Page 1

AP450 Motion Sensors

U

L

¤

C

LISTED

US

Models: AP450, AP450A

Installation Instructions

Preliminary

Description

The AP450 sensors are passive infrared motion detectors

that are highly sensitive to moving infrared sources. They

feature superior immunity to RFI, vibration, static

electricity , temperature changes, and other false alarm

sources.

The sensors provide jumper-selectable sensitivity, range,

and LED settings. The masks included allow the coverage

pattern to be modified for a wide variety of applications.

Parts

The following parts are included:

• AP450 or AP450A sensor

• Three factory-installed jumpers

• T wo plastic masks

• Sheet of adhesive masking labels

• Cardboard undercrawl window mask

• One screw to secure the housing cover

Selecting a Mounting Location

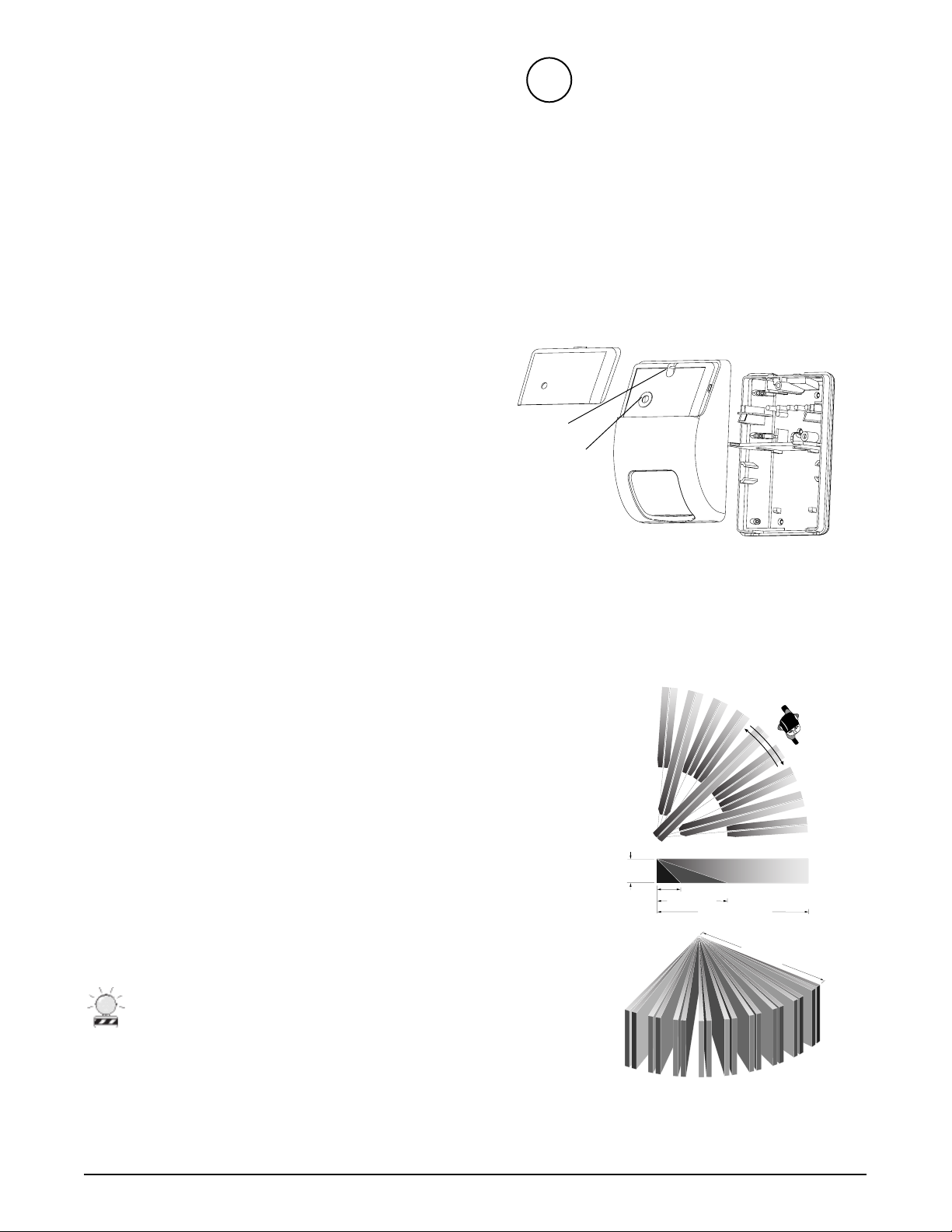

Install the unit so that the expected movement of an intruder will

be across the detection pattern. See Figure 2.

