GE Security FireShield FS302, FireShield FS502, FireShield FS1004 Technical Reference Manual

Page 1

FireShield

Technical Reference Manual

P/N 3100353 • Rev 3.0 • 12MAY03

Page 2

DEVELOPED BY

Phone: (941) 739-4200

Copyright © 2002

IMPORTANT INFORMATION

Limitation of liability

This product has been designed to meet the requirements of

the standards listed in “Compliance statement” below.

Installation in accordance with this manual, applicable

codes, and the instructions of the Authority Having

Jurisdiction is mandatory. The manufacturer shall not under

any circumstances be liable for any incidental or

consequential damages arising from loss of property or other

damages or losses owing to the failure of products beyond

the cost of repair or replacement of any defective products.

The manufacturer reserves the right to make product

improvements and change product specifications at any

time.

While every precaution has been taken during the

preparation of this manual to ensure the accuracy of its

contents, the manufacturer assumes no responsibility for

errors or omissions.

FCC warning

This equipment can generate and radiate radio frequency

energy. If this equipment is not installed in accordance with

this manual, it may cause interference to radio

communications. This equipment has been tested and found

to comply within the limits for Class A digital devices

pursuant to Subpart B of Part 15 of the FCC Rules. These

rules are designed to provide reasonable protection against

such interference when this equipment is operated in a

commercial environment. Operation of this equipment is

likely to cause interference, in which case the user, at his

own expense, will be required to take whatever measures

may be required to correct the interference.

Compliance statement

FireShield, when properly installed, operates as a Local

Protected Premises Fire Alarm System in accordance with

the following standards:

• NFPA Standard 72, 1999 Edition

• NFPA 70 National Electrical Code

• Underwriters Laboratories Standard 864, 8th Edition

• Underwriters Laboratories of Canada Standard ULC

S527-99

• Canadian Electrical Code Part I

• Standard for Installation of Fire Alarm Systems

ULC S524

• Standard for the Inspection and Testing of Fire Alarm

Systems ULC S536

FireShield also complies with Local Protective Signaling

(type L) - manual (M), automatic (A), waterflow (WF), and

sprinkler supervisory (SS) for:

• Coded (C) and non-coded signaling (NC)

• Remote Station (type RS) - with RPM or FSDACT

• Auxiliary (type A) - with CTM4.7 (this may include Local

with Shunt type connection to Master Box - type LS)

• Central Station (Type CS) - with FSDACT

–2003

Content

Chapter 1 System overview and operation • 1.1

System overview • 1.1

Operations overview • 1.1

Controls and indicators • 1.1

Component descriptions • 1.3

Operating the panel • 1.4

FSDACT LCD messages • 1.7

Chapter 2 Installation • 2.1

Installation checklist • 2.1

Installing the cabinet • 2.1

Installing the Remote System Indicator • 2.2

Installing the Remote Zone Indicator • 2.3

Installing the Remote Relay Module • 2.5

Installing the Power Expander Transformer • 2.7

Installing the FSDACT • 2.8

Connecting an RPM module • 2.10

Connecting a CTM module • 2.11

Connecting an auxiliary power supply • 2.12

Installing the terminal shield • 2.12

Chapter 3 Programming • 3.1

Overview • 3.1

Using the factory default settings • 3.2

Using an FSDACT • 3.2

Custom programming the panel • 3.2

FSDACT programming • 3.8

Chapter 4 Maintenance • 4.1

Preventive maintenance • 4.1

Appendix A Calculations • A.1

Battery calculation worksheet • A.1

Notification appliance voltage drop

calculation • A.3

Notification appliance circuit maximum wire

length calculation • A.4

Appendix B Programming templates • B.1

Panel programming worksheet • B.1

FSDACT programming worksheet • B.2

Appendix C Jumper settings and wiring diagrams • C.1

Appendix D Panel specifications • D.1

Appendix E Default event codes • E.1

Default Contact ID event codes • E.1

Default (4/2) event codes • E.2

Z Index • Z.1

FireShield Fire Alarm Control Panel Operating

Instructions • 1

Page 3

Chapter 1

System overview and operation

System overview

FireShield is available in three models: three-zone, five-zone,

and ten-zone. Each model is similar except for the number of

initiating device circuits (IDCs) and notification appliance

circuits (NACs), as shown in the following table.

Model IDCs NACs

FS302 (three-zone) 3 2

FS502 (five-zone) 5 2

FS1004 (ten-zone) 10 4

Model numbers may have the following suffixes: G or R

indicates gray or red enclosure, GD or RD indicates panel with

FSDACT, GC indicates ULC panel with terminal shield, GF

indicates a French ULC panel with terminal shield, and G-2

indicates 230 Vac input.

Each panel is configured for Class B operation. All models

except for the three-zone can be easily converted to Class A

by using two Class B circuits to make one Class A circuit.

If the optional FSDACT is installed, the panel:

• Sends a record of the event to the FSDACT LCD and to

the history log

• Uses the FSDACT to transmit event messages to a

monitoring station as programmed

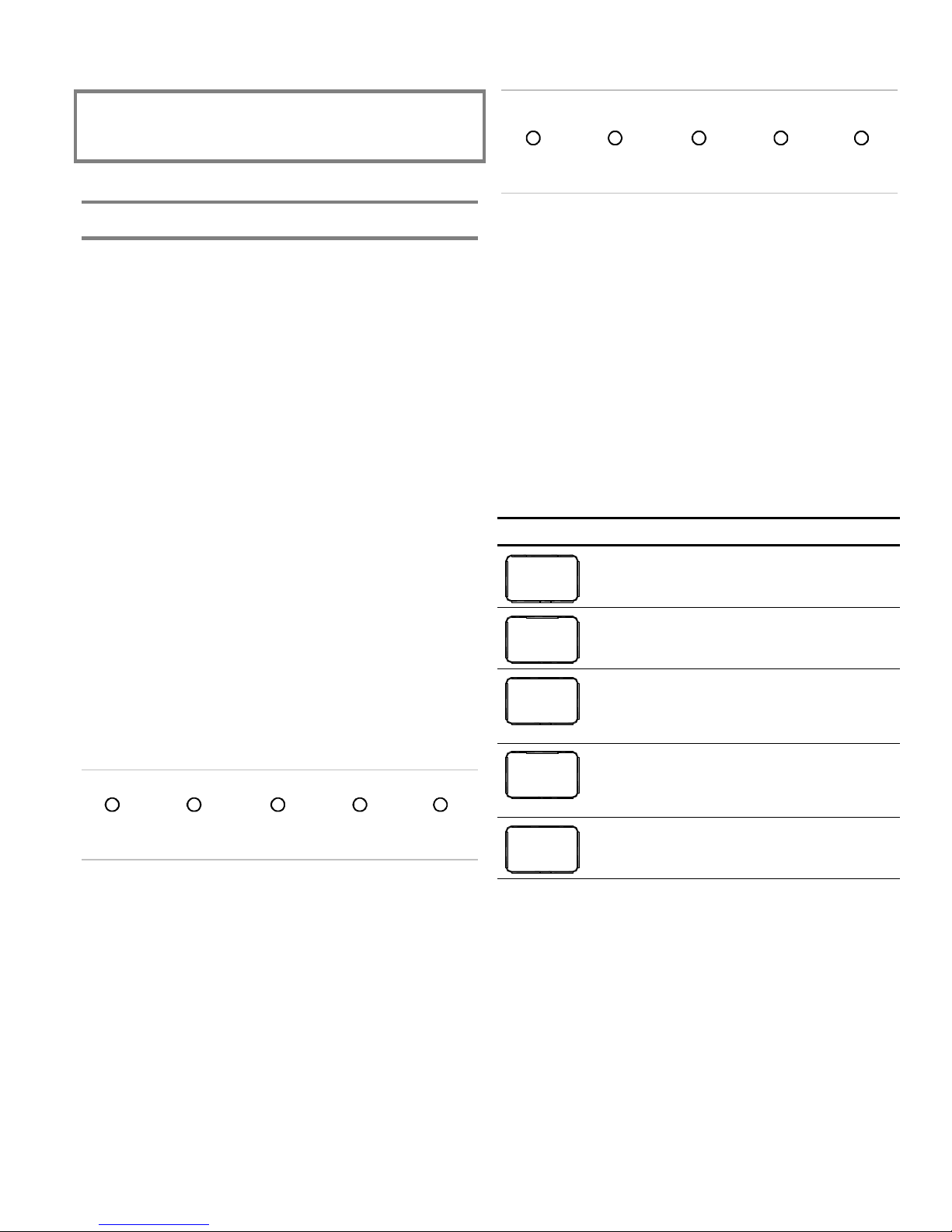

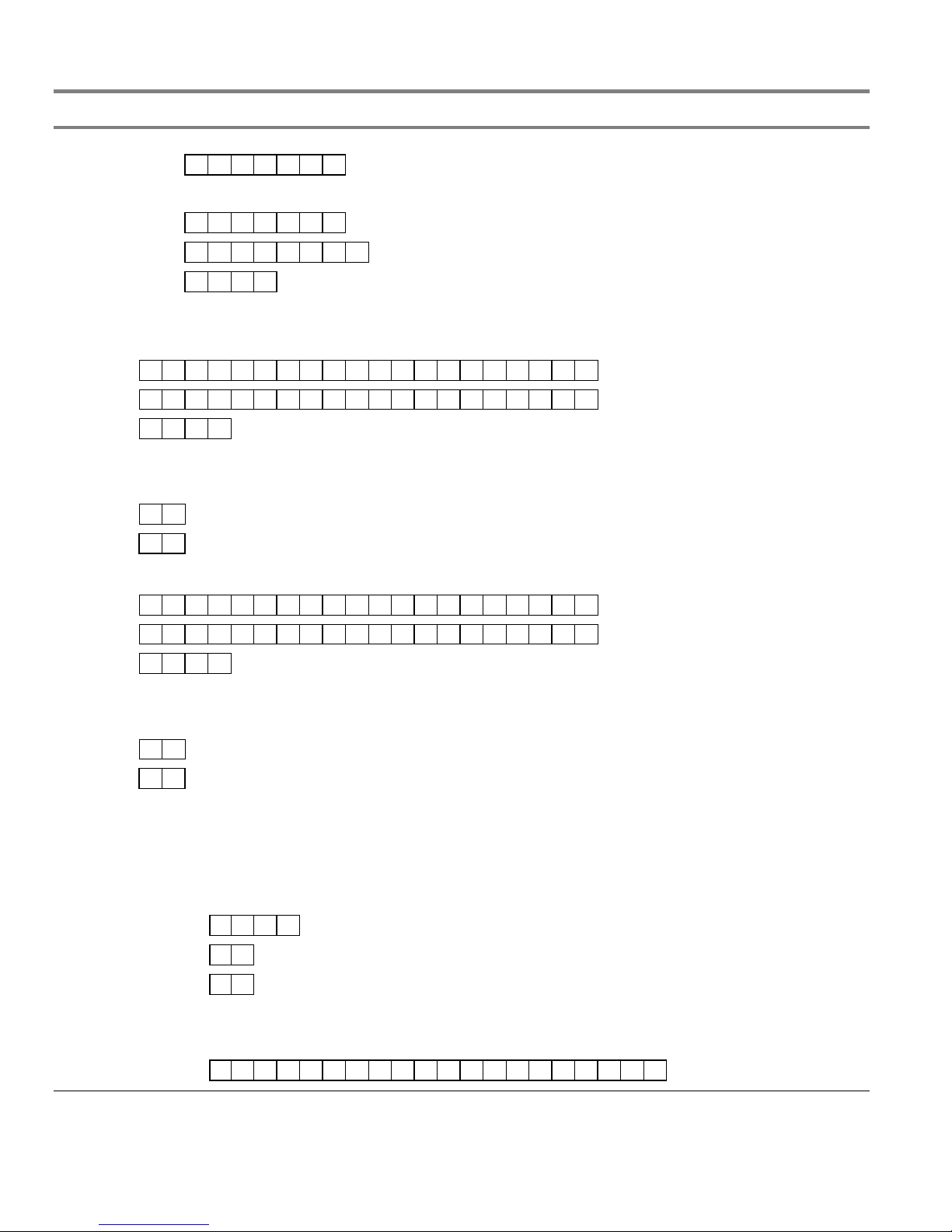

Controls and indicators

REMOTE

DISCON-

1

2

3

4

LAMP TEST

NECT

WALK

TEST

RESET

SIGNAL

SILENCE

& DRILL

PANE L

SILENCE

DISABLE

DISABLE

DISABLE

DISABLE

DISABLE

ALARM

BATT

ANNUN

TROUBLE

TROUBL E

ALARM TROUBL E SUP/MON

1

2

3

NAC 1

NAC 2

SUPTROUBLE POWER DISAB LE

SIGNAL

WALK

GND

FAULT

TEST

SILENC ED

6

5

FireShield has the following optional components:

• Remote System Indicator (FSRSI)

• Remote Zone Indicator (FSRZI-A)

• Remote Relay Module (FSRRM)

• Power Expander Transformer (XTR3A120, XTR3A230)

(ten-zone only)

• DACT (Dialer)/Modem (FSDACT)

• City Tie Module (CTM4.7)

• Reverse Polarity Module (RPM)

• Battery Cabinet (BC-2)

Refer to Chapter 2 “Installation” for optional module details.

Operations overview

The panel operates in normal mode in the absence of any

alarm, supervisory, trouble, or monitor events. In normal

mode, the control panel monitors the system.

