GE Sensing and Inspection PT900 User Manual

GE

Measurement & Control

Flow

© 2014 General Electric Company. All rights reserved.

Technical content subject to change without notice.

PT900

User’s Manual

Jun 2016

GE

Measurement & Control

Flow

© 2014 General Electric Company. All rights reserved.

Technical content subject to change without notice.

PT900

Portable Ultrasonic Liquid Flow meter

User’s Manual

Jun. 2016

www.gemeasurement.com

Contents

PT900 User’s Manual

Contents

CHAPTER 1. INTRODUCTION ................................................................................................................................................ 6

1.1 OVERVIEW ................................................................................................................................................................ 6

1.2 THEORY OF OPERATION ................................................................................................................................................... 7

1.2.1 Transit-T ime Flow Measurement .................................................................................................................... 7

CHAPTER 2. INSTALLATION .................................................................................................................................................. 8

2.1 INTRODUCTION ............................................................................................................................................................. 8

2.2 UNPACKING THE PT900 SYSTEM ........................................................................................................................................ 9

2.3 MOUNT THE PORTABLE TRANSMITTER ................................................................................................................................. 10

2.4 INSTALLING PT900 CLAMP-ON FIXTURE .......................................................................................................................... 11

2.4.1 Mounting the Bracket .................................................................................................................................... 11

2.4.2 Installing the Transducers Bracket ................................................................................................................ 12

2.4.3 Installing the Transducers ............................................................................................................................. 13

2.5 MAKING ELECTRICAL CONNECTIONS .................................................................................................................................. 17

2.5.1 Wiring the Line Power ................................................................................................................................... 18

2.5.2 Wiring the Transducers ................................................................................................................................. 19

2.5.3 Wiring System Ground .................................................................................................................................. 20

2.5.4 Wiring Analog Output/HART Communication ............................................................................................... 20

2.5.5 Wiring Modbus Communication .................................................................................................................... 21

2.5.6 Wiring Frequency/Totalizer/Alarm Output ..................................................................................................... 21

2.5.7 Wiring Gate Input .......................................................................................................................................... 22

CHAPTER 3. INITIAL SETUP AND PROGRAMMING ............................................................................................................... 23

3.1 INTRODUCTION ........................................................................................................................................................... 23

3.2 CHARGE THE PT900 AND TABLET ..................................................................................................................................... 24

3.3 DOWNLOAD APP ONTO TABLET ....................................................................................................................................... 25

3.4 PT900 APP SETUP ...................................................................................................................................................... 25

3.5 FIRST TIME IN APP SCREEN ............................................................................................................................................. 27

3.6 HOW TO PROGRAM ....................................................................................................................................................... 29

3.6.1 How to set up a channel ................................................................................................................................ 29

3.6.2 How to set up PIPE ....................................................................................................................................... 30

3.6.3 How to set up FLUID ..................................................................................................................................... 32

3.6.4 How to set up transducer .............................................................................................................................. 34

3.6.5 How to set up PLACEMENT ......................................................................................................................... 36

3.6.6 How to set program options .......................................................................................................................... 39

3.6.7 How to change UNIT ..................................................................................................................................... 49

3.7 HOW TO MEASURE ....................................................................................................................................................... 50

3.7.1 Set up measurement ..................................................................................................................................... 50

3.7.2 View the measurement.................................................................................................................................. 51

3.8 HOW TO LOG ............................................................................................................................................................. 56

3.8.1 ADD LOG ...................................................................................................................................................... 56

3.8.2 STOP and DELETE LOG .............................................................................................................................. 58

3.8.3 EDIT LOG ...................................................................................................................................................... 59

3.9 HOW TO CONFIG TRANSMITTER ........................................................................................................................................ 60

3.9.1 How to configure transmitter SERVICE ........................................................................................................ 62

3.9.2 How to Calibration transmitter ....................................................................................................................... 62

3.9.3 How to Setup Meter....................................................................................................................................... 64

3.9.4 How to test meter .......................................................................................................................................... 66

3.9.5 How to Set ERROR LIMITS .......................................................................................................................... 68

3.10 HELP ........................................................................................................................................................................ 71

3.10.1 About ............................................................................................................................................................. 71

3.10.2 Help Topics ................................................................................................................................................... 72

3.10.3 Quick Start Guide .......................................................................................................................................... 73

Contents

PT900 User’s Manual

CHAPTER 4. ERROR CODES AND TROUBLESHOOTING ........................................................................................................ 74

4.1 ERROR DISPLAY IN THE MEASUREMENT .......................................................................................................................... 74

4.1.1 Error Channel ................................................................................................................................................ 74

4.1.2 Flow Error String ........................................................................................................................................... 74

4.2 DIAGNOSTICS ............................................................................................................................................................. 75

4.2.1 Introduction .................................................................................................................................................... 75

4.2.2 Flowcell Problems ......................................................................................................................................... 75

4.2.3 Transducer Problems .................................................................................................................................... 77

4.2.4 Bluetooth Connection Problems .................................................................................................................... 77

CHAPTER 5. COMMUNICATION .......................................................................................................................................... 78

5.1 MODBUS ................................................................................................................................................................. 78

5.1.1 Introduce ....................................................................................................................................................... 78

5.1.2 MODBUS Map ............................................................................................................................................... 78

5.2 BLUETOOTH ............................................................................................................................................................ 91

5.2.1 Introduce ....................................................................................................................................................... 91

APPENDIX A. SPECIFICATIONS ............................................................................................................................................. 92

APPENDIX B. DATA RECORDS .............................................................................................................................................. 95

APPENDIX C. MENU MAP ..................................................................................................................................................... 98

APPENDIX D. MEASURE TYPE ........................................................................................................................................... 99

D.1 CHANNEL 1 ...................................................................................................................................................................... 99

D.2 CHANNEL 2 ...................................................................................................................................................................... 99

D.3 CHANNEL AVERAGE .......................................................................................................................................................... 100

D.4 CHANNEL GENERAL .......................................................................................................................................................... 101

APPENDIX E. TRANSDUCER TYPE ....................................................................................................................................... 102

Contents

PT900 User’s Manual 1

Information Paragraphs

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not essential

to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper setup of

the equipment. Failure to follow these instructions carefully may cause unreliable performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to

the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these instructions

are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national codes,

regulations, rules and laws related to safety and safe operating conditions are met for each

installation. The safety of any system incorporating the equipment is the responsibility of the

assembler of the system.

WARNING! It is the responsibility of the user to make sure the PWR, Hart, Modbus and IO cable can

meet the cable spec, which is described in Appendix A.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As

equipment can move suddenly and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before

you perform maintenance procedures or service on the equipment.

Contents

PT900 User’s Manual 2

Paragraphes d’informations

Remarque: Ces paragraphes fournissent des informations à même de faciliter la compréhension de la situation, mais

n'est pas indispensable à la bonne utilisation des instructions.

IMPORTANT: Ces paragraphes fournissent des informations qui mettent l'accent sur les instructions qui sont

essentielles à une configuration correcte de l'équipement. Le non-respect de ces instructions peut

entraîner une dégradation des performances.

ATTENTION! Ce symbole indique un risque potentiel mineur de blessure aux personnes et / ou de

sérieux dommages à l'équipement, à moins que ces instructions soient rigoureusement suivies.

ATTENTION! Ce symbole indique un risque potentiel grave de blessures aux personnes, à moins

que ces instructions sont soient rigoureusement.

Questions de sécurité

ATTENTION! Il est de la responsabilité de l'utilisateur de s'assurer que tous les règlements, codes

et lois locaux, nationaux et européens relatifs à la sécurité et aux conditions d'exploitation en toute

sécurité soient respectés pour chaque installation. La sécurité de tout système intégrant l'équipement

est de la responsabilité de celui qui l’assemble.

ATTENTION! Il est de la responsabilité de l'utilisateur de s'assurer que les câbles d’alimentation, Hart,

Modbus et Entrées/Sorties répondent à la spécification décrite à l'annexe A.

Matériel auxiliaire

Standards de sécurité locaux

L'utilisateur doit s'assurer que les équipements auxiliaires utilisés sont en tout point conforme aux codes,

standards et réglementations relatifs à la sécurité.

Zone de travail

ATTENTION! Les équipements auxiliaires peuvent avoir à la fois des modes de fonctionnement

manuel et automatique. Comme l'équipement peut bouger brusquement et sans signe préalable, ne

pas entrer dans la zone de travail de ce dernier pendant le fonctionnement automatique, et ne pas

s’en approcher de trop près pendant le fonctionnement manuel. Si vous le faites, cela peut entraîner

de graves blessures.

ATTENTION! Assurez-vous que l'alimentation de l'équipement auxiliaire est éteinte et verrouillée

avant d'effectuer toute opération de maintenance ou d’entretien de l'équipement.

Contents

PT900 User’s Manual 3

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary

equipment. Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE) take-

back initiative, directive 2002/96/EC.

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the

natural resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle

most of the materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Visit

http://www.ge-mcs.com/en/about-us/environmental-health-and-safety/1741-weee-req.html

for take-back

instructions and more information about this initiative.

Contents

PT900 User’s Manual 4

Caution:

This device complies with Part 15 of the FCC Rules / Industry Canada licence-exempt

RSS standard(s). Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de

l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

This equipment has been tested and found to comply with the limits for

a Class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates

uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following

measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

Under Industry Canada regulations, this radio transmitter may only operate using an

antenna of a type and maximum (or lesser) gain approved for the transmitter by

Industry Canada. To reduce potential radio interference to other users, the antenna

type and its gain should be so chosen that the equivalent isotropically radiated power

(e.i.r.p.) is not more than that necessary for successful communication.

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut

fonctionner avec une antenne d'un type et d'un gain maximal (ou inférieur) approuvé

pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de

brouillage radioélectrique à l'intention des autres utilisateurs, il faut choisir le type

d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une communication

Contents

PT900 User’s Manual 5

satisfaisante.

This device complies with Industry Canada’s licence-exempt RSSs. Operation is subject to the

following two conditions:

(1) This device may not cause interference; and

(2) This device must accept any interference, including interference that may cause

undesired operation of the device.

MPE Reminding

To satisfy FCC / IC RF exposure requirements, a separation distance of 20 cm or more should be

maintained between the antenna of this device and persons during device operation.

