Page 1

SuperBus 2000 Commercial RF Transceiver

Installation Instructions

466-1653D • March 2009

Copyright © 2009, GE Security Inc.

Introduction

This is the GE SuperBus 2000 Commercial RF Transceiver

Installation Instructions for models 60-821-95 and 60-856-95.

The transceiver adds or extends a compatible panel’s wireless

capabilities in both residential and commercial installations.

You can mount the transceiver near the panel cabinet or up to

4,000 ft. (1219 m) away. The transceiver receives information

from wireless sensors and touchpads and sends the data to the

panel, via the SuperBus 2000 digital data bus. Power for the

module is provided by the panel.

Advent systems support up to five transceiver modules.

Transceiver features include:

• Spatial diversity reception to minimize wireless signal nulls

or dead spots.

• Compatibility with all GE Security 319.5 MHz crystal learn

mode wireless sensors and touchpads.

• Open air receiving range of 3,500 ft. (1067 m) typical in

metal case and 2,500 ft. (762 m) in plastic case.

• LED indications of transceiver power, wireless packet

reception, and bus status.

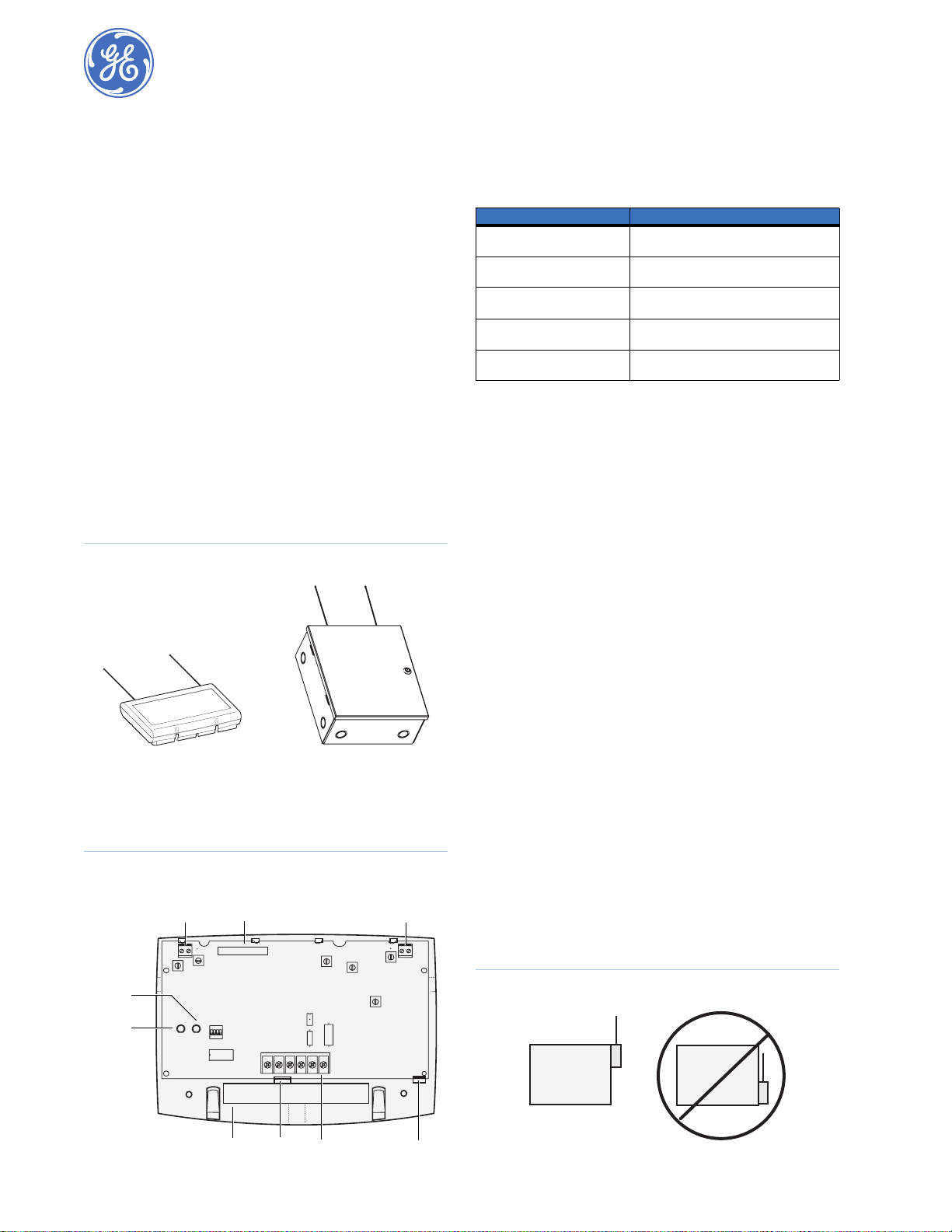

• two case versions (Figure 1), 60-821-95 (plastic) and

60-856-95 (metal).

