Page 1

Legend IP

Installation Manual

Page 2

Copyright Copyright © 2006, GE Security Inc. All rights reserved.

This document may not be copied or otherwise reproduced, in whole or in part, except as

specifically permitted under US and international copyright law, without the prior written

consent from GE.

Document number: 1055712A (August 2006)

Disclaimer THE INFORMATION IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. GE ASSUMES

NO RESPONSIBILITY FOR INACCURACIES OR OMISSIONS AND SPECIFICALLY DISCLAIMS ANY

LIABILITIES, LOSSES, OR RISKS, PERSONAL OR OTHERWISE, INCURRED AS A CONSEQUENCE,

DIRECTLY OR INDIRECTLY, OF THE USE OR APPLICATION OF ANY OF THE CONTENTS OF THIS

DOCUMENT. FOR THE LATEST DOCUMENTATION, CONTACT YOUR LOCAL SUPPLIER OR VISIT US

ONLINE AT WWW.GESECURITY.COM.

This publication may contain examples of screen captures and reports used in daily operations.

Examples may include fictitious names of individuals and companies. Any similarity to names

and addresses of actual businesses or persons is entirely coincidental.

Trademarks and patents GE and the GE monogram are registered trademarks of General Electric.

Legend product and logo are trademarks of GE Security.

Other trade names used in this document may be trademarks or registered trademarks of the

manufacturers or vendors of the respective products.

Software license agreement GE software supplied with GE products is proprietary and furnished under license and can be

used or copied only in accordance with the license terms.

THE ENCLOSED PROGRAM IS FURNISHED SUBJECT TO THE TERMS AND CONDITIONS OF THIS

AGREEMENT. RETENTION OF THE PROGRAM FOR MORE THAN 30 DAYS, OPENING OF THE SEALED

WRAPPER, IF ANY, SURROUNDING THE PROGRAM, OR USE OF THE PROGRAM IN ANY MANNER

WILL BE CONSIDERED ACCEPTANCE OF THE AGREEMENT TERMS. IF THESE TERMS ARE NOT

ACCEPTABLE, RETURN THE UNUSED PROGRAM AND ANY ACCOMPANYING DOCUMENTATION TO

GE FOR A FULL REFUND OF THE LICENSE FEE PAID. (FOR INFORMATION REGARDING THE RETURN

OF PROGRAMS ENCODED OR INCORPORATED WITHIN EQUIPMENT, CONTACT THE NEAREST GE

SALES OFFICE.)

Intended use Use this product only for the purpose it was designed for; refer to the data sheet and user

FCC compliance This equipment has been tested and found to comply with the limits for a Class A digital device,

documentation. For the latest product information, contact your local supplier or visit us online

at www.gesecurity.com.

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

Page 3

Contents

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Conventions used in this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Safety terms and symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Chapter 1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operational overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Product contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Components supplied by the customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Recommended power management equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Compatible network switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Compatible video cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Compatible IP decoders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Compatible digital video management software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Compatible digital video viewers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Compatible web browsers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Compatible operating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Compatible digital video storage devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Dome requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Minimum load requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cable requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cable management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power cable size and length requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Digital video networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Video resolution and compression standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Storage requirements and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Networking IP domes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

iii

Page 4

Legend IP

iv

Installation Manual

Chapter 2. Installing the housing and cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Various mounting and housing styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Flush-mount housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Preparing the mounting surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Pendant-mount housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preparing the mounting surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installing the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Preparing the cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 3. Wiring and addressing the dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Components used for basic and advanced operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wiring the housing board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installing the cable ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Addressing the camera site and setting the protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Setting the termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 4. Installing the camera assembly and bubble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing the camera assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Installing the bubble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 5. Using passcodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Passcodes off by default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Turning on passcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 6. Troubleshooting, maintenance, support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Common installation issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Diagnostic LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Verifying network connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Rebooting versus resetting a dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Cleaning the bubble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Spare parts list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Contacting technical support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Online publication library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Appendix A. Installing the individual mounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

GEA-102 wall-mount arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Installing the wall-mount arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Opening the conduit hole. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

GEA-114 T-bar ceiling support kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Installing the T-bar ceiling support kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Appendix B. Tyco/AD wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Verifying dome software and AHC firmware versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Wiring Tyco/AD keypads to Legend IP domes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Page 5

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

v

Page 6

Legend IP

vi

Installation Manual

Page 7

Preface

This is the GE Legend IP Installation Manual. It provides an overview of the product and detailed instructions

explaining how to install all models. There is also information describing how to contact technical support if you

have questions or concerns. For programming and operation instructions, refer to the Legend IP User Manual.

To use this document effectively, you should have the following minimum qualifications:

• a basic knowledge of CCTV systems and components; and

• a basic knowledge of electrical wiring and low-voltage electrical connections.

v

Read these instructions and all ancillary documentation entirely before

installing or operating this product. The

most current versions of this and related documentation may be found on our website. Refer to Online

publication library on page 59 for instructions on accessing our online publication library.

Note: A qualified service person, complying with all applicable codes, should perform all required hardware installation.

Conventions used in this document

The following conventions are used in this document:

Bold Menu items and buttons.

Italic Emphasis of an instruction or point; special terms.

File names, path names, windows, panes, tabs, fields, variables, and other GUI elements.

Titles of books and various documents.

Blue italic (Electronic version.) Hyperlinks to cross-references, related topics, and URL addresses.

Monospace Text that displays on the computer screen.

Programming or coding sequences.

Safety terms and symbols

These terms may appear in this manual:

CAUTION: Cautions identify conditions or practices that may result in damage to the equipment or other property.

WARNING: Warnings identify conditions or practices that could result in equipment damage or serious personal injury.

Page 8

Legend IP

vi

Installation Manual

References

If you want to investigate related topics, these other documents may prove helpful:

• GE Security. Legend IP User Manual (1055713)

• GE Security. SymNav Video Navigator User Manual (0150-0303)

• GE Security. SymSecure System Guide (1055580)

• GE Security. SymSecure User Guide (online help)

• GE Security. KTD-405 Controller Keypad User Manual (1036547)

• GE Security. Networking Cable Types Technical Reference Guide (1047213)

• GE Security. ASCII Protocol Reference Manual (1038010)

Page 9

Chapter 1 Introduction

This chapter provides an overview of your Legend IP dome system, including

product description, dome and system requirements, and system planning.

In this chapter:

Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operational overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Components supplied by the customer . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Dome requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Minimum load requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cable requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cable management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power cable size and length requirements. . . . . . . . . . . . . . . . . . . . 11

System planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Digital video networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Video resolution and compression standards . . . . . . . . . . . . . . . . . 15

Storage requirements and options . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Networking IP domes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Page 10

Legend IP

2

Installation Manual

Product description

Legend IP™ is a line of advanced PTZ domes that stream digital video. Digital video is easier to transmit,

share, and store than conventional analog video signals. Digital video systems also integrate well into most

communications and media networks and are easily operated from software applications that manage digital

video, such as GE’s SymSecure™ or SymNav™. SymSecure is GE’s complete digital video management

software. SymNav is GE’s free digital video viewer that is provided with each dome. Compatible software

applications, like these, allow you to control your domes and video over an IP (Internet Protocol) network from

computers, instead of using analog keypads, recorders, multiplexers, and switchers.

Legend IP domes use an MPEG-4 video encoder to compress and digitize streaming video that is of up to

30 fps (frames per second) for NTSC and up to 25 fps for PAL. At the maximum frame rates, the domes

require a bandwidth from 1 to 2 Mbps (Megabits per second). The encoder supports QCIF, CIF, and D1 video

resolutions. The MPEG-4 video stream that is created is compatible with GE’s SymDec family of MPEG-4

recorders, SymNet family of MPEG-4 codecs, and Video Navigator™ software. The Legend IP interface is

open to allow compatibility with third party software and recording equipment.

Besides their networking ability, Legend IP domes also feature powerful cameras, SilkTrak™ direct-drive

positioning for smoother camera travel, a graphical programming interface for easier customization of camera

settings, passcodes for protection against unauthorized access, and the ability to flash software upgrades over

your IP network using a standard web browser.

CAUTION: To ensure the security of your surveillance system, your IP network should be isolated and secured from

unauthorized access.

The Legend IP protocol is backward compatible with the Digiplex protocol. You can replace older domes in an

existing Digiplex system with Legend IP domes. You must, however, replace the entire dome (camera,

housing, and mounts), because the hardware is not backward compatible.

Be aware that digital Legend IP domes have greater power requirements than do CyberDome or analog Legend

domes. Refer to Power requirements on page 11 and Power cable size and length requirements on page 11.

For additional details, refer to the data sheet and the Legend IP User Manual (1055713) for product

specifications and programming and operation instructions.

Installation overview

The installation of domes has been made much easier with many of the innovations that are now available in the

Legend IP line of domes. To start, all cable connections are now built into the housing. The Ethernet cable

provides both video and data. You can also connect UTP and coaxial cables for analog video and data, if

desired. Cameras operate using the housing's memory, since programming is now stored in the housing. This

allows you to replace cameras or move them between housings without having to reprogram them for each new

site.

After installation, programming will be completed by using either the web-based programming menus from a

PC, or the graphical menus on the analog video output. Both methods provide the same programming menus.

Optional installer, administrator, and operator passcodes are available to protect the dome from unauthorized

access. By default, no passcodes are enabled. For details, see Chapter 5, Using passcodes on page 47.

Page 11

Chapter 1

Introduction

The general steps for installing your dome include:

• preparing the mounting surface and installing the mount (if used) and housing;

• preparing the cables and wiring the housing;

• addressing the camera site, setting the protocol, and setting the termination;

• installing the camera assembly;

• installing the bubble; and

• turning on passcodes, if passcodes are to be used.

Operational overview

Legend IP domes work in both IP network and in analog systems (see System configurations). In a network

system, Legend IP domes use a standard Ethernet connection to provide video and control to a software

application, such as GE’s SymSecure or SymNav. When used in an analog system, Legend IP domes also

include analog video and data connections, along with the network connection. You can mix analog Legend

and digital Legend IP domes in the same system.

Legend IP domes can be operated from keypads, in addition to digital video management software. The

housings have Ethernet, RS-485, and RS-422 connections for data control, and Ethernet, UTP, and coaxial

connections for video. The Ethernet cable provides both video and communication data. The network interface

is 10/100/Base-T Ethernet compliant and supports TCP/IP communication protocols on private networks,

intranets, and the Internet.

