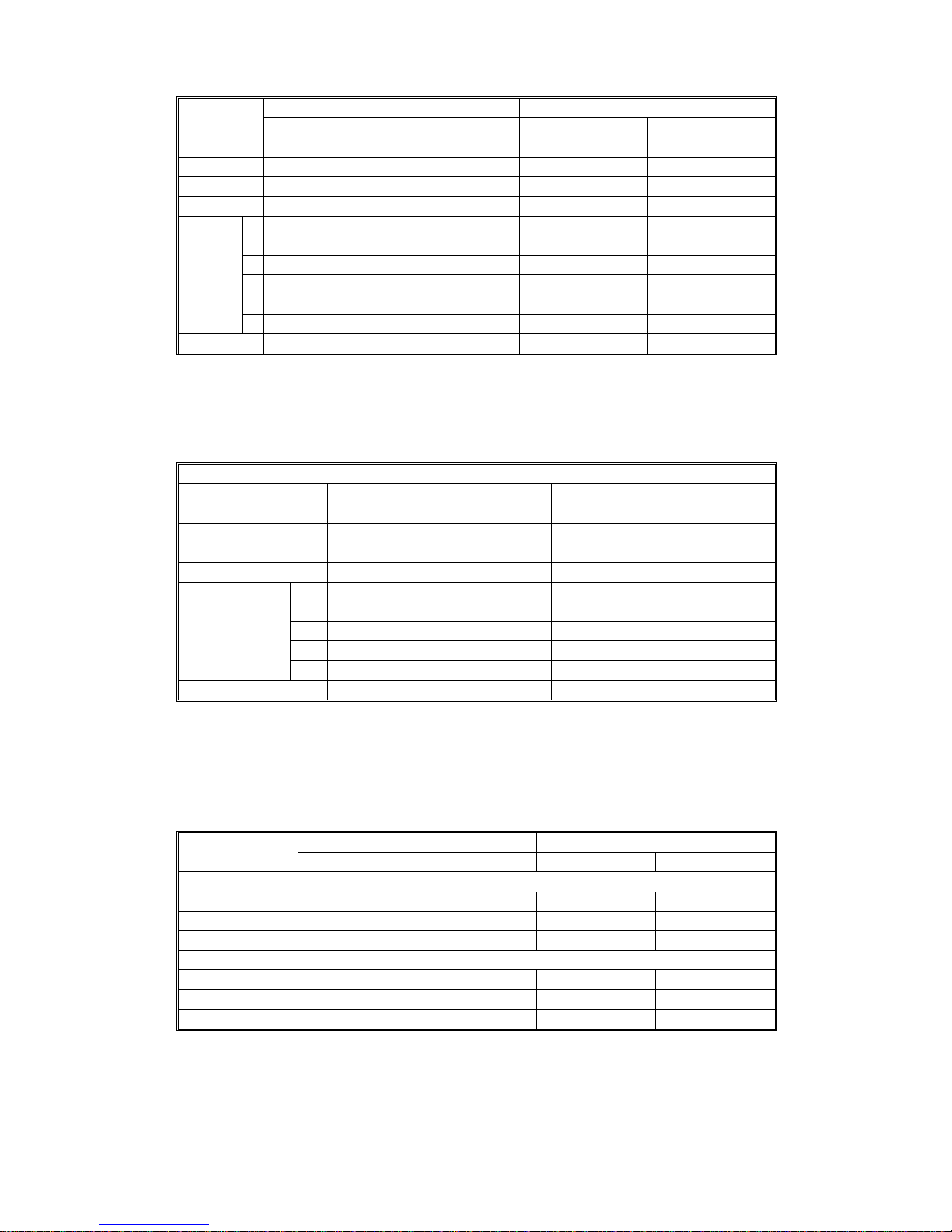

Noise Emission:

A153, and A156 copiers A157, and A160 copiers

Copier Only Full System* Copier Only Full System*

1. Sound Power Level

Copying 66 dB(A) 68 dB(A) 61 dB(A) 67 dB(A) (L

WA

)

Warm-up 41 dB(A) 41 dB(A) 39 dB(A) 40 dB(A) (L

WA

)

Stand-by 41 dB(A) 41 dB(A) 39 dB(A) 40 dB(A) (L

WA

)

2. Sound Pressure Level at the operator position

Copying 58 dB(A) 57 dB(A) 54 dB(A) 56 dB(A) (L

PA

)

Warm-up 33 dB(A) 27 dB(A) 32 dB(A) 27 dB(A) (L

PA

)

Stand-by 33 dB(A) 27 dB(A) 32 dB(A) 27 dB(A) (L

PA

)

NOTE:

The above measurements are to be made according to ISO 7779.

* : Full System: Copier + ADF + Paper Tray Unit +10 Bin S/S.

Rev. 7/95

A156/A160/A162 1-2 STM

Page 31

Dimensions:

Width Depth Height

A153 copier 1030 mm (40.6") 655 mm (25.8") 606 mm (23.9")

A157/A161 copier 900 mm (35.5") 655 mm (25.8") 606 mm (23.9")

A156 copiers 1258 mm (49.6") 655 mm (25.8") 606 mm (23.9")

A160/A162 copiers 1128 mm (44.5") 655 mm (25.8") 606 mm (23.9")

Measurement Conditions

1) With by-pass feed tabl e close d

2) With platen cover and copy tray attached

3) With LCT cover closed

Weight:

Weight

FT5035 A153 copier About 70 kg (154.2 lb)

FT5535 A156 copier About 82 kg (180.7 lb)

FT4027 A157 copier About 67 kg (147.7 lb)

FT4527 A160 copier About 80 kg (176.4 lb)

FT4022 A161 copier About 67 kg (147.7 lb)

FT4522 A162 copier About 80 kg (176.4 lb)

Zoom: From 50% to 200% in 1% steps

Copying Speed (cop i es/ m inu te):

A4 sideways/

11" x 8

1/2

"

A3/11" x 17" B4/8

1/2

" x 14"

A153, and A156

copiers

35 20/19 22

A157, and A160

copiers

27 15/14 17

A161, and A162

copiers

22 12 -

Warm-Up Time A153, and A156 copiers:

Less than 110 seconds (20°C)

A157, and A160 copiers:

Less than 80 seconds (20°C)

A161 and A162 copier s:

Less than 60 seconds (20°C)

First Copy Time:

Paper Feed Station

A4/11" x 8

1/2

" (sideways)

A153, and A156

copiers

A157, and A160

copiers

A161, and A162

copiers

1st Tray

5.2 s (except for

A156)

5.9 s (except for

A160)

5.9 s (except for

A162)

2nd Tray 5.7 s 6.6 s 6.6 s

By-pass 4.8 s 5.6 s 5.6 s

LCT 5.0 s 5.9 s 5.9 s

Note:

In A156, A160 and A161 copiers, the 2nd tray in the above table is

called the 1st tray (see Inst allation - Paper Feed Station Definitio n).

