Page 1

G130/G131 Product Support Guide

Gestetner

NOTE: In addition to the above method of certification, Service Education will offer an

Introduction

Launch Date: 7/15/2005

S/N Configuration: Q37xxxxxxxxx/ Q38xxxxxxxxx

Product Code: G130/G131

Savin CLP128/CLP135

Ricoh Aficio CL7200/C7300

Lanier LP332c/LP335c

C7528n/C7535hdn

Training Information:

All support technicians previously certified via the G080 series instructor -led training

program, or the G080 series self-pace training program, are automatically certified on the

G130/G131 product after a complete and thorough review of the update package.

Description EDP Code

Service Update Package 002372MIU

Service Manual 002373MIU

Parts Catalog 002447MIU

Technicians not certified on the above models can be trained on the G080 by first

completing the existing G060Self-Pace Training Program (001186MIU), and then by

completing the G080 Self-Pace Update Computer-Based Training Program .

instructor-led B202 series training course, which will cover all models in the series,

including, G060/G080/G570/G082/G106/G130/G131/B147/B149/B202/B178/B180.

Product Concept:

Flagship color laser printer expanding on the existing J-P

engine and providing a lower CPP. Engine/Controller

Enhancements include new polymerized toner, faster

controller and new controller options for improved

productivity

Print Speed:

G130 FC 28ppm, BW 32ppm

G131 FC 35ppm, BW 35ppm

Version – 1.0

Page 2

G130/G131 Product Support Guide

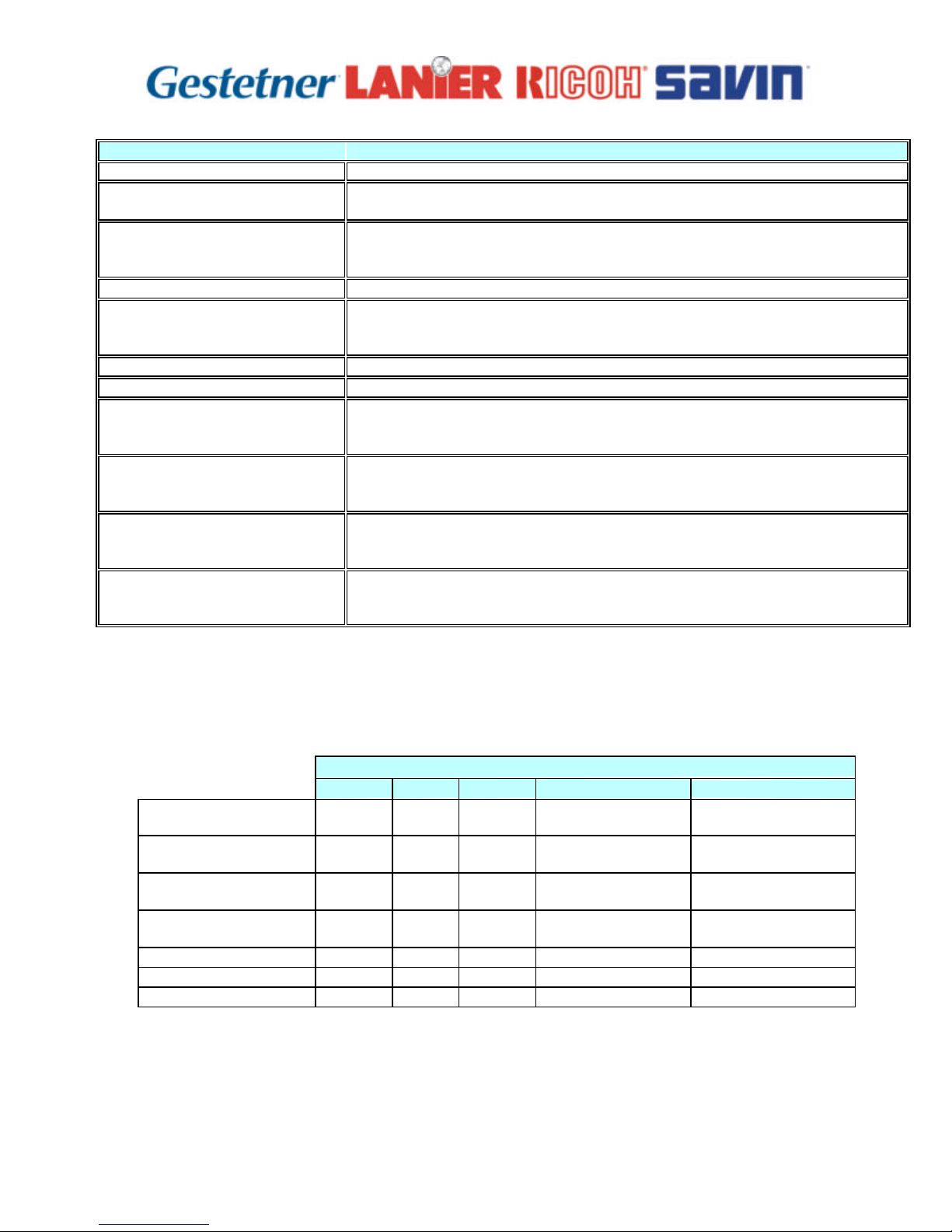

EDP Order Numbers

Model Name EDP Code Lanier ID Product

Paper Feed Unit Type 7300 (500x1) 402431 481-0943 G567

Paper Feed Unit Type 7300 (500x2)

Paper Bank Type 7300 (LCT)

Stand FAC28 402373 481-0878 FAC28

SR960 (Two Tray Finisher) 412139 216-1218 G599

Punch Kit Type 1045 (2 Tray

Finisher)

SP 950 (Booklet Finisher)

Punch Kit Type 2238 411585 216-7062 B647

User Account Enhance Unit Type E 402270 481-0877 G395

Memory Unit Type C 64MB 001345MIU 481-0518 G330

Memory Unit Type C 128MB 001347MIU 481-0519 G331

Memory Unit Type C 256MB 001348MIU 481-0520 G332

1394 Interface Unit Type B 411264 481-0683 B581

802.11b Interface Unit Type H 402378 481-0907 B813

IEEE 1284 Type A 411699 481-0786 B679

Bluetooth Unit Type 3245 412178 216-7092 G736

USB Host Interface Unit Type 7300 402304 481-0894 G819

Direct Camera Printing utilizing a

PictBridge™ enabled camera.

