Page 1

®

SERVICE MANUAL

PN: RCPC0200

A193/A224

RICOH GROUP COMPANIES

Page 2

Page 3

SERVICE MANUAL

A193/A224

RICOH GROUP COMPANIES

®

®

®

Page 4

Page 5

A193/A224

SERVICE MANUAL

PN: RCSM0200

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

Page 8

Page 9

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or certified

by successfully completing a Ricoh Technical

Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

WARNING

Page 10

Page 11

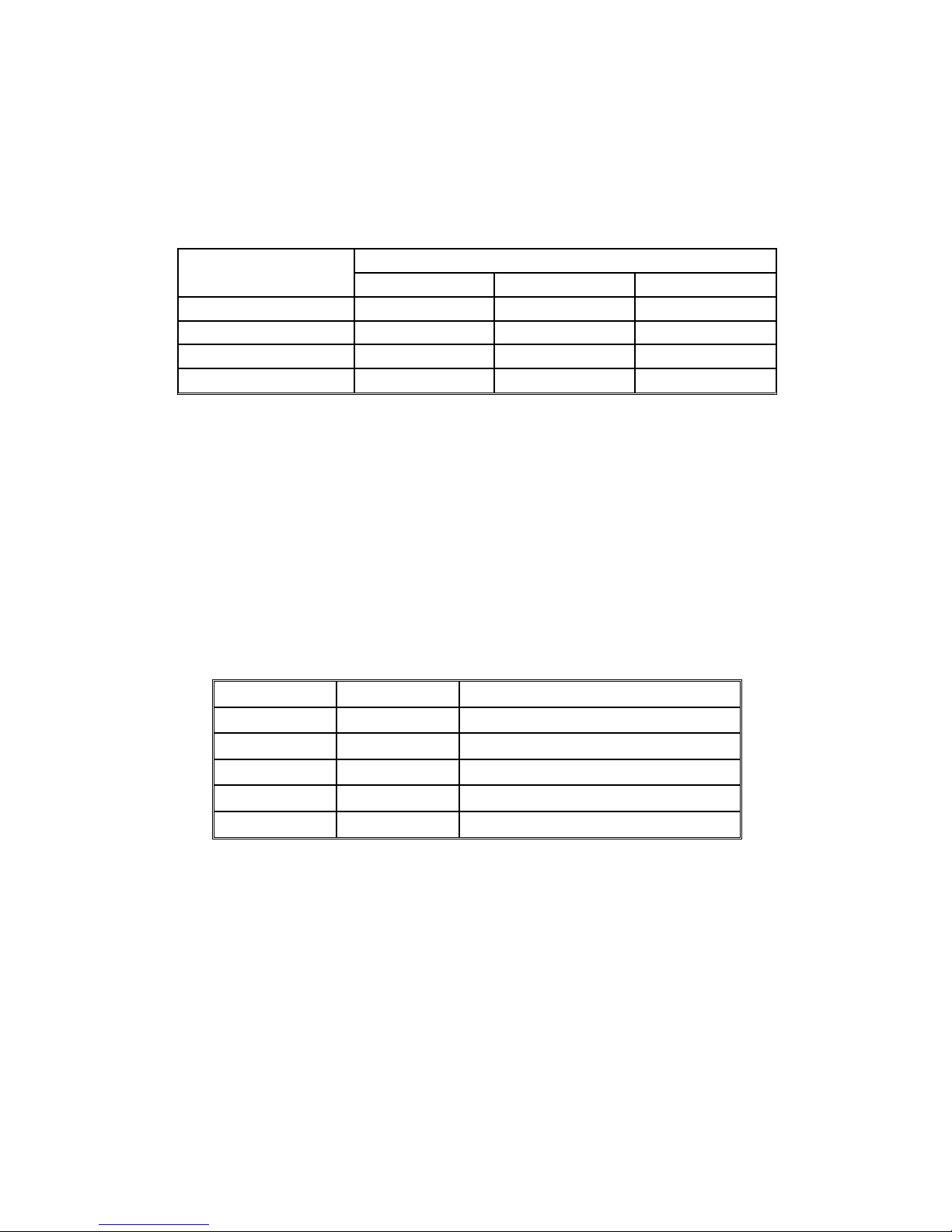

LEGEND

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

A193 3220 AFICIO 200 9920DP

A224 3225 AFICIO 250 9925DP

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

11/96 Original Prin tin g

1 1/97 A661 Additi on

2 4/97 A666 Additi on

3 7/97 A224 Additi on

Page 12

Page 13

Table of Contents

COPIER

A193 OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. MACHINE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3. PAPER PATH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 1-6

5. ELECTRICAL COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . 1-8

6. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

7. COPY PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

7.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

8. BOARD STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

8.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

8.2 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

A193 DETAILED DESCRIPTIONS

1. SCANNING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.3 ORIGINAL SIZE DETECTION IN PLATEN MODE . . . . . . . . . . . . . . . . . . . . . 2-3

