Page 1

ZCore Depth Filters

Featuring patented Z.Plex* Technology

Benefits:

• Greater contaminant capacity compared to filters

with equivalent removal efficiency

moval efficiency at rating using ASTM F-795 Retention based on GE efficiency test protocol)

• High Temperature Capability (see Table 3)

• Melt-bonded exterior ensures no media migration

and helps prevent premature surface blinding

• Provides lower total cost of filtration operations

• FDA compliant

• Product meets criteria for USP Class VI

• High strength polypropylene core

Figure 1: ZCore using Z.Plex Technology

• Resists contaminant unloading even at high differential pressures

Fact Sheet

(Note: 90% re-

Features and Benefits

ZCore is manufactured using patented Z.Plex* filter technology and is engineered specifically for

high strength filtration. (See Figure 1) The patented

filter matrix of the ZCore provides unmatched performance in these applications.

The ZCore filter composition incorporates small

diameter fibers and an innovative 3-dimensional

fiber matrix. The filter matrix maintains structural

integrity while greatly increasing the filter’s particle holding capacity and reducing pressure drop.

An additional polypropylene support core enhances strength and temperature resistance. This

unique construction allows for excellent removal

efficiency, high contaminant capacity and long

life.

Typical Applications

• Elevated temperature uses such as hotwater sanitizing in food and beverage processes, process