Figure 1. Model cases

60-821-95

plastic case model

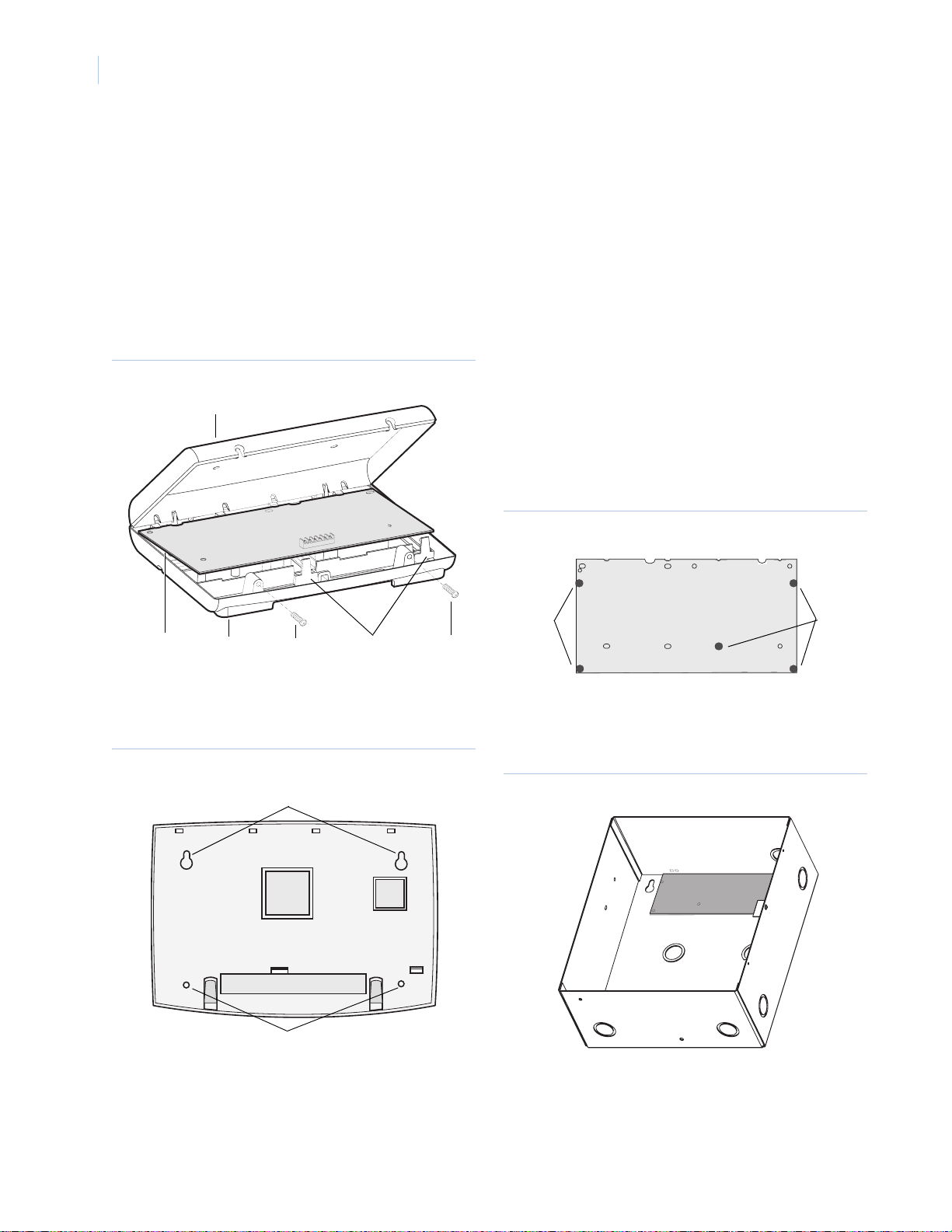

Figure 2 shows the transceiver components (plastic case version

shown) and Table 1 describes the components.