3

GE’s SymSecure digital video management software offers many ways to complete tasks so as to

accommodate the various ways that people are comfortable working. The documentation for Legend IP will

provide one basic method for each basic task described. For complete usage instructions for SymSecure, refer

to the SymSecure online help. If you are using SymNav or another compatible digital video management tool

to operate your Legend IP domes, refer to that software’s documentation for its instructions.

System configurations

Legend IP domes can be used in a variety of digital and analog system configurations. They still maintain their

built-in receivers that decode analog commands originating from a compatible controlling devices, such as a

Digiplex controller keypad or ASCII control software.

Page 12

Legend IP

4

Installation Manual

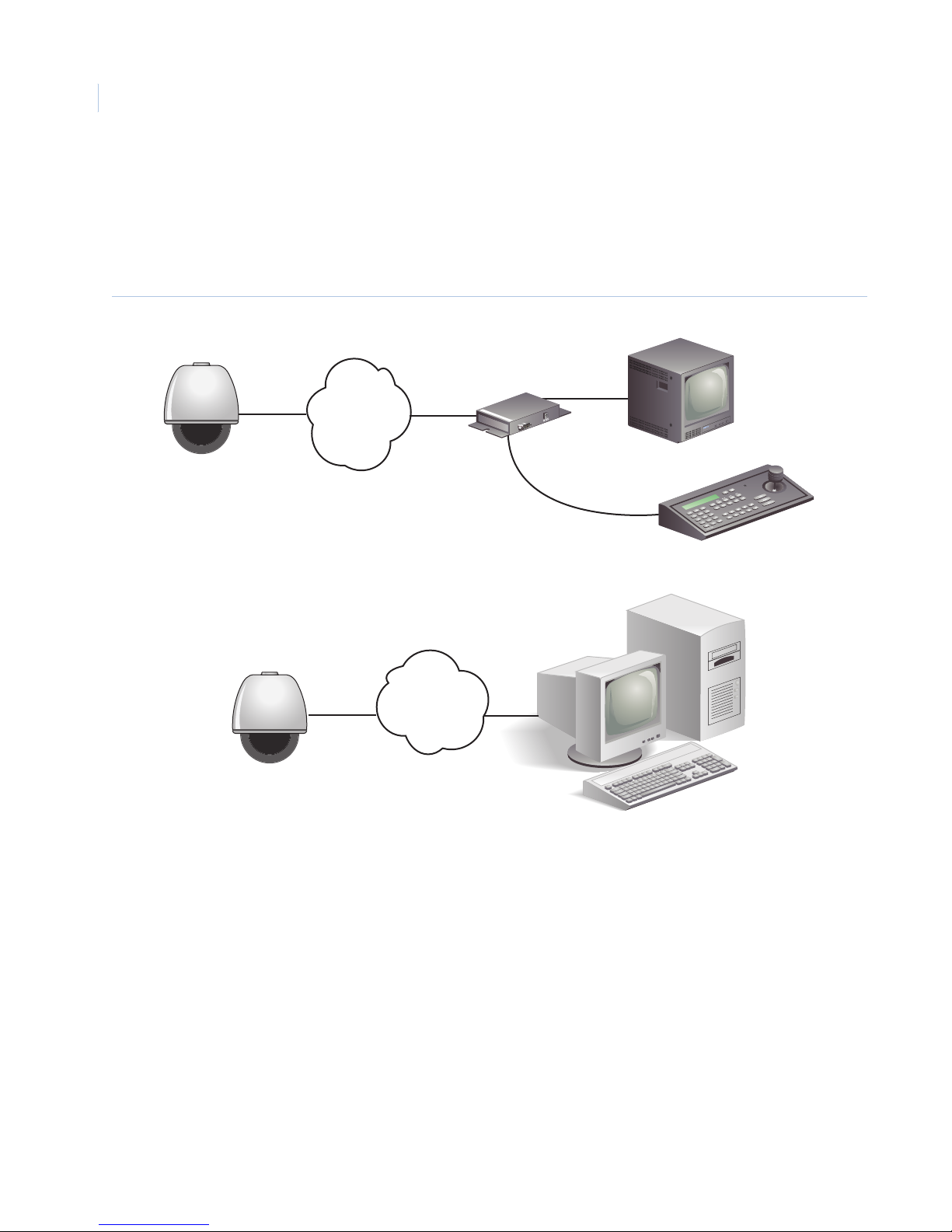

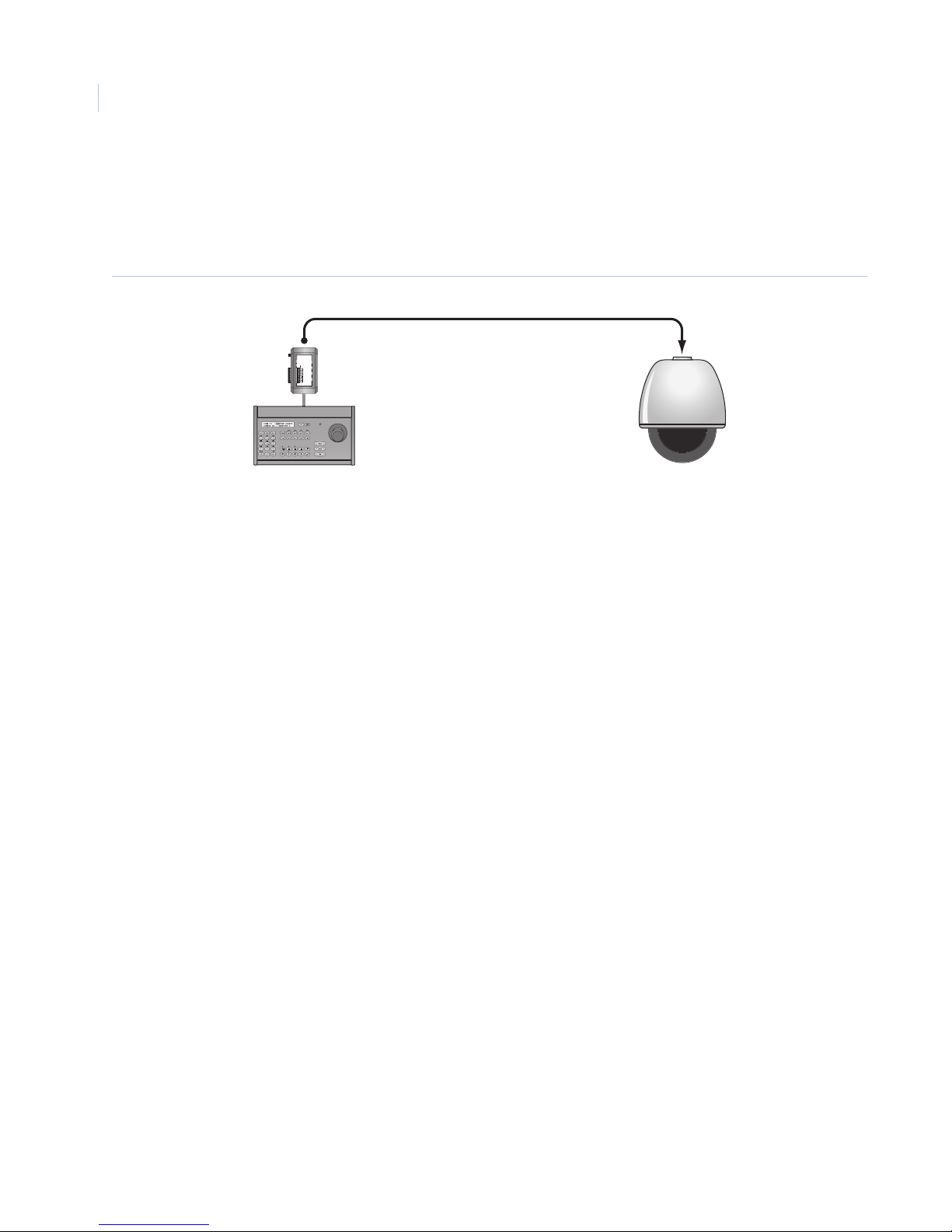

Typical digital system

A typical digital system is shown in Figure 1. In this configuration, control commands come from a software

application, such as GE’s SymSecure or SymNav, instead of keypads or ASCII control software. The dome’s

built-in encoders stream video to external decoders before it is transmitted to monitors, digital recorders, and

alarm equipment. For additional details, refer to the data sheet, user manual, or application guide.

Figure 1. Typical digital system in an IP codec network

Legend

SymNet

Ethernet

decoder

Ethernet

Network

Coax analog

line

CCTV monitor

Legend

Ethernet

KTD-405

Ethernet

Network

Client PC with SymNave. Used

for setup and control.