To ensure compliance, operations at closer than this distance is not recommended.

Les antennes installées doivent être situées de facon à ce que la population ne puisse

y être exposée à une distance de moin de 20 cm. Installer les antennes de facon à ce

que le personnel ne puisse approcher à 20 cm ou moins de la position centrale de l’

antenne.

La FCC des éltats-unis stipule que cet appareil doit être en tout temps éloigné d’au

moins 20 cm des personnes pendant son functionnement.

Contents

PT900 User’s Manual 6

CHAPTER 1. INTRODUCTION

1.1 OVERVIEW

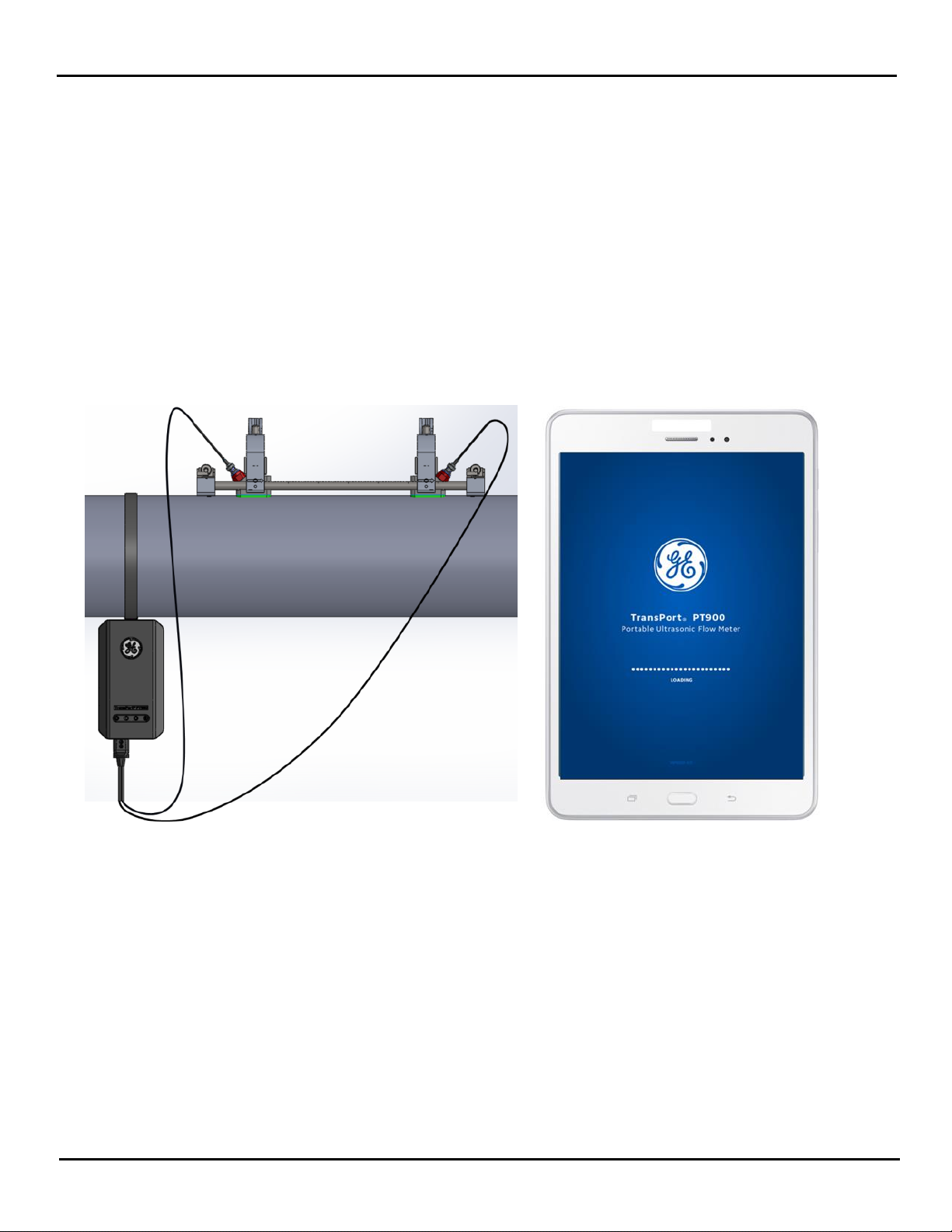

Thank you for purchasing the PT900 ultrasonic flow meter. PT900 is a portable transmitter for measurement of liquids

phase product. It’s designed for the industrial market including water, wastewater, steel, campus energy etc. PT900

will utilize a new electronics platform and industrial design to make it extremely simple to install and use in the field.

The PT900 consists of a transmitter with electronics, CRR transducers system including the new clamp-on fixture and

cable.

The PT900 system will also have optional accessories including a thickness gauge, clamp-on temperature

transmitters, and a fixture for up to 48”. PT900 system will connect via Bluetooth to a separate display (tablet) for

programming.

Figure 1: PT900 system (Pipe Mounting)

Contents

PT900 User’s Manual 7

1.2 Theory of Operation

1.2.1 Transit-T ime Flow Measurement

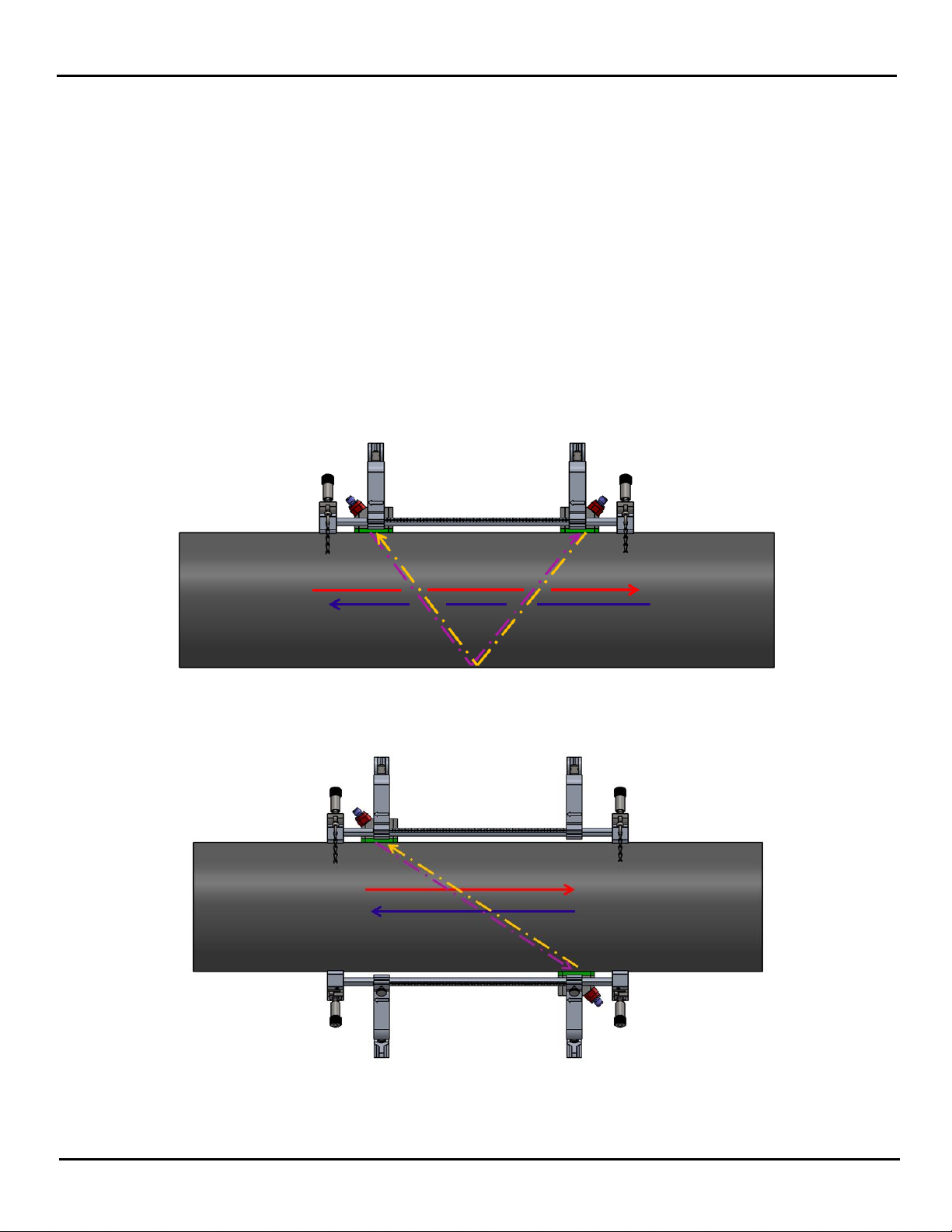

In this method, two transducers serve as both ultrasonic signal generators and receivers. They are in acoustic

communication with each other, meaning the second transducer can receive ultrasonic signals transmitted by the

first transducer and vice versa.

In operation, each transducer functions as a transmitter, generating a certain number of acoustic pulses, and then as

a receiver for an identical number of pulses. The time interval between transmission and reception of the ultrasonic

signals is measured in both directions. When the liquid in the pipe is not flowing, the transit-time downstream equals

the transit-time upstream. When the liquid is flowing, the transit-time downstream is less than the transit-time

upstream.

The difference between the downstream and upstream transit times is proportional to the velocity of the flowing liquid,

and its sign indicates the direction of flow.

Figure 2: Flow and Transducer Paths (Dual Traverse)

Figure 3: Flow and Transducer Paths (Single Traverse)

Contents

PT900 User’s Manual 8

CHAPTER 2. INSTALLATION

2.1 Introduction

To ensure safe and reliable operation of the PT900, the system must be installed in accordance with the established

guidelines. Those guidelines, explained in detail in this chapter, include the following topics:

Unpacking the PT900 system

Installing the electronics enclosure

Installing the clamp-on fixture and transducer system

Wiring the electronics enclosure

WARNING! The PT900 flow transmitter can measure the flow rate of many fluids, some

of which are potentially hazardous. The importance of proper safety practices cannot be

overemphasized.

Be sure to follow all applicable local safety codes and regulations for installing electrical

equipment and working with hazardous fluids or flow conditions. Consult company safety

personnel or local safety authorities to verify the safety of any procedure or practice.

