Page 1

Fire & Life Safety

Smoke Detection

Overview

GE brand 500 Series two- and four-wire conventional photoelectric

smoke detectors bring together trusted technology and a full line

of features that meet the demands of every type of application. The

500 offers sounders in two- and four-wire applications, specifically

to meet residential code requirements.

The 500 Series also offers choices for optional auxiliary relays and

isolated heat sensors, not available before in the 500 Series.

GE is also proud to offer proven technology like CleanMe®, dust

compensation, field replaceable optical chambers, and self-diagnostics. CleanMe® is only available on the 500 2-wire models and

will communicate to the GE FireworX panels when servicing is

required.

500 Series detectors work on a light-scattering principle. A pulsed

infrared light-emitting diode serves as the light source, and a highspeed photo diode as the sensing element. This design has superior

protection against nuisance alarms caused by dust, insects, RF

interference, and ambient light.

The proprietary optical chamber is field replaceable. In the event of

a confirmed alarm the LED will light continuously. The unit indicates

trouble by flashing the LED every second. This meets the NFPA 72

field sensitivity testing requirements.

Units with built-in 85dBA sounders emit a temporal 3-3-3 tone

pattern when in alarm and will emit a steady tone when the input

power is reversed. All wiring terminates in clamp-type screw terminals. The detectors mount to a standard single-gang electrical box,

a four-inch octagonal, four-inch square electrical box, or WIREMOLD

No. 5739 fixture box.

Standard Features

•

Remote maintenance (CleanMe®) reporting (2-wire models)

and built-in drift compensation reduces false alarms

Self diagnostics eliminates the need for external meters

•

Field-replaceable optical chamber makes service fast and simple

•

Small, low profile design blends with any environment

•

Optional auxiliary functions include:

•

Integral sounder

•

Fixed/Rate-of-Rise heats

•

Auxiliary relay

•

Single station smoke with system heat

•

Built-in power supervision relay

•

Smoke Detectors

with Auxiliary

Functions

500 Series

Page 2

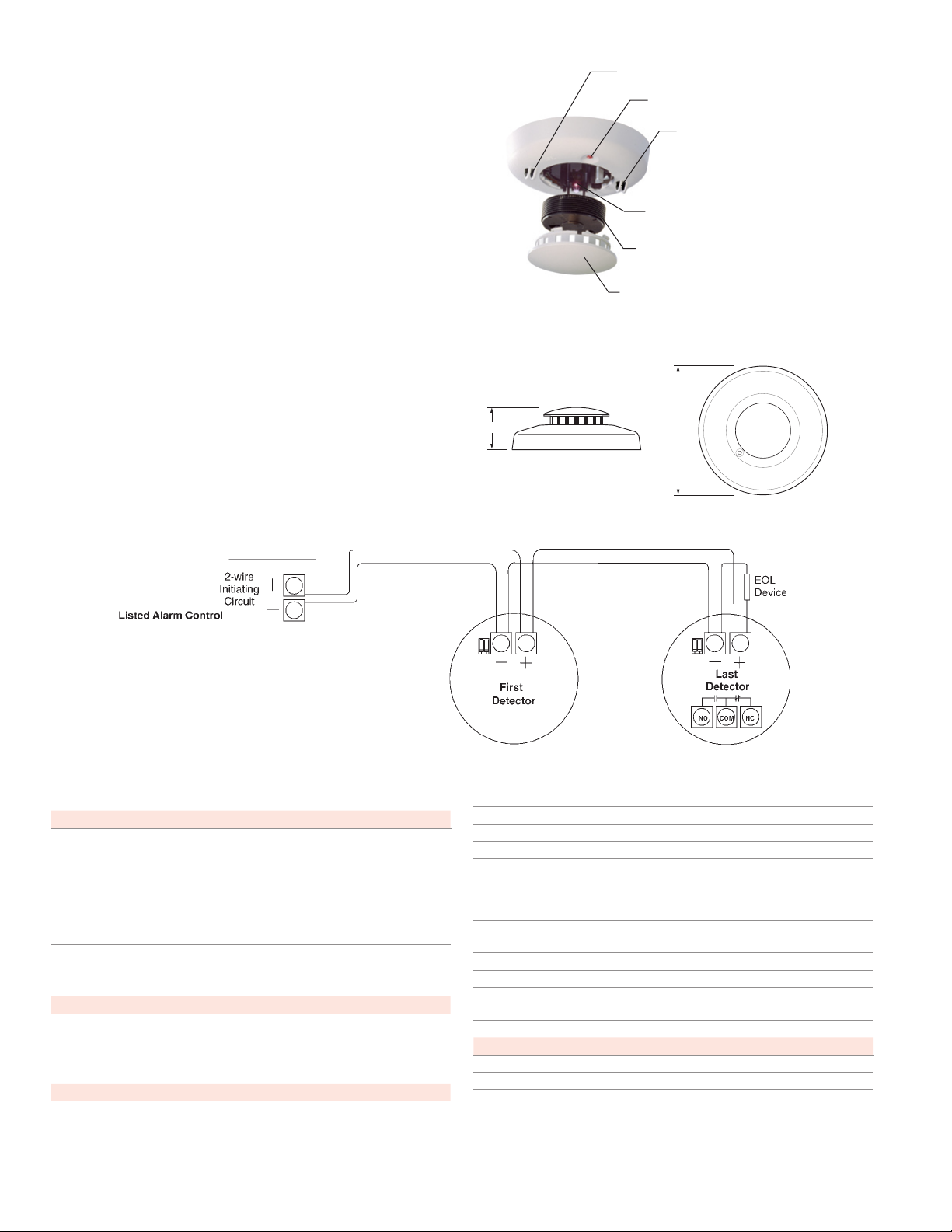

2" (5cm)

5" (12cm)

500 Series detectors are ideal for both retrofit applications and new

installations alike. They are particularly well-suited for installations

where detector reliability is essential, but where analog devices may

not be appropriate or feasible. With their replaceable optical chambers, these detectors are equally well-suited to dusty environments

where detectors require frequent cleaning.

