GE Security ACURT2-EX-MU, ACURT2-EX-PP-GE, ACURT2-EX-PP, ACURT2, ACURT4-EX-PP Installation Manual

...Page 1

TOPAZ ACURT2 & ACURT4

Hardware Installation Guide

Page 2

Copyright Copyright © 2010, UTC Fire & Security. All rights reserved.

This document may not be copied or otherwise reproduced, in whole or in part, except as

specifically permitted under US and international copyright law, without the prior written

consent from UTC Fire & Security, 9 Farm Springs Road, Farmington, CT 06034-4065.

Document number 460933001G (December 2010).

Disclaimer THE INFORMATION IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT

Trademarks and patents Trade names used in this document may be trademarks or registered trademarks of the

Intended use Use this product only for the purpose it was designed for; refer to the data sheet and user

FCC compliance This equipment has been tested and found to comply with the limits for a Class A digital

Modems The Part 68 rules require the following or the equivalent information be provided to the end

NOTICE. UTC FIRE & SECURITY ASSUMES NO RESPONSIBILITY FOR

INACCURACIES OR OMISSIONS AND SPECIFICALLY DISCLAIMS ANY LIABILITIES,

LOSSES, OR RISKS, PERSONAL OR OTHERWISE, INCURRED AS A CONSEQUENCE,

DIRECTLY OR INDIRECTLY, OF THE USE OR APPLICATION OF ANY OF THE

CONTENTS OF THIS DOCUMENT. FOR THE LATEST DOCUMENTATION, CONTACT

YOUR LOCAL SUPPLIER OR VISIT WWW.UTCFIREANDSECURITY.COM.

This publication may contain examples of screen captures and reports used in daily

operations. Examples may include fictitious names of individuals and companies. Any

similarity to names and addresses of actual businesses or persons is entirely coincidental.

manufacturers or vendors of the respective products.

documentation. For the latest product information, contact your local supplier or visit us

online at www.utcfireandsecurity.com.

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications.

You are cautioned that any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

user of equipment containing a pre-approved modem module.

Type of S e r v i c e The TOPAZ System operates on a UTC Fire & Security ACURT field panel and is designed

Telephone Company

Procedures

to use a standard device telephone lines. It connects to the telephone line by means of a

standard jack called the USOC RJ-11C (or USOC FJ45S.) Connection to the telephone

company provided coin service (central office implemented systems) is prohibited.

Connection to party line services is subject to state tariffs.

The goal of the telephone company is to provide you with the best service it can. In order to

do this, it may occasionally be necessary for them to make changes in their equipment,

operations, or procedures. These changes might affect your service or the operation of

your equipment, the telephone company will give notice, in writing, to allow you to make

any changes necessary to maintain uninterrupted service.

In certain circumstances, it may be necessary for the telephone company to request

information from you concerning what equipment you have connected to your telephone

line. Upon request from the telephone company, provide the FCC registration number and

the ringer equivalence number (REN); both of these items are listed on the equipment

label. The sum of all the RENs on your telephone line should be less than five in order to

assure proper service from the telephone company. In some cases, five may not be usable

on a given line.

Page 3

If problems Arise If any of your telephone equipment is not operating, you should immediately remove it from

your telephone line, as it may cause harm to the telephone network. If the telephone

company notes a problem, they may temporarily discontinue service. When practical, they

will notify you in advance of this disconnection. If advanced notice is not feasible, you will

be notified as soon as possible. When you are notified, you will be given the opportunity to

correct the problem and informed of your right to file a complaint with the FCC. Contact

your telephone company if you have any questions about your phone line. In the event

repairs are ever needed on the UTC Fire & Security ACURT field panel they should be

performed by UTC Fire & Security technicians or an authorized representative.

Contact Us Returning Procedure

Contact the distributor where the product was purchased for return policy and procedures.

Correspondence:

Correspondence should be sent to the following address:

UTC Fire & Security

9 Farm Springs Road,

Farmington, CT 06034-4065

Technical Support:

Phone: 888 437 3287

Fax: 561 998 6224

Email: rs-bctsupport@fs.utc.com

Page 4

I.iv

TOPAZ ACURT2 & ACURT4

Hardware Installation Guide

UL Standards

The following has been determined by Underwriters Laboratories to be compatible with the ACURT2/

ACURT4.

• UTC Fire & Security Remote Input Modules (RIM)

• UTC Fire & Security Remote Relay Modules (RRM)

• UTC Fire & Security Keypad (K11)

• HID ProxPro Model 5355 with and without keypad

• HID ProxPoint Model 6005

• HID MiniProx Model 5365

• HID MiniProx Model 5375

• UTC Fire & Security Magstripe Extender

Note: Any reader or keypads other than the ones listed are not to be used on a UL listed system.

UL/CUL Specifications

TOPAZ Software Revision 1.4.9

In order to comply with UL 1076 and/or UL 294 the following items must be adhered to, if not, the installation

site will be in violation of the UL requirements.

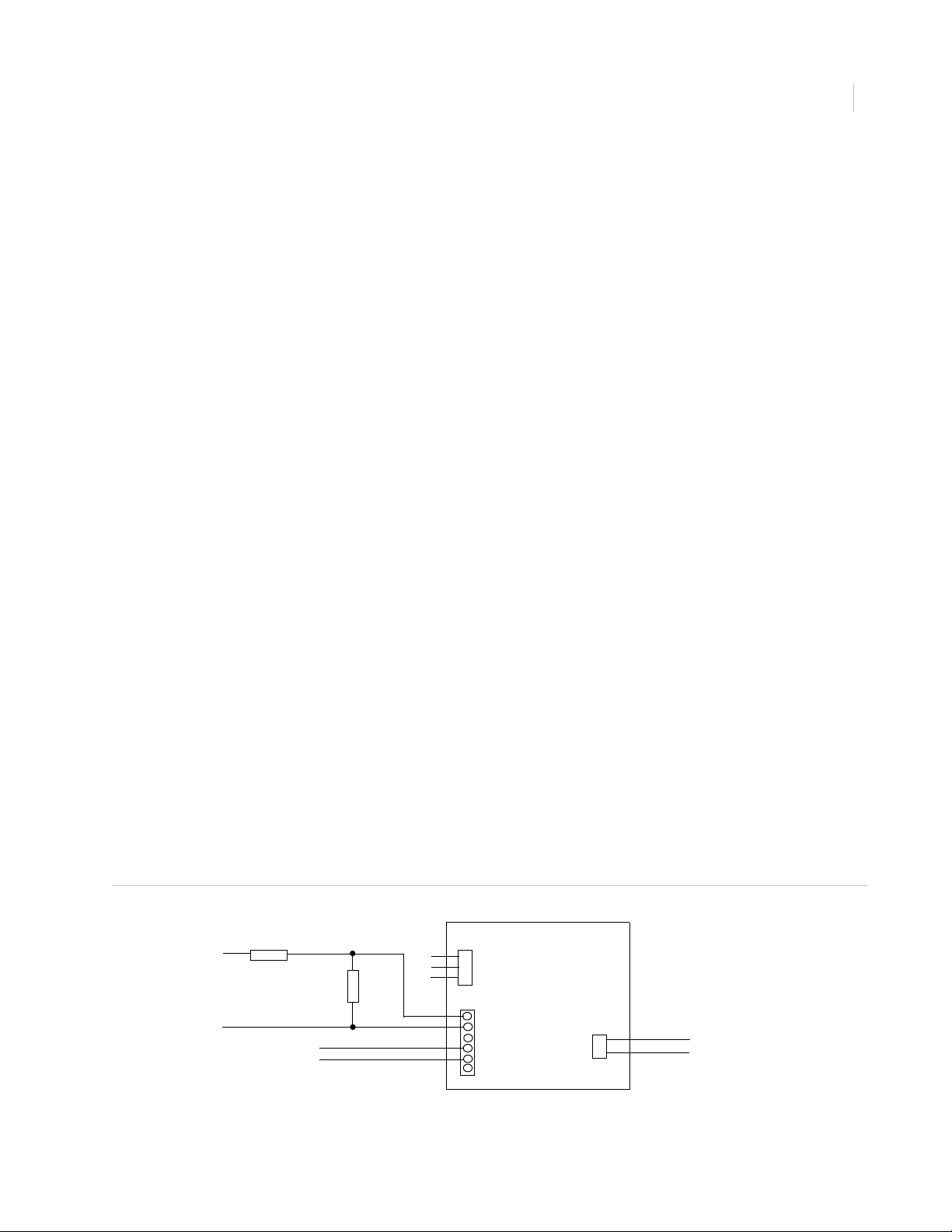

• The ACU panel must be powered by an Altronix AL400UL3 Power Supply. This must be located in

the same room as the panel and no more than 25 feet (7.82 m) from the unit. See Figure 1

• The DC input rating on the ACURT2/ACURT4 is +24 VDC +-4 V @ 750 ma maximum, with all

outputs at maximum load.

• Combined Auxiliary Power rating for all four readers on the ACURT4 must not exceed a maximum of

900 ma.

• Only UL listed equipment may be connected to the UTC Fire & Security system. This includes

external power supplies, motion detector, door contacts, enclosures, etc.

• All RRM and RIM modules must be installed in the room with panel and no more than 25 feet from the

unit.

• The End-Of-Line resistor must be located within the alarm zone sensor enclosure.

• Shielded cables must be used for all communication and read head runs.

• The use of the dial up modem or any other network connection on the ACURT2/ACURT4 must not be

used for UL-certified Installations.

All Receiving equipment must meet the following conditions:

The Central Supervising Station Equipment shall have the following minimum system configuration:

400 Mhz Pentium II with 512 KB Cache, 128 MB of RAM, 6 GB hard drive and 2 MB video memory,

Windows 2000 or XP Professional. (This is the minimum system requirements. However, a 1.2 Ghz

Pentium IV with 512 MB of RAM is recommended.) Data processing equipment and office appliance and

business equipment used as central supervisory station equipment shall comply with;

The Standard for Office Appliance and Business Equipment, UL 114;

The Standard for Information-Processing and Business Equipment, UL 478; or

The Standard for Safety of Information Technology Equipment, UL 60950.

Page 5

Line transient protection complying with the Standard for Transient Voltage Surge Suppressors, UL 1449, with

AL400UL3

AC

Input

Bat

Fail

AC

Fail

24VDC

Ouput

-

+

TB10 - 7

TB10 - 6

TB6-5

1K 1%

1K

1%

TB6-6

TB11-1

TB11-2

See Low Battery Alarm

setup procedure

a maximum marked rating of 330 V shall be used.

Signal line transient protection complying with the Standard for Protectors for Data Communications and Fire

Alarm Circuits, UL 497B, with a maximum marked rating of 50 V shall be used.

Communication circuits and network components connected to the telecommunications network shall be

protected by secondary protectors for communication circuits. These protectors shall comply with the Standard

for Secondary Protectors For Communications Circuits, UL 497A. These protectors shall be used only in the

protected side of the telecommunications network.

Equipment shall be installed in a temperature controlled environment. A temperature controlled environment is

defined as one that can be maintained between 55º – 95º F (13º – 35º C) by the HVAC system. Twenty-four

hours of standby power shall be provided for the HVAC system. The standby power system for the HVAC

system may be supplied by an engine driven generator alone. A standby battery is not required to be used.

All receiving equipment shall be completely duplicated with provision for switchover to the backup system

within 30 seconds. The backup system shall be fully operational within 6 minutes of the loss of the primary

system. This allows 30 seconds for the backup system to be fully energized and connected to necessary

communication lines and other devices, followed by 5-1/2 minutes for the system to boot up, conduct memory

tests, file system check, security verifications and prepare for full system operation. The backup computer shall

have the capabilities of the primary, such as memory, speed and the like.

I.v

Failure of the main computer system, hard disk, and alarm monitor shall result in switchover to the backup

system and shall be indicated by an audible or obvious visual indication.

A fault tolerant system may be used in lieu of complete duplication of the system if every component in the

fault tolerant system, including the software and the power supply, is duplicated.