Interface Unit Type 7300

Version – 1.0

402432 481-0944 G568

402433 481-0945 G569

410785 481-0319 B377

412143 216-1219 B602

402361 481-0895 G814

Page 3

G130/G131 Product Support Guide

Pre-Configured Models

G130

Brand Model Description

Ricoh Aficio CL7200 Aficio CL7200

Savin CLP128

Gestetner C7528n

Lanier LP332c LP332c

Brand Model Description

Ricoh Aficio CL7200D

Savin

Gestetner C7528n D

Lanier LP332c D LP332c with Duplex

Brand Model Description

Ricoh Aficio CL7200DT1 CL7200 with Duplex & PFU (1)

Savin CLP128 DT1

Gestetner C7528n DT1

Lanier LP332c DT1 LP332c with Duplex & PFU (1)

Brand Model Description

Ricoh Aficio CL7200DT2 CL7200 with Duplex & PFU (2)

Savin CLP128 DT2 CLP128 with Duplex & PFU (2)

Gestetner C7528n DT2 C7528n with Duplex & PFU (2)

Lanier LP332c DT2 LP332c with Duplex & PFU (2)

Brand Model Description

Ricoh Aficio CL7200DL CL7200 with Duplex & LCT

Savin CLP128 DL NA with Duplex & LCT

Gestetner C7528n DL

Lanier LP332c DL LP332c with Duplex & LCT

N/A – Pre-configured unit will not be offered. Options must be ordered separately.

CLP128

CLP128

C7528n

Aficio CL7200 with Duplex

CLP128 with Duplex

C7528n with Duplex

CLP128 with Duplex & PFU (1)

C7528n with Duplex & PFU (1)

LP332c with Duplex & LCT

Lanier ID #

-

-

-

479-1575

- 402411

-

-

479-1576

-

-

-

479-1577

-

-

-

N/A

-

- N/A

- N/A

N/A

EDP

402410

402391

402391

-

EDP

402392

402392

-

EDP

402412

402293

402293

-

EDP

402413

N/A

N/A

-

EDP

402414

-

Version – 1.0

Page 4

Ensure that the machine is level

B C A

B C A

G131

G130/G131 Product Support Guide

Brand Model Description

Ricoh Aficio CL7300 D

Savin

Gestetner C7535n D

Lanier LP335c D LP335c with Duplex

Brand Model Description

Ricoh Aficio CL7300 DT1 CL7300 with Duplex & PFU (1)

Savin CLP135 DT1

Gestetner C7535n DT1

Lanier LP335c DT1 LP335c with Duplex & PFU (1)

Brand Model Description

Ricoh Aficio CL7300 DT2 CL7300 with Duplex & PFU (2)

Savin CLP135 DT2 CLP135 with Duplex & PFU (2)

Gestetner C7535n DT2 C7535n with Duplex & PFU (2)

Lanier LP335c DT2 LP335c with Duplex & PFU (2)

Brand Model Description

Ricoh Aficio CL7300 DL CL7300 with Duplex & LCT

Savin CLP135 DL CLP135 with Duplex & LCT

Gestetner C7535n DL

Lanier LP335c DL LP335c with Duplex & LCT

N/A – Pre-configured units will not be offered. Options must be ordered separately

CLP135 D

Aficio CL7300 with Duplex

CLP135 with Duplex

C7535n with Duplex

CLP135 with Duplex & PFU (1)

DSc38U with Duplex & PFU (1)

