Page 1

SENTROL

AP633/AP643

Passive Infrared Detectors

Installation Instructions

INTRODUCTION FEATURES

The AP633 and AP643 offer the detection of motion for

infrared targets in selectable ranges extending 40 ft., 80 ft.

and 200 ft.(12 m, 24 m, and 60 m). The detector’s sensitivity

may be programmed to suit most environmental applications. Aritech’s traditional viewing angle selection (mirror

blocking) allows the installer to select and delete any portion

of the coverage pattern to customize the optical performance

of the unit. In addition, the mounting plate of the sensor is

equipped with precise adjusting screws to allow the installer

to alter the horizontal viewing point as much as 2 degrees to

the left or right, above or below the unit. These features

combine to make this passive infrared sensor the most stable

detector available for commercial and industrial installation

needs in the security industry today. The more sophisticated

model AP643 enhances standard operation with options

such as alarm memory, unit to unit double check, eye to eye

check, and first in alarm indication as well as remote control

of the walk test mode.

SPECIFICATIONS

Input Power....................................................... 9.5 –15 V DC

Peak to Peak Ripple ................................... 2 V max. (@12V)

Current Consumption ................... 20mA Nominal 35mA Max

Contact Rating.............................Alarm–100 mA @ 28 V DC

Tamper–100 mA @ 28 V DC

Coverage Pattern ........12 selectable patterns using snap-on

blockers (see last page for patterns)

Mounting Height ....................... 6 ft. to 10 ft. (1.8 m to 3.0 m)

Environmental Limitations .. 0°F to +131°F (–18°C to +55°C)

Dimensions ..................................6.30 in. x 4.13 in. x 2.95 in.

(160 mm x 105 mm x 75 mm)

T

S

I

L

U

N

D

E

R

U

W

R

I

T

L

E

R

S

L

A

B

LISTED

• Integral Coverage 200 ft. max. (60 m)

• Precision Mirror Optics

• Step Focus Curtain

• 12 Different Protection Patterns

• Form C Contacts

• Calibrated Sensitivity

• Measures And Adjusts To Temperature Changes

• UL and ULC Listed

AP643 Additional Features

• Eye To Eye Checker Mode

• First To Alarm Memory

• Programmable Double Checker Mode

• Remote Control Of Walk Test LED

• UL and ULC Listed

DETECTION HAZARDS

Planning Installation of the Unit:

Avoid these sources of disturbance:

• Sunlight or vehicle headlights shining directly onto the

detector.

• Heat sources or mobiles in the field of view.

• Strong air drafts blowing onto the detector.

• Animals in the field of view.

• Insects in the housing or on the face of the unit.

• Objects or circumstances which may cause rapid

temperature changes in the field of view.

• Very strong sources of RF energy and induction of

electrical noise.

D

E

B

Y

A

D

A

N

A

C

F

O

S

E

I

R

O

T

O

A

R

Page 2

MOUNTING TIPS

SENSOR HOOKUP

• This sensor is for interior applications only.

Do not mount outside.

• Do not block the viewing angle of the sensor.

• Mount this and all passive infrared sensors so that would

be intruders will cross the pattern of detection at 90°

(or as close to 90° as possible).

• Seal all openings and cable entries.

• When mounting sensor on masonry surfaces use appropriate moisture barrier.

• Use of the vertical adjustment screw may result in a

reduction of range.