Page 13

Chapter 1

Introduction

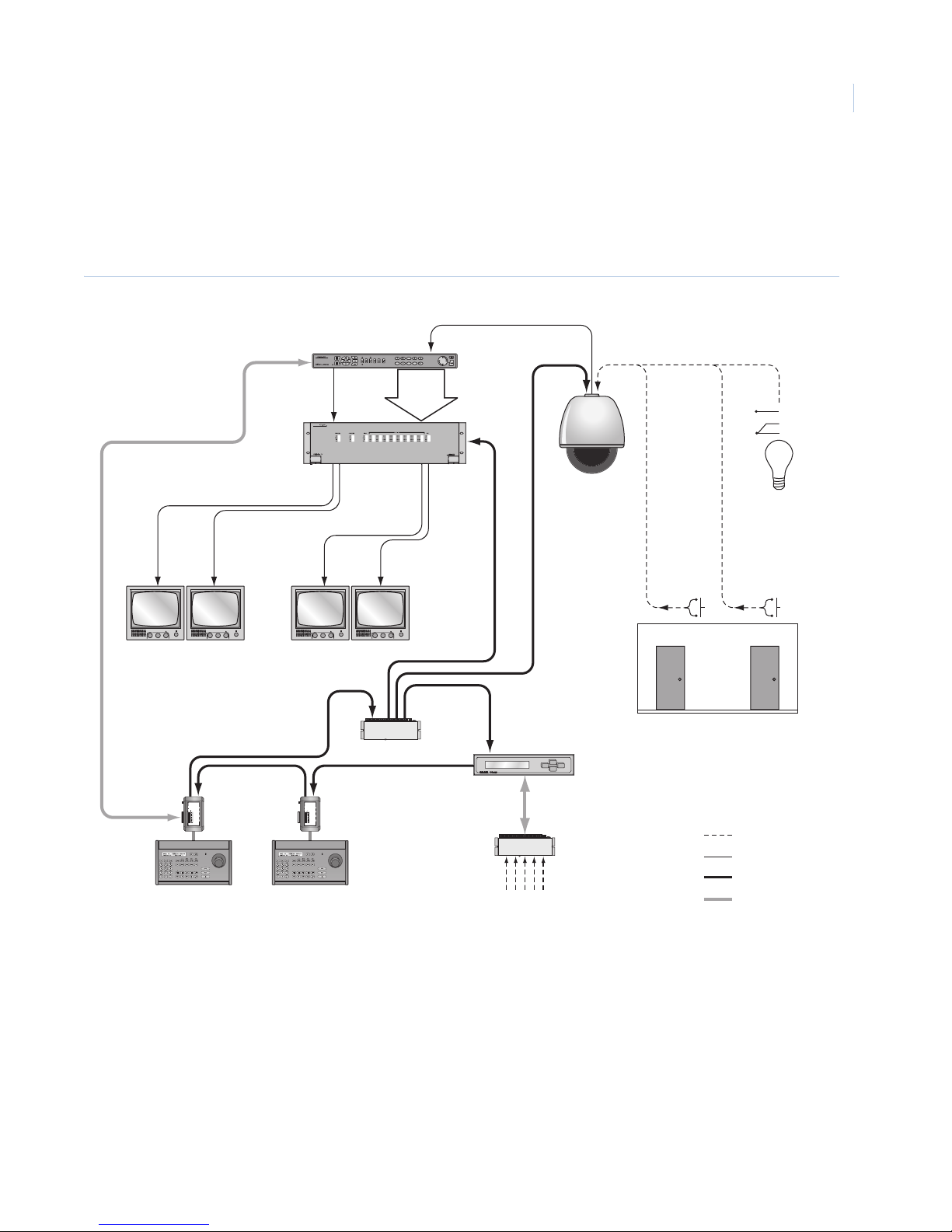

Typical advanced analog system

A typical advanced analog system is shown in Figure 2. In this configuration, control commands pass through

digital recorders and alarm equipment and video is switched to various monitors. For additional details, refer to

the data sheet, user manual, or application guide.

Figure 2. Typical advanced analog system

Digital recorder

Video

loop-

through

N/O

COM

N/C

5

Matrix switcher

Mon 1 Mon 2 Mon 3 Mon 4

Data distributor

SWITCH

BIAS

REMOVABLE

TERMINAL STRIP

POWER

12 VDC

EARTH GROUND

A

RS485

B

A

RS422 IN

B

A

RS422 OUT

78910653214

78910653214

B

SPEAKER SHIELD

AUDIO KEYPAD RS485 RS485

+

SPEAKER

Controller

keypad

SWITCH

BIAS

REMOVABLE

TERMINAL STRIP

POWER

12 VDC

EARTH GROUND

A

RS485

B

A

RS422 IN

B

A

RS422 OUT

78910653214

78910653214

B

SPEAKER SHIELD

AUDIO KEYPAD RS485 RS485

+

SPEAKER

Controller

keypad

Alarm input

module

Alarm chassis

Alarm inputs

Dome

Local alarm

inputs

(dry contacts)

Local relay

outputs

1 8

Alarms/relays

Video

RS-422 data

RS-485 data

Page 14

Legend IP

6

Installation Manual

Typical basic analog system

A minimum of one keypad, which is the most common controlling device, is required for operation. See

Figure 3. From the keypad, an operator can pan, tilt, and zoom the camera, find presets, and start macros and

ShadowTours.

Figure 3. Basic analog system

SWITCH

BIAS

REMOVABLE

TERMINAL STRIP

POWER

12 VDC

EARTH GROUND

A

RS485

B

A

RS422 IN

B

A

RS422 OUT

78910653214

78910653214

B

SPEAKER SHIELD

AUDIO KEYPAD RS485 RS485

+

SPEAKER

Product contents

Each Legend IP dome system consists of the following:

• 1 housing

• 1 package containing 4 connectors (one 2-pin for power, one 4-pin for data, one blue 12-pin for six

alarms, and one green 12-pin for two alarms, two relays, and UTP video), and 1 small screw driver

• 2 manuals (installation and user, which covers programming and operation)

• 1 PTZ camera assembly (with built-in IP encoder)

• 1 bubble (mirror bubbles are shipped with cotton gloves for special handling)

• 1 mount (wall-mount and flush-mount versions only)

You may receive the package contents in one large carton containing several smaller boxes, or if shipped

individually, you may receive the smaller boxes separately. One box will contain the housing, connectors, and

manuals. The PTZ assembly, bubble, and mount (for wall-mount versions) are each packaged in separate

boxes.

Inspect the package and contents for visible damage. If any components are damaged or missing, do not use the

unit; contact the supplier immediately. If you need to return the unit, you must ship it in the original box.

Spare parts can be purchased for the domes. See Spare parts list on page 58.

Page 15

Chapter 1

Introduction

Components supplied by the customer

Legend IP domes are part of an overall IP video system. Customers supply the other components of the system,

such as network switches, IP decoders, and power management equipment. See the following recommended

and required system components that the customer must supply. See Dome requirements on page 9 for what

cables are required.

Recommended power management equipment

The following are recommended to protect your equipment from power issues.

CAUTION: All network-based video equipment should be provided with surge suppression, power conditioning, and

UPS protection.

Exterior cameras are susceptible to power surges due to electrical storms. Power surges can disrupt system

performance and/or damage equipment. In-line surge suppressors can protect performance and

equipment. Provide them for all at-risk cameras.

7

Recommended power management equipment:

• Surge suppressor

• Power conditioner

• UPS (uninterruptible power supply)

Compatible network switches

The following network switches have been tested and found compatible with Legend IP domes. For

performance differences, see Qualified network switches on page 13.

• D-Link DES-3526

• D-Link DES-3550

• D-Link DGS-3024

• Nortel 425-24T

• Nortel 425-48T

Compatible video cards

The following video cards have been tested and found compatible with Legend IP domes.

•ATI

•ATI

•ATI Rage

•nVIDIA

•nVIDIA

™

Radeon® X300 series

™

Rage® XL PCI 8MB

®

XL PCI B41

®

GeForce® FX 5900

®

Quadro® FX1400

Page 16

Legend IP

8

Installation Manual

Compatible IP decoders

The following IP decoders have been tested and found compatible with Legend IP domes.

•SymNet

Compatible digital video management software

The following digital video management software applications have been tested and found compatible with

Legend IP domes. For differences, see Product description on page 2.

• GE’s SymSecure

• OMNICAST version 3.6 or higher

Compatible digital video viewers

The following digital video viewers have been tested and found compatible with Legend IP domes. For

differences, see Viewing options on page 19.

• GE’s free SymNav (provided)

• GE’s free SymBrowser

• GE’s SymNet

• GE’s SymSecure

Compatible web browsers

The following web browsers have been tested and found compatible with Legend IP domes.

• Internet Explorer 5 (or later) for viewing and control

Compatible operating systems

The following operating systems have been tested and found compatible with Legend IP domes.

•Windows

•Windows

•Windows

®

2000

®

XP

®

XP Pro

Compatible digital video storage devices

The following digital video storage devices have been tested and found compatible with Legend IP domes. For

performance differences, see Storage requirements and options on page 16.

• GE’s SymSecure NVR archiver

• GE’s SymDec

Page 17

Chapter 1

Introduction

Dome requirements

For proper operation, adhere to the following operational, load, cable, and power requirements for Legend IP domes.