C7535n with Duplex & LCT

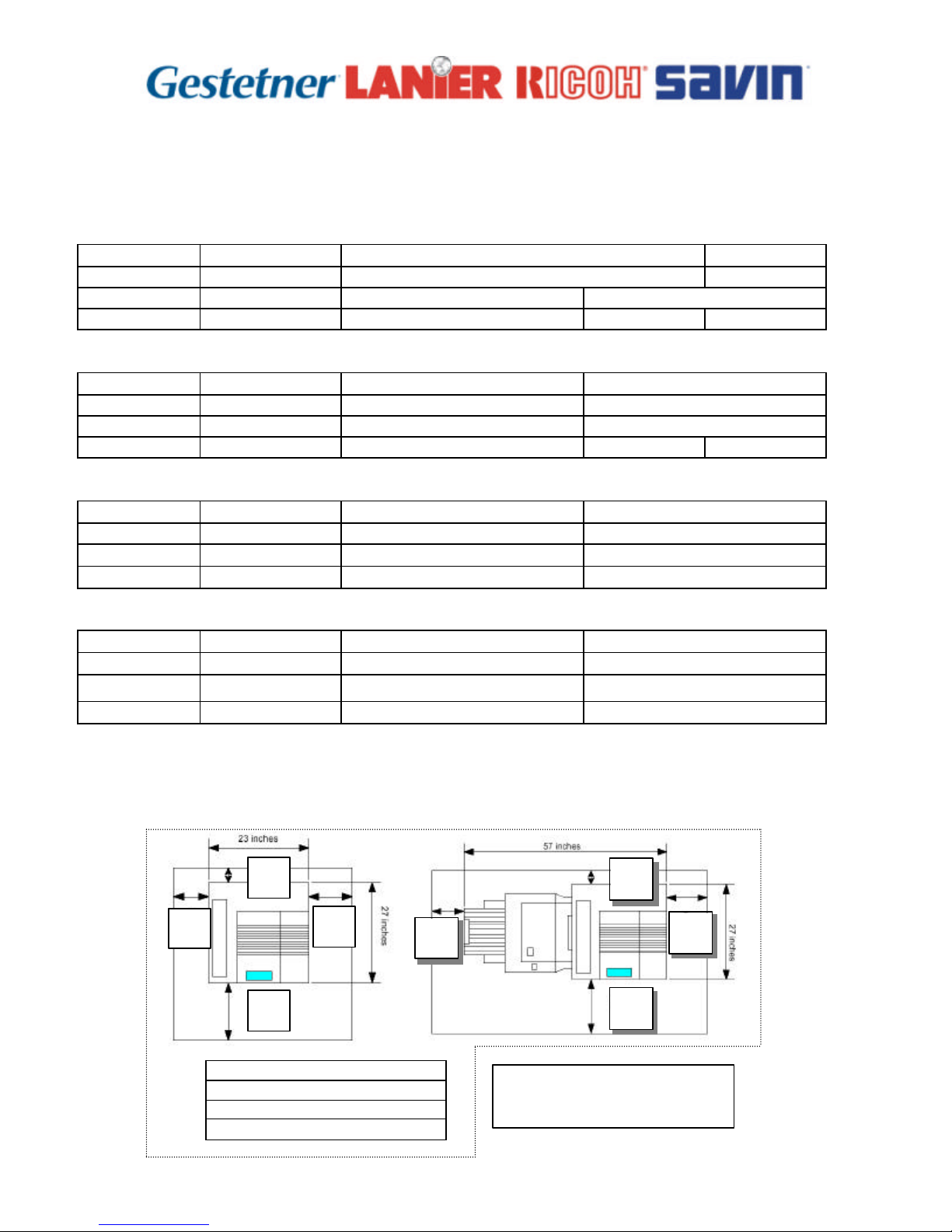

G130/131 - Machine Space Requirements

Version – 1.0

D

A: At least 18 inches

B: At leas t 04 inches

C: At least 22 inches

D: At least 28 inches

Front to Back: Within 0.2 inches

Right to Left: Within 0.2 inches

Lanier ID #

- 402415

-

-

479-1578

-

-

-

479-1579

-

-

-

N/A

-

-

-

N/A

D

EDP

402397

402397

-

EDP

402416

402398

402398

-

EDP

402417

N/A

N/A

-

EDP

402418

N/A

N/A

-

Page 5

G130/G131 Product Support Guide

Machine level

Installation Requirements

1. Temperature Range: 10°C to 32 °C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 2,000 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hour/person or more

5. Do not expose the machine to the following:

1) Direct cool air from an air conditioner

2) Direct heat from a heater

6. Do not install the machine in areas that get exposed to corrosive gas.

7. Install the machine locations lower than 2,500 m (8,200 ft.) above sea level.

8. Install the machine on a strong, level base.

9. Do not install the machine in areas that get strong vibrations.

Front to back: Within 5 mm (0.2")

Right to left: Within 5 mm (0.2")

Power Requirements

• Input voltage level: 120 V, 60 Hz: More than 11A (G130) / 12A (G131)

• Permissible voltage fluctuation: ±10 %

• Do not place anything on the power cord

• The required wall outlet is a NEMA 5-15R

CAUTION: Make sure the outlet and the machine are grounded.

CAUTION: Insert the plug firmly into the outlet.

CAUTION: Avoid using an extension cord or adapter plug.

Installation Times

Mainframe: 30 minutes

Peripherals:

Peripherals, which can be installed by users:

PFU/LCT 15 minutes

Duplex Unit 15 minutes

IEEE1284 5 minutes

IEEE1394 5 minutes

Blue tooth 5 minutes

Wireless LAN 5 minutes

USB Host I/F ____________________5_____minutes

Direct Camera Printing ______________ 5_____minutes

Gigabit Ethernet____________________5_____minutes

Peripherals, which should be installed by technicians:

Finishers 15 minutes

Punch Kit 15 minutes

NOTE:

These are installation times for after the machine has been removed from the carton.

Version – 1.0

Page 6

G130/G131 Product Support Guide

• The RPCS printer drivers provide hig

h productivity and simple

Utility Software

Software Description

Font Manager (Win95/98/ME,

NT4, 2000, XP, Server 2003):

Smart Device Monitor for Admin:

Smart Net Monitor for Client

(Win95/98/ME, NT4, 2000, XP,

Server 2003)

Device Graphic Update Module

DeskTop Binder

Printer Utility for Mac

PS Descriptions

IEEE 1394 Printer Removal

Utility

PPD Installer

LAN FAX Driver

RPCS Driver

• The Font Manager 2000 installs the screen fonts in your

• Windows 95/98/Me/NT 4.0/2000/XP/Server 2003. Installing the screen

fonts for the printer fonts improves the WYSIWYG quality.

• A utility for administrators who need to manage and monitor printers

over the network.

• The Smart Device Monitor for Admin for Windows 95/98/Me/NT

4.0/2000/XP/Server 2003

• Setup utilities are also available.

• Our device monitoring software has been renamed from Smart Net Monitor to

Smart Device Monitor. Operation of Smart Device Monitor is the same as

SmartNetMonitor. In case you already have SmartNetMonitor installed in your

PC overwrite it with Smart Device Monitor, software settings and log data will

be carried over.

• A utility enables you to access networked printers to print, to monitor

and to receive notices without a server. This utility also enables the

following features:

• Recovery Printing

• Parallel Printing

• Our device monitoring software has been renamed from SmartNetMonitor to

SmartDeviceMonitor. Operation of Smart Device Monitor is the same as Smart

Device Monitor. In case you already have SmartNetMonitor installed in your

PC overwrite it with Smart Device Monitor, software settings and log data will

be carried over.

• Device Graphic Update Module provides bitmap images used to represent the

various statuses of devices graphically within Smart Device Monitor or Web

Smart Device Monitor.

• DTB enables you to connect a client computer to an I/O device. You

can efficiently input, edit, and output the data on your computer.

• This is a utility for Macintosh that provides access to several network

printing administrative features.