The panel operates in off-normal mode any time an event is

introduced into the system. When this happens, the panel:

• Changes contact positions on appropriate common relays

• Activates alarm outputs (for alarm events only)

• Turns on the appropriate LEDs and the panel buzzer

• Executes the appropriate programmed output response for

the input that signaled the event

• Communicates event information to appropriate optional

components (FSRSI, FSRZI-A, CTM4.7, or RPM)

Front panel display

(1) Lamp test

Buttons Description

REMOTE

DISCON-

NECT

Press the Remote Disconnect and Walk Test

buttons simultaneously to initiate a panel

lamp test. This lets you verify proper

operation of the LEDs on the panel and the

WAL K

TEST

remote annunciators.

(2) Control buttons

Button Description

REMOTE

DISCON-

NECT

Operating mode with FSDACT: Disables or

enables FSDACT. Has no effect on alarm

relay.

Operating mode without FSDACT: Disables

or enables the common alarm relay.

Programming mode: Selects the next option.

WAL K

TEST

Operating mode: Places the panel in walk

test mode. The Walk Test LED is on when

the panel is in walk test mode.

Programming mode: Selects the previous

option.

FireShield Technical Reference Manual 1.1

Page 4

System overview and operation

Operating mode: Initiates a panel reset.

RESET

Programming mode: Selects the next

setting for the current option.

SIGNAL

SILENCE

& DRILL

Alarm mode: Silences active notification

appliances. Pressing Signal Silence a

second time turns NACs back on. The Signal

Silenced LED indicates when the panel is in

alarm and operating with notification

appliances turned off. Visual appliances may

or may not turn off when Signal Silence is

pressed depending on panel programming.

Normal mode: Activates the drill function.

Turns notification appliances on according to

the panel programming but does not place

the panel in alarm or activate the alarm

relay. Pressing Drill a second time turns off

the drill function.

Programming mode: Selects the previous

setting of the current program option.

PANEL

SILENCE

Operating mode: Silences the panel and

FSRSI sounders during an active trouble,

supervisory, or alarm event.

Programming mode: Saves the program

setting.

(3) Indicating Device Circuits (IDCs) LEDs and controls

LED/button Description

Alarm LED

On steady when an alarm input device is

activated.

Trouble LED

On steady when there is a wiring fault on the

circuit. Double-flashes when the circuit is

disabled. Fast-flashes, during walk test,

when the IDC is resetting.

Supervisory /

Monitor LED

(SUP/MON)

On steady when a supervisory input device

is activated. Stays on until panel is reset.

Also flashes when active if programmed as a

monitor zone. Monitor zone programming

option is not approved for use in Canada.

Operating mode: Renders an IDC

DISABLE

inoperative. A disabled circuit can not initiate

a change in panel state. A disabled IDC’s

Trouble LED double-flashes. If pressed

when an IDC is active, it has no effect on the

panel’s current state but no further activity on

that IDC will be reported. Disabled IDCs

remain disabled after a system reset.

Walk test mode: Selects an IDC to place it

into or remove it from walk test mode.

Programming mode: Selects an IDC so

that settings can be viewed or changed.

(4) Notification Appliance Circuits (NACs) LEDs and

controls

LED/button Description

Trouble LED On steady when there's a wiring fault on

circuit. Double-flashes when circuit is disabled.

Operating mode: Used to render an NAC

DISABLE

inoperative. A disabled NAC trouble LED

double-flashes. If pressed when an NAC is

active, notification appliances remain active.

Once silenced, a disabled NAC does not

resound unless enabled. Disabled NACs

remain disabled after a system reset.

Programming mode: Selects an NAC so that

settings can be viewed or changed.

(5) Common system LEDs

LED Description

Alarm

On steady when there is an active alarm

event on any IDC.

Trouble

Flashes when there's a fault with a monitored

circuit or system component, when a circuit is

disabled, or when panel is in walk test mode.

Supervisory On steady when there is an active supervisory

event on any IDC.

Power On when the panel has AC power.

Disable Double-flashes when there is a disabled

circuit, FSRRM, alarm relay, or FSDACT.

Pressing Disable also places the panel in the

trouble state.

Annunciator

Trouble

On steady when there is a communication

failure between the panel and a remote

annunciator. Also places the panel in the

trouble state.

Battery

Trouble

Flashes for voltage supervisory or charger

trouble. Steady means placement trouble.

Also places the panel in the trouble state.

Ground Fault

On steady during an active ground fault. Also

places the panel in the trouble state.

Walk Test Flashes when performing an audible walk

test. Steady indicates a silent walk test. Also

places the panel in the trouble state.

Signal

Silenced

On steady indicates that NAC circuits are

turned off but the panel is still in alarm.

(6) LCD display when FSDACT is installed

Notes on LEDs:

During an alarm condition, all flashing

LEDs, regardless of their function, go steady.

When NAC or IDC pairs are configured for Class A operation,

trouble conditions may be indicated by the Trouble LED on

either NAC or IDC in the pair.

1.2 FireShield Technical Reference Manual

Page 5

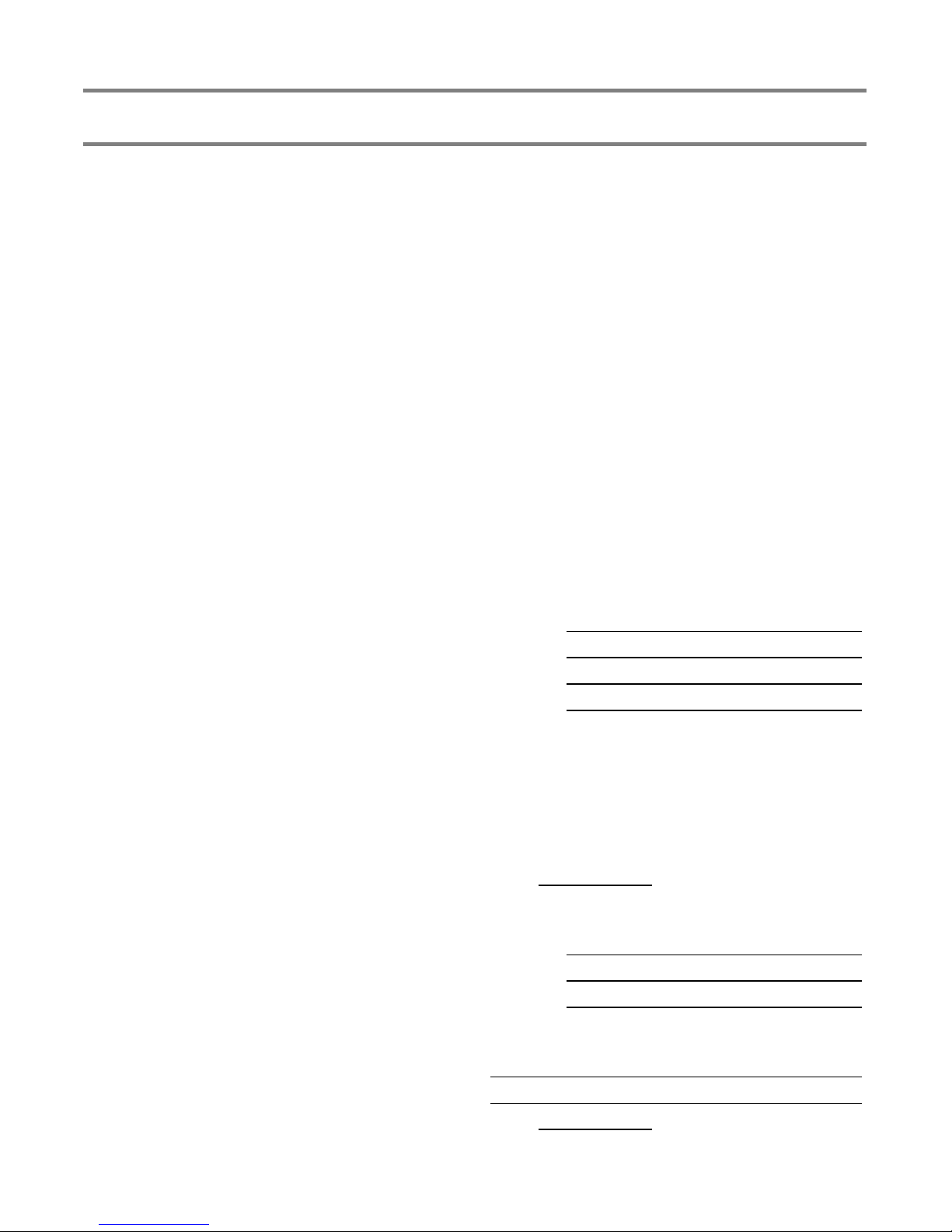

Component descriptions

System overview and operation

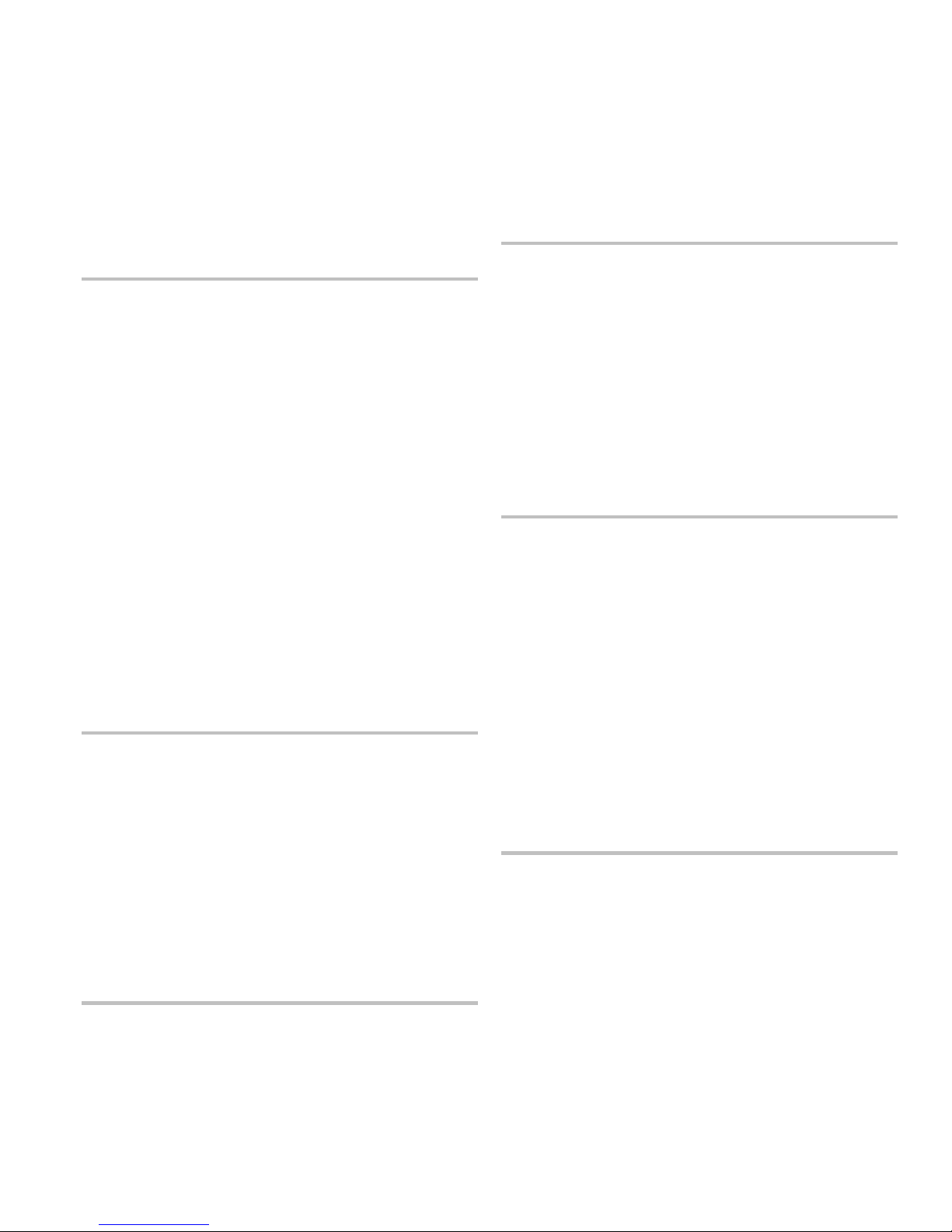

2

1

3 4 5 7 8

6

9

(1) Main AC wiring block and fuse holder: Provides

connections for 120 or 230 volt AC (primary power) from

dedicated service. Includes a primary power fuse (5 A).

PRG

10

1211

13

(8) Cabinet enclosure: Houses the panel electronics and

standby batteries. In some cases the batteries may be housed in

an external battery cabinet (BC-2).

(2) Dual Transformer AC wiring block: Ten-zone panel only.

Provides connections between primary side of both main and

expander transformer and 120 or 230 volt AC (fused primary

power).

(3) Transformer: Changes 120 or 230 volt AC supply voltage

to 24 volt AC.

(4) Power expander transformer (XTR3A120, XTR3A230):

Optional. Available for the ten-zone panel only. Provides

additional primary power to increase the available NAC

current for the ten-zone panel.

(5) Main circuit board: Provides connections for all circuits.

Also includes the operator interface.

(6) FSDACT plug: Used to connect the FSDACT to the circuit

board.

(7) Operator Interface: Includes operator controls, LED

indicators, and circuit identification labels.