Rev. 7/95

Overall Machine

Information

STM 1-3 A156/A160/A162

Page 32

Copy Number Input: Ten-key pad, 1 to 999 (count up or count down)

Manual Image Density

Selection:

7 steps

Automatic Reset: 1 minute is the standard setting; it can be

changed to a maximum of 999 seconds or no

auto reset by SP mode.

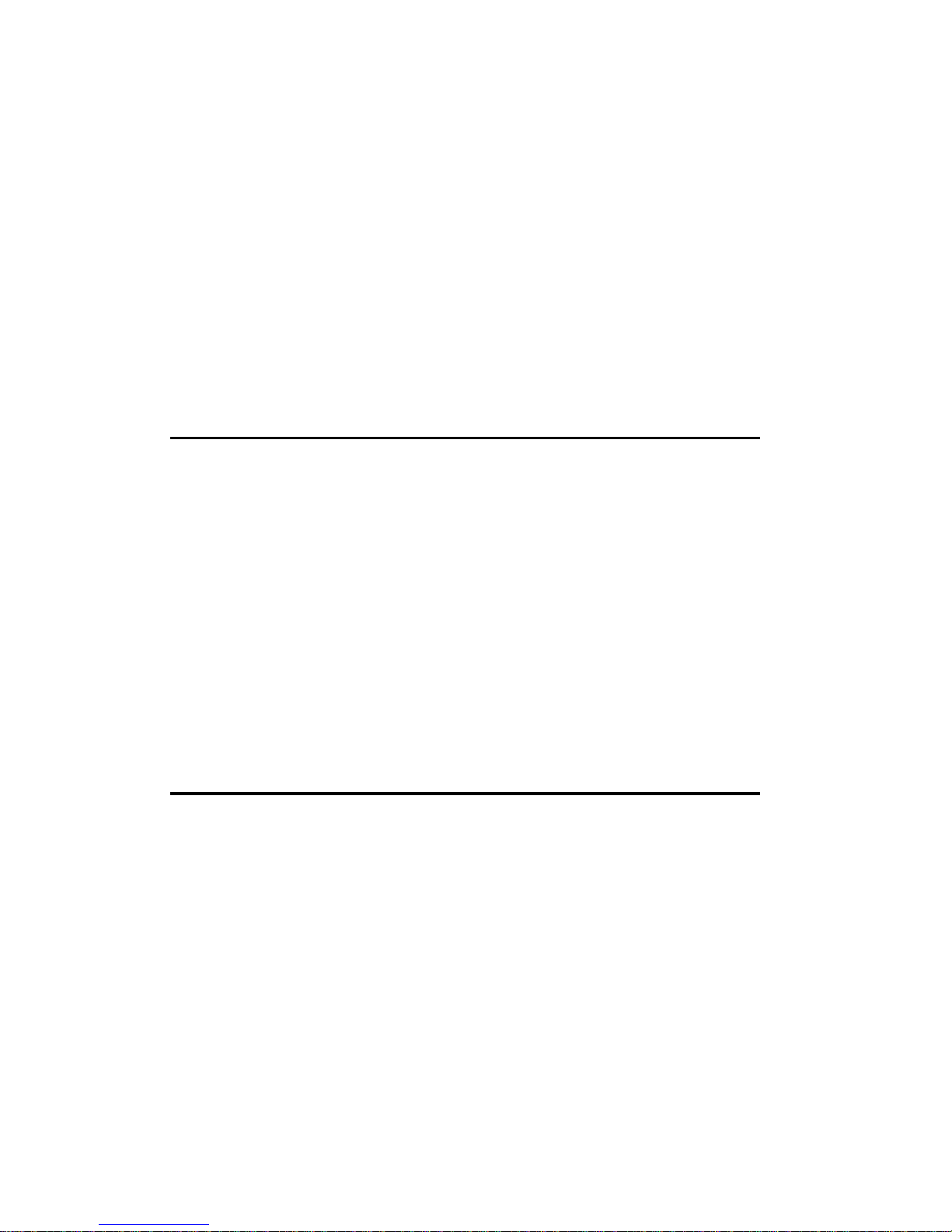

Copy Paper Capacity:

Paper Tray By-pass Feed LCT

A153 copier About 500 sheets x2 About 40 sheets –

A156 copier About 500 sheets x1 About 40 sheets About 1000 sheets

A157 copier About 250 sheets x2 About 40 sheets –

A160 copier About 250 sheets x1 About 40 sheets About 1000 sheets

A161copier About 250 sheets x2 About 40 sheets –

A162 copier About 250 sheets x1 About 40 sheets About 1000 sheets

Duplex Tray Capacity

[A156/A160/A162]:

50 sheets (30 sheets for A3/11"x17"

81 ~ 105g/m2, 21.5 ~ 27.9 lb paper)

Toner Replenishment: Cartridge exchange (415 g/cartridge)

Toner Yield: 17K Copies/cartridge

Developer Replenishment: Type 1 (1kg bag)

Developer Yield: A153/A156 @ 120K copies

A157/A160 @ 100K copies

A161/A162 @ 100K copies

Optional Equi p m en t: • Platen cover

• Document feeder

• Paper tray unit with tw o pa pe r tr ays

•

Paper tray unit with thr e e pa pe r tr ays

•

10 bin micro sorter

•

20 bin mini sorter

• 10 bin sorter stapler

• 20 bin sorter stapler (Not used with A161 and A1 62)

•

Sorter adapter (required when installing 20

bin mini sorter, 10 bin sorter stapler, or 20 bin

sorter stapler for A157, A160, A161, and A162 copiers)

•

Key counter

•

Tray heater

•

Optical anti-condensation heater

•

Original length sensor for 11" x 15" size

paper (only for LT/DLT version)

•

ADS sensor for par ticu lar types of r ed orig ina l

•

Zoom (10 Key) Function Decal *

•

Margin Adjustment Function Decal *

Rev. 7/95

* Not used on FT4022/4522 (A161/A162 copiers)

A156/A160/A162 1-4 STM

Page 33

2. MACHINE CONFIGURATION

2.1 COPIER

Rev 7/95

Overall Machine

Information

STM 1-5 A156/A160/A162

Page 34

2.2 OPTIONAL EQUIPMENT

*

Only available on models FT5535, FT4527 and FT4522

** Not for use on FT4022/4522 (A161/A162) copiers.

Rev 7/95

A156/A160/A162 1-6 STM

Page 35

3. MECHANICAL COMPONENT LAYOUT

– A156 copier –

NOTE:

The A153 copier is the same as the A156 copier except that the

A153 does not hav e a duplex tray or an LCT.