2. IMAGE PROCESSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2 SBU (SENSOR BOARD UNIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3 AUTO IMAGE DENSITY (ADS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4 IPU (IMAGE PROCESSING UNIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4.2 Image Processing Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.4.3 Auto Shading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.4 Filtering and Main Scan Magnification/Reduction. . . . . . . . . . . . . . . . . . . 2-11

2.4.5 Gamma (γ) Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.4.6 Gradation Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.4.7 Line Width Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.5 MSU (MEMORY SUPER-CHARGER UNIT) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

TOC i A193

Page 14

2.6 FCI (FINE CHARACTER AND IMAGE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

3. LASER EXPOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

3.2 OPTICAL PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

3.3 GRADATION CONTROL (LASER POWER MODULATION). . . . . . . . . . . . . . 2-20

3.4 AUTO POWER CONTROL (APC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

3.5 LD SAFETY SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

4. PCU (PHOTOCONDUCTOR UNIT). . . . . . . . . . . . . . . . . . . . . . . . 2-23

4.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

4.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

4.3 NEW PCU DETECTION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

4.4 DRUM CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

4.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

4.4.2 Charge Roller Contact Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

4.4.3 Drum Charge Roller Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

4.4.4 Temperature Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

4.5 DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

4.5.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

4.5.2 Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

4.5.3 Mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

4.5.4 Development Bias. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

4.5.5 Toner Density Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

4.5.6 Toner Supply in Abnormal sensor Conditions . . . . . . . . . . . . . . . . . . . . . 2-37

4.5.7 Toner Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

4.6 DRUM CLEANING AND TONER RECYCLING. . . . . . . . . . . . . . . . . . . . . . . . 2-42

4.6.1 Drum Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

4.6.2 Toner Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

5. PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

5.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

5.2 PAPER TRAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

5.2.1 Paper Feed Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

5.2.2 Paper Lift Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

5.2.3 Paper End Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

5.2.4 Side Fence Double Stopper Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

5.2.5 Paper Size Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

A193 ii TOC

Page 15

5.3 BY-PASS FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

5.3.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

5.3.2 Paper Feed Mechanism and Paper End Detection . . . . . . . . . . . . . . . . . 2-51

5.3.3 By-pass Feed Paper Width Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

5.4 PAPER REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

6. IMAGE TRANSFER AND PAPER SEPARATION. . . . . . . . . . . . . 2-54

6.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

6.2 IMAGE TRANSFER AND PAPER SEPARATION MECHANISM . . . . . . . . . . 2-55

6.3 ROLLER CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

6.4 PAPER SEPARATION AND TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . 2-57

7. IMAGE FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

7.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

7.2 FUSING DRIVE AND RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . 2-59

7.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM . . . . . . . . . . . . . . . . . . . . 2-60

7.4 PRESSURE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

7.5 CLEANING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

7.6 FUSING TEMPERATURE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

7.7 OVERHEAT PROTECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

8. ENERGY SAVER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

8.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

8.2 COPIER ONLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

8.3 COPIER/PRINTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

8.4 COPIER/FAX, COPIER/PRINTER/FAX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

8.5 ENERGY SAVER CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

8.6 ENERGY SAVER TIMING CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

9. PAPER EXIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

INSTALLATION PROCEDURE (A193)

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 ENVIRONMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 MACHINE LEVEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.3 MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.4 POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2. COPIER INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

TOC iii A193

Page 16

2.2 COPIER INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

2.3 AUTO DOCUMENT FEEDER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

2.4 PAPER TRAY UNIT INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

2.5 DUPLEX UNIT INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

2.6 1-BIN SORTER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2.7 MEMORY BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

2.8 KEY COUNTER HOLDER INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

2.9 ANTI-CONDENSATION HEATER INSTALLATION. . . . . . . . . . . . . . . . . . . . . 3-21

2.10 TRAY HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

2.11 TRAY HEATER (OPTIONAL PAPER TRAY UNIT) . . . . . . . . . . . . . . . . . . . . 3-23

A193 SERVICE TABLES

1. SERVICE REMARKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -1

1.1 GENERAL CAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2 PCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 TRANSFER ROLLER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.4 SCANNER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.5 LASER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.6 FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.7 PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.8 OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

2. SERVICE PROGRAM MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

2.1.1 Service Program Access Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

2.1.2 Accessing Copy Mode from within an SP Mode. . . . . . . . . . . . . . . . . . . . . 4-4

2.1.3 How to select the program number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2.1.4 To Input a Value or Setting for an SP Mode . . . . . . . . . . . . . . . . . . . . . . . 4-5

2.2 SERVICE PROGRAM MODE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.2.1 Main SP Mode Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.2.2 Test Pattern Printing (SP 5-902). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

