Operating instructions

Rota – Disc*

Corn header

Carl Geringhoff – Vertriebsgesellschaft mbH & Co. KG

Gersteinstraße 18, D – 59227 Ahlen

Tel. ++49-2382-9814-0, Fax ++49-2382-981440

E –BA-RD-03

E-Mail: info@geringhoff.de Internet: www.geringhoff.de

Content

General

Certificate of conformity EC 02 / 000

General safety arrangements 01 / 020

Introduction 01 / 000

To the customer 01 / 010

Warning label (pictograms) 01 / 030

Corn header

Contrate gearing speed change 09 / 600

Couplers between the stripping plates 09 / 640

Corn header to mount 09 / 120

Corn header drive 09 / 160

Corn header to unpack 09 / 000

Cross belt auger / feeding 09 / 720

Cut-off block

Divider noses to mount 09 / 320

Drive coupler folding corn headers 09 / 280

Gathering chains 09 / 520

Gearing and oil control 09 / 560

Hydraulic connections to mount 09 / 200

Hydraulic function of folding corn headers 09 / 240

Mounting arrangements on combine 09 / 080

Operation and function of monitor 09 / 440

Overload protections and sliding clutches 09 / 800

Stripping plate adjustment 09 / 480

Trial run 09 / 680

Weights 09 / 040

Rota Disc*

Knife disk shaft 10 / 100

Stripping rotors 10 / 200

Stubble cutter / stripper 10 / 000

Maintenance and Care

Maintenance and care 10 / 300

Help in case of malfunctions

Cross belt auger 10 / 915

Drive 10 / 905

Hydraulics 10 / 900

Stripping unit 10 / 910

Special equipment

Corn ear saver 35 / 050

Change speed gear 35 / 010

Change speed gear 35 / 005

Lodged maize augers

Sunflower harvester 35 / 000

Special tools

Chain tension tool 36 / 000

Starting torque for screws 36 / 100

Puller for rotor bearing 36 / 000

Wiring diagrams etc.

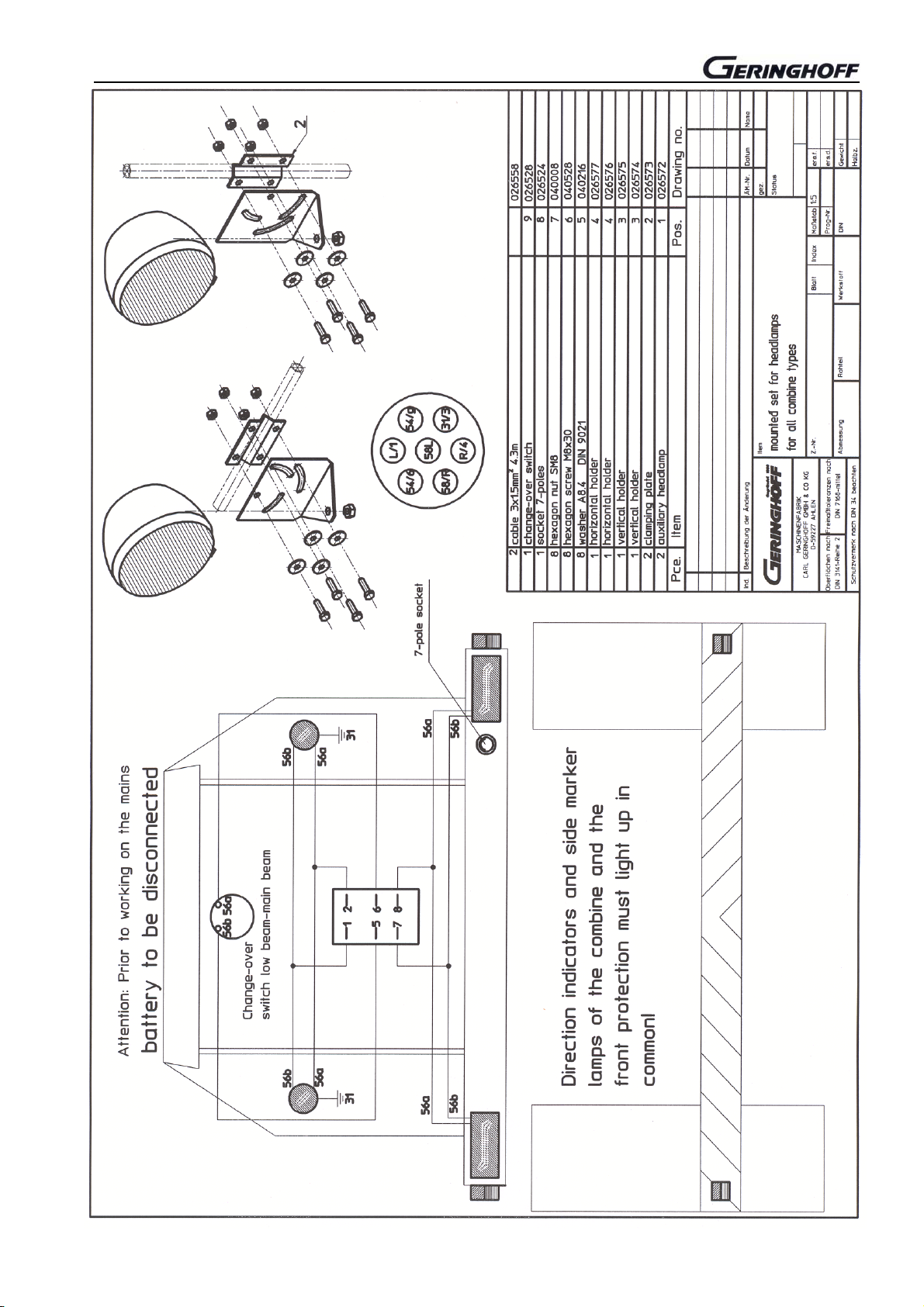

Wiring diagram combine lighting 36 / 500

Wiring diagram hydraulics folding headers 36 / 300

Corn header

10 / 210

00-001

Introduction

These operating instructions describe the most

essential working steps for a safe handling and use

of the Geringhoff products.

Read these instructions and observe the safety

notes.

A regular maintenance and care will help to keep

the value of the product and to ensure a troublefree use over many years to your benefit.

Tell us about your experience made with the

machine to enable us to put it into practice. The

partnership with our customers is very important to

us and will contribute to our common success.

01 / 000

To the customer

01 / 010

We thank you for the confidence placed in us on

the purchase of a Geringhoff product.

Hereunder you’ll find some important information

for the use of these operating instructions:

• When using the operating instructions, we

recommend using also the spare part

catalogue for gaining an in-depth

understanding of essential details.

• Note the most important data of your

machine in the fields provided. That makes

it easier to you answering the questions of

your supplier.

Machine no.:_______________________

Machine type.:_______________________

Year of construction:__________________

Row distance:_____________________

Working width/ Number of row units: _____

Combine type.:___________________

• The series no. is on the typeplate left on

the supporting frame.

• The operating instructions contain the

international standard SI-measures.

• Right and left means always towards travel

and/or working direction.

• If you are in need for spare parts, keep the

required data available and get in touch

with your dealer.

• Do only us original Geringhoff spare

parts.

• Send the completed consignment note

directly to the manufacturer. This

information is very important for potential

guarantee claims. Failing which, these

potential claims cannot be handled.

• Do not make any modifications on

important, load-bearing and safety-relevant

elements. The manufacturer does not

assume any guarantee for damages

resultant therefrom.

General safety arrangements

To prevent accidents, follow strictly these

operating instructions and warning notes on

the

machine.

Before starting the machine, check it for operational

dependability and traffic safety!

Apart from these operating instructions, follow also the

current safety instructions!

The warning signs and labels give important notes for

the safe operation of the machine and serve to your

and the health of others!

Prior to starting the works, make yourself familiar with

all operating elements and functions.

Check the driving characteristics, steering and braking

behaviour.

No riders unless sitting on the provided places.

When working on the machine, the provided supporting

devices must be used.

Admissible axle loads and total weight must absolutely

be observed.

Before the start-up, all guards and maintenance holes

to close.

Whilst the machine is running, keep off the dangerous

area.

Maintenance and repairing works to be performed only

with Diesel motor cut off.

On public roads the legal provisions to observe.

All machines have a valid ABE or EBE governing the

road transport licensing regulations.

If required, additional headlights for the road transport

to mount.

(see road transport licensing regulations)

The instructions of the combine manufacturer for the

operation with headers to follow.

01 / 020

Warning label (pictograms)

ISO 11684

Prior to performing maintenance and repairing

works, the motor to turn off and the key to withdraw! It’s only allowed to go into the dangerous zone

when the lifting cylinder safety is put in!

Keep off the dangerous zone between During the operation guards must not

header and machine! be opened or removed!

Whilst motor is running, guards never to Whilst the motor is running, guards must not be

open or remove! opened or removed!

Keep a sufficient safety distance to the header. Never go into the slewing range of

Prior to maintenance works or clearing of cloggings the machine!

header to switch off, motor to stop and key to

withdraw!

01 / 030

02 / 000

02 / 000

EG-Konformitätserklärung

EG-Konformitätserklärung

Rota – Disc* corn header

Rota – Disc*

We reserve the right of making modifications

for the sake of progress.

Sizes and weights are approximate values and refer each to

the standard versions of the different header types.

Due to the great number of header models and combines

this list cannot show all the different illustrated variants.

For this reason, we hope you will understrand the general

sense of the wordings, which requires a sufficient basic

knowledge of the carrier machine.

