Page 1

User Guide

Super 130.3

Super 135.3

Super 145.3 Works

Super 150.3

Super 160.3 Works

(07.2018)

Page 2

The instruction consists of 4 parts. Part 1:3 Safety

Instructions. Part 2:3 User Guide. Part 3:3 Troubleshooting, Technical Data and Disposal. Part Warranty

Conditions.

Part 1:3 - Safety Instructions

maintenance.

During use of high pressure washers, aerosols

may be formed. Inhalation of aerosols can be haz-

ardous to health, for the protection against aerosols

a respiratory mask of class FFP 2 or equivalent may

be needed, depending on the cleaning environment.

Before rst use of the machine, read the instruc-

tions carefully. Save instructions for later use.

Safety instructions marked with this symbol

must be observed to prevent personal injury

or serious damage to property.

WARNING

This machine has been designed for use with

cleaning agents supplied or recommended by Gerni. The use of other cleaning agents or chemicals

may adversely aect the safety of the machine.

High pressure jets can be dangerous if

subject to misuse. The jet must not be directed at persons, live electrical equipment or

the machine itself.

Do not use the machine within range of persons

unless they wear protective clothes.

Do not direct the jet against yourself or others in

order to clean footwear.

Risk of explosion – Do not spray ammable liq-

uids. High pressure washers shall not be used

by children or untrained personnel.

High pressure hoses, ttings and couplings are

important for the safety of the machine. Use only

hoses, ttings and couplings recommended by Ger-

ni.

To ensure machine safety, use only original spare

parts recommended by Gerni.

Water that has own through back-ow preven-

ters is considered to be non-potable.

Don’t use the machine if a supply cord or important parts of the machine are damaged, e.g. safety

devices, high pressure hoses, trigger gun.

Inadequate extension cords can be dange rous.

If an extension cord is used, it shall be suitable for

outdoor use, and the connection has to be kept dry

and o the ground. It is recommended that this is

accomplished by a cord reel which keeps the socket at least 60 mm above the ground.

Switch o and unplug the machine when leaving

it unattended, when nished using it or when converting it to another function, when doing repair and

Intended Use and Terms of Liability

•

The Super-series have been developed for do-

mestic cleaning pur poses only and for use in an

upright position. Any other use is considered as

improper use.

A high pressure washer operates with dierent

•

levels of pressure and cleaning detergents for

various cleaning tasks and results. Always follow

instructions on detergents for use, emergency

and disposal.

• Do not operate the machine at temperatures be-

low 0°C. Never start a frozen machine, never use

it indoor and never cover it during use. This is

considered improper and wrongful use. Use of

wrongful pressure, detergent and/or applications

may cause damage to machine, surfaces, material

and devices.

All of the above is considered improper and wrongful use. Gerni accepts no liability for any damage

resulting from any improper or wrongful use.

Safety devices and their functioning

The machine automa tically stops when releasing

the trigger. The machine will start again when re-

activating the trigger. The spray handle features a

locking device. When activated, the spray handle

cannot be operated.

The machine has an automatic self-resetting thermal

protector. If the machine is overheated, the thermal

protector will cut the power supply. In this case, wait

for the machine to cool down. An integrated hydraulic safety valve protects the system from excessive

pressure.

Precautions

The electric supply connection shall be made by a

qualied electrician and comply with IEC 60364-1.

It is recommended that the electric supply to this

machine should include either a residual current

device that will interrupt the supply if the leakage

current to earth exceeds 30 mA for 30 ms or a device

that will prove earth circuit.

• Use motor start/delayed fuses with characteristic

D according to IEC 947-2 or corresponding standards outside IEC.

2

Page 3

• If the supply cord is damaged, it must be replaced

by an authorized Gerni distributor or similar qualied

person in order to avoid a hazard.

No actions needed for adjusting machines marked

•

with dual voltage and frequency.

• Supervise children not to play with the machine.

The operator and any one in the immediate vicinity

•

of the site for cleaning should take action to protect oneself from being struck by debris dislodged

during operation.

• Always wear safety boots, respiratory mask, ear

protection, goggles and protective clothing during

operation.

• The high pressure generated by the machine is a

particular source of danger. Hold the spray lance

rmly with both hands. The spray lance is aected

by a kickback force and a sudden torque during

operation.

• See PART 3:3 for the actual size of the kickback

force.

• During transportation: Position the machine hori-

zontally on the backside and secure with straps.