2.2.3 Input Check (SP5-803). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

2.2.4 Output Check (SP5-804) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

2.2.5 Copy Jam History Display (SP7-903). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

2.2.6 Original Jam History Display (SP7-905). . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

2.2.7 System Parameter And Data Lists (SP5-992) . . . . . . . . . . . . . . . . . . . . . 4-39

A193 iv TOC

Page 17

2.2.8 Memory All Clear (SP5-801). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

2.2.9 Program Download. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

3. USER PROGRAM MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

3.1 HOW TO ENTER AND EXIT UP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4. SWITCHES/LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4.1 SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4.2 LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4.3 TEST PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

5. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . 4-44

5.1 SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

6. PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . . . 4-45

6.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

7. SERVICE PROGRAM MODE TABLE . . . . . . . . . . . . . . . . . . . . . . 4-47

7.1 SERVICE PROGRAM TABLE INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

7.2 COPIER USER TOOLS/PRINTER TOOLS/FAX SERVICE MODES . . . . . . . 4-53

A193 REPLACEMENT AND ADJUSTMENT

1. EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1 FRONT COVER/INNER COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.2 REAR COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.3 LEFT/RIGHT COVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.4 EXPOSURE GLASS/OPERATION PANEL/UPPER COVER . . . . . . . . . . . . . . 5-3

2. PHOTOCONDUCTOR UNIT (PCU). . . . . . . . . . . . . . . . . . . . . . . . . 5-4

2.1 PCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

2.2 DRUM CHARGE ROLLER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

2.3 DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

2.4 CLEANING BLADE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

3. TRANSFER UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

3.1 TRANSFER UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

3.2 TRANSFER ROLLER/SEPARATION UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

4. SCANNER UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

4.1 LENS COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

4.2 SCANNER FRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

4.3 ORIGINAL SIZE SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Rev. 08/98

TOC v A193

Page 18

4.4 LENS BLOCK/SBU ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

4.5 XENON LAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

4.6 SCANNER H. P. SENSOR/PLATEN COVER SENSOR . . . . . . . . . . . . . . . . . 5-14

4.7 SCANNER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

4.8 SCANNER WIRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5. LASER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.1 LASER UNIT/MAIN SCAN SYNCHRONIZATION DETECTOR . . . . . . . . . . . 5-19

5.2 POLYGON MIRROR MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.3 LD UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.4 LASER UNIT POSITIONING ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

6. FUSING/EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

6.1 HOT ROLLER STRIPPERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

6.2 FUSING THERMISTOR/THERMOFUSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

6.3 HOT ROLLER/FUSING LAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

6.4 PRESSURE ROLLER/CLEANING ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

7. EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

7.1 EXIT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

7.2 UPPER EXIT SENSOR/LOWER EXIT SENSOR . . . . . . . . . . . . . . . . . . . . . . 5-27

8. PAPER FEED/ REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

8.1 BY-PASS FEED TRAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

8.2 BY-PASS FEED PAPER END SENSOR/REGISTRATION SENSOR. . . . . . . 5-29

8.3 PAPER FEED ROLLER/FRICTION PAD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

8.4 BY-PASS FEED PAPER WIDTH SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

8.5 PAPER FEED ROLLERS/PAPER SIZE DETECTOR . . . . . . . . . . . . . . . . . . . 5-31

8.5.1 Paper Feed Rollers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

8.5.2 Paper Size Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

8.6 PAPER END SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

8.7 PAPER FEED CLUTCHES/RELAY CLUTCHES. . . . . . . . . . . . . . . . . . . . . . . 5-33

8.8 RELAY SENSOR/RIGHT VERTICAL GUIDE SWITCH. . . . . . . . . . . . . . . . . . 5-34

9. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

9.1 IOCSS BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

9.2 MSU BOARD/BICU BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

9.3 PSU BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

10. STANDARD WHITE DENSITY ADJUSTMENT. . . . . . . . . . . . . . 5-38

Rev. 08/98

A193 vi TOC

Page 19

11. COPY ADJUSTMENT PRINTING/SCANNING . . . . . . . . . . . . . . 5-39

11.1 PRINTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

11.1.1 Registration - Leading Edge/Side-to-Side . . . . . . . . . . . . . . . . . . . . . . 5-39

11.1.2 Blank Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

11.1.3 Main Scan Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

11.1.4 Double Copy Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

11.2 SCANNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

11.2.1 Registration: Platen Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

11.2.2 Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

11.3 ADF IMAGE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

11.3.1 Registration and Blank Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

11.3.2 Sub Scan Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

12. IMAGE DENSITY ADJUSTMENT BY KEY OPERATOR . . . . . . 5-44

A193 TROUBLESHOOTING

1. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1 SUMMARY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. SC CODE DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

3. ELECTRICAL COMPONENT DEFECTS. . . . . . . . . . . . . . . . . . . . 6-11

3.1 SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

3.2 SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

4. BLOWN FUSE CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

5. ROM MODIFICATION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

DOCUMENT FEEDER A628

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. COMPONENT LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.2 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