FireShield Technical Reference Manual 1.3

(9) FSDACT: Optional. Digital alarm communicator

transmitter. Provides LCD display for status messages and

programming menus. Provides two telephone line connections

for sending system messages to a compatible digital alarm

communicator receiver (DACR). Includes an event history log

of panel and FSDACT events.

(10) Program jumper PRG: Used to place the panel in

programming mode.

(11) Tie wrap mounts: Nonpower-limited. Used to secure

wires and to help maintain proper separation between powerlimited and nonpower-limited conductors.

(12) Tie wrap mounts: Power-limited. Used to secure wires

and to help maintain proper separation between power-limited

and nonpower-limited conductors.

(13) Standby batteries: Provide secondary/standby power to

the panel electronics in the absence of primary power.

Page 6

System overview and operation

Operating the panel

Resetting the panel

Pressing Reset places the panel in the reset state. The panel

should not be reset until the appropriate authority has

determined that the hazard is no longer present.

When you reset the panel:

• All LEDs on the panel light for five seconds

• The trouble and power lights remain on for an additional

15 seconds

• When reset is complete, the buzzer sounds (then turns off)

and the trouble LED turns off

In this state:

• All panel indicators are temporarily cleared

• All notification appliances are turned off

• All latched IDCs are cleared

• Alarm, trouble, and supervisory relays are returned to the

inactive state

• Auxiliary power (if programmed as resettable)

momentarily turns off

At the conclusion of the reset, if an IDC is in an off-normal

state, the panel treats the event as a new event and activates

the programmed responses. Pressing Disable for the active

IDC within 30 seconds after the panel has reset turns off the

NACs and disables the IDC.

If one or more IDCs are disabled prior to initiation of the reset,

those IDCs remain disabled.

If signal silence inhibit or reset inhibit is enabled, system reset

is inhibited during the silence or reset inhibit period.

To reset the panel:

To silence an FSRSI buzzer:

1. Press the Silence button on the FSRSI.

2. Determine the type of condition that caused the buzzer to

sound: alarm, trouble, supervisory, or monitor.

3. Determine the cause of the condition.

Silencing notification appliances

Pressing the Signal Silence & Drill button turns off all audible

devices. Visual devices or NAC circuits may or may not turn

off, depending on panel programming.

When you silence the signals, the Signal Silenced LED lights,

indicating that the notification appliances are off. The panel

does not indicate a trouble condition. If GENESIS,

horn/strobe, or horn-only devices are used on NACs

programmed for GENESIS operation, Signal Silence & Drill

silences only the horns.

WARNING: The notification appliances should not be silenced

until the building is fully evacuated and the cause of the alarm

has been determined.

To silence notification appliances:

1. Press the Signal Silence & Drill button.

When the auto signal silence timer is programmed

When an event activates the notification appliances, the 20minute auto signal silence timer is activated. The notification

appliances are activated for the 20-minute period. When the

timer expires, any NACs that are programmed as silenceable

are deactivated, and the Signal Silenced LED is illuminated.

If another event takes place that activates the previously

silenced notification appliances, the Signal Silenced LED

turns off. At any time, you can deactivate silenceable NACs

by pressing Signal Silence & Drill.

1. Press the Reset button.

Silencing panel and FSRSI buzzers

Both the panel and the optional FSRSI module have buzzer

silence buttons. Pressing the Panel Silence button silences the

buzzer on the panel and on remote FSRSIs.

Pressing the FSRSI Silence button silences the buzzer on the

FSRSI only.

To silence the panel buzzer:

1. Press the Panel Silence button on the panel.

2. Determine the type of condition that caused the buzzer to

sound: alarm, trouble, supervisory, or monitor.

3. Determine the cause of the condition.

1.4 FireShield Technical Reference Manual

Note: NACs activated by IDCs programmed as waterflow

cannot be silenced until the activated devices are restored to

normal. After the devices restore, the Signal Silence & Drill

button or the auto signal silence timer can silence the NACs.

Resounding an alarm condition

Pressing the Signal Silence & Drill button again turns the

audible devices back on if they were silenced.

To resound notification appliances:

1. Press the Signal Silence & Drill button.

Note: NACs resound automatically if a new alarm (from

another IDC) is received.

Page 7

System overview and operation

Disabling an IDC

Pressing an IDC Disable button prevents the panel from

responding to any status change from that IDC. When you

disable an IDC:

• The common Disable LED double-flashes

• The IDC Trouble LED double-flashes

• The common Trouble LED lights and the panel goes into

a trouble state

• The common trouble relay changes state

Resetting the panel has no effect on a disabled IDC, but

removing all power from the panel clears the disable and

enables the IDC.

Note: During an alarm condition, all flashing LEDs go steady.

To disable an IDC:

1. Press the Disable button for the IDC that you want to

disable.

Disabling a NAC

When you disable an NAC:

• The common Disable LED double-flashes

• The NAC Trouble LED double-flashes

• The common Trouble LED lights and the panel goes into

a trouble state

• The common trouble relay changes state

Resetting the panel has no effect on a disabled NAC, but

removing all power from the panel clears the disable and

enables the NAC.

To disable a NAC:

1. Press the Disable button for the NAC that you want to

disable.

To re-enable an IDC or NAC:

1. Press the Disable button for the IDC or NAC you want to

re-enable.

Using the drill command

You can use the drill command to activate all of the

notification appliance circuits. Pressing Drill activates all

audibles and visuals according to the panel programming, but

does not activate the Alarm relay. The FSDACT can be

programmed to transmit a drill condition, but it will never

report the drill as an alarm. Drill will not operate with an

active alarm or supervisory event at the panel.

To perform a fire drill:

1. Press and hold the Signal Silence & Drill button for one

second.

2. To stop the drill, press and hold the Signal Silence & Drill

button for one second.

Using the walk test command

A walk test lets you test IDC zones without having to create

an actual alarm condition. You can conduct a walk test in

silent or audible mode. In silent mode the audible devices

(NACs) do not sound. Walk test will not operate with an

active alarm or supervisory event at the panel.

Zones should be placed in walk test one at a time. This allows

the balance of the system to remain in service.

In a walk test, the panel responds to the first signal it receives

and ignores all others on that IDC until it clears that signal or

the panel is reset. The input must be restored to the normal

state before the next input is tested. When the input is restored,

the panel automatically resets the circuit being tested. The

automatic reset takes eight seconds. After the circuit is reset

the next device can be tested.

The panel terminates the walk test if any of the following

occur:

Re-enabling an IDC or NAC

You can re-enable a disabled IDC or NAC. When you reenable an IDC or NAC:

• The common Disable LED turns off

• The IDC or NAC trouble LED turns off

• The common Trouble LED turns off and the panel returns

to normal

• The IDC or NAC LEDs are updated to show current

status (e.g. if the IDC or NAC is in trouble, the Trouble

LED lights). After enabling an IDC, alarms from that IDC

are inhibited for 30 seconds. During this time the IDC can

be disabled to avoid an unwanted alarm.

FireShield Technical Reference Manual 1.5

• The panel enters an alarm or supervisory state

• There are 30 minutes of inactivity on the zone being

tested

• The panel is reset

• Walk Test is pressed

When you press Walk Test:

• The Walk Test LED flashes for an audible walk test and

is steady for a silent walk test

• The panel enters a trouble state. There is no fire

protection for the IDC in walk test. If an unselected IDC

goes into alarm or trouble, all programmed outputs

operate as programmed.

Page 8

System overview and operation

The IDC you are testing behaves as follows:

• For alarm events, the appropriate panel, FSRSI, and

FSRZI-A LEDs and buzzers are turned on

• In the audible test mode the notification appliances sound

for a number of times equal to the zone number (e.g. three

rings for zone three)

• After activation, the panel resets the IDC. This will take

eight seconds. During the reset period, the IDC trouble

LED fast-flashes. If the device being tested is not

restored, the IDC does not reset. If the device is restored

(no alarm is present) the panel is ready to test another

device or detector.

• If auxiliary power is programmed as resettable, the

auxiliary power is deactivated while the zone is reset

• Input zones programmed as waterflow with retard require

10 to 15 seconds of activation to initiate the test signals

• For trouble events, the appropriate LEDs and the buzzers

are turned on. In the audible (NAC) test mode a onesecond pulse sounds on the audible devices. After

sounding, the zone resets in preparation for continued

testing.

• For ground fault events, the appropriate LEDs and the

buzzers are turned on. In the audible (NAC) test mode a

one-second pulse sounds on the audible devices. After

sounding, the zone resets in preparation for continued

testing.

To conduct an audible walk test:

Conducting lamp tests

Panel lamp test

A panel lamp test lights all the LEDs on the panel, FSRSIs,

and FSRZI-As so you can verify proper operation.

To test panel lamps:

1. Press and hold the Remote Disconnect and Walk Test

buttons simultaneously.

2. Verify proper operation of all LEDs on the panel.

During lamp tests the LCD displays:

DB# xx P: x.yy.zz

D: x.yy.zz

Where: DB# is the database revision number

P: x.yy.zz is the main panel version

D: x.yy.zz is the FSDACT version

FSRSI and FSRZI-A lamp test

FSRSI and FSRZI-A modules can be installed individually or

in groups to create a complete remote annunciator. You can

perform a local lamp test on the FSRSI and FSRZI-A. An

FSRSI is required to initiate this function.

To do an FSRSI and FSRZI-A lamp test:

1. Press and hold the FSRSI Silence button for five seconds.

2. Verify proper operation of all LEDs on the FSRSI and

FSRZI-As.

1. Press the Walk Test button once.

2. Press the Disable button for the IDC you want to test.

3. Conduct your walk test for the IDC.

4. When you are finished testing an IDC, press the Disable

button to turn off the walk test for that IDC.

5. Select another IDC to walk test (steps 2 through 4) or exit

from the walk test by pressing the Walk Test button.

To conduct a silent walk test:

1. Press the Walk Test button two times.

2. Press the Disable button for the IDC you want to test.

3. Conduct your walk test for the IDC.

4. When you are finished testing an IDC, press the Disable

button to turn off the walk test for that IDC.

5. Select another IDC to walk test (steps 2 through 4) or exit

from the walk test by pressing the Walk Test button.

1.6 FireShield Technical Reference Manual

Page 9

FSDACT LCD messages

Message Description

System overview and operation

Peripheral trouble

Battery Bad

Battery Missing The battery is no longer connected

AC Failure The panel lost AC power

Charger Trouble

Ground Fault The panel detected a ground fault

Transformer 2 TR The panel detected a trouble condition

AUX Power Troub

Internal Comm TR Panel-to-FSDACT communication fault

RRM(s) disabled One or more FSRRMs are disabled

Dialing... The FSDACT is dialing a DACR

DACT Configuration

TRBL

DACT Delivery TR

DACT Line 1 Trbl A ground fault or line fault has been

DACT Line 2 Trbl A ground fault or line fault has been

The panel lost communications with the

peripherals

The battery is bad and needs to be

replaced

The panel detected a battery charger

trouble condition. The charger may not

be able to charge the batteries.

in the Power Expander Transformer

The panel detected a trouble condition

in the AUX power circuit.

FSDACT is not programmed or has

unverified changes

FSDACT failed to deliver a message to

the receiver or CMS

detected on Line 1 of the FSDACT

detected on Line 2 of the FSDACT

FireShield Technical Reference Manual 1.7

Page 10

System overview and operation

1.8 FireShield Technical Reference Manual

Page 11

Chapter 2

Installation

Installation checklist

Prepare the site: Make sure the installation location is

free from construction dust and debris and extreme

temperature ranges and humidity.

Unpack the equipment

Install the cabinet: See “Installing the cabinet” for cabinet

dimensions.

Remove the clear protective plastic from the front

panel display

Install optional components (FSRSI, FSDACT, etc.):

See module installation instructions in this chapter.

Set the panel jumpers: See Appendix C or the panel

label.

Review wire routing: See Appendix C or the panel label.

Connect the field wiring: See Appendix C or the panel

label. Meter for opens, grounds, and shorts before

connecting.

Connect AC power and ground: See Appendix C or the

panel label. Panel can not be started on batteries only.

WARNING: Make sure that the AC power circuit breaker

is off before connecting wires to the terminal block.