RD / 000

Corn header to unpack

Scope of supply / state at time of supply

Subject to model and type the header can be supplied in

horizontal position or upright on a shipping crate.

Each consignment is accompanied by a detailed and typereferred packing list.

Packages attached to the header to remove.

Check the scope of supply!

Check the supplied row distance!

Ensure the safe standing of the

machine!

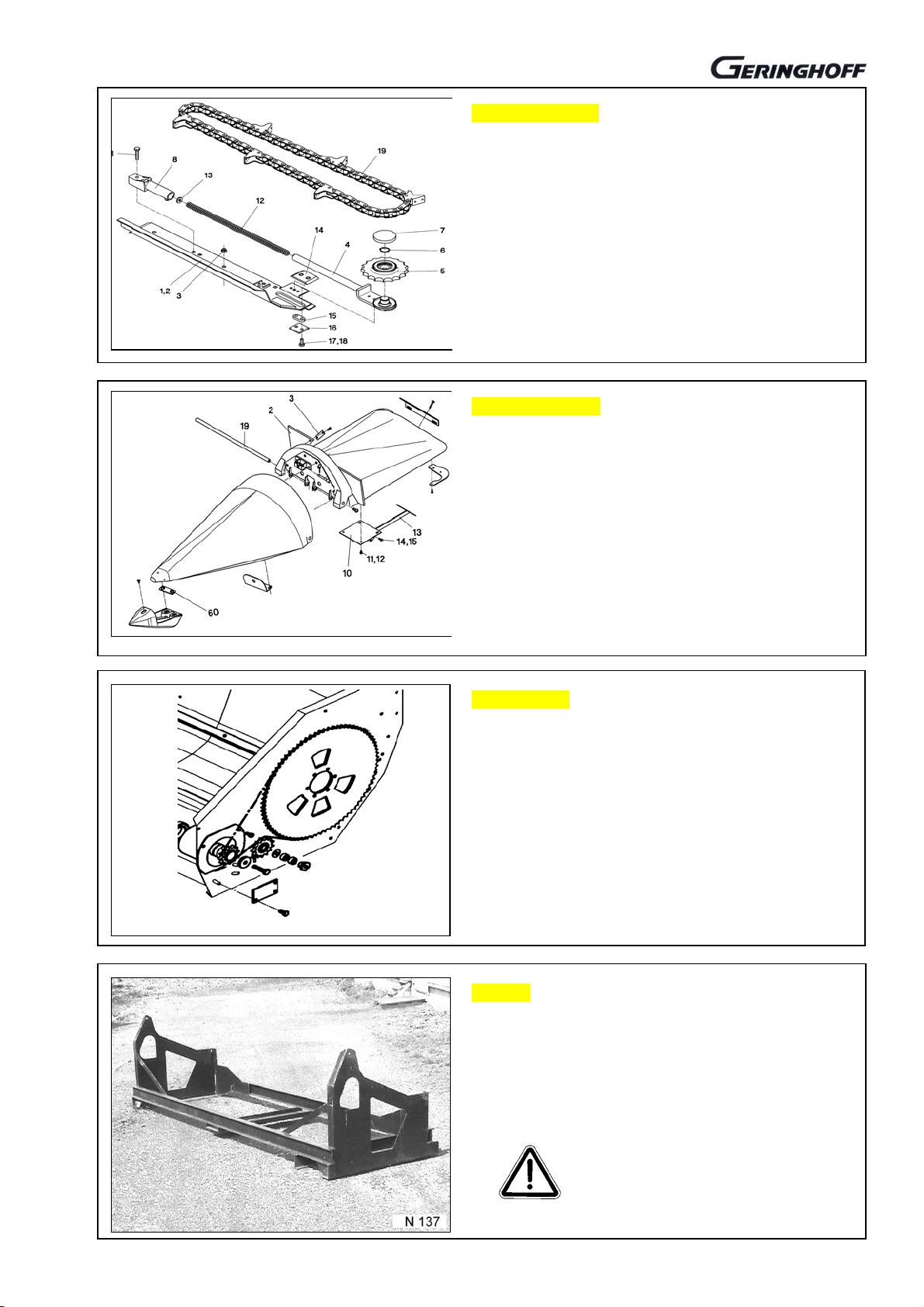

Remove the shipping crate

Extend the supports (S). Move the hoist to the bottom side

of the header.

Suitable chains or belts to attach to the drawbar eyes (W),

slightly to lift and hoist slowly to move away from the

header.

Header carefully to lower considering the tilting angle.

Use hoist, which is strong enough!

Do not go into the dangerous zone!

Follow the instructions for hoists!

Remove screws (B) and shipping crate.

Further use of the trestle

The trestle (T) is recommended to be stored for a later use.

Possible after-season and service works are to be

performed easier with the machine standing in upright

position.

Folding corn headers to lift by crane

Folding headers are possibly supplied without shipping

crate (T).

For the transport with hoists only provided eyes (L) and

location on the front transport angle (S) to be used.

If required, transport protection to remount.

Before mounting the header to the combine, transport

protection to remove (S).

Protection to remove only when the header stands on firm

ground.

09 / 000

Corn header to unpack

A

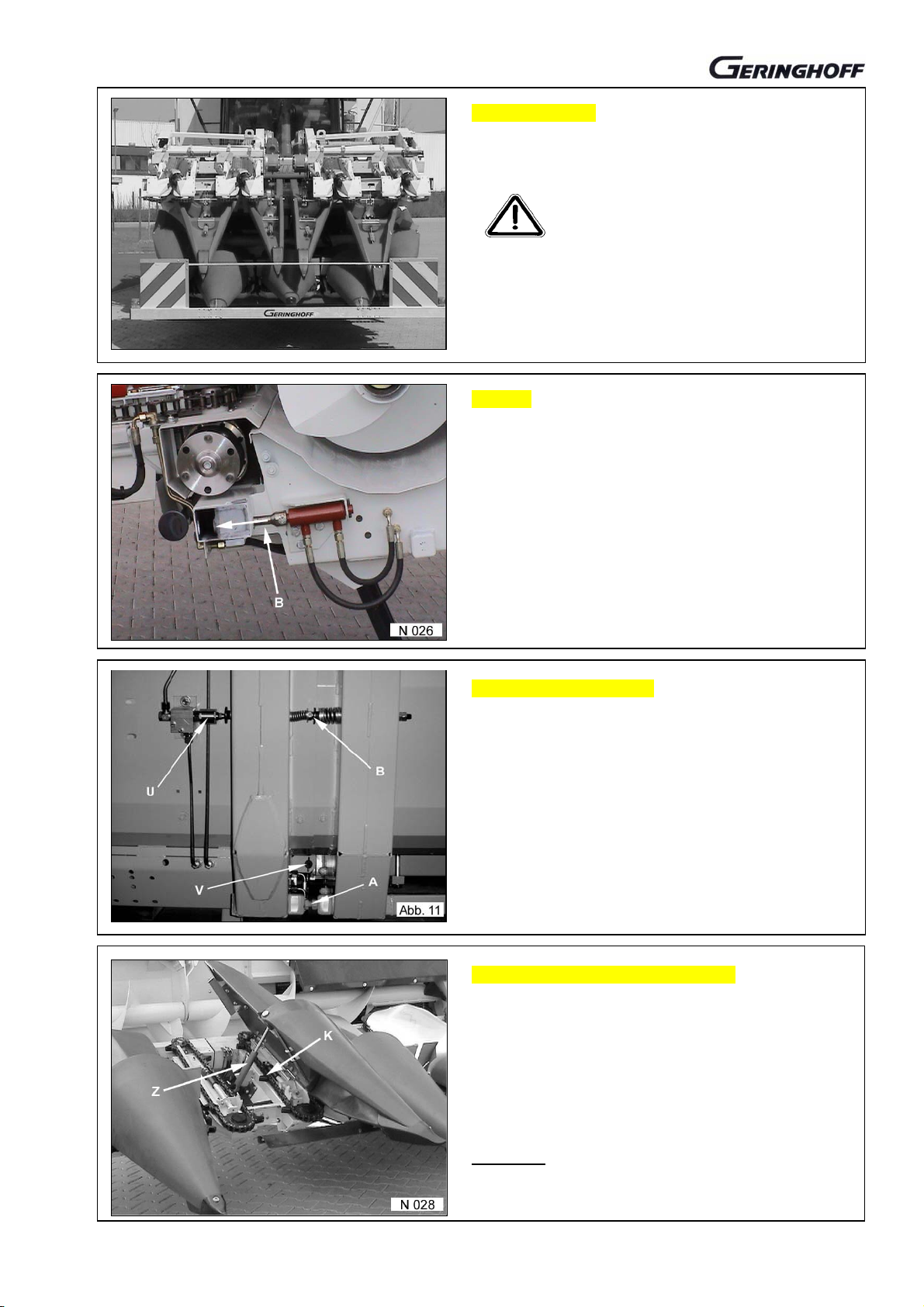

Transport protection folding corn headers

part from the transport protection as shown in picture

N 003, folding corn headers from 8 rows are fitted with an

additional protection (B) on the frame.

Bolts (B) not to remove before

definite placing down of the

header and removing of the hoist.

When using the hoist again, locking bolt (B) must be put in

before.

Corn header Approximate weight

in kg

4-rows 1290

5-rows 1640

6-rows 1975

6-rows (folding) 2250

7-rows (folding) 2400

8-rows 2520

8-rows (folding) 3025

Take a hoist, which is strong enough

The weight of the different header models to be learnt from

the opposite table.