• PDD for Mac

• By interacting with the Adobe PostScript 3 controller in the device, this

PPD is able to produce an accurate representation of the screen

image.

• This utility completely removes all printers connected via IEEE 1394

interface from your Windows 2000/XP/Server 2003 system. This will

prepare your Windows 2000/XP/Server 2003 system for the proper

reinstallation of IEEE 1394 printers.

• This PPD installer is used to install a PPD (Postscript Printer

Description) file on Mac OSX. PPD files contain descriptions of printer

capabilities such as paper sizes, number of input trays and duplexing.

Once the PPD file is installed on the system using the PPD installer,

the PS driver that comes bundled with Mac OS X can use the

information in the PPD to control the print device and enable full

functionality. Please see the ReadMe file for information about

compatibility with versions of Mac OS X.

• This software enables you to fax documents directly from your

computer. The Address Book Editor and Cover Sheet Editor are

installed as well. This software requires the optional fax unit to be

installed on the machine.

Version – 1.0

Page 7

G130/G131 Product Support Guide

Toner Type 160 Magenta

Software Description

operation.

PCL 6 Driver

PCL 5c Driver

Post Script Driver

USB Print

ICM Profiles

Network TWAIN Driver

Microsoft Windows NT 4.0 Terminal

Server Edition PCL 5c Driver

Microsoft Windows NT 4.0 Terminal

Server Edition PS Driver

Microsoft Windows 2000 Terminal

Services PCL 5c

Microsoft Windows 2000 Terminal

Services

Supplies and Maintenance Kits

EDP Codes

Toner Type 160 Black 888442 888450 888454

Toner Type 160 Cyan 888445 888453 888457

Toner Type 160 Yellow 888443 888451 888455

Staple Cartridge 410801 410803 410805 - 480-0062

Staple Refill 410802 410804 410806 - 480-0063

Staple (Set + Refill) Booklet

Ricoh Savin Gestetner

885374 888452 888456

411730 411733 411731 - 480-0215

NOTE: Toner is not compatible with previous models.

Version – 1.0

• The PCL 6 printer drivers provide faster printing and better what -yousee-is-what-you-get (WYSIWYG) than PCL 5c drivers.

• The PCL 5c printer drivers are the recommended printer drivers for this

printer. The PCL 5c printer drivers are recommended for users who

need compatibility with PCL 5c printer.

• The PostScript printer drivers generate PostScript commands.

• The USB Printing Support provides the solution for USB printing under

Windows 98SE/Me. Windows will prompt for these support modules

after it recognizes the printer on an USB port for the first time.

• The ICM profiles work under Windows 98/Me/2000/XP/Server2003.

• TWAIN scanner driver for network connections.

• Printer driver for color printing in Windows. It supports HP PCL 5c

commands. Basically, this is the same driver as PCL5e with color

printing functionality added.

• By interacting with the Adobe PostScript 3 controller in the device, this

driver is able to produce an accurate representation of the screen

image.

• Printer driver for color printing in Windows. It supports HP PCL 5c

commands. Basically, this is the same driver as PCL5e with color

printing functionality added.

• By interacting with the Adobe PostScript 3 controller in the device, this

driver is able to produce an accurate representation of the screen

image.

Lanier Lanier ID

Black toner for

LP332c/LP335c

Cyan toner for

LP332c/LP335c

Magenta toner for

LP332c/LP335c

Yellow toner for

LP332c/LP335c

480-0295

480-0298

480-0297

480-0298

Page 8

G130, G106, G080 and

G130/G131 Product Support Guide

*

Yield Name EDP Lanier ID Description Compatibility

40KP

80KP

80KP

80KP

Printer Maintenance Kit Type

7200/7300A

Printer Maintenance Kit Type

7200/7300B

Printer Maintenance Kit Type

7200/7300C

Printer Maintenance Kit Type

7200/7300 D

402305 481-0896 Color PCU's (CMY) G130/G131 only

402306 481-0897 Color Development Units (CMY) G130/G131 only

402307 481-0898 Fusing Unit G130/G131 only

402308 481-0899 Black Development Unit G130/G131 only

40KP Printer Maintenance Kit Type 3800E 400662 481-0347 Waste toner bottle

40KP

150KP Printer Maintenance Kit Type 3800 H 400576 481-0423 Feed Roller G106 and G080

*

* 50% Color ratio

The indicated Yields are based on:

1) A4 (8.5”x11”)/ 5% Chart is used to measure the above yield.

2) 3 prints per job

3) The condition is standard temperature and humidity.

4) This yield number may change depending on the circumstances and printing conditions.

5) 5% image coverage ratio

Printer Maintenance Kit Type

7200/7300 F

402310 481-0900 Black PCU G130/G131 only

G060

The expected yield differs depending on the maintenance units. Also, each maintenance

unit has its own counter to detect the near end or end condition. The yield is counted up

by using machine operation time. Therefore, the number of prints differs depending on

operation factors such as paper size and prints per job (P/J).

Supported Paper Weight Specifications

Paper trays: 16 lb. Bond to 28 lb. Bond (60 to 105g/m2)

Bypass Tray: 16 lb. Bond to 43 lb. Bond (60 to 163g/m2)

Optional Paper Trays 16 lb. Bond to 28 lb. Bond (60 to 105g/m2)

Recommended Paper

TBA

Version – 1.0

Page 9

G130/G131 Product Support Guide

Recommended Printer Driver Settings for Paper Types

Paper Type Used Driver Setting – G130/131

Normal Thick Paper Thick

Labels Thick

Card Stock Thick

Envelope Thick

28 lb. Plain Paper

Transparency OHP Transparency

Other paper types (color, preprinted, recycled and letterhead) at the printer driver cannot be

interpreted to change the machine settings according to the type of paper selected. They are

used only to lock the paper tray and to prevent designated papers from being automatically

selected.