In addition to the main power supply and secondary power supply that are required to be provided at the central

supervisory station, the system shall be provided with an uninterruptible power supply (UPS) with sufficient

capacity to operate the computer equipment for a minimum of 15 minutes. If more than 15 minutes is required

for the secondary power supply to supply the UPS input power, the UPS shall be capable of providing input

power for at least that amount of time.

The UPS shall comply with the Standard for Uninterruptible Power Supply Equipment, UL 1778, or the

Standard for Fire Protective Signaling Devices, UL 1481.

In order to perform maintenance and repair service, a means for disconnecting the input to the UPS while

maintaining continuity of power to the automation system shall be provided

Figure 1. Wiring Diagram for Altronix AL400UL3

For Canadian Certification installations, the model Brownsville or Easton 2 Computer must be used with this

system and the installation must follow the Canadian Electrical Code, Part 1.

Page 6

I.vi

TOPAZ ACURT2 & ACURT4

Hardware Installation Guide

Low Battery Alarm Setup

1. From Topaz main screen go to Hardware then Alarm Point tab.

2. Click Clear then enter Alarm Name: Low Battery Panel #.

3. Select Field Panel (this procedure must be done for each ACURT panel.)

4. Select Security Area.

5. Select Alarm Category.

6. Select Alarm Instruction.

7. Select Active.

8. Select Input Number 22.

9. Select Priority 5.

10. Uncheck User ACK Required and Alarm Can Be Masked.

11. Set Alarm Reporting Delay to “0” and enter the Description.

12. Click Save.

NFPA Standard

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7454

617-984-7000

www.nfpa.org

NFPA 70 Article 250, NEC

Page 7

FOR YOUR SAFETY

The following WARNINGS: and CAUTIONS: appear here for your safety. They are general in nature and do

not pertain to specific procedural steps. There are, however, additional safety precautions that do pertain to

specific procedural steps. These precautions appear at the point in the installation and/or maintenance

procedures where a hazard is most likely to be encountered.

BE SURE to read and follow all personal safety WARNINGS and equipment CAUTIONS appearing in this

document PRIOR to beginning ACU installation.

WARNING: The ACURT components described in this manual contain electrical shock hazard potential. Only

qualified personnel should perform installation and maintenance. Use the appropriate procedures to

remove power before proceeding with servicing.

WARNING: Do not use the ACURT Controller, Remote Input Module (RIM) or Remote Relay Module (RRM)

to switch any voltage above 30 volts. Failure to heed this WARNING: can cause death, personal

injury or damage to unit(s).

I.vii

WARNING: Make certain that the AC power source circuit breaker is OFF BEFORE proceeding. Failure to

heed this WARNING can cause damage to unit(s).

CAUTION: The ACURT controllers must have separate conduit run to each enclosure. Only cables/wires that

begin or terminate in the enclosure should run into the enclosure. DO NOT use the enclosure(s) as

"pull-boxes" for any foreign wiring. The enclosures should be arranged for separate conduit runs.

NOTICE: Fire Safety Notice

WARNING: NEVER connect any card reader devices or locks onto doors, gates or barriers that may be fire

exits without first consulting and getting approval of applicable local officials. Use of push

buttons to exit may be illegal. Single action exit may be required. Obtain proper permits and

approvals in writing before installation.

Page 8

I.viii

TOPAZ ACURT2 & ACURT4

Hardware Installation Guide

Page 9

Table of Contents

UL Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

UL / CUL Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

NFPA Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

FOR YOUR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

List of Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Chapter 1. The TOPAZ ACURT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Bandwidth requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ACURT2 System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ACURT4 System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2. Installing the ACURT Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Running the Wire and Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RS-485 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pulling Wire and Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Baud Rates and Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grounding Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Alarm Zone Sensor Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Network Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Flashing the ACURT with new PROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing UPS Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing and Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dial-up Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing Dial-up Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Connecting the Dial-up Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

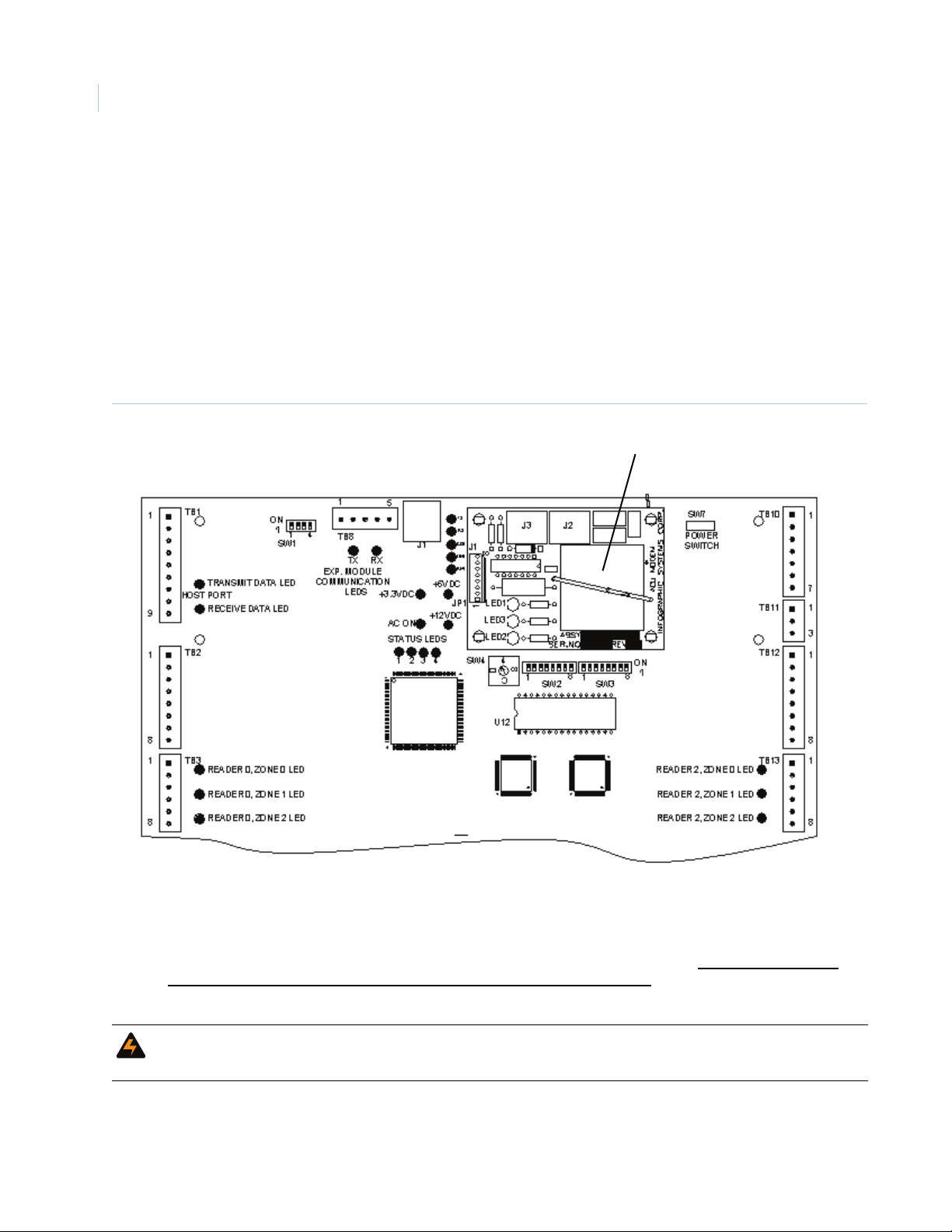

Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

LEDs on Modem Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting (MDD) Multi-Drop Dial-Up Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Modem Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installing Server External Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

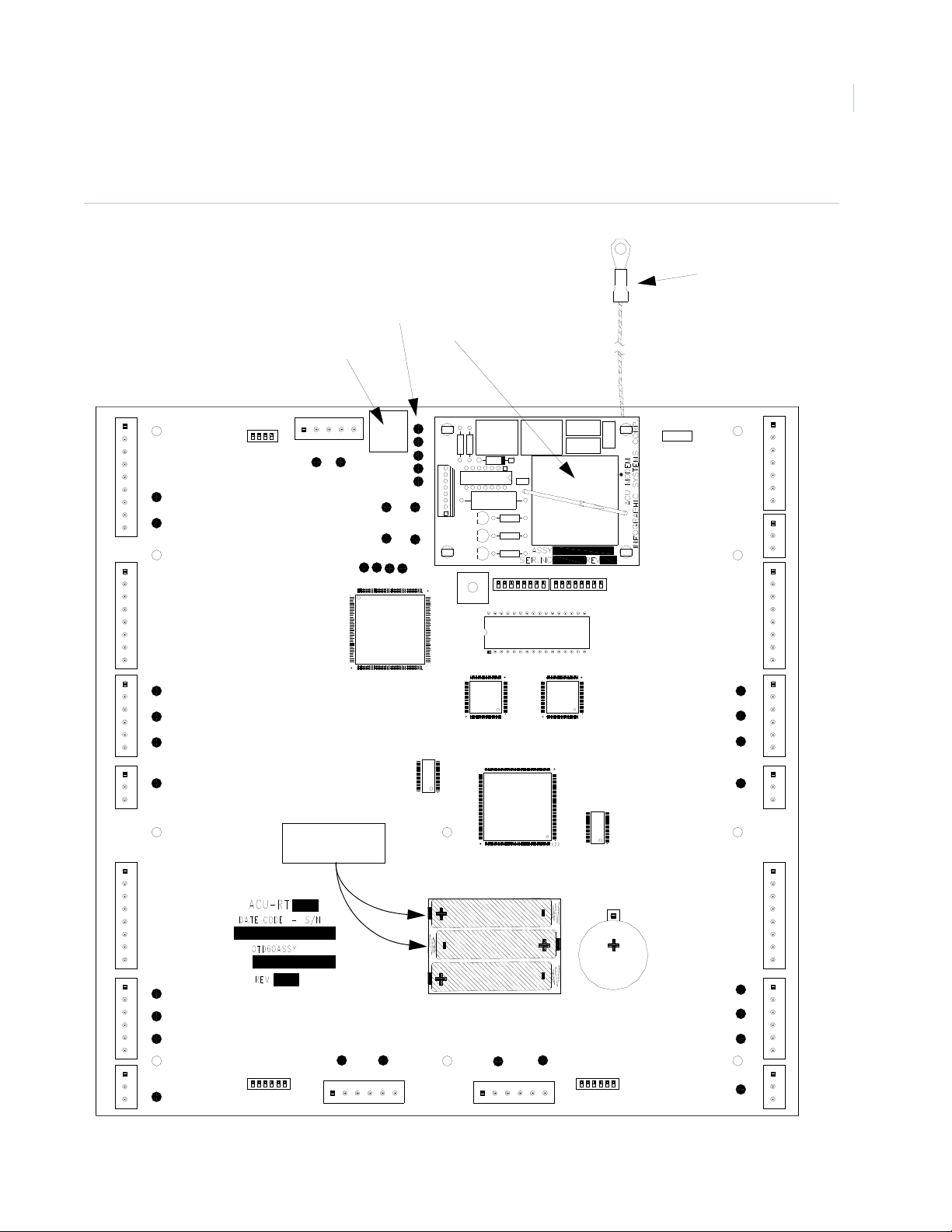

ACURT2 and ACURT4 Enclosure Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ACURT2 and ACURT4 Component Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

I.ix

Page 10

TOPAZ ACURT2 & ACURT4

I.x

Hardware Installation Guide

Terminal Connector Pin Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Connections for Terminal Block 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Connections for Terminal Block 2, 3, and 4 (ACURT2 and ACURT4) . . . . . . . . . . . . . . . . . . . . . . .31

Connections for Terminal Block 5, 6, and 7 (ACURT2 and ACURT4) . . . . . . . . . . . . . . . . . . . . . . .32