2.3 ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

2.4 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

3. DETAILED DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

3.1 ORIGINAL SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

3.2 PICK-OFF AND SEPARATION MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Rev. 08/98

TOC vii A193

Page 20

3.3 ORIGINAL TRANSPORT AND EXIT MECHANISM . . . . . . . . . . . . . . . . . . . . . 7-9

3.4 STAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

3.5 TIMING CHARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

3.5.1 A4 Lengthwise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

3.5.2 A4 Sideways (Stamper Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

3.6 OVERALL ELECTRICAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

4. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 7-14

4.1 ORIGINAL FEED UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

4.2 SEPARATION ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

4.3 PICK-UP ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

4.4 FEED BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

4.5 ORIGINAL SET SENSOR AND WIDTH SENSOR REPLACEMENT . . . . . . . 7-18

4.6 DF COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

4.7 DF FEED COVER OPEN , DF POSITION, AND APS START SENSOR

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

4.8 ORIGINAL LENGTH SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . 7-21

4.9 DF FEED CLUTCH AND DF PICK-UP SOLENOID REPLACEMENT. . . . . . . 7-22

4.10 REGISTRATION SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 7-23

4.11 STAMPER SOLENOID REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

4.12 SP MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

PAPER TRAY UNIT G697

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.2 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

2.3 ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

2.4 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

3. DETAILED DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

3.1 PAPER FEED AND TRAY LIFT/LOWER MECHANISM . . . . . . . . . . . . . . . . . . 8-6

3.2 TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

3.3 OVERALL ELECTRICAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

4. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 8-9

4.1 EXTERIOR COVER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

4.2 PAPER FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Rev. 08/98

A193 viii TOC

Page 21

4.3 PAPER FEED AND RELAY CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . 8-11

4.4 PAPER FEED MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

4.5 LIFT MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

4.6 PAPER END AND UPPER LIMIT SENSOR REPLACEMENT . . . . . . . . . . . . 8-13

4.7 UPPER RELAY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

4.8 LOWER RELAY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

4.9 PAPER SIZE SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

4.10 TRAY COVER SWITCH REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

DUPLEX G694

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. COMPONENT LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

2.2 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

2.3 ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

3. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

4. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

4.1 A3 PAPER SIZE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

4.2 SHORTER THAN A4 LENGTHWISE (MEMORY COPY)

8 Original (

~

)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

5. DETAILED DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

5.1 DUPLEX JUNCTION GATE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

5.2 PAPER TRANSPORT AND FEED MECHANISM . . . . . . . . . . . . . . . . . . . . . . 9-13

5.3 TIMING CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

5.3.1 A3 (without memory). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

5.3.2 A4 sideways (Memory). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

5.4 OVERALL ELECTRICAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

6. DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

6.1 DUPLEX CONTROL BOARD : DSW1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

7. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 9-18

7.1 DUPLEX TRANSPORT UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

7.2 DUPLEX TRANSPORT AND FEED MOTOR REPLACEMENT . . . . . . . . . . . 9-19

7.3 DUPLEX TURN AND DUPLEX EXIT SENSORS . . . . . . . . . . . . . . . . . . . . . . 9-19

7.4 DUPLEX JUNCTION GATE SOLENOID AND DUPLEX ENTRANCE

SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Rev. 08/98

TOC ix A193

Page 22

1-BIN SORTER A629

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. COMPONENT LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