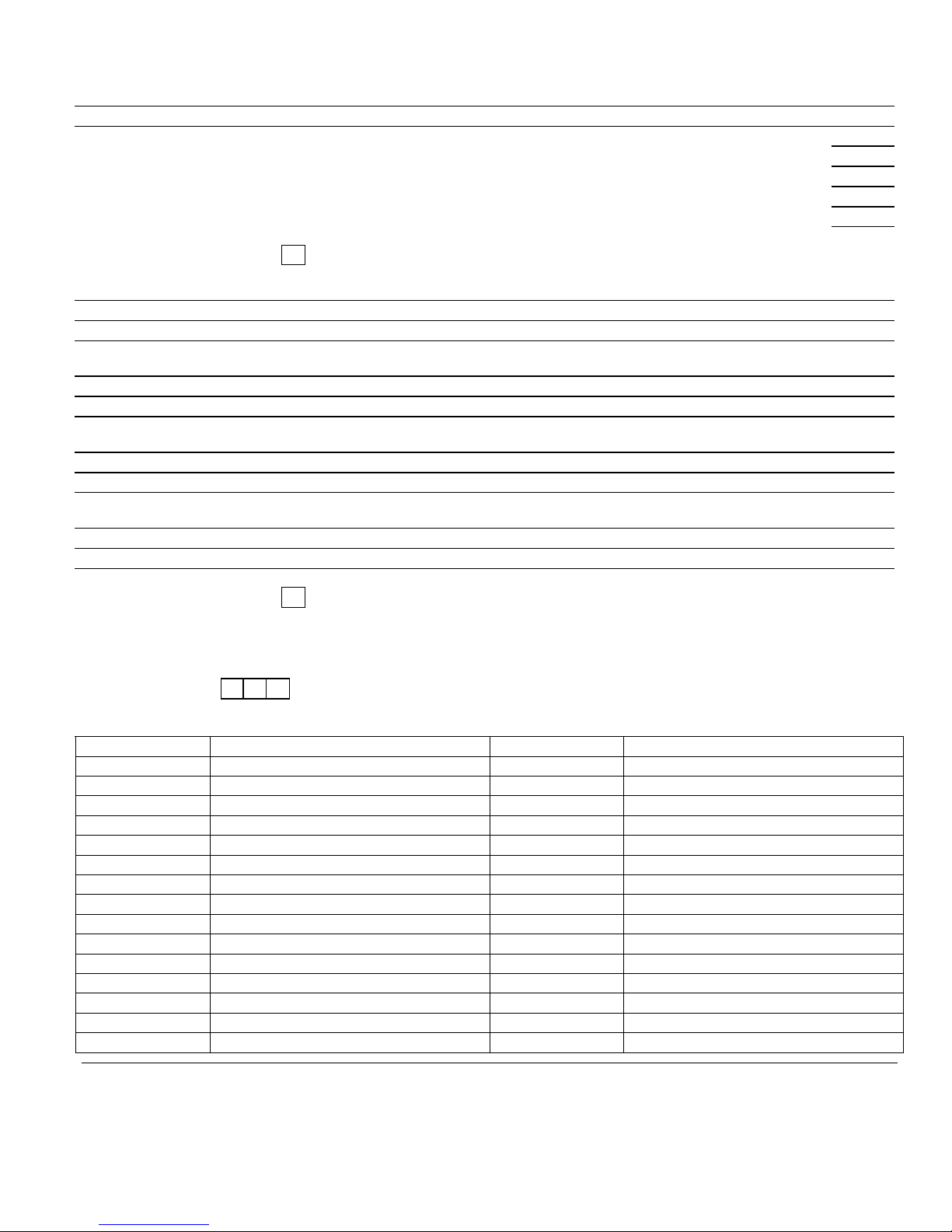

Panel dimensions

ModelD1 [1]D2D3D4D5 [1]

Threeand fivezone

Tenzone

[1] Add 1-1/2 in (3.81 cm) to D1 and D5 dimensions for trim kit.

D1

16.5 in

(41.9

cm)

23.65 in

(60 cm)

D2 D3

Semi-flush mounting holes

3.75 in

(9.5 cm)

3.75 in

(9.5 cm)

Surface mounting holes

9.13 in

(23.2

cm)

7.75 in

(19.7

cm)

D5

10.5 in

(26.67

cm)

21.27 in

(54.0

cm)

14.23 in

(36.14

cm)

16.25 in

(41.27

cm)

D4

Connect batteries: See Appendix C or the panel label.

Program the panel: Refer to Chapter 3.

Test for proper operation

Installing the cabinet

Cabinets can be surfaced mounted or semi-flush mounted. See

the “Panel dimensions” figure and table for framing and

mounting dimensions.

To surface mount the cabinet:

1. Position the cabinet on the finished wall surface.

2. Fasten the cabinet to the wall surface where indicated.

To semi-flush mount the cabinet:

1. Frame the interior wall as required to support the full

weight of the cabinet and standby batteries.

2. Install (optional) semi-flush trim to cabinet.

3. Fasten the cabinet to the framing studs where indicated.

FireShield Technical Reference Manual 2.1

Page 12

Installation

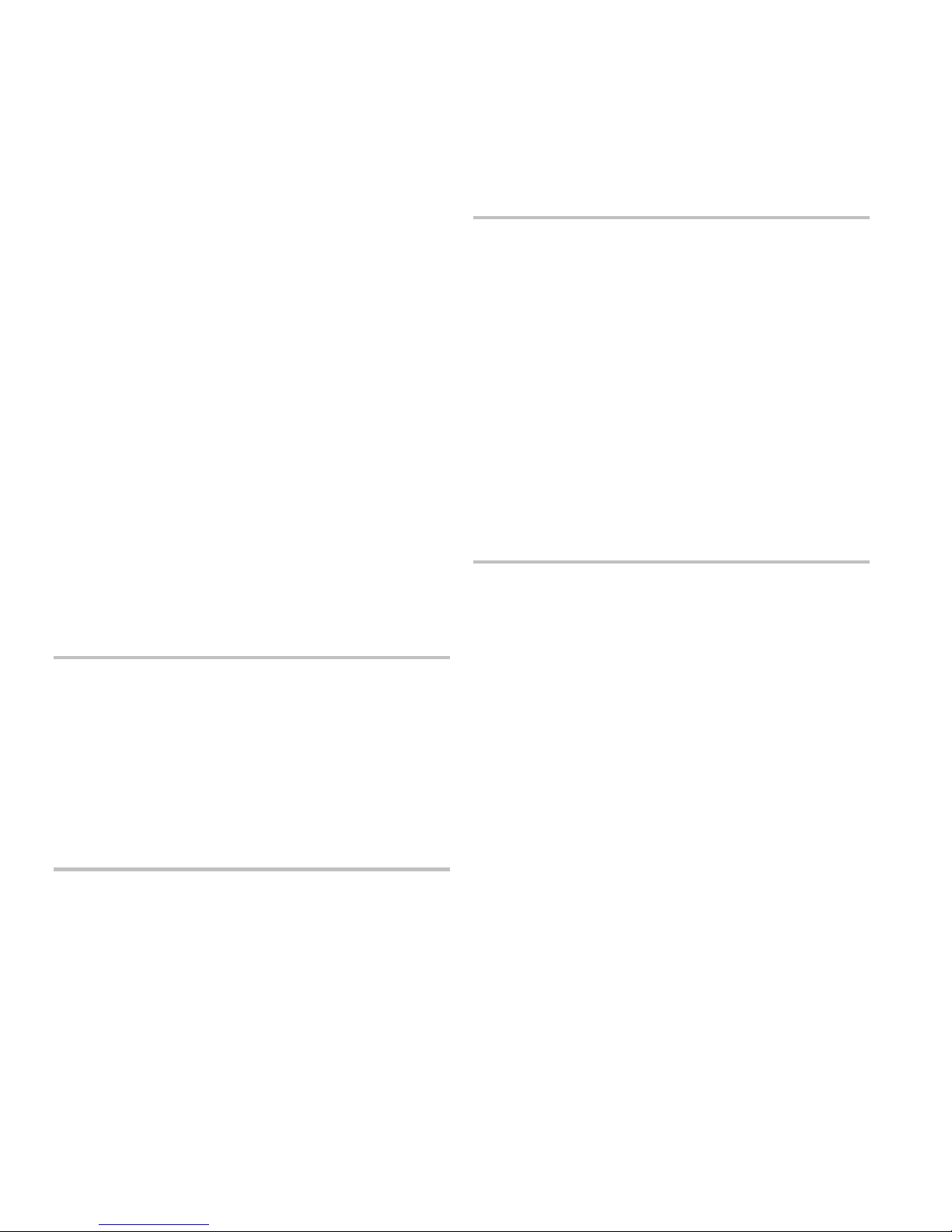

Installing the Remote System Indicator

The Remote System Indicator (FSRSI) is a supervised remote

annunciator that provides remote LED indication of power,

alarm, supervisory, trouble, and ground fault conditions. A

sounder gives audible indication during a trouble, alarm, or

supervisory condition. The sounder can be silenced with the

FSRSI Silence switch.

Note: You must run the Find Annunciators program option

after adding or removing a remote annunciator. The remote

annunciators will not operate properly until the panel detects

them. For more information see Chapter 3 “Programming.”

LED State Description

Supervisory

(yellow)

Trouble (yellow) On System trouble

Ground fault

(yellow)

Buzzer On

On Active supervisory device

On System ground fault

System trouble

On (temporal)

On (slow pulse)

On (intermittent)

Off

Alarm condition

Supervisory condition

AC fail

Normal or silenced

Jumper setup

Jumper Name Description

J2 Group

jumper

Note: For jumper location, refer to the FSRSI wiring diagram.

Allows two FSRSIs to be connected

to the same panel.

Install the jumper on only one of the

two FSRSIs.

Specifications

Max. per system: 2

Voltage range

Minimum: 21 Vdc

Maximum: 25 Vdc

Current requirements

Standby: 12 mA

Alarm: 48 mA

Max. circuit capacitance: 0.03 µF

Max. circuit resistance: 13 ohms

Wire size

Minimum: 18 AWG (0.75 sq mm)

Maximum: 12 AWG (2.5 sq mm)

Compatible electric box: ANSI/NEMA OS1-1996 1-3 gang

electrical box

Operating environment

Temperature: 32 to 120 °F (0 to 49 °C)

Humidity: 93% RH, noncondensing

Installation instructions

A single FSRSI can be mounted in a standard, single gang

electrical box (ANSI/NEMA OS1-1996) using the single gang

cover plate that is included. Up to three FSRZI-As with or

without an FSRSI can be mounted in an approved multiple

gang electrical box (ANSI/NEMA OS1-1996) with

appropriate two, three, or four gang cover plates (model

numbers FSAT-2, FSAT-3, or FSAT-4).

Caution: Make sure all power is disconnected from the panel

before installing. Observe static-sensitive handling practices.

To install the FSRSI:

1. Verify that all field wiring is free of opens, shorts, and

ground faults.

2. Connect wires to the FSRSI as shown (see wiring diagram).

3. Using the two plain machine screws provided, mount the

module to the electrical box.

Note: If you are using a surface mounting box, you must

install washers (provided) between the FSRSI and the

surface mounting box.

LEDs and buzzer

LED State Description

Power (green) On AC power present

Alarm (red) On Active alarm state

2.2 FireShield Technical Reference Manual

4. Using the white machine screws provided with the

faceplate, mount the faceplate to the module.

5. Connect the wires to the terminals in the control panel.

6. Program the FSRSI using the Find Annunciators program

option. Refer to Chapter 3 “Programming.”

Page 13

Installation

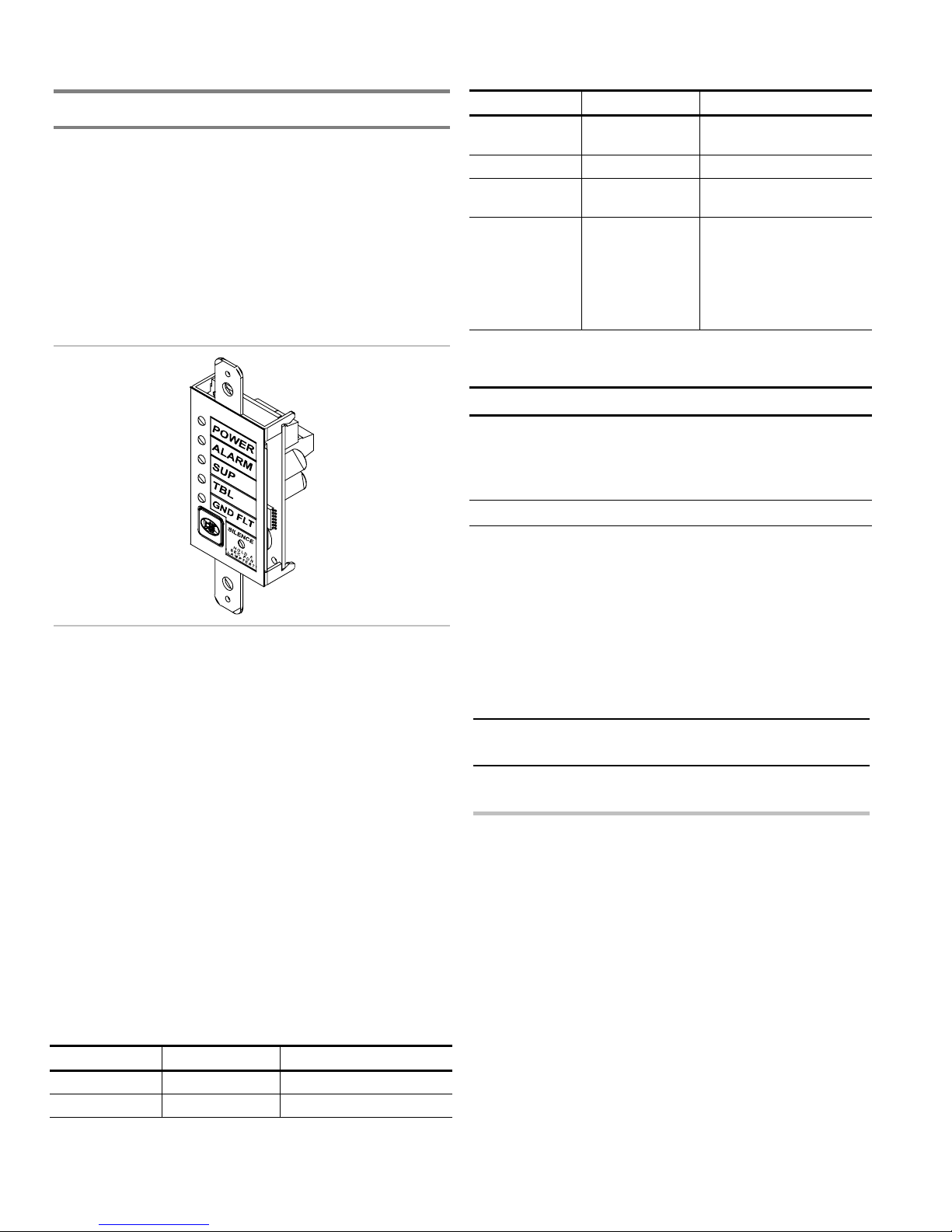

Installing the Remote Zone Indicator

Compatible electrical box

Installing the FSRSI in an electrical box

Wiring diagram

From control panel

or pr evious device

Communication in -

Communication in +

The Remote Zone Indicator (FSRZI-A) is a supervised remote

annunciator that provides remote LED indication of IDCs in

alarm state. The FSRZI-A indicates conditions for five IDCs.