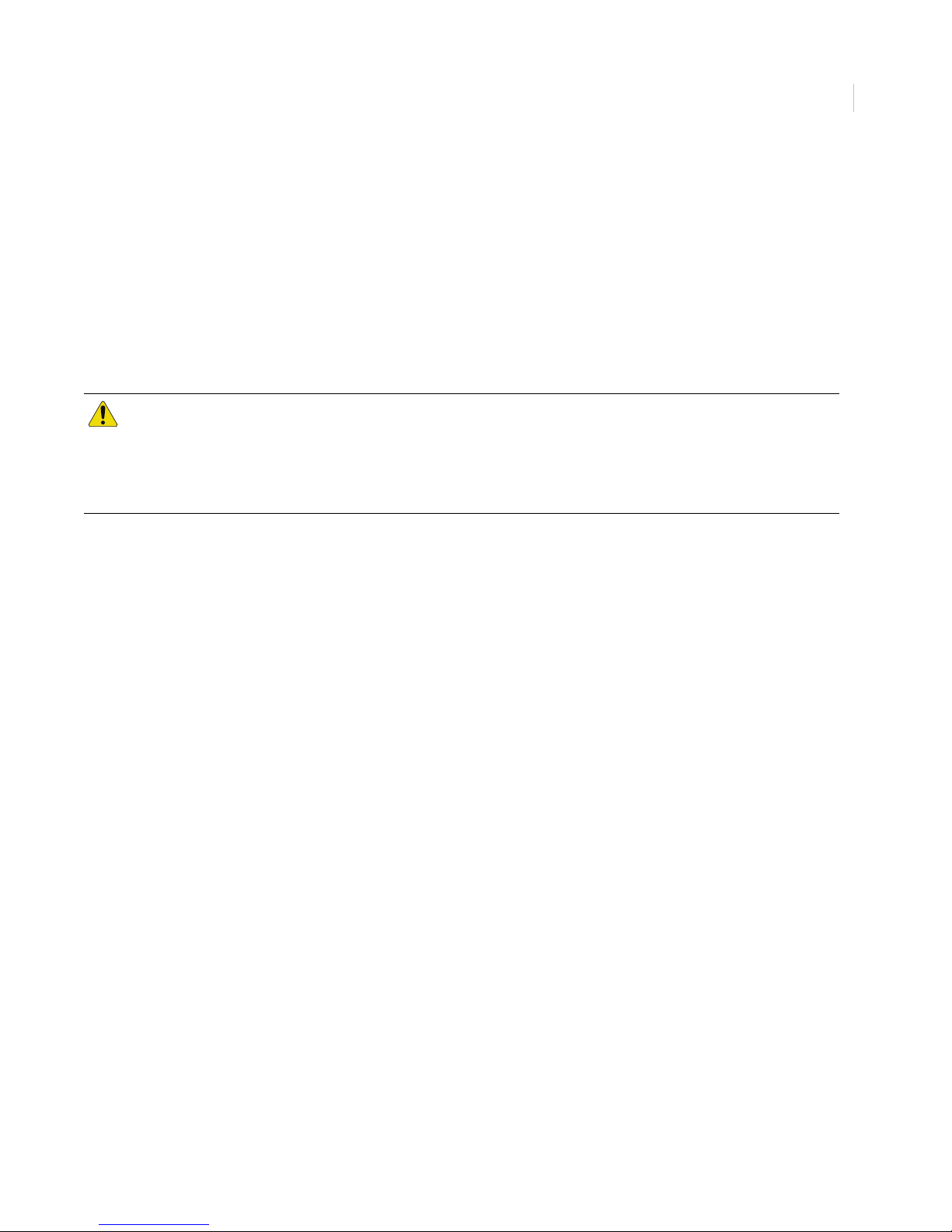

Minimum load requirements

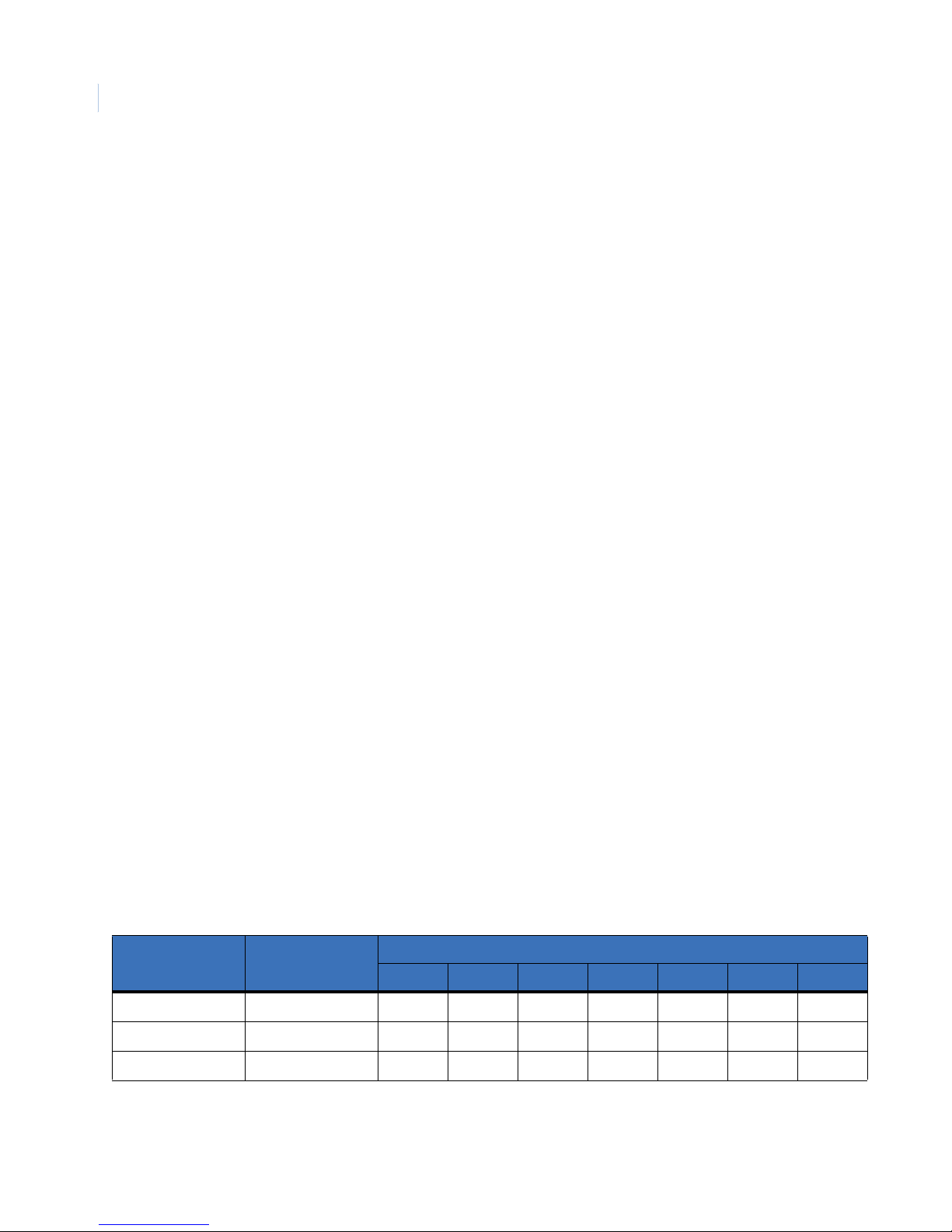

Table 1 lists the load requirements for all Legend IP dome configurations.

CAUTION: For safety, the mounting surface, hardware, and procedure used for securing the dome must support

the weight of the dome, mount (if used), cables, and any structural or environmental vibration according

to local codes.

Table 1. Minimum load requirements of dome configurations

Minimum load Dome configuration

100 lb. • Rugged, cast aluminum pendant-mount housing (with any mount)

• Heavy duty housing (with any mount)

• Pressurized housing (with any mount)

• Swing-arm mount (with any dome)

9

50 lb. All other dome and mount configurations

Cable requirements

Table 2 lists the requirements for the cables that connect to the dome.

CAUTION: To ensure the security of your surveillance system, your IP network should be isolated and secured from

unauthorized access.

Table 2. Cable requirements

Operation Cable requirement

Ethernet (for digital

video and data)

Power 24 VAC cable. To determine the size of cable needed for individual applications, see

Alarms and relays 22 to 26 gauge (0.64 to 0.4 mm) unshielded, two-conductor, twisted-pair (UTP) cable

Analog video 75 ohm coaxial cable; or

CAT-5 Ethernet cable (without cable boots) 385 100

Power cable size and length requirements on page 11.

22 gauge (0.64 mm) unshielded, two-conductor, twisted-pair (UTP) cable

Note: Use only crimp-on BNC connectors. Do not use screw-on connectors.

Length

feet meters

Analog data For RS-422: 22 gauge (0.64 mm) unshielded, two-conductor, twisted-pair (UTP) cable 10,000 3,000

For RS-485: 22 gauge (0.64 mm) shielded, two-conductor, twisted-pair (STP) cable 3,000 900

Note: When using unshielded twisted-pair cable for video and data, the wires can share the same jacket but must remain

separate twisted pairs.

Page 18

Legend IP

10

Installation Manual

Cable management

Follow all local codes for cable management. As a general rule, you can fill a cable conduit to a maximum of

60% of its capacity. You must maintain 40% free space. A variety of factors will determine how many cables

you can run into the dome. Capacity limitations include:

• number of cables

• size of the cables

• number of alarms and relays wired

• use of single-conductor or multiple-conductor cable

• use or lack of use of a junction box

Figure 4 provides an illustration of the cable capacity of three typical applications. It is important to note that

all cables of the same gauge are not of the same diameter. Manufacturer, shielding, and rating affect the actual

diameter of cables of the same gauge. GE leaves the selection of the appropriate cable to the discretion of the

installer who is working with the local codes of the installation site.

Figure 4. Three acceptable typical cabling scenarios

3/4 in. dia. 3/4 in. dia. 3/4 in. dia.

3/4in. dia.

Power

Power

Ethernet

Ethernet

Percentage conduit fill = 16%

Includes:

• Ethernet: CAT-5 (0.16 in. dia.)

• Power: one 18 AWG UTP (0.21 in. dia.)

• Alarms: none

• Relays: none

• Video: no analog video cable

• Data: no analog data cable

3/4in. dia.

Video

Video

Ethernet

Ethernet

Power

Power

Data

Data

(daisy-chained)

(daisy chained)

Data

Data

(daisy chained)

(daisy-chained)

Percentage conduit fill = 38%

Includes:

• Ethernet: CAT-5 (0.16 in. dia.)

• Power: one 16 AWG UTP (0.25 in. dia.)

• Alarms: none

• Relays: none

• Video: one 59U/6U coaxial (0.24 in. dia.)

• Data: two 22 AWG UTP (0.19 in. dia.)

Alarms (4)

Alarms (4)

Relays (2)

Relays (2)

Video

Video

3/4in. dia.

Alarms

Alarms

(multiconductor)

(multiconductor)

Ethernet

Ethernet

Power

Power

Data

Data

(daisy-chained)

(daisy chained)

Data

Data

(daisy-chained)

(daisy chained)

Percentage conduit fill = 53%

Includes:

• Ethernet: CAT-5 (0.16 in. dia.)

• Power: one 18 AWG UTP (0.21 in. dia.)

• Alarms: 24 AWG UTP (0.11 in. dia.)

• Relays: 24 AWG UTP (0.11 in. dia.)

• Video: one 59U/6U coaxial (0.24 in. dia.)

• Data: one 22 AWG UTP (0.19 in. dia.)

Note: The diameters for cables of the same gauge will vary per manufacturer, rating, and shielding. So be aware that

you may get more or fewer cables within the 60% conduit fill requirement depending on the cables that you select.

Page 19

Chapter 1

Introduction

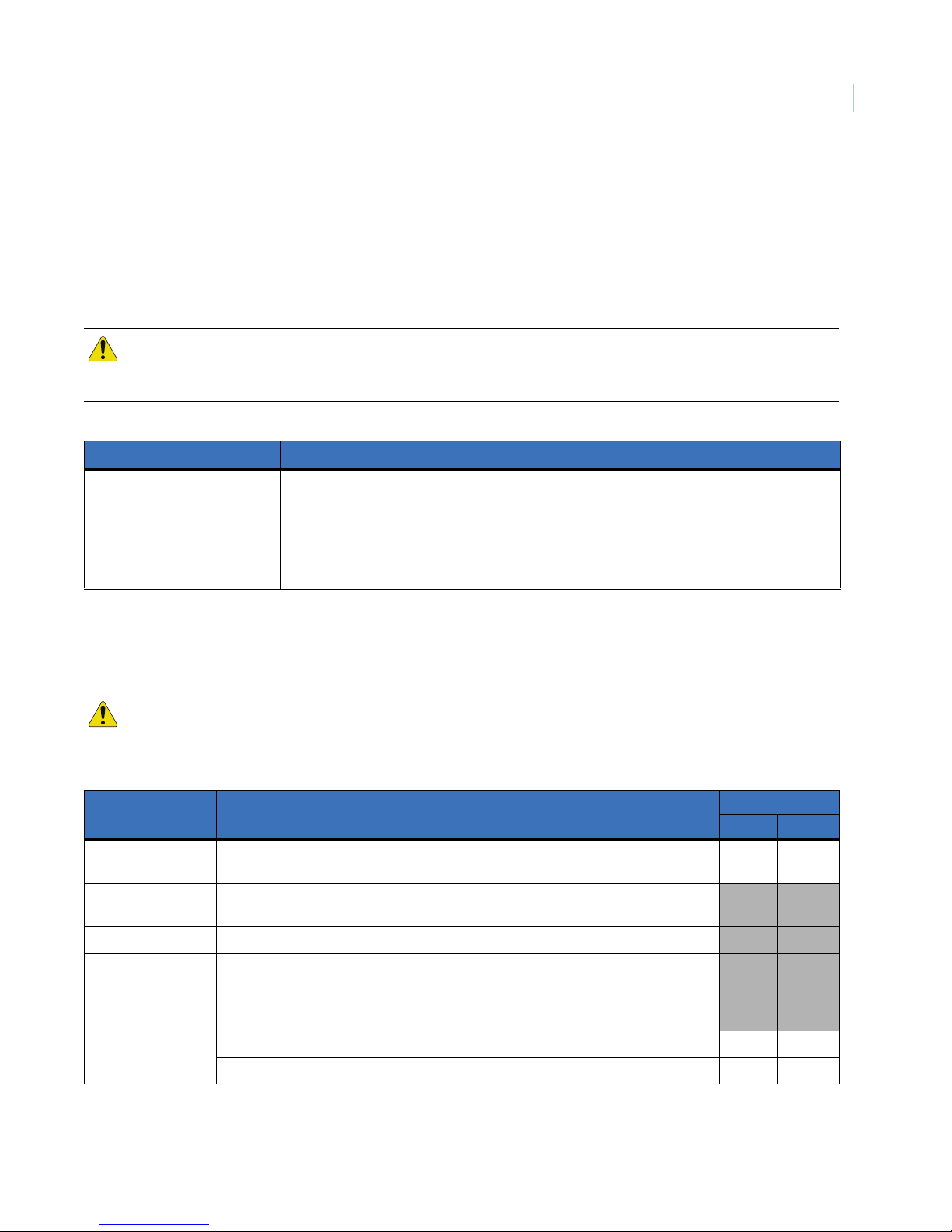

Power requirements

All Legend IP domes require a 24 VAC power supply to operate the domes’ PTZ, camera, and heater/blower,

if present. The startup and running power requirements vary depending on the model (Table 3).