2.2 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

2.3 ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . 10-4

2.4 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

3. DETAILED DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

3.1 BIN JUNCTION GATE AND PAPER TRANSPORT MECHANISM. . . . . . . . . 10-6

3.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

3.3 TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

3.4 OVERALL ELECTRICAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

4. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 10-9

4.1 BIN JUNCTION GATE SOLENOID, TRANSPORT MOTOR AND SORTER

DRIVE BOARD REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

4.2 BIN PAPER SENSOR AND INDICATOR REPLACEMENT . . . . . . . . . . . . . 10-10

AUTO REVERSE DOCUMENT FEEDER A661

1. OVERALL MACHINE INFORMATION . . . . . . . . . . . . . . . . . . . . . 11 -1

1.1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

1.2 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

1.3 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

1.4 ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . 11-4

1.5 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

2. DETAILED DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

2.1 ORIGINAL SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

2.2 PICK-OFF AND SEPARATION MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . 11-8

2.3 ORIGINAL TRANSPORT AND EXIT MECHANISM . . . . . . . . . . . . . . . . . . . . 11-9

2.3.1 Single-sided Original. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

2.3.2 Double-sided Original. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

2.4 STAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

2.5 TIMING CHARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

2.5.1 LT Sideways (Single-sided Original Mode). . . . . . . . . . . . . . . . . . . . . . . 11-13

2.5.2 LT Sideways-Stamper Mode (Single-sided Original Mode) . . . . . . . . . . 11-14

Rev. 08/98

A193 x TOC

Page 23

2.5.3 LT Sideways (Double-sided Original Mode). . . . . . . . . . . . . . . . . . . . . . 11-15

2.5.4 LT Sideways-Stamper Mode (Double-sided Original Mode) . . . . . . . . . 11-16

2.6 JAM DETECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-17

2.7 OVERALL ELECTRICAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-18

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-19

4. PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 11-22

5. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 11-23

5.1 ORIGINAL FEED UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

5.2 SEPARATION ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . 11-24

5.3 PICK-UP ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-25

5.4 FEED BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-26

5.5 ORIGINAL SET SENSOR AND WIDTH SENSOR REPLACEMENT . . . . . . 11-27

5.6 DF COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-28

5.7 DF FEED COVER OPEN , DF POSITION, AND APS START SENSOR

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-29

5.8 ORIGINAL LENGTH SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 11-30

5.9 DF FEED CLUTCH, DF PICK-UP SOLENOID, AND JUNCTION

SOLENOID GATE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-31

5.10 REGISTRATION SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 11-32

5.11 ORIGINAL EXIT SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . 11-33

5.12 STAMPER SOLENOID REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 11-34

FINISHER A666

1. OVERALL MACHINE INFORMATION . . . . . . . . . . . . . . . . . . . . . 12 -1

1.1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

1.2 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

1.3 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

1.4 ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . 12-4

1.5 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

2. DETAILED DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

2.1 JUNCTION GATE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

2.2 PAPER REVERSING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

2.3 JOGGER UNIT PAPER POSITIONING MECHANISM . . . . . . . . . . . . . . . . . . 12-8

2.4 STAPLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

2.5 FEED OUT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-10

2.6 SHIFT TRAY UP/DOWN MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-11

Rev. 08/98

TOC xi A193

Page 24

2.7 SHIFT TRAY SIDE-TO-SIDE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . 12-12

2.8 TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

2.8.1 Face-up Mode (A4: 2 sheets). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

2.8.2 Face-down Mode (A4: 2 sheets) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

2.8.3 Staple Mode (A4: 2 sheets) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

2.8.4 Jam Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

2.8.5 Electrical Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

3. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 12-18

4. PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 12-21

5. SERVICE TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

5.1 LED TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

5.2 DIP SWITCH TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

5.2.1 Factory Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

5.2.2 Stapling Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

5.2.3 Sensor Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

5.2.4 FREE RUN WITHOUT PAPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-23

6. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 12-24

6.1 EXTERIOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-24

6.2 ALIGNMENT BRUSH ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 12-25

6.3 BELT TENSION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-26

6.4 STACK HEIGHT SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . 12-27

6.5 EXIT SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-28

6.6 INVERTER SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-29

A224 COPIER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

2. MACHINE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

3. ELECTRICAL COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . 13-6

4. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-9

5. COPY PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-10

5.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-10

6. MAIN SCAN MAGNIFICATION/REDUCTION. . . . . . . . . . . . . . . 1 3-1 1

7. LASER EXPOSURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-12

7.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-12

Rev. 08/98

A193 xii TOC

Page 25

7.2 OPTICAL PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-12

8. PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

8.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

8.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

9. PAPER SEPARATION AND TRANSPORT. . . . . . . . . . . . . . . . . 13-14

10. IMAGE FUSIN G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

10.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

10.2 PRESSURE ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

10.3 FUSING UNIT FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-17

10.4 FUSING TEMPERATURE CONTROL AND OVERHEAT PROTECTION. . 13-18

11. ENERGY SAVER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-19

12. SERVICE PROGRAM MODE TABLE . . . . . . . . . . . . . . . . . . . . 13-20

12.1 MAIN SP MODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-20

12.1.1 Input Check (SP5-803) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-49

12.1.2 Output Check (SP5-804). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-53

13. PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . 13-55

13.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-55

14. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . 13-57

14.1 LASER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-57

14.2 LASER UNIT/MAIN SCAN SYNCHRONIZATION DETECTOR . . . . . . . . . 13-58

14.3 POLYGON MIRROR MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-59

14.4 POLYGON MOTOR DRIVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-60

14.5 FUSING THERMISTOR/FUSING EDGE THERMISTOR . . . . . . . . . . . . . . 13-61

14.6 FUSING UNIT FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-62

15. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . 13-63

15.1 SUMMARY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-63

16. SC CODE DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-64

17. ROM MODIFICA TION HISTROY . . . . . . . . . . . . . . . . . . . . . . . . 13-77

LARGE CAPACITY TRAY A667

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

2. COMPONENT LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

2.2 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

2.3 ELECTRICAL COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . 14-4

Rev. 08/98

TOC xiii A193

Page 26

2.4 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5

3. DETAILED SECTION DEACRIPTION. . . . . . . . . . . . . . . . . . . . . . 14-6

3.1 PAPER LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

3.2 PAPER FEED MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

3.3 PAPER NEAR END/END DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-8

3.4 PAPER FEED TIMING AND JAM DETECTION . . . . . . . . . . . . . . . . . . . . . . 14-10

4. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

4.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

4.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

4.3 PAPER SIZE CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

5. PREVENTIVE MAINTENANCE TABLE . . . . . . . . . . . . . . . . . . . 14-16

6. SERVICE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

6.1 TEST POINT TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

6.2 FUSE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

7. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 14-17

7.1 EXTERIOR COVER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-17

7.2 PAPER FEED ROLLER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-18

7.3 TRAY LIFT MOTOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-19

7.4 PAPER FEED MOTOR AND TRNSPORT MOTOR . . . . . . . . . . . . . . . . . . . 14-20

7.5 PAPER SIZE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-20

7.6 LOWER LIMIT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-21

Rev. 08/98

A193 xiv TOC

Page 27

Table of Contents

FAX

OVERALL MACHINE INFORMATION A639

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2.1 FEATURES LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2.2 CAPABILITIES OF PROGRAMMABLE ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.3 POSSIBLE COMBINATIONS OF OPTIONAL IC CARDS . . . . . . . . . . . . . . . . . 1-6

3. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -7

3.1 SYSTEM CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.2 POWER DISTRIBUTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

3.3 MEMORY BACK-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4.VIDEO DATA PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4.1 TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4.2 RECEPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

DETAILED SECTION DESCRIPTIONS A639

1. AUTOMATIC SERVICE CALLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 PERIODIC SERVICE CALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1.3 PM CALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1.4 EFFECTIVE TERM OF SERVICE CALLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2. PARALLEL MEMORY TRANSMISSION. . . . . . . . . . . . . . . . . . . . . 2-4

3. TRANSFER BROADCASTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

4. ORIGINAL SCAN PROCESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

4.1 MAIN SCAN DIRECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

4.2 SUB SCAN DIRECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

5. PAGE SPLIT TRANSMISSION (BOOK TRANSMISSION). . . . . . 2-10

6. IMAGE ROTATION BEFORE TRANSMISSION . . . . . . . . . . . . . . 2-11

7. SMOOTHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

8. PAPER SIZE SELECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

8.1 WIDTH PRIORITY AND LENGTH PRIORITY . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

TOC i A193

Page 28

8.2 IMAGE ROTATION BEFORE PRINTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

8.3 SUB SCAN REDUCTION AND PAGE SEPARATION. . . . . . . . . . . . . . . . . . . 2-14

8.4 PAGE REDUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

8.5 TWO IN ONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

8.6 PAPER SIZE SELECTION PRIORITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

9. TWO-SIDED (DUPLEX) PRINTING. . . . . . . . . . . . . . . . . . . . . . . . 2-25

10. PCBs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

10.1 FCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

10.2 NCU (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

10.3 NCU (Europe/Asia). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

10.4 NCU (France). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

INSTALLATION A639

1. FAX UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 INITIAL PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

2. ISDN G4 UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

2.1 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

2.2 INITIAL PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3. HARD DISK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.1 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.2 INITIAL PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

4. HANDSET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

4.1 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

5. IC CARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

5.1 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

5.2 ITEMS INITIALIZED WHEN FUNCTION UPGRADE CARD IS INSTALLED OR

REMOVED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

SERVICE TABLES AND PROCEDURES A639

1. SERVICE LEVEL FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 HOW TO ENTER AND EXIT THE FAX SERVICE MODE. . . . . . . . . . . . . . . . . 4-1

1.2 BIT SWITCH PROGRAMMING (FUNCTION 01). . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 SYSTEM PARAMETER LISTS (FUNCTION 02). . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.4 ROM VERSION DISPLAY (FUNCTION 02). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

A193 ii TOC

Page 29

1.5 ERROR CODE DISPLAY (FUNCTION 03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

1.6 SERVICE MONITOR REPORT (FUNCTION 04). . . . . . . . . . . . . . . . . . . . . . . . 4-5

1.7 G3 PROTOCOL DUMP LIST (FUNCTION 05) . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

1.8 G4 PROTOCOL DUMP LIST (FUNCTION 05) . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

1.9 RAM DISPLAY AND REWRITE (FUNCTION 06) . . . . . . . . . . . . . . . . . . . . . . . 4-6

1.10 NCU PARAMETERS (FUNCTION 06). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

1.11 RAM DUMP (FUNCTION 06). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

1.12 RAM CLEAR (FUNCTION 07) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

1.13 HARD DISK (FUNCTION 08). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1.14 SERVICE STATION FAX NUMBER (FUNCTION 09) . . . . . . . . . . . . . . . . . . . 4-8

1.15 SERIAL NUMBER (FUNCTION 10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.16 MODEM TEST (FUNCTION 11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.17 DTMF TEST (FUNCTION 11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.18 MODEM SIGNAL DETECTION TEST (FUNCTION 11) . . . . . . . . . . . . . . . . 4-10