14

5

30

31

32

33

34

35

36

37

38

1

2

3

4

28 27 26

25

24 23

22

21

20

19

18

17

16

13

12

11

1098

7

6

29

15

Overall Machine

Information

STM 1-7 A156/A160/A162

Page 36

– A160/A162 copier –

NOTE:

The A157/A161 copiers are the same as the A160/A162 copiers

except that the A157 and A161 do not have a duplex tray or an LCT.

Rev. 7/95

14

5

30

31

32

33

34

35

36

37

38

1

2

3

4

28

27

26

25

24

23

22

21

20

19

18

17

16

13

12

11

1098

7

6

29

15

A156/A160/A162 1-8 STM

Page 37

Rev. 7/95

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lens

6. Quenching Lam p

7. Drum Cleaning Blade

8. Drum Charge Roller

9. 6th Mirror

10. OPC Drum

11. Erase Lamp

12. 4th Mirror

13. 5th Mirror

14. Toner Supply Unit

15. Pre-transfer La m p

16. Development Unit

17. Registration Rollers

18. Feed Roller

19. Pick-up Roller

20. Separation Roller

21. Large Capacity Tray

22. Vertical Transport Rollers

23. Paper Feed Roller

The roller for A153/A156

copiers is different from that

for A157/160/161/162 copiers.

24. Friction Pad

25. Duplex Friction Roller

26. Duplex Feed Roller

27. Jogger Fence

28. Transfer Belt

29. Transfer Belt Cleaning Blade

30. Lower Paper Tray

31. End Fence

32. Entrance Rollers

33. Pick-off Pawls

34. Pressure Roller

35. Hot Roller

36. Junction Gate

37. Hot Roller Strippers

38. Transport Fan

Overall Machine

Information

STM 1-9 A156/A160/A162

Page 38

4. PAPER PATH

4.1 NORMAL COPYING

– A156 copier –

–A160/A162 copier –

Rev. 7/95

A156/A160/A162 1-10 STM

Page 39

4.2 DUPLEX COPYING

– A156 copier –

– A160/A162 copier –

Rev. 7/95

Overall Machine

Information

STM 1-11 A156/A160/A162

Page 40

5. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point to point diagram on the

waterproof paper in the pocket for symbols and index numbers.

Symbol

Index

No.

Description Note

Printed Circuit Boards

PCB1 14

Main Control Controls all copier functions both directly or

through other control boards.

PCB2 12

AC Drive Provides ac power to the exposure lamp and

fusing lamps.

PCB3 11 DC Power Supply Provides dc power.

PCB4 96 Main Motor Control Controls the rotation of the main motor.

PCB5 1

CB High Voltage

Supply

Supplies high voltage to the drum charge

roller and development roller.

PCB6 55 T High Voltage Supply Supplies high voltage to the transfer belt.

PCB7 3

Operation Panel Controls the LED matrix, and monitors the

key matrix.

PCB8 8

Noise Filter (220 ~

240 V machines only)

Removes electrical noise.

PCB9 63

Duplex Control

(Duplex machines only)

Controls the operation of the duplex tray.

PCB10 6

Liquid Crystal Display

(A156 machines only)

Controls the guidance display and displays

guidance for machine operation.

PCB11 102

LCT Interface

(LCT machines only)

Interfaces the LCT control signal between

the main board and the LCT.

Motors

M1 88 Main Drives the main unit components.

M2 79

Toner Bottle Drive Rotates the toner bottle to supply toner to

the toner supply unit.

M3 97

Upper Tray Lift

(A153 machines only)

Raises the bottom plate in the upper paper

tray.

M4 86

Lower Tray Lift

(A153/A156

machines only)

Raises the bottom plate in the lower paper

tray.

M5 99

LCT Lift

(LCT machines only)

Lifts up and lowers the LCT bottom plate.

M6 94 Optics Cooling Fan 1 Removes heat from the optics unit.

M7 95

Optics Cooling Fan 2

(A153/A156

machines only)

Removes heat from the optics unit.

M8 89 Exhaust Fan 1 Re m oves the h eat fro m around the fu s ing uni t .

M9 90

Exhaust Fan 2

(A153/A156

machines only)

Removes the heat from around the fusing

unit.

M10 92 Scanner Drive Dri v e s t h e 1 s t and 2nd scanners (dc stepper motor).

M11 78 3rd Scanner Drive Drives the 3rd scanner (dc stepper motor).

M12 87 Lens Vertical Drive Shifts the lens vertical position.

M13 77 Lens Horizontal Drive Shifts the lens horizontal position.

M14 58

Duplex Feed

(Duplex machines only)

Drives the feed roller and moves the bottom

plate up and down.

M15 61

End Fence Jogger

(Duplex machines only)

Drives the end fence jogger to square the

paper stack.

A156/A160/A162 1-12 STM

Page 41

Symbol

Index

No.

Description Note

M16 60

Side Fence Jogger

(Duplex machines only)

Drives the side fence jogger to square the

paper stack.

Sensors

S1 27

By-pass Feed Paper

Width

Informs the CPU what width paper is in the

by-pass feed table.

S2 31

By-pass Feed Paper

End

Informs the CPU that there is no paper in

the by-pass tray.

S3 51

Upper Tray Paper End

(Non-duplex machines

only)

Informs the CPU when the upper paper tray

runs out of paper.

S4 107

Upper Relay Detects the leading edge of paper from the

upper tray to determine the stop timing of

the upper paper feed clutch,

and detects

misfeeds.

S5 29

Upper Tray Upper Li mit

(A153 machines only)

Detects the height of the paper stack in the

upper paper tray to stop the upper tray lift motor.

S6 52

Lower Tray Paper

End

Informs the CPU when the lower paper tray

runs out of paper.