Connections for Terminal Block 8 (ACURT2 and ACURT4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Connections for Terminal Block 9 (ACURT2 and ACURT4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Connections for Terminal Block 10 (ACURT2 and ACURT4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Connections for Terminal Block 11 (ACURT2 and ACURT4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Connections for Terminal Block 12, 13, and 14 (ACURT4 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Connections for Terminal Block 15, 16, and 17 (ACURT4 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Connections for Terminal Block 18 (ACURT4 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Relay Numbering for ACURT2 and ACURT4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Alarm Numbering for ACURT2 and ACURT4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Wiring the Host Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Connecting RS-232C Interface to ACURT2 and ACURT4 Controllers. . . . . . . . . . . . . . . . . . . . . . .41

Connecting RS-485 Converter to the ACURT2 or ACURT4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Installing the NCIC-5 RS-485 Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Wiring a NCIC-5 RS-485 Converter to the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Multi-dropping RS-485 from a LAN Connected ACURT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DIP Switch Settings for ACURT2 and ACURT4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

DIP switch SW1 Communication Port Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

DIP Switch SW2 Settings Baud Rate, Dial-up, Parity, and Com Type . . . . . . . . . . . . . . . . . . . . . . .47

DIP Switch SW3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Dip Switch SW4 (rotary switch) Settings ACURT Panel Addressing . . . . . . . . . . . . . . . . . . . . . . . .49

DIP Switch SW5 and SW6 Settings Alarm Zone Termination for Readers . . . . . . . . . . . . . . . . . . .50

DIP Switch SW7 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Status LEDs on the ACURT2 and ACURT4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Defaulting the Memory on the ACURT2 and ACURT4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Chapter 3. Reader Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Overview of Reader Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Reader Installation Direct Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Wiring HID ProxPoint Plus 6005. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

HID ProxPoint Plus 6005 Point to Point Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Wiring HID MiniProx Model 5365 Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

HID MiniProx Model 5365 Point to Point Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Wiring Optional HID ProxPro Model 5355 Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Wiring Optional HID MaxiProx Model 5375 Long Range Reader. . . . . . . . . . . . . . . . . . . . . . . . . . .61

Wiring Optional K11L Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Wiring the RMS-10 to the ACURT 2/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Wiring Transition Series readers to the ACURT 2/4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Page 11

Chapter 4. Remote Expansion Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Remote Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Remote Input Module Circuit Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

RIM Terminal Block Connector Pin Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Setting the DIP Switches on the RIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Setting the Jumper on the RIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Alarm Numbers for the Remote Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Relay Numbers for RIM Remote Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Field Testing the RIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Replacing The RIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Optional Remote Relay Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Remote Relay Module Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

RRM Terminal Block Connector Pin Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Setting the DIP Switches on the RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Relay Numbers for the RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Alarm Numbers for the RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Field Testing The RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Replacing The RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Elevator Control Relay Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Configuring the Elevator Control is a five-step process: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Elevator Relay Numbering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Standard Elevator Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

I.xi

Chapter 5. Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Altronix Power Supply Charger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Enclosure Dimension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Altronix Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Wiring an RCR-REX Request to Exit Dual Technology

Motion Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Door Strike. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Magnetic Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendix A. Alarm Input and Relay Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Alarm Input Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Reader Physical Alarm Zone Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Reader Logical Alarm Zone Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

RIM Zone Input Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Relay Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

ACURT2 and ACURT4 Relay Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

ACURT2 and ACURT4 Relay Numbers for RRM with Elevator Control . . . . . . . . . . . . . . . . . . . . 106

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Page 12

I.xii

TOPAZ ACURT2 & ACURT4

Hardware Installation Guide

List of Tables

Table 1. General Specifications ACURT2 and ACURT4 Networked Intelligent Controller ...........................3

Table 2. Communication Bandwidth Reference............................................................................................4

Table 3. General Data: Packet size .............................................................................................................. 4

Table 4. Recommended baud rates............................................................................................................10

Table 5. Alarm State Resistance ................................................................................................................12

Table 6. Network communications guidelines.............................................................................................13

Table 7. Dial-up Modem LED Indicators. ....................................................................................................25

Table 8. Explanation of Table Headings .....................................................................................................30

Table 9. Terminal Block TB1 Pin Number Identification .............................................................................30

Table 10. Terminal Block TB2, 3, and 4 Pin Number Identification ..............................................................31

Table 11. Terminal Block TB5, 6, and 7 Pin Number Identification ..............................................................32

Table 12. Terminal Block TB8 Pin Number Identification .............................................................................33

Table 13. Terminal Block TB9 Pin Number Identification .............................................................................33

Table 14. Terminal Block TB10 Pin Number Identification ...........................................................................34

Table 15. Terminal Block TB11 Pin Number Identification ...........................................................................34

Table 16. Terminal Block TB12, 13, and 14, Pin Number Identification .......................................................35

Table 17. Terminal Block TB15, 16, and 17, Pin Number Identification .......................................................36

Table 18. Terminal Block TB18 Pin Number Identification ...........................................................................37

Table 19. Relay Numbers for ACURT2 and ACURT4 Readers.................................................................... 37

Table 20. Relay Numbers for RIM Remote Input Module .............................................................................37

Table 21. Relay 128 Numbers for RRM Remote Relay Module ...................................................................38

Table 22. Physical to Logical Zone Numbering ............................................................................................38

Table 23. RIM Alarm Numbers for UTC Fire & Security’s TOPAZ................................................................39

Table 24. RRM Alarm Numbers....................................................................................................................39

Table 25. Host PC to/from D1010 Transciever connections.........................................................................

Table 26. Multi-drop ACURT to/from D1315 Fiber Converter connections................................................... 40

Table 27. RIM/RRM to/from D1315 Fiber Converter connections ...............................................................40

Table 28. PC (9-pin) to ACURT2 or ACURT4 (RS-232) ...............................................................................41

Table 29. PC (25-pin) to ACURT2 and ACURT4 (RS-232) ..........................................................................41

Table 30. Model NCIC-5 RS-485 Converter to ACURT2 or ACURT4 .......................................................... 43

Table 31. Connecting DB-9 RS-485 Converter............................................................................................. 44

Table 32. Switch SW1 Settings on the ACURT2 and ACURT4....................................................................47

Table 33. DIP Switch SW2 Settings on the ACURT2 and ACURT4 Controller ............................................47

Table 34. DIP Switch SW3 Settings on the ACURT2 and ACURT4 Controller ............................................49

Table 35. Rotary Switch SW4 Settings on the ACURT2 and ACURT4 ........................................................49

Table 36. DIP Switch SW6 settings alarm termination for readers ............................................................... 50

Table 37. DIP Switch SW6 settings alarm termination for readers ............................................................... 50

Table 38. Switch SW7 Power Switch on the ACURT2 and ACURT4 ........................................................... 50

Table 39. Power-Up LED Status...................................................................................................................51

Table 40. ACURT Online Status LEDS.........................................................................................................51

Table 41. LAN LED Status ............................................................................................................................51

Table 42. Host Port LED Status....................................................................................................................52

Table 43. Reader Zone LED Status ..............................................................................................................52

Table 44. Relay and Door Strike LED Status................................................................................................52

Table 45. Wiring HID ProxPoint Reader to the ACURT................................................................................55

Table 46. Wiring HID MiniProx Model 5365 Reader to the ACURT..............................................................57

Table 47. Wiring HID ProxPro Model 5355 Reader to the ACURT...............................................................59

Table 48. DIP Switch SW1 Settings..............................................................................................................60

Table 49. Wiring HID MaxiProx Model 5375 Reader TB1 to the ACURT .....................................................61

Table 50. Wiring HID MaxiProx Model 5375 Reader TB1 Tamper to the ACURT........................................ 61

40

Page 13

Table 51. Wiring HID MaxiProx Model 5375 Reader TB2 to the ACURT .....................................................62

Table 52. DIP Switch SW1 Factory Defaults.................................................................................................62

Table 53. DIP Switch SW2 Settings..............................................................................................................62

Table 54. DIP Switch SW 5 Settings .............................................................................................................63

Table 55. Jumper Pin settings.......................................................................................................................63

Table 56. 5375 Reader Switch Settings For Wiegand Mode ........................................................................63

Table 57. Wiring UTC Fire & Security K11L Keypad to the ACURT .............................................................64

Table 58. Alarm Zone Resistance Value.......................................................................................................70

Table 59. RIM Wiring Connections for Expansion Port 1..............................................................................72

Table 60. RIM Wiring Connections for TB1 - TB3.........................................................................................73

Table 61. RIM Wiring Connections for TB4 - TB7.........................................................................................73

Table 62. Input Zone Status By Resistance..................................................................................................74

Table 63. Alarm Zone Status LED indicators. ...............................................................................................74

Table 64. RIM Wiring Connections for TB8 - TB10.......................................................................................74

Table 65. RIM DIP Switch Settings ...............................................................................................................75

Table 66. RIM Switch SW2 for RS485 Terminations. ...................................................................................75

Table 67. RIM Switch SW3 for Input Terminations. ......................................................................................76

Table 68. RIM SW4 input terminations .........................................................................................................76

Table 69. RIM Jumpers W1 and W2. ............................................................................................................76

Table 70. RIM Alarm Numbers for UTC Fire & Security’s TOPAZ................................................................77

Table 71. RIM Relay Numbers ......................................................................................................................77

Table 72. RIM Test Points and Voltages.......................................................................................................78

Table 73. Power-up LED Indicators on the RIM............................................................................................78

Table 74. RIM and RIM Normal LED Status .................................................................................................79

Table 75. RRM Wiring Connections for Expansion port 1.............................................................................81

Table 76. RRM Wiring Connections for Relays 1 & 2 ...............................................................................

Table 77. RRM Wiring Connections for Relays 3 - 5.....................................................................................82

Table 78. RRM Wiring Connections for Relays 5-7.......................................................................................83

Table 79. RRM Wiring Connections for Relays 8-11.....................................................................................83

Table 80. RRM Wiring Connections for Relays 12-16...................................................................................84

Table 81. RRM DIP Switch Settings .............................................................................................................84

Table 82. RRM DIP Switch SW2 Settings....................................................................................................85

Table 83. Relay 128 Numbers for RRM Remote Relay Module....................................................................85

Table 84. RRM Alarm Numbers ....................................................................................................................86

Table 85. RRM Test Points and Voltages .....................................................................................................86

Table 86. Power-up LED Indicators on the RRM..........................................................................................87

Table 87. Normal LED Indicators on the RRM ..............................................................................................87

Table 88. Parts Replacement Chart for RRM ...............................................................................................88

Table 89. Parts Replacement Chart for RRM ...............................................................................................91

....82

I.xiii

Page 14

I.xiv

TOPAZ ACURT2 & ACURT4

Hardware Installation Guide

List of Figures

Figure 1. Wiring Diagram for Altronix AL400UL3 ...........................................................................................v

Figure 2. ACURT2 Block Diagram .................................................................................................................5

Figure 3. ACURT2 Block Diagram .................................................................................................................6

Figure 4. RS-485 Communication Wiring for ACURT2 and ACURT4. ...........................................................9

Figure 5. RS-485 Communication Wiring for Remote Modules .....................................................................9

Figure 6. Zone Sensor with 1000-Ohm Resistors........................................................................................ 12

Figure 7. ACU Utility: Flash ACURT ............................................................................................................22

Figure 8. ACU Utility: Confirmation dialog.................................................................................................... 22

Figure 9. ACU Utility: Flash successful ........................................................................................................22

Figure 10. Dial-up Modem Installed on Top of the ACURT Board .................................................................24

Figure 11. Component Layout of the Dial-up Modem Board..........................................................................25

Figure 12. RS485 Port Wiring For Multi-Drop Dial-Up Panels .......................................................................26

Figure 13. Components Mounted Inside the ACURT Controller Enclosure ...................................................28

Figure 14. ACURT2 and ACURT4 Component Layout ..................................................................................29

Figure 15. Typical RS-232C Interface Wiring from PC to ACURT2 or ACURT4 Controller ...........................41

Figure 16. RS485 Communication wiring for Multiple ACURTs with NCIC-5 RS485 Converter....................43

Figure 17. RS485 wiring for the ACURTs with NCIC-5 RS-485 converter in the middle of the loop..............44

Figure 18. Hyper-Terminal .............................................................................................................................45