ATTENTION EUROPEAN CUSTOMERS! To

meet CE Mark and UL Mark requirements, all cables

must be installed as described in “Wiring Cable Spec and Requirement” on page 157.

Contents

PT900 User’s Manual 9

2.2 UNPACKING THE PT900 SYSTEM

Before removing the PT900 system from the carrier case, please inspect the flow meter. Each instrument manufactured

by GE Measurement & Control is warranted to be free from defects in material and workmanship. Before discarding

any of the packing materials, account for all components and documentation listed on the packing slip. If anything is

missing or damaged, contact GE Customer Care immediately for assistance.

Please note that your PT900 system may come in different configuration based on your selection, so the packing list

could be a little different, below is the typical packing list:

10. One PT900 electronics

20. One Battery Pack

30. One AC power adaptor

40. One Power cord

50. One soft strap with metal clip for pipe mounting of PT900

60. One magnet clamp

70. One SD card with user manual and calibration sheet

80. Two transducers with couplant

90. One transducer cable

100. One clamp-on fixture

110. Two clamping fixture mounting chains

120. One OD tape

130. One thickness gauge

140. Quick installation guide

150. Calibration Sheet

Figure 4: Standard Packing List

Contents

PT900 User’s Manual 10

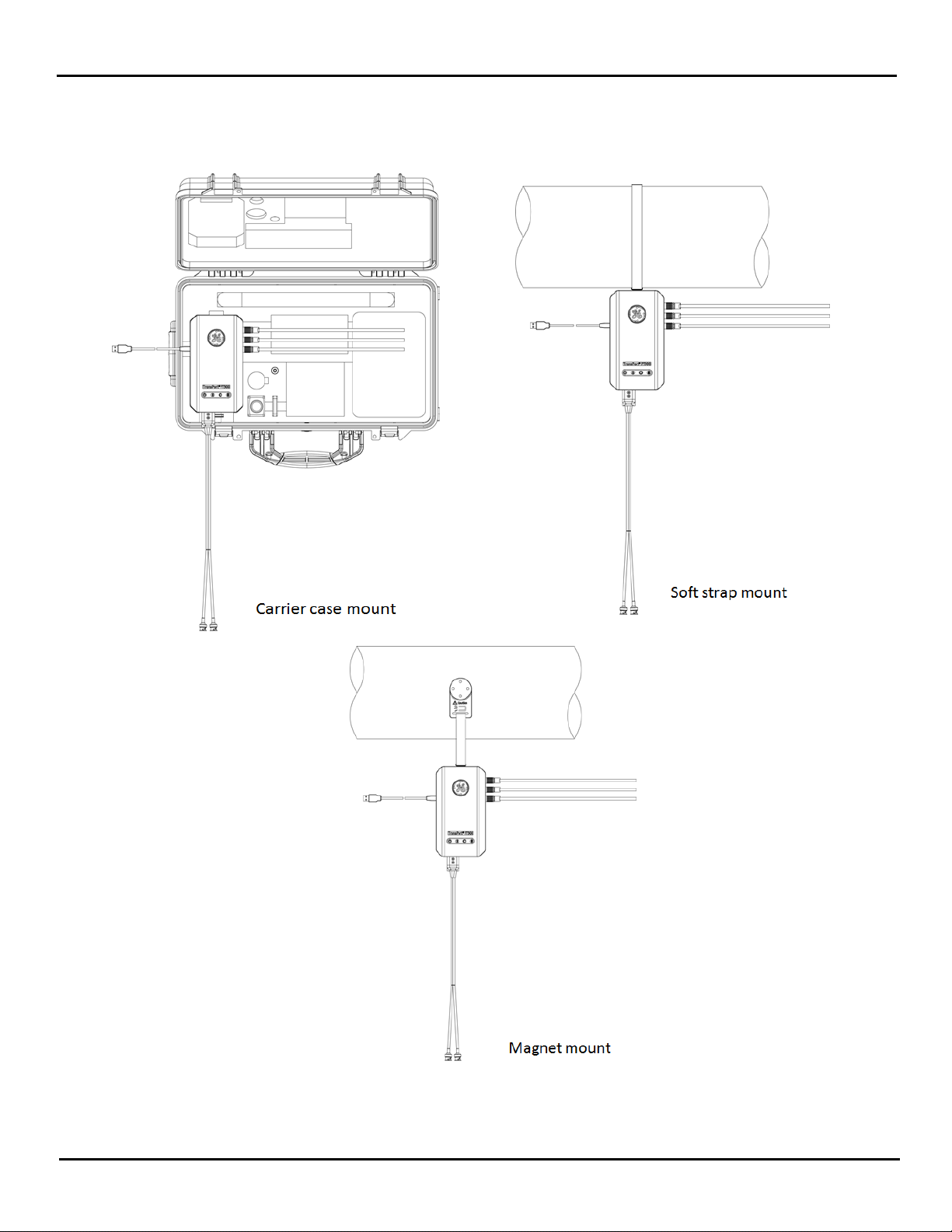

2.3 MOUNT THE PORTABLE TRANSMITTER

The PT900 portable transmitter is housed in a plastic enclosure suitable for indoor or outdoor use, it can be put in the

hard case or be clamped onto the pipe, or be mounted by a magnet clamp, See Figure 5 below for the three different

mounting,

Figure 5: PT900 Electronics Mounting

Contents

PT900 User’s Manual 11

2.4 INSTALLING PT900 CLAMP-ON FIXTURE

[Include any steps for unboxing and pre-assembly if necessary. Also there needs to be a section in the manual that

pertains to batteries, wiring, APP installation and necessary software/hardware platforms for installation purposes.

Other sections can be noted in PT878 manual.]

2.4.1 Mounting the Bracket

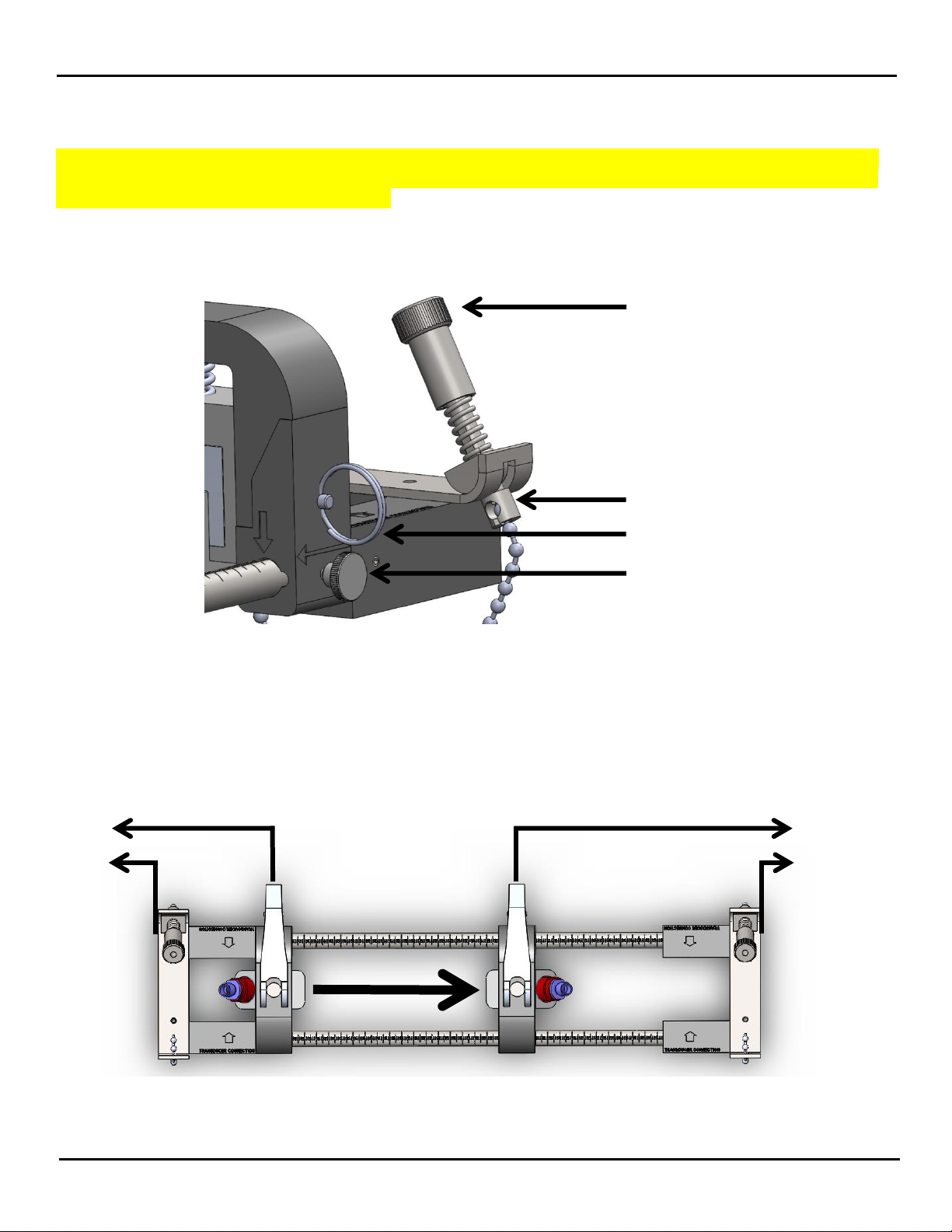

Figure 6: Pre-Assembly Process

Before mounting, check that the screw mechanisms (chain mechanism screws) that are pre-attached to the end

pieces (end flats) are unscrewed to their full potential [A] and that the last joint in the chain is secured within the

chain mechanism screw slot on both sides of the fixture [B]. It is highly recommended that the pin is engaged

securing the bottom portion of the clamp mechanism to the top portion [C] and that the thumb screw is tightened on

the movable clamp [D] so that no motion is allowed throughout the mounting process.