Additional Comments

Ricoh has tested the above papers. However, Ricoh recommends that end users test any

paper before purchasing large quantities. The print quality may differ according to the

temperature, humidity and printing applications in which the paper is used. In addition, paper

specifications or methods of manufacturing are subject to change, over which Ricoh has no

control.

When using special paper: Feed from the bypass tray, and select the proper paper type from the

printer driver. Whenever printing from the bypass tray, the paper will be fed out to the face-up

external tray. Printing numerous sheets of special paper in a short amount of time may create

some printing problems. Exclusive printing of special paper may result in more frequent service

calls, and may significantly reduce the maximum yield of maintenance kits. Ricoh’s reliability data

assumes only occasional use of special paper.

Paper Not Recommended for this Printer

l Paper meant for an inkjet printer

l Bent, folded or creased paper

l Curled or twisted paper

l Torn paper

l Wrinkled paper

l Damp paper

l Paper that is dry enough to emit static electricity

l Special paper, such as thermal paper, aluminum foil, carbon paper and conductive

paper

l Paper weight with heavier or lighter specifications than recommended

l Paper or envelopes with windows, holes, perforations, cutouts or embossing

l Label paper on which glue or base paper is exposed

l Paper with clips or staples

l Chrome Coat Paper

l Paper that has already been printed onto, except a preprinted letterhead.

Plain

Do not select "Special".

Version – 1.0

Page 10

G130/G131 Product Support Guide

Appendix. Printing Envelopes

Check the print side is facing up.

• Check there is no air in the envelopes before loading.

• For better print quality, we recommend the right, left, top, and

bottom print margins to be at least 15 mm (0.6”) each.

• Load only one size and type of envelope at a time.

• When loading envelopes, be sure to unfold the flaps and position

them opposite to the paper feed direction.

• Before loading envelopes, flatten their leading edges (the edge

going into the printer) by running a pencil or ruler across them.

• Some kinds of envelope might cause misfeeds, wrink les or

print poorly.

• Print quality on envelopes may be uneven if parts of an envelope

have differing thicknesses. Print one or two envelopes to

check print quality.

Note: Only envelope type 1 and 2 are supported

Misfeeds might also occur when using envelopes 1 and 2 depending on the length

and shape of the flaps.

Version – 1.0

Page 11

G130/G131 Product Support Guide

Printing Envelopes (Cont.)

Paper thickness 72 - 90 g/m 2 (19 - 24 lb.)

Recommended weight and size

• Inch version

24 lb, Com 10

Note: Make sure paper is not stacked higher than the paper guides inside the bypass tray.

Printing on both-sides is not possible

Do not place envelopes of differing sizes at the same time.

You can place envelopes in short-edge feeding orientation, but this might result in creasing.

Printer Driver Settings

In the [Paper source tray] list, click [Bypass tray], and then in the [Paper type] list, click [Thick].

To set the print size, in the [Original size] list, click [Com10 Env.] or [Monarch Env.], and then in

the [Printout paper size] list, click [Same as original size].

Limitations

· Surface bumps may occur around stuck-down and overlapping areas.

· Print positioning is easier with Com10 type envelopes than with the Monarch type.

· If envelopes are bent or creased and do not feed in smoothly, paper jams may occur.

· No more than 10 envelopes should be placed on the bypass tray at a time.

· Envelopes should be printed under the normal temperature and humidity.