S7 106

Lower Relay Detects the leading edge of paper from the

lower paper tray to determine the stop timing

of the lower paper feed clutch,

and detects

misfeeds.

S8 30

Lower Tray Upper Limit

(A153/A156

machines only)

Detects the height of the paper stack in the

lower paper tray to stop the lower tray lift motor.

S9 100

LCT Lower Limit

(LCT machines only)

Sends a signal to the CPU to stop lowering

the LCT bottom plate.

S10 26

LCT Paper End

(LCT machines only)

Informs the CPU when the LCT runs out of

paper.

S11 28

LCT Upper Limit

(LCT machines only)

Sends a signal to the CPU to stop lifting the

LCT bottom plate.

S12 28

Registration Detects the leading edge of the copy paper

to determine the stop timing of the paper

feed clutch,

and detects misfeeds.

S13 50

Image Density

(ID)

Detects the density of various patterns on

the drum during process control.

S14 53

Toner Density

(TD)

Detects the amount of toner inside the

development unit.

S15 39

Lens Horizontal HP Informs the CPU that the lens is at the

horizontal home position.

S16 20

Lens Vertical HP Informs the CPU that the lens is at the

full-size position.

S17 15

Scanner HP Informs the CPU when the 1st and 2nd

scanners are at the home position.

S18 24

3rd Scanner HP Informs the CPU when the 3rd scanner is at

the home position.

S19 21

Original Length-2 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

S20 45 Fusing Exit

Detects misfeeds.

S21 16

Platen Cover Informs the CPU whether the platen cover is

up or down (related to APS/ARE functions).

ARE: Auto Reduce and Enlarge

S22 54

Toner End Instructs the CPU to add toner to the toner

supply unit, and detects toner end conditions.

Rev. 7/95

Overall Machine

Information

STM 1-13 A156/A160/A162

Page 42

Symbol

Index

No.

Description Note

S23 43

Auto Response (Not

used on A161/A162

copiers)

Returns the operation panel display and

exits from the energy saver mode.

S24 23

Transfer Belt ContactHPInforms the CPU of the current position of

both the transfer belt unit and the drum

charge roller unit.

S25 13

Auto Image Density

(ADS Sensor)

Detects the background density of each

original in ADS mode.

S26 44

Original Width Detects the width of the original. This is one

of the APS (Auto Paper Select) sensors.

S27 19

Original Length-1 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

S28 56

Duplex Paper End

(Duplex machines only)

Detects paper in the duplex tray.

S29 57

Duplex Turn

(Duplex machines only)

Detects the trailing edge of the copy paper to

determine the jogging timing, and detects misfeeds.

S30 62

Duplex Entrance

(Duplex machines only)

Detects misfeeds.

S31 59

Side Fence Jogger

HP (Duplex machines

only)

Detects the home position of the duplex side

fence jogger.

S32 64

End Fence Jogger

HP (Duplex

machines only)

Detects the home position of the duplex end

fence jogger.

S33 22

Original Length

(Option for N.

American models)

Detects original length for 11" x 15" paper.

Switches

SW1 33

By-pass Feed Table Detects whether the by-pass feed table is

open or closed.

SW2 36

Upper Tray

(Non-duplex

machines only)

Detects whether the upper paper tray is in

place or not.

SW3 35

Lower Tray Detects whether the lower paper tray is in

place or not.

SW4 104

Tray Down

(LCT machines only)

Sends a signal to the CPU to lower the LCT

bottom plate.

SW5 25

Upper Tray Paper Size

(Non-duplex

machines only)

Determines what size of paper is in the

upper paper tray.

SW6 34

Lower Tray Paper

Size

Determines what size of paper is in the

lower paper tray.

SW7 32

Vertical Guide Set

(Non-LCT machines only)

Detects whether the vertical guide is open or not.

SW8 105

LCT Cover-1

(LCT machines only)

Detects whether the L CT cover is op en o r n ot.

SW9 103

LCT Cover-2

(LCT machines only)

Cuts the dc power line of the LCT lift motor.

SW10 42 Main Supplies power to the copier.

SW11 41

Front Cover Safety Detects whether the front door is open and

via relays cuts the ac power.

SW12 48

Exit Cover Safety

(A157/A160

machines only)

Detects whether the exit cover is open or not.

Rev. 7/95

A156/A160/A162 1-14 STM

Page 43

Symbol

Index

No.

Description Note

Magnetic Clutches

CL1 72

Toner Supply Turns the toner supply roller to supply toner

to the development unit.

CL2 71 Development Drives the development roller.

CL3 93

Transfer Belt Contact

(1/3 Turn Clutch)

Controls the touch and release movement of

both the transfer belt unit and the drum

charge roller unit.

CL4 73 Registration Drives the registration rollers.

CL5 74

By-pass Feed Starts paper feed from the by-pass feed

table or LCT.

CL6 76 Relay Drives the relay rollers.

CL7 84

Upper Paper Feed

(Non-duplex

machines only)

Starts paper feed from the upper paper tray.

CL8 85

Lower Paper Feed Starts paper feed from the lower paper tray.

Solenoids

SOL1 75

LCT machines:

LCT/By-Pass Pick-up

Solenoid

Non-LCT machines:

By-pass Pick-up

Solenoid

Picks paper up from the by-pass feed table.

When paper is fed from the LCT, this

solenoid assists SOL3.

SOL2 91

Junction Gate

(Duplex machines

only)

Moves the junction gate to direct copies to

the duplex tray or to the paper exit.

SOL3 98

LCT Pick-up

(LCT machines only)

Picks up paper from the LCT.

SOL4 80

Upper Tray Pick-up

(A153/ machines

only)

Controls the up/down movement of the

pick-up roller in the upper paper tray.

SOL5 82

Lower Tray Pick-up

(A153/A156

machines only)

Controls the up/down movement of the

pick-up roller in the lower paper tray.

SOL6 81

Upper Tray

Separation

(A153/ machines

only)

Controls the up-down movement of the

separation roller in the upper paper tray feed

station.

SOL7 83

Lower Tray

Separation

(A153/A156

machines only)

Controls the up-down movement of the

separation roller in the lower paper tray feed

station.

Lamps

L1 17

Exposure Applies high intensity light to the original for

exposure.

L2 65

Main Fusing Provides heat to the central area of the hot

roller.

L3 66 Secondary Fusing Provides heat to both ends of the hot roller.