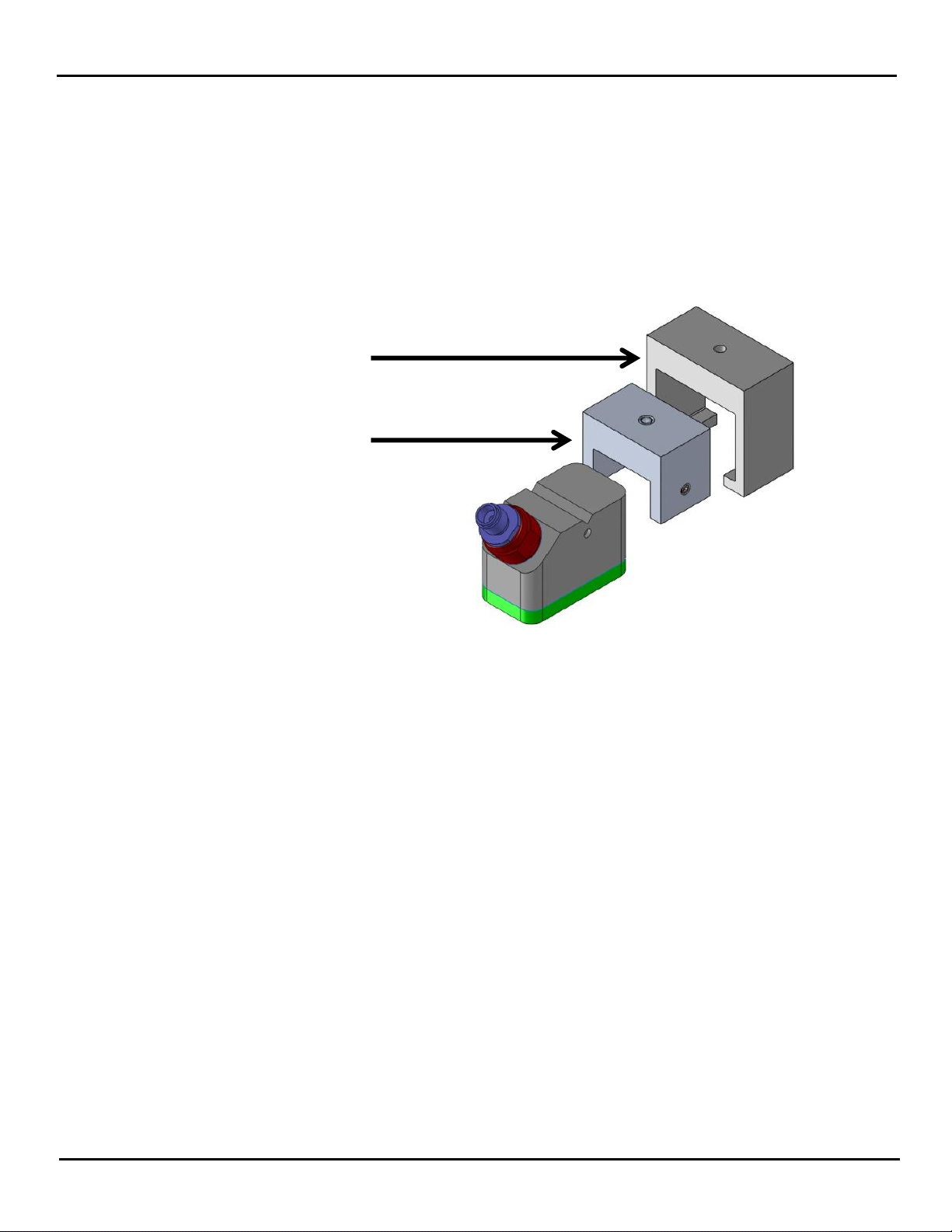

Figure 7: Distance Parameters

Adjust the bracket position so that the closest end flat rests at the preferred distance from inlet/outlet/joint/fitting of

the pipe.

A

B

C

D

Flow Direction

Fitting

Fitting

Joint

Joint

Upstream

Downstream

>10 Diameters

>5 Diameters

>6”

>6”

Contents

PT900 User’s Manual 12

IMPORTANT: There must be allotted a straight run of at least 10 diameters (nominal pipe diameters) before the

upstream transducer and, preferably, at least 5 diameters after the downstream transducer. A

clearance of at least 6in should be provided from the edge of each end flat to the nearest

joint/welding/flange. Please see figure 2.2 for clarification.

Place the fixture so that minimal effort is required to maintain the fixture position (e.g. even if horizontal positioning is

eventually preferred, place the bracket on top of the pipe for mounting). Check that the pipe rests in the small slot

cutout on the bottom edge of the end flats.

Note: Make sure to mount the bracket with the final orientation in mind so that the markings on the rail rod can be

easily read.

Figure 8: Chain Connection

While holding the end flat closest to the pivotal inlet/outlet/joint/fitting, loop the metal chain around the pipe so that

it wraps all the way around. Pull the chain firmly, without compromising the brackets position, and force the chain to

slide into the small slot located at the opposite side of the end flat from the chain mechanism screw [E].

Repeat this process for the opposite chain so that the bracket is firmly mounted but has enough leeway to be able to

adjust bracket alignments.

Adjust the bracket into the preferred orientation on the pipe. Re-center the end flats on the pipe using the small slot

cutout on the bottom edge of the end flats as a tangent-to-pipe indicator. (Level may be necessary, depending on

accuracy required, to verify that the bracket is aligned down the center of the pipe.)

Once aligned, tighten the chains by twisting the nut on top of both chain mechanisms’ screws until the chain is tight

enough to resist the bracket’s movement [A, Figure 2.1]. Verify that this extra restraint did not affect the center

alignment. If this is the case, loosen the nuts, realign, and tighten the screws until the bracket is aligned and secured

tightly.

2.4.2 Installing the Transducers Bracket

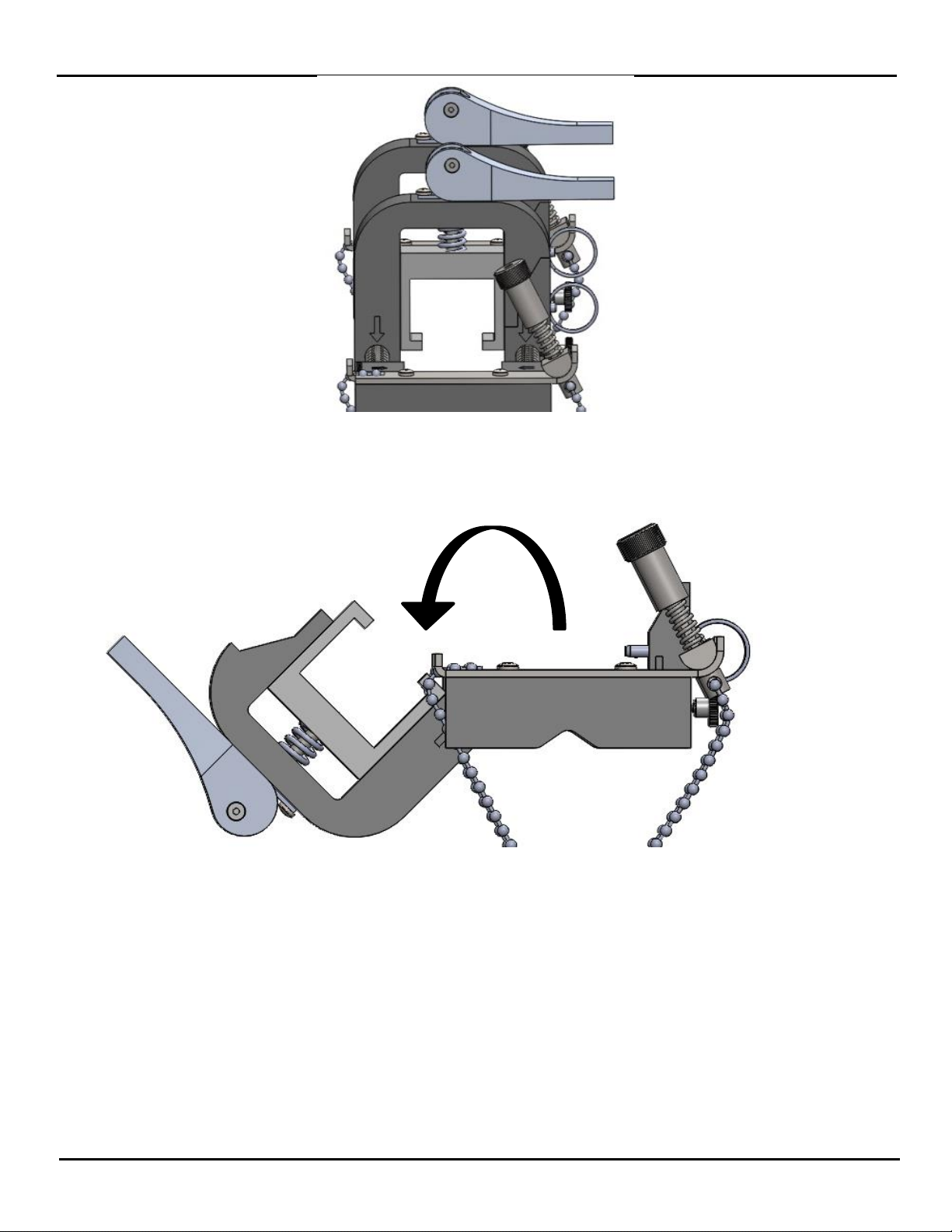

Before installing the transducers, the transducer holder must be attached to the transducer. In many cases, the

transducer holder will already be installed when shipped. If this is the case, skip to section 2.4.3 for installation of the

transducers.

E

End Flat

Chain Screw

Mechanism

Contents

PT900 User’s Manual 13

Screw the plunger mechanism into the bottom, central hole of the transducer holder until the first thread can just

barely be seen above the top lip of the holder.

In order to attach the transducers to their holder, slide the holder onto the top of the transducer so that the circle

slots near the top of the transducer sides are closely aligned with the filled holes on the side of the transducer holder.

Screw the hex socket set screws from the transducer housing into the holes of the transducer. Once tightened, these

screws will lock the housing into place. See Figure 2.4 for clarification.

Figure 9: Transducer Assembly

2.4.3 Installing the Transducers

If necessary, unscrew the thumb screw on the movable clamp to permit axial positioning.

Position the movable bottom clamp so that it rests at the measurement marking matching that of the preferred axial

distance. Measurement markings should be read on the side of the clamp indicated by the arrows.

