Page 1

GE Water & Process Technologies

RCC

®

Thermal Products

3006 Northup Way #200

Bellevue, WA 98004

Phone: 425-828-2400

Fax: 425-828-0526

www.ge.com/water

Copyright © 2009 General Electric Company. All rights reserved.

GEA17904 (10/2009)

GE Water & Process Technologies

Zero Liquid Discharge

Eliminate Liquid Discharge,

Recover Valuable Process Water

Page 2

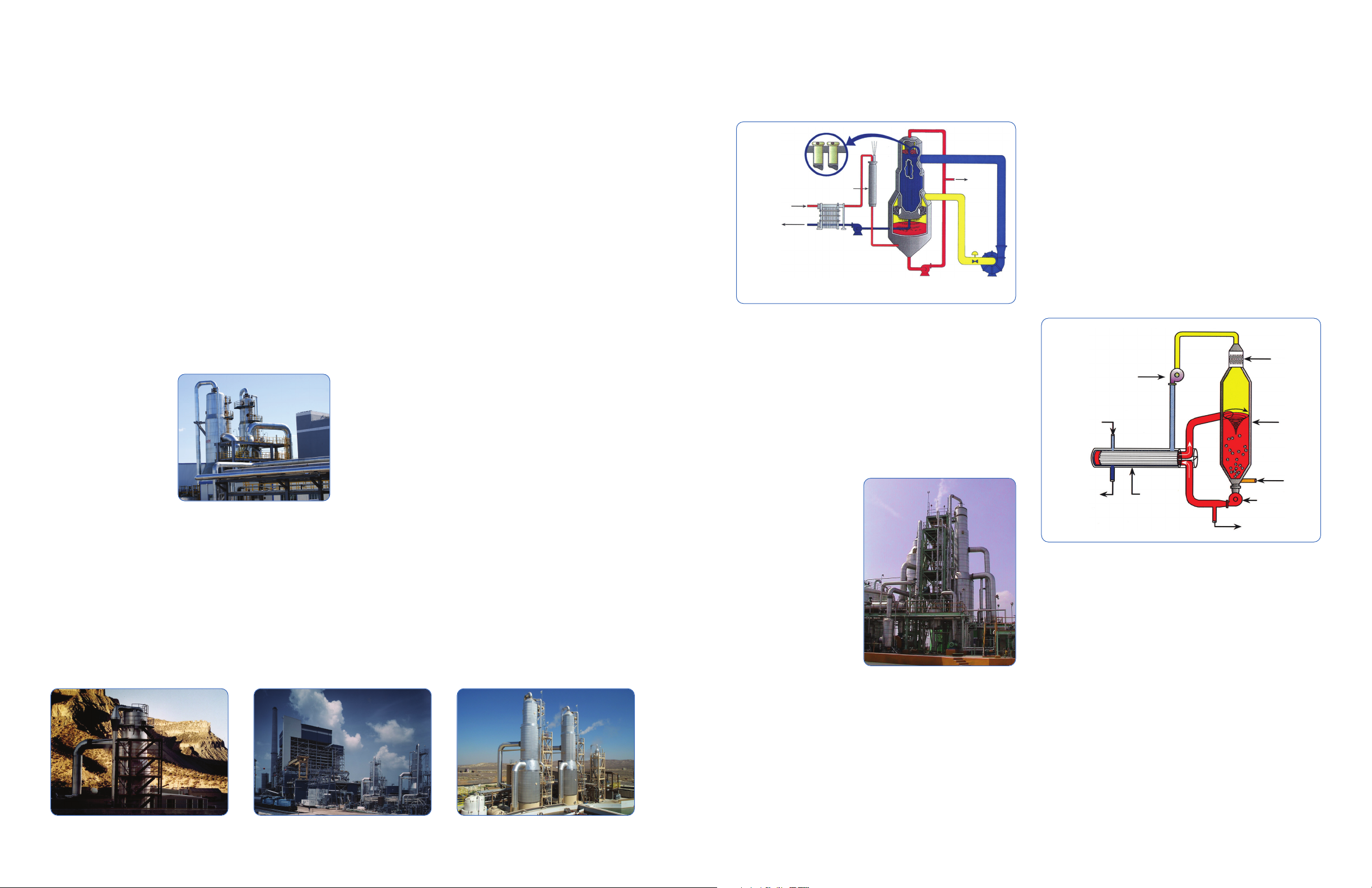

Brine Concentrator

GE brine concentrators recover up to 95% of industrial wastewater

as high purity distillate. This can be used for boiler makeup, NOx

control, cooling tower makeup and process use. The remaining

five percent is a slurry concentrate that may be sent to a small

solar pond, reduced to dry solids in a crystallizer or spray dryer,

or used for ash wetting.