L4 4

Pre-transfer Reduces the charge remaining on the drum

surface before transfer.

L5 5

Quenching Neutralizes any charge remaining on the

drum surface after cleaning.

Overall Machine

Information

STM 1-15 A156/A160/A162

Page 44

Symbol

Index

No.

Description Note

L6 2

Erase After exposure, this eliminates the charge on

areas of the drum that will not be used for

the image.

Heaters

H1 38

Drum Turns on when the main switch is off to keep

the temperature around the drum charge

roller at a certain level. Also prevents

moisture from forming around the drum.

H2 46

Optics

Anti-condensation

(option)

Turns on when the main switch is off to

prevent moisture from forming on the optics.

H3 37

Lower Tray

(option)

Turns on when the main switch is off to keep

paper dry in the lower paper tray.

Thermistors

TH1 69

Main Fusing Monitors the temperature at the central area

of the hot roller.

TH2 70

Secondary Fusing Monitors the temperature at the ends of the

hot roller.

TH3 47 Optics Monitors the temperature of the optics cavity.

TH4 49

Drum Charge Monitors the temperature of the drum charge

roller.

Thermofuses

TF1 68

Main Fusing Provides back-up overheat protection in the

fusing unit.

TF2 67

Secondary Fusing Provides back-up overheat protection in the

fusing unit.

TF3 18

Exposure Lamp Opens the exposure lamp circuit if the 1st

scanner overheats.

Counters

CO1 40

Total Keeps track of the total number of copies

made.

CO2 N/A

Key

(option)

Used for control of authorized use. The

copier will not operate until it is installed.

Others

CB1 9

Circuit Breaker

(220 ~ 240V

machines only)

Provides back-up high current protection for

electrical components.

CC1 10

Choke Coil

(220 ~ 240V

machines only)

Removes high frequency current.

TR1 7

Transformer

(220 ~ 240V

machines only)

Steps down the wall voltage to 100 Vac.

Rev. 7/95

A156/A160/A162 1-16 STM

Page 45

6. DRIVE LAYOUT

6.1 ALL MODELS

1. Drum Drive Pu lley

2. Drum Cha rge Roller Drive Gear

3. Transfer Belt Contact Clutch

Gear

4. Scanner Drive Motor

5. Sca nner Drive Pulley

6. Transfer Belt Dr i ve Ge ar

7. Fusing Unit Drive Gear

8. Main Motor

9. Main Pulley

10. Registration C lutch Gear

11. By-pass Feed Clutch Gear

12. Development Drive Clutch Gear

13. Toner Supply Clutch Gear

1

2

3

4

5

6

9

10

11

12

13

7

8

Overall Machine

Information

STM 1-17 A156/A160/A162

Page 46

6.2 A153/A156

1. Upper Paper Feed Clutch Gear (A153 only)

2. Lower Paper Feed Clutch Gear

3. Relay Clutch Gear

6.3 A157/A160/A161/A162

1. Upper Paper Feed Clutch Gear (A157 and A161 only)

2. Lower Paper Feed Clutch Gear

3. Relay Clutch Gear

Rev. 7/95

1

3

2

1

3

2

A156/A160/A162 1-18 STM

Page 47

DETAILED DESCRIPTIONS

Page 48

Page 49

1. PROCESS CONTROL

1.1 OVERVIEW

1.1.1 Copy Process around the Drum

1. DRUM CHARGE

In the dark, the dru m char g e r oll e r gives a un i fo r m neg at i ve cha rge to the

organic photo-co nd uctive (OPC) drum. The charge re m ain s on th e sur f ace of

the drum because th e OP C la yer ha s a high el ect r i cal resi st an ce i n th e da r k.

The amount of negative charge on the drum is proportional to the negative

voltage applied to the drum charge roller.

9. QUENCHING

2. EXPOSURE

3. ERASE

5. PRE-TRANSFER

LAMP

6. IMAGE

TRANSFER

7. PAPER

SEPARATION

8. CLEANING

PICK-OFF

PAWLS

1. DRUM CHARGE

ID

SENSOR

TRANSFER BELT

4. DEVELOPMENT

Fig. 1 Copy Process Around the Drum

Detailed

Descriptions

STM 2-1 A156/A160/A162

Page 50

2. EXPOSURE

An image of the original is reflected onto the OPC drum surface via the

optics assembly. The charge on the drum surface is dissipated in direct

proportion to th e i nt en si ty of t he refl e cte d l i gh t, thu s prod uci n g an el ect r i cal

latent image on the drum surface .

The amount of remaining charge as a latent image on the drum de pe nd s on

the exposure lamp intensity, which is controlled by the exposure lamp

voltage.

3. ERASE

The erase lamp illuminates the areas of the charged drum surface that will

not be used for the copy image. The resistance of the drum in the illuminated

areas drops and the charge on those areas dissipates.

4. DEVELOPMENT

As a result of the development potential (the difference of charged voltage

between the drum and the toner), toner is attracted to the areas of the drum

where the negative charge is greater than that of the toner, and the latent

image is developed.

The development bi as voltage applied to the developm en t r oll e r shaf t

controls two things:

1) The threshold level for whether toner is attracted to the drum or

whether it remains on the development roller.

2) The amount of toner to be attracted to the drum.

The higher the negat i ve de velo pm e nt bias voltage is, the less toner is

attracted to the drum surface.

5. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove almost all the negative charge from

the exposed areas of the dr um. This prevents the toner particles from being

reattracted to the drum surface during paper separation and makes paper

separation easier.

A156/A160/A162 2-2 STM

Page 51

6. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer belt at

the proper time so as to align the copy paper and the developed image on

the drum surface. Then, the transfer bias roller applies a strong negative

charge to the reverse side of the copy pa pe r thro ug h th e tr a nsf er be l t. This

negative charge produces an electrical force which pulls the toner particles

from the drum surface on to the copy paper. At the same ti me, the copy

paper is electrically attracted to the transfer belt.

7. PAPER SEPARATION

Paper separates fr om th e OP C drum as a r esu lt of the electrical attracti o n

between the paper and the transfer belt. The pick-off pawls help s eparate

the paper from the drum.

8. CLEANING

The cleaning blade removes toner remaining on the drum after the image is

transferred to th e pa pe r .

9. QUENCHING

Light from the quenching lamp electrically neutralizes the ch arge on the

drum surface.