Follow the instructions for the use of hoists!

The exact weight of the different headers is

indicated well visible on the typeplate of

each machine!

9-rows 2750

9-rows (folding) 3250

12-rows 3650

12-rows (folding) 4150

09 / 040

Assembly preparations on the combine

A

leuchten des M╠hdreschers

und des Frontschutzes m¤s-

Gegr¤ndet 1880

f¤r alle Md Typen

Front protection on gathering channel

The standard front protection (S) on top of the feeding

chain and the stripping angles (A) on the gathering

channel front are to be dismounted.

The corn header itself is fitted with a special front

protection.

When working on the combine, the

Diesel motor must be turned off!

Assembly preparations gathering channel

The feeding chain, its tension and the distance to the

channel bottom is to be adjusted according to the

instructions of the manufacturer.

(See combine manual)

Prior to the first mounting of the header, the anti-lowering

device of the gathering channel to check. Never to

perform works on the header without using this device.

On all service works on the mounted

header, lowering lock to activate!

Additional headlights

Some combine models require to mount additional

headlights for the road travel, see the scope of supply of

the header.

wiring diagram is enclosed to the headlight set. A

position switch must be used for changing between

standard and additional headlights!

Instructions of the TÜV-expertise to observe!

General terminal connecting diagram on page 36 / 500

Monitor

Display unit (M) to mount well readable but without visual

obstruction on top of the fittings.

The 12 V current is supplied independent of the ignition

lock via the plug (Z). (fuse max. 10 Amp.).

Connecting cable (S) right below with seal (T) to lead out

of the cabin bottom. Ensure that the cable is long enough

outside the cabin.

The monitor reads both the speed of the header and the

position of the stripping plates (P) via a changing number

of diodes.

09 / 080

Mounting of the corn header

Adaptation to the combine

The corn header is to be placed down on the supports (C).

Check the correctness of the adaptation parts. Fur further

information, see spare part catalogue 3061000 from

picture table 60/..

Combine to move to the header.

Header with the gathering channel to lift.

Correct seat of the adaptation parts (A) to check.

Persons are not allowed to stay

between comb between combine

and header during the mounting

process.

Corn header to lock on gathering channel

Corn header to secure against

unwanted lowering by u lowering!

Use locking mechanism

on the hydraulic cylinders!

The header (R) to be mounted to the points and devices

of the combines as provided.

Corn headers always slowly to lower to the ground to

keep

unwanted forces away from the locking.

Follow the instructions of the combine manufacturer!

Additional lifting cylinder

Subject to the size and weight of the corn header, one or

two additional hydraulic cylinders (Z) may be required.

The combine manufacturer holds the corresponding kits

ready.

Subject to the design of the corn header and carrying

capacity of the different combines, the steering axle may

require using additional weights and the tires being filled

with water.

Follow the instructions of the combine manufacturer and

TÜV-expertise

Additional counterweights

Subject to the weight of the mounted corn header,

additional loading weights may be required for being

mounted to the steering axle of the combine.

The dimensions of these additional weights are to be

learnt from the road permit, combine manual or TÜVexpertise of the corn header.

The road transport licensing

roads must regulations must

absolutely be followed.

09 / 120

Corn header drive

A

A

Drive with PTO-shaft

Unfolding corn heads are driven by a simple PTO-shaft on

the right side.

Subject to the combine models, they can also be driven on

the left side, e.g. machines > 6 rows.

PTO-shaft protection to prevent from turning via chain (K).

If the combine is fitted with a pivoting shield, overlapping to

be checked in extended state.

Protective devices (S) to be checked

prior to start-up. Do not open or

remove them during operation.

Folding headers with PTO-shaft coupler

Check the PTO-shaft between coupler and channel

connection for sufficient overlapping. If required, pivoting

shield to actuate.

The heel compensation of some

models requires to be blocked.

On RD600F / RD800FB e.g. to John Deere series 20... /

22... + WTS / STS / CTS with PTO-shaft coupler, the

pivoting shield must be blocked ( follow the instructions).

Hillside combines cannot be operated with automatic

PTO-shaft coupler.

Drive for hillside combines

ll hillside combines are directly driven by PTO-shafts (W)

to be slipped on by hand.

Certain combine-header combinations require wide angle

or even special PTO-shafts.

Instructions absolutely to follow and PTO-shaft design to

consider.

Prior to start up, check pivoting

range and PTO-shaft length. Check

for sufficient overlapping.

The fastening (T) of the PTO-shaft is for transport.

Use of the pivoting shield (heel compensation)

On principle, the pivoting shield of the combine can be

used combined with the majority of the corn headers

without any limitation, unless otherwise specified.

The instructions of the combine manufacturer to follow!

PTO-shaft length to check in all positions.

If required, special locks (R) to mount to upper adapter

frame and secure.

lways trial run to conduct!

Instructions for PTO-shaft drives to observe!

09 / 160

Hydraulic connections

Multicoupler

If the combine is fitted with a multicoupler (optional), the

header should be fitted likewise.

The suitable coupler (optional) can be added to the supply.

The operation to be made according to the instructions of

the combine manufacturer.

When checking the functions, keep off

the dangerous zone.

Tightness to check!

In case of leakages the conditions for

environmental protection to follow !

Connection via control valve coupler

Some combine makes require using a control valve

coupler (M) for connecting the header.

The respective headers are fitted accordingly as

standard.

The operation to be made according to the instructions of

the combine manufacturer.

When checking the functions, keep off

the dangerous zone.

Tightness to check!

In case of leakages the conditions for

environmental protection to follow

!

Connection via simple screw and/or slip-on

couplers

If only simple slip-on and/or screw couplings are available,

first double and simple-acting lines are to mark.

The simple-acting line is to connect to the line of the

stripping plate adjustment.

The double-acting lines serve to the control of the folding

process of the respective headers.

Establish a safe connection to allow the oil flowing !

Lines to mark and always immediately to connect so that

the working purpose remains unchanged!

Hydraulic actuation of the folding process

Reel:

“ Lifting and lowering ” = stripping plates

closed ”

Reel horizontal adjustment: (optional)

“ forward and backward ” = folding process “ open and

closed ”

When checking the functions, keep

off the dangerous zone.

Tightness to check!

In case of leakages the conditions for

environmental protection to follow.

“ open and

09 / 200

Hydraulic functions of folding corn headers

Folding process (from transport in working position)

Reel horizontal adjustment of the combine to actuate until

the header has reached its working position.

Keep off the dangerous zone!

Keep off the working range of the

header! header!

Valve actuation not to finish until 10 seconds after complete

closing of the cover shields (to assure the locking function).

Machine to run idle to get the drive coupler engaged.

Locking

Once the header is completely open in working position,

the locking (B) is automatically activated.

If the header is not completely open in working position, to

troubleshoot.

(see help in case of malfunctions, page 10 / 900)

There are possibly foreign substances hindering the

function.

Bolt (B) must completely extend in locked state.

Check drive coupler! Cams are spring-loaded and turn off

unless cam and opening in driving plate are not in line!