1.19 RINGER TEST (FUNCTION 11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

1.20 STAMP TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

1.21 G4 PARAMETER PROGRAMMING (FUNCTION 12). . . . . . . . . . . . . . . . . . 4-11

1.22 FILE PRINTOUT (FUNCTION 13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

1.23 TCR/JOURNAL PRINTOUT (FUNCTION 14) . . . . . . . . . . . . . . . . . . . . . . . . 4-11

1.24 USAGE LOG PRINTOUT (FUNCTION 15) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

1.25 SOFTWARE DOWNLOAD (FUNCTION 16) . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

1.26 SOFTWARE UPLOAD (FUNCTION 16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

1.27 SRAM DATA DOWNLOAD (FUNCTION 16) . . . . . . . . . . . . . . . . . . . . . . . . 4-16

2. BIT SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

2.1 SYSTEM SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

2.2 SCANNER SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

2.3 PRINTER SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

2.4 COMMUNICATION SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

2.5 G3 SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

3. NCU PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

4. DEDICATED TRANSMISSION PARAMETERS . . . . . . . . . . . . . . 4-63

4.1 PROGRAMMING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

4.2 PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

TOC iii A193

Page 30

5. SERVICE RAM ADDRESSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

6. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . 4-77

7. SERVICE PROGRAM / BIT SWITCH TABLE INDEX. . . . . . . . . . 4-79

REMOVAL AND REPLACEMENT A639

1. PRECAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. NCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

3. FCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

TROUBLESHOOTING A639

1. ERROR CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. FAX SC CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

2.1 SC1201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

2.2 SC1701. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

2.3 FAX SC CODE TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

3. ROM MODIFICATION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

FAX UNIT A804

1. OVERALL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1.1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1.2 OVERALL MACHINE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2. DETAILED DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

2.1 DOUBLE-SIDED ORIGINAL TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

2.1.1 Portrait Original - Side Binding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

2.1.2 Portrait Original - Top Binding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

2.1.3 Landscape Original - Side Binding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

2.1.4 Landscape Original - Top Binding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

2.2 PAPER SIZE SELECTION PRIORITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

3.1 INITIAL PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

4. SERVICE TABLES AND PROCEDURE . . . . . . . . . . . . . . . . . . . . 7-21

4.1 BIT SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

4.1.1 System Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Rev. 08/98

A193 iv TOC

Page 31

4.1.2 Printer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

4.2 RAM ADDRESSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

5. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

5.1 SC681 (A224 Copier only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

5.2 OTHER POSSIBLE CASES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

5.2.1 Possible Cases and Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

5.2.2 When A804 Software is Downloaded to the A639 Fax Unit . . . . . . . . . . . 7-24

5.2.3 When A639 Software is Downloaded to the A804 Fax Unit . . . . . . . . . . . 7-24

6.0 ROM MODIFICATION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Rev. 08/98

TOC v A193

Page 32

Table of Contents

ISDN

INSTALLATION A644

1. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 USER LEVEL PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 SERVICE LEVEL PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2. SWITCH SETTINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.1 INTERNAL SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.2 PARAMETER SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SERVICE TABLES AND PROCEDURES A644

1. SERVICE LEVEL FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. BIT SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1 G4 INTERNAL SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 G4 PARAMETER SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3. DEDICATED TRANSMISSION PARAMETERS

TROUBLESHOOTING A644

1. ERROR CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1. D-CHANNEL LAYER MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.2. D-CHANNEL, LAYER 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3. D-CHANNEL LINK LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.4. D-CHANNEL NETWORK LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.5. B-CHANNEL LINK LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.6. B-CHANNEL NETWORK LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

1.7. TRANSPORT LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

1.8. SESSION LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

1.9. DOCUMENT LAYER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

1.10. PRESENTATION LAYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2. G4CCU STATUS CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

2.1. LAYER 1 (PHYSICAL LAYER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

2.2. LAYER 2 (LINK LAYER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

2.3. NETWORK LAYER (LAYER 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

2.4. TRANSPORT LAYER (LAYER 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

A193 i TOC

Page 33

2.5. SESSION LAYER, SESSION CONTROL LAYER (LAYER 5) . . . . . . . . . . . . . 3-8

2.6. SESSION LAYER, DOCUMENT CONTROL LAYER

(LAYER 5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3. LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

4. BACK-TO-BACK TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

APPENDIX A A644

1. D-Channel Layer 1 Dump List . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

1.1. How to Print the Dump List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

1.2. How to Read the Dump List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

1.2.1. Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

1.2.2. Reading the Sample Dump List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

1.2.3. Layer 1 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

1. Activation Procedure from the TE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

2. Activation Procesure from the NT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

3. Termination Procedure from the NT . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

APPENDIX B A644

1. G4 Parameter Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

1.1. Initial Programming Items Comparison List. . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

1.2. Switch Locations Comparison List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

1. Communication Parameter Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

2. Default Communication Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

3. Network Used for G3 Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

4. Network Used for G3 transmission in G4-to-G3 Fallback . . . . . . . . . . . . B-3

5. Automatic G4-to-G3 Fallback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

6. Specified Two Step Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

7. Cable Equalizer for ISDN Transmission . . . . . . . . . . . . . . . . . . . . . . . . . B-4

8. Cable Equalizer for ISDN Reception . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

APPENDIX C A644

1. Conditions for Receiving a Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

TOC ii A193

Page 34

Table of Contents

PRINTER

1. OVERALL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 CONTROLLER SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2. DETAILED SECTION DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . 1-3