Detailed

Descriptions

STM 2-3 A156/A160/A162

Page 52

1.1.2 Factors Affecting Process Control

In this copier, the following items are controlled during the copy process to

maintain good copy quality:

•

Exposure lamp voltage

•

Drum charge roller voltage

•

Development bias voltage

•

Toner supply

The machine controls the items listed above by monitoring the following

electrical components:

•

Operation panel (manual ID selection and reproduction ratio)

•

ADS sensor

•

TD sensor

•

ID sensor

•

Drum charge thermistor

•

Paper size detectors

•

RAM board (drum rotation time, SP mode data, and paper size data)

Fig. 2 Process Control

Rev. 7/95

A156/A160/A162 2-4 STM

Page 53

1.1.3 Process Control Procedures

This section outlines how the ma chin e con tr o ls the copy pr o cess ba sed on

the inputs from various sensors.

1.1.3.1 Copy Image Control

This is how the machine adjusts copy processes based on settings input at

the operation panel.

- Manual ID Correction -

If the user inputs the i m ag e de nsi t y ma nu all y, the machine adjusts the

exposure lamp voltage and the development bias to achieve the selected

image density.

- Reproduction Ratio Correction -

If the user selects a 116% or greater enlargement ratio or a 50% reduction

ratio, the machine corrects the developmen t bia s to compen sat e fo r the loss

in light intensity reaching the drum.

- ADS Pattern Detection and ADS Correction -

If the user selects Auto Image Density (ADS) mode, the machine monitors

the output from the ADS sensor and adjusts the development bias to

compensate for variations in ADS sensor response. This preve nt s dirty

background.

Every 1,000 copies, the ma chine calibrates the ADS sensor out pu t by

reading the white ADS pattern under the left scale of the exposure glass.

The ADS sensor must also be recalibrated:

• If the drum is changed

• If the ADS sensor is cleane d or cha ng ed

• If the exposure lamp or opt ics ar e clea ned or changed.

1.1.3.2 Image Density Control

This is how the machine cor r e cts th e con centration of toner in the devel o pe r

based on readings from the ID (Image Density) and TD (Toner Density)

sensors.

- VSP and VSG Detection/ID Correction -

The machine uses VSP and VSG readings by the ID sensor, along with

readings from th e to ne r den s ity sen s or, t o dete r m ine if the ton er

concentration in the de veloper is at the optimum level.

Rev. 6/95

Detailed

Descriptions

STM 2-5 A156/A160/A162

Page 54

The amount of toner supplied to the VSP pattern must remain constant. To

ensure this, the machine applies a correction to the development bias for

VSP patterns when combined readings from the TD and ID sensors indicate

that the carrier is aging. This correction is called "ID Correction".

- Toner Supply -

There are three toner supply modes.

Detect toner supply:

Toner supply varies with paper size, the latest TD

sensor reading, and the l at est VSP and VSG readings by the ID sensor. For

example, toner supply will be increased if the toner weight ratio in the

developer is decreasing, or if the most recent VSP pattern was detected as

being relatively light.

Fixed supply mode:

The toner supply remains constant, but can be

adjusted with an SP mode.

TD supply mode:

Toner supply varies with TD sensor output. For example,

if the toner weight ratio has decr eased since TD sensor supply mode was

selected, toner supply is increased.

1.1.3.3 Drum Potential Control

This is how the machine com p en sates for aging of the drum and the

exposure lamp, and for the temperature around the drum charge roller.

- VR Pattern Detection and VR Correction -

As the drum gets older, the drum’s residual voltage gradually inc r eases due

to electrical fatigue. Light from the exposure lamp will not dissipate the

increased residual voltage effectively and dirty background will result.

Every 1,000 copies, par t of th e dr u m is de velo pe d w i th the VR pattern

development bias . If the r e i s re sidu al vol t ag e on the dr um , thi s ar e a of the

drum will attract some toner, making a VR pattern. The ID sensor respon se

to this pattern is compa r ed wit h the response of the ID sensor to a bare ar e a

of the drum. The higher the residual voltage on the drum is, the darker the

VR pattern is. If the pattern is too dark, the drum will not be discharged

sufficiently. As a result, the machine will increase the negative development

bias to prevent dirty background. If it does, image density will drop. To

prevent this, the machine will also increase the negative drum charge roller

voltage.

(The VRP/VRG range to which the above mentioned bias and charge

corrections are applie d m ay be shift ed to can cel th e effect of ID correction.)

VR correction data must be reset by SP mode (forced VR detection) if the

drum is changed or if th e ID sen s or i s cle an ed or re pl a ced .

Rev. 6/95

A156/A160/A162 2-6 STM

Page 55

- VL Pattern Detection and VL Correction -

This is how the machine adjusts the exposure lamp voltage to compensate

for the effects of dr um w ea r , dir ty optics, and response of the drum to light.

Every 1,000 copies, an im ag e of the VL pattern under the left scal e bra cket is

made on the drum. The machine compares the respons e of the ID sensor to

this image with the re spo nse to a ba r e ar e a of the dr um .

The exposure lamp voltage is ad just ed if the r e ha ve be en signi f i can t

changes from the measurements made from when a new drum or lamp was

installed.

(The VLP/VLG range to which the above mentioned lamp voltage adjustment

is applied may be shifted to can cel th e ef fe ct of ID corr ect ion .)

Initial VLP/VLG detection must be done by SP m od e i f a ne w dr um is insta l l ed

or if the exposure lamp is cleaned or replaced.

- T/H Correction -

The efficiency of the tran sfe r of cha r ge from th e dr u m char g e roll e r to th e

drum varies with the temperature near the drum charge roller. Also, the

drum potential after charging v aries with the accumulated rotation time of the

drum.

A thermistor measures the temperature near the drum charge roller, and the

CPU keeps track of how long the drum has been rotating.

The machine adjusts the drum charge roller voltage depending on the

temperature an d accu m ul a te d r ot at i on ti me.

This section has provided an overview of all the process control procedures

done by the machine. The next few pages will explain each of these in more

detail. At the end, there will be a summary.

Detailed

Descriptions

STM 2-7 A156/A160/A162

Page 56

1.2 COPY IMAGE CONTROL

Copy image control adjusts the development bias and exp osu re l amp

voltage to take account of the reproduction ratio an d i m ag e de nsi t y. The

image density is either selected by the user or detected automatically.

1.2.1 Manual ID Cor rection

If the user selects the image density manually, the selected manual ID level

affects the exposure la m p volt age and the development bias as fo ll ows .