Brine Concentrators Can Recycle:

• Cooling tower blowdown

• Oil and gas field

produced water

• Demineralizer waste

• Reverse osmosis reject

• Electrodialysis reject

• FGD wastewaters

• Boiler blowdown

• Softener waste

• Plant drains

• Salty effluents

• Mine drainage

• Landfill leachate

Benefits:

• Corrosion resistant titanium—High grade construction

materials mean GE brine concentrators will last for decades

and provide reliable operation.

• Scale control—Proprietary seeded slurry technology controls

scale, often limiting cleanings to only once per year.

• Patented brine distributors—Individual tube distributors

ensure a smooth flow of brine, avoiding scale formation.

• Variable waste flows—GE’s largest single brine concentrator

treats 1,200 gpm, while small units treat as little as 10 gpm.

• Energy-efficient operation—In the vapor compression

configuration, the brine concentrator uses 21 to 37 BTU

per pound of waste feed. This converts to 50 to 90 kWh per

1,000 gallons of feed, which is 25 to 50 times more efficient

than conventional single-effect, steam-driven evaporators

• Ability to run on electricity or steam—Typical operation

is by mechanical vapor compression, but brine concentrators

may also run on steam in a multiple-effect configuration.

• Fully automated operation—Maintain precise system control

while minimizing operator interaction

Crystallizer

Meeting stringent zero-liquid-discharge requirements also

requires a crystallizer, to reduce brine concentrate to a dry solid.

Recovered water can be recycled back to plant processes, while

an easy-to-handle dry solid can be safely disposed of in an

approved landfill.

• Ease of use—With simple color graphic controls and an

automatic wash system, GE’s crystallizers are easy to operate.

• Ease of installation—Skid-mounted, fully packaged systems

with all auxiliary equipment and controls.

• Valuable product recovery—Systems can be designed to

recover specific salts from a waste stream.

• Expertise in zero liquid discharge—GE has more than

35 years of experience developing and implementing thermal

technologies to solve zero liquid discharge challenges for

customers worldwide.

Complying with stringent wastewater treatment regulations

and reducing water usage are critical considerations in industry

today. Numerous environmental regulations, rigorous permitting

processes, and lack of water availability, among other factors,

are driving many industrial facilities to implement zero liquid

discharge (ZLD) systems as a solution.

GE’s ZLD systems eliminate liquid waste streams from your plant

and produce high purity water for reuse. In many cases, your

plant’s water consumption can be reduced by up to 90 percent—

saving money and helping to protect the environment. You may

even be able to capture valuable by-products and sell them to

offset your costs.

With more than 35 years of experience in the design, delivery,

commissioning and service of ZLD systems, GE provides a

comprehensive portfolio of technologies for ZLD applications,

including brine concentrators, evaporators, and crystallizers.

Proven performers and

highly reliable, GE ZLD

systems offer 95%

availability and are up to

30 percent more energy

efficient than conventional

designs. These technologies

can often be combined

with other GE equipment,

such as ultrafiltration (UF),

reverse osmosis (RO),

electrodeionization (EDI)

and ion exchange to provide the optimal solution. Our specialists

can tailor a system to fit your wastewater characteristics, flow

rates, and end-product requirements.

As the pioneer of thermal ZLD systems, GE is continually developing

new thermal solutions that respond to changing market needs. Our

extensive global experience can help you tackle the challenges of

stringent discharge regulations, process optimization and effective

water and wastewater management. GE ZLD systems can help

simplify the permitting process, thereby accelerating your plant

development schedule and alleviating environmental concerns.

Our strong vendor relationships enable strategic sourcing

agreements and, in turn, offer you the most competitive pricing

available. With multiple contracting methods, a variety of system

options, and highly experienced design and delivery teams, GE

can custom-design a system for your maximum benefit.

Robust Solutions

for Demanding Applications

GE’s large installed base of robust systems is proven to perform

across a broad range of applications, including:

• Power

• Synthetic fuels

• Primary metals processing

• Microelectronics

• Chemical

• Pulp and paper

• Coal mining

• Battery manufacturing

• PVC manufacturing

• Uranium mining

• Petroleum and petrochemical

• Oil refining

• SAGD heavy oil recovery

• Cogeneration

• Fertilizer

• Solid waste (leachate and secondary sewage effluent)

• Coal liquefaction

• Ethanol production

Compressor

Vent

Distillate

Wastewater

Heat Exchanger

Deaerator

Brine

Distributors

Waste

Brine

Recirculation

Pump

Distillate

Pump

Vapor Compressor

Steam

Condensate

Heating

Element

Waste

Recirculation

Pump

Feed

Flash Vessel

Mist Eliminator

Shenhua Coal Liquefaction Project,

Inner Mongolia, 590 gpm, 2009

Huntington Power Station, Huntington, UT,

200 gpm, 1974

Indiantown Generating Plant, Indiantown, FL,

580 gpm, 1995

Gila River Power Station, Gila Bend, AZ,

2,400 gpm, 2003

PEMEX Cadereyta Refinery, Monterrey,

Mexico, 116 gpm, 1998

Experience, Reliability, Results Achieving ZLD: Equipment Overview

Loading...

Loading...