Description

The 301-BT Series 300 DPST safety interlock switch is designed for use with

safety monitored relays or monitored circuits. To achieve the optimum Series

300 defeat resistant feature of the 301-BT, both the switch circuit (Circuit 1)

and the tamper circuit (Circuit 2) must be connected. An optional third circuit

can be provided to indicate at the panel which guard is open.

Notes:

1.Environmental: Pollution Degree II

2.Correct use of this control device is an essential part of

proper machine cycle control.

3.Failure to follow ALL instructions could lead to serious

bodily injury or death.

4.Maintenance to be done by qualified personnel only.

5.The connecting cables between the INT devices and the switches

must be located in an IP 23 type enclosure (minimum).

6.The mounting for the switch and the actuator magnet must

be accomplished per this specification.

7.Non-removable hardware must be used for installation.

8.The housing of the 300-BT must be connected to the

PE (Primary Earth) ground circuit via a lock washer on

the mounting screw. The PE ground symbol must be

placed adjacent to the screw.

Industrial Contacts

Safety Switches

To verify switch operation with an ohmmeter:

Set range at 20 mega ohms (switches with triac output, set ohm

range at 20 kilo ohms). For a normally open switch, the meter will

read a high impedance with the actuator away. It will read high kilo

ohm to infinity range) with the actuator within sense range. You will

see the opposite reading for a normally closed switch.

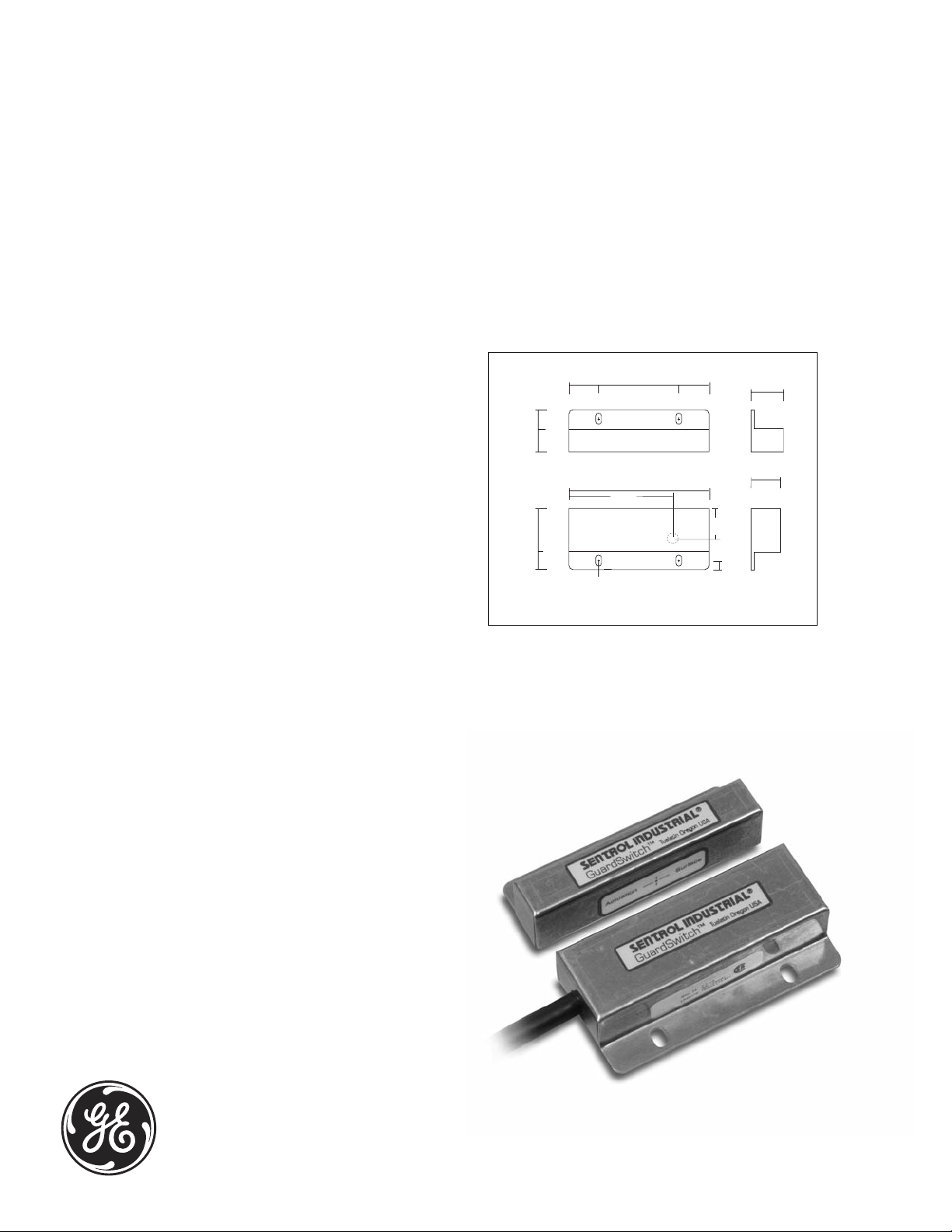

Dimensions

0.98''