and chemical streams

• High viscosity fluids that require filter strength

under heavy loading and high pressure conditions

• Applications that experience high pressure drop

General Properties

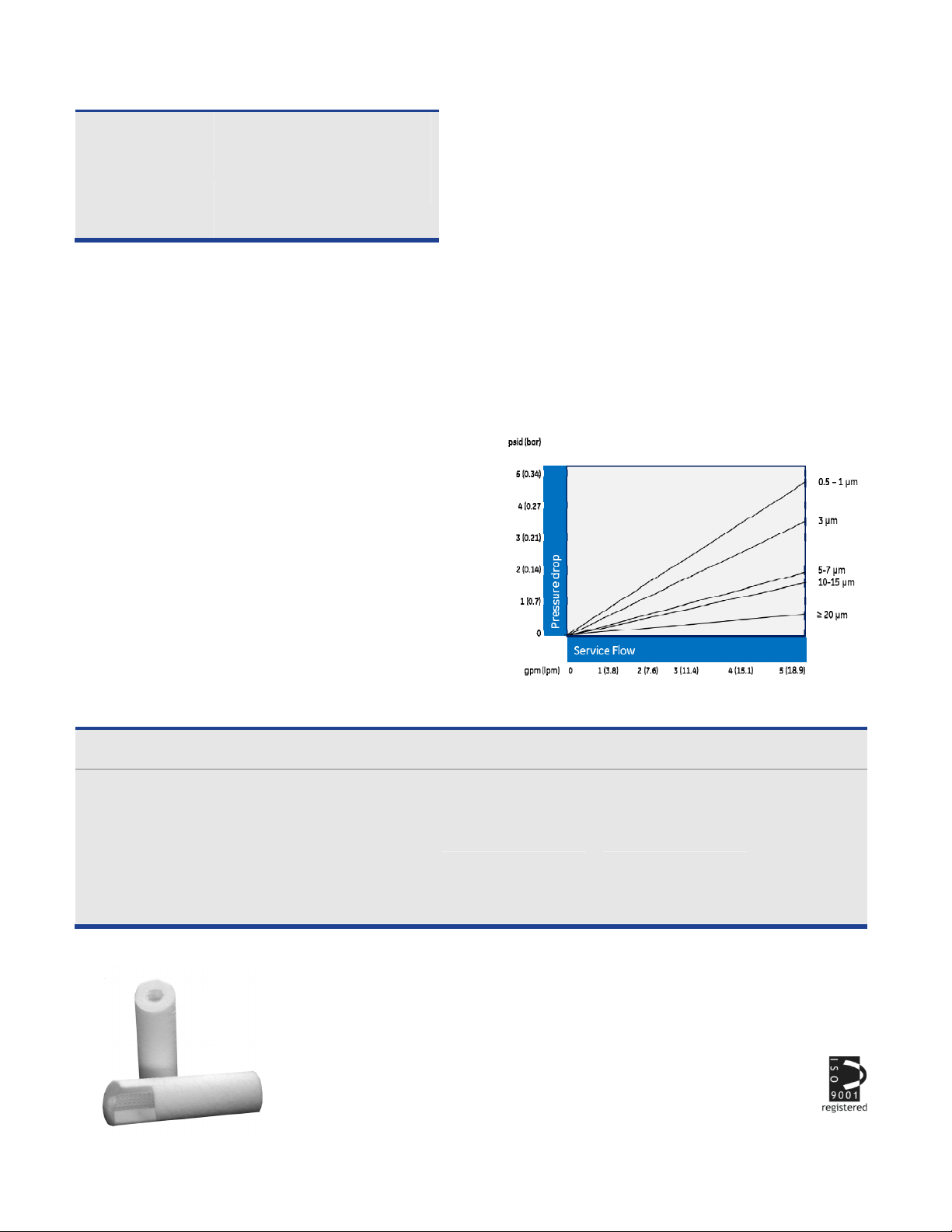

Tables 1, 2, 3 and 4 provide information on dimensions and flow performance.

Table 1: Materials of Construction

Core Polypropylene

Media Polypropylene

Adapters Polypropylene

Table 2: Nominal Outside Diameter

0.5, 1.0, 3.0 micron 2.75in (6.99 cm)

5.0 to 200 micron 2.55 in (6.48 cm)

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2012, General Electric Company. All rights reserved.

FSfilZCore_EN.doc Oct-12

Page 2

Table 3: Operational Limits

Maximum forward

differential pressure

Maximum recommended change-out

pressure

15 psid (1.03 bar) at 180°F (82°C)

25 psid (2.07 bar) at 150°F (66°C)

60 psid (4.14 bar) at 86°F (30°C)

35 psid (2.41 bar)

Additional Information

• ZCore cartridge filters are made from thermally

bonded fibers of polypropylene. GE certifies that

it uses no resin binders, lubricants, antistatic or

release agents, in the manufacture of these filter

cartridges. The resin used for manufacturing the

filter media meet the food contact requirements

of the U.S. FDA 21CFR 177.1520. ZCore cartridge

filters meet the safety requirements of Article 3

of the EU Framework Regulation No.

1935/2004/EC and may be used as intended in

all of the EU Member states in full compliance

with the EU Plastics Regulation No. 10/2011.

ZCore cartridge filters meet the criteria for USP

class VI-121 C Plastics..

• ZCore cartridge filters may be autoclaved for 30

minutes at 250°F (121°C) under no end load

conditions. The autoclaved cartridges must feature single open-end connections (222 o-ring

with closed end). Filter cartridges should be allowed to cool to normal system operating temperatures prior to use.

• If you are ordering ZCore filters with standard

ends (with no adapter on either end), select one

designation from each of the first three columns.

Your Product Order Number will look like this:

ZCore 05-40. If you are ordering ZCore with end

adapters, select designations from all applicable

columns. Your Product Order Number will look

like this: ZCore 05-40 XK.

Table 4: Flow Performance in Clean Water

(based on 10 inch length filter)

• ZCore cartridge filters are designed and manu-

factured for resistance to a wide range of chemical solutions. Conditions will vary with each

application and users should carefully verify

chemical compatibility. Please contact your GE

representative for more information.

Table 5: Ordering Information

Type Micron Rating Nominal cartridge

ZCore

1

95 = 0.5 µm

01 = 1 µm

03 = 3 µm

05 = 5 µm

07 = 7 µm

10 = 10 µm

15 = 15 µm

20 = 20 µm

25 = 25 µm

Viton is a registered trademark of DuPont.

30 = 30 µm

40 = 40 µm

50 = 50 µm

75 = 75 µm

100 = 100 µm

120 = 120 µm

150 = 150 µm

200 = 200 µm

Length

1 = 10 in (25 cm)

2 = 20 in (51 cm)

3 = 30 in (76 cm)

4 = 40 in (102 cm)

End #1 Adapter End #2 Adapter Elastomer

X = Plain End (no adapter)

Y = Open End Gasket

E = 222 O-Ring

F = 226 O-Ring

L = Extended Core

X = Plain End (no adapter)

K = Self-Spring Seal

Y = Open End Gasket

S = Closed End Cap

H = Fin Adapter

material

S = Silicone

E = EPDM

V = Viton1

B = Buna

P = Santoprene

(flat gasket only)

Page 2 FSfilCore_EN

Loading...

Loading...