Version – 1.0

Page 12

G130/G131 Product Support Guide

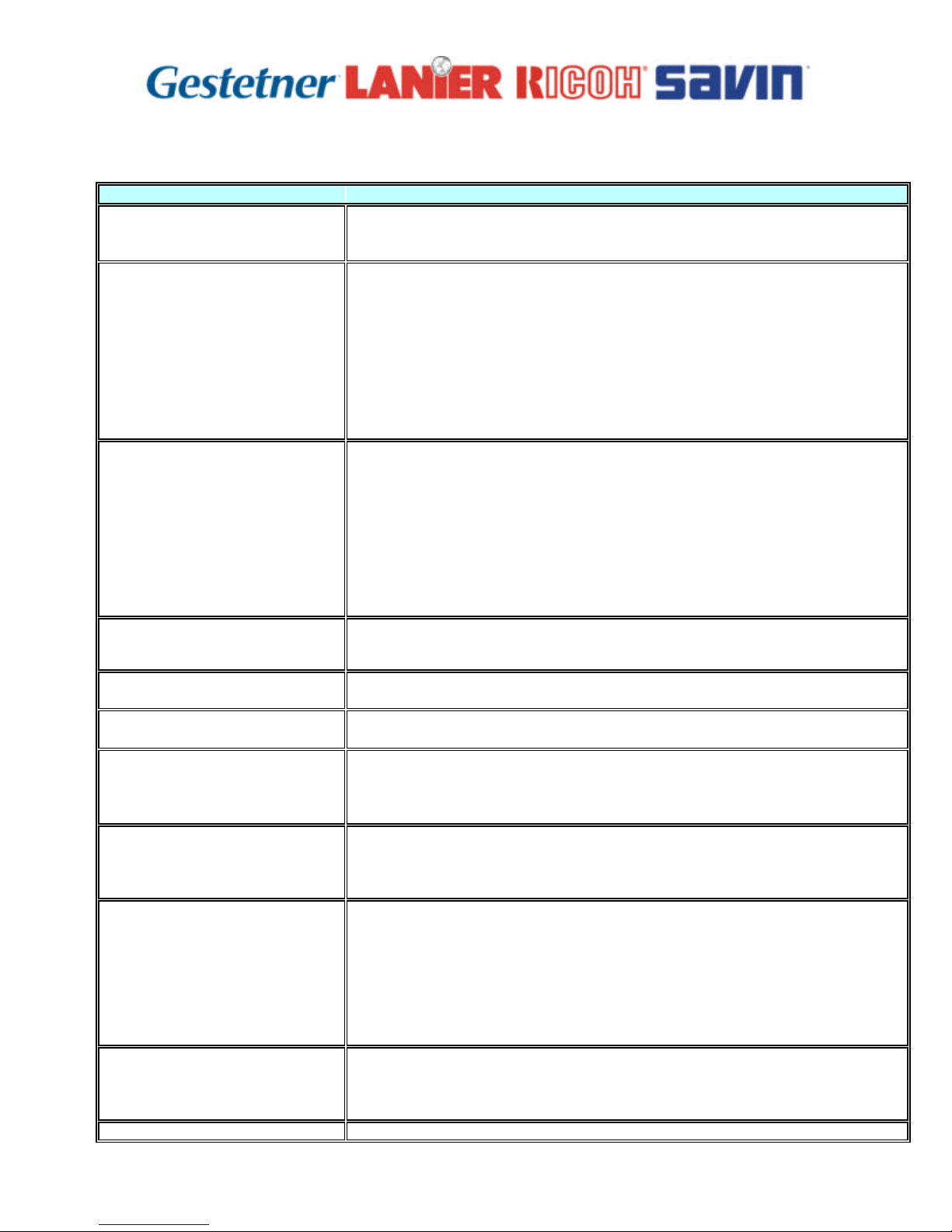

Service Maintance Table

Unique/Common

U: Unique for this model

C: Common with listed model

Expected

Yield

(Prints)

Expected

Yield

(Prints)

Expected

Yield

(Prints)

Expected

Yield

(Prints)

Unique or

Common

Unique or Common

Unique or Common

Unique or Common

Part Number Description

B1803810 Transfer Unit (Note 1) 1 1,000k C (B147/B149)

B2423830 Transfer Cleaning Unit (Note 1) 1 250k C (B147/B149)

AF031049 Feed Roller (Note 2) 2 150k C (B135/B138 series)

AF030049 Pick-up Roller (Note 2) 2 150k C (B135/B138 series)

AF032049 Separation Roller (Note 2) 2 150k C (B135/B138 series)

AF031046 Bypass Feed Roller (Note 2) 1 150k C (B147/B149 series)

AF030049 Bypass Pick-up Roller (Note 2) 1 150k C (B147/B149 series)

AF032046 Bypass Separation Roller (Note 2)

1-Tray Paper Feed Unit: G567

Part Number Description

AF031049 Feed Roller (Note 2) 1 150k C (B135/B138 series)

AF030049 Pick-up Roller (Note 2) 1 150k C (B135/B138 series)

AF032049 Separation Roller (Note 2) 1 150k C (B135/B138 series)

2-Tray Paper Feed Unit: G568

Part Number Description

AF031049 Feed Roller (Note 2) 2 150k C (B135/B138 series)

AF030049 Pick-up Roller (Note 2) 2 150k C (B135/B138 series)

AF032049 Separation Roller (Note 2) 2 150k C (B135/B138 series)

Large Capacity Tray: G569

Part Number Description

AF031049 Feed Roller (Note 2) 1 150k C (B135/B138 series)

AF030049 Pick-up Roller (Note 2) 1 150k C (B135/B138 series)

AF032049 Separation Roller (Note 2) 1 150k C (B135/B138 series)

NOTE 1: These units are considered EM parts since their expected lifetimes are relatively

long, and because the actual roller lifetime depends on specific machine

operations performed and type of paper used..

NOTE 2: The actual lifetime of the rollers depends on the type of paper used and machine

operation. Therefore, the paper feed rollers are treated as EM parts.

Q’ty/

Unit

1 150k C (B147/B149 series)

Q’ty

/Unit

Q’ty

/Unit

Q’ty

/Unit

Version – 1.0

Page 13

G130/G131 Product Support Guide

PM Unit Yield

The yield of the development units, PCUs, fusing unit is affected by the number of print / job (P/J).

This is because the actual life of them is determined how many times each unit rotates, as shown

in the following table.

Yield Target PM unit Expected Yield

(prints)

3P/J

Black PCU 40K

Color PCU 40K

Black Development 80K 860k 80K

Color Development Unit 80k 870K 80k

Fusing Unit 80k 8190k 80k

The number of rotation per page depends on the P/J. If the P/J is lower than “3”, the number of

rotations made for a page increases because the machine always stops a specific time after the

last sheet is fed out regardless of the P/J condition.

The following table shows the expected number of prints made depending on the P/J. It also

shows the expected yield at 1P/J, and 2P/J as a percentage when the percentage for 3P/J is

100%.

G130/G131

Number of Prints (%) Maintenance Kit

1P/J 2P/J 3P/J

Black PCU

Color PCU

Black Development

Color Development Unit

Fusing Unit

19.8

(49.5%)

19.8

(49.5%)

58.3

(72.9%)

58.8

(73.5%)

40.5

(50.6%)

Number of

Number of

Rotations

280k 40K

280k 40K

31.7

(79.2%)

31.8

(79.6%)

73.3

(91.6%)

74.6

(93.2%)

64.4

(80.5%)

Prints

40

(100%)

40

(100%)

80

(100%)

80

(100%)

80

(100%)

Version – 1.0

Page 14

G130/G131 Product Support Guide

PM Inerval (P/J)

P/J

prints

The diagram on the below is a graph made from the data in the above table.

As explained on the previous page, the yield of the PM parts depends on the number of rotations

for a page. (This system for asses sing yield is common in the printer field.) The expected yield of

all PM parts is calculated under a specific condition (3P/J, A4/LT long-edge feed, and 5% image

coverage ratio). P/J particularly affects the unit yield.

100.0

80.0

60.0

PCU(Bk)

PCU(FC)

Dev(Bk)

40.0

Dev(FC)

20.0

0.0

1 2 3

Note: Machine works for making patterns in process control self-check and lines

position adjustment (MUSIC) or performs idling when turning on the main switch.

While the machine is in these modes (self-check, MUSIC, and idling), the yield

counter (rotation counter) of maintenance kits counts up without making outputs.

Performing self-check, MUSIC or power OFF/ON of machine excessively affects the

unit yield.