Figure 19. Connection Description.................................................................................................................45

Figure 20. Port Settings .................................................................................................................................46

Figure 21. Multi-Drop RS-485 Wiring from a LAN Connected ACURT. .........................................................46

Figure 22. HID ProxPoint Plus 6005 ..............................................................................................................55

Figure 23. HID ProxPoint Plus 6005 Point to Point Wiring (ACURT2 and 4) ................................................. 56

Figure 24. HID ProxPoint Plus 6005 Point to Point Wiring - ACURT4 Only...................................................56

Figure 25. HID MiniProx 5365........................................................................................................................57

Figure 26. HID MiniProx Model 5365 Point to Point Wiring (ACURT2 and 4)................................................58

Figure 27. HID MiniProx Model 5365 Point to Point Wiring - ACURT4 Only.................................................. 58

Figure 28. HID ProxPro 5355.........................................................................................................................59

Figure 29. HID MaxiProx 5375 Long Range Reader .....................................................................................61

Figure 30. UTC Fire & Security K11L Keypad ............................................................................................... 64

Figure 31. Rear View of the K11 Keypad.......................................................................................................65

Figure 32. K11L Board Only with Jumper Locations......................................................................................65

Figure 33. Wiring the RMS-10 to the ACURT ...............................................................................................66

Figure 34. Wiring Transition Series readers to the ACURT ..........................................................................67

Figure 35. RIM Component Location ............................................................................................................71

Figure 36. Locations of Components on RRM ...............................................................................................80

Figure 37. Elevator Floor Definition................................................................................................................90

Figure 38. Elevator Control Relay Interface ................................................................................................... 92

Figure 39. Altronix AL400UL3 Power Supply/Charger Cabinet layout ...........................................................94

Figure 40. Altronix AL400UL3 Power Supply/Charger Enclosure Dimensions ..............................................95

Figure 41. Typical RCR-REX/reader configuration ........................................................................................97

Figure 42. Door Strike Wiring for ACURT with Supplied Diode......................................................................98

Figure 43. Door Strike Wiring for ACURT with Optional Door Strike Noise Suppressor #122610 .................98

Figure 44. Door Lock Wiring for ACURT with Supplied Diode .......................................................................99

Page 15

Chapter 1 The TOPAZ ACURT

This chapter provides an overview and general information required for the

installation of the TOPAZ ACURT2 and ACURT4. This will include system

diagrams of each product.

In this chapter:

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ACURT2 System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ACURT4 System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Page 16

TOPAZ ACURT2 & ACURT4

2

Hardware Installation Guide

This section provides technical information on models ACURT2 and ACURT4. These intelligent networked

devices provide access control, alarm monitoring and output control. The ACURT4 provides support for four

(4) Wiegand output card readers and/or keypads, while the ACURT2 provides support for two (2) Wiegand

output card readers and/or keypads. ACURT2 and ACURT4 models provide one (1) host serial port for

connections to a server computer using either RS-485 or RS-232 communications and one (1) 10BaseT

Ethernet port.

Each controller consists of a printed circuit board (PCB) assembly with optional battery backup. The processor

is a 90 MHz Motorola 5307 Coldfire with 8 Mbytes of RAM memory. Additional program memory consists of

4 Mbytes FLASH ROM.

Communication to external devices is a polled serial protocol up to 4000 feet (1220 meters) for Remote

Electronics Modules, such as inputs (RIM modules) or outputs (RRM modules).

Twelve (12) supervised inputs on the ACURT4 or six (6) supervised inputs on the ACURT2 are available for

alarm monitoring. These supervised inputs are for exit push buttons and door contacts for the card readers, and

for auxiliary monitor points.

Each model is also equipped with a low battery detection alarm and two (2) unsupervised alarms (AC power

fail and cabinet tamper). Eight (8) Form-C relays are provided on the ACURT4 and four (4) for the ACURT2

for strike activation and/or remote control. All relay contacts are rated for 30 VDC at 2 amperes. DO NOT

switch any voltages over 30 volts.

DIP Switches are used to set the device’s communication baud rate and a rotary switch is used to set the device

address. DIP Switches are also used to terminate alarm inputs and host communications ports.

Page 17

General Specifications

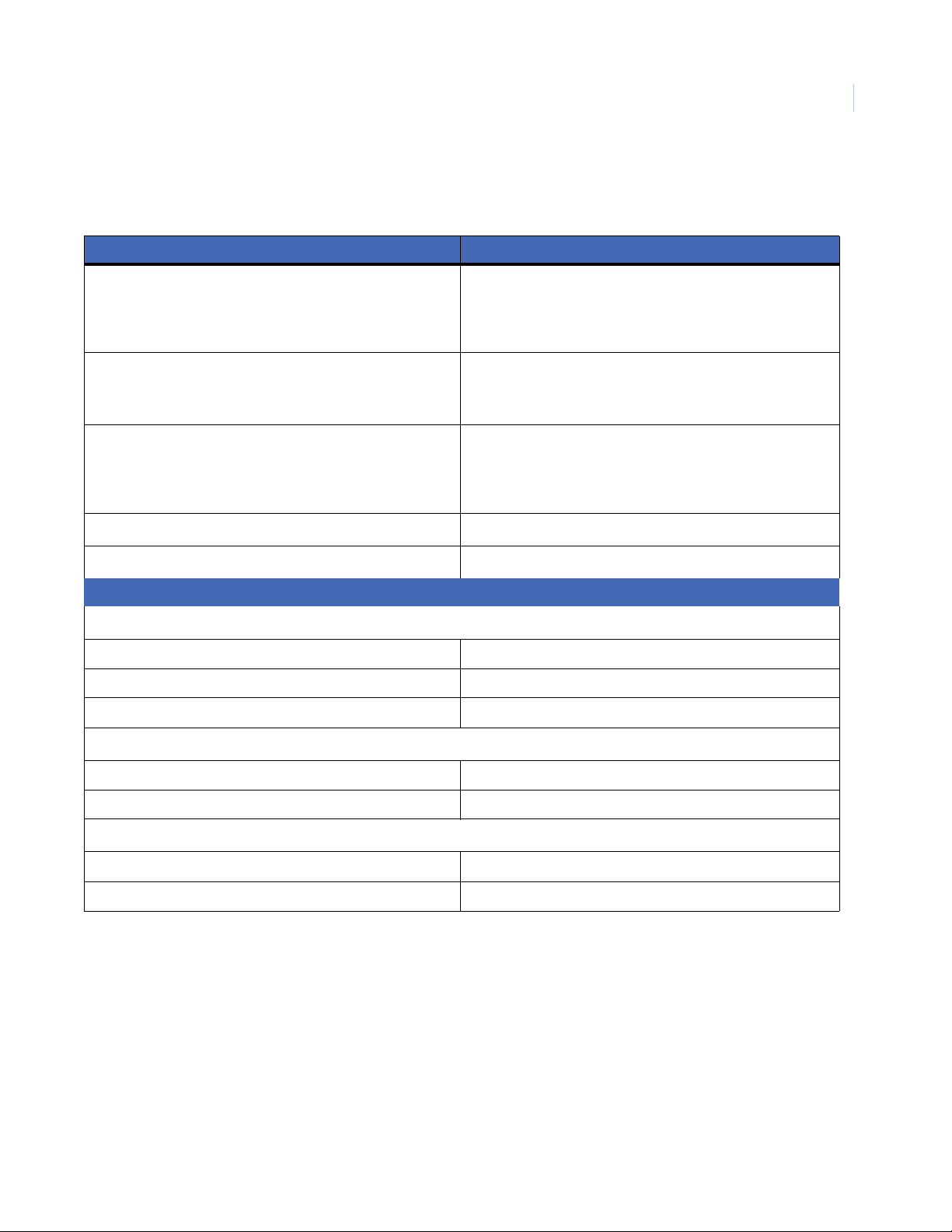

Table 1. General Specifications ACURT2 and ACURT4 Networked Intelligent Controller

Characteristic Specification

DIMENSIONS

HEIGHT

WIDTH

DEPTH

WEIGHT

WITH BATTERIES

WITHOUT BATTERIES

ENVIRONMENTAL

MAXIMUM TEMPERATURE

MINIMUM TEMPERATURE

HUMIDITY

INPUT POWER VOLTAGE

16.25 in (41.28 cm)

16.375 in (41.59 cm)

4.125 in (10.48 cm)

19 lb. (8.6 kg)

16 lb. (7.3 kg)

+150F (+65C)

+32F (0C)

0 to 95% Relative (non-condensing)

24 VAC, 40 VA

The TOPAZ ACURT

Chapter 1

1

3

DC STANDBY BATTERY BACKUP

Current Specification

4-Hour Backup

ACURT

Main AC power 24 VAC, 40 VA, 1 amp Current Limited

Backup Battery 2@12 VDC, 4.0 amp/hr

Reader Combined Max of 750ma

RRM

Main Input 24 VDC@ .040 amp board

Relays Add 0.013 amps for each energized relay.

RIM

Main Input 24 VDC@ .140 amp board

Relays Add 0.013 amps for each relay.

1. For UL Listed applications, the ACURT2/ACURT4 must be powered by a UL Listed Altronix power supply, model AL400UL3. If a

Listed class 2 transformer is used, it is not a UL listed application.

Page 18

TOPAZ ACURT2 & ACURT4

4

Hardware Installation Guide

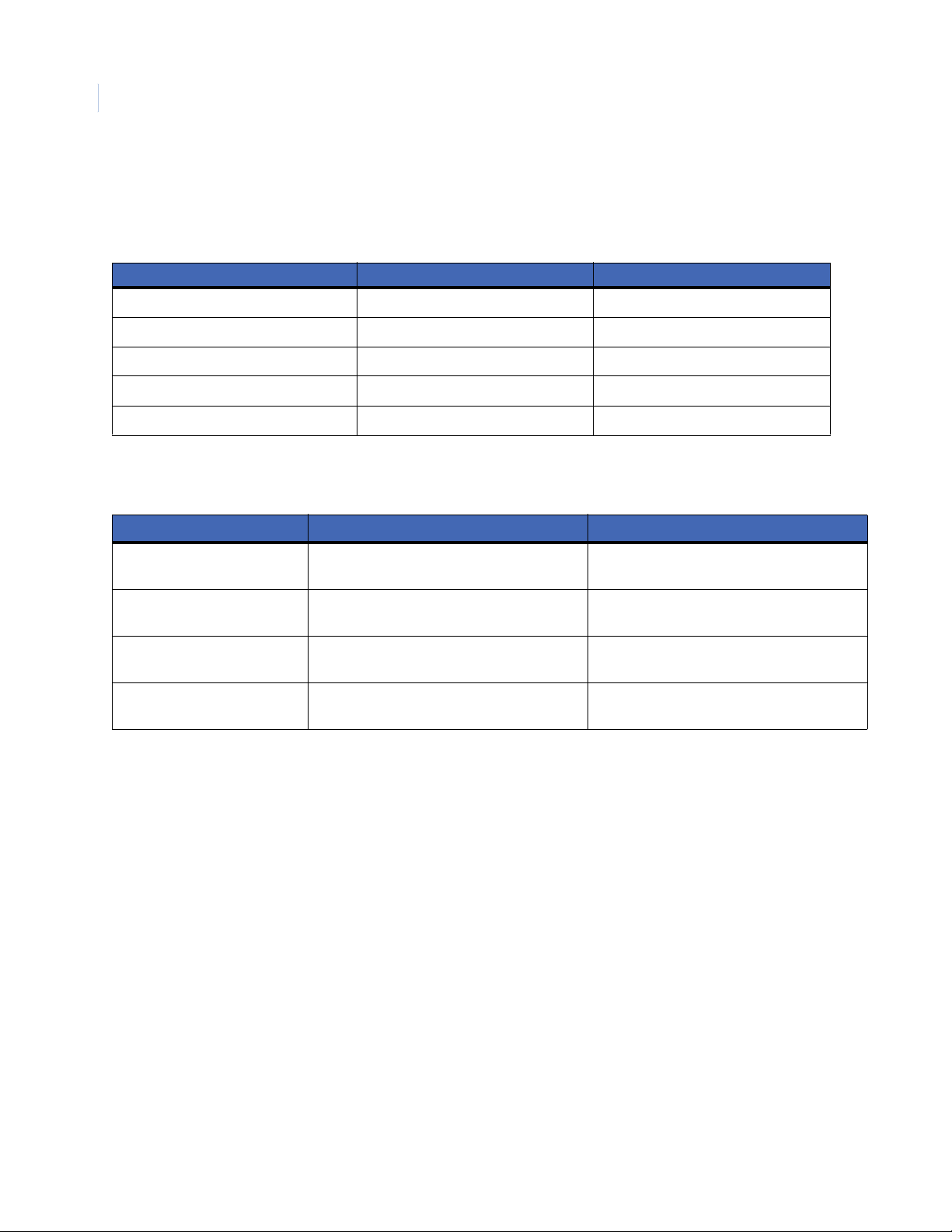

Bandwidth requirements

The tables below provide the typical bandwidth requirements for the Topaz file server and workstations.