AssemblyApplication

Optional fixed temperature sensor

Diagnostic LED

Optional rate-of-rise sensor

Photoelectric sensor

Replaceable optical chamber

Detector cap

Mounting and Installation

500N detector bases mount directly to standard single-gang electrical boxes, three-inch round, or four-inch octagonal boxes. Detector

heads simply twist onto the base. Heads are equipped with a breakaway locking tab, which prevents unauthorized removal. Terminals

accept 12 to 24 AWC field wiring.

Typical Wiring

Specifications

Electrical

Power Supply 8.5-33VDC (12/24 V operation) polarity

sensitive

Maximum ripple pk-pk (6/12/24V) 10% (Vpk-pk)

Typical average standby current 70 μA

Typical alarm current (6/12/24V) up to 60 mA max if not limited by

control panel

Auxiliary relay contacts 1.0 A @ 30 VDC; Form C

Alarm contacts 500 mA @ 36 VDC (resistive)

Photoelectric sensitivity 3.1% + 0.5 - 1.0%

Environment

Operating temperature 32° to 100° F (0° to 37° C)

Operating humidity range 0 to 95% non-condensing

RFI immunity 20 V/m min; 0-1000 MHz

Physical

Dimensions

Color White

Field wiring size 12-24 AWG (16-22 recommended)

Detector packaging 10 detectors per carton

Heat detector specifications Rate-of-Rise:

UL 2-wire compatibility

identifiers

Drift compensation adjustment 1.0% ft. max

Detector head dimensions 5.5 D x 2" H (14.0 x 5 cm)

Mounting dimensions 5.25" (13.3 cm) diameter;

Regulations

Reset time 1 second min

Listings C-UL-US, CSFM, MEA

15° F/min and >105° F

(8.3° C/min and >40.6° C)

Fixed Threshold: 135° F (57.2° C)

S10A, S11A

0.3" (0.8 cm) height

Page 3

Ordering Information

Model Description Compatibility Alarm Current (mA) Reverse

521B 2-wire, photoelectric, 6-33VDC S09A/S10A 5 min. - 60 max.

521BXT 2-wire, photoelectric, 6-33VDC, fixed temp and rate-of-rise heat S09A/S10A 5 min. - 60 max.

521NCRXT 2-wire, photoelectric, 8.5-33VDC, fixed temp and rate-of-rise heat, aux. relay S11A 15 min. - 60 max.

521NCSXT 2-wire, photoelectric, 8.5-33VDC, fixed temp and rate-of-rise heat, temporal 3

sounder

521NCSRXT 2-wire, photoelectric, 8.5-33VDC, fixed temp and rate-of-rise heat, aux. relay

temporal 3 sounder

541C 4-wire, photoelectric, 6-33VDC N/A 20

541CXT 4-wire, photoelectric, 6-33VDC, fixed temp and rate-of-rise heat N/A 20

541NCSRXT 4-wire, photoelectric, 8.5-33VDC, fixed temp and rate-of-rise heat, aux. relay,

temporal 3 sounder

541NCSXTE 4-wire, photoelectric, 8.5-33VDC, fixed temp and rate-of-rise heat, built-in end

of line relay, temporal 3 sounder

541NCSRH 4-wire, photoelectric, 8.5-33VDC, isolated fixed temp and rate-of-rise heat, aux.

relay, temporal 3 sounder, non-latching LED with auto reset

541NCRXT 4-wire, photoelectric, 8.5-33VDC, fixed temp and rate-of-rise heat, aux. relay N/A 25

541NCXTE 4-wire, photoelectric, 8.5-33VDC, fixed temp and rate-of-rise heat, built-in end

of line relay

541NCSXT 4-wire, photoelectric, 8.5-33VDC, fixed temp and rate-of-rise heat, temporal 3

sounder

548C 4-wire, photoelectric, 8.5-33VDC, ULC Listed

548CT 4-wire, photoelectric, heat, 8.5-33VDC, ULC Listed

Note: Only 500 Series 2-wire smoke detectors are CleanMe compatible.

S10A 10 min. - 60 max 10

S11A 15 min. - 60 max 10

N/A 35 13

N/A 45 28

N/A 35 13

N/A 35

N/A 30 13

polarity (mA)

Options (add the following suffixes as appropriate)

B 6-33VDC operation

C 8.5-33VDC operation

E End-of-Line relay

H Isolated rate-of-rise and fixed temp sensors

R Auxiliary relay

S 85dBa sounder

XT Rate-of-rise and fixed temp sensors

Accessories

405-05 Polarity reversal module enables sounder interconnection of all 4-wire smoke detectors, when initiating detector sounds all smokes sound.

401 Test magnet in a plastic shell for pole mounting

SM200-12PKG Smoke in a Can!® canned smoke for functional testing

SM-ext1L Smoke in a Can!® extension tube

211-10PKG Replacement optical chambers (set of 10)

500PLT-5PKG 6" trim ring for wider coverage area

Loading...

Loading...