2.49cm

1.48''

3.76cm

0.57''

1.45cm

0.40''

1.02cm

0.67''

1.70cm

2.13''

5.41cm

0.16'' x 0.24''

0.41cm x 0.61cm

slot

3.07''

7.80cm

1.75''

4.45cm

3.07''

7.80cm

0.69''

1.75cm

0.20''

0.51cm

0.74''

1.88cm

0.66''

1.68cm

Safety Interlock Switch

300 Series

301-BT

301-BT-SPNHJ6

301-BT-SPNHJ12

301-BT-SPNHJ15

301-BT-SPNHJ25

301-B3T-SPNHJ12

301-B3T-SPNHJ25

303-BT

303-BT-SPNHJ6

303-BT-SPNHJ12

303-BT-SPNHK12

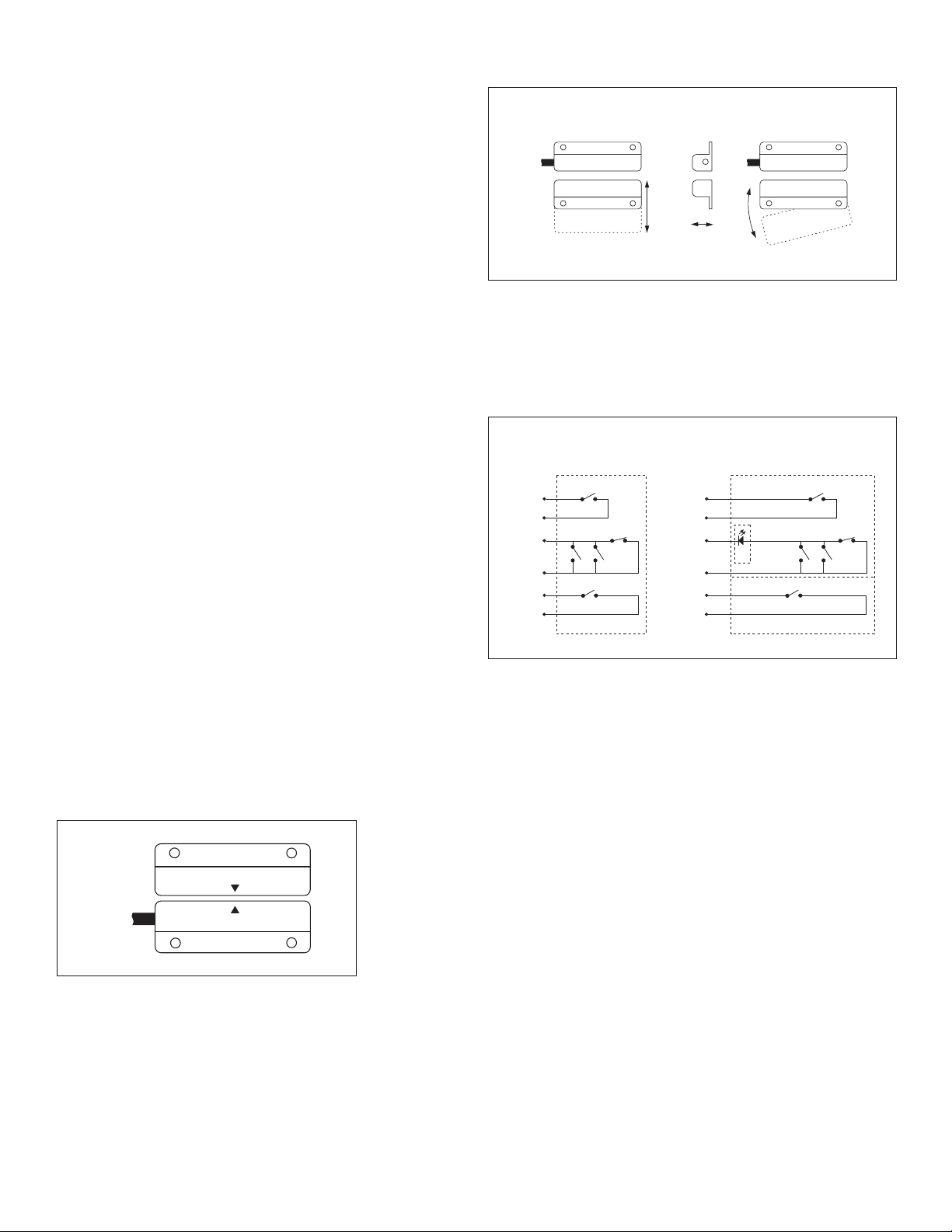

Installation

Use non-removable screws, bolts or nuts to mount the switch

and actuator. Do no over-torque mounting hardware.