The IDC groups are set by jumpers to indicate zones 1–5 or

zones 6–10. Paper inserts are provided for labeling the LEDs.

Note: You must run the Find Annunciators program option

after adding or removing a remote annunciator. The remote

annunciators will not operate properly until the panel detects

them. For more information see Chapter 3 “Programming.”

24 V in +

24 V in -

Group

C OUT

+ -

J2

24 V out +

24 V out -

Communication out -

Communication out +

To next devi ce

Notes

24V IN

- +

24V OUT

- +

C IN

+ -

1. All wiring is supervised and power limited.

2. 24 V out (aux power) must be programmed as nonresettable.

Specifications

Max. per system

FS302 (three-zone): 2

FS502 (five-zone): 2

FS1004 (ten-zone): 4

Voltage range

Minimum: 21 Vdc

Maximum: 25 Vdc

Current requirements

Standby: 8 mA

Alarm: 35 mA

Max. circuit capacitance: 0.03 µF

Max. circuit resistance: 13 ohms

Wire size

Minimum: 18 AWG (0.75 sq mm)

Maximum: 12 AWG (2.5 sq mm)

Compatible electric box: ANSI/NEMA OS1-1996 1-3 gang

electrical box

Operating environment

Temperature: 32 to 120 °F (0 to 49 °C)

Humidity: 93% RH, noncondensing

FireShield Technical Reference Manual 2.3

Page 14

Installation

Jumper setup

Jumper Name Description

J2 Reserved

N/A

for future

use

J3 Zone 6 -

10

Sets the five LEDs to report alarms

in zones 6 - 10. [1]

jumper

J4

Zone 1- 5

jumper

J5 Group

jumper

Sets the five LEDs to report alarms

in zones 1 - 5. [1]

Allows two FSRZI-As to be

connected to the same panel and

set to the same zone output option.

Install the jumper on FSRZI-As in

only one of the two groups.

[1] Install only one zone jumper on J3 or J4.

Note: For jumper location, refer to the FSRZI-A wiring

diagram.

Installation instructions

A single FSRZI-A can be mounted in a standard, single gang

electrical box (ANSI/NEMA OS1-1996) using the single gang

cover plate that is included. Up to three FSRZI-As with or

without an FSRSI can be mounted in an approved multiple

gang electrical box (ANSI/NEMA OS1-1996) with

appropriate two, three, or four gang cover plates (model

numbers FSAT-2, FSAT-3, or FSAT-4).

Caution: Make sure all power is disconnected from the panel

before installing. Observe static-sensitive handling practices.

To install the FSRZI-A:

1. Verify that all field wiring is free of opens, shorts, and

ground faults.

2. Connect wires to the FSRZI-A as shown (see wiring

diagram).

3. Using the two plain machine screws provided, mount the

module to the electrical box.

Note: If you are surface mounting the FSRZI-A, you must

install washers (provided) between the FSRZI-A and the

surface mount box.

4. Using the two white machine screws provided with the

faceplate, mount the faceplate to the module.

5. Connect the wires to the terminals in the control panel.

6. Program the FSRZI-A using the Find Annunciators

program option. Refer to Chapter 3 “Programming.”

Compatible electrical box

Installing the FSRZI-A in an electrical box

Wiring diagram

Communication in -

Communication in +

24 V in +

24 V in -

From control

panel or

previous

device

Notes

1. All wiring is supervised and power limited.

2. 24 V out (aux power) must be programmed as nonresettable.

J5

J4

J3

J2

24V IN

- +

24V OUT

- +

C IN

+ -

C OUT

+ -

24 V out +

24 V out -

Communication out -

Communication out +

To next device

2.4 FireShield Technical Reference Manual

Page 15

Installation

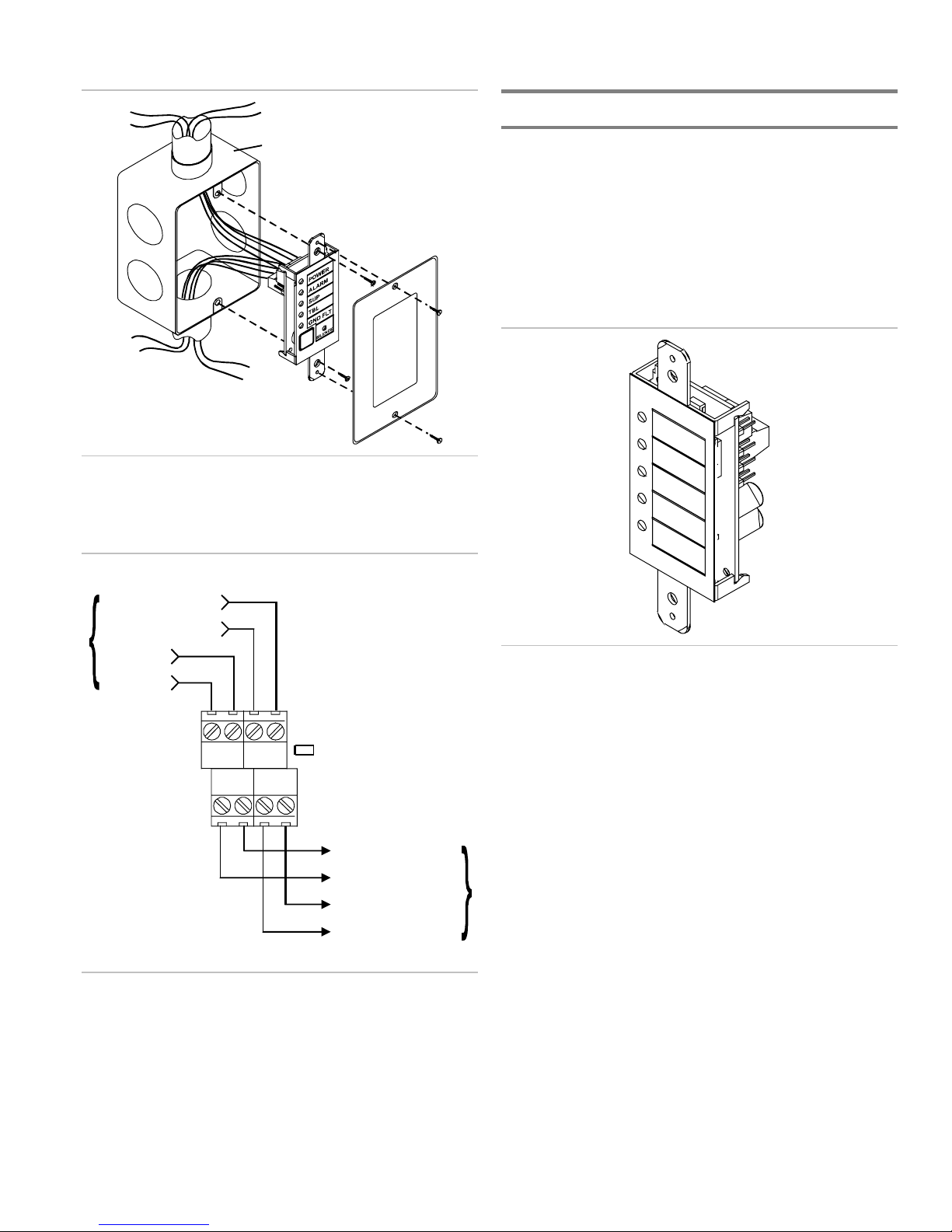

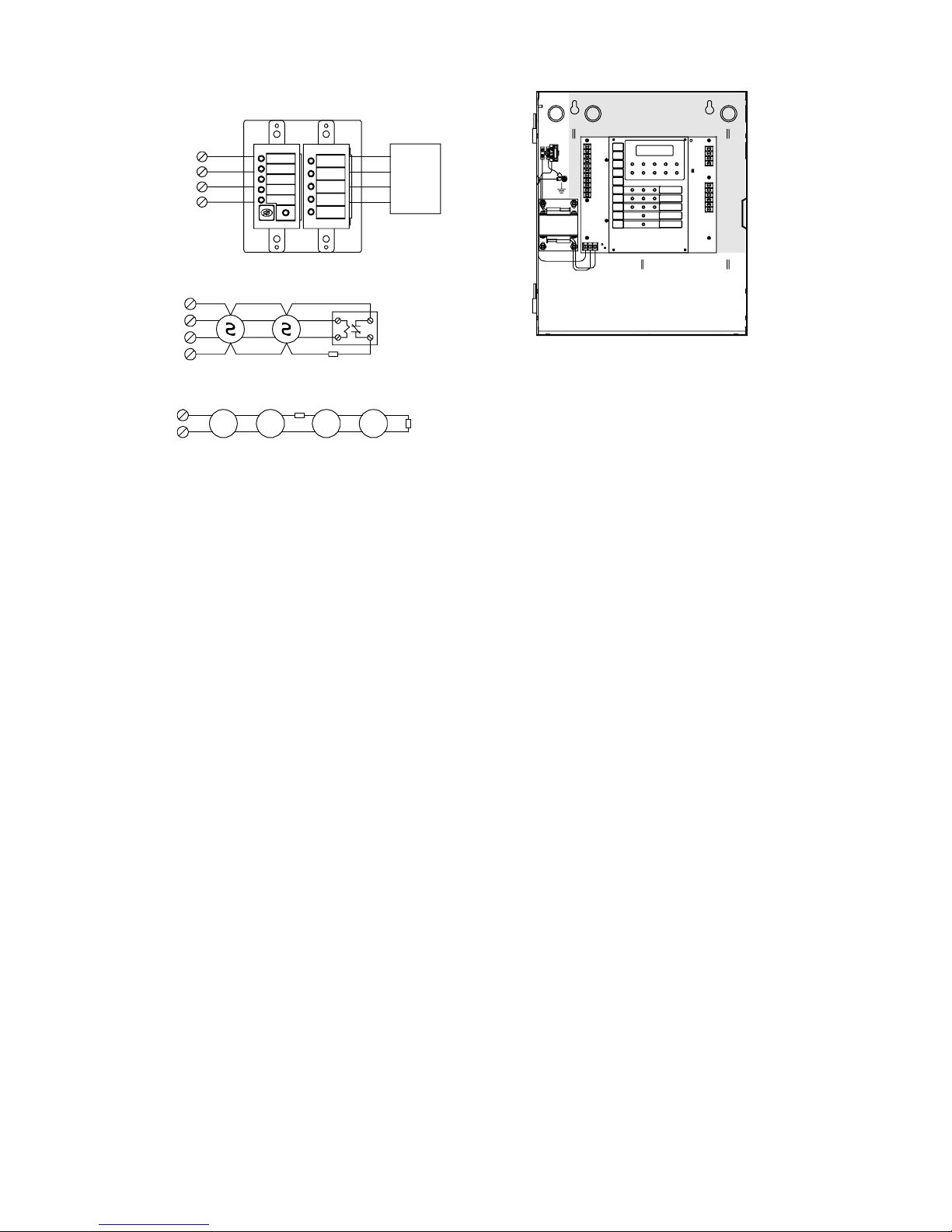

Installing the Remote Relay Module

The Remote Relay Module (FSRRM) provides five dry

contact relay outputs. The outputs can be wired as both

normally open and normally closed. The outputs can be set to

common or zone notifications (see the “Command options”

table below). Installing the appropriate jumper (JP3 - JP5)

configures the dry contact relay output options.

Five diagnostic LEDs provide visual indication of the status of

each relay. If the LED is lit, the relay is energized. If the LED

is off, the relay is de-energized. If configured for common

operation the trouble relay and the power relay will be

energized when the system is normal.

Note: You must run the Find Annunciators program option

after adding or removing a remote annunciator. The remote

annunciators will not operate properly until the panel detects

them. For more information see Chapter 3 “Programming.”

ACTIVE

IN

OUT

DS4

OUT 1

DS5

OUT 2

DS2

OUT 3

DS3

OUT 4

DS1

OUT 5

TB1 TB2 TB3 TB4

DISABLE

JP1

OUTPUTS

JP1 IN

MODULE TYPE

JP2

ZONE 11-15

JP3

ZONE 6-10

JP4

ZONE 1-5

JP5

COMMON

GROUP

JP6

#1

JP6

JP6

#2

Specifications

Max. per system

FS302 (three-zone): 4

FS502 (five-zone): 4

FS1004 (ten-zone): 6

Voltage range

Minimum: 21 Vdc

Maximum: 25 Vdc

Zoned operation current requirements

Standby: 8 mA

Alarm: 65 mA

Common operation current requirements

Standby: 30 mA

Alarm: 41 mA

Max. circuit capacitance: 0.03 µF

Max. circuit resistance: 13 ohms

Relay ratings: 30 Vdc @ 1 A (resistive load)

Wire size

Minimum: 18 AWG (0.75 sq mm)

Maximum: 12 AWG (2.5 sq mm)

Mounting: MFC-A cabinet or listed fire alarm enclosure

Operating environment

Temperature: 32 to 120 °F (0 to 49 °C)

Humidity: 93% RH, noncondensing

Jumper setup

Jumper Name Description

JP1 Disable

jumper

JP2 Reserved for future use.