A void possible false alarm sources such as:

• Direct sunlight on the sensor

• Heat sources in the field of view (heaters, radiators, etc.)

• Strong air drafts onto the sensor (fans, air conditioning etc.)

• Large animals (dogs, cats) in a field of view

The unit should be mounted at a height of 6 to 10 feet

(1.8 to 3.0m).

Cover plate

Housing screw

10.0 ft.(3.0m) maximum

8.0 ft.(2.4m) typical

6.0 ft. (1.8m) minimum

LED

Figure 1. Exploded view

Cover

8 ft. (2.4m)

25 ft. (7.6m)

Base

50 ft. (15.2m)

50 ft. (15.2m)

CAUTION

You must be free of static electricity before handling

sensor circuit boards. Touch a grounded, bare metal

surface before touching circuit boards or wear a

grounding strap.

Figure 2. Detection pattern

AP450 and AP450A Motion Sensors

1

Page 2

2

1

21

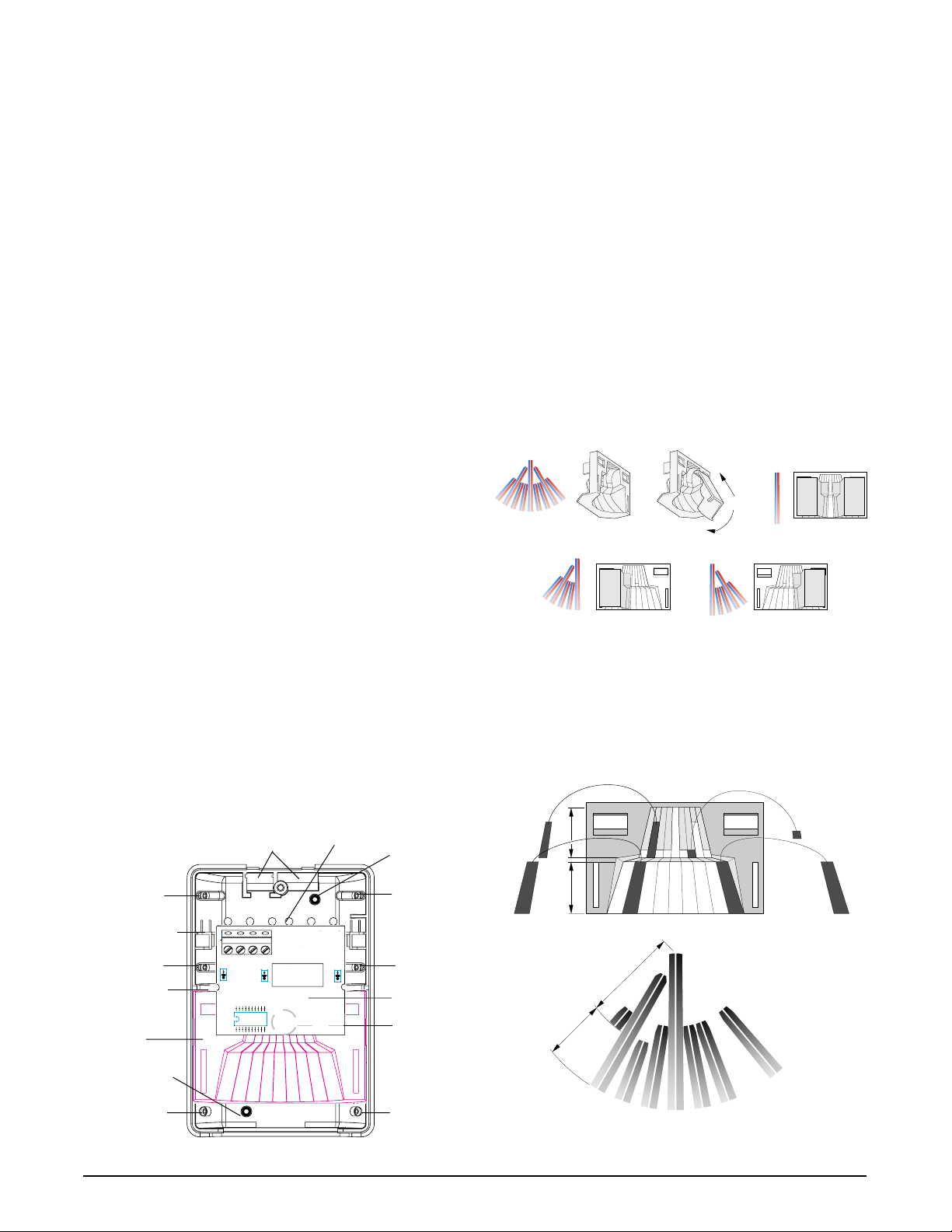

Mounting the Sensor

1. T o remove the cover plate, insert a flat-bladed screwdriver

between the notch on the top of the cover plate and the

cover. Pry up the cover plate. See Figure 1.

2 . Remove the housing screw that holds the cover to the

base, insert a flat-bladed screwdriver into the slot above

the screw hole. Pry the cover off the base. See

Figure 1.

3. Pull up on the top edge of the electronics module while

rocking down on the lower edge to remove the module

from the base. Be careful not to touch the pyroelectric

sensor located on the bottom of the module. See Figure 3.

4. Select mounting holes for corner or wall mounting. Use

the base as a template for marking screw hole locations

on the wall. See Figure 3.

5. Strip the cable for 2 inches (5cm) and pull it through the

cable entry hole(s) and strain relief. Make sure that the

cable has slack in the wall. See Figure 3.

6 . Use screws and wall anchors, if necessary, to attach the

base to the wall.

7 . Select the appropriate coverage pattern. See Selecting the

Coverage Pattern.

8 . Replace the electronics module by lining up the notches

on the module with the module notch guides and press

the top of the module down until it snaps into the module

guides. See Figure 3.