High pressure washers shall not be used nor main-

•

tained by children or untrained people or people with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge.

Part 2:3 - User Guide

E

Leaving the machine unattended > 5 min.

See listed warnings. Follow the illustrations in E.

F After use and storage

After use always: Turn o the machine. Empty machine and accessories of water to avoid frost damage.

Remove the plug from socket. Disconnect water inlet

hose. Wind up electrical cable and high pressure

hose to avoid damage of cable, high pressure hose

and ttings. Storage of machine shall be frost free.

• Follow illustrations in F.

G Maintenance, inspection and repair

Maintenance of the machine should always be done

when starting up after long time of storage.

Before use, always inspect the machine and

equipment for damages. In case of damages, act

according to listed warnings.

Do not attempt any maintenance not described

•

in the instructions. If the machine refuses to start,

stops, pulsates, pressure uctuates, motor buzzes,

fuse blows or no water comes out, check Part 3.3

Troubleshooting.

• User maintenance according to illustrations in G.

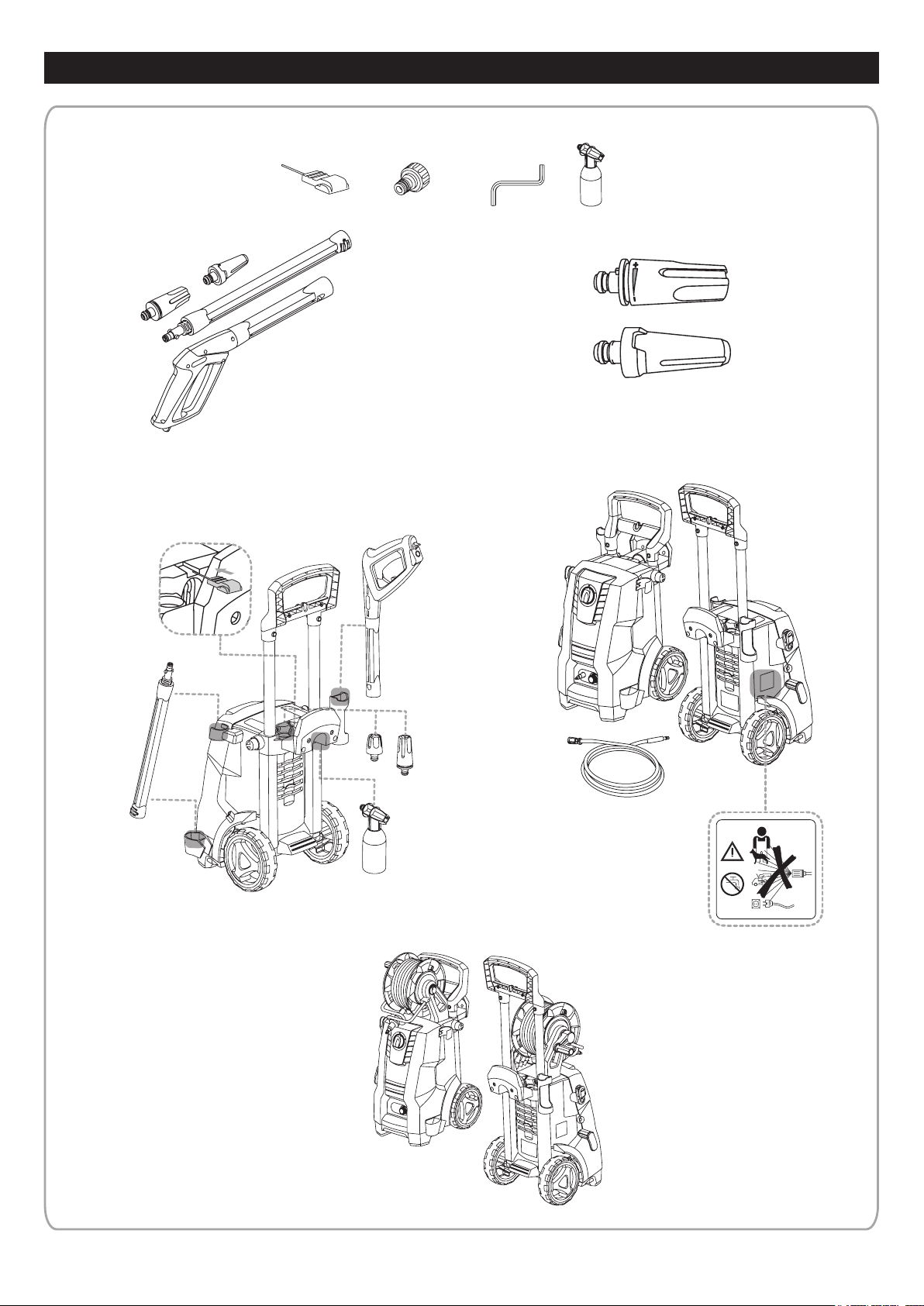

Provides a general overview of the machine and

operation elements along with illustrated sections on

preparation, operation, water connection, storage,

and user maintenance.