Be aware that Legend IP domes have greater power requirements than do CyberDome or analog Legend

domes, which may require upgrading the power cabling for Legend IP domes.

CAUTION: Use only a Class 2 power supply of the required output rating as listed on individual units and specified.

Table 3. Power requirements at 24 VAC (±4 VAC) operating voltage

Model Start-up power Running power

Dome without heater/blower 30 W 24 W

Dome with heater/blower 60 W 44 W

Rugged and HD dome with 25 W heater/blower 100 W 74 W

11

Power cable size and length requirements

Using the proper gauge of power cable will ensure proper operation and avoid voltage drops. See Table 4 for the

recommended cable gauge for varying maximum cable lengths for the different models of domes.

Table 4. Recommended power cable gauges based on maximum lengths for an operating voltage of 24 VAC (±4 VAC)

Domes without

heater/blower

Wire gauge

AWG mm

10 2.60 1565 477 780 238 470 143

12 2.05 985 300 490 149 295 90

14 1.62 620 189 310 94 185 56

16 1.29 390 119 195 59 115 35

18 1.02 245 75 120 37 70 21

20 0.81 150 46 75 23 45 14

22 0.64 95 29 45 14 25 8

2

(30 W)

feet meters feet meters feet meters

Domes with

heater/blower

(60 W)

HD domes with

heater/blower

(100 W)

Page 20

Legend IP

12

Installation Manual

System planning

Before you install and program your surveillance equipment, make sure that you have planned a system that

will meet your needs. You need to balance the various network issues that affect the compression and

transmission of video to get the video quality, transmission speed, and storage capacity that you need your

system to deliver. Consider each of the following related issues.

If you have questions that this section does not answer, GE Security has system design engineers available to

help you design your system. Contact your dealer, sales representative, or GE Security at www.gesecurity.com.

Digital video networks

Network topologies can be quite different between the design of a single building with a high-speed network

and the design for a number of satellite locations being managed by a central location. If you are connecting

remote offices to each other or to a central office, you must consider the network throughput, latency, and

bandwidth when defining the speed and capacity of a network. Bandwidth is the physical component that is

most easily controlled.

• Throughput is the amount of data that can be transmitted over a network connection in a fixed amount

of time, which is usually expressed as bits per second (bps) for digital devices and as cycles per second

(Hz) for analog devices. The higher the throughput, the faster the transmission speed will be.

• Latency is the a

lower the latency, the faster the transmission speed will be.

• Bandwidth is the actual capacity of a network cable. The higher the bandwidth, the faster the

transmission speed will be.

mount of time it takes a packet to travel from a source to a destination. The

Bandwidth

First, determine what your video payload (amount of video data, not operational data) is likely to be, then

determine how fast you need your video to transmit through the network. After you have considered such

issues as resolution (Video resolution standards on page 15), data rate (Video compression standards and data

rates on page 15), throughput, and latency, you can determine what capacity you need your network cable to

be. Real-time digital video generally requires the bandwidth found on high-speed (gigabit-per-second) LAN

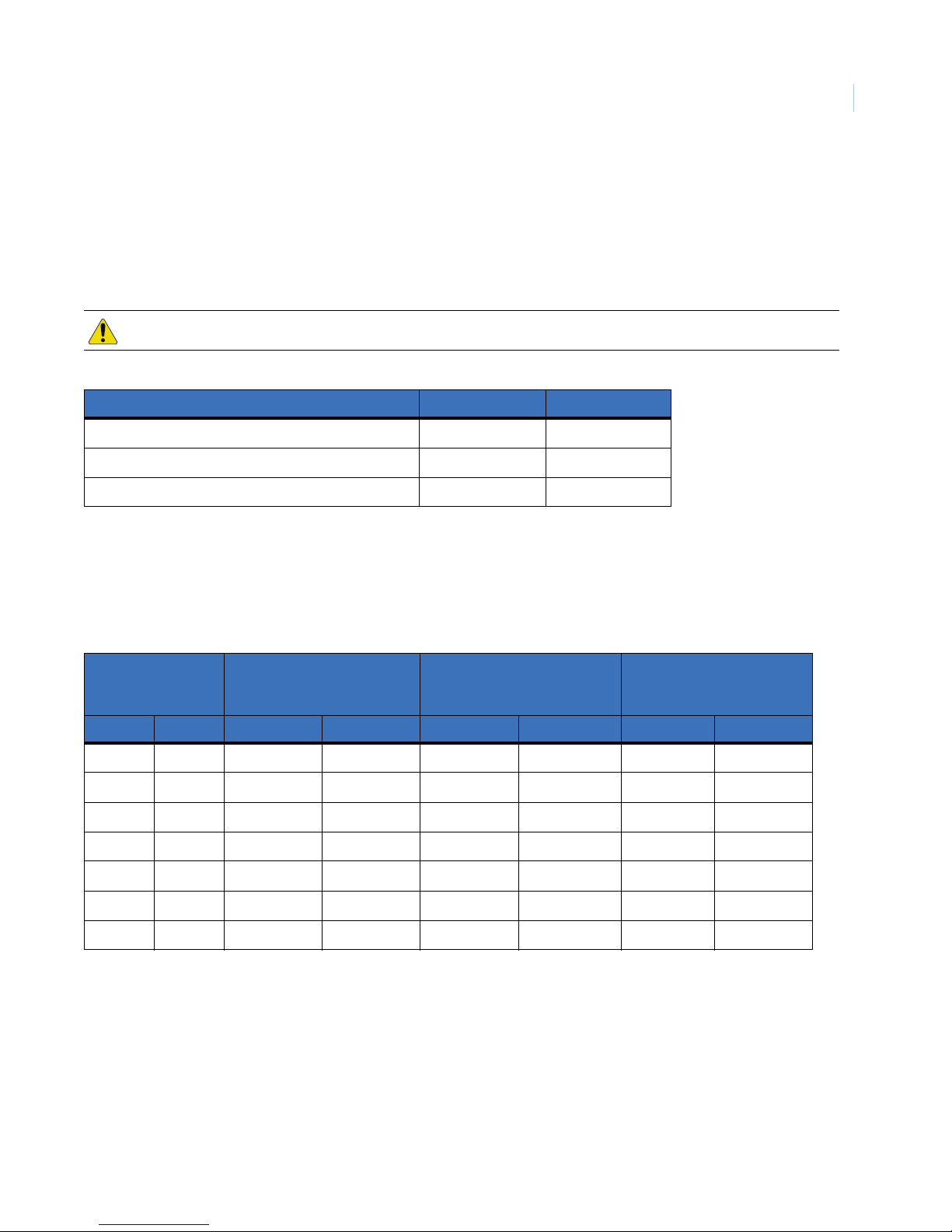

networks for reasonably high resolution, bitrate, or channel count.

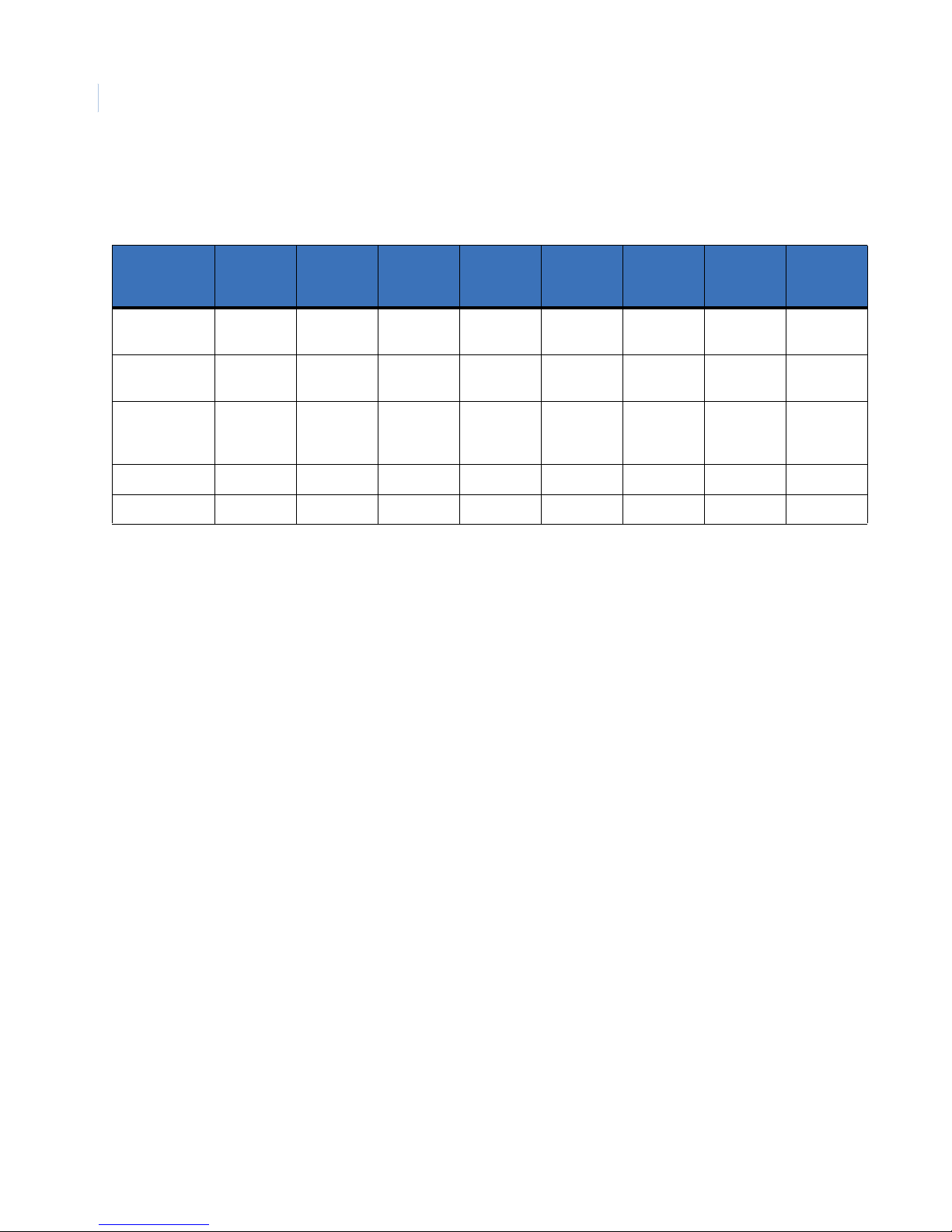

Table 5 shows a range of sample bandwidths. For help analyzing your system, contact GE Security System

Design or Technical Support.