Note: Distance between transducers vary based on pipe dimensions, number of traverses, wall thickness, etc. APP

can automatically calculate distance and help to position the transducer at a preferred distance for optimal

signal quality (described further in Chapter 3.6.5).

Tighten the thumb screw to lock movable clamp into place while being cautious not to adjust set axial positioning.

Clamp Holder

(Permanently Attached to

Top Portion of Clamp)

Transducer Holder (Semi-

Permanently Attached to

Transducer)

Note: Previous to any mounting,

transducer installed into

transducer housing via set

screws. When mounting, the

transducer housing slides into

the clamp housing and

attaches via a plunger.

Contents

PT900 User’s Manual 14

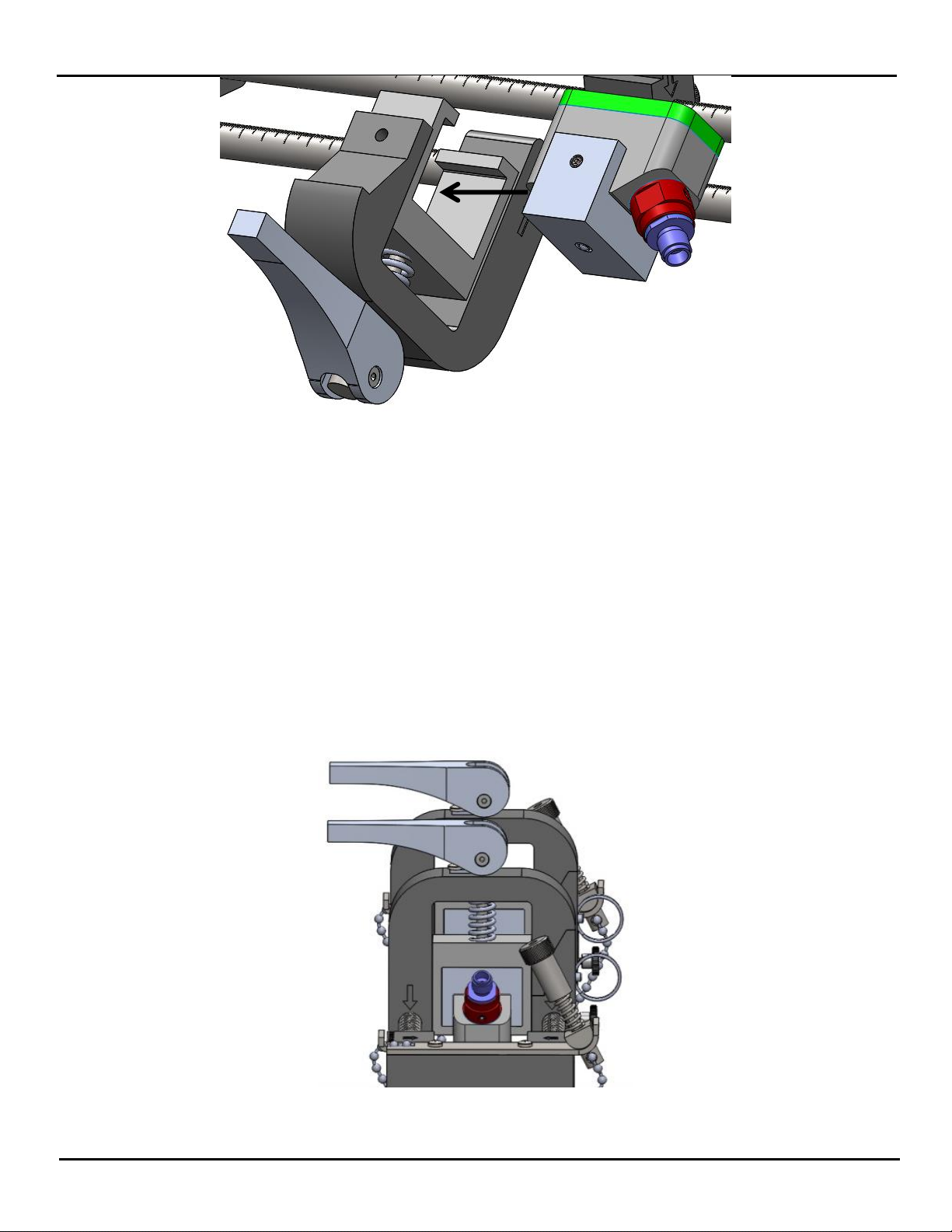

Figure 10: Loaded Cam

Adjust the cam on both clamps into the loaded position so that the clamp holder rests in its furthest radial position

from the pipe (Figure 10).

Figure 11: Clamp “Assembly” Position

Release the pin on both clamps so the top portion of the clamp can swing down freely, allowing easy access for

transducer installation (Figure 11).

Contents

PT900 User’s Manual 15

Figure 12: Transducer Insertion

Slide both transducers, already locked into the transducer housing, into the clamp housing until the plunger from the

top of the transducer housing snaps into its position on the bottom of the clamp housing (Figure 12).

IMPORTANT: Slide the transducers into place with an orientation so that the wire connector is pointed away from

the opposing clamp. In other words, the wire connectors should be oriented in opposite directions.

The arrows on the end flats help to indicate the wire connector direction if needed.

Apply proper coupling to both of the transducer bottoms to help remove air impurities from readings and supply a

more fluent contact with the pipe.

Note: Water based lubricant is not recommended for heated, long term, or multiple traverse measurements.

Swing both of the top portions of the clamp back into alignment with the clamp bottom and lock them back into

place by sliding the pin through the hole on the side of the top portion into the hole on the side of the bottom clamp.

Figure 13: Released Cam

Contents

PT900 User’s Manual 16

Release the cam so that the transducer is forced towards the pipe to make a firm contact surface for measurement

(Figure 13).

Caution! While releasing the cam, make sure that you are not making any contact with the clamp

surface. Potential that stored energy acting on cam will cause cam to make hard contact with clamp

face. Objects or body parts in between contact faces could result in minor injuries.

Contents

PT900 User’s Manual 17

2.5 MAKING ELECTRICAL CONNECTIONS

! ATTENTION EUROPEAN CUSTOMERS!

To meet CE Mark requirements, all cables must be installed as described in Appendix A,

CE Mark Compliance.

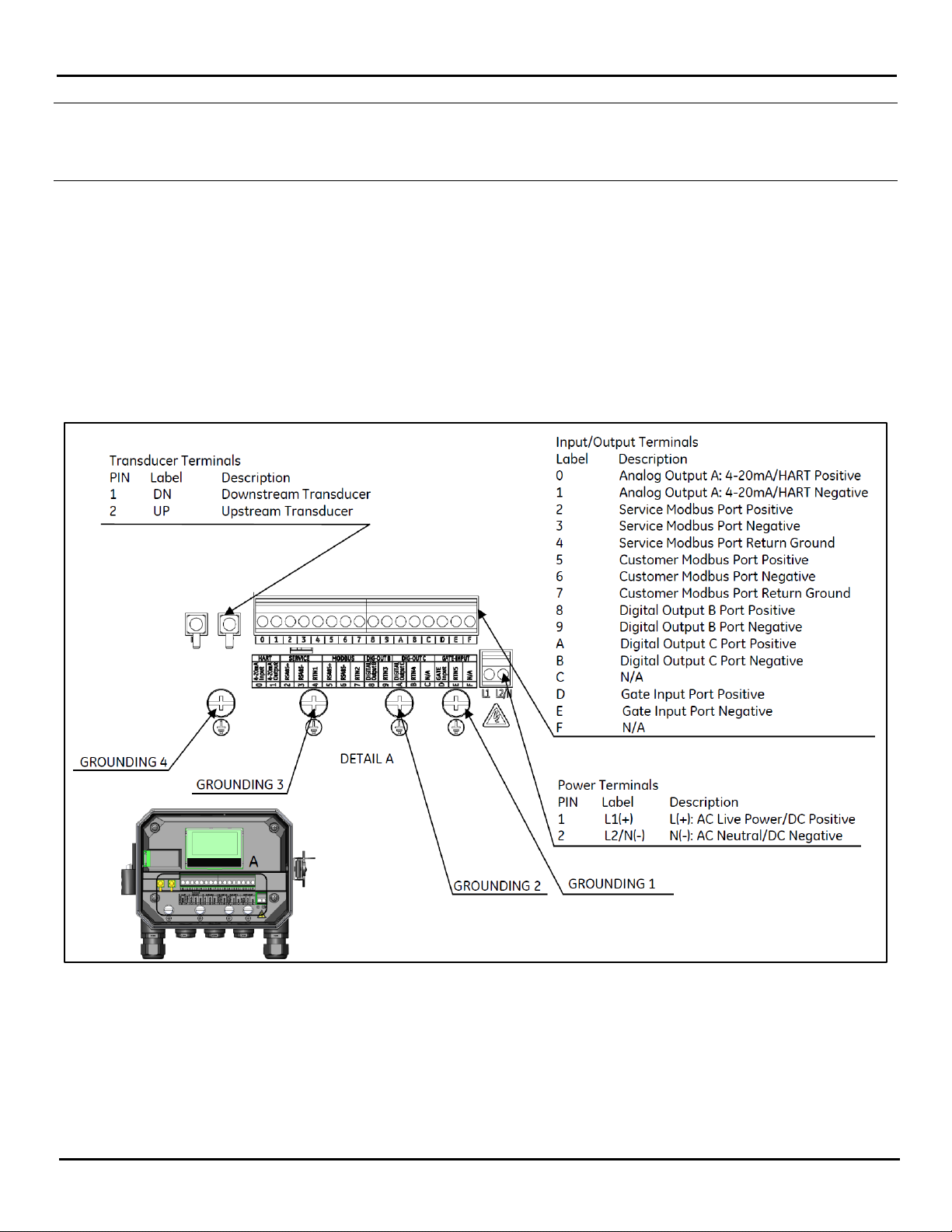

This section contains instruction for making all the necessary electrical connections to the AT600 flow meter. Refer to

Figure 22 for the complete wiring diagram of the unit.

IMPORTANT:

Expect for the transducer connector, all electrical connectors are stored in their terminal blocks during shipment and

may be removed from the enclosure for more convenient wiring. Feed the cables through the cable gland holes on the

bottom of the enclosure, attach the wires to the appropriate connectors and plug the connectors back into their

terminal blocks.