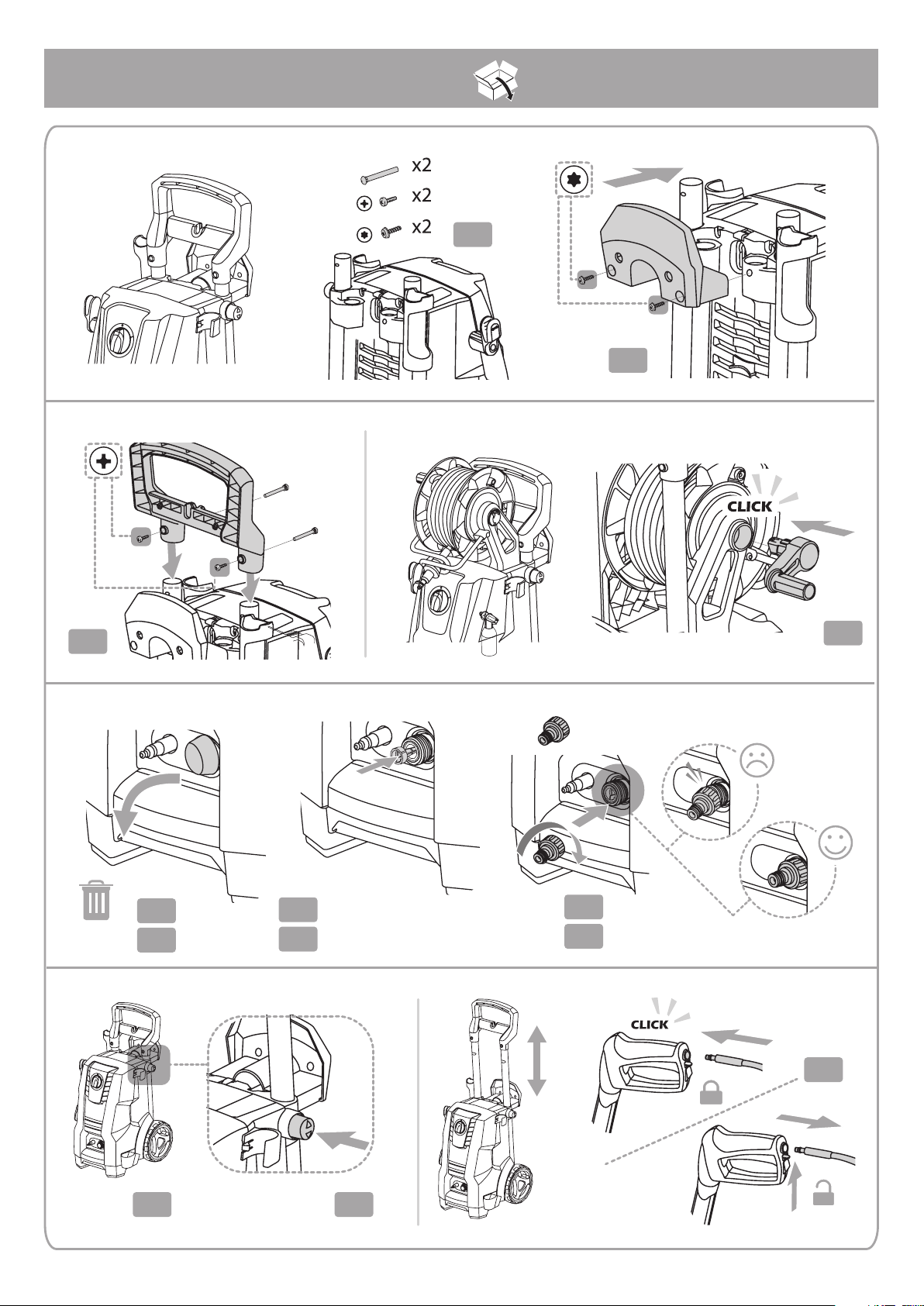

A Unpacking and preparing for use

Follow illustrations in A.