Figure 2. Transceiver components

Antenna

terminal

SuperBus

ID label

ID: XXXXXXXX

60-856-95

metal case model

Antenna

terminal

Table 1. Transceiver components

Component Description

Antenna terminals Provide antenna connections (outer termi-

Unique SuperBus 2000 ID label Indicates the unique identif ication number

Module power LED On when module is powered, flickers when a

Bus status LED Flashes when the transceiver communicates

Wiring terminals Connections for power, bus, and hardwire

nals are used with optional metal enclosure).

of the module.

wireless signal is received.

with the panel via the SuperBus.

zone.

Tools and supplies

You will need the following tools and supplies to install the

transceiver:

• Mounting screws and anchors for plastic enclosure

(included).

• Two 9-in. (22 cm) antennas (included).

• Two antenna grounding screws (included in metal case kit).

• 1/4 in. plastic spacers (included in metal case kit).

• Small standard and Phillips screwdrivers.

• Four-conductor, 18-gauge or larger, stranded hookup wire

(recommended).

Installation

Use the following guidelines to install the transceiver:

• Advent systems can accommodate up to 250 sensors/zones.

Refer to your panel documentation for maximum zone

count.

• Advent systems can have up to 62 SuperBus devices.

• Leave at least 10 in. (25 cm) above the transceiver for the

antennas.

• Avoid areas that expose the transceiver to moisture.

• Use 4-conductor, 18-gauge or larger stranded wire from the

transceiver to the panel.

For power wiring, refer to your panel documentation for

maximum wire length recommendations. If the maximum

recommended wire length must be exceeded, a remote DC

power supply is required. When using a remote power

supply, the power and ground connections of panel and

remote supplies must remain isolated and the power supply

output must be isolated from earth ground. Do not connect

the panel and remote power supplies together.

• Avoid areas with excessive metal or electrical wiring,

including furnace and utility rooms. If unavoidable, mount

on or near metal with the antennas extending above the

metallic surfaces (Figure 3).

Status

LED

Power

LED

Wire

access

Card

latch

Wiring

terminals

Card

latch

Figure 3. Mounting near metal

Metal

Metal

Page 2

SuperBus 2000 Commercial RF Transceiver

2

Installation Instructions

• Mount the transceiver on any interior wall (protected from

the elements).

• If possible, temporarily mount, connect, and test the RF

transceiver at the desired location to evaluate performance

in the particular environment.

Plastic case module installation

To install the module in the plastic case (60-821-95), do the

following:

1. Disconnect the panel backup battery and turn off power to

the AC power transformer.

2. Remove the transceiver cover and the circuit board and set

them aside (Figure 4).

Figure 4. Remove cover and circuit board

Cover

Antenna installation

To install the antennas, do the following:

1. Loosen the inside terminals of the left and right antenna

terminal block (Figure 2 on page 1).

2. Insert an antenna into each inside terminal.

3. Tighten the antenna terminal screws.

Metal case installation

To install the module in the metal case (60-856-95). do the

following:

1. Remove the metal case cover and transceiver circuit board,

and set aside.

2. Hold the case against the mounting surface and mark the

four (larger) mounting holes. Remember to leave at least 10

in. (25 cm) above the case for the antennas.

3. Drill the mounting holes in the wall and insert the appropriate anchors.

4. Remove the case wiring knockouts as necessary.

5. Secure the case to the wall with panhead screws.

6. Snap the 1/4 in. plastic spacers (included) into the back of

the circuit board (Figure 6).

Figure 6. Plastic spacers

Circuit

board

Backplate

Cover

screws

Card

latches

Cover

screws

3. Hold the backplate against the mounting surface and mark

the four mounting holes (Figure 5). Remember to leave at

least 10 in. (25 cm) above the base for the antennas.

Figure 5. Mounting holes

Mounting holes

Mounting holes

Plastic

Plastic

spacers

spacers

7. Snap the circuit board into the case (Figure 7).

Figure 7. Snap the circuit board in the metal case

Plastic

spacers

4. Drill holes and insert appropriate anchors.

5. Secure the backplate to the wall with panhead screws.

6. Snap the circuit board back into the backplate.

Page 3

3

Antenna installation

To install the antennas in the metal case, do the following:

1. Loosen the left and right antenna terminal blocks

(Figure 8).