JP3 Zone 6 -

10 jumper

JP4 Zone 1- 5

jumper

JP5

Common

jumper

JP6 Group

jumper

[1] Install only one zone jumper on J3 or J4 or J5.

Disables all outputs. This allows the

installer to test the system while the

FSRRM is disabled. Removing the

jumper reactivates the FSRRM.

The disable jumper is supervised.

With the disable jumper in place, the

panel displays Trouble, Annunciator

Trouble, Disable, sounds the panel

buzzer, and de-energizes any

energized relay.

Sets the five dry contacts to report

events on zones 6 through 10. See

“Command options” table. [1]

Sets the five dry contacts to report

events on zones 1 through 5. See

“Command options” table. [1]

Sets the five dry contacts to report

common events. See “Command

options” table. [1]

The group jumper (JP6) allows two

FSRRMs to be connected to the

same panel and set to the same

output option. Install the jumper (JP6)

to only one of the two grouped

FSRRMs.

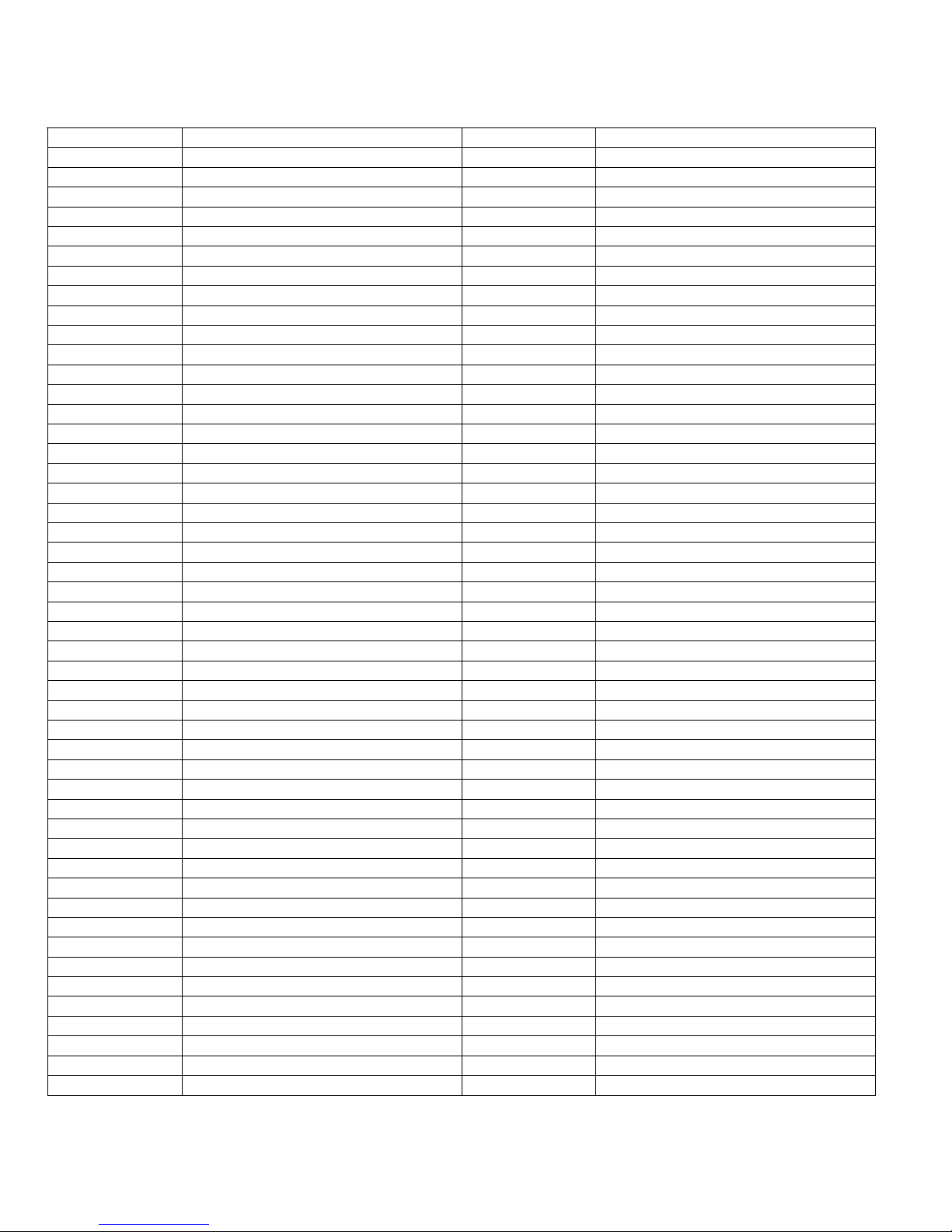

Command options

Module type Jumper Output 1 Output 2 Output 3 Output 4 Output 5

Common JP5 Alarm Trouble [1] Supervisory Monitor Power [1]

Zone 1 - 5 JP4 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

Zone 6 - 10 JP3 Zone 6 Zone 7 Zone 8 Zone 9 Zone 10

[1] Under normal conditions the relay is energized (the internal LED is lit). Loss of power de-energizes the relay.

FireShield Technical Reference Manual 2.5

Page 16

Installation

Installation instructions

The FSRRM snaps into a snap track (shipped with the

FSRRM), which mounts inside a listed fire alarm enclosure.

The FSRRM can be positioned in the snap track with the

terminal block facing vertically or horizontally.

Caution: Make sure all power is disconnected from the panel

before installing. Observe static-sensitive handling practices.

To install the FSRRM:

1. Mount the MFC-A cabinet using the installation sheet

provided (P/N 387453).

2. Drill mounting holes in the snap track using the template

provided (P/N 3100463). These holes will align to the

mounting holes on the MFC-A. An optional extended

track (P/N FSRRM-S11) is available for mounting two to

four FSRRM modules.

3. Mount the snap track to the MFC-A cabinet.

MFC-A

Snap

track

Snap

track

5. Verify that all wiring is free of opens, shorts, and ground

faults.

6. Connect the FSRRM to the panel or other peripheral

devices.

7. Power up the panel and confirm that all relays are in the

correct state before connecting the field wiring.

8. Connect field wires to the FSRRM as shown in the wiring

diagram. Be sure connection will not adversely affect

controlled devices (e.g. elevators, fans, etc.).

9. Connect wiring to the controlled devices.

10. Program the FSRRM using the Find Annunciators

program option. Refer to Chapter 3 “Programming.”

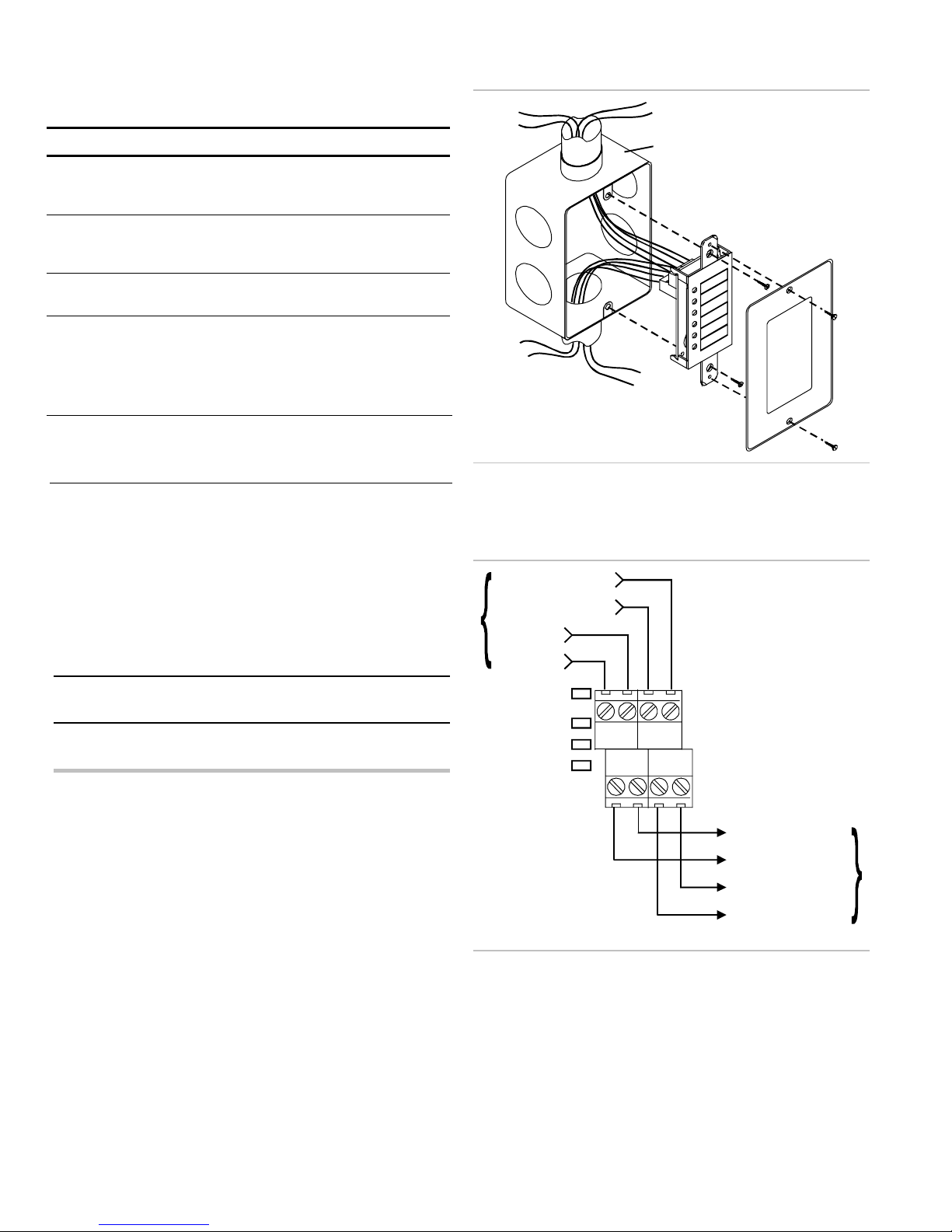

Wiring diagram

From control panel

or previous d evice

Communication in +

Communication in -

24 V in -

24 V in +

[1]

[1]

[1]

[2] [2]

To next device

Communication out -

Communication out +

MFC-A

Snap

track

Snap

track

4. Insert one side of the FSRRM into the first snap track slot

and snap in the opposite side.

Mount in first

slot only

RRM

Snap tr ack

C IN

24V IN

+ -

24V OUT

+ -

C OUT

- +

- +

[2] [2] [2]

OUT 5

X

NO C NC

OUT 3

NO C NC

OUT 4

NO C NC

OUT 1

NO C NC

NO C NC

[1]

OUT 2

24 V out -

24 V out +

To next device

Notes

[1] Supervised and power limited.

[2] Must be connected to a power limited source.

3. 24 V out (aux power) must be programmed as nonresettable.

Service and troubleshooting

If the Disabled and Annunc Trouble LED are lit but no IDC or

NAC is disabled then the FSRRM output is disabled.

2.6 FireShield Technical Reference Manual

Page 17

Installation

Installing the Power Expander

Transformer

The Power Expander Transformer (XTR3A120, XTR3A230)

provides additional primary AC power to increase the NAC

capacity for the ten-zone panel. It provides an additional 2.5

amps of NAC current. The Power Expander Transformer

installs in the cabinet with four nuts (provided). The input side

of the Power Expander Transformer connects to 120 Vac or

230 Vac through the Dual Transformer AC Wiring Block. Its

output connects to the circuit board (J4) with the attached

cable harness. One Power Expander Transformer can be

installed in the 10-zone panel.

Note: The Power Expander Transformer does not work with

the three-zone or five-zone panels.

3. Connect the cable harness to J4 on the circuit board. Push

the cable harness until the connector clicks into place.

4. Connect the incoming power wires to the dual transformer

AC wiring block above the existing transformer.

5. Secure the incoming power wires to the side of the control

panel with the tie strap provided.

From 120 Vac, 15 A, 60 Hz

Dedicated branch circuit

—OR—

From 230 Vac, 15 A, 50/60 Hz

Dedicated branch circuit

LN

Cabinet

Main AC

wiring block

and fuse

holder

Fuse

Dual transformer

AC wiring block

Specifications

Power input

120 Vac @ 60 Hz (P/N XTR3A120)

230 Vac @ 50/60 Hz (P/N XTR3A230)

Operating environment

Temperature: 32 to 120 °F (0 to 49 °C)

Humidity: 93% RH, noncondensing

Fuse: Primary winding has thermal current protection and is

not field serviceable

Note: Input current rating is included with the overall ten-zone

ratings.

Installation instructions

Caution: Make sure all power is disconnected from the panel

before installing. Observe static-sensitive handling practices.

To install the Power Expander Transformer:

1. Position the Power Expander Transformer so that the

mounting holes align with the four mounting studs on the

control panel cabinet.

N2 L2

NL

Main

Tie wrap

mounts

Power Expander Transformer installation and wiring

Main

transformer

XTR

(optional

transformer)

controller

board

TB1

Mounti ng

studs

Plug connector

J4

2. Secure the transformer to the panel using the four nuts

provided.