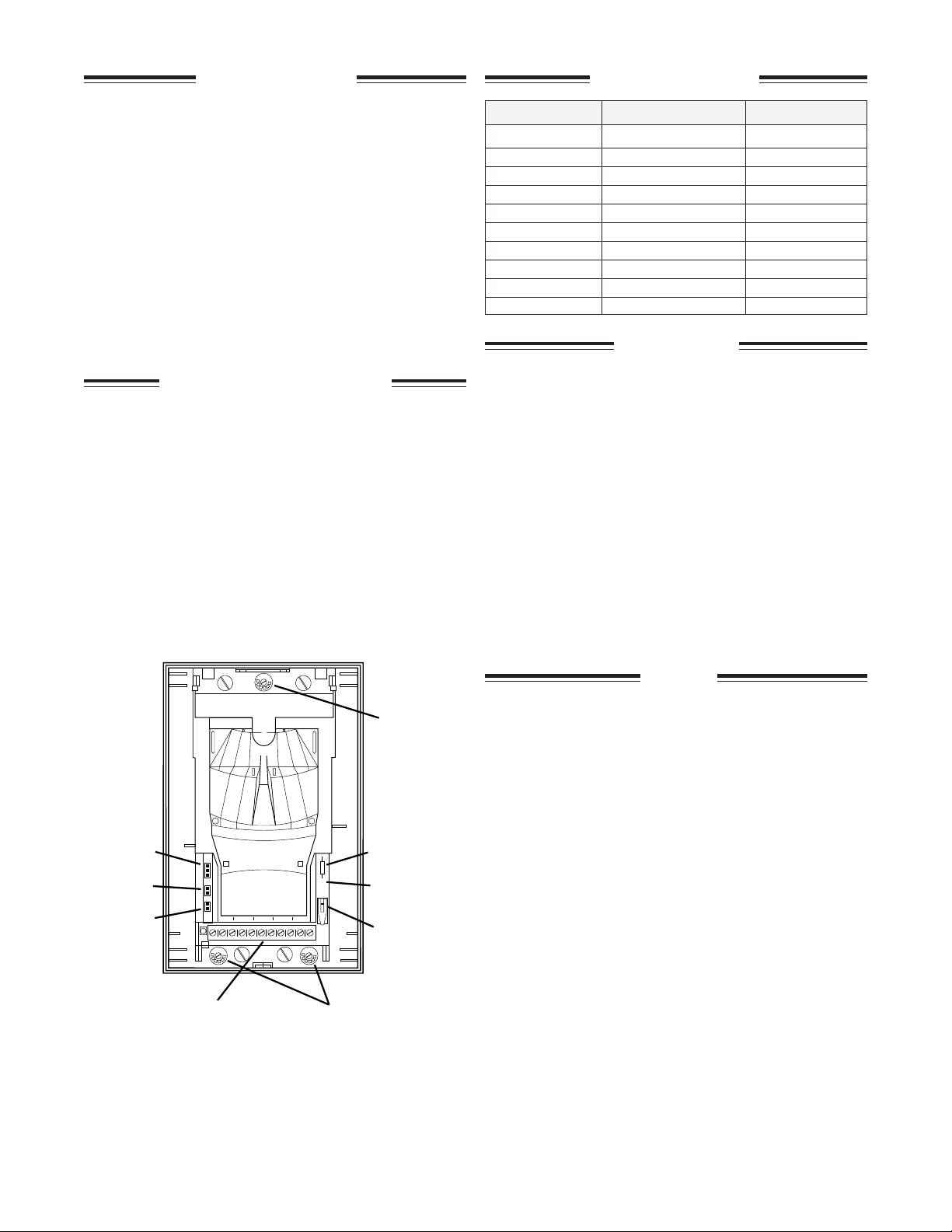

MOUNTING THE SENSOR

The ideal mounting height for this sensor is 6 ft. to 10 ft.(1.8

m to 3.0 m). Loosen the retaining screw and lift the front

cover off of the unit. Using an awl or similar punch type

device, remove the necessary knockouts and create a path for

the cables to enter the backplate. Remove only those

knockouts which you plan to use. Pull cable through the

entries and level the backplate on the wall. Mark the screw

holes and insert 8-32 x 2 inch screws and tighten until

secure. Be careful not to over-tighten the backplate as you

may wish to adjust the viewing angle after walk testing. It is

important to leave a 1/2 inch clearance space between the top

of the sensor and any surfaces above it (i.e. ceiling, shelves

or cabinets, etc.). This will allow the cover to be replaced

with ease.

TERMINAL AP633 AP643

#1 (–) Negative (–) Negative

#2 (+) Positive (+) Positive

#3 N.C. Contact N.C. Contact

#4 Common Common

#5 N.O. Contact N.O. Contact

#6 Tamper N.C. Tamper N.C.

#7 Tamper N.C. Tamper N.C.

#8 Spare (not used) Spare

#9 N/A Alarm Latch

#10 N/A Walk Test

USAGE TIPS

Both units are equipped with a Form C alarm initiation

circuit (Terminals 3,4, and 5) and a closed loop tamper

circuit (Terminals 6 and 7). The installer may wire these

circuits in series if desired. If the control panel requires class

B supervision, the spare terminal (# 8) may be used to

anchor the EOL device. This allows the installer to place the

EOL device in the sensor without the use of splice connectors. Some of the advanced detection features of the AP643

(discussed later) require an additional switched voltage from

the control. If the protective loop and the control panel

power supply share a common negative, both may use the

same conductor. This will free up a single conductor for use

in one of the advanced features.