Figure 8. Metal case antenna installation

Antennas

Antenna

grounding

screw

Antenna

terminal

block

Antenna

terminal

block

Antenna

grounding

screw

2. Screw an antenna grounding screw (included) into each

outside terminal.

3. Insert an antenna into each inside terminal.

4. Tighten the antenna and ground terminal screws.

Wiring

This section describes how to wire the transceiver to compatible

panels and how to wire the transceiver hardwire zone input

terminals.

CAUTION: Improper connections can result in

damage to the equipment.

Advent panel wiring

Wire the transceiver to the panel SuperBus wiring harness as

shown in Figure 9.

Hardwire zone wiring

Connect the module Zone 1 and Zone Com terminals to the hardwired device as shown in Figure 10 using 2.0 Kohm EOL resistors (49-467) on the last device.

Figure 10. Hardwire zone wiring

SuperBus commercial

RF transceiver module

Zone 1 Zone COM

(OR)

UL listed

normally closed (N/C)

contacts in series

EOL resistor

EOL resistor

UL listed

normally open (N/O)

contacts in parallel

Module device address

Each bus module connected to the panel SuperBus must have a

unique (different) device address number set for correct communication. SuperBus 2000 compatible panels such as Advent set

the address automatically when the module is added (learned)

into panel memory.

Figure 9. SuperBus wiring harness connections

SuperBus commercial

RF transceiver module

+12VDC Bus A Bus B GND

To other

SuperBus

devices

Black

White

Green

Red

Panel SuperBus

wiring harness 46-462

Power up

Splice

Use the following procedures for powering up the system and

verifying bus communications for both new and existing installations.

New installations

To power up the system in new installations, do the following:

1. Verify that all wiring at the panel and the transceiver is

correct.

2. Connect the panel backup battery and the AC power transformer. Alphanumeric touchpad displays should come on.

3. Verify that the transceiver module green power LED is on

and the red bus LED flashes to indicates successful communication with the panel (Figure 2 on page 1).

Note: If the transceiver power LED is not on or the red bus

LED does not flash, unplug the panel AC power

transformer, disconnect the backup battery, and see

Troubleshooting on page 4.

Page 4

SuperBus 2000 Commercial RF Transceiver

4

Installation Instructions

Existing installations

To power up the system in existing installations, do the

following:

1. Verify that all wiring at the panel and the transceiver is

correct.

2. Connect the panel backup battery and the AC power transformer. Alphanumeric touchpad displays should come on.

3. Press 8 to select System menu.

4. Press 0 to enter program mode.

5. Enter the install code (defaults to 0123).

6. Enter item number 48001 to add SuperBus devices. All

installed devices are automatically added (learned) into

panel memory when Devices Added is indicated.

7. Press * twice to return to normal mode of operation and

refer to the testing sensors/inputs section of your panel

documentation for testing module operation.

8. Verify that the transceiver module green power LED is on

and the red bus LED flashes to indicate successful communication with the panel.

Note: If the transceiver power LED is not on or the red bus

LED does not flash, unplug the panel AC power

transformer, disconnect the backup battery, and see

Troubleshooting.

Programming

Refer to your panel documentation for adding (learning) wireless

devices into panel memory.

Testing

Verify that the module red bus LED flickers when wireless

devices are activated. Verify that the panel recognizes wireless

device and hardwire zone actuation (if used).

For complete testing procedures, refer to your panel documentation.

Troubleshooting

The module green power LED stays off.

Check for incorrect wiring connections and for panel power.

If the module power LED still stays off, replace the trans-

ceiver.

The module green power LED is on, but doesn’t flicker when

wireless transmitters are tripped (no or limited wireless operation).

Check transceiver antenna connection.

Check for transceiver antenna proximity to metal obstruc-

tions such as duct work or AC wiring.

Verify sensors are learned into panel memory.

If the transceiver still malfunctions, replace the module.

The red bus status LED flashes, but system does not respond.

Check panel/transceiver programming.

Delete transceiver from panel memory and relearn. Refer to

the Advent panel installation instructions for specific

details.

If the transceiver still malfunctions, replace the module.

Wireless device compatibility

The transceiver is compatible with the wireless devices listed in

Tab le.