Table 2. Communication Bandwidth Reference

Description Equation Max Bandwidth

9,600 BPS - PPP

14,400 BPS - PPP

28,800 BPS - PPP

57,600 BPS - PPP

Ethernet

Table 3. General Data: Packet size

Description Minimum Maximum

Server to Workstation Polling

- 10 Sec =

Server to Server Polling - 10

Sec =

Card Record (depends on

number of fields used) =

Alarm Condition Transaction = 2 Kbytes 2 Kbytes

10 Bytes 10 Bytes

10 Bytes 10 Bytes

2 KBytes 13.5 Kbytes

9,600 BPS x 60 sec ÷ 8 Bits =

28,800 BPS x 60 sec

14,400 BPS x 60 sec

57,600 BPS x 60 sec

10,000,000 BPS x 60 sec

÷ 8 Bits =

÷ 8 Bits =

÷ 8 Bits =

÷ 8 Bits =

72 KB per minute

108 KB per minute

216 KB per minute

432 KB per minute

7500 KB per minute

Page 19

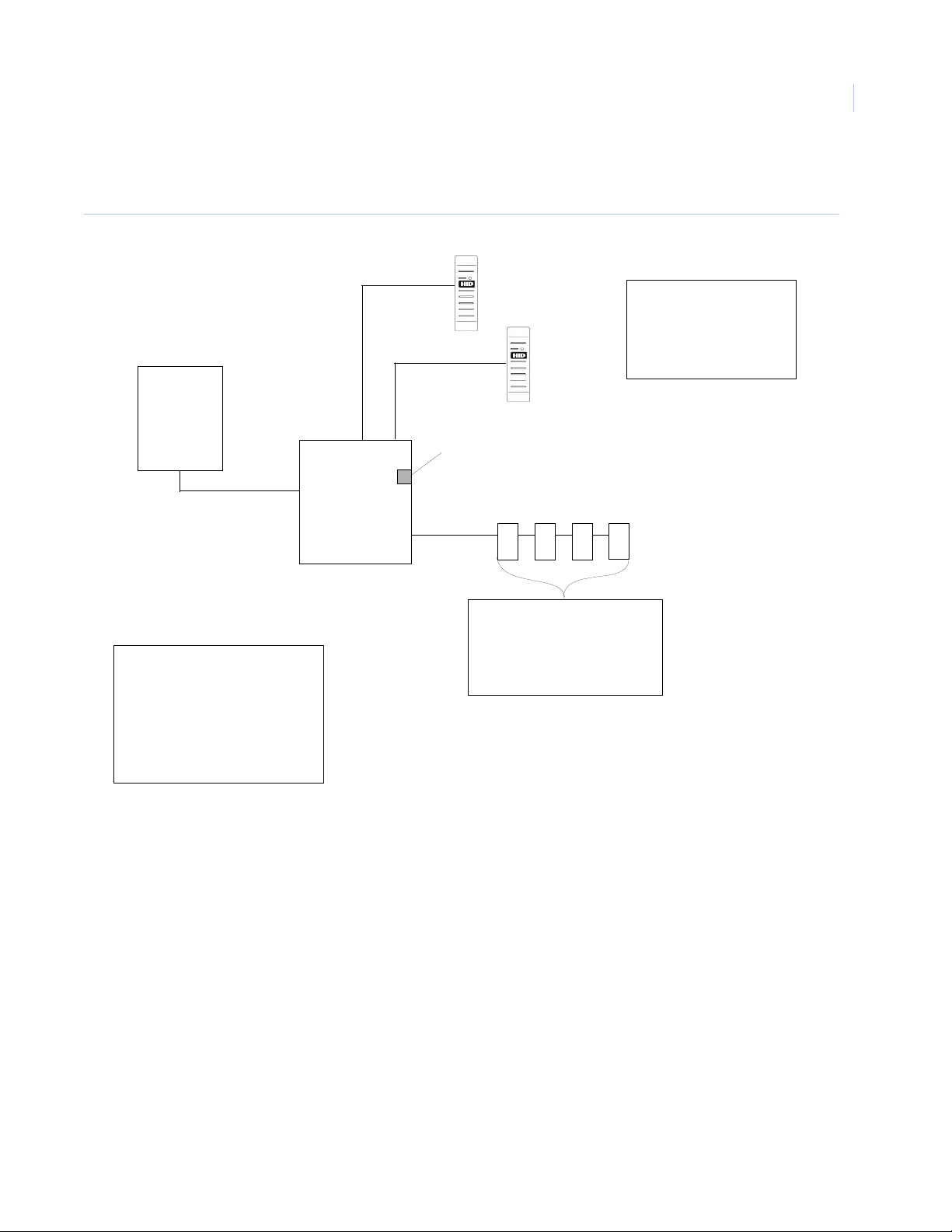

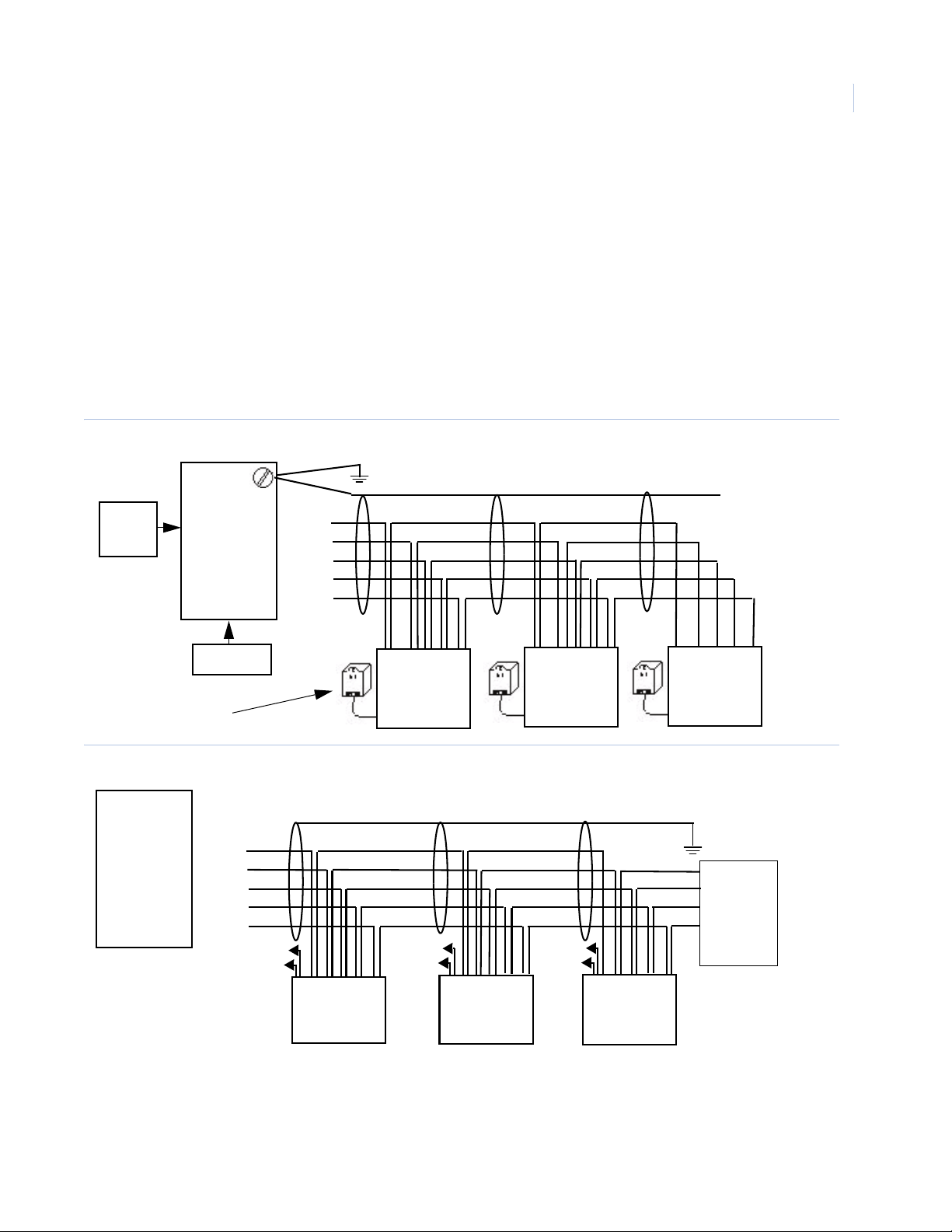

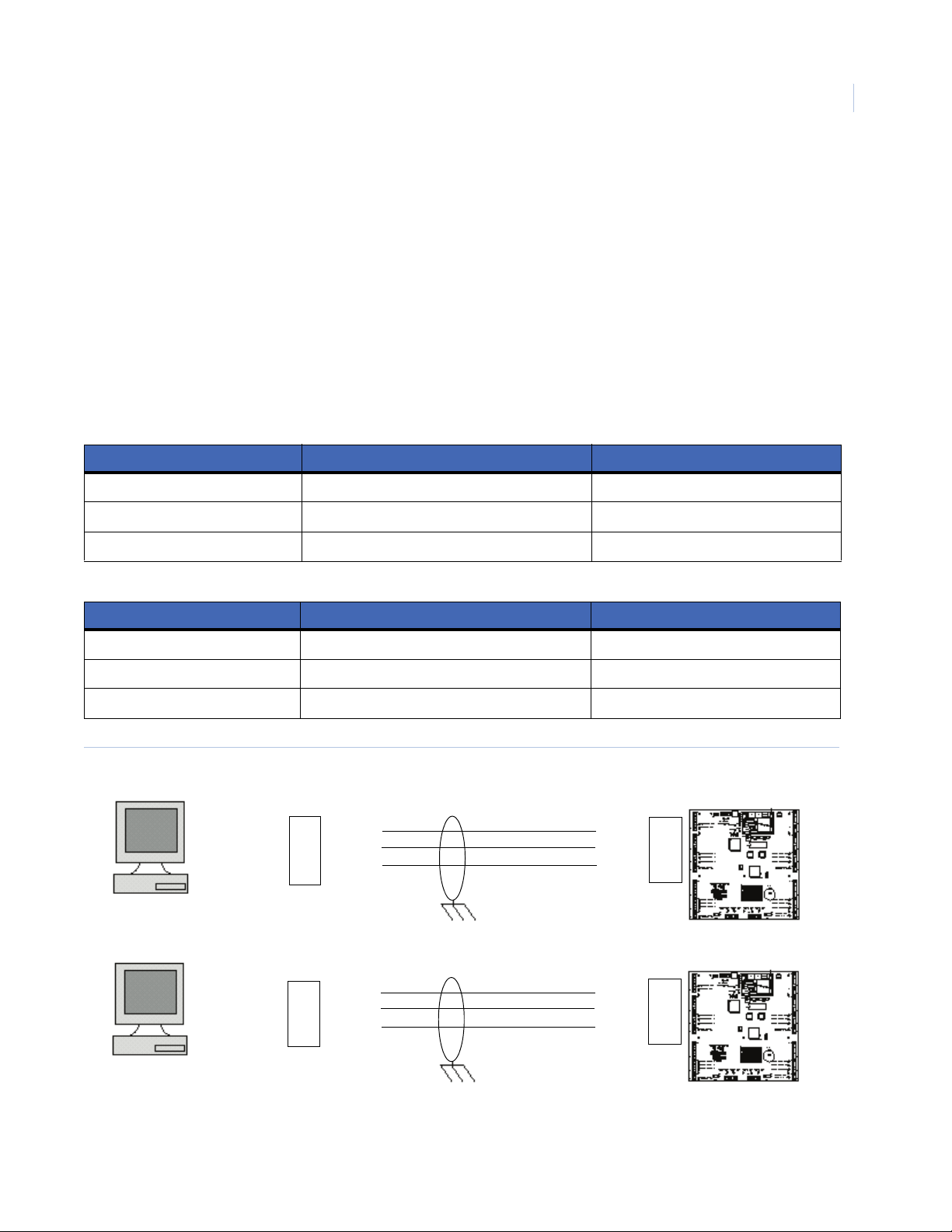

ACURT2 System Diagram

Host

PC

ACURT2

Expansion

Port

Host Port

Ethernet

Port

These readers use the on-

board alarm inputs and

relay outputs for door

monitor, REX, and lock

7

654

Combination of up to four RIMs

and/or RRMs may be connected

to the Expansion Port using

address 4, 5, 6, & 7

Features

1 - Host Port (RS-232 or RS-485)

