Page 1

GE Power & Water

Water & Process Technologies

Analytical Instruments

Sievers InnovOx

Laboratory and On-Line TOC Analyzers

Overview

GE Analytical Instruments designed the Sievers* InnovOx

Total Organic Carbon (TOC) Analyzers to provide industryleading sample handling robustness and instrument uptime

for process, environmental, and wastewater organic carbon

analysis. Available in both Laboratory and On-Line models,

the InnovOx uses an innovative Supercritical Water Oxidation technique that offers enhanced reliability, greater ease

of use, and lower maintenance than typical combustion or UV

persulfate TOC analyzers.

Features and Benefits

Wide Dynamic Operating Range—Measures up to 50,000

parts per million (ppm).

• Versatile Measurement Modes—Measures

Total Inorganic Carbon (TIC), NPOC, Total Carbon (TC) and TOC by difference (TC-TIC).

• Sample Handling Robustness—Uses an

innovative Supercritical Water Oxidation

(SCWO) technique to achieve superior TOC

recoveries regardless of organic compounds

and particulate impurities in the sample. The

InnovOx can handle a wide variety of traditionally difficult sample matrices, including

brine, cellulose, and humic acid (see table on

page 4) with unprecedented reliability.

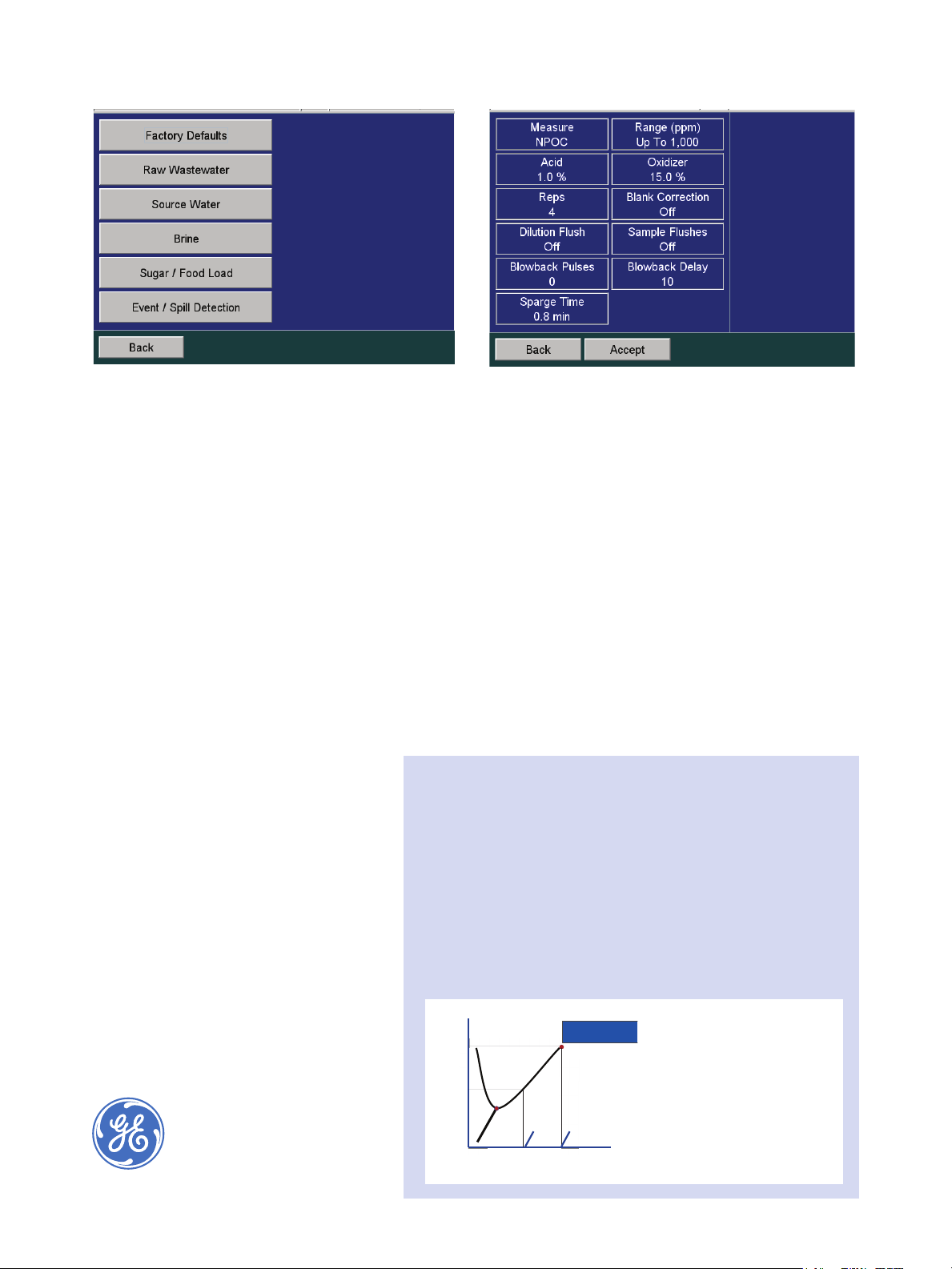

• Easy Operation—The InnovOx On-Line offers

preset protocols for easy startup. Both OnLine and Laboratory models have intuitive

color touch-screen interfaces, and operate

immediately without any necessary heater

warm-up or detector stabilization.

Fact Sheet

• Low Maintenance and Cost of Ownership—Robust by

design, the InnovOx requires minimal operator intervention or preventive maintenance, offers up to six months’

calibration stability, and features a solid state nondispersive infrared (NDIR) detector.

• Ethernet Web browser interface (Lab)—Allows users to

remotely monitor and control Analyzer operations and

results using a Web-based interface via the instrument’s

Ethernet port.

• User-configurable alarms and outputs (On-Line)—No-

tifies user of water system events and enables remote

monitoring of analysis results and performance.

InnovOx Laboratory TOC Analyzer Web Interface

Page 2

InnovOx On-Line TOC Analyzer Touch-Screen Interface InnovOx On-Line TOC Analyzer Touch-Screen Interface

pressure (psi)

Key Applications

• Petrochemical

• Food and Beverage

• Chlor-alkali Chemistry