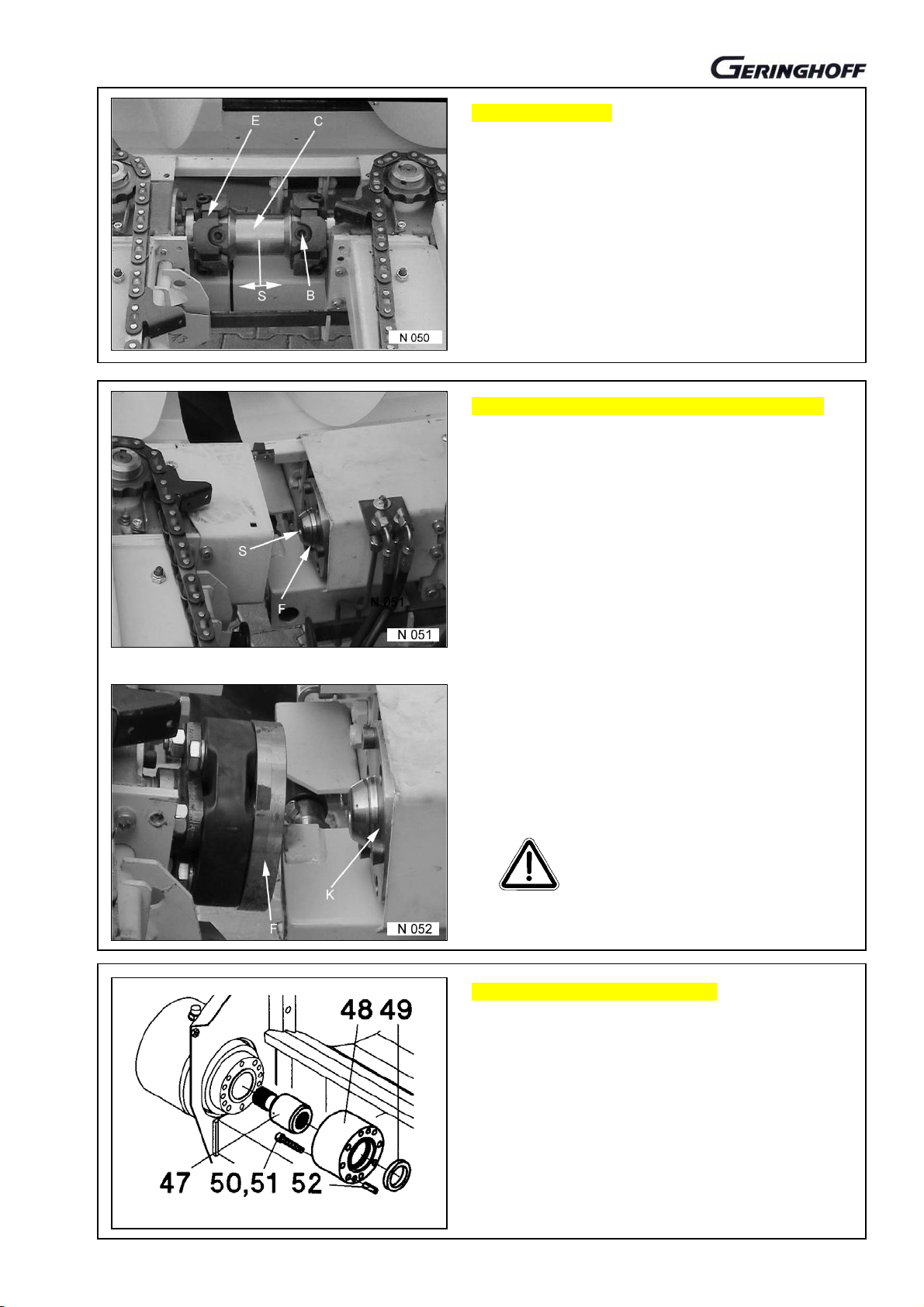

Control valve for locking

The locking (V) is triggered by the valve (U) and closes

only if the header has really reached its working position.

If the locking is not activated despite of sitting closely on

the stop screws (A), on-off valve (U) to readjust with screw

(B), if required!

If required, stop screws on the bottom frame and locking

bolts (V) to readjust.

Automatically closing cover shields

Cover shields (A) close only after complete extension of the

locking bolt.

Failing which, to troubleshoot.

Factory adjustment has been checked. Corrections are in

general not required.

Folding process is not finished until the cover shields are

completely closed.

Attention!

Machine not to run with opened shields. Hydraulic cylinder

(Z) would get in contact with the gathering chain.

09 / 240

Drive coupler folding headers

y

A

Drive coupler folding headers

The drive coupler, if any, ensures an automatic coupling of

the PTO-shaft drive.

Prior to start-up and then in regular intervals the correct

osition of the coupling halfs to check. p

Check the protective devices (S) for correct fitting.

Machine always to let idle.

Persons to keep off the dangerous

zone!

Drive coupler 6-row folding headers

The coupling half mounted to the folding element is

adjusted only via the protective tube (R).

If the coupling halves must be readjusted, screws (S) to

loosen and protective tube to displace accordingly.

Parallel fitting of the coupling halves absolutely to assure.

The coupling halves to axially regulate only via spacers (Z)

below the bearing.

Correct fitting of the protective ring (G) to ensure.

Header with drive couplers on both sides

From a certain number of rows the headers are fitted with a

both-sided drive.

If the coupling halves require an axial regulation, spacers

(Z) only to use on the marked positions.

The radial adjustment is made on the bearing points b

displacing the bearings into the bores provided.

The parallel fitting of the coupling halves absolutely to

ensure.

Maintenance and care

Coupling washers (S + B + K) to be slightly greased in

regular intervals.

Sliding parts of the respective coupling halfs once to

dismount prior to start working and sliding parts to grease.

xial fastening screw carefully to tighten with standard

torque.

Header drive not to set into operation

if the header is in collapsed state.

Risk of accident on the coupling halfs!

09 / 280

Divider noses to mount

Selection of the divider noses for mounting

Divider noses with bore (D)

The supplied center divider noses differ only by a bore

(D) about 18 mm Ø if the header has been supplied with a

transport protection.

These center divider noses are to mount right and left (T)

from the center (M) for receiving the transport protection.

Corn header to lift and secure via

support on the lifting cylinders against

unwanted lowering!

Mounting of the center divider noses

Shield to open by throwing over the lever (H) and slightly to

press upwards from the centerings to the stop of the gas

pressure spring.

Shields may jump upwards by gas

pressure cylinder!

Tube (R) to remove once unscrewed the axial screwing (S).

Tube to put in provided bore of the divider nose and shield.

Screwing to tighten.

Divider nose to lift and setting bar (E) to hang into the

support (A). Safety bolt (B) to mount and secure by cotter

pin.

Shield strongly to press down for closing and to check that

locking pin hooks in. Via lever (H) shield to close with

moderate prestress. If required, locking hook to readjust.

Mounting of outer divider

The same procedures as with the center divider noses.

Risk of bruising when mounting

shields and divider noses !

The divider noses are adjusted via the screw (E).

09 / 320

Divider noses to mount

A

The center divider noses to mount to the shields

Only possible with the hydraulic connection already mounted.

Start folding process. If folding shields are open, procedure

to stop.

Motor to turn off !

Corn header to secure against

unwanted lowering!

Mounting procedure of the divider noses is the same as for

the other center noses.

The divider noses are adjusted via the screw (E).

Adjustment of the divider noses

Protection against lowering to remove.

Header to lower to a ground distance of about 10 cm on an

even surface.

Divider noses with screw (E) to adjust such that their

distance to the ground is 2 cm (normal adjustment).

On the harvest of lodged maize and if the combine sinks

into the deep ground, the noses are to lower deeper.

Attention!

In case of an extremely lower adjustment, ensure that the

divider noses don’t get in touch with the gathering chains!

Mounting of the increased shield

For transport size and package reasons the

increased side shield is supplied unpacked.

It is mounted to the outer bodywork into the provided

threaded bores (G).

Attention!

ll screws of the plastic parts normally to tighten to prevent

the bores from being damaged.

The harvest can be made on option even without these

Bores to drill for transport protection

If divider noses have been mixed up on assembly or

supply, the required bores can be drilled into the both

center divider noses on the site.

Directly behind the divider nose top plate an 18 mm Ø bore

to drill only into the upper plastic surface.

The respective center divider noses are selected according

to the specifications of the transport protection or to picture

N 017 on page 09 / 320.

09 / 360

Road transport

A

Front protection

Unfolding headers up to a transport width of 3,0 m are

fitted with an unlighted transport protection.

ll foldable headers up to a transport width of 3,3 m are

fitted with a lighted transport protection.

The connection is made via a standard socket which, if

not available, must be mounted on or below the driver

stand.

The outer unfolding center divider noses are provided

with bores for locking the transport protection.

(see page: divider noses to mount, page 09 / 320)

Front protection with lighting connection

on multicoupler and/or control valve unit

In certain combine makes the lighting connection for the

front protection is integrated into the general supply line

(M) to the header.

- The front connection is then connected to the

socket (E).

- If required, the front protection is connected via

another individual connection.

Instructions of the combine manufacturer to follow!

Transport on public roads

It’s not allowed to transport the corn header on public

roads without transport protection.

The maximum admissible height of the slewing arm of the

ejecting channel on the transport on public roads is about

0,45 m as measured on the front protection (H) and is

determined for each machine in the separate licensing

documents.

Road transport licensing and

TÜV-regulations as well as instructions

of the combine manufacturer absolutely

m to observe.

A TÜV-expertise is enclosed to

each machine.

09 / 400

Operation and function of monitor

Monitor to connect to the header

Plug-type connector of the monitor cable coming from the

driver cabin to connect right with the header coupler.

Current supply to activate as described on page 09 / 080

Speed indication on monitor reads „ O “.

If the machine is running on operational conditions, a value

of about 720 - 750 r/min is indicated.

The speed indication allows to reliably evaluate the state

and load of the combine against the header.

Dropping speeds signal either an insufficient belt tension or

overload of the combine drive.

Stripping plate adjustment

Subject to the position of the stripping plates, a certain

number of green (G), yellow (Y) or red (R) diodes light up.

The more the stripping plates are open, the more diodes

are lighting up.

The number of the flashing diodes is only to be seen

on the monitor. Before the start-up, the proportion of

the flashing diodes to the position of the stripping

plates as a function of the harvest conditions is to be

determined.

Prior to checking, Diesel motor

to turn off! Keep your hands off the

stripping plates!

Recording tachometer

The recording tachometer (S) is located between two rows

on the drive connection claw of the Centaflex-coupler.

The distance between the magnetic switch (S) to the

magnet (M) and/or claw should at least be 1,5 mm and at

max. 2,5 mm.

Rheostat of stripping plate adjustment

The rheostat (A) and the slider (W) should be cleaned in

regular intervals.

Via the axial adjustment of the spindle (G) and by

displacing the position of the rheostat (A), the indication of

the diodes allows individually to be changed.

Electric supply lines to be checked in regular intervals.

Prior to checking, Diesel motor to

turn off!

Header to be secured against

09 / 440

Stripping plate adjustment

j

A

Function and basic adjustment

The basic front adjustment is 20 mm and the rear one

23 mm in position „ narrow “. That means, the stripping

plates are pushed together as far as possible.

The wedge-shaped adjustment is of essence for the

function of the header.

These values are set via the screwed down stripping plate

(R) and the screws (K).

For the harvest, the stripping plates are operated

hydraulically via „reel to lift and lower“.

The average corn ear diameter is important for the setting

of the stripping plate distance. For this reason, the plates

for the harvest works should be opened as far as possible,

ust as far as to prevent cob losses.

Prior to checking, Diesel motor

to turn off!

Header to secure against unwanted

lowering!