FireShield Technical Reference Manual 2.7

Page 18

Installation

Installing the FSDACT

The FSDACT is a digital alarm communicator transmitter

(DACT) that transmits panel events to a compatible digital

alarm communicator receiver (DACR). Messages are

transmitted over standard loop-start telephone lines. The dialer

is capable of split reporting to two different account and

telephone numbers.

In addition to the DACT functions, this module includes:

• An alphanumeric LCD to display

programming prompts

• An event history log of panel and DACT events, viewable

through compatible software

• A modem for uploading and downloading panel

configuration, history, and current status to a PC running

compatible software

Note: The FSDACT modem is only rated for 2400 baud

communication. Some PC modems may not be compatible

with this baud rate.

The FSDACT can be programmed to operate as a single or

dual line DACT/Modem/LCD display, a Modem/LCD

display, or an LCD display only. For the FSDACT to be

NFPA 72 CS compliant, the following is required:

1. The factory installed warning label must be removed from

the FSDACT's line two phone jack.

2. A second phone line, independent of that used for line one

must be connected to phone jack two.

3. The FSDACT must be programmed for dual line

operation.

4. The FSDACT must be programmed for a daily

transmission test frequency.

UL 864 compliance requires the dual line setting.

The FSDACT can be configured for attended or unattended

downloading. JP1 is a wire loop (located near the top of the

FSDACT) that controls which download method is used.

Leaving the JP1 wire loop intact configures the FSDACT for

attended downloading. The panel will not allow changes to the

panel or dialer configuration unless the program jumper is

inserted. It will allow changes to receiver information (account

code, telephone numbers, etc.). UL requires the red wire loop

to be intact for all remote station systems.

system messages and

changes shall be 100 percent tested. In addition, 10 percent of

initiating devices that are not directly affected by the change,

up to a maximum of 50 devices, also shall be tested, and

correct system operation shall be verified. A revised record of

completion in accordance with 1-6.2.1 shall be prepared to

reflect any changes.”

For additional download security, the FSDACT can be

programmed to perform a call back function. This call back

option applies whether the FSDACT is configured for

attended or unattended downloading.

Specifications

Current requirements

Standby: 40 mA

Alarm: 60 mA

Operating environment

Temperature: 32 to 120 °F (0 to 49 °C)

Humidity: 93% RH, noncondensing

Phone line type: one or two loop-start lines on a public,

switched network

Phone line connector: RJ31/38X (C31/38X). Two 7 ft plug

cords are shipped with the FSDACT.

FCC registration number: US: EDWAL01BFSDACT

Ringer equivalence number: 0.1

Industry Canada Registration number: IC: 3944-FSDACT

Connection between panel and FSDACT: 6-pin connector

Communication formats: Contact ID (SIA DC-05) and

EST 4/2 (SIA DC-02 P3 with hexadecimal event codes)

Installation instructions

Note: It is not necessary to remove the main panel board from

the cabinet to install the dialer.

Cutting the JP1 wire loop configures the FSDACT for

unattended downloading. This means that the program jumper

need not be inserted to accept any panel or dialer

configuration changes.

NFPA 72 1999 edition states in 7-1.6.2.1 that reacceptance

testing shall be performed after any change to site-specific

software.

"All components, circuits, systems operations, or site-specific

software functions known to be affected by the change or

identified by a means that indicates the system operational

2.8 FireShield Technical Reference Manual

Caution: Make sure all power is disconnected from the panel

before removing or installing an FSDACT. Failure to

disconnect power will damage the panel and the FSDACT.

Observe static-sensitive handling practices.

To install the FSDACT:

1. Remove the blank insert from the display window.

2. Remove the clear protective plastic film from the

FSDACT LCD display.

Page 19

Installation

3. Use JP1 to configure the FSDACT for attended or

unattended downloading:

• Attended: leave the JP1 wire intact

• Unattended: cut the JP1 wire

4. Install the dialer to the back of the circuit board. Align the

LCD display with the opening in the circuit board.

5. Secure the dialer to the circuit board with the two

machine screws provided.

6. Connect the power cable to J2 on the control panel.

7. Connect RJ31X/C31X jacks to the supplied cables.

8. Connect the telephone circuits as required.

Line 1

Line 2

Phone cables

(supplied)

JP1 jumper wire

To w all

phone jack

RJ31 jacks

FCC Information

1. The dialer complies with Part 68 of the FCC rules. The dialer’s FCC

certification number and Ringer Equivalence Number (REN) is

displayed on the panel’s programming label and in this manual. This

information must be provided to the telephone company if requested.

2. Two FCC compliant telephone cords with 8-pin modular plugs at both

ends are supplied with the FSDACT. The dialer is designed to be

connected to the telephone network using the supplied cord and an

RJ31X or RJ38X jack, which must also comply with FCC Part 68 rules.

3. The REN is used to determine the maximum number of devices that may

be connected to a single telephone circuit. All telephone devices are

assigned a REN. The sum of the RENs for all connected devices may

not exceed five. The maximum REN may vary in some areas. Contact

the local telephone provider for more information.

4. If the dialer causes harm to the telephone network, the telephone

company will notify you an advance that temporary discontinuance of

service may be required. If advance notice is not practical, the telephone

company will notify you as soon as possible. You will also be advised of

your right to file a complaint with the FCC, if you believe it is

necessary.

5. The telephone company may make changes in its facilities, equipment,

operations, or procedures that could affect the operation of the dialer. If this

happens, the telephone company will provide advance notice in order for

you to make necessary modifications to maintain uninterrupted service.

6. If trouble is experienced with the dialer, for repair or warranty

information, contact the manufacturer at: (941) 739-4200. If the dialer is

causing harm to the telephone network, the telephone company may

request you disconnect the dialer until the problem is resolved.

7. No repairs may be performed on the dialer by the user.

8. The dialer can not be used on public coin phones or party line service

provided by the telephone company.

Circuit board

FSDACT installation and telephone circuit connection

The FSDACT is listed for use with the following DACRs

Receiver Models Formats

Ademco 685 EST 4/2*, Contact ID

FBII CP220 EST 4/2*, Contact ID

Osborne-Hoffman OH 2000 EST 4/2*, Contact ID

Radionics D6500 EST 4/2*

Silent Knight 9000 EST 4/2*

Sur-Gard MLR1, MLR2,

MCDI TLR, TLR+

* EST 4/2 is SIA DCS-02 P3 with the ability to transmit hexadecimal

event codes.

EST 4/2*, Contact ID

Industry Canada Information

NOTICE: This equipment meets the applicable Industry Canada Terminal

Equipment Technical Specifications. This is confirmed by the registration

number. The abbreviation, IC, before the registration number signifies that

registration was performed based on a Declaration of Conformity indicating

that Industry Canada technical specifications were met. It does not imply that

Industry Canada approved the equipment.

Before installing this equipment, users should ensure that it is permissible to

be connected to the facilities of the local telecommunications company. The

equipment must also be installed using an acceptable method of connection.

The customer should be aware that compliance with the above conditions may

not prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative

designated by the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the telecommunications

company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines, and internal metallic water

pipe system, if present, are connected together. This precaution may be

particularly important in rural areas.

Caution: Users should not attempt to make connections themselves, but

should contact the appropriate electric inspection authority, or electrician, as

appropriate.

NOTICE: The Ringer Equivalence Number (REN) for this terminal

equipment is 0.1. The REN assigned to each terminal equipment provides an

indication of the maximum number of terminals allowed to be connected to a

telephone interface. The termination on an interface may consist of any

combination of devices subject only to the requirement that the sum of the

Ringer Equivalence Numbers of all the devices does not exceed five.

FireShield Technical Reference Manual 2.9

Page 20

Installation

Connecting an RPM module

The Reverse Polarity Module (RPM) is an interface between

FireShield and a reverse polarity receiver. It provides offpremises signal transmission for systems that must comply

with NFPA requirements. When used as a reverse polarity

remote station transmitter, it can be connected to either a

single circuit (alarm or alarm and trouble) or up to three

circuits (alarm, supervisory, and trouble).

Note: For detailed information and wiring, refer to the RPM

installation sheet P/N 3100430.

Below are application diagrams for using the RPM.

Note: The RPM must be mounted in an MFC-A enclosure

immediately adjacent to the panel and in conduit.

Alarm transmitted only

FireShield

TB3

NO

C

TRBL

NC

NO

SUP

NO

ALM

C-

C+

24VOUT

+

From ALRM on RPM

(brown wire)

From COM on RPM

(black wire)

From +24 on RPM

(red wire)

Alarm and trouble transmitted on a single circuit

Note:

JP1 on the RPM must be OUT.

FireShield

TB3

From TRBL on RPM

(yellow wire)

TRBL

NO

C

NC

NO

SUP

NO

ALM

From ALRM on RPM

(brown wire)

C-

C+

From COM on RPM

24VOUT

+

(black wire)

From +24 on RPM

(red wire)

Alarm, supervisory, and trouble transmitted on separate

circuits

Note: JP1 on the RPM must be IN.

FireShield

TB3

From TRBL on RPM

(yellow wire)

TRBL

NO

C

NC

NO

SUP

NO

ALM

From SUPV on RPM

(orange wire)

From ALRM on RPM

(brown wire)

C-

C+

From COM on RPM

24VOUT

+

(black wire)

From +24 on RPM

(red wire)

2.10 FireShield Technical Reference Manual

Page 21

Installation

_

_

_

_

A

Connecting a CTM module

The CTM4.7 City Tie Module is an interface between the

control panel notification appliance circuit and a master box. It

provides off-premises signal transmission for systems that

must comply with NFPA requirements for Auxiliary

Protective Systems. The CTM4.7 activates a local energy fire

alarm box, which provides a 24 Vdc alarm signal (current

limited at 200 mA). The 4.7 KΩ end of line resistor required

by the NAC is built in to the CTM4.7.

Requirements

When connecting a CTM to the panel, the following hardware

and programming requirements must be met:

• The NAC used must be dedicated to CTM use only

• All alarm zones must be programmed to activate the

dedicated NAC

• The NAC used must not be programmed for Signal

Silence

Specifications

Power: Nominal 24 Vdc @ 200 mA

Municipal box operation: Nominal 24 Vdc

Maximum wiring resistance: 25 Ω

Trip current: 200 mA into 14.5 Ω coil

Maximum current: 300 mA

Standby current: 20 mA

Mounting: Single gang box

Operating environment

Temperature: 32 to 120 °F (0 to 49 °C)

Humidity: 93% RH, noncondensing

Panel in alarm condition

larm condition

Master box

CTM4.7

[2]

+

[1]

+

1

[5]

2

Municipal circuit

+

_

[4]

_

+

[3]

Notification

2

1

appliance circuit

Notes

[1] 200 mA into a 14.5 Ω trip coil max., loop resistance = 25 Ω

[2] This circuit is nonpower-limited and is supervised for

grounds and opens, but not shorts

[3] Supervised and power-limited

[4] NAC must be programmed for continuous signal

[5] CTM4.7 must be mounted in the same room as the panel

The following are wiring diagrams showing how the polarity

switches during an alarm condition.

Panel in normal condition

Normal condition

Master box

CTM4.7

_

+

[4]

+

_

[3]

Notification

1

2

2

1

[5]

+

[1] [2]

+

Municipal circuit

appliance circuit

FireShield Technical Reference Manual 2.11

Page 22

Installation

Connecting an auxiliary power supply

Aux power supplied by the panel cannot exceed 0.5 A. If more

than 0.5 A is required, you must use a compatible UL/ULC

listed fire alarm power supply.

When using an auxiliary power supply, you must connect the

-24 Vdc auxiliary terminal at the panel to the -24 Vdc output

terminal of the listed auxiliary power supply used to power

FireShield devices.

Note: For detailed wiring information, refer to the installation

instructions that came with the auxiliary power supply.

Aux. Power

FireShield

FACP

UL Listed

Aux. Power Source

+

To Devices

24 Vdc @ 0.5 A Max.

-

+

To Devices

Requiring Additional

Power

-

Installing the terminal shield

The terminal shields for the three, five, and ten zone panels

(model numbers ending in GC or GF) required for Canadian

installation, cover and protect the wire connections at the

terminal blocks.

To install the terminal shield:

1. Remove the four corner mounting screws from the circuit

board. Refer to the diagram below for location.

2. Mount the supplied standoffs to the four corner locations

where you removed the screws.

3. Mount the terminal shield to the standoffs using the

screws you removed in step 1. Refer to the diagram

below.

Standoff

2.12 FireShield Technical Reference Manual

Page 23

Chapter 3

T

Programming

Overview

ANNUN

TROUBLE

16 8 4 2 1

Bottom row of LEDs

BAT

TROUBLE

GND

FAULT

Binary numbers

WALK

TEST

SIGNAL

SILENCED

Program options and settings

The features and functions of FireShield can be customized

through programming. To customize the panel, you choose a

program option, then choose a setting for that option. This

chapter shows you how to program the panel.

Programming methods

FireShield panels can be programmed using either of two

methods.

First, you can use the panel’s LEDs and switches, with or

without an FSDACT installed.

Second, you can use a PC with an FSDACT installed. PC

programming requires an optional software package, the

FireShield Configuration Utility (model number FSCU). Refer

to the FSCU online help system for complete programming

instructions.