9. Strip 1/4 inch (0.6cm) of insulation from each wire. Insert

each wire into the appropriate terminal and tighten

screws. See Figure 7.

10 . Set the sensitivity, range and LED jumpers for the

application desired. See Figure 7 and Setting the

Sensitivity, Range and LED.

11. To replace the cover, insert the closing tabs at the bottom

of the cover into the guides at the bottom of the base and

snap the cover down. Insert the screw. Fit the hole in the

cover plate over the LED and snap the cover plate into

place. See Figure 1.

Selecting the Coverage Pattern

The coverage pattern for the unit can be modified to fit specific

applications by masking off mirror curtains. Curtains should be

masked to avoid sources of false alarms, such as heaters, air

conditioners, and windows.

If necessary , use one or more of the following methods to

modify the coverage pattern:

• Use one or both of the plastic masks provided to mask off

large areas of coverage as shown in Figure 4.

• Mask the appropriate mirror curtains with the adhesive

labels provided. See the example shown in Figure 5. Do

not use sharp objects to remove unwanted labels. If

necessary , carefully peel the label off.

• Use the cardboard undercrawl window mask to improve

false alarm immunity in the presense of objects within 5

feet (1.5m) and directly under the sensor. See Figure 6.

Figure 4. Plastic masks

2

Corner mount

knockout

Module guide

Corner mount

knockout

Module notch

guide

Mirror

Flat wall mount

knockout

Corner mount

knockout

Cable entry

holes

Figure 3. Base

Cable strain

relief

Flat wall mount

knockout

Corner mount

knockout

Corner mount

knockout

Electronics

module

Pyroelectric

sensor

Corner mount

knockout

A

19

2 34567 8

1

B

B

9

8

2 3456789

A

7

6

Figure 5. Adhesive labels

1

2

3

4

5

AP450 and AP450A Motion Sensors

Page 3

AP450 (Form C)

0V +12V

NC NOC

ALARM

10Ω

TAMPER

LED/

SPARE

LED

7.9 ft.

(2.4m)

5.0 ft.

(1.5m)

Figure 6. Cardboard undercrawl window mask

Setting the Sensitivity, Range, and

LED

The unit provides three jumpers to set sensitivity (J1), range

(J2) and LED (J3). See Figure 7.