B Connection to potable water mains

High pressure washers are not suitable for connection to the potable water mains. Always check

national regulations before connecting the machine

to potable water mains and use a back-ow preventer

if required.

• Use ½" garden hose, 10-25 m.

• Follow illustrations in B.

C Connection to other water sources

You can connect the machine to e.g. rain water vessels, rivers, lakes and cisterns etc. and operate it in

suction mode. Follow illustrations in C.

D Pairing of spray handle and machine

Not relevant.

3

Page 4

Part 2:3 User Guide

Super 130

S

uper 135

Super 145 Works

Super 150

Super 160 Works

4

Page 5

A

A1.1

A1.2

A1.3

A1.4

A2.2

A1.5

A2.3

A2.1

x1

A1.6

A2.4

A3.3

A3.1

A3.2

5

Page 6

A

A3.4

A3.7

B

A3.5

A3.8

A3.6

B1.1 B1.3

B1.5

B1.4

B1.6

6

B1.2

B1.7

B1.8

Page 7

B

B1.9

B1.10

MPa

bar

B2.1

MPa

bar

C

B1.11

B1.12

B2.2

C1.3

C1.4

C1.5

C1.1

C1.2

C1.6

7

Page 8

C

C1.7

C1.8

C1.11

D

C1.9

C1.10

Not relevant

E

E1.1

E1.2

E1.

3

E1.4

8

Page 9

F

F1.1 F1.2 F1.3

F1.4

F1.9

F1.5

F1.10

F1.6

F1.11

F1.14

F1.7

F1.8

F1.12

F1.13

F1.15

9

Page 10

G

G1.2

G1.1

G1.3

G1.4

G1.6

G1.5

G1.7

10

Page 11

H

128500382

Water

Suction Kit

128470462

Rim Brush Head

128500671

Inlet Water

Suction Hose 3 m

128500385

Click&Clean

Auto Brush

128500386

Click&Clean

Underchassis Nozzle

128500387

Click&Clean

Auto Nozzle

128500461

Garden Brush Head

128500380

Rotary Brush

28500388

Drain & Tube

Cleaner - 15 m

128500701

Classic Patio

128470460

Multi Brush

(incl. car brush head)

128500464

Car Brush Head

128500976

Power Patio

11

Page 12

Part 3:3 - Troubleshooting, Technical Data and Disposal

Troubleshooting

To avoid unnecessary disappointments, you should check the following before contacting the Gerni service organization.

Symptom Cause Recommended action

Machine refuses to start Machine not plugged in

Defective socket

Fuse has blown

Defective extension cable

Fluctuating pressure Pump sucking air

Valves dirty, worn out or

stuck

Pump seals worn out

Machine stops Fuse has blown

Incorrect mains voltage

Thermal sensor activated

Nozzle partially blocked

Fuse blows Fuse too small Change to an installation higher than the amp. consumption

Machine pulsating

Machine often starts and

stops by itself

Machine starts, but no

water comes out

Air in inlet hose/pump

Inadequate supply of

mains water

Nozzle partially blocked

Water lter blocked

Hose kinked

Pump/spray handle is

leaking

Pump/hoses or accessory frozen

No water supply

Water lter blocked

Nozzle blocked

Plug in machine

Try another socket.

Replace fuse. Switch o other machines.

Try without the extension cable.

Check that hoses and connections are airtight.

Contact tour local Gerni Service centre.

Clean and replace or refer to local Gerni distributor.

Replace fuse. Switch o other machines.

Check that the mains voltage corresponds to specication on

the model tag.

Leave the washer for 5 minutes to cool down.

Clean the nozzle (see Part 2.3 User Guide, G)

of the machine. You may try without the extension cable.

Allow machine to run with open trigger until regular working

pressure resumes.

Check that the water supply corresponds to specications

required (see model tag)

NB! Avoid using long, thin hoses (min. 1/2")

Clean the nozzle (see Part 2.3 User Guide, G)

Clean the lter (see Part 2.3 User Guide, G)

Straighten out hose.

Contact your nearest Gerni Service Centre.

Wait for pump/hoses or accessory to thaw.

Connect inlet water.

Clean the lter (see Part 2.3 User Guide, G)

Clean the nozzle (see Part 2.3 User Guide, G)

In case problems other than the above occur, please phone 1300 733 171 or check our website www.gerni.com.au for

your nearest service agent.