If making a meter charge contract with customers and if the meter charge fee is always the same

for all users, this may cause a reduction in profits depending on how a customer makes prints.

Therefore, it is recommended to consider the expected P/J and print volume for each user when

making a service contract.

Version – 1.0

Page 15

Waste

Black

Color

G130/G131 Product Support Guide

Maintenance Kit / Supply Locations

Dust Filter

Fusing Unit

Toner Bottle

User Maintenance Table

Main Unit

Item

Black PCU Prints R Included in maintenance kit F

Color (Y/M/C) PCU Prints R Included in maintenance kit A

Black Development Unit Prints R Included in maintenance kit D

Color (C/M/Y) Development Unit

Fusing Unit Prints R Included in maintenance kit C

Waste Toner Bottle

Dust Filter

Punch Kit

Item 10K Remarks

Chads

Developments

Prints or

Prints R Included in maintenance kit B

Prints

Prints

30K 40K 80K 150K

R Included in maintenance kit E

R Included in maintenance kit D

I Discard chads

NOTE: The replacement timings are based on:

8.5 x 11 LEF, 5% image coverage / color, 5 P/J and 50% color usage.

Toner

PCU/ Development Unit

PCU’s/ Development Units

Remarks

Version – 1.0

Page 16

G130/G131 Product Support Guide

B&W

Color

Color

B&W

B&W

Auto Color Selection (ACS) and Total Counters

B&W pages after a color page has been printed are counted as B&W for B&W and color mixed

originals in ACS even if Meter Charge mode (SP5-930-001) is on or off.

After the transfer unit has moved into contact with all the color PCUs to print a color page, the

transfer unit does not detach from the color PCUs during a print job even for B&W page printing.

For instance, if sending 10 sets of 5 pages as one job and only the 2nd page contains color, the

transfer belt unit moves into contact with all the color PCUs for the 2nd page of 1st set. Then it

stays in contact with all the PCUs until all 50 pages have been printed.

1st

2nd

3rd

4th

When you send the above print job, the machine counts as shown in the following table.

SP Number

SP8-581004

SP8-581005

SP8-581008

SP8-581-

009

D: Developments (Color = CMY PCUs, B&W = K PCU)

C: Copies

Type of

counter

D: Color 6

D: B&W 5

P: Color 2

P: B&W 3

Counter

The counters count up in the manner explained above, in order to reflect the number of color and

black/white outputs accurately. This means that, while printing B&W pages after a color page has

been printed, the color counters do not count up even when the color PCUs and development

units rotate, so the usage of the various PCUs is not reflected accurately.

5th

Version – 1.0

Page 17

G130/G131 Product Support Guide

Initial Recommended Service Parts Items in Red = PM

Part Description Part Description

G1312211 PCU - CMY AE040042 Oil Supply Roller:Pressure:DIA16

G2600152 Development Section:Service:JP-4:M AE044066 Stripper Pawls:pFa

G2600153 Development Section:Service:JP-4:Y AE044050 Stripper Pawl

G2600151 Development Section:Service:JP-4:C B1804101 Fusing Belt:MM60:Ass’y

B1803780 Transfer Belt: Ass’y B1804300 Pressure Roller Ass’y

AF031046 Feed Roller – Manual Feed AE020155 Pressure Roller:DIA42

AF030049 Pick-up Roller

AF032046 Separation Roller – Manual Feed

G0802900 Torque Limiter – Manual Feed

AF031049 Feed Roller

AF032049 Separation Roller

B1802900 Torque Limiter

AZ320143 Power Pack:CAC/DC:BDC

B1805130 PCB:DRB

AZ240106 Power Supply Unit:Main:Dom/NA

G1315051 PCB:BCU

G1315701 PCB:JP4:Assy

AW100102 Thermistor: Fusing

B1804066 Thermostat: Welding

AX430146 Heater:120V:200W

AX440231 Heater:120V:1100W

B1804246 Thermofuse: Ass’y

AW100103 Thermistor: Pressure

AD042081 Cleaning Blade: Ass’y

G1311854 Imaging Unit

AX060286 Ploygon Mirror Motor

B1803301 Air Pump:Toner Supply:Ass’y

G0803301 Air Pump:Toner Supply

Version – 1.0

Page 18

G130/G131 Product Support Guide

NOTE: SP5

-

930-1 (Meter Charge) must be set to ON if the maintenance contract is

Firmware Structure

Type of Firmware

Engine Main G130_engine_vxxx.exe BCU Flash ROM

Printer Version (G 130/131)

Firmware File Name

Updated Component

Engine

Controller

MUSIC G130_music_vxxx.exe BCU MUSIC CPU

DSP G130_dsp_vxxx.exe BCU DSP CPU

NIB G130_pnib_vxxx.exe SD Card

System G130_psystem_vxxx.exe SD Card

Printer Application G130_printer_vxxx.exe SD Card

Suggested Settings at Installation

SP Mode Item Setting

SP 5-930-1 Meter Charge 0=>1

SP 5-930-3 Menu 1 (keep at default)

SP 5-045 Counter Method 1(prints) or 0 (developments) [either one]

SP 5-104 Double Count 0=>1 (double count)

based on the meter reading or if it has a volume limit.

Branding

Branding is required as the machine is shipped as a generic version.

Ricoh version machines: You must adhere the model label (provided) to the front cover.

Savin/Gestetner/Lanier version: You must adhere the model label (provided) to the front cover

and set the Plug and Play name with SP 5-907-1. Set the data to 2 or 3 for Savin, 4 or 5 for

Gestetner and to 10 or 11 for Lanier.

NOTE: Pre -Configured models have an instruction sheet for Technicians packed in the carton

box.