- Exposure Lamp Voltage -

As the ID level increases from 1 to 7, the exposure lamp voltage is increased

as shown in the following table.

Table 1. Exposure lamp voltage control by manual ID level

ID Level Lamp Voltage

1 Vexp –4.0 V

2 Vexp –3.0 V

3 Vexp –1.5 V

4

Vexp ±0.0 V

5 Vexp +1.5 V

6 Vexp +4.0 V

7 Vexp +6.0 V

Vexp = Lamp voltage selected with SP4-001. It can be be tween 50 and 75

V. It is factory set, and varies from copier to copier.

- Development Bias -

The greater the nega ti ve vol ta ge , th e pa l er the image on the drum. However ,

the development bias is adjusted only at the extreme light and dark ends of

the manual ID range.

Table 2. Development bias control by manual ID level

ID Level Development Bias

1 +80 V

2

±

0 V

3

±

0 V

4

±

0 V

5

±

0 V

6

±

0 V

7 SP2-201-002 (see below)

Note:

The base development bi as voltage is -240 Volts.

A156/A160/A162 2-8 STM

Page 57

For ID Level 7 (lightest copies), there are four possible development bias

correction settings that can be selected with SP2-201-002, as shown below.

Table 3. Lightest ID level development bias (ID Level 7)

SP2-201-002 Setting Density

Dev. Bias

Correction Voltage

1 (Factory Setting) Normal –40 V

2 Dark

±

0 V

3 Lighter –80 V

4 Lightest –120 V

In summary, the develo pme nt bi as at vari ou s ID level set ti n gs is show n

below.

1.2.2 Reproduction Ratio Correction

At reproduction ratios of 50% and 116% or greater, the intensit y of light

reaching the drum from the original drops significantly, which could cause

copies to become un derexposed (too dark).

To compensate for this, a development bias correction voltage is applied as

shown in Table 4. This correction increases the development bias voltage,

restoring the copy image de nsi t y to no rm al.

Table 4. Reproduction ratio correction

Reproduction

Ratio (%)

Development Bias

Correction Voltage

181 ~ 200 –100 V

161 ~ 180 –80 V

142 ~ 160 –60 V

123 ~ 141 –40 V

116 ~ 122 –20 V

51 ~ 115

±

0 V

50 –30 V

–280

–240

–320

1765432

ID Level

Development Bias Voltage

–320

(Lighter)

–240

(Darker)

–280

(Normal)

–360

(Lightest)

SP2-201-002

for ID Level 7

–160

Detailed

Descriptions

STM 2-9 A156/A160/A162

Page 58

1.2.3 ADS Correction

If the user selects Auto Image Density (ADS) mode, the output of the ADS

sensor is used to correct the development bias; the exposure lamp voltage is

kept at the setting fo r ID level 4 an d is not adju sted.

In ADS mode, the ADS sensor [A] det ect s the or igi n al ba ckgr o un d density.

To prevent dirty background from appearing on copies, the CPU corrects the

development bias voltage for the original. To do this, it compares the ADS

sensor output from th e original [V

ADS

(original)] with a stored reference value

[V

ADS

(pattern)] that wa s take n ea r l ier fr o m t he ADS sen s or pattern. The

correction is shown in table 5, and is applied every copy.

Table 5. ADS data correction

ADS Density SP5-106

Development Bias Correction Voltage

Setting

Copy Density

0 Darker 816 x (AR – 0.79)

1 Normal 816 x (AR – 0.85)

2 Lighter 816 x (AR – 0.95)

Where AR (ADS Ratio) = V

ADS

(original)/V

ADS

(pattern)

Note that there are three possible corrections. The default setting is 1

(normal). Howe ver , for exa mpl e , i f th e use r re qu ir es cop i es to be dar ker

when using ADS mode, a technician can set SP5-106 to 0.

V

ADS

(pattern) is checked every 1,000 copies. (See proce ss control che cks

at every 1,000 copies on p2-29.) It is kept at 2.7±0.1 volts by a gain

adjustment.

See the "Optics - Automatic Image Density Control System (ADS)" section

for more details on how th e ADS sensor measures the background an d on

how [V

ADS

(pattern)] is corrected every 1,000 copies.

ADS pattern

[A]

Fig. 3 ADS pattern

A156/A160/A162 2-10 STM

Page 59

1.3 IMAGE DENSITY CONTROL

1.3.1 Overview

The machine controls the toner supply mechanism using the toner density

sensor (TD sensor) and the image density sensor (ID sensor).

Readings from the TD sensor are used to keep the toner concentration in the

developer at a constant level. However, the image on the OPC drum varies

due to the variation in toner chargeability, which is influenced by the

environment, eve n if th e to ne r conce nt r at i on is con sta nt . Because of this,

readings from th e ID sensor are used to change the toner conce nt r ation to

keep the image density on the OPC drum constant.

1.3.2 VSP and V

SG

Detection

The ID sensor [A] (below the drum cleaning section) che cks the following

voltages.

• V

SG

: the ID sensor output when checking the erased drum surface.

•

VSP: the ID sensor output when checking the Vsp pattern image.

In this way, the reflectivity of both the erased drum surface and the pattern

on the drum are checked. This compensates fo r any variatio ns in ligh t

intensity from th e LE D compo ne nt of the sensor or the reflectivity of t he drum .

The VSP pattern [B] is made on the OPC drum by the drum charge roller [C]

and the erase lamp [D].

65 mm

35 mm

[B]

[C]

[A]

[D]

Dev.

bias

Drum

LED

ON

LED

ON

V

SG

V

SP

Detailed

Descriptions

STM 2-11 A156/A160/A162

Page 60

• V

SG

is measured at the start of every copy run.

• V

SP

is detected at the end of a cop y ru n if 10 or mo re cop i es ha ve be en

made since VSP was last measured. The transfer be lt m ust be rele ase d

to measure VSP, so it cannot be checked during a copy run.

1.3.3 ID Correction for the VSP Pattern

Background

Developer consists of carrier particles (ferrite and resin) and toner particles

(resin and carbon). The positive triboelect ric charg e on the ton er is caused

by friction between the carrier and toner particles. However, the chargeability

of carrier decreases with time. Therefore, if the toner weight ratio in the

developer is the same, the amount of positive triboelectric charge for one

particle of toner decreases. This is because the number of toner particles

which surround one carrier particle is the same, but the chargeability of one

particle of carrier is less than before.