Detectors must be connected to a UL listed control or

power supply which will provide a minimum of four

hours standby power.

Jumper A

Jumper B

Jumper C

#2 to #10 Jumper

Factory Installed

AP643

Terminal 9 requires a +12 V DC input during the armed

Viewing Angle

Adjustment

(tighten or

loosen screw to

adjust)

cycle to latch the LED of any violated detectors. Terminal 10

requires a +12 V DC input while the walk test LED response

is desired. The unit has a factory installed jumper at Terminals 2 and 10. This jumper must be removed if any of the

advanced detection (Alarm Memory, First to Alarm, etc.)

features are to be used.

Eye to Eye

Jumper

A

B

C

2

8

1046

(AP643 Only)

Jumper D

(AP633 only)

Tamper

Notes:

1. The AP633 uses pin jumper D to enable/disable the walk

test LED. The pin cover connects to both pins to enable

this feature.

2. This unit uses a 33Ω (ohm) current limiting resistor for

transient protection on the protective loop. It is important

to consider this value when calculating loop resistance.

Viewing Angle

Adjustment

Page 3

SENSITIVITY

The sensor uses a unique signal processing method known as

Dynamic Data Discrimination. “4D” allows the sensor to

analyze the size and shape of a waveform produced in the

detector and determine whether the signal is generated by an

intruder or an environmental source. The sensor has three

field changeable settings of sensitivity for “4D”: High

Sensitivity, Increased Sensitivity and Standard Sensitivity.

The installer may select standard sensitivity by moving the

pin connector of jumper A to cover the lower two (2) of the

three (3) pins. High sensitivity is selected by inserting the pin

connector in such a way that it only makes contact with one

of the three (3) pins of jumper set A. Increased sensitivity is

selected by inserting the pin connector of jumper set A so

that the upper two (2) pins are covered.

Standard Sensitivity should be selected for normal and all

40-foot-wide angle applications. For use with patterns E,

G, and H only.

High Sensitivity should only be used in hazard free, high

security applications. For use with patterns A through L.

Increased Sensitivity should be used in 80-foot-wide angle

areas, 40-foot curtain only or long range applications. For

use with patterns A through L.

ZONE LOCATION TESTING

This sensor is equipped with a test feature which goes

beyond walk testing and allows the installer to identify

exactly each zone of coverage. This advantage allows the

installer to avoid splitting a zone of coverage between two

areas of dissimilar background infrared energy levels, such

as a metal door and a freezer. By inserting the pin connector

so that both of the pins in jumper set B are covered, the zone

location test mode is active. After activating this mode, walk

without stopping across the coverage pattern and observe the

sensor. Each time the green LED illuminates, you enter a

zone. If the green LED goes out, you are in the center of a

zone (between two pyroelectric elements) or you are between

two zones. By connecting the armed output of the control

panel (+12 VDC) to Terminal 9 of all detectors connected on

this run (up to 40 units), the LED will latch in alarm any and

all sensors which were activated during the armed period.

After determining all zone locations, return to the normal

mode by inserting the pin connector so that the two pins of

jumper set B are not connected.

ALARM MEMORY SETTING–AP643

By connecting the armed output of the control panel

(+12 VDC) to Terminal 9 of all detectors connected on this

run (up to 40 units), the LED will latch in alarm any and all

sensors which were activated during the armed period.

The jumper from Terminal 2 to Terminal 10 must be

removed after walk test to enable this feature.

FIRST TO ALARM SIGNAL–AP643

An added feature to the Alarm Memory Setting is the First to

Alarm Signal. By connecting Terminal 10 of the first sensor

on the run to Terminal 10 of subsequent sensors, as well as

wiring described in Alarm Memory Setting, the first unit

activated in an armed cycle will indicate activation by

flashing. Subsequently activated sensors will annunciate by a

solid indication on the walk test LED.

The jumper from Terminal 2 to Terminal 10 must be

removed after walk test to enable this feature.