1.Position the switch and actuator so the labels are reading

in the same direction (See Figure 1).

2.Mount the switch on the stationary frame of the machine and

mount the actuator on the moveable guard, door or gate.

Keep the switch and actuator within the listed sense range.

(See Ordering Information.) See Figure 2 for recommended

mounting configurations.

3.Mounting on a ferrous material will effect the sense range

a minimum of 50%. However, a ¼” non-ferrous spacer

positioned under the magnet and/or switch should restore

most of the lost sense range.

4.For best protection against operator defeat, mount with

non-removable screws, bolts or nuts. See Ordering

Information for details.

5.Caution! When not used with a Sentrol INT relay, particular care

must be taken to determine the actual load of the switch circuit.

High voltage transients from coils, motors, contactors and

solenoids must be considered. Transient protection, such as

back-to-back zener diodes (TransZorb

®

) or an RC network, is

recommended for such loads to ensure that maximum ratings

of the switch are not exceeded. Not recommended to be used

with tungsten filament loads because of high current inrush surges.

Line capacitance and load capacitance must be considered.

Excessive line capacitance can be caused by cable lengths over

50’ when using a maximum 48 VAC. A resistor can be added in

series to limit the inrush current (at least 48 ohms for 24 Volt

applications).

- The resistor can be added in series just before the load.

- The voltage drop and the power rating of the resistor

must be considered.

Voltage drop = I•R

Watts = I

3

•R

(I = maximum continuous current of the load)

6.When mounting the switch on an ungrounded machine, ground

the switch housing by connecting your ground lead to one of the

switch mounting screws.

The parallel actuation can result in on/off/on signal if the actuator

passes by the switch rather than coming to rest in proximity to it.

This is NOT a recommended configuration for safety interlock

applications.

Figure 1

Mounting Configurations

Figure 2

Actuator

Switch

Circuits*

without LED

Circuits*

with optional LED

*Circuits shown with magnet actuator away from switch.

S1 Normally open reed switch, closed when actuator

is within 0.6”

S2, S3 Normally open reed switches, will close if misaligned

or tampered with a standard magnet

S4 Biased closed reed switch, open when actuatior

is between 0.3” and 0.6”

N.O. circuit: Black and white wires.

N.C. biased tamper circuit: Red and blue wires.

N.O. monitor circuit: Orange and brown wires.

sensing face

Perpendicular

Actuation

Best Best Good Not Recommended

Door

Actuation

Pivot

BLK

CIR.

1

WHT

BLUE

2

CIR.

RED

BRN

CIR.

3

ORG

S1

S4

S2 S3

S5

CIR.

CIR.

CIR.

1

2

3

BLK

WHT

BLUE

RED

BRN

ORG

Parallel

ActuationActuation

Optional LED

D1

S2 S3

S5

S1

S4

sensing face

Wiring Diagram for Category 3

Inputs shown with safety gates/guards in closed position.

One Series 300-BT GuardSwitch™ required for each safety gate.

Note: The LED on the BLT model will be ON

when the guard is open.

Fuses: 1A (250V)

Multiple DPST GuardSwitches: Show with

actuators in position, all guards

closed. The LED of the BLT model will

be on when the guard is open. If

multiple guards are open, LED will

be dimmer. The maximum number

of GuardSwitches that can be used

is 50, although troubleshooting and

line resistance must be considered.

(Do not exceed 30 Ohms of combined

contact and line resistance. Each

GuardSwitch will have less than

0.5 Ohms of resistance.)

Wiring Diagram for Category 4

Inputs shown with safety gate/guard in closed position.

Two Series 300-BT GuardSwitches™ with one INT relay are required for each safety gate.

When first applying the INT Safety Monitor Relay, the inputs must be cycled to check for proper operation

before the output contacts close. To cycle the inputs, the guard must be opened and closed. This start-up

test is sufficient; however we recommend that the proper operation of the switches and relay be checked

at least every 24 hours.

Note:

The LED on the BLT model will be ON

when the guard is open.

Fuses: 1A (250V)

General Specifications

Enclosure 304 Folded Stainless Steel

Temperature Range -40°F to 180°F (-40°C to 80°C)

Environmental Hermetically Sealed Contact Switch Encapsulated in Polyurethane

NEMA Rating 1, 2, 4, 4X, 5, 12, 12K

Protection Class IP 66

Response Time 1 msec (5.4VA); 10 msec (150VA)

Individual Circuits The two circuits do not switch simultaneously, and depend on the speed of the guard closure.