Table 2. Compatible wireless devices

Part number Description

60-348 Learn mode handheld wireless touchpad

60-362 Learn mode door/window sensor

60-452 Learn mode pendant panic sensor

60-453 Wall-mount wireless touchpad

60-457 Dual-button panic sensor

60-458 Single-button panic sensor

60-459 Sound sensor

1 Rate-of-rise heat sensor

60-460

60-461 Learn mode shock sensor (with 13-214 detector)

60-462 Learn mode glass guard sensor

60-499 Learn mode SlimLine door/window sensor

60-504 Learn mode freeze sensor

60-506

1 Learn mode smoke sensor (System Sensor) 2001RF

60-511 Learn mode DS924i PIR motion sensor

60-578 Water-resistant pendant panic sensor

60-589 Learn mode fire pull station sensor

60-597 HiTech handheld wireless touchpad

60-606 Four-button keychain touchpad

60-607 Two-button keychain touchpad

60-615 Quik Bridge learn mode repeater

60-641 Learn mode long life door/window sensor

60-652 Carbon monoxide sensor

60-688 Learn mode micro door/window sensor

60-703 PIR motion sensor

60-741 Learn mode recessed micro door/window sensor

60-834 Learn mode FlexGuard sound sensor

60-848

1 Wireless smoke sensor (for UL 217 listed residential installa-

60-849

1 Wireless smoke sensor (for UL 268 listed commercial instal-

1. Learn mode repeaters are not UL 864 listed. All wireless fire devices (rate-ofrise heat sensors and smoke sensors) cannot be used with repeaters. Fire

sensor signals transmitted from repeaters cannot be processed by the RF

transceiver.

tions)

lations)

Page 5

5

FCC compliance

FCC part 15 information to the User

Changes or modifications not expressly approved by GE Security can void the

user’s authority to operate the equipment .

FCC part 15 class A

This equipment has been tested and found to comply with the limits for a class

A digital device, pursuant to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment .

This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, and may

cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

users will be required to correct the interference at their own expense.

FCC part 15 class B

This equipment has been tested and found to comply with the limits with a class

B digital device, pursuant to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful

interference to radio communication. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the affected equipment and the panel receiver to separate outlets,

on different branch circuits.

Consult the dealer or an experienced radio/TV technician for help.

Specifications

Compatibility Advent panels (60-562-01, 60-562-02, 60-

Number of wireless sensors Limited to the maximum capacity of the

Hardwire zones One class B, style A supervised, fire-rated,

Power required 12 VDC nominal at 50 mA maximum (from

Data bus SuperBus 2000, auto-addressing digital data

Data bus range Up to 4,000 ft . (1219 m) from panel, 18 gauge

Signal range 3,500 ft. (1067 m) typical in metal case,

Operating temperature 32 to 120°F (0 to 49°C) for extended periods,

Storage temperature -30 to 140°F (-34 to 60°C)

Max. relative humidity 90% noncondensing

Dimensions (L x W x D)

60-821-95 commercial burg

60-856-95 commercial fire

Case material

60-821-95

60-856-95

Listings UL 365: Police Connected Burgl ar Alarm Units

562-03), GE Security 319.5 MHz crystal learn

mode wireless sensors and touchpads, all dry

contact-type hardwire contacts

panel

normally open or closed dry contact zone

input

panel)

bus

or larger hookup wire

open air

2,500 ft. (762 m) typical in plastic case,

open air

(may vary with application)

up to 140°F (60°C) under temporary conditions

6.0 x 8.5 x 1.5 in. (152 x 216 x 38 mm)

11.25 x 9.75 x 4.63 in. (285 x 248 x 118 mm)

excluding antennas

High-impact, ABS plastic

16-gauge steel

and Systems

UL 609: Local Burglar Alarm Units and

Systems

UL 985: Household Fire Warning System

Units

UL 1023: Household Burglar Alarm System

Units

UL 1610: Central Station Burglar Alarm

System Units

ULC Canada Commercial Fire/Burglary

Warning System (applied for)

CSFM California State Fire Marshall

DOD Sensitive Compartment Information

Fac. (applied for)

FM Factory Mutual (applied for)

MEA New York City Material Equipment

Acceptance (applied for)

Complies with NFPA for Fire Alarm Code

Toll-free: 888.GESECURity (888.437.3287 in the US, including Alaska and Hawaii; Puerto Rico; Canada).

Outside the toll-free area: Contact your local dealer.

Technical support

www.gesecurity.com

Loading...

Loading...