Page 1

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FSufZW1500-600_EN.doc Jun-13

ZeeWeed* Pressurized Ultrafiltration

Model ZW1500-600

Description and Use

As a pioneer of membrane technology, GE leverages

decades of research, development, and operational

experience in developing the most advanced pressurized ultrafiltration technology in the market,

ZeeWeed 1500. ZeeWeed systems are proven to

consistently outperform conventional filtration

technology while meeting or exceeding regulatory

requirements, regardless of source water quality.

Typical Applications

Versatile and reliable, the pressurized ZeeWeed

1500 is ideally suited for use in numerous applications including drinking water treatment, tertiary

filtration and RO pre-treatment for brackish water

and seawater. Compared to granular filter media,

ZeeWeed membranes produce superior water quality and are virtually unaffected by variable raw water

quality - all at a cost comparable to conventional

filtration technology.

General Properties

• 0.02 µm nominal pore diameter - for optimal

• PVDF hollow fiber membrane - provides high

• Outside-in filtration - provides uniform flow

removal of particulates, bacteria and viruses

mechanical strength and chemical resistance

distribution and high solids tolerance

Storage and Handling

Modules may be stored in the original factory

packaging for up to 1 year prior to installation.

Modules must be stored between 5°C and 35°C

(41°F to 95°F). Do not expose the membrane module to direct sunlight (UV light).

Safety Precautions

A Material Safety Data Sheet containing information about this product is available on request.

Page 2

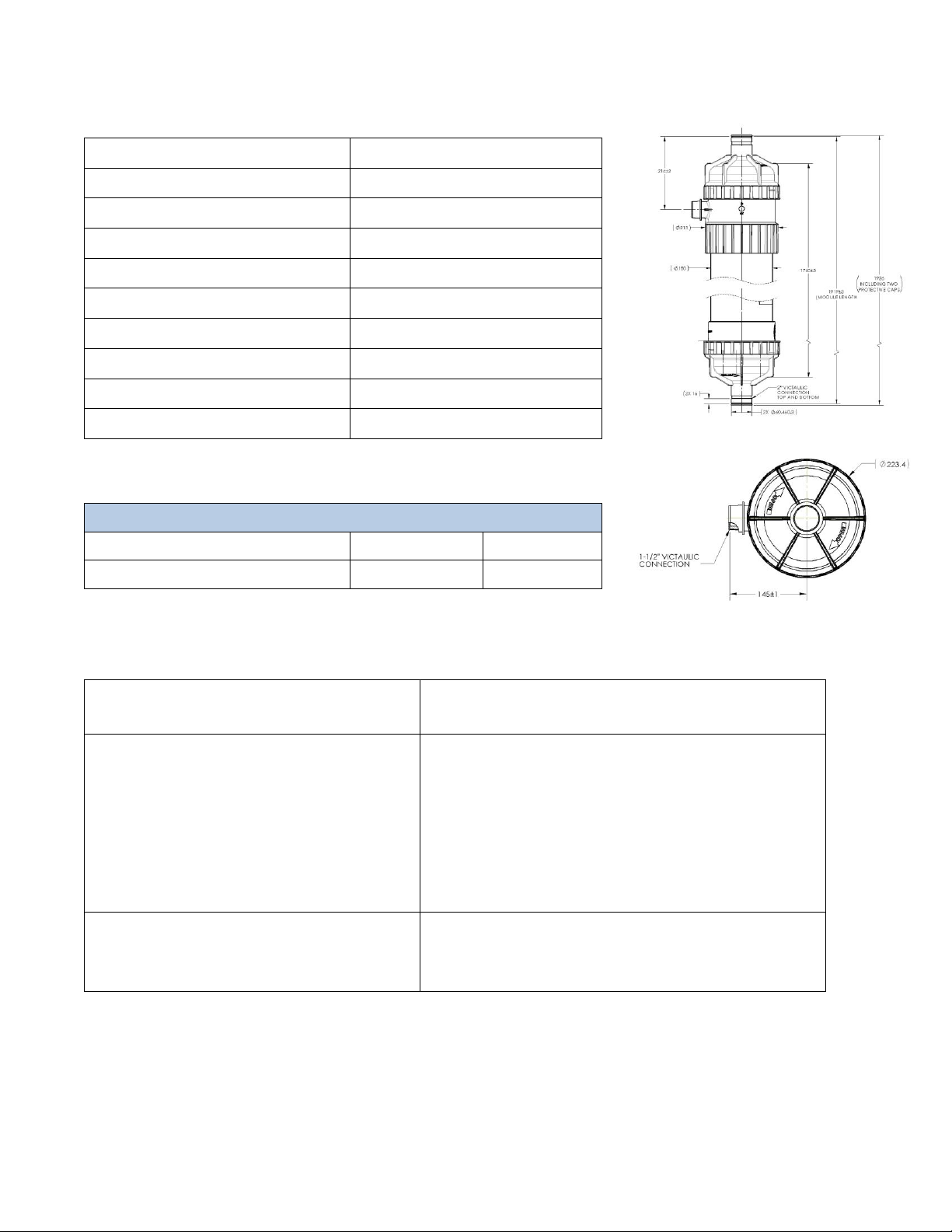

Product Specifications

Model

ZeeWeed 1500-600

Module part number

3098728

Nominal membrane surface area

55.7 m2 (600 ft2)

Max shipping weight1

32 kg (70 lb)

Lifting weight2

30-36 kg (65-80 lb)

Membrane material

PVDF

Nominal pore size

0.02 micron

Nominal fiber diameter

OD: 1.1 mm, ID: 0.66 mm

Flow path

Outside-in

Housing material

PVC housing with Noryl caps

Module Dimensions

Connections: Permeate/Feed/Reject

Height

Pipe diameter

Victaulic/Victaulic/Victaulic3

1920 mm (75.6 in)

180 mm (7.1 in)

Performance

Flow range

45 – 180 m3/day (8-33 gpm)

Operating conditions

Max shell inlet pressure

TMP range

Max temperature

Operating pH

Max air scour flow

Max backwash flow

379 kPa (55 psi)

0-276 kPa (0-40 psi)

40°C (104°F)

5.0-10.0

8.5 m3/h (5 dcfm)

1.8 m3/hr (8 gpm)

Cleaning

Cleaning pH range

Max chlorine concentration

2.0-12.0

1,000 mg/L (as NaOCl)4

All lengths in mm

1

Packaged

2

Varies with solids accumulation

3

Module available with compression permeate and/or threaded reject connection(s)

Operating Parameters

4

NOTE: Higher concentrations are possible depending on feedwater and pH.

Page 2 Fact Sheet

Loading...

Loading...