1 - Ethernet Port

2 - Reader Support

1 - Expansion Module Port

for up to 4 RRMs or RIMs

6 - Alarm Inputs

4 - Relay Outputs

Reader 0

Reader 1

Figure 2. ACURT2 Block Diagram

The TOPAZ ACURT

Chapter 1

5

Page 20

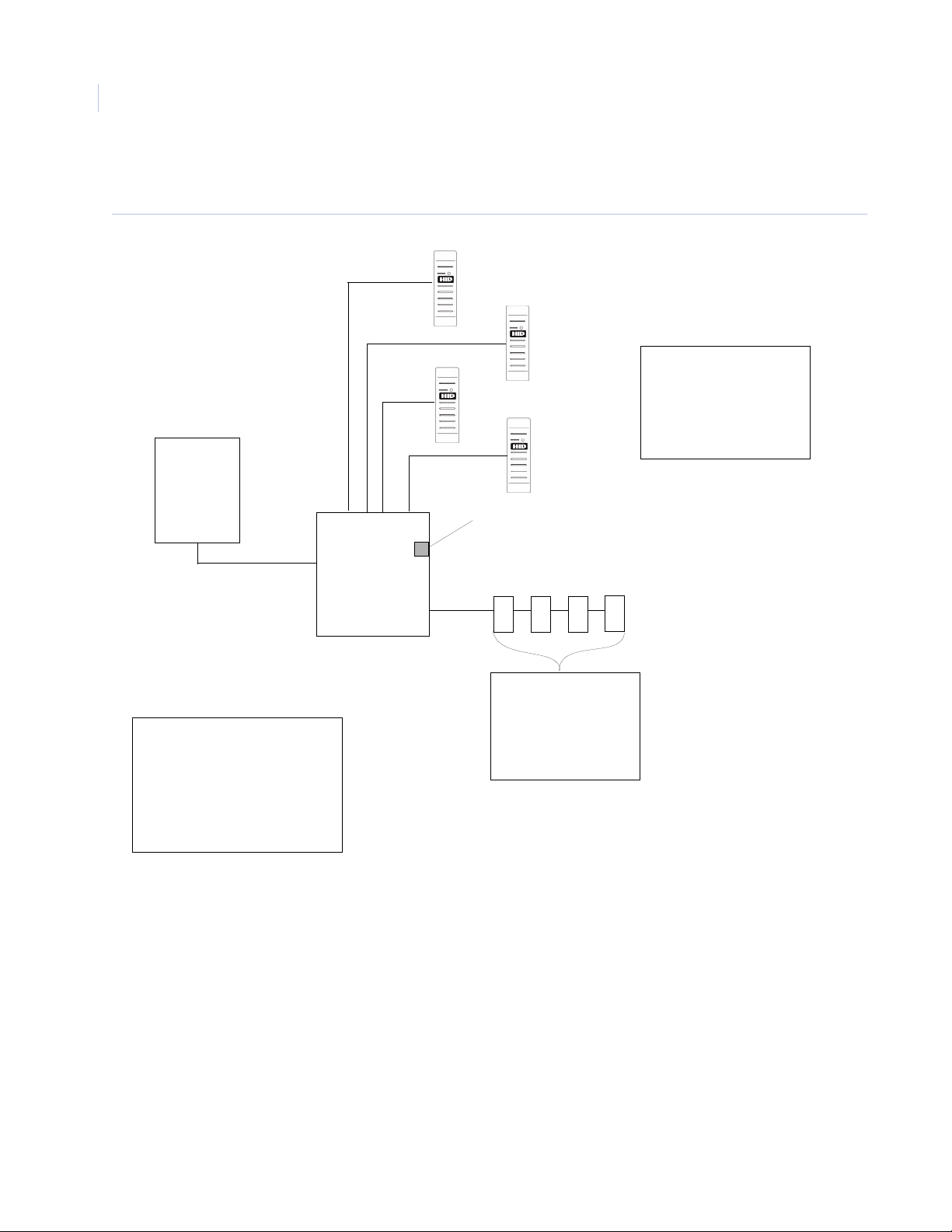

TOPAZ ACURT2 & ACURT4

Host

PC

ACURT4

Expansion

Port

Host Port

Ethernet

Port

These readers use

the on-board alarm

inputs and relay outputs

for door monitor, REX,

and lock

7

654

Combination of up to four

RIMs and/or RRMs may be

connected to the

Expansion Port using

address 4, 5, 6, & 7

Features

1 - Host Port (RS-232 or RS-485)

1 - Ethernet Port

4 - Reader Support

1 - Expansion Module Port

for up to 4 RRMs or RIMs

12 - Alarm Inputs

8 - Relay Outputs

Reader 0

Reader 1

Reader 2

Reader 3

6

Hardware Installation Guide

ACURT4 System Diagram

Figure 3. ACURT2 Block Diagram

Page 21

Chapter 2 Installing the ACURT Panel

In this chapter you will learn the basics of installing and wiring the ACURT2 and

ACURT4 panels. This includes:

Running the Wire and Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RS-485 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pulling Wire and Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Network Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flashing the ACURT with new PROM . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing UPS Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dial-up Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing Server External Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Terminal Connector Pin Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Relay Numbering for ACURT2 and ACURT4 . . . . . . . . . . . . . . . . . . . . 37

Alarm Numbering for ACURT2 and ACURT4 . . . . . . . . . . . . . . . . . . . . 38

Wiring the Host Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Page 22

TOPAZ ACURT2 & ACURT4

8

Hardware Installation Guide

Running the Wire and Cable

The procedure for running the wire and cable is described in the following paragraphs.

Note:

1. In running wire and cable, be sure to observe and follow applicable building codes.

2. The dry relay contacts are rated at 2 amps at 30 AC/DC volts.

3. All wires should be stranded.

4. The maximum length of the wiring between the farthest Remote Module (RIM, or RRM) and the

ACURT controller is 4000 feet (1220 meters) provided the remote module is locally powered.

5. Guard against lightning damage.

6. All bare Shields should be taped or protected against accidental shorting against electronic

components.

Page 23

Installing the ACURT Panel

From

Server

NCIC-5

RS-485

converter

Connect earth ground via stud in ACURT box. See page 7

- GND

- RDB

- RDA

- TDB

- TDA

12 VDC

Signal T+ R+

Ground

T- R-

ACURT2/RT4

Signal T+ R+

Ground

T- R-

ACURT2/RT4

Signal T+ R+

Ground

T- R-

ACURT2/RT4

AC Plug-In

Power Supply

ACURT

Expansion

Module

Port

SIG

- GND

- RX+

- RX-

- TX+

- TX-

+24 T+ R+

0v T- R-

RIM or RRM

+24 T+ R+

0v T- R-

RIM or RRM

Connect to

earth ground

via stud in

ACURT box

See page 7

Terminate

using DIP

switch or

RS-485

terminator

PN 124824

* Aux

Power

+

-

* Aux

Power

+

-

* Aux

Power

+

-

+24 T R+

0v T- R-

RIM or RRM

Chapter 2

RS-485 Communications

RS-485 is a differential voltage communication circuit. The impedance is 120 ohms. End-of-line terminators

are required on both ends of the communications path. Multi-drop configurations are allowed with a maximum

length of 4000 feet. Off the RS-485 cable, stubs can be dropped, but the length of any stub should not be

longer than 10 feet. Stubs can connect to ACURT controllers or remote modules (RIM or RRM). Stubs must

not be terminated. We strongly recommend star configurations be avoided. (See Figure 4)

The ACURT2 and ACURT4 controllers are switch selectable for RS-485 termination on each host and

expansion module port.

The UTC Fire & Security ACURT2/ACURT4 requires a RS-485 terminator at the NCIC-5 RS-485 converter.

See Figure 16 and 17.

Figure 4. RS-485 Communication Wiring for ACURT2 and ACURT4.

9

Figure 5. RS-485 Communication Wiring for Remote Modules

Notes:

• If Auxiliary power is not provided locally, another pair of wires will be required to each RIM / RRM.

• Shield refers to the over all braided shield, GND refers to the shield drain wire. Transmit should use

one twisted pair and receive should use the other twisted pair.

Page 24

TOPAZ ACURT2 & ACURT4

10

Hardware Installation Guide

Pulling Wire and Cable

Pull the wiring to the remote module from the ACURT controller.

All the wires except the strike pair may be run as one cable. The cable should have low-capacitance twisted

pairs and a shield. Attach pigtail to shield and connect to chassis ground. The following Belden cable numbers

(or equivalent) are suggested:

Belden No. 9842-24 AWG for 1000 feet (305 meters) maximum distance

Pull a single pair of wires from the enclosure to the electric door strike. The following Belden cable number (or

equivalent) is suggested:

Belden No. 9409-18 AWG

Pull the wires to the enclosure from each alarm zone sensor, door contact and exit push button. The following

Belden cable number (or equivalent) is suggested:

Belden No. 9407-22 AWG

Pull the wires to the enclosure from passive exit device if the device requires power, otherwise use cable listed

above. The following Belden cable number (or equivalent) is suggested:

Belden No. 8741-22 AWG

Baud Rates and Distances

The information in the table below may vary according to the quality of the cable used and the number of

panels in a chain.

Table 4. Recommended baud rates

Baud rate Distance

115,200 75 to 100 feet

(23 to 30.5 meters)

57,600 800 to 1000 feet

(244 to 305 meters)

38,400 1000 to 3000 feet

(305 to 915 meters)

Page 25

Installing the ACURT Panel

Chapter 2

Grounding Connections

It is important to connect each ACU panel on the communication loop individually to earth ground, not to

chassis or electrical ground. Grounding is imperative for proper data communications between panels and to

ensure full functionality of the lighting and transient voltage protection devices. Voltage protection device are

designed into all ACU panels and will channel most transient surges to ground if the panel is properly

connected to earth ground. If the panels are not properly connected to ground, the surge suppression devices

may not function and data communications may be erratic.

For proper grounding all ACUs should be connected to earth ground, not to chassis or electrical ground. Cold

water pipes or a grounding rod usually make a good earth ground. The grounding wire should be as heavy as

possible with as short and straight a run as possible. Avoid sharp bends in the wire because a large power surge

might arc across the board.

Recommended Grounding Sources

• Cold Water Earth Ground

• Building Ground

• Electrical Ground

11

The UTC Fire & Security system should use a consolidated earth ground, in which the public utilities and the

security system ground rods are bonded together. A consolidated earth ground eliminates the problem of step

voltage blowout, in which measurable voltage potential exists between earth ground rods, resulting in a current

flow path and damage to the system during a lighting strike.