Once the AT600 is completely wired, proceed to Chapter 3, Initial Setup, to configure the unit for operation.

Figure 14: Wiring Diagram

Note that HART or MODBUS communication are optional selections for the AT600 electronics and must be chosen at

the time of ordering.

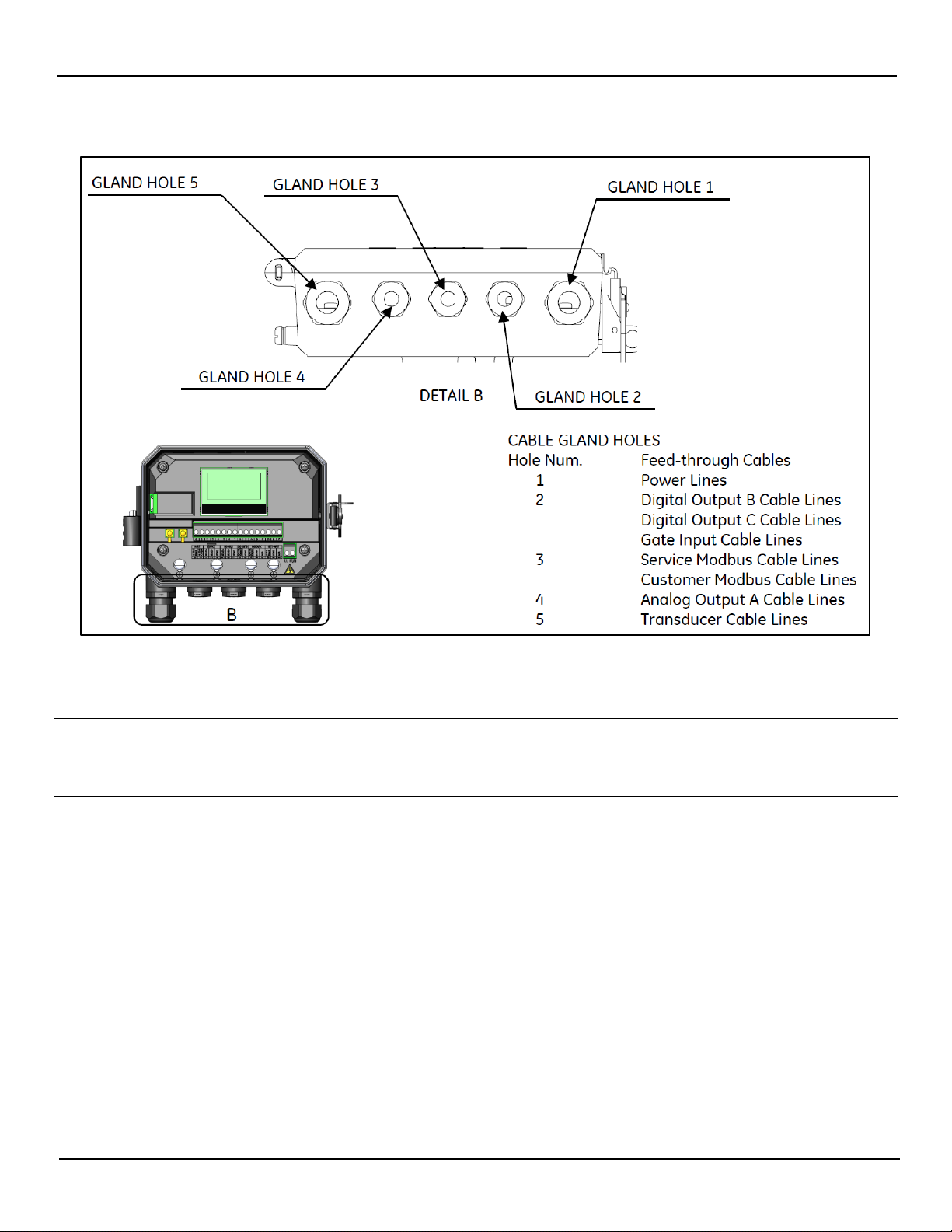

To lead the wiring cables into the enclosure, power lines, transducer line and I/O lines are distributed to different gland

holes.

Refer to Appendix A.2 for cable criteria. Be sure to select the cable to connect the meter only to the specified cables.

Contents

PT900 User’s Manual 18

Refer to Figure 23 for cable gland usage definition. If no cables feed through the cable clamp holes, it must be

blocked with the gland-insert provided together with meter.

Figure 15: Gland Usage Definition

2.5.1 Wiring the Line Power

!ATTENTION EUROPEAN CUSTOMERS!

To meet CE Mark requirements, all cables must be installed as described in Appendix A,

CE Mark Compliance.

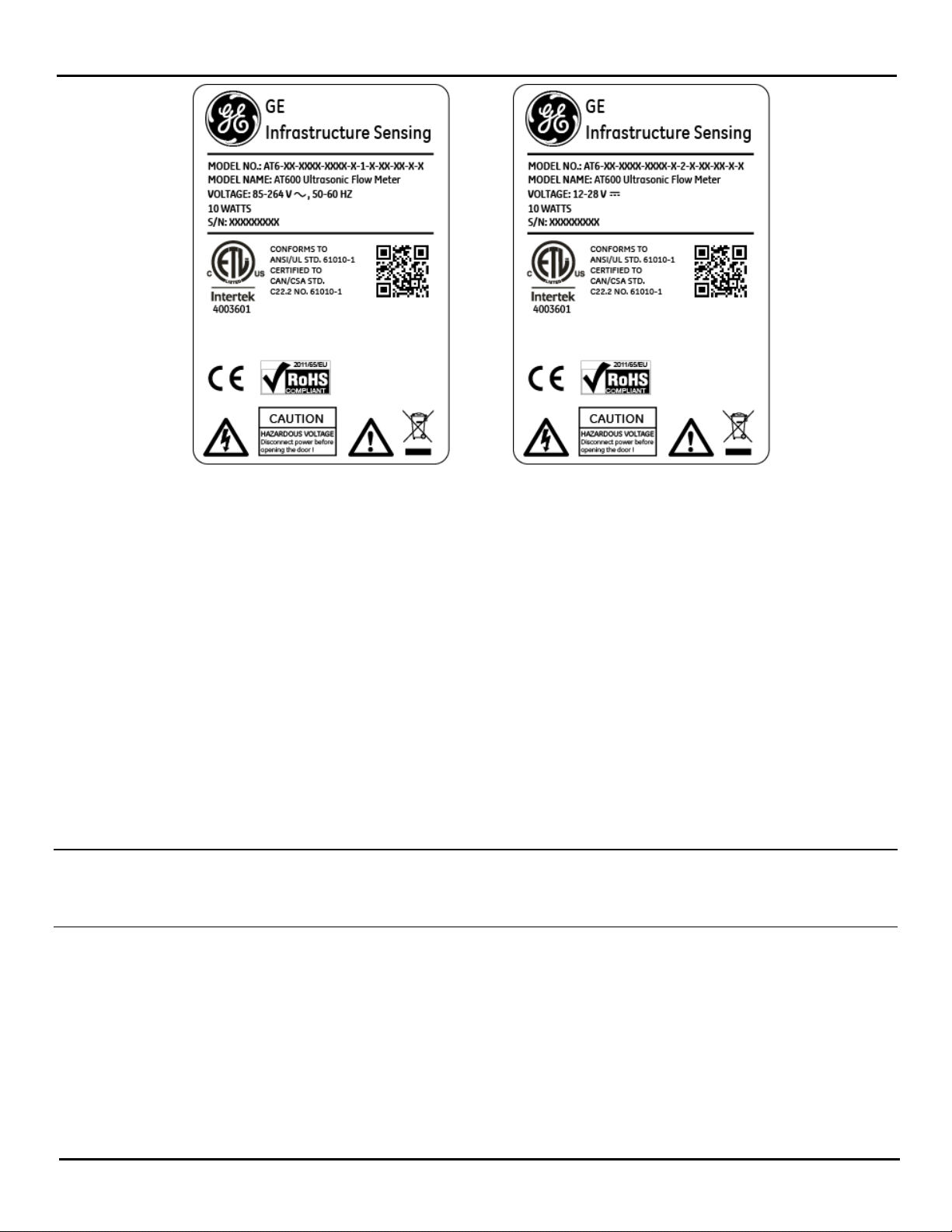

The AT600 may be ordered from operation with power inputs of 85-264 VAC, or 12-28 VDC. The label on the shroud

inside the electronics enclosure, lists the required line voltage. Be sure to connect the meter only to the specified line

voltage.

Refer to Figure 16 below for power inputs of the meter.

Note: For compliance with the European Union’s Low Voltage Directive (LV Directive 2006/95/EC), this unit requires

and external power disconnect device such as a switch or circuit breaker. The disconnect device must be marked as

such, clearly visible, directly accessible, and located within 1.8 m (6 ft) of the AT600.

Refer to Figure 14 to locate terminal block and connect the line power as follows:

WARNING! Improper connection of the line power leads or connecting the meter to the incorrect line voltage will

damage the unit. It will also result in hazardous voltages at the flowcell and associated piping and within the

electronics console.

Contents

PT900 User’s Manual 19

Figure 16: Meter SN Label (AC and DC Version)

Wiring the Line Power (cont.):

1. Strip 1/4” of insulation from the end of the power and neutral or line leads (or the positive and negative DC power

leads), and 1/2” from the end of the ground lead.

2. Connect the ground lead to the internal ground connection (GROUNDING 1) located on the bottom panel of the

enclosure (See Figure 14).

IMPORTANT: The incoming ground lead must be connected to the internal ground connection.

3. Connect the neutral or line lead (or the negative – DC power lead) to L2/N(-) and the line power lead (or the

positive +DC power lead) to L1(+) as shown in Figure 14.

IMPORTANT: Do not remove the existing PC board ground wire or the cover ground wire.

2.5.2 Wiring the Transducers

!ATTENTION EUROPEAN CUSTOMERS!

To meet CE Mark requirements, all cables must be installed as described in Appendix A,

CE Mark Compliance.

Wiring a typical AT600 ultrasonic liquid flow meter system requires interconnection of the following components:

• A pair of transducers installed inside of fixture;

• The electronics console

To wire the transducers, complete the following steps:

WARNING! Before connecting the transducer, take them to a safe area and discharge any static build-up by

shorting the center conductor of the transducer cables to the metal shield on the cable connector.