Table 5. Sample bandwidth requirements for 1 to 48 high-quality, MPEG-4 video streams

Video resolution

standard

D1 30 2.42 9.68 19.36 38.72 58.08 77.44 116.16

D1 15 1.27 5.09 10.18 20.36 30.54 40.71 61.07

2CIF 15 0.70 2.72 5.44 10.88 16.32 21.76 32.64

fps (frames per

second)

Bandwidth by number of streams in Mbps (megabits per second)

1 4 8 16 24 32 48

Page 21

Chapter 1

Introduction

Needed network switch features

Network switches have many associated features, but only a few affect the transmission of digital video and

need to be considered when designing a system. Those few are port speed, switching capacity, multicast

protocol, and IGMP snooping.

• Port speed is the data transmission rate of an input or output channel. Switches provide ports ranging

from Base-T with RJ-45 connectors for CAT-5/5E/6 cabling to fiber optic interconnects with SFP

module connectors for fiber optic cabling. Base-T ports are more common and typically less costly

than fiber optic ports. Copper gigabit Ethernet cable is typically acceptable for most cable runs. Fiber

optic cable, however, may be needed when signal integrity over long high-speed cable runs is an issue.

• Switching capacity is the bandwidth (transmission capacity) of the switch as opposed to the

bandwidth of the network cable. The higher the bandwidth, the faster the transmission speed will be.

Data packets may be lost, however, if network traffic between the switch’s ports reaches the

switch’s bandwidth. It is recommended that each port have a switch capacity of at least

10 Mbps each.

• Multicast protocol is a one-to-many transmission format. With multicast protocols, data is sent to

multiple recipients (that are specified) at the same time. This one-to-many format is similar to

broadcasting, except that in broadcasting the data is sent to everyone. Because multicasting sends data

once from a source through distributed pathways to the recipients, you can send larger volumes of data

using less bandwidth. Unicast systems send data in its entirety, as many times as there are recipients.

• IGMP snooping is a protocol used to manage membership in multicast groups. IGMP stands for

Internet Group Management Protocol. Multicast groups are used to replicate digital video to many

destinations from a single source without requiring retransmission from the source. IGMP snooping is

a special optional feature on most managed switches, as well as many higher-end unmanaged switches

that monitor traffic for IGMP messages and use the contents to send multicast packets to certain ports.

When IGMP is available, it generally must be turned on.

13

Qualified network switches

Since the network switch is a critical point of failure for a digital video network, we recommend that you use

the highest quality switch you can. High-end switch manufacturers include Cisco, Nortel, and HP. The switch

you use must support multicast protocols and must provide IGMP snooping.

Be aware that you may have to enable the IGMP snooping feature. Many switches are shipped with this feature

turned off by default. Refer to the switch’s documentation. If you do not turn on the IGMP snooping feature

before you use the switch, system errors may occur. Such errors can range from the entire system not working

to severe performance and packet errors as more devices are added to the system.

When evaluating switches, make sure that you verify all of the interdependencies and constraints that can be

expected with varying operating modes. Be aware that not all switch manufacturers publish complete

specifications and that you may have to discuss details with the manufacturer before making a purchase.

GE has qualified several D-link and Nortel switches as compatible with their IP products. These switches need

to have IGMP snooping turned on before they will operate properly. Refer to the switch’s documentation. You

Page 22

Legend IP

14

Installation Manual

can expect many switches to turn on this feature by using a serial cable to configure the IP address of the builtin management interface, then accessing that interface and using a web browser to change the settings.

Table 6. GE qualified IP-compatible network switches

Cisco

D-Link

Model

10/100 Mbps

ports

10/100/1000

Mbps ports

Internal

switching

capacity (Gbps)

IGMP snoopingYesYesYes---YesYes

Price level Entry-level Entry-level Entry-level Entry-level Entry-level Entry-level High-end High-end

DES-3526

24480 2448242448

222422- 22

8.813.648---1616

D-Link

DES-3550

D-Link

DGS-3024

WS-C296024TT-L

Cisco

WS-C296048TT-L

Cisco

WS-2970G24T

Nortel

425-24T

Nortel

425-48T

Edge networks and network address translation

Centralized networks can be configured with periphery networks and a core network. An edge network is one

of the periphery networks that is located on the periphery of a centralized network and feeds data to the core

network, which is the single hub of the overall centralized network.

One issue that is becoming more prevalent with edge networks is the use of NAT (Network Address

Translation) to allow multiple network devices on a private, centralized network to share a single public IP

address. Routers, firewalls, and computers can be NAT-enabled to convert their private internal network IP

addresses to and from one or more public IP addresses for the Internet. Although NATs can increase network

security by keeping internal addresses hidden from the outside world, they should be used in conjunction with

appropriate firewalls to maintain that security.

Only use NAT devices that provide the ability to configure port forwarding. Port forwarding tells the NAT

device to forward incoming traffic from a specific port number on the public IP to a specified device on the

private internal network.

Page 23

Chapter 1

Introduction

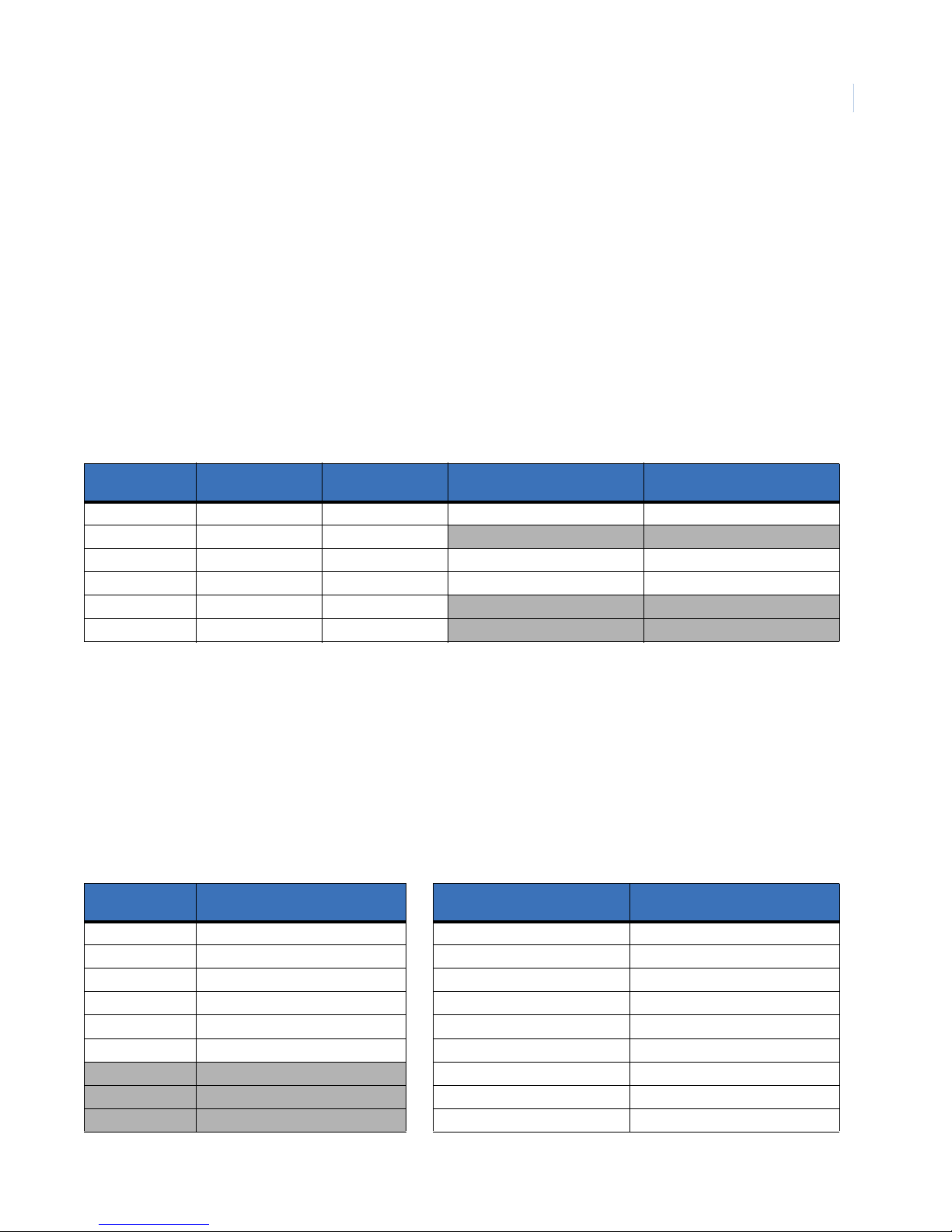

Video resolution and compression standards

Video resolution and compression standards affect video quality, file size, and storage requirements. Table 7

and Table 8 outline the video and compression standards that are available with Legend IP and SymSuite

products. Program your system with the standards that will best meet your overall surveillance needs.

Video resolution standards

The NTSC and PAL video signal standards (Table 7) have the same data transmission rates at the same

resolutions. NTSC’s higher frame rate is offset by PAL’s higher vertical resolution. Briefly, analog video

signals are interlaced, meaning each picture consists of two fields of half-pictures. NTSC video consists of 60

half-pictures per second, while PAL video consists of 50 half-pictures per second. This translates to 30 fps

(frames per second) for NTSC and 25 fps for PAL in terms of noninterlaced (or progressive scan) digital video.