It is recommended that 12 AWG wire be used to connect the earth ground in the shortest and straightest path

possible. Avoid sharp turns and use a minimum radius of eight inches (203 mm) for bends. Ground wires

should be run separate from other wires and be routed toward the earth. Use of eight-foot (2.4 m) copper clad

ground rod is recommended.

Page 26

TOPAZ ACURT2 & ACURT4

Normally Closed

Sensor

Normally Open

Exit Push Button

Normally Open

Sensor

Z+

Z-

Z+

Z-

Z-

Z+

12

Hardware Installation Guide

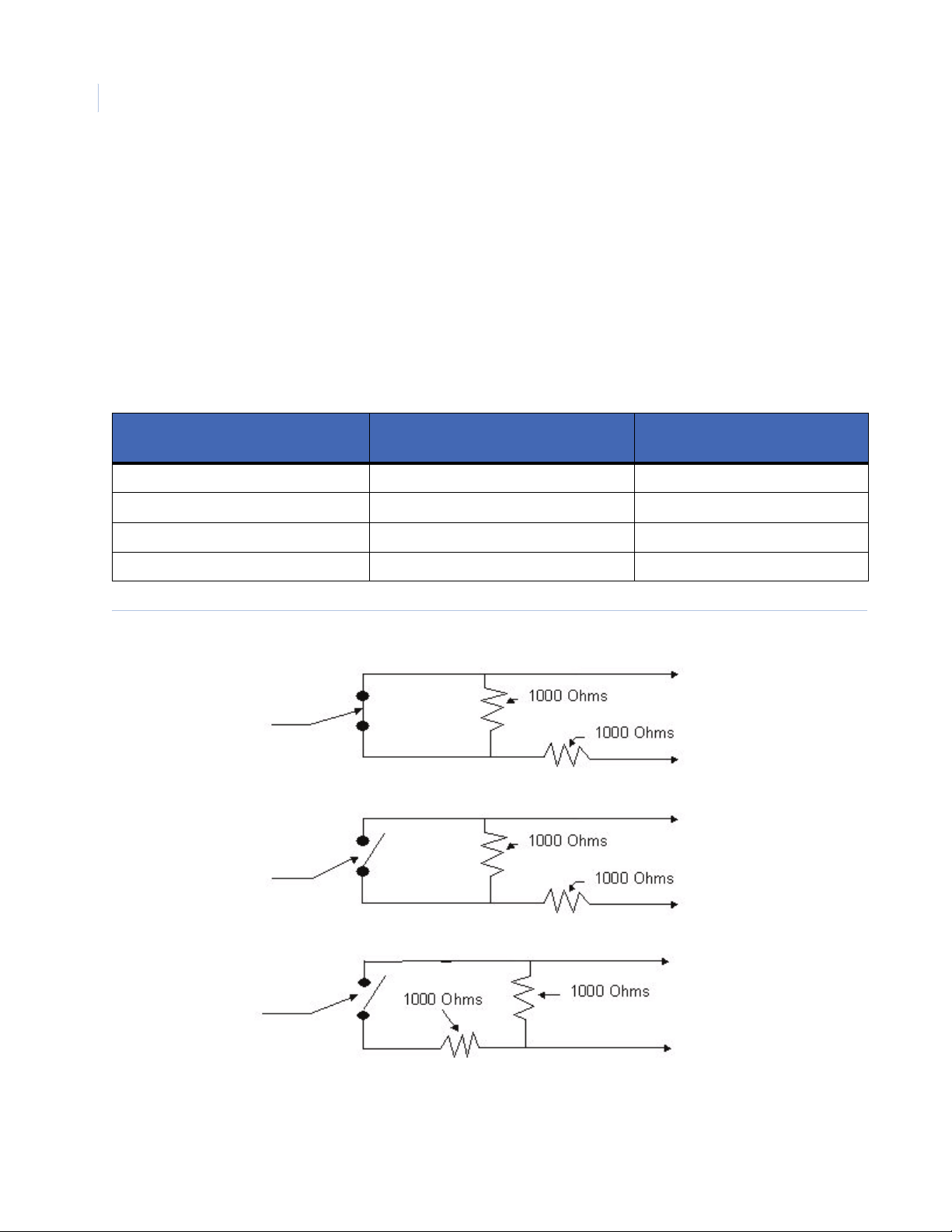

Alarm Zone Sensor Wiring

Pull twisted pair of wire (Belden 9407-22 AWG or equivalent) from each alarm zone sensor to the assigned

input terminals on the ACURT controller or Remote Module (RIM). (See Terminal Block Tables in each

section for alarm zone terminations.) End-of-line (EOL) resistor for the SECURE state is 1000 ohms. The EOL

(End-Of-Line) resistor must be located within the alarm zone sensor enclosure, otherwise the alarm zone

circuit will be considered unsupervised.

When 1000 ohms terminators are used, the sensors can be either normally closed contacts or normally open

contacts providing the SECURE or inactive state is 1000 ohms. See Figure 6. (Note: A normally open exitpush-button is wired the same as a normally closed alarm).

Table 5. Alarm State Resistance

Figure 6. Zone Sensor with 1000-Ohm Resistors

Sensor Circuit in Ohms

Zone Input State

Secure 1000 1000

Active 2000 500

Open > 50000 > 50000

Short < 50 < 50

Normally Closed

Sensor Circuit in Ohms

Normally Open

Page 27

Installing the ACURT Panel

Chapter 2

Network Communications

This section provides guidelines for the network environment needed to support communication between a UTC

Fire & Security Topaz Server and ACU Networked Intelligent Controller Field Panels. While it is not possible to

address every variable that may exist in a customer’s network environment, this highlights key network considerations.

The information in the following table is assuming a minimum Topaz server software revision of 1.47.

Table 6. Network communications guidelines

Port The TCP/IP port number that the ACU panel listens to is 3000 plus the system WAN number (typically

3001).

Protocol TCP/UDP

All messages are less than 255 bytes. The protocol is a simple command and response protocol with a

sequence number retry mechanism.

13

Timing Polling

Frequency

Server Wait

and Delay

Time

Server Retry If the server does not receive a response from the panel within the delay time described

Panel

Timeout

Timing

Calculations

400 milliseconds per ACU panel (fixed)

Wait time for the server to receive a response is 500 milliseconds. Networks should be

able to respond to a ping for each panel within 500 milliseconds for optimum

performance.

Additional user-configurable delay time of up to 3000 milliseconds can be set for each

panel. Typical additional delay is 500 milliseconds.

above, the server will re-send another poll to the panel. The default number of retries is

3. The Retry for each panel can be increased up to 10 by the system administrator.

Setting the number of retries above three is usually for testing purposes only, and not

intended for normal operation of the system.

If a panel does not receive a correct message from the server within 10 seconds, the

panel will no longer respond to the server (a “local panel off-line” condition). This could

be caused by a network interruption or incorrect message(s). An example of an

incorrect message might be if the network corrupts a server message, resulting in a

checksum error. This causes the server to resynchronize communications with the

panel. A corresponding message will be reported at the server as a “panel off-line”.

To determine proper panel settings for optimal communication, perform the following

calculations for each panel. The total delay, including retries, should be less than 10

seconds (Panel Timeout); The lower the total, the more optimal system performance.

ACU LAN Panel with no downline panels via serial connection:

#Retries X [Delay Time(secs) + Wait Time(secs)] = Total

For example: 3 X [1.2 + 0.5] = 5.1

ACU LAN Panel hosting down-line panels via serial connection:

#Down-line panels X #Retries X [Delay Time(secs) + Wait Time(secs)] = (Total)

For example: 3 x 3 x [0.5 + 0.5] = 9

Bandwidth

Dynamics

Network Hops To ensure consistency, the number and distance of hops between a field panel’s LAN port and it’s

It is important that allocated bandwidth remains consistent at all times and is not clamped down (or

reduced) during off-hours such as at night or on weekends. Inconsistent or dynamic bandwidth can

result in inconsistent on-line/off-line behavior of field panels, especially if network throughput is

marginal.

hosting server should be kept to a minimum.

Page 28

TOPAZ ACURT2 & ACURT4

14

Hardware Installation Guide

Table 6. Network communications guidelines (continued)

Download

Activity

Two types of download activity can occur: Full panel downloads or smaller downloads that occur

during routine use of the system. During the download operation, the ACU is fully operational after

power-up. Access requests are processed and normally, little delay is experienced. However, large

amounts of activity have an adverse effect on system performance.

A full panel download can be initiated manually by the system administrator, or automatically when:

• A panel is powered-up or reset

• A change is made to Access Groups

• A panel definition is modified

• A new reader is defined

• An elevator floor definition is modified.

Note: During a full panel download, the entire card database is downloaded to the panels, however

only those cards which are authorized for access through doors controlled by a panel are

downloaded to that panel, thus reducing per-panel traffic.

Following a server restart, all alarm points, relays, time schedules, and other user-programmed

settings and parameters are downloaded. The card database is only downloaded if, after a

comparison, the server detects that cardholder changes were made at the server but not updated to

the ACU.

If an initial download from the server to the ACU is interrupted, the ACU waits for the download to

restart.

Note: ACU2X: After a successful download, the ACU2X saves the count of cards in its database. If

a subsequent full card download is interrupted, the panel restores the original pointers so that

a backup mechanism exists until a successful download is achieved.

ACU

Comparison

The ACU2XL, ACURS, and ACURT panels are approximately 100 times faster for communication that

an ACU2 or ACU2X panel with the LanTronix kit. This is because a panel using the LanTronix kit

connects to the kit from the panel serial port that runs at an average of 9600 baud, whereas the

ACU2XL, ACURS, and ACURT panels run at the 10 Mbps rate of their built in network card.

Page 29

Installing the ACURT Panel

Chapter 2

Setting IP Address

If the installation requires UL Listing, Network connections cannot be used.

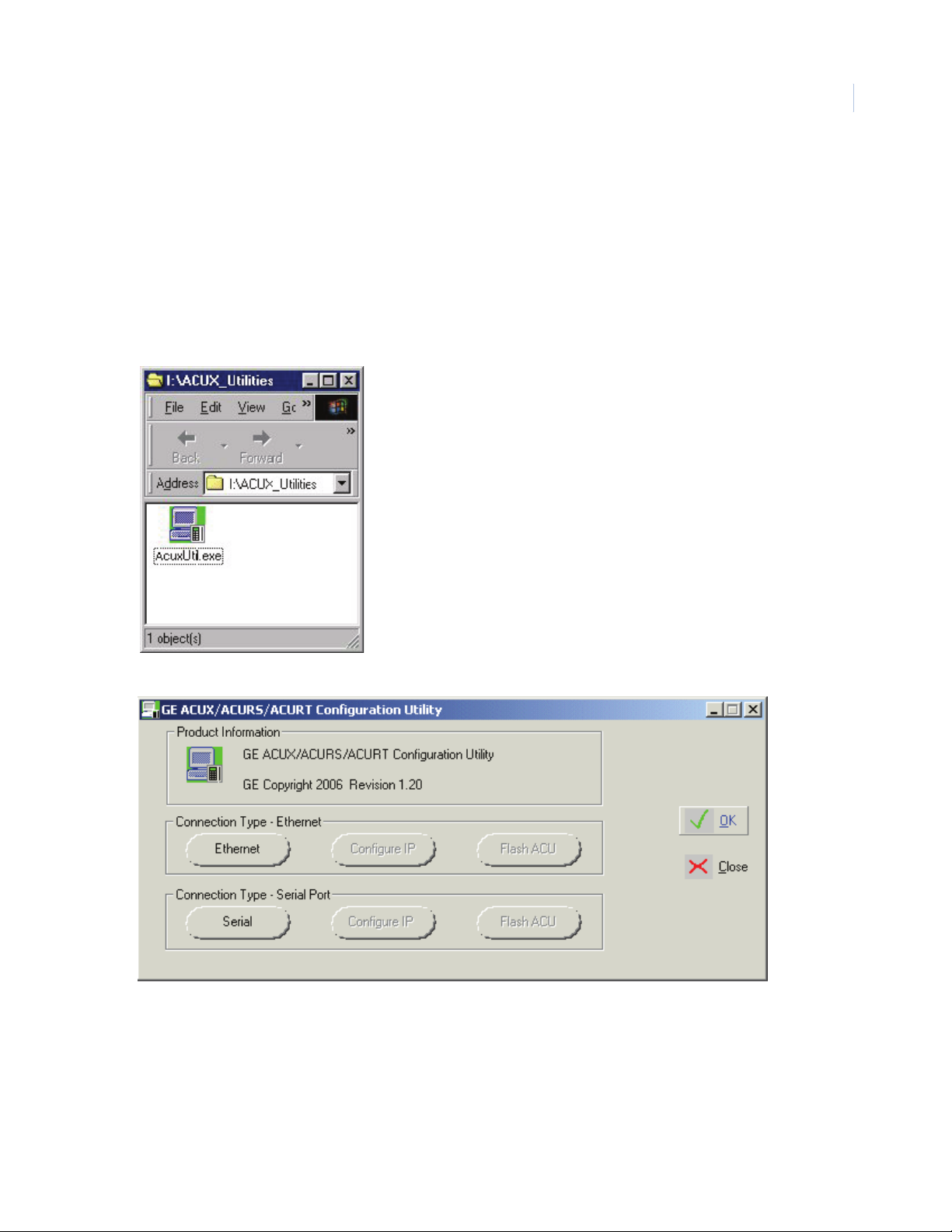

One of the simplest ways to set the IP address on the ACURT2 or ACURT4 is with a laptop computer in the

field running the AcuxUtil.exe program.