Based on closure speed of 1’ per second and a gap of 1/8”, a delay of less than 50 msec is typical.

Life Cycles 100,000 Under Full Load;

Up to 200,000,000 Under Dry Circuit

Lead Types/O.D. 18/4 SJTOW (K)/0.34” (0.86cm)

22/4 PVC Jacketed (J)/0.19” (0.48cm)

22/6 PVC Jacketed (J)/021” (0.53cm)

* Or other DPST GuardSwitch

(See the 300-BT Series installation instructions)

* Or other DPST GuardSwitch

(See the 300-BT Series installation instructions)

(–)

INT-03-230: 230V AC

INT-03-120: 120V AC

INT-03-024: 24V DC

(+)

Required Fast or

Slow-Acting Fuse:

(250V, 5x20 mm F)

INT-03-230: 40mA

INT-03-120: 80mA

INT-03-024: 1/4A

Required Fast or SlowActing Fuses: 4A (250V,

5x20 mm F

230 VAC

60 VDC

RESET

L1 L2 1 2 X1 X2 Y1 Y2

–

+

Safety Monitor Relay

INT-03

OUTPUTS

SAFE AUX.

A

BCD

LOADS

N.O. N.C.

EFG

120 VAC

30 VDC

W

H

T

Series Circuit

R

B

E

L

D

K

*300-BLT-

B

L

U

W

H

T

R

B

E

L

D

K

*300-BLT-

B

L

U

W

H

T

Parallel

Circuit

R

B

E

L

D

K

*300-BLT-

B

L

U

(–)

INT-03-230: 230V AC

INT-03-120: 120V AC

INT-03-024: 24V DC

(+)

Required Fast or

Slow-Acting Fuse:

(250V, 5x20 mm F)

INT-03-230: 40mA

INT-03-120: 80mA

INT-03-024: 1/4A

Required Fast or

Slow-Acting

Fuses: 4A (250V,

5x20 mm F

230 VAC

60 VDC

LOADS

RESET

L1 L2 1 2 X1 X2 Y1 Y2

–

+

N.O. N.C.

Safety Monitor Relay

INT-03

OUTPUTS

SAFE AUX.

A

BCD

EFG

120 VAC

30 VDC

W

H

T

R

B

E

L

D

K

*300-BLT-

B

L

U

W

H

T

R

B

E

L

D

K

*300-BLT-

B

L

U

GE

Security

Electrical Specifications

Applies to all models

Circuit Circuit Contact Load Switching Switching

Number Type Configuration Rating Voltage Current

1 Switch: S1 N.O. 40W/VA 48VAC/VDC 1.0ADC 0.7AAC

2 Tamper: S2, S3, S4 N.C. 3W/VA 48VAC/VDC .25A

2 w/optional LED: D1 N.C. 0.1-1.4W 48VDC (3V drop) 30mA

3 Monitor: S5 N.O. 10W/VA 48VAC/VDC 0.3ADC 0.3AAC

Ordering Information

Part Contact Sense Range Break Lead Length

Number Configuration Maximum Range Nominal

301-BT-SPNHJ6 DPST: 1 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 6' (1.8m)

303-BT-SPNHJ6 DPST: 1 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 6' (1.8m)

301-BT-SPNHJ12 DPST: 1 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 12' (3.6m)

303-BT-SPNHJ12 DPST: 1 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 12' (3.6m)

303-BT-SPNHK12 DPST: 1 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 12' (3.6m)

301-BT-SPNHJ15 DPST: 1 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 15' (6.1m)

301-BT-SPHNJ25 DPST: 1 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 25' (7.5m)

301-B3T-SPNHJ12 TPST: 2 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 12' (3.6m)

301-B3T-SPNHJ25 TPST: 2 N.O., 1 N.C. 0.6" (1.5cm) 1.2" (3.0cm) 25' (7.5m)

Accessories

Part Number Tamper Proof Screws and Screwdriver

1953 #6 x 3/4"L Tampruf Roundhead Screw

1954 #8 x 1-1/2"L Tampruf Roundhead Screw

1955 Tampruf Screwdriver

1956 Tampruf 1/4" Drive Bit for #6 and #8 Screws

Warning - Each electrical rating is an individual maximum and cannot be exceeded!

1. The part numbers 301 and 303 are the same in all respects except the cable exits, 301 left and 303 right.

Not all models are available in 303.

2. Configuration with actuator away from the switch.

3. Proximity of ferrous materials usually reduces sense range- typically by 50%. The shape and type of material

cause a wide diversity of effects. Testing is required to determine actual sense range for specific applications.

Loading...

Loading...