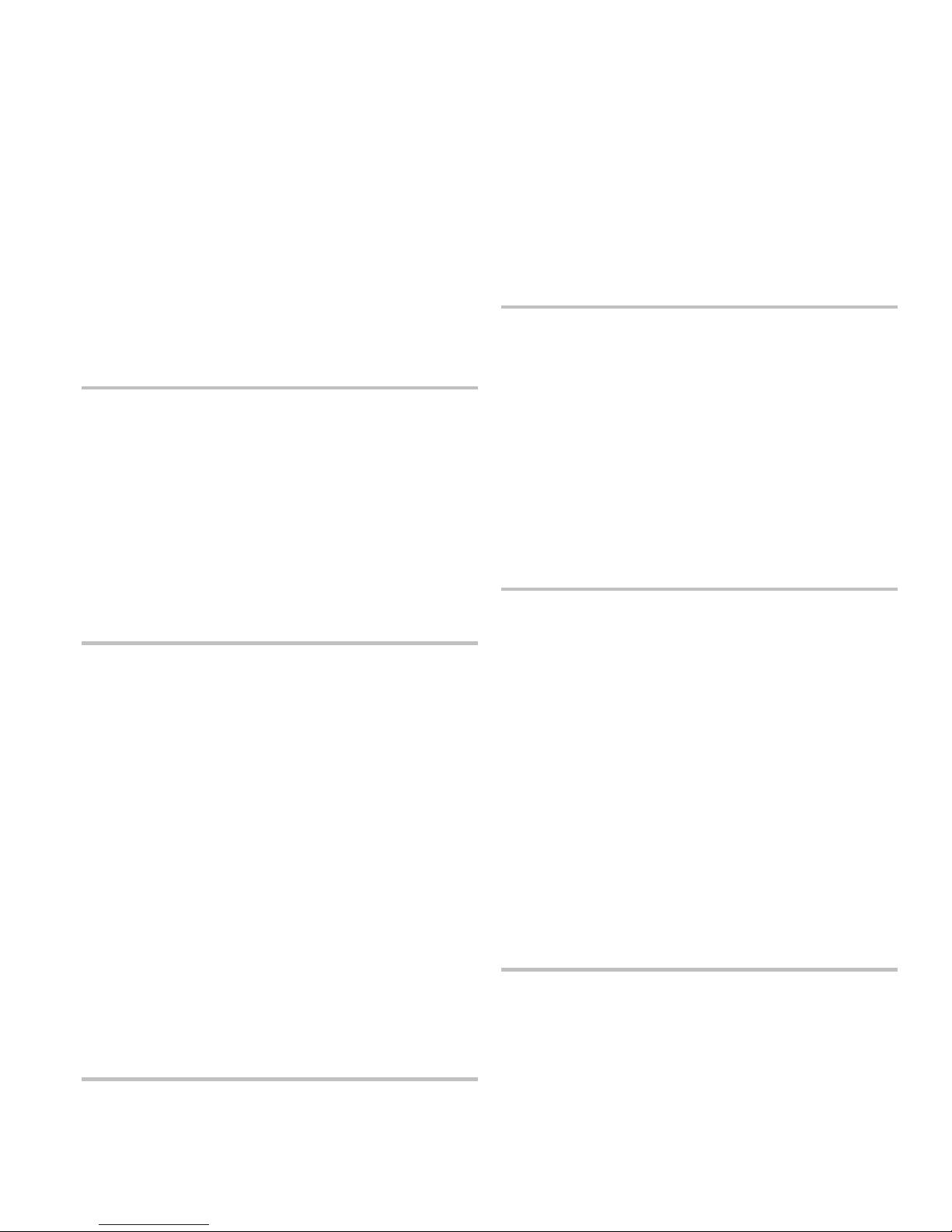

Programming LEDs

In programming mode, the top row of panel LEDs indicates

which program option is selected. Each LED is assigned a

binary number, and the total value of the top row equals the

option number. If you are not familiar with binary numbers,

you can simply match the pattern of the LEDs with the

programming instructions.

ALARM

16 8 4 2 1

Top row of LEDs

TROUBLE

SUP

Binary numbers

POWER DISABLE

FSDACT display

If you are using the optional FSDACT to program the panel,

each option and setting is displayed on the LCD display.

The top row of the LCD displays the program option, and the

bottom row displays the setting for that option. You can use

the programming buttons to step through the options and

select the settings you want.

Programming buttons

The panel buttons take on a different function when the panel

is in programming mode. The following table shows the

buttons and describes what they do in programming mode.

Button Description

REMOTE

DISCON-

NECT

WAL K

TEST

RESET

SIGNAL

SILENCE

& DRILL

PANEL

SILENCE

Selects the next program option. The top

row of LEDs and the FSDACT LCD change

to show the option selected.

Selects the previous program option. The

top row of LEDs and the FSDACT LCD

change to show the option selected.

Selects the next setting for the current

option. The bottom row of LEDs and the

FSDACT LCD change to show the setting

selected.

Selects the previous setting for the current

option. The bottom row of LEDs and the

FSDACT LCD change to show the setting

selected.

Saves the setting you selected for the

current program option.

Each option has a number of possible settings. The bottom

row of panel LEDs indicates which setting is selected for the

current option. The settings are detailed below in “Custom

programming the panel.” Again, each LED is assigned a

binary number, and the total value of the bottom row equals

the setting number.

The values of all LEDs lit on a single row are added to

determine the option or setting number. For example, if the

Gnd Fault, Walk Test, and Signal Silenced LEDs are lit, the

value is 7 (4+2+1). This means that setting seven for the

current option is selected.

FireShield Technical Reference Manual 3.1

Page 24

Programming

Using the factory default settings

2. Press Remote Disconnect to select the Load Defaults

The panel comes from the factory programmed with a predefined set of defaults. The default settings are:

Option Default setting

Find annunciators None found

Auto signal silence timer None

Aux power reset No

Signal silence/reset inhibit timer None

IDC zone types Alarm (unverified)

All IDCs activate all NACs

IDC class Class B

NAC class Class B

NAC output (NAC1 – NAC4) GENESIS

NAC silenceable Silenceable

For a more detailed list of defaults, see Appendix B,

“Programming templates.”

If you want to use the factory programmed settings as they

are, you do not need to perform any programming. If you do

not want to use the panel’s default settings, refer to “Custom

programming the panel.”

Note: You must run the Find Annunciators program option

after adding or removing a remote annunciator. The remote

annunciators will not operate properly until the panel detects

them. These include the FSRSI, FSRZI-A, and FSRRM.

Reloading the factory default settings

When you reload defaults, you return the panel to the factoryprogrammed settings. The primary purpose for loading the

defaults is to return the panel to its original settings if the need

arises. You can then start fresh by using these settings or

custom program one or more options.

Program option

Top LEDs/LCD

Load Defaults

Key: = OFF, = ON

To reload the default settings:

1. Install program jumper PRG.

Setting

Bottom LEDs/LCD

No

Yes

Description

Do not load default

settings

Load default settings

3. Press Reset to select Yes, the setting to reload the factory

4. Press Panel Silence to perform the reload.

The trouble buzzer sounds a long beep as confirmation.

5. Exit program mode by removing the program jumper or

Using an FSDACT

If you have an FSDACT connected to your system, it must be

recognized by the panel before programming. Also, if you

remove an FSDACT from your system, it must be removed

from the panel’s memory.

To do this, install the program jumper (PRG), then remove the

program jumper. This allows the panel to recognize that an

FSDACT was installed or removed from the system.

Custom programming the panel

FireShield functionality can be custom programmed when the

factory defaults do not meet your needs. The following

options can be custom programmed:

1. Load defaults

2. Find annunciators

3. Auto signal silence timer

4. Aux power reset

5. Signal silence/reset inhibit timer

6. IDC zone types (and NACs that activate)

7. IDC class

8. NAC class

9. NAC output

10. NAC silenceable

11. Program FSDACT (if installed)

Tip: We recommend that you program the options in the order

they are listed. This matches the order of the LEDs as you

increment through each option. The lighting pattern of the

LEDs corresponds to the program option you are

programming and follows the binary number pattern

associated with each row of LEDs.

program option.

default settings.

continue to the next topic to custom program the panel.

Refer to “Custom programming the panel” for more

information.

The panel common LEDs flash and the panel enters a

trouble state. The trouble buzzer sounds.

3.2 FireShield Technical Reference Manual

Page 25

Programming

Getting started

You should complete the programming templates found in

Appendix B before you program the panel. NFPA 72 requires

that you keep a copy of these sheets on file.

The following table and procedures prepare the panel for

custom programming.

1. Program load defaults

In this topic, you do not need to load the defaults. To load the

default settings, see the topic “Reloading the factory default

settings,” above.

Program option

Top LEDs/LCD

Load Defaults

Key: = OFF, = ON

To get started:

1. Install program jumper PRG.

Setting

Bottom LEDs/LCD

No

Yes

Description

Does not load default

settings

Loads the default settings

next option or Walk Test to return to the previous option. To

save your changes, you must press Panel Silence before

advancing to the next option.

2. Program find annunciators

Description: Verifies and logs each remote annunciator

(FSRSI, FSRZI-A, and FSRRM) connected to your system.

Notes

• This process may take up to 40 seconds. During this time

do not remove the program jumper. If the program

jumper is removed, you must power down and power up

the panel to get back into the programming mode.

• The Find Annunciators program option must be

performed if you are using remote annunciators (FSRSI,

FSRZI-A, or FSRRM) or if you add or remove a remote

annunciator from your system.

Program option

Top LEDs/LCD

Find Annunc

Setting

Bottom LEDs/LCD

xx now on bus

Find devices

Description

Does not look for devices.

Logs all devices

connected to the panel.

The top rows of LEDs flash and the panel enters a trouble

state. The trouble buzzer sounds.

2. Press Remote Disconnect to advance to the first

programming option (Load Defaults).

The LEDs stop flashing, the Disable LED (binary value 1)

lights, and “Load Defaults” is displayed on the FSDACT

LCD display (if installed). The trouble buzzer turns off;

however, the panel is still in a trouble state.

The Signal Silenced LED is on, showing that setting No is

selected.

3. You can press Reset to step through the settings available

for this option (No or Yes). Notice how the Signal

Silenced and Walk Test LEDs switch to indicate the

different options.

You are now ready to program your panel.

Notes

• You can exit program mode at any time by removing the

program jumper. All saved program selections remain

intact. When the jumper is removed, the panel resets.

• If no buttons are pressed for 90 seconds, the system

returns to the initial program start state with the top row

of LEDs flashing and the buzzer sounding.

To program the panel

If no programming is required for a particular option, it can be

skipped. You can use Remote Disconnect to advance to the

To find remote annunciators:

1. Press Remote Disconnect to select the program option.

If an FSDACT is installed, the lower line of the LCD

displays “xx now on bus” where xx is the number of

devices (between 0 and 12).

2. Press Reset to select Find devices.

3. Press Panel Silence to begin finding devices.

The bottom row of LEDs flashes and the second line of

the LCD displays “Finding devices” while the panel

searches for all remote annunciators.

When the search is complete, the bottom row of LEDs

shows (in binary) the number of devices found. The

second line of the LCD displays “was xx now yy.” The

number of devices found (now) should equal the number

of devices installed. If not, there is a wiring or device

problem.

4. To end programming now, remove the program jumper.

Otherwise, continue with “Program auto signal silence

timer,” below.

3. Program auto signal silence timer

Description: A timer that, when programmed, automatically

silences the NAC circuits 20 minutes after the last alarm event.

FireShield Technical Reference Manual 3.3

Page 26

Programming

Program option

Top LEDs/LCD

Auto Sig Sil

Setting

Bottom LEDs/LCD

None

Sil aft 20 mins

Description

NACs stay on until Signal

Silence is pressed

NACs automatically turn

off after twenty minutes

To program the auto signal silence timer:

1. Press Remote Disconnect to select the program option.

2. Press Reset to select your setting.

3. Press Panel Silence to save.

The trouble buzzer sounds a long beep as confirmation.

4. Program aux power reset

Description: Causes a temporary interruption of aux power

when Reset is pressed. This is so that four-wire smoke

detectors can be reset. If this is not programmed, pressing

Reset has no effect on the aux power output.

Caution: This option must be set to No (continuous) if remote

annunciators or relays are being used.

Program option

Top LEDs/LCD

Aux Power Reset

To program aux power reset:

Setting

Bottom LEDs/LCD

No

Yes

Description

Continuous 24 Vdc on

AUX PWR terminals

Resettable 24 Vdc on

AUX PWR terminals

1. Press Remote Disconnect to select the program option.

2. Press Reset to select your setting.

3. Press Panel Silence to save.

The trouble buzzer sounds a long beep as confirmation.

5. Program signal silence/reset inhibit timer

Description: Programs all NACs with a one-minute silence

inhibit. This means that, the NACs cannot be silenced and the

panel cannot be reset during their first minute of activation.

Program option

Top LEDs/LCD

Sig Sil Inhibit

Setting

Bottom LEDs/LCD

None

Inhibit one min

Description

Signal Silence/Reset

operational immediately

after NACs turn on

Signal Silence/Reset

operational one minute

after NACs turn on

To program the signal silence/reset inhibit timer:

1. Press Remote Disconnect to select the program option.

2. Press Reset to select your setting.

3. Press Panel Silence to save.

The trouble buzzer sounds a long beep as confirmation.

6. Program IDC zone types

Description: Selects the type and functionality of each IDC.

Note: See the FireShield ULI and ULC compatibility lists P/N

3100468 for restrictions.

Default: Alarm - unverified, with all NACs active