If the development potential, that is, the difference of voltage between the

development roller and the drum for the VSP pattern is the same, more toner

particles are attracted to the VSP pattern, because on e pa r ti cl e of to ne r has

less positive charge than before. (More toner particles are required to

balance the charge of the VSP pattern.)

If the ID sensor were to check the VSP pattern’s reflectivity under this

condition, the VSP pattern would be darker than before. The CPU would then

incorrectly conclude that the toner weight ratio in the develo per is too high

even though the ratio act ua ll y rem ain s the same. The C PU wou l d th en

decrease the toner clutch on time, leading to a low per cen ta ge of to ne r in t he

developer by weight as the copy count rises.

If uncontrolled, this would cause some side effects, such as low image

density or developer adhering to the copy. To prevent these side effects, ID

correction is done when the VSP pattern is made.

12345678 9101112

13

14 15

29

30

31

VSP Detection

V

SG

Detection

V

SP

Detection

1st Series of Copies

(8 copies)

3rd Series of

Copies (17

copies)

2nd Series

of Copies

(5 copies)

V

SG

Detection

V

SG

Detection

V

SG

Detection

V

SP

Detection

A156/A160/A162 2-12 STM

Page 61

The idea behind ID corr e ctio n i s t o can cel th e ef fe ct on the VSP pattern of

the decrease in the chargability of carrier with time. ID correction is done by

changing the develo pm e nt bi as fo r t he VSP pattern so that it has the same

darkness even though the chargeability of the carrier has changed.

ID Correction Method

The machine determines whe th er th e de vel o pme nt bi as ne ed s adju stin g by

monitoring the de nsi t y of th e to ne r /ca r ri er m i xtu re i n th e de velo pm e nt unit.

When the toner weight rati o in the developer changes, the voltage output by

the TD sensor changes accordingly. The smaller the toner weight ratio in the

developer is, the great er th e TD sensor out pu t is, as sho w n in th e di a gra m

below.

When new developer with the standard concentration (2.0% by weight, 20 g

of toner in 1,000 g of developer) is installed, the TD sensor initial setting

must be done with SP mode 2-214. This sets the sensor output to 2.5 ± 0.1

V.

As shown earlier, the chargeability of carrier in the developer decreases with

the copy count. If no correction is done, the CPU tries to decrease the toner

weight ratio in th e de vel o pe r . So this eve nt ua l ly cause s the re ad i ng fr om th e

TD sensor to exceed its maximum acceptable value (initial value + 1.0 V).

If the corrected TD sensor output V

TREF

exceeds the upper limit over 100

times continuously, devel op ment bias for the VSP pattern is corrected. V

TREF

is the current TD sensor output with a correction factor included that is based

on the VSP/VSG ratio from the ID sensor (see VSP and VSG Detection)

calculated every 10 copies or so (see Toner Supply Control - Detect Supply

Mode for more about V

TREF

).

The first time this happens, the correction is -40 V. If the upper limit is

exceeded 100 consecutive times again later, an extra -40 V correction is

applied (see the following table). There should be no need for further steps,

because the toner proportion by weight will stabilize before this.

Rev. 6/95

Detailed

Descriptions

STM 2-13 A156/A160/A162

Page 62

Table 6. ID correction

Step Development Bias Correction for the VSP Pattern

Initial 0 V

1st –40 V

2nd –80 V

If no correction is ap pli e d, the charge on the drum for the VSP pattern is

–600 V, and the development bias for the VSP pattern is –300 V. So the r e is

a difference of 300 V between the development roller and the drum for the

VSP pattern.

When the ID correction is applied, the voltage difference is reduced. For

example, if a –40 V ID correction is applied, the difference in voltage is:

Before ID Correction: –300 – (–600) = 300 V

After ID Correction: –300

– 40

– (–600) = 260 V

As a result, the effect of the change in chargeability of the carrier particles is

canceled. The darknes s of the VSP pattern returns to normal.

1.3.4 Toner Supply Control During Copying

There are three modes for controlling the toner supply.

• Detect supply mode

• Fixed supply mode

• TD sensor supply mode

The mode can be selected with SP2-208-001. The factory setting is detect

supply mode.

Toner clutch on time is calculated by the following formula.

Toner CL on time [ms] =

S x AT x TSC

⁄

100

TS

(Formula 1)

where: S = Copy paper size [cm2]

AT = Amount of ton er de veloped on the latent image per un i t area

= 0.7 [mg/cm2] (constant)

TSC = Toner supply coefficient [%]

TS = Amount of toner supplied per unit of time

= 0.183 [mg/ms] (f or A1 53 , A1 55 , an d A1 56 copi e r s)

= 0.133 [mg/ms] (f or A1 57 , A1 59 , an d A1 60 copi e r s)

AT and TS are constant, and S depends only on paper size, but TSC is

determined in different ways depending on which toner supply mode is in

use.

A156/A160/A162 2-14 STM

Page 63

Determination of TSC

TSC is an estimate of the proportion of black area in the image that is made

by the machine.

(1) Detect Supply Mode

In detect supply mode, TSC is determined from outputs from both the TD

and ID sensors, in conjunction with the toner supply ratio that has been

selected for this mode.

- Toner Supply Ratio -

This is selected with SP2-22 2. The set ti n gs are 1 (7%) , 2 ( 15% ), 3 ( 30 %), or

4 (60%). The default is 15%.

- TD and ID Sensor Outputs -

The machine calculates a value fo r VT-V

TREF.

•

VT: Current TD sensor output

• V

TREF

: TD sensor output at the lat est VSP detection corrected for ID

sensor output (VSP/VSG); this is calculated every 10 or so copies (see

VSP/V

SG

Detection for more on VSP and VSG)

.

V

TREF

is determined as follows.

V

TREF

= VTP + ∆ V

REF (Formula 2)

•

V

TP

= TD sensor output at VSP detection

•

∆

V

REF

= Correction factor based on VSP/V

SG

(from the ID sensor

output), deter mi ne d by th e fo l l owi n g ta bl e .

Table 7.

V

SP/VSG

∆ V

REF

[V]

~ 0.075 +4 x 0.0196

0.076 ~ 0.090 +2 x 0.0196

0.091 ~ 0.105

±

0

0.106 ~ 0.125 –2 x 0.0196

0.126 ~ 0.160 –4 x 0.0196

0.161 ~ 0.205 –6 x 0.0196

0.206 ~ 0.500 –8 x 0.0196

0.501 ~ The previous V

TREF