Via the shifting cylinder (Z) the left stripping plates are

opened by the sliding bar (T) and lever (H). The plates are

closed again by one or several restoring springs.

The regulation of the uniform setting of all stripping plates

on the different rows is made by shifting the levers (H) on

the sliding bar (T).

Before going to make a readjustment, it is recommended to

check the basic adjustment „in front 20 mm, rear 23 mm“.

Stripping plate adjustment folding headers

The function and layout is identical to the unfolding

machines.

The stripping plates on the folding parts are actuated via

the spring-loaded sliding bar contact. Additional, right and

left differently mounted restoring springs open the plates

on activation of the folding process.

Pressure plates should well overlap.

djustment and setting to be made in working position and

adequate locking only.

Maintenance and care of the stripping plate

adjustment

Impurities are not to exclude. For that reason, at least once

the day the stripping plates (L) to open and close several

times to assure the free floating and to remove impurities.

Joints to oil every 100 h. Restoring springs to clean.

Once finished the harvest works, bearing (C) of the

adjustable stripping plate (L) to clean and to protect

against corrosion using adequate means.

Check that the cut-off block is centrically arranged in

central working position.

09 / 480

Gathering chains

A

A

Gathering chains

Special slipping wheels (R) are to secure the gathering

chains and to prevent the penetration of foreign substances.

The position of the gathering chain drivers (A) to each other

is permanently changing, even on normal harvest operation

by response of the slipping function.

When stating a chain elongation (ill. N 107), there is the

unique chance of shortening the chain by one outer and inner

link plate each (B). The shortening to be made in the area

(14) = 14 pces. link pin distance from driver to driver.

The plastic protective rings (O) beneath the slipping wheels

to be checked for good state.

Chain tensioner

The maintenance-free gathering chains are automatically

tensioned via constant spring pressure.

The preset chain tension is also to regulate the driving torque

of the gathering chain and thus the efficiency of the slipping

wheels.

When to change the gathering chains?

= 83 mm chain in new state

= 113 mm chain worn-out, replacement required.

Attention!

Consider also the wear of the frontal reversing wheels!

Dismounting of the gathering chains

The chains can be dismounted with ease by using a special

tool, spare part no.

501190 attached to the header.

Prior to working on the machine,

Diesel engine to turn off.

Special tool may jump back!

The gathering chains are recommended to be

changed once the year from right to left and

viceversa to ensure thus a uniform wear.

Frontal chain reversion to dismount

Tool for chain dismounting to place to pos. (B) as shown in

ill. N 058 and N 198 and to pull tight. Lever to secure under

hook (E).

The frontal reversing chain wheels to be dismounted in the

same way. Special tool to mount into bore (L). Lever to

secure under hook (E), then the fastening beneath the

reversing wheel to remove and tool slowly and carefully to

relieve.

Tool jumps back by !

spring pressure

Risk of accident!

09 / 520

Transmission – oil control (maintenance intervals)

g

g

Row unit transmission

Corn header to lift to a height of about

1 m to allow the lowering protection to

The oil level is controlled by a standard dip stick on the oil

filling plug.

Gauge position: Header lifted to about 1 m.

Filling level: 1,5 l gear oil SAE 90 (commercial quality)

Changing interval: 50 h from start-up, then once before

each harvest but at latest after 500 h.

Oil drain plug (not visible) is fitted with magnet, which must be

cleaned on each oil change.

engage. Turn of Diesel engine!

Angular transmission

Oil level control of angular gear via central gauge plug (K).

Filling level: 1,5 l gear oil SAE 90 (commercial quality)

to fill to the escape on gauge opening.

Changing interval: 50 h from start-up, then once before

each harvest but at latest after 300 h.

Oil drain plug (A) is fitted with magnet, which must be

cleaned on each oil change.

In folded state, exhauster (E) to be checked in regular

intervals.

Oil level to be checked in re

ular intervals!

Contrate gear transmission

Oil level control via gauge plug beneath gear center (K).

Filling level: 1,5 l gear oil SAE 90 (commercial quality)

To fill up to the escape on the gauge opening.

Changing interval: 50 h from start-up, then once before

each harvest but at latest after 200 h.

Oil drain plug (A) is fitted with magnet, which must be

cleaned on each oil change.

In folded state, exhauster (E) to be checked in

regular intervals.

Oil level to be checked in re

ular intervals!

Change speed gear 2, 3 or 5 gears (optional)

Oil level control via gauge plug (K).

Filling level: 1,5 l gear oil SAE 90 (commercial quality)

To fill up to the escape on the gauge opening.

Changing interval: 50 h from start-up, then once before

each harvest but at latest after 200 h.

Oil drain plug (A) is fitted with magnet, which must be

cleaned on each oil change.

In folded state, exhauster (E) to be checked in

regular intervals.

Oil level to be checked in regular intervals!

09 / 560

Contrate gearing speed change

Nominal speed is not reached

Unless reaching the nominal speed of the header of about

n = 720 -750 U/min., the speed can be corrected by

changing the contrate gear within the transmission (K).

First to check whether the speed of the combine on the

PTO-shaft connection (B) in question is in line with the

factory specifications.

On the transmission box is marked a number on the pos.

(Z) showing the teeth number of the contrate gear.

The following formula allows to calculate the speed:

Combine speed x teeth number of contrate gear / 32 = header

speed

Change of contrate gear

PTO-shafts (B+G) to remove.

Screws of the transmission fastening on the backside to

remove and the complete contrate gear transmission to

take off the header.

New contrate gear to get from the manufacturer or dealer.

Attention!

The contrate gears are available only in certain gradations.

If intermediate speeds are required or wanted, change

speed gear to be mounted (page 35 / 010).

Changed teeth number of the contrate gear to mark on the

transmission box!

Opening of the transmission

Transmission to put down horizontally to avoid oil losses.

Screws (6) to remove.

Box cover to loosen by knocking with an adequate tool and

to take off. Shaft (12) with bearing (11) is still in the cover

(5).

Shaft (12) to drive out of the box cover (5) in arrow

direction.

Screws (13) to remove and contrate gear (15) to replace.

Works to be performed by an expert only.

Contrate gear transmission to remount to the

header

Contrate gear transmission to mount to the provided place,

if required together with PTO-shafts.

Fastening screws slightly to tighten such as to allow the

transmission still to be aligned (see white line X).

Only original screw length (6) to use, since longer screws

would destroy the transmission housing.

Guards to mount and trial run to conduct. Check the speed!

Oil level to check.

09 / 600

Couplings between the row units

A

Centaflex-couplers

Centaflex-couplers (C) to be checked in regular intervals

for the state of the flexible elements (E) and engaging

dogs.

Worn parts to replace immediately.

xial clearance (S) of 2 mm for the center part (C)

absolutely to keep.

Hexagon socket screws (B) to tighten with 140 Nm.

Row unit drive connections on the folding parts

The axial movability of the coupling half (F) to be checked

in regular intervals by mounting lever to be pressed in.

If required, axial safety bolt (S) to unscrew, coupling half to

pull off, splined shaft section to clean and grease.

The parallel position of the cam plate (K) towards the

punched disk (F) to be checked in regular intervals with the

machine put out of operation and the coupler engaged.

Radial differences are to be compensated by

readjustments made on the pivot of the folding part

suspension.

Drive couplers to get engaged

only at minimum speeds.

Corn header with shaft extension (optional)

Corn headers with certain row distances can be fitted with

a shaft extension on the drive side.

Flange (48) and intermediate shaft (47) are arranged

between angular gear and the row unit gear.

The intermediate shaft needs no maintenance at all.

09 / 640

Trial run

A

First trial run

Corn header to lower near to the

ground. Keep off the dangerous zone.

All guards to close!

Machine first to let idle.

Check the smoothness of running.

In case of trouble turn off immediately!

Secure against unwanted lowering!

Troubleshoot!

Check the working speed on the monitor.

(n =720-750 r/min)

Reversing

ll modern combines are fitted with a standard reversing

device for the header drive.

This device for allowing the machine to reverse can be

used for cleaning during the operation of the header

without any limitation.

• Function to check

Test of the heeling compensation

Prior to start-up, the pivoting shield function of the combine

is to be checked combined with the corn header.

• PTO-shaft length and sufficient overlapping to

check!

• Slope steering to check

Keep off the dangerous zone whilst

the machine is running !

(optional)

09 / 680

Cross conveying auger/ Feeding

A

Conveying aids

The conveying aids (F) are mounted as standard on the

cross conveying auger.

On option, these conveying aids can be enclosed

unpacked and mounted on the site.

In the event of a not uniform feeding all over the combine

width, the conveying aid (size B) is to mount 40 mm

narrower than the inside gathering channel width is.

That means the size (B) must be 40 mm smaller than the

channel opening of the combine.

Feed opening of the corn header

Certain opening sizes of the header for all combine makes

and models are determined for the feeding to the gathering

channel of the combine.

The exact opening width to be learnt from the sketches in

the spare part catalogue from picture table 60/.. .

For standardization reasons, slight variations from the rated

size are allowed.

In particular when working on slopes a regular feeding is of

essence for the harvest material to be distributed evenly

within the machine.

Auger drive up to 6 row units

The auger is driven from the side opposite to the main

drive. The speed is subject to the main shaft of the header

and thus preset.

Chain tension to check in regular intervals, if required, to

readjust via the idler (S).

Chain to oil in regular intervals.

Protection box to clean in regular intervals.

Corn header never to operate without

guards mounted and closed!

Auger drive from 8 row units

The auger is driven from the feed shaft of the contrate gear

transmission and is not subject to the speed of the header.