12

Page 13

Technical Data

Super 130.3 Super 135.3

Electric specications Unom 230-240 V

fnom 50 Hz

Pnom 2.1 kW 2.0 kW 2.1 kW 2.3 kW 2.3 kW

Inom 9 A 9 A 10.5 A 10A 10.5 A

Protection Class Class I/

Class II

Protection degree IP XX IP X5

Hydraulic specications

Max. water inlet pressure

Max water inlet temperature

Max water inlet temp. suction

mode

Kick-back force

Weight

Hand-arm vibration according to:

Standard nozzle

Sound pressure level LpA

Guaranteed sound power level

LWA

p

nom

p

max

Q

Q

max

p

inlet max

t

inlet max

t

inlet max

F

kickback

M

machine

a

ha

LpAstandard

LwA-

standard

12.5 MPa /

125 bar

13.0 MPa /

130 bar

7.5 l/min /

450 l/h

18 kg 18.6 kg 22.1 kg 20.6 kg 22.1 kg

12.5 MPa /

125 bar

13.5 MPa /

135 bar

7.5 l/min /

450 l/h

Super 145.3

Works

Class I

14.0 MPa /

140 bar

14.5 MPa /

145 bar

6.7 l/min /

402 l/h

8.3 l/min / 500 l/h

1 Mpa / 10 bar

60° C

20° C

< 20N

< 2.5 ± 1 m/s

69 ± 3 dB(A)

83 dB(A)

Super 150.3

14.5 MPa /

145 bar

15.0 MPa /

150 bar

6.7 l/min /

410 l/h

2

Super 160.3

Works

14.5 MPa /

145 bar

16.0 MPa /

160 bar

6.7 l/min /

410 l/h

We reserve the right to make alterations.

Recycling the high pressure washer

Make the old machine unusable immediately.

• Unplug the machine.

• Cut the electric cable.

Do not discard electrical appliances with household waste. As specied in WEEE Directive 2012/19/EC on old electrical

and electronic appliances, used electrical goods must be collected separately and recycled ecologically. Contact your

local authorities or your nearest dealer for further information.

13

Page 14

Warranty Conditions

Our goods come with guarantees that cannot be excluded

under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or dam-

age. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure. Gerni high pressure washers for domestic use are warranted for 2 years

from the date of purchase by:

AUSTRALIA: Nilsk Pty LTd, Unit 1/13 Bessemer

Street, Blacktown NSW 2148, Phone: 1300 556 710,

E-mail: Warranty.au@nilsk.com

NEW ZEALAND: Accent Tools Ltd, 232 Bush Rd,

Albany, Auckland 0632, Phone: 09 968 2610,

E-mail: sales@accent-tools.co.nz

Equipment defects covered by this warranty will be re-

paired or replaced by one of the service centres of the

Gerni organisation. Find your local service agent here:

http://www.gerni.com.au/. If your high pressure washer or

accessories are handed in for repair, it must be followed

by a description/specication of the fault, and the original

purchase receipt, or a copy, must be enclosed. Packing

and postage/carriage is not covered by the warranty. This

warranty is provided in addition to the other rights and

remedies of the purchaser under the laws in relation to the

goods to which the warranty relates. Guarantee repairs are

made on the following conditions:

• that defects are attributable to aws or defects in materials

or workmanship (wear and tear as well as misuse are not

covered by the guarantee).

• that the directions of the instruction manual have been thor-

oughly observed.

•

that repair has not been carried out or attempted by other

than Gerni-trained service sta.

• that only original Gerni accessories have been applied.

•

that the product has not been exposed to abuse such as

knocks, bumps or frost.

• that only water without any impurities has been used.

• that the high pressure washer has not been used for rental

nor used commercially in any other way.

Repairs not covered by the guarantee conditions will be

invoiced. (i.e. malfunctions due to Causes mentioned in

section Troubleshooting of Part 3:3.

Please phone 1300 733 171 (Australia) or

09 9682610 (NZ) for service or warranty

assistance only after checking possible

causes in Part 3:3.

14

Page 15

AUSTRALIA:

NEW ZEALAND:

Nilsk Pty Ltd

Unit 1/13 Bessemer Street

Blacktown NSW 2148

Phone: 1300 556 710

E-mail: Info.au@nilsk.com

Accent Tools Ltd

232 Bush Rd

Albany

Auckland 0632

Phone: 09 968 2610

E-mail: sales@accent-tools.co.nz

Loading...

Loading...