2.1 BLOCK DIAGRAM (OVERALL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2.2 INTERFACE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.2.1 Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.2.2 Machine Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2.3 BLOCK DIAGRAM (INTERNAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2.3.1 Printer Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2.3.2 Printer Enhancement Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

2.4 Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

2.5 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2.5.1 Sorting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2.5.2 Duplex Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

3. INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

3.1 PRINTER CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

3.2 PRINTER ENHANCEMENT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

3.3 HARD DISK DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

3.4 SIMM MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

3.5 CONNECTING THE INTERFACE CABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

3.5.1 Parallel Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

3.5.2 Serial (RS-232C) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

3.5.3 LocalTalk Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

3.6 CHECKING THE CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

3.6.1 Connection Between Printer Controller (and related options; Printer

Enhancement Unit, Hard Disk Drive, SIMM) and Copier . . . . . . . . . . . . . 1-20

3.6.2 Connection Between Printer Controller (Printer Enhancement Unit) and Host

PC or Macintosh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

A193 i TOC

Page 35

4. SERVICE TABLES AND PROCEDURES . . . . . . . . . . . . . . . . . . . 1-24

4.1 SERVICE REMARKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

4.1.1 Hard Disk Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

4.1.2 About Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

5. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

5.1 ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

5.2 HARDWARE ERRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

5.3 CONNECTION ERRORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

5.4 IMAGE PROBLEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

6.0 Printer Controller ROM Modification History

Printer Controller (A643) ROM Modification History . . . . . . . . . . . . . . . . . . . . . . . 1-29

APPENDIX A

TOC ii A193

Page 36

+ IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and

peripherals, make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the cop ier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior

covers off or open while the main switch is turned on, keep hands away

from electrifie d or m ech an i cal ly dri ve n com p on en ts.

5. If the Start key is presse d be fo re th e cop ier comp let es th e warm-up

period (the Start key starts blinking red and green alternatively), keep

hands away from the mechanical and the electrical co mponents as the

copier starts making copi es as soo n as the w ar m- u p pe r iod is

completed.

6. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your ba r e ha nd s.

HEALTH SAFETY CONDITIONS

1. Always repl a ce th e ozo ne fi lte r s wit h th e spe c ifi e d on es at the speci f i ed

intervals.

2. Toner and de vel o pe r ar e no n-toxic, but if you get either of them in your

eyes by accident, it may cause tempo rar y eye discom f or t . Try to

remove with eye drops or flush with water as first aid. If unsuccessful,

get medical attent i on .

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The RAM board on the system control board has a lithium battery

which can explode if replaced incorrectly. Replace the battery only with

an identical one. The manufacturer recommends replacing the entire

RAM board. Do not rechar g e or bu r n th i s bat te r y. Us ed bat te ri es must

be handled in accordance with local regulations.

Page 37

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later,

do not put more than 100 batteries per sealed box. Storing larger

numbers or not sealing them apart may lead to chemical reactions and

heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair

of laser-based optical units in the field. The optical housing unit can only be

repaired in a factory or at a location with the requisite equipment. The laser

subsystem is replaceable in the field by a qualified Customer Engineer. The

laser chassis is not repairable in the field. Customer engineers are therefore

directed to return all chassis and laser subsystems to the factory or service

depot when replacement of the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

DANGER

INVISIBLE LASER RADIATION

WHEN OPEN.

AVOID DIRECT EXPOSURE TO

BEAM.

>PS<

!

DANGER

INVISIBLE LASER RADIATION

WHEN DISCONNECT OPTICAL

FIBER CABLE.

AVOID DIRECT EXPOSURE TO

BEAM.

>PS<

!

>PS<

Page 38

A193/A224 TAB INDEX

A193 OVERALL MACHINE INFORMATION

DOCUMENT FEEDER A628

OVERALL MACHINE INFORMATION A639

PRINTER CONTROLLER A643

A224 OVERALL MACHINE INFORMATION

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

A193 DETAILED DESCRIPTIONS

PAPER TRAY UNIT G697

DETAILED DESCRIPTIONS A639

A193 INSTALLA TION

DUPLEX UNIT G694

INST ALLATION A639

TAB

POSITION 4

A193 SERVICE TABLES

1 BIN SORTER TRAY A629

SERVICE TABLES A639

TAB

POSITION 5

Rev. 7/97

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

A193 REPLACEMENT & ADJUSTMENT

REPLACEMENT & ADJUSTMENT A639

AUTO REVERSE DOCUMENT FEEDER

A661

A224 OVERALL MACHINE INFORM

A193 TROUBLESHOOTING

FINISHER A666

TROUBLESHOOTING A639

LARGE CAPACITY TRAY A667