Version – 1.0

Page 19

G130/G131 Product Support Guide

Comp

atible printers

Main Unit

Options

Interface

Configuration

Product Configurations

?G421 Scanner Option

Include with USB card USB cable

USB (for printer)*standard

10/100BASE-T/TX (for printer and scanner)*standard

Wireless LAN (IEEE802.11b (for scanner)*option

-IPU

-Wireless LAN (IEEE802.11b)

-Rack

G106, G071, G091

Version – 1.0

Page 20

G130/G131 Product Support Guide

3-2.System Configurations

Scan Router Server

Scan Router Server

SMTP Server

SMTP Server

Send Network

Send Network

Output to printer

Output to printer

TCP/IP

TCP/IP

USB2.0

USB2.0

FTP Server

FTP Server

Windows

Windows

shared folder

shared folder

Global Scan

Global Scan

Server

Server

Network

Network

Printer

Printer

Local Printer

Local Printer

Network TWAIN

Network TWAIN

Version – 1.0

TWAIN

TWAIN

Application

Application

Page 21

G130/G131 Product Support Guide

Specifications

Basic Mainframe Specifications

Scanner Type: Flatbed color image scanner

ARDF: Sheet pass through type (with Mechanical Auto Reverse

Duplex function)

Scanning area: Max.: Contact glass mode 300 x 432 mm

ARDF mode: Simplex, B/W Binary 297 x 2000 mm

Simplex, B/W Gray Scale 297 x 630 mm

Simplex, color 297 x 630 mm

Duplex 297 x 432 mm

Mini.: Contact glass mode: 5 x 5 mm

ARDF mode: 105 x 128 mm

<Notes>

In case of using Twain driver, maximum size is 297 x 432mm and

minimum size is 10 x 10mm.

Resolution: Optical 600dpi

Output 100 / 200 / 300 / 400 / 600dpi

100 – 1200 dpi / 1dot step

<Notes>

In case of using Twain driver, you can specify 100 – 2400 dpi as

resolution.

Scanning Speed:

<Simplex> PPM

B/W Binary B/W 8 bit Color

200dpi 600dpi 200dpi 600dpi 200dpi 600dpi

A4 Portrait 30 10 22 3 10 1.3

A4 Landscape 38 13 22 3 11 1.3

Letter Portrait 31 10 22 2.9 10 1.3

Letter Landscape 37 13 22 2.9 11 1.3

A3 23 8 12 1.5 5 0.7

<Duplex>

B/W: 12 ipm / A4 portrait, 200 dpi, binary

Color: 3 ipm / A4 portrait, 200 dpi, color

Warm-up time: less than 40 sec

ADF Capacity: 50 sheets

Output Capacity: 50 sheets

Paper weight: Simplex: 40.7 – 128.0 g/m2

Duplex: 52.3-104.7 g/m2

Memory: 128 MB

Version – 1.0

Page 22

G130/G131 Product Support Guide

Compression Method MH, MR, MMR, JPEG

Interface: For scanner: 10 / 100 BASE-TX (Standard), IEEE802.11b (Option)

For printer: USB 2.0, 10 / 100 BASE-TX (Standard)

SD slot (Standard)

Physical Specifications

Power Requirements 120V/60Hz, 220-240V/50/60/Hz

Power Consumption Max. less than 140W

Dimensions: 590 x 647 x 265 mm

Weight: less than 29kg

Sound Power Level: 61dB or less

*Measured by Ricoh Standard methodology

Safety Standard US version UL60950

EU version EN60950

EMI US version FCC Part 15 Class B

EU version EN55022 Class B

Reliability Specifications

Average scanning volume: 4,000 pages per month

Maximum scanning volume: 10,000 pages per month

Power On time 160 hours per month

Special Tools

The following special tools should be prepared for maintenance of the new model in the

field:

Unique or Common:

U: Unique

C: Common

Item Part Number

1 A0069104 Scanner Positioning Pin (4pcs/set) 1 C (Russian-SC)

2 G4129310 Ricoh Gray Scale 1 C (Russian-SC)

3 G4049004 RS-13 chart 1 C (Russian-SC)

4 B6455010 SD Card 1 C (Belini-C2)

5 B6456700 PCMCIA Card Adapter 1 C (Belini-C2)

6 B6456800 USB Reader/Writer 1 C (Belini-C2)

7 - Service tool (software) 1 U

Description Q’ty Unique or Common

Version – 1.0

Page 23

G130/G131 Product Support Guide

EDP Codes

Model Name EDP Product Code

Image Scanner IS300e 402252 G421-17

Option EDP Codes

Model Name

Ship To RC /RE /RA RC /RE //RA RC

Product Site

Product Code G514-21 G948-17 B373-17

EDP Code 400306 402267 402001

(Kg) Gross

Packing Method CTN CTN CTN

Individual

Ctn

Packing

(mm)

W x D x H H 52 140 52

Measurement (M3) 0.00187772 0.141610 0.001901

Outer Ctn W N/A N/A N/A

Packing

(mm)

W x D x H H N/A N/A N/A

Number of units No Outer Carton

Measurement (M3) N/A N/A N/A

Remarks

Version – 1.0

Product

Net 0.152 kg Weight

W

D

D

Option

IPU

Image

Processing Unit

Type A

Japan (Ricoh

Hadano)

0.165 kg 32.0 kg 0.3 kg

230 1190 224

157 850 156

N/A N/A N/A

Common with

G412

Rack

Table Type

7100

Japan Japan

No Outer

Carton

Wireless

LAN

IEEE802.11b

Interface Unit

Type A

No Outer

Carton

Common with

G094/G095

and G081 etc

Page 24

G130/G131 Product Support Guide

SERVICE TIME ESTIMATION

Installation Times

MAINFRAME

30 minutes

PERIPHERALS

Rack: 20 minutes

IPU: 10 minutes

Wireless LAN: 20 minutes

Major Technical Enhancements

Mainframe

Network Board Standard.

Connectivity

• Support the network functions as follows.

• Web Status Monitor

• Scan to E-Mail with LDAP

• Scan to PC (FTP/SMB)

• Scan to print

• Option for connectivity.

• IEEE802.11b

Note: The IEEE802.11b card and USB card cannot be used simultaneously. This is

because both use the same interface.

Version – 1.0

Loading...

Loading...