• Pharmaceutical

• Environmental Labs

• Manufacturing

• Municipal/Industrial Wastewater

• Power

• Research

• Pulp and Paper

• Brine and Seawater

• Unconventional Oil & Gas

Technology and Operation

The InnovOx features three main steps, each with

significant process innovations:

Sample Handling and Reagent Mixing

The InnovOx ensures superior sample representation and accuracy by processing a large sample

volume and thoroughly agitating the sample in

the Sample Mixing Chamber. The sample and reagents are added through a sample coil delivery

system which prevents syringe contamination.

Supercritical Water Oxidation (SCWO)

Using a patented SCWO technique (see sidebar below), the

Sievers InnovOx takes the water sample to a supercritical

state by increasing the temperature, and subsequently the

pressure, within the reactor. The properties of supercritical

water enable an ultra-efficient oxidation of TOC to carbon

dioxide, even in the presence of chloride and other inorganic species that negatively interfere with traditional

oxidation techniques.

NDIR Detection

The InnovOx uses a highly stable, nondispersive infrared

(NDIR) detector. Unlike other NDIR detectors, the InnovOx

NDIR has no moving parts, and features tight temperature

control of the IR source and detector.

Visit the library at www.geinstruments.com to see animations of

key components and the innovative SCWO oxidation technique.

Supercritical Water Oxidation (SCWO)

Supercritical Water Oxidation (SCWO) was originally developed to

treat large volumes of aqueous waste streams, sludges, and contaminated soils. SCWO destroys organic wastes using an oxidant in water

and temperatures and pressures above the critical point of water:

375 °C (770 °F) and 22.1 mPa (3,200 psi). These conditions enable rapid

and complete oxidation of organic carbon to CO2.

Today, SCWO research and development is focused on treating a variety of toxic and hazardous organic wastes. GE Analytical Instruments

is the first company to use this technique in a commercial laboratory

TOC instrument.

Super criti cal fluid ―

Super criti cal

not gas or liquid

gas

gas

normal

boiling

point

uid

critical point

critical point

o

375

C

o

C

Supercritical Water

Oxidation (SCWO)

Organic + S

→

O

2

CO

-

2

+ heat + pressure

8

+ H2O + SO

2

-2

4

3200

liquid

liquid

15

solid

solid

pressure

temperature

Page 3