Maintenance and care of the chain drive to be made via the

flap (K)

The chain tension is adjusted by shifting the tension lever

(S) downwards.

ll bearings of the cross conveying auger are maintenance-

free.

The bores (B) serve to fasten the contrate gear

transmission.

09 / 720

Cross conveying auger / Feeding

A

A

Sliding clutch cross conveying auger

ll auger drives are fitted with a maintenance-free and not

readjustable sliding clutch.

If the sliding clutch reacts, machine immediately to turn off

and troubleshoot.

Insufficient torque of the clutch cannot be decisive for the

response behaviour.

In case of overfeeding, the reversing device of the combine

allows for a refeeding.

Chain drive to grease and tension in regular intervals.

Driving clutch cross conveying auger

The coupling halfs (K) in the folding auger elements are

spring-loaded mounted on a splined shaft section engaging

automatically after the folding process.

xial spring load of the clutch (K) several times to be

checked during the harvest season by simple pressing in.

The screw joint of the bearing holders (L) serves to the

adjustment of the auger elements.

Once finished the setting works, the screws to remove.

Setting of the cross conveying auger

The cross auger is factory-mounted in ideal position and

not provided for being displaced.

Provided setting facilities serve only to the assembly of the

cross conveying auger.

Bearing holders (L) must in working position be parallel and

close to each other (max. 2 mm distance).

If the bearing holders (L) are too far from each other, the

corresponding auger element can be regulated by axial

displacement. For doing so, the locking ring of the

respective bearing to loosen.

Covering cap cross conveying auger

The height adjustment of the covering cap is made via the

screwing (S).

The distance between auger and cap should be as big as

possible to ensure a free passage of husks, leaf and even

stalk parts.

Prior to working on he corn header,

Diesel motor to turn off!

09 / 760

Overload protections and slipping clutches

A

A

Basic equipment of all headers

number of overload protections and slipping clutches are

provided for the safe operation of the machine.

If these devices respond, corn header

immediately to turn off!

Diesel motor of the combine also to

turn off and header to secure against

unwanted lowering!

Troubleshoot and trouble to rectify.

Never switch the header on and off to get it turning again.

Sliding clutch in the row unit gear

One maintenance-free and wear-poor cam clutch each (19)

is arranged within the gears.

If it responds, there is a trouble beside the normal

operational conditions.

Once stated that the foreign body did not cause the

response behaviour, the reversing device of the combine

allows the header to be turned backwards and to remove

sticking harvest material.

Clutch must not run hot!

Slipping wheels on the gathering chains

See also page 09 / 520

The special tooth form of the driving chain wheels (K)

combined with the automatically tensioned gathering

chains effect a well-balanced driving torque of the

gathering chain drive.

In case of overload or foreign bodies the driving chain

wheel turns within the gathering chain without moving it

ahead. That ensures that damages are prevented and

foreign bodies kept away from the combine.

Never to change the chain tension using inadequate tools.

Slipping clutch in the cross auger drive

not readjustable cam clutch is mounted on the drive side

of the auger shaft.

If it responds, there is a trouble beside the normal

operational conditions.

Once stated that the foreign body did not cause the

response behaviour, the reversing device of the combine

allows the header to be turned backwards and to remove

sticking harvest material.

09 / 800

Rota –Disc* Working angle adjustment

A

g

Working angle (basic position)

working angle of 27° is factory-set. If the combine is fitted

with larger or smaller tires than the series equipment, we

recommend checking the working angle. The same applies

also to crawlers.

The real angle is to be determined with ease by placing an

adjustable angle on the stripping plates in working position

and a bubble level.

This check should be made on real working conditions on

the field with the usual ground spacing.

When putting the header down to 27°, a control dimension

of about 400 mm of shaft spacing to the ground will result.

Adjustment of the working angle

Combine and corn header, completely mounted, to put

down in working position on a level surface.

Screwing of the outer bodywork suspension on the frame to

remove.

Guard (C) of the gear drive to remove.

On foldable headers, the locking must absolutely be

activated in working position (see 09/240).

Header, completely relieved but firmly

connected to the combine, to be put

down to the

round!

Adjusting device

When the machine has been put down, first the screw (V) to

remove from all frame connections and to put into the bore

(B).

Then, screws (S) on all frame connections, also on the

sidewalls, slightly to loosen for allowing the elements to be

moved to each other.

The required working angle to adjust via the lifting device of

the combine (header to lift and/or lower).

Then all screws of the frame connection to retighten with the

header being put down!

Drive gear to align

Corn header with the gathering channel to lift and secure

against unwanted lowering.

Only the four screws (S) Sw 8 of the angular gear and the

four screws of the contrate gear fastening on the backside

to loosen. Both the gears to turn until reaching the exact

alignment (see line X).

Gear to refasten and guard to remount.

Outer framework to be connected again. If required,

spacing to be compensated by spacers.

09 / 840

Rota-Disc* - stubble cutter / stripper

A

Adjustment of stubble cutters

The cutter (M) to place as near as possible to the rotating

knives (R). Distance max. 1 mm.

For setting the knife (M) the row unit to turn one rotation.

ipe wrench to place on the gaps of the knife disk shaft. P

fter the adjustment, knife support (X) via slight knocking

to drive to the knife.

Special screw (S) to tighten to max. value.

Prior to working on the machine, Diesel

motor to be turned off and header

secured against unwanted lowering!

Rotor knives

Worn knives or knives with round cutting edges

immediately to replace!

The rotor knives (M) to mount on level and clean surface.

Only new original special screws (S) with protection to

use.

Screw thread (L) must only slightly project. Longer

screws would cause the rotors to block.

The use of worn tools would increase the power demand

and costs.

Only an exactly adjusted stubble cutter allows to get

a good stripping performance.

Strippers on rotors

The strippers (A) und (B must run close to the provided

area.

Distance less than 0,2 mm

Stripper on big rotor

The stripper (A) serves to cleaning the rotor head and

prevent the rotor from blocking.

The clearance within the fastening bores is great enough

to allow for an adjustment according to the requirements.

The distance of the stripper nose (M) to the rotor shaft

should be less than 0,2 mm.

10 / 000

Rota-Disc* - Knife disk shaft

A

Cutting disk shafts

The frontal 4 cutting disks are the most stressed ones.

The disks to replace in time to prevent the rotor working

edges from further wearing.

It is recommend to replace the knife disks from a diameter

of 110 mm.

When working on the machine, Diesel

motor to turn off and header to be

secured against unwanted lowering!

The cutting disks must deeply engage into the grooves

of the rotor core. Failing which, replace them.

Cutting disk shaft to dismount

Fixed stubble cutter to dismount once removed the screws

(S).

Screw of flange (F) to remove. Screws of bearing shell (L)

to remove and bearing shell to take off.

Cutting disk shaft via mounting lever to press out of bearing

and flange.

Adequate safety gloves

Cutting disks to replace

Nut (S) to remove. Complete bearing (D, V, A, R, U) to pull

off.

dequate tool to take for driving the cutting disks from the

shaft.

New greased cutting disks to mount. Bearing to check and

the not greased ball bearing (R) to mount with open side

forwards.

Nut (H) to loosen for one turn. Nut (S) to tighten.

Nut (H) to tighten and secure.

The axial regulation of the disk position towards the

grooves can be made via the nuts (H + S).

Remounting of the cutting disk shafts

Bearing shells to clean.

Cutting disk shaft first to put into the gearbox flange and

then into the bearing shell half.

Bearing shell cover to put on and the O-ring (0) to check for

exact fitting.

Flange only to use with original safety screws

(M8 x 14 - 10.9).

Longer screws destroy the gear.

Bearing thoroughly to grease.

Check again after a short operation time.

to use!

10 / 100

Rota-Disc* stripping rotors

Rotors to dismount

Unscrew the skid screws (S).

Cutting disk shaft to dismount (see page 10 / 100).

If required, stripper on the big rotor to remove. (see page

10 / 000).

Bolt (B) to remove.

Complete rotor with frontal bearing holder via mounting

lever in pos. (M) to pull forward off the section shaft without

damaging the aluminium housing.

When remounting, section shaft of the gear well to grease

and the toothing of the rotors to check for being uniform.

Stripping row gear

View without rotors

Rotor shafts (G)

Oil drain plug (A)

Flange (F) for cutting disk shaft

Spur gear is accessible without the need for dismounting

the gear.

Bearing holder to take off the rotor

Stud screw (I) SW 5 to remove.

Bearing to turn such that the stud screw with hexagon

socket SW3 gets visible in the threaded bore.

Stud screw via spanner to loosen for one left turn and

spanner to remove.

Bearing holder to turn by 180° until the bore gets visible in

the set collar (M). Mandrel to put into the bore for blocking

thus the set collar. Bearing holder with mandrel to unscrew

to the left and pull off when set collar is unblocked.

Bearing to remove from the rotor

Seeger circlip ring (R1) to remove.

Use Geringhoff special tool, spare part 501165, for pulling

out the bearing and set collar.

Seeger circlip ring (R2) before the rear bearing to remove.

Via special tool rear bearing to pull out.

Remounting in reverse order .

Attention!

Special nut (M) to mount with the nose to the frontal

bearing (L1)!

10 / 200

Row unit RD

A

A

Cut-off block

The cut-off block (P) is mounted with screws (S) beneath

the stripping plates in front of the gearbox.

If required, the spacing (A) to the rotors (max. 1 mm) is to

be adjusted via spacers put between the cut-off block and

the row unit gear.