Table 7. Video resolution standards available with Legend IP domes and SymSuite products

15

Video resolution

standard NTSC (60 Hz) PAL (50 Hz)

D1 720 x 480 720 x 576 XX

4CIF 704 x 480 704 x 576

2CIF 704 x 240 704 x 288 XX

CIF 360 x 240 360 x 288 XX

QCIF 180 x 120 180 x 144

QQCIF 88 x 60 88 x 72

Supported by Legend IP

domes

Supported by SymSuite

products

Video compression standards and data rates

When considering the overall data rate of how fast the video travels through your surveillance system, you need

to consider the speed of the chosen video resolution standard and the speed of your network connection

(Table 8). For instance, if you choose to use the CIF video resolution standard, which transmits at an

uncompressed data rate of 61 Mbps (Megabits per second), your network connection needs to be at least an

OC3 line, because the T3 line only transmits up to a data rate of 45 Mbps. For details about digital video

compression standards, such as MPEG-4 and Wavelet, refer to the Compression standards section of the

SymSecure System Guide (1055580).

Table 8. Comparison between video and network data rates

Video resolution

standard

D1 249 Dial-up 0.04

4CIF 244 Cable modem upchannel 0.25

2CIF 122 DSL 0.50

CIF 61 T1 line 1.54

QCIF 16 T3 line 45.00

QQCIF 4 OC3 line 155.00

uncompressed data rate (Mbps)

Video speed as

Network speed as

Network connection

OC12 line 622.00

OC48 line 2560.00

OC192 line 9830.40

transmission data rate (Mbps)

Page 24

Legend IP

16

Installation Manual

Storage requirements and options

Your storage requirements and options are based on what storage capacity is required to maintain the duration

of video that is recorded at the video resolution, fps, and data rate you require to meet your surveillance needs.

First, determine what video resolution, fps, data rate, and duration will meet your surveillance requirements.

Second, determine what storage options will maintain that capacity of recorded video.

GE provides two digital video storage options: SymDec and SymSecure. SymDec devices can store a limited

amount a video directly from one external IP dome and/or encoded from several analog cameras. SymSecure

NVR archivers can be attached to RAID or NAS devices for large-scale centralized storage.

If you are using a SymSecure NVR archiver to archive your recorded video, refer to the Storage size section of

the SymSecure System Guide (1055580). If you are using other video storage equipment, contact GE Security

System Design or Technical Support for assistance in estimating storage requirements and choosing

appropriate storage options.

Page 25

Chapter 1

Introduction

Networking IP domes

Networking your IP domes requires a compatible network. The following sections discuss the capabilities

required by the customer-supplied components of the IP network and the capabilities that Legend IP brings to

the IP network. For a diagram of a typical system configuration, see Figure 1 on page 4, which shows the

placement of the required customer-supplied IP components.

Network compatibility

The network interface of the Legend IP domes offers flexibility by being compatible with 10/100/Base-T

Ethernet networks and supporting the TCP/IP set of communication protocols. The network interface will also

support static and dynamic IP addressing. Dynamic addressing will require a DHCP server that can assign and

monitor IP addresses for the domes connected to the network. The network interface is also responsible for

transmitting the MPEG-4 encoded digital video streams, control commands, and alarm information to/from the

video recorders and managing software.

IP addressing

You can use either static or dynamic IP addressing for your domes. If using static addressing, you can specify

the dome’s IP address, the network’s subnet address, the default gateway address, and the DNS address. If

using dynamic addressing, you can use the DHCP client protocol to receive the IP addresses from a DHCP

server. When you are using dynamic addressing, the IP addresses are not shown on the setup menus, but are

available on the diagnostic menus.

17

Performance monitoring

The dome has an integrated self-monitoring software that periodically verifies the dome’s performance. This

self-monitoring software can be programmed to poll the dome manually or at user-defined intervals to retrieve

status information. It can also synchronize the time for networked domes.

Alarm management

There are eight built-in alarm inputs in the housings of the Legend IP domes to use as internal alarm triggers.

Changes of alarm status are sent through the network interface to specified IP addresses (Recipient e-mail

addresses on page 17) or monitoring software. You can program the duration, resolution, and fps of video clips

to be captured before and/or after a triggered alarm. For details about alarm management, see the Legend IP

User Manual (1055713).

Recipient e-mail addresses

You can use e-mail for alarm and event notifications. Events can include mechanical and electrical equipment

issues with the camera, motors, or data communication. Each dome can be programmed with up to 10 recipient

e-mail addresses. When an alarm or event is triggered, an e-mail is sent to each recipient on the list that is

assigned to receive e-mail notification.

Browser options

You can use Internet Explorer 5.

Page 26

Legend IP

18

Installation Manual

Security options

You can actively protect access to your Legend IP domes three ways—with passcodes, SSL, and IP filtering.

Passcodes

The passcodes (Using passcodes on page 47) control who has access to the features of your dome. Only the

installer through the installer passcode has permission to turn on, turn off, or change the passcodes. If no

passcodes are programmed, all users are given installer access and are not required to log on. If only the Admin

and Operator passcodes are programmed, then anyone can still access the entire programming interface as an

installer, since the Installer passcode was not programmed.

Page 27

Viewing options

GE offers four products for viewing digital video—two are free. You can use (Figure 5):

• the free SymNav software on a computer (provided);

• the free SymBrowser plug-in on a computer (not provided);

• a SymNet device attached to a keypad and monitor; or

• a SymSecure software client.

Figure 5. Viewing options for digital video

Chapter 1

Introduction

19

SymBrowser plug-in SymNav

SymNet

LAN/WAN

LAN/WAN

Monitor

Keypad

SymSecure server

SymSecure software client

Page 28

Legend IP

20

Installation Manual

Page 29

Chapter 2 Installing the housing and cables

This chapter provides instructions for installing the housing and cables.

In this chapter:

Various mounting and housing styles. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Flush-mount housings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Preparing the mounting surface. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pendant-mount housings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preparing the mounting surface. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installing the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Preparing the cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Page 30

Legend IP

22

Installation Manual

Various mounting and housing styles

There are three basic mounting styles: pendant, wall, and flush. A pendant-mount lowers a dome from a

ceiling, a wall-mount extends a dome from a wall, and a flush-mount raises a dome’s bubble even with a

ceiling. See Figure 6. This document provides the instructions for all mounting styles.

Figure 6. Basic mounting styles

Pendant-mount Wall-mount Flush-mount

There are four basic housing styles: flush-mount, plastic pendant-mount, cast aluminum pendant-mount, and

heavy-duty (Figure 7). Installation is generally the same for all housing styles. There are some differences,

such as how the bubble rings attach to the housings (Figure 20 on page 45). Where differences exist, the

instructions will specify.

Figure 7. Basic housing styles

Flush-mount

Plastic

pendant-mount

Cast aluminum

pendant-mount

Heavy-duty

Page 31

Installing the housing and cables

Chapter 2

Flush-mount housings

Flush-mount and pendant-mount housings require different preparation of the mounting surface and different

installation procedures of the housings. Follow the instructions given here for flush-mount housings.

CAUTION: The flush-mount housing is for indoor applications only. Do not expose it to moisture, or the unit may

be damaged.

Preparing the mounting surface

Following are the steps for preparing the mounting surface if you are mounting the housing directly into a solid

surface that does not require reinforcement. If the mounting surface does require reinforcement, first install a

GEA-113 T-bar ceiling panel or a GEA-114 T-bar support kit. Instructions for installing the GEA-114 are

available in this manual (GEA-114 T-bar ceiling support kit on page 67). If you are installing a GEA-113, refer

to the instructions that came with the panel (1052914).

CAUTION: For all installations, heed these cautions:

• Complete all installation steps before supplying power to the dome.

• To ensure proper operation of a PTZ unit, install the mount level.

• For safety, the mounting surface, hardware, and procedure used for securing the dome

must support the weight of the dome, mount (if used), cables, and any structural or environmental

vibration according to local codes. See Table 1, Minimum load requirements of dome configurations on

page 9.

23

To prepare the mounting surface, see Figure 8 and do the following:

1. Mark the position and size of the housing pass-through hole on the mounting surface. The size of the

cutout for the pass-through must be 8-3/8 to 8-7/16 in. (21.27 to 21.42 cm).

2. Following all local codes, cut the housing pass-through hole.

3. Make sure that the facility cables (Ethernet and power, and if used, alarm, relay, and analog video and

data) for the dome comply with the recommendations provided in Cable requirements on page 9.

4. Feed the facility cables through the housing pass-through hole in the mounting surface.

• Pull enough cable to make connections. You can always cut off unneeded length later.

• How many cables you have depends upon how many alarms and relays you are connecting in

addition to the Ethernet and power cables, and whether you will be installing cables for analog

data and video. See Wiring and addressing the dome on page 31.

Figure 8. Preparing the mounting surface for flush-mount housings being mounted into solid surfaces not requiring reinforcement

Cutout size:

Position and size marked

8-3/8 to 8-7/16 in.

(21.27 to 21.42 cm)

Page 32

Legend IP

24

Installation Manual

Installing the housing

With the surface prepared and/or the mount now installed, install the housing.

To install the housing, see Figure 9 on page 25 and do the following:

1. Remove either conduit knockout (side or top) in the housing.

2. Hold the housing up near the housing pass-through of the mount or cutout.

3. Connect a steel safety cable, if required by local codes.

a. Obtain a steel safety cable of 0.125 in. (3 mm) maximum diameter that complies with local codes.

b. Snip off the nipple that opens access to the safety cable clip.

c. Feed your safety cable through the exposed hole.

d. Secure one end of the safety cable into the safety clip surrounding the exposed hole inside

the housing.

e. Secure the other end of the safety cable to the building superstructure.

WARNING: DO NOT run any cables next to the heaters. Doing so could damage the dome or cause an electrical fire.

4. Feed the facility cables through the opened conduit hole of the housing. Allow enough cable length to

make connections. Figure 9 on page 25 shows how the cables run through the housing.

CAUTION: For safety, the mounting surface, hardware, and procedure used for securing the dome must support the

weight of the dome, mount (if used), cables, and any structural or environmental vibration according to local

codes. See Table 1, Minimum load requirements of dome configurations on page 9.

5. Attach the housing to the mount or ceiling by screwing the housing tabs open and down.

Page 33

Figure 9. Installing the flush-mount housing

Safety cable

3/4 in. conduit knockouts (2)

Building superstructure

Housing tabs (3)

(screwed open and down

against the mount or ceiling)

Ceiling ring

Angle brackets (2)

Ceiling

Installing the housing and cables

Chapter 2

25

(snipped off to access

the safety cable clip,

which is inside the housing)

Nipple

Cables fed

through mount

and housing

Clip for safety cable

(inside housing)

Flush-mount cabling

Upper bracket

Power cable

Cables are fed as follows:

• all cables run in through the cable entry

hole in the side or top of the housing;

• the power cable runs over the top of the

upper bracket and down beside the power

connector; and

• the remaining cables run down through the

center hole in the upper bracket.