Sensitivity (J1)

BI = Bi-Curtain Mode (factory default). Increases false alarm

immunity in smaller areas. Requires the intruder to pass

through two curtains to trigger an alarm. Do not use for single

curtain applications or ranges under 5 feet (1.5m).

STD = Standard Sensitivity . Use for most wide-angle or singlecurtain applications. Requires the intruder to pass through

only one curtain to trigger an alarm.

J1 J2

BI

STD

SENS

AP450A (Form A)

0V +12V

J1

50FT

BI

STD

33FT

SENS

50FT

33FT

RANGE

NC COM

10Ω

J2

RANGE

Figure 7. Wiring and Jumpers

OFF/

REMOTE

ON

OFF

ON

J3

LED

J3

LED

Range (J2)

Program J2 for range under 33 feet (10.1m, factory default for

AP450A) or to 50 feet (15.2m, factory default for AP450). It is

important to program the sensor correctly for optimum

sensitivity. Walk test the sensor regularly by walking across

the fields of view and checking that the LED lights and that the

opening relay is indicated back at the control panel.

LED (J3)

Y ou can change the LED from enabled (factory default) on the

AP450 sensor (does not apply to the AP450A) to remote

controlled, by moving jumper J3 to the OFF/Remote position.

The LED can then be enabled remotely by applying a 0V

potential to terminal 8.

Pet Alley Application

T o create a detection-free area close to the floor, mount the unit

3.5 feet (1.1m) above the floor, upside down (sensor window

towards the ceiling). The cardboard undercrawl window mask

should be in place to reduce exposure to the ceiling.

As shown in Figure 8, pets are free to roam below the

mounting height of the unit without causing an alarms.

3.5 ft.

(1.1m)

AP450 and AP450A Motion Sensors

Figure 8. Pet Alley

3

Page 4

Operation Information

x

The relay contacts will open and the LED will turn on (if

enabled) every time an alarm occurs. The unit should be

allowed to settle for at least one minute after power-up before

walk testing. When walk testing, walk across the curtains, not

directly toward or away from the unit.

Maintaining the Sensor

When installed and used properly, the unit provides years of

service with minimum maintenance. T o ensure proper

operation, you should walk test the unit annually.

Clean the inside of the unit with a soft bristled brush or

compressed air. Clean the outside with a damp (water) cloth as

needed to keep it free of dust and dirt. Always test the unit

after cleaning.

Dimensions

4.0"

10.2cm

Specifications

Input voltage .............................................9 to 15VDC (12V nom.)

Peak to peak ripple ........................................... 2V max at 12VDC

Current consumption .................................................... 15mA max.

Mounting height............................................ 6' to 10' (1.8m to 3m)

Tar get speed range......................... 0.7' to 13.0' (0.2m to 4.0m)/sec.

Relay rating w/10 ohms in series........................... 50mA at 28VDC

Alarm time ...................................................................2.5 sec. min.

Tamper switch rating ..........................................100mA at 28VDC

Operating temperature ....................... 0° to 131° F (-18° to 55° C)

Relative humidity.................................. 93% max. non-condensing

Weight ............................................................... 4.25 ounce (120 g)

Dimensions:

Width..................................................................... 2.8" (7.1cm)

Depth .................................................................... 2.0" (5.1cm)

Height ................................................................. 4.0" (10.2cm)

Number of curtains ....................................................................... 9

View angle ................................................................................. 89°

Detection range ......................................................50' (15.2m) max.

Housing meets (with sealed cable entry)................................ IP301

Listings .............................................................................C-UL US

2.8"

7.1cm

2.0"

5.1cm

Ordering Information

Model Number Loop Ty pe Electrical Configuration Comments

AP450A Closed Normally Closed Form A

AP450 Open or Closed Normally Closed or Form C w/tamper

Normally Open (SPDT)

The unit shall be connected to a UL Listed power supply or control unit capable of providing a minimum of 4 hours standby power.

The equipment shall be installed in accordance with NFPA 70. The unit shall be tested at least once a year.

GE Interlogi

www.GE-Interlogix.com

© 2002 GE Interlogix

4

12345 SW Leveton Drive

Tualatin, OR 97062

Phone: 503-692-4052

USA & Canada: 800-547-2556

T echnical Service: 800-648-7424

FaxBack: 800-483-2495

1038277 Rev A 07/02

AP450 and AP450A Motion Sensors

Loading...

Loading...