If the spacing is more than mm, in particular on humid

conditions, the rotor runs into the risk of blocking in this

area.

Note: The individual number of each row unit is indicated

on the pos. (no.).

Control dimension row unit frame

The correct frame carrier spacing (X) in the frontal zone (A)

is of essence for the function of the corn header.

This spacing can be changed by collisions. In particular on

the outer rows (right and left) the carrying arms may

become bent because there aren’t further rows for support.

In the event of a collision or when starting a faulty operation

of a row unit, the spacing (A) 317,5 which may vary +/- 0,5

mm, is to be checked. The variance mentioned is to be

strictly maintained.

To be able to isolate which carrying arm (X) is bent, the

screws (S) must be loosened at least once by hand without

any harvest material building up. The resultant gap (U)

indicates the bent side. Slight differences of up to 4 mm

can be compensated via slotted washers put between the

fork (G) and the area (F).

Attention!

If a spacer is mounted below the fork (G), the stripping

plate attached must be readjusted separately to

reestablish the basic setting (see page 09 / 480).

In the event of greater damage, the carrying arm in

question must be aligned or replaced!

View of knife disks and rotors

It is a sure sign damage to the carrying arms of the row

units if the new knife disks do not engage deeply enough

into the grooves (R) of the rotors.

part from that, the stubble cutter does not allow for further

adjustment to the counter-knives (see page 10 / 000).

The row unit absolutely must be checked.

visual control of the row unit position for isolating any

problems is insufficient.

10 / 210

Maintenance and care

A

Cleaning after the harvest season

Once finished quite a dry harvest season, a dry cleaning is

recommended using only compressed air.

If the machine was exposed to humidity with thus getting

strongly soiled, a high-pressure cleaner should be used.

First, the shields and gathering chains to take off and all

bearings lubricated.

Greasing points

The greasing points are located as follows: ( hours)

Stripping rows: on front bearing ( 15)

PTO-shafts: general (100)

PTO-shafts: tubes and sliders

Folding mechanisms: joints and pivots (100)

Shaft coupler: sliders / flange (200)

The brackets show the greasing intervals in hours.

fter each cleaning, the machine should be greased again

and put into operation for short time.

(200)

Stripping plates

When cleaning the machine, the stripping plates must be

moved quite often for removing dust and corn remainders

out of the pushing channels (Z).

If the machine is cleaned with water, the chain guides (K)

to remove and the pushing area (Z) of the stripping plates

to clean and protect against corrosion.

The pivots (D) should be oiled or greased.

Gear (see also page 09 / 560)

Filling quantity: 1,5 l gear oil SAE 90 (commercial quality)

To fill up to the escape on gauge opening and/or according

to dip stick indicator.

Change intervals: 50 h from start-up, then once before

each harvest, but at latest after 200 h.

Oil drain plug (A) is fitted with magnet, which must be

cleaned on each oil change.

Oil level to check !

Prior to winterizing the header, vent screws on the folding

elements to be checked for tightness.

10 / 300

Maintenance and care

A

Gathering chains

Prior to winterizing the header, the gathering chains should

be protected against corrosion using an adequate oil.

In the season to follow, the right and left chains should be

changed to get a uniform stress.

Plastic bodywork

The plastic elements do not need a special care.

However, they should be stored free from distortion if the

bodywork is not mounted to the machine.

Ensure that the shield extension rubbers (2) don’t get

deformed.

If required, metal parts are to be protected against

corrosion.

Roller chains

The only roller chain mounted for the cross auger drive

must be kept rustfree when winterizing the header.

The recommendations for the roller chain care to follow.

Storage

The corn header best to be stored in a well ventilated hall

either upright in the transport rack or on a dry ground.

ll metallic and bright parts should be protected against

corrosion.

Corn header not to store in lifted state

on the combine.

Prevent the combine tires from

unnecessary loads.

10 / 400

Help in case of malfunctions

Hydraulics

Trouble: Cause: Remedial action: Page:

Corn header cannot be lifted

Lifting force too low

Hydraulic functions of the header

don’t work

Optional: Control valve does not work Control valve to check 09/200

Insufficient pressure of the hydraulic

Locking blocks Locking and/or reversing

Not enough hydraulic oil

Folding header does not close on

point of separation

Folding shields do not close

Folding shields open automatically

Folding process is not quick

enough

Not enough hydraulic oil

No flowing-through in the hydraulic

connections

Transport protection blocks folding

process

system

Foreign bodies hinder folding process Foreign bodies or corn

Locking not made Locking and/or reversing

Control valve does not close reliably Control valve to check,

Combine is possibly fitted with a

throttle in the reel horizontal adjuster

Oil to refill

Additional lifting cylinder

required

Connections / couplers /

screwings to check

Transport protection on 8

and/or 12-row header to

remove

Pressure to check, if allowed

to increase

valve to readjust

Oil to refill

remainders to remove

valve to readjust

correct operation to secure

If allowed, throttle to remove

Hydraulic pump to check

09/200

09/120

09/200

09/040

Combine

manual

09/240

09/200

09/240

09/240

09/200

Combine

manual

10 / 900

Help in case of malfunctions

Drive

Trouble Cause: Remedial action: Page:

Drive is turned on but does not turn

Header stops during operation

PTO-shaft

PTO-shaft coupler does not engage

PTO-shaft to check

Locking not made,

coupling halves to check for

complete engaging

09/160

09/160

09/240

Driver of the drive coupler defective Drivers to check 09/640

Coupler does not engage Alignment to check

Slider to make moving

09/640

09/280

Combine

V-belt not tensioned Drive to check manual

Overload

Working speed to adapt

10 / 905

Help in case of malfunctions

Trouble: Cause: Remedy: Page:

Stripping unit

Header stops during the harvest

Stubble cutter cutting edge round Parts to replace 10/000

Working speed too high To adapt

Rotors are blocked

Slipping clutch of the row unit does

not react

Straw portion too high

Cloggings within the row unit

Sluggishness Stubble cutter

knife distance too great

10/000

Stripper Stripper to adjust 10/000

Rotor knife screws too long Original screw to mount 10/000

Cutting disks worn Cutting disks to change 10/100

Foreign bodies Foreign bodies to remove,

wearing to check

09/800

Overload Working speed to reduce

and/or speed to increase

09/440

Stripping plates Stripping plates to open as

far as possible

09/480

Working speed Working speed to adapt to

the conditions

Parallelism of stripping plates wrong Stripping plates to adjust 09/480

Gathering chains slip Chains to replace or shorten

09/520

Foreign bodies in or beneath the row

unit

To remove, dragging maize

chaff to remove

Speed too low Check via monitor 09/440

Cut-off block Missing or defective 10/210

Maize cob losses

Speed too high To reduce, if required 09/440

Shield extension rubber Missing or defective 10/500

Cob saver To mount in addition 10/500

Working speed Considerably to increase 09/360

Outer bodywork Increases to mount

Row distance Machine to adapt to the

09/000

conditions

Corn losses

Stripping plates To adjust narrower 09/480

Speed To reduce, if required 09/440

Refeeding from

gathering channel conveying chain

Abdeckung oberhalb der

Querförderschnecke

niedriger einstellen

09/760

Combine

manual

Working speed To increase until header is

better filled with material.

10 / 910

Help in case of malfunctions

Trouble: Cause: Remedy: Page:

Stripping unit (continued)

Corn stubbles too long

Stripping plates are blocking

Throttle in shifting cylinder To clean 09/440

Hydraulic supply line To check 09/200

Restoring spring To clean and/or readjust 09/480

Basic adjustment To check 09/480

Working height Header to adjust lower, if

required ground adaptation

system to mount

Stubble cutter worn Parts to replace, if required

Divider noses To adjust flatter, header to

put nearer to the ground

Row distance Not suitable 09/000

Working speed Speed to reduce

Dirty Mechanism to clean, plates

daily to open and close

several times

09/360

10/000

09/360

10/300

10 / 911

Help in case of malfunctions

Trouble: Cause: Remedy: Page:

Cross conveying auger

Cross conveying auger stops during

operation

Auger half of folding header stops

Auger ejects corn cobs out of the

machine

Overload Material quantity to reduce

Chaff portion too high

Sliding clutch responds Foreign bodies to remove

Stripper to check

09/800

Drive Chain and clutch to check 10/400

Original combine splashboard

mounted in front of the gathering

Splashboard to remove

09/080

channel

Driver clutch Adjustment and gearing to

check, axial spring-loaded

half to check for function

09/760

(lubrication)

Locking of the header Exact locking to assure

09/240

Speed To check via monitor 09/440

Position of the conveying aids Position to check via table

09/720

Insufficient feeding Advance to increase

10 / 915

Sunflower equipment

Y

Cutter to mount

Right gathering chain to release and plastic block

(4) to put in.

Holding down device for gathering chain

to put on pin (5), see ill.

Stripping plates to open so much that premounted

cutter (M) can be pushed in, see above graph (ill.

A-A) and also (ill. N 147 M).

Size (LV) in above graph, min. 510 mm, max. 600

mm allows for an individual axial cutter setting.

The more the cutter is pushed rearwards the

stronger the rotors start pulling the sunflower

through.

In consequence, the cutter to be pushed forwards

so far that the sunflower head, if possible, won't

be pushed downwards too much.

ou must avoid that the head gets in touch with

the chains before the stalk has been cut off.

Stripping plates to close and screw (S) to tighten.

Holding-down device for gathering chain not

shown on the photos.