Contents

PT900 User’s Manual 20

1. Locate the transducer cables and connect them to the two transducers.

2. Connect the cable connector with yellow “DN” jacket on the cable to DN and connect cable connector with white

“UP” jacket on the cable to UP as shown in Figure 14. Then, secure the cable gland.

3. Make vertical insertion during cable connector is plugged into the receptacle to avoid connector destroy.

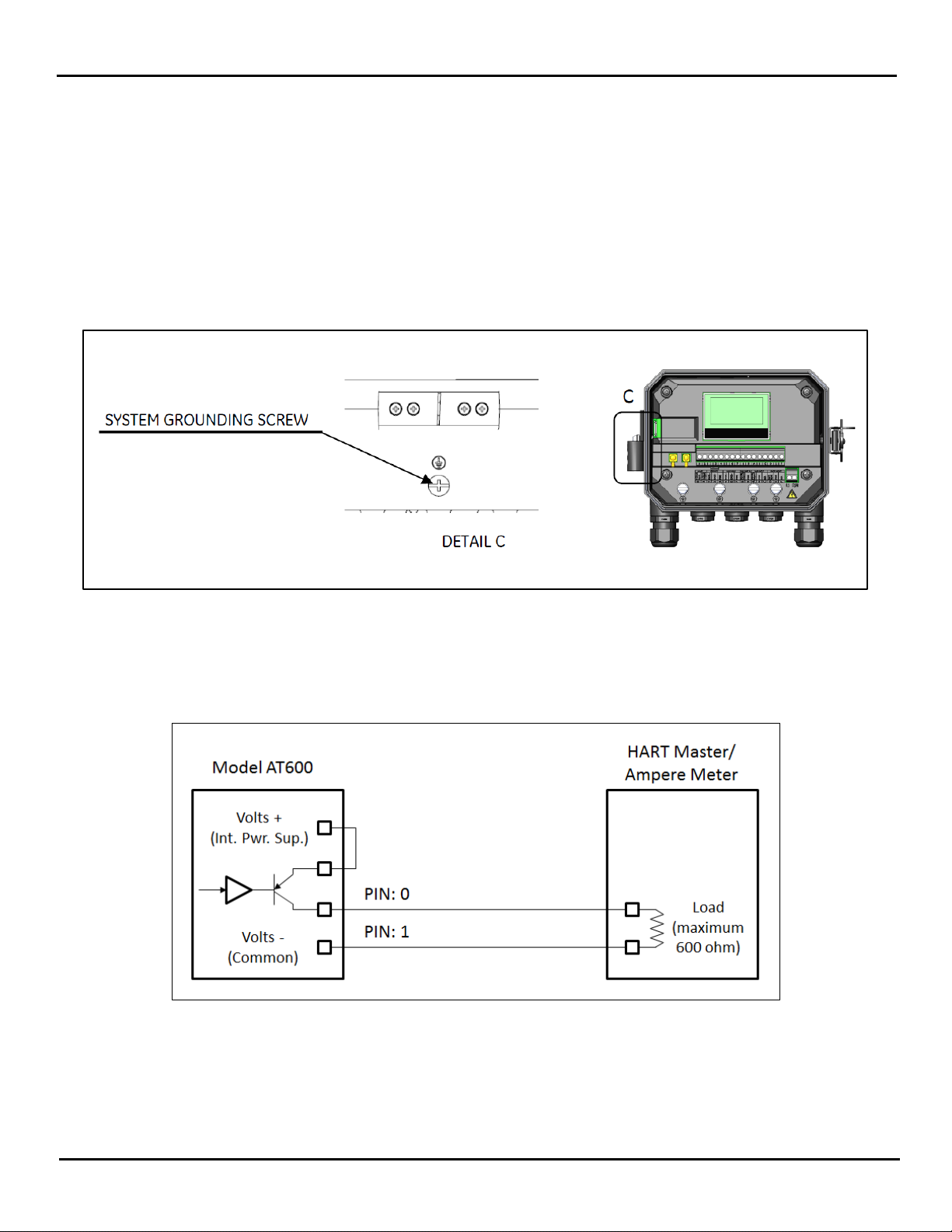

2.5.3 Wiring System Ground

Proper system ground must be connected to AT600 Meter. Refer to Figure 17 to locate the system ground screw. This

ground screw must be connected to a safe ground in the field.

Figure 17: System Grounding Screw

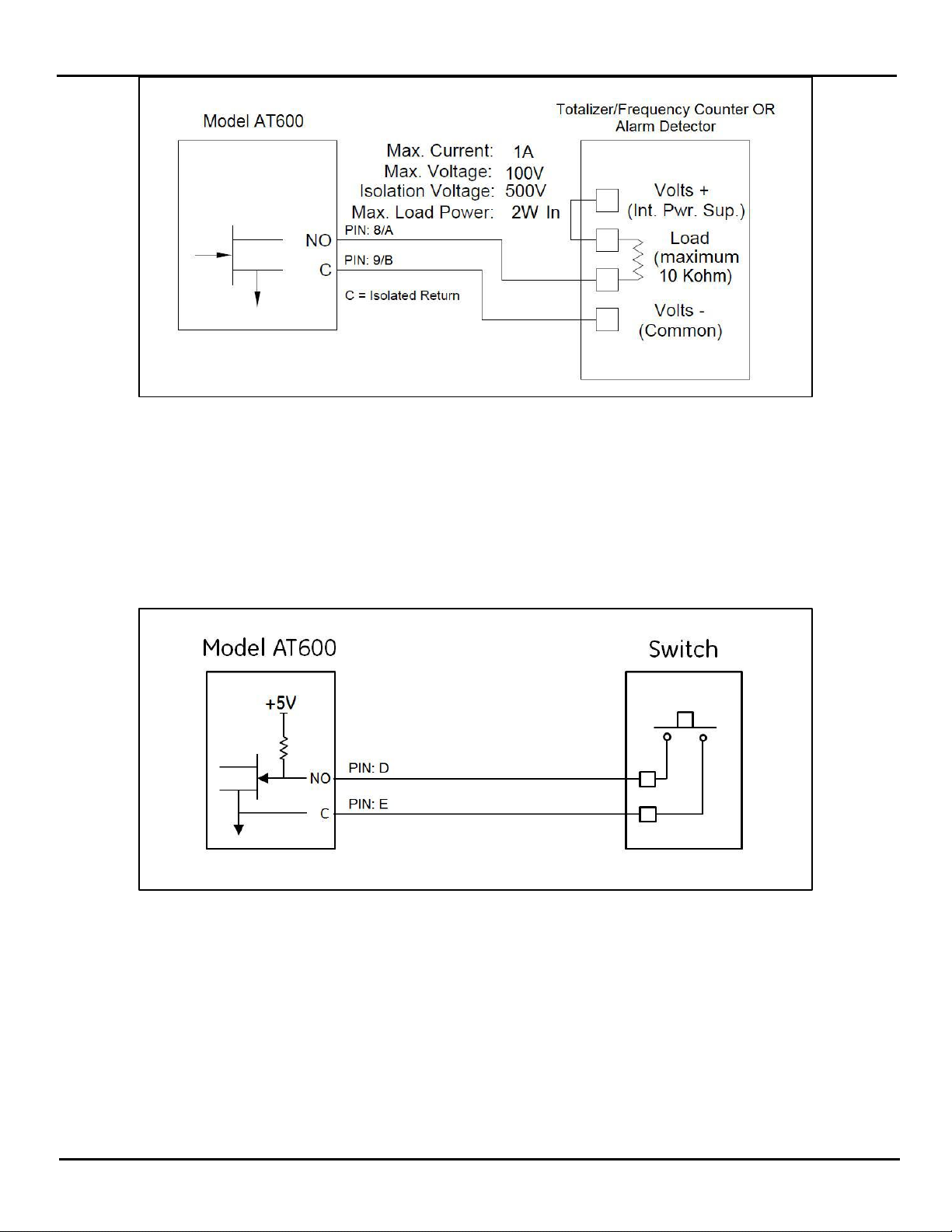

2.5.4 Wiring Analog Output/HART Communication

The standard configuration of the AT600 flow meter includes one isolated 0/4-20mA analog output. Connections to

this output may be made with standard twisted-pair wiring. The current loop impedance for this circuit must not

exceed 600 ohms.

Figure 18: Analog Output/HART Communication

To wire the analog output, complete the following steps:

1. Disconnect the main power to the unit and open the enclosure.

2. Install the required cable gland in the chosen gland hole on the bottom of the enclosure.

Contents

PT900 User’s Manual 21

3. Refer to Figure 14 for the location of terminal block I/O and wire the terminal block as shown. Secure the cable

clamp.

The standard port is only 0/4-20mA analog output, but the HART communication is optional upon request.

Note: Analog Output is active mode. Do not supply a 24V supply to this circuit. The circuit is powered by the flow

meter.

Note: Prior to use, the analog output must be set up and calibrated. Proceed to the next section to continue the initial

wiring of the unit.

Note: When in meter configuration, the analog output will go to 3.6 mA. After exiting from configuration mode, the

meter will go leave 3.6mA.

2.5.5 Wiring Modbus Communication

The AT600 is equipped optionally Modbus communication port. The port is a two-wire, half-duplex RS485 interface.

The standard AT600 disables the Modbus communication. Proceed to the appropriate configuration for menu

instructions to activate the Modbus communication.

To wiring Modbus RS485 serial port, refer to Figure 14 and complete the following steps:

1. Disconnect the main power to the unit.

2. Install the required cable clamp in the chosen gland hole on the side of the electronics enclosure.

3. Feed one end of the cable through the gland hole, wire it to terminal block and secure the cable gland as shown

in Figure 23.

2.5.6 Wiring Frequency/Totalizer/Alarm Output

The AT600 can accommodate up to 2 channels of totalizer/frequency/alarm outputs. Each totalizer/frequency/alarm

can be configured as totalizer, frequency or alarm output by software setting. Refer to 3.6.4 section for output

setting.

Each totalizer/frequency/alarm output requires two wires. Wire this terminal block in accordance with the pin

number assignments shown in Figure 19. Figure 19 shows sample wiring diagrams of totalizer/frequency/alarm

output circuit.