Page 34

Legend IP

26

Installation Manual

Pendant-mount housings

Pendant-mount and flush-mount housings require different preparation of the mounting surface and different

installation procedures of the housings. Follow the instructions given here for pendant-mount housings.

Pendant-mount housings can be mounted to a pipe to lower them from a ceiling or to a wall-mount arm to

extend them from a wall. Instructions are provided in this document for both mounting methods.

Preparing the mounting surface

Following are the steps for preparing the mounting surface if you are mounting the housing to a pipe. If you are

mounting the housing to the GEA-102 wall-mount arm, instructions for installing the GEA-102 are available in

this manual (Installing the wall-mount arm on page 62). If you are installing one of the other mounts, refer to

the instructions that came with the mount.

CAUTION: For all installations, heed these cautions:

• Complete all installation steps before supplying power to the dome.

• To ensure proper operation of a PTZ unit, install the mount level.

• For safety, the mounting surface, hardware, and procedure used for securing the dome

must support the weight of the dome, mount (if used), cables, and any structural or environmental

vibration according to local codes. See Table 1, Minimum load requirements of dome configurations on

page 9.

To prepare the mounting surface:

1. Following all local codes, install the pipe.

2. Make sure that the facility cables (Ethernet and power, and if used, alarm, relay, and analog video and

data) for the dome comply with the recommendations provided in Cable requirements on page 9.

3. Feed the facility cables through the pipe in the mounting surface.

• Pull enough cable to make connections. You can always cut off unneeded length later.

• How many cables you have depends upon how many alarms and relays you are connecting in

addition to the Ethernet and power cables, and whether you will be installing cables for analog

data and video. See Wiring and addressing the dome on page 31.

Page 35

Installing the housing and cables

Chapter 2

Installing the housing

With the pipe or mount now installed, install the housing.

If you are installing the housing outdoors and onto a pipe, you must install the rubber water-sealing boot that

provides an additional layer of water protection. Applying PTFE thread sealing tape (for example, Teflon

tape) to the pipe is required as a first layer of protection.

CAUTION: Avoid getting rain or moisture in the housing or electronics may be damaged.

To install the housing to a pipe or mount, see Figure 10 on page 28 and do the following:

1. If you are installing the housing outdoors and onto a pipe:

a. Spray the pipe with soapy water.

b. Slide the rubber boot onto the pipe and above the threads.

c. Wrap the pipe threads with the supplied PTFE thread sealing tape in the direction that the dome

will screw onto the pipe. Overlap the tape and cover the threads.

®

27

d. After you have attached the housing in the following steps, slide the rubber boot down the pipe and

fit it securely over the housing’s flange.

2. Hold the housing up near the pipe or mount. If you installed the GEA-102 wall-mount arm, make sure

that the safety chain is securely attached (GEA-102 wall-mount arm on page 62).

WARNING: DO NOT run any cables next to the heaters. Doing so could damage the dome or cause an electrical fire.

3. Feed the facility cables through the cable entry hole and dust seal in the top of the housing. Allow

enough cable length to make connections. Figure 10 on page 28 shows how the cables run through

the housing.

CAUTION: For safety, the mounting surface, hardware, and procedure used for securing the dome must support the

weight of the dome, mount (if used), cables, and any structural or environmental vibration according to local

codes. See Table 1, Minimum load requirements of dome configurations on page 9.

4. Attach the housing to the pipe or mount.

• For pipe installations, thread the housing onto the pipe. If necessary, first turn the housing

counterclockwise to compensate for the cable twisting.

• For wall-mount installations, use the fasteners that were provided with the mount.

Page 36

Legend IP

28

Installation Manual

Figure 10. Installing the pendant-mount housing

Typical pipe-mount

Soapy water

sprayed on

pipe before

the boot is

slid up.

Ceiling

See Table 1, Minimum load re-

quirements of dome configurations on page 9.

Pendant-mount cabling

Cable entry hole

Dust seal

Upper bracket

Power cable

Cables are fed as follows:

Water-sealing rubber boot

(for outdoor applications)

Teflon tape applied to

pipe threads after the

boot is slid up.

If necessary,

housing turned

counterclockwise

to compensate

for cable twist.

• all cables run down through

the cable entry hole and the

dust seal;

• the power cable runs over the

top of the upper bracket and

down beside the power

connector; and

• the remaining cables run

down through the center hole

in the upper bracket.

Ceiling

Cables fed through

pipe and housing.

Typical wall-mount

Use the safety chain

and screws provided.

Safety

chain

Cables fed through

mount and housing.

Water-sealing rubber boot

(for outdoor applications)

Teflon tape

Housing lifted

and threaded

(turned clockwise)

onto pipe.

Wall

Wall mount

Page 37

Installing the housing and cables

Chapter 2

Preparing the cables

Which and how many cables you will be preparing depends upon how many alarms and relays you are

connecting in addition to the Ethernet and power cables, and whether you will be installing cables for analog

video and data.

To prepare the facility camera cables, terminate the cable ends as shown in Figure 11.

Figure 11. Prepared cables

Ethernet (for digital video and data): terminate standard CAT-5 Ethernet

cable with RJ-45 connector

Note: If you are making your cables, do not add a boot. If you are using ready-made

cables that include a boot, cut off the boot and reterminate the cable.

Power: strip ends of wires

Alarms and relays: strip ends of wires

29

Analog data: strip ends of wires (UTP for RS-422 or STP for RS-485)

Note: Analog video and data wires can share the same

jacket but must remain separate twisted pairs.

Analog video (UTP): strip ends of UTP wires

Note: Analog video and data wires can share the same

jacket but must remain separate twisted pairs.

Analog video (coaxial): terminate coaxial cable with BNC connector

Note: Use only crimp-on BNC connectors. Do not use screw-on connectors.

Page 38

Legend IP

30

Installation Manual

Page 39

Chapter 3 Wiring and addressing the dome

This chapter provides instructions for how to wire and address the dome. There

are two boards attached up inside of the housing that you will be handling while

you wire and address the dome. The larger board is the housing board and the

smaller board is the active housing card (AHC).

In this chapter:

Components used for basic and advanced operation. . . . . . . . . . . . . . . 32

Wiring the housing board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installing the cable ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Addressing the camera site and setting the protocol . . . . . . . . . . . . . . . 37

Setting the termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Note: If you have experience with the earliest analog Legend domes, you may be used to the

terminal strip that provides the relay connections being oriented another direction.

Read the decal to ensure that you connect to the correct terminals.

Page 40

Legend IP

8

32

Installation Manual

Components used for basic and advanced operation

For basic operation, you need to connect Ethernet and power cables to the components in the dome shown in

Figure 12. The Ethernet connection provides both video and data. For advanced operation, you can also connect

any combination of alarm, relay, or analog data and video cables to the dome. How many cables you will be

feeding into the housing depends upon how many alarms and relays you are connecting in addition to the

Ethernet and power cables, and whether you will be installing cables for analog data and video. For pipe

capacity, see Cable management on page 10. For other cable requirements, see Cable requirements on page 9.

Figure 12. View of housing boards attached to upper bracket as viewed from below the housing with factory-installed cables

Power

Housing board

HEATER

HEATER/BLOWER

(1 of 2)

THERMOSTAT

POWER

LED

POWER

Coaxial analog video

Note: The pressure

sensor connection

is for pressurized

housings only.

Analog data

Digital video and data

Active housing card

(AHC)

FOR FUTURE

USE

AUX B

RS485--

AUX A

RS485+

B

ETHERNET

PRESSURE

RS485--

A

SENSOR

RS485+

ON

O

N

1234

OFF

TERMINATION

HEATER/BLOWER

D

D

E

E

F

0

1

2

AUXMAIN

3

4

6

5

C

C

F

B

B

0

A

A

1

9

9

2

8

8

3

7

7

4

6

5

PROTOCOL

(1 of 2)

1

I/C

2

I/C

3

I/C

4

I/C

5

I/C

6

I/C

7

8

6

9

5

0

4

1

3

2

7

I/C

8

I/C

N/C

N/O

O/C

N/C

N/O

O/C

---

UTP analog

video

+

6

7

5

8

4

9

3

0

2

1

1's10's100's

INTERCONNECT CARD

Page 41

Wiring and addressing the dome

Wiring the housing board

To wire the housing board, see Figure 13 on page 34 and Figure 14 on page 35 and do the following:

WARNING: DO NOT run any cables next to the heaters. Doing so could damage the dome or cause an electrical fire.

CAUTION: To ensure the security of your surveillance system, your IP network should be isolated and secured from

unauthorized access.

1. Connect the facility Ethernet cable for digital video and data.

2. Connect the facility power cable. Make sure that the power cable is fed over the top of the upper

bracket and down beside the power connector. Use the provided 2-pin terminal strip. If you are using a

heavier gauge cable, ensure that it is properly seated in the connector. Power in the Legend IP domes is

not polarity sensitive.

When power is received by the housing board through the power connection, the housing board’s

diagnostic power LED will appear orange. There are additional diagnostic LEDs that indicate the

proper installation of the camera assembly (see Installing the camera assembly and bubble on

page 41).

Chapter 3

33

3. If you are installing alarms and relays, connect the alarm and relay cables to the two provided 12-pin

terminal strips. One is blue and one is green.

• Use dry contacts for alarms.

• Use relays with a maximum operating voltage of 30 VAC, 30 VDC at 0.5 A.

Note: Because of space constraints, if you are installing more than five alarms and/or relays, use a multiconductor

cable instead of individual single-pair cables

.

4. If you are installing analog video, connect the facility analog video cable.

• If you are installing UTP video, use the provided green 12-pin UTP terminal strip. It provides

connections for UTP video, in addition to alarms 7 and 8 and relays 1 and 2.

Note: If you have earlier analog Legend domes, be aware that the terminal strip providing the UTP video

connections has been flipped upside down in later domes. Read the decal to ensure you connect to the

correct terminals.

• If you are installing coaxial video, locate the BNC connector.

Note: Use only crimp-on BNC connectors. Do not use screw-on connectors.

5. If you are installing analog data, connect the facility analog data cables to the main connections, which

are the orange B and A terminals on the provided green 4-pin terminal strip. The AUX connections

(yellow B and A terminals) are wired only if you want streaming position reporting or are using the

Tyco/AD (RS-422) protocol.

The main data connections on the terminal strip are for control wires that

are coming in from the keypad. You may also daisy-chain the data signal on to additional domes.

If you are installing RS-485 data, float the shield at the dome and ground it at the keypad.