If using the default IP address (SW3 switch 3 on) attach and configure only one ACURT at a time.

To set up the TCP/IP address for an ACURT field panel start by locating the AcuxUtil.exe file on the CD and

start the utility by double-clicking on its icon.

15

After starting the utility the following screen is displayed.

Page 30

TOPAZ ACURT2 & ACURT4

16

Hardware Installation Guide

Set IP Address Through Ethernet

Before continuing make sure your PC has a network card installed with TCP/IP enabled. The IP address must

able to communicate to the ACURT. In other words, the first three sets of numbers of the computer’s IP address

must match the first three sets on numbers of the ACURT IP address. The default IP address of the ACURT is

192.168.0.132

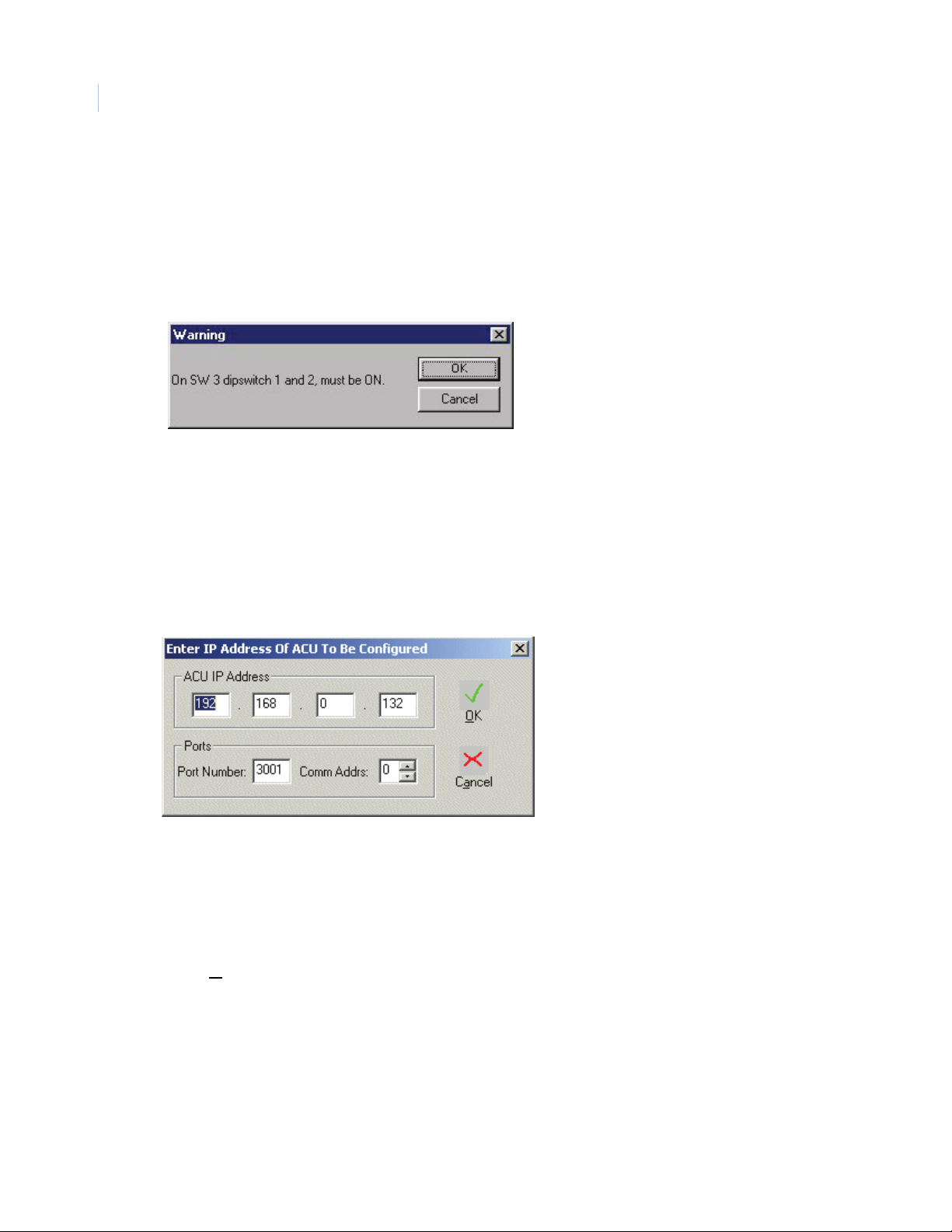

1. Click the Ethernet button.

2. Make sure that SW3 DIP switches 1, 2, and 3 are ON before continuing.

Note: If you change switch settings, you must restart the ACU by powering down and back up.

3. You must also know the IP address of the ACURT before continuing. If you do not know the current IP

address for the ACURT, turn SW3 switch 3 ON to use the default IP address of 192.168.0.132.

4. Power must be cycled on the ACURT for the switches to be read.

5. After the switches are set properly, click OK

.

The IP Address of the ACURT is set at the factory default of 192.168.0.132.

6. Enter the IP address for the ACURT.

7. The Port Number will be left at the default 3001 unless you have multi servers on your system. If

using multi server, change the last three digits (3000 plus the LAN number) of the Port Number to

reflect the server number. For server number two the Port Number would be 3002.

8. Click O

K to continue.

Page 31

9. Click Configure IP to start the configuration of the IP Address

.

Installing the ACURT Panel

Chapter 2

17

10. Make sure SW3 DIP Switches 1 and 2 are turned ON at the ACURT and click OK.

The addresses for this screen must be obtained from your MIS department.

Page 32

TOPAZ ACURT2 & ACURT4

18

Hardware Installation Guide

11. Enter the new ACURT IP Address, Sub Net Mask, Gate IP Address, (Gateway or Router).

12. The Existing Port No. will be left at its default 3001 unless you have multi servers on your system.

Change the last three digits of the Port No. to reflect the server number (3000 plus the LAN number).

For server number two the Port No. would be 3002.

The Time Out Period is used for redundant systems only. The default is 30 Sec.

13. Click OK to continue.

The ACURT was updated successfully.

14. Click OK to continue

.

15. Before continuing, make sure DIP switch 3 at the ACURT is turned OFF.

16. Click OK to continue and reset the ACURT. The ACURT is updated with the new IP address.

17. Click OK to complete the setup.

Page 33

Installing the ACURT Panel

Set IP Address Through Serial Connection

The ACURT must be able to connect to the computer and power to the ACURT must be turned on.

1. Click the Serial button.

2. Turn SW3 DIP switch 1 OFF and 2 ON at the ACURT.

3. Power must be cycled on the ACURT for the switches to be read.

4. Click OK to continue.

Chapter 2

19

5. Select the Communication port to which the ACURT is connected.

6. Select the Baud Rate at which the ACURT is set to communicatet. The default is 9600.

7. Parity should be left at Even.

8. The SCP Address is the communication address at which the ACURT is set with SW4.

9. Click OK.

If the ACURT is not communicating the following message will appear.

Page 34

TOPAZ ACURT2 & ACURT4

20

Hardware Installation Guide

10. Click OK, check your Serial connection, and try again.

The addresses for this screen must be obtained from your MIS department. The IP Address of the

ACURT has been set at the factory to 192.168.0.X. The X number is different for each ACURT.

11. Enter the new ACURT IP Address, Sub Net Mask, Gate IP Address, (Gateway or Router).

12. The Existing Port No. will be left at its default 3001 unless you have multi servers on your system.

Change the last three digit of the Port No. to reflect the server number (3000 plus the LAN number).

For server number two the Port No. would be 3002.

13. The Time Out Period is used for redundant systems only. The default is 30 Sec.

14. Click OK to continue.

The ACURT was updated successfully.

15. Click OK to continue.

Page 35

Installing the ACURT Panel

16. Before continuing, make sure DIP switches 2 and 3 at the ACURT are turned OFF.

17. Click OK to continue and reset the ACURT to update the new IP address.

18. Click OK to continue.

Note: The panel will ping at 100mbsp, but it will only come online at 10mbsp.

Determining the MAC address

The IGS IEEE assigned MAC address for the ACU XL LAN unit is: 00 06 0e 00 00 00

where the last 4 digits are the serial number in hexadecimal.

For example, a serial number of 1000 would be: 00 06 0e 00 03 e8

Troubleshooting LAN Communication

LAN panels do not come online:

1. Access the Command Prompt screen. From the taskbar, click Start Programs Accessories

Command Prompt.

Chapter 2

21

2. Type the following commands to troubleshoot your LAN communication:

IPCONFIG

This command will tell you what the IP Address of your PC is.

PING 192.168.0.132

192.168.0.132 is the default panel address.

• If you are connected to the panel with a cross over cable and SW3 switch 3 is On, you should be

able to ping the panel at the default IP address assuming your PC’s IP address starts with an

address of 192.168.0. If you can’t ping the default panel, you may have a faulty cable or the

network jack on PC/panel may have a problem.

• If you are not using the default IP address, insert your panel’s IP address in place of the

192.168.0.132 address and verify the connection.

• If you unplug the network cable from the panel but can still ping the panel address from the server

than you have a duplicate address on your network and need to contact your System Administrator.

• You can also type ping -t and the IP address to do a continual ping to see if the connection

between your PC and your panel is stable.

Page 36

TOPAZ ACURT2 & ACURT4

22

Hardware Installation Guide

Flashing the ACURT with new PROM

TOPAZ supports firmware levels 3.49 to series 8.xx.xx or later.

Note: To update surface mount panels with firmware earlier than version 5.85.00, first flash the ACU with firmware with

version 5.85.00. Then flash it with the 8.xx.xx series or later PROM.

The ACU Utility (AcuxUtil.exe) can be used to upload program information to the ACURT.

From a PC running the utility, attach to the Field Panel you want to upload. In order to flash a panel with the

ACU Utility, you must first have a connection between the Utility and the panel. See Setting IP Address on

page 15 for steps on connecting the ACURT to the ACU Utility.

Figure 7. ACU Utility: Flash ACURT

3. Click FlashACU and browse to the file containing the firmware. A confirmation dialog, similar to the

following displays.

Figure 8. ACU Utility: Confirmation dialog

4. Click OK to continue. As instructed, do not power off the ACU during the update. You may need to

wait up to two minutes. When the update is complete, the following dialog displays:

Figure 9. ACU Utility: Flash successful

Page 37

Installing the ACURT Panel

Installing UPS Batteries