FIRST TO ALARM INDICATION–AP643

Z1100 J-16 #8 (Yellow) Through Auxiliary Relay

1st

Control

+12 V

Armed Output

Apply on arming system

Remove on disarming

NOTE: Avoid viewing customer exit path with this application

#9

#10

2nd 3rd 4th

Up to 40 Sensors

DOUBLE CHECKER MODE–AP643

The Double Checker Mode is a special discrimination

method in which a valid alarm signal will be given only

when a minimum of 2 detectors have recognized an event or

when the same sensor detects 2 events within a specific time

frame. This feature will allow the installer to station 2 or

more detectors in a premises along a projected path of

intrusion. Should the sensors see any 2 events within a 2

minute time period then the violated sensors will activate

the control panel. To select this mode of operation, insert

the pin connector of jumper set C so that both pins are

disconnected. (Wire same as First to Alarm Indication).

Not for use in UL installations.

Settings: Increased sensitivity, walk test off, eye to eye

not cut, jumper 2 to 10 removed.

EYE TO EYE CHECKER–AP643

In extremely hazardous environments or installations

requiring absolute accuracy of an alarm, dual detector

verification may be desired. By cutting a special compo-

nent on the sensor and aligning the viewing angle of 2

sensors so that they view a common area, the sensors will

only activate the control if both share a violation within a

short time frame (10 sec.). This offers an unparalleled

accuracy of detection. An intruder must violate the coverage

pattern that the 2 sensors share in common. (Wire same as

First to Alarm Indication).

For use in UL installations, protection patterns must

overlap and provide detection by both sensors per UL

standard walk test procedures.

Settings: High or increased sensitivity, walk test off,

double checker off, eye to eye on.

ALARM MEMORY WIRING

Z1100 J-16 #8 (Yellow) Through Auxiliary Relay

Control

+12 V

Armed Output

Apply on arming system

Remove on disarming

NOTE: Avoid viewing customer exit path with this application

1st

#9

#10

Up to 40 Sensors

2nd 3rd 4th

EV on.

EV on.

curtain

EV off.

TEST off.

TEST on.

CHECKER off.

CHECKER on.

A 1

A 2

A 3

B 4

B 5

C 6

C 7

A

B

C

21046

8

EYE TO EYE off.

EYE TO EYE on.

D8

D9

Page 4

REMOTE CONTROL OF WALK TEST LED

1

4

6

If your control panel provides a switchable +12 V output which can be activated and de-activated by the user or installer, this

can be used as the ‘walk test enable’ as shown. Select a timed access (through auxiliary relay) output from the Z1100 System

1 or System E for this feature.

Control

+12 V

#9

#10

2nd 3rd 4th

1st

Up to 40 Sensors

Walk test is active as long as +12 V is present.

Link between terminals 2 and 10 must be removed.

PATTERN OPTIONS AS VIEWED BY THE SENSOR

Removes Right 40 ft., Wide Angle Pattern ➀

Removes Left 40 ft., Wide Angle Pattern ➁

Removes Left 80 ft., Wide Angle Pattern ➂

12

3

4

Removes Right 80 ft., Wide Angle Pattern ➃

Removes 80 ft. Center Pattern Only ➄

Removes 200 ft. Long Range Pattern Only ➅

INSTALLATION NOTE: Be certain to locate field of view

carefully for required detection. As with all PIR sensors, there is

no detection between fields of view. Installation must be tested

one or more times yearly.

Example of factory setting

A

6

40 ft. 80 ft.

D

B

2

1

4

3

6

E

2

3

4

3

5

6

40 ft. 80 ft.

G

1

4

3

H

5

6

40 ft.

J

K

6

2

4

3

5

6

40 ft. 80 ft.

40 ft.

40 ft.

C

F

I

L

5

6

Curtain Pattern

2

1

4

3

5

6

40 ft. 80 ft.

40 ft.

40 ft. 80 ft. 200 ft.

2

1

4

3

40 ft. 80 ft. 200 ft.

The unit is to be connected to a UL Listed power supply or control unit capable of providing a minimum 4 hours of standby power.

The equipment should be installed in accordance with NFPA 70. The unit shall be tested at least once a year.

CORPORATE HEADQUARTERS

12345 SW Leveton Dr.

Tualatin, OR 97062

Tel.: 503.692.4052 F ax: 503.691.7566

U.S. & Canada: 800.547.2556

Technical Service: 800.648.7424

SENTROL

FaxBack: 800.483.2495

1

4

40 ft. 80 ft. 200 ft.

2

3

40 ft. 80 ft. 200 ft.

Sentrol reserves the right

to change specifications

without notice.

©1998

P–3412-0398

15597 Rev A

Loading...

Loading...