Contents

PT900 User’s Manual 22

Figure 19: Totalizer/Frequency/Alarm Output Wiring

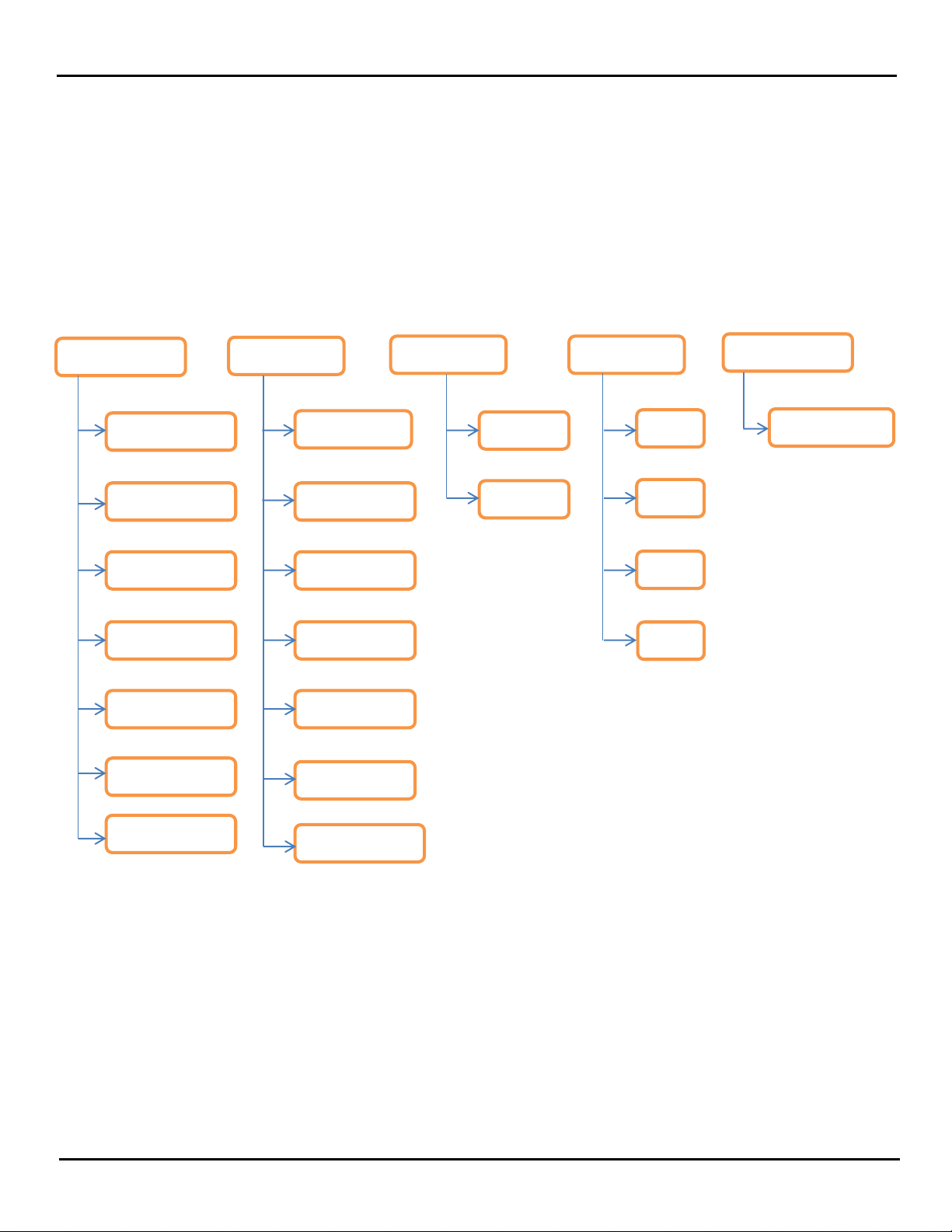

2.5.7 Wiring Gate Input

The AT600 provides a Gate Contact Input port. This port is designed to start/stop the totalizer. During normal

measurement mode, operator can start the totalizer functionality by clicking the switch. And if operator wants to

stop the totalizer, another switching ON/OFF action is to stop the totalizer.

Refer to Figure 20 below for wiring Gate Input port.

Figure 20: Gate Input Wiring

Contents

PT900 User’s Manual 23

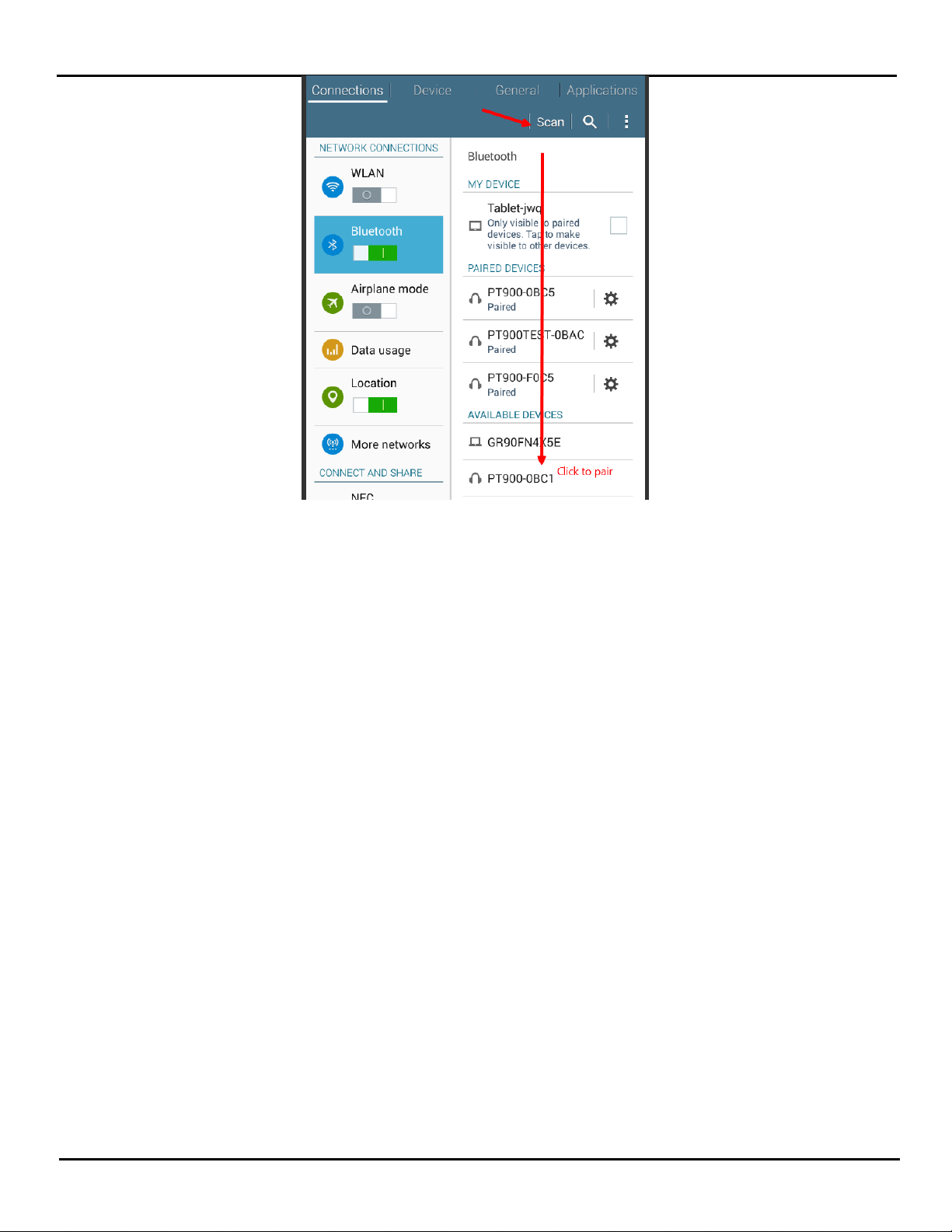

CHAPTER 3. INITIAL SETUP AND PROGRAMMING

3.1 INTRODUCTION

This chapter provides instructions for programming the PT900 flow meter via APP to place it into operation. Before

the PT900 begin taking measurements, the User Preferences, Inputs/Outputs, and Sensor setup must be entered and

tested. All these items could be accessed via side bar menu at the top left. The basic function structure could be

summarized in below map.

Figure 21: APP High Level Map

Program

Measure

Logs

Unit options

Transmitters

Help

Device name

Connect/Disc

Service

Storage

Battery

Information

Transducer

Pipe

Fluid

Placement

Channel

Preset

View

Edit

Add

Edit

Stop

Delet

User manual

Language

Contents

PT900 User’s Manual 24

3.2 CHARGE THE PT900 AND TABLET

Firstly, please make sure PT900 transmitter and tablet is charged. AC adaptor could be found in the attached box. If

any of them could not be powered on, please consult GE representative or www.gemeasurement.com for help.

Contents

PT900 User’s Manual 25

3.3 DOWNLOAD APP ONTO TABLET

If the tablet is not pre-installed the application, please download the installation package from GE website, or

contact with local sales agent for help.

If the installation package is acquired, please download it to tablet via USB connection. And click install it like normal

Android application.

3.4 PT900 APP SETUP

Find and click the icon below will start up the PT900 application.

Figure 22: PT900 APP icon

After the PT900 APP is activated, the initial screen display like figure 23.

Figure 23: PT900 APP loading screen

After the loading screen, the default connection interface will be displayed as below.

If the user prefers to simulate the operation without actual device connection, please click the

WORK_OFFLINE to choose offline mode.

On the otherwise, if the user prefers to connect the actual device, please click Scan, and all the available

devices will be searched via BLUETOOTH and displayed as figure 24.

Contents

PT900 User’s Manual 26

Figure 24: PT900 APP scan screen

IMPORTANT: As a common protocol, blue tooth could be preinstalled in kinds of devices. But our APP would filter the

surrounding potential devices and only display the device which name is prefixed by “PT900”.

Click BACK button of the tablet, it will back to PT900 application and all available flowmeter devices will be listed like

figure 25. Click the target device will activate pairing operation between the tablet and PT900 flowmeter.

Loading...

Loading...