35 / 000

Sunflower equipment

(

)

A

!

Plastic driver

To improve the material transport and due to the better

feeding angle, the plastic blocks (K) as shown in the

illustration, must be mounted on all chain drivers via the

enclosed screws.

Attention!

For the harvest of maize, the plastic blocks (K) must be

dismounted.

Stripping row for the sunflower harvest

The holding-down device (N) for the gathering chain is not

shown on opposite illustration.

Prior to mounting the plastic block (K2), first the holdingdown device (N) (see graph on page 35 / 000) to be put in

behind the chain guide such that the pins (B) of the plastic

block secure also the holding-down device (N).

Attention!

For the harvest of maize, the plastic blocks (K) must be

dismounted again.

Ill. N 149 shows the ready sunflower series with holdingdown device.

N

Change speed gear maize and sunflowers

To get a good function on the harvest of sunflowers, we

recommend to reduce the speed to n= about 470 r/min.

The 2-speed gear (G) has a fixed speed each for maize and

sunflowers.

The speed is selected by shifting the lever

2 ←→ 1

5-speed gear, see page 10 / 600

Important!

For the harvest of sunflowers the working speed should

be as high as possible to allow the sunflowers quickly

falling rearwards into the cross conveying auger without

touching the gathering chains. Check that the stalks are

long enough for allowing such a procedure.

Due to the bodywork form and the real operation

purpose of the header for the harvest of maize, some

small corn losses cannot be avoided, in particular if the

harvest material is very dry.

ttention

The sunflower speeds must not be taken for the harvest

of maize.

Gear to shift in idleness only!

35 / 005

Change speed gear (special equipment)

A

A

!

A

!

A

!

Change speed gear for speed reduction

On option, 3 different change speed gears (G) are

available.

Particular harvest and harvest material may require

changing the speed.

• 5 – speed for the corn and sunflower harvest

• 3 – speed only for the corn harvest

Information to the sunflower harvest, see page 35 / 000

(Ill. N 143 guard removed)

Change speed gear corn and sunflowers

5 - speed

The speed is selected via a commercially available wrench

SW 24.

ttention! The sunflower speeds must not be

taken for the corn harvest.

Change speed gear corn

3 - speed

ttention

Change speed gear corn and sunflowers

The 2 -speed gear (G) has a fixed speed each for corn and

sunflowers.

The speed is selected by shifting the lever

2 ←→ 1.

ttention

for the corn harvest.

The sunflower speeds must not be taken

ttention

Gear to shift in idleness only!

35 / 010

Bodywork increase (lateral, special equipment)

Bodywork increase laterally right and left

For sunflower and corn harvest to avoid harvest losses

Mounting instructions:

1. Bores (in front: Ø9; rear 2x11-2x Ø9) to bore via

template (504286 left; 504287 right).

2. In the area of the bores, one mounting hole each

from below and/or inside to bore into the outer

divider nose (Ø 50-55).

3. Threaded bar (2) through the mounting hole from

inside to screw down via the screws (3) to the

outer divider nose (3).

4. Clamping plate (7) with 3 spacers (8) to screw

down to the outer divider nose (3,12,13).

5. Outer divider nose extension with the frontal nose

to push under the clamping plate so that the

welded screw in the rear area engages into the

pocket of the threaded bar.

6. Outer divider nose increase and threaded bar to

screw down to each other (4,5,6).

7. Covering rubber to mount (9,10,11,12).

View A

View B

1 washer 8,4 DIN 9021 13 040216

5 hexagon nut M8-DIN 985 12 040008

4 washer V9-DIN 440 11 040300

4 saucer-head screw M8*16-DIN 10 040612

1 covering rubber 9 504297

3 washer A8-DIN 125 8 040201

1 clamping plate 7 504298

1 hexagon screw M10x30 DIN 6 040438

1 spring ring A10-DIN 9021 5 040109

1 washer 10,5-DIN 9021 4 040217

flat mushroom head screw 8x20

3

1 threaded bar 2 504299

1 outer divider nose increase l+r 1 504290/291

3 040917

Bodywork increase

Order no.: 504288 (links)

Order no.: 504289 (right)

35 / 015

Notes for special harvest conditions

A

A

Y

Shield extension rubber

If the maize plants are thin or even crumbly, the shield

extension rubbers (G) can be screwed off.

There is also the chance of extending the gap (S)

according to the conditions by removing a uniform piece

each right and left.

Additional cob saver (optional)

dditional cob savers are available for being put onto the

center divider noses.

Certain maize sorts can produce cob losses, which

requires using this additional device.

Once drilled the respective bores into the existing divider

noses (see graph hereunder) the cob saver can simply be

slipped on. As shown in ill. N 114, they are also fitted with

the respective rubber flaps (G).

Top for reducing cob losses

ccording to opposite graph bores are to be drilled for

mounting the additional cob saver.

A = 500 mm

X = 60 mm at a row width of 70 cm

95 mm at a row width of 75 cm

= 11 Ø after adaptation of the top

L = oblong holes 20 x 10 mm

35 / 050

Special tools

A

Dismounting tool

Order no. 501165

Chain dismounting tool

Order No.: 501190

djustment for dismounting the

gathering chains

Adjustment for dismounting the

front chain wheels

36 / 000

Starting torque for bolts

Minimum starting torque for screwing grade II in conformity with 1c

Current for bolts

Dimension size M rated in Nm M rated in Nm M rated t in Nm

degree of firmness 8.8

M4 2,7 3,8 4,6

M5 5,4 7,6 9,1

M6 9,2 13,0 15,5

M8 22,0 31,0 37,5

M8 x 1 24,0 33,5 40,0

M10 43,5 61,0 73,5

M10 x 1,25 46,0 65,0 77,5

M10 x 1 50,0 70,0 84,0

M12 76,0 106,0 127,0

M12 x 1,5 79,0 111,0 133,0

M12 x 1,25 82,5 116,0 139,0

M14 120,0 168,5 202,0

M14 x 1,5 130,0 183,0 219,0

M16 187,0 262,0 314,0

M16 x 1,5 198,0 278,0 333,0

M18 257,5 362,0 433,0

M18 x 2 272,0 382,0 457,5

M18 x 1,5 287,0 403,0 483,0

M20 362,5 509,0 610,0

M20 x 2 381,0 535,0 641,0

M20 x 1,5 400,0 562,0 673,0

degree of firmness 10.9

degree of firmness 12.9

36 / 100

Hydraulic circuit diagram folding headers

Hydraulic circuit diagram for foldable headers from 6 – 12 rows

In case of queries o r possible troubles on the hydraulic control of the corn header, please get in

touch with our customer service at: Phone no. ++49-2382-981452 Fax ++49-2382-981456

36 / 300

Headlights for combines with foldable corn heads

36 / 500

New Holland CX/CR combine changes on the gathering channel

Changes on the CNH combine gathering channel

Before mounting a header to the CNH-combine of the

series CX and CR it is a must to remove the brackets (L) of

the upper arm location.

Attention !

Only the brackets to remove, since the other mechanism

forms the swivel of the pivoting shield!

Channel view: Brackets removed

Flat steel with screws (S) must be left on the machine.

Holder for upper arm location

To allow for a later use of the upper arm location, an

additional part no. 550900 is supplied along with the

machine.

This additional part is screwed on the existing bracket with

longer screws (M16 x 50).

Holder for upper arm location

Do not weld in the area of the bore

e New Holland.doc

John Deere series 22… conversion to WTS, CTS, STS

A

Setting angle Geringhoff Rota – Disc* header

The ideal working angle for the Rota–Disc header is

about 27°.

When converting the header from one combine make to

another one, in general new adapter parts are required.

When changing from a rigid, not foldable header from the

series JD 22.... to WTS, CTS or STS, that could be done

without the need for using new adapter parts.

That does not apply to „ Hillmaster“ versions

John Deere WTS, CTS and STS combines

If a not foldable corn header is provided for the series JD

22.... to WTS, CTS or used to STS, the channel angle (M)

is to be adjusted to the lowest possible size (M).

This adjustment allows approaching to the required

working angle of the corn header Rota-Disc.

further adjustment of the working angle of the header can

be made via the standard angle adjustment of the header

(see also 09/480.

Multicoupler for hydraulic connection

Combines of the series WTS, CTS and STS are fitted with

a multicoupler for the hydraulic connection to the header.

This coupler must be provided along with the adapter parts

for being able to operate the header.

Conversion of folding Rota-Disc* headers from

JD 22... to John Deere WTS, CTS or STS

These changes require in any case using new adapter

parts, since the PTO-shaft coupler requires an exact

adaptation of the driving point.

New adapter parts are also required when changing from

series JD 22.. to WTS, CTS or STS on „ Hillmaster“

versions.

e John Deere.doc

John Deere series 22… conversion to WTS, CTS, STS

Feed opening of the corn header

Certain opening sizes of the header for all combine makes

and models are determined for the feeding to the gathering

channel of the combine.

The exact opening width to be learnt from the sketches in

the spare part catalogue from picture table 60/.. .

For standardization reasons, slight variations from the rated

size are allowed.

In particular when working on slopes a regular feeding is of

essence for the harvest material to be distributed evenly

within the machine.

Adaptation to combine width

If the corn header is changed between different combine

makes and types, it must possibly be adapted to the

different machine width.

The plates (12 and 13) are to be put to the required size to

ensure a homogenous machine feeding.

The width (M) of the header opening is to be adapted to

that of the combine.

John Deere-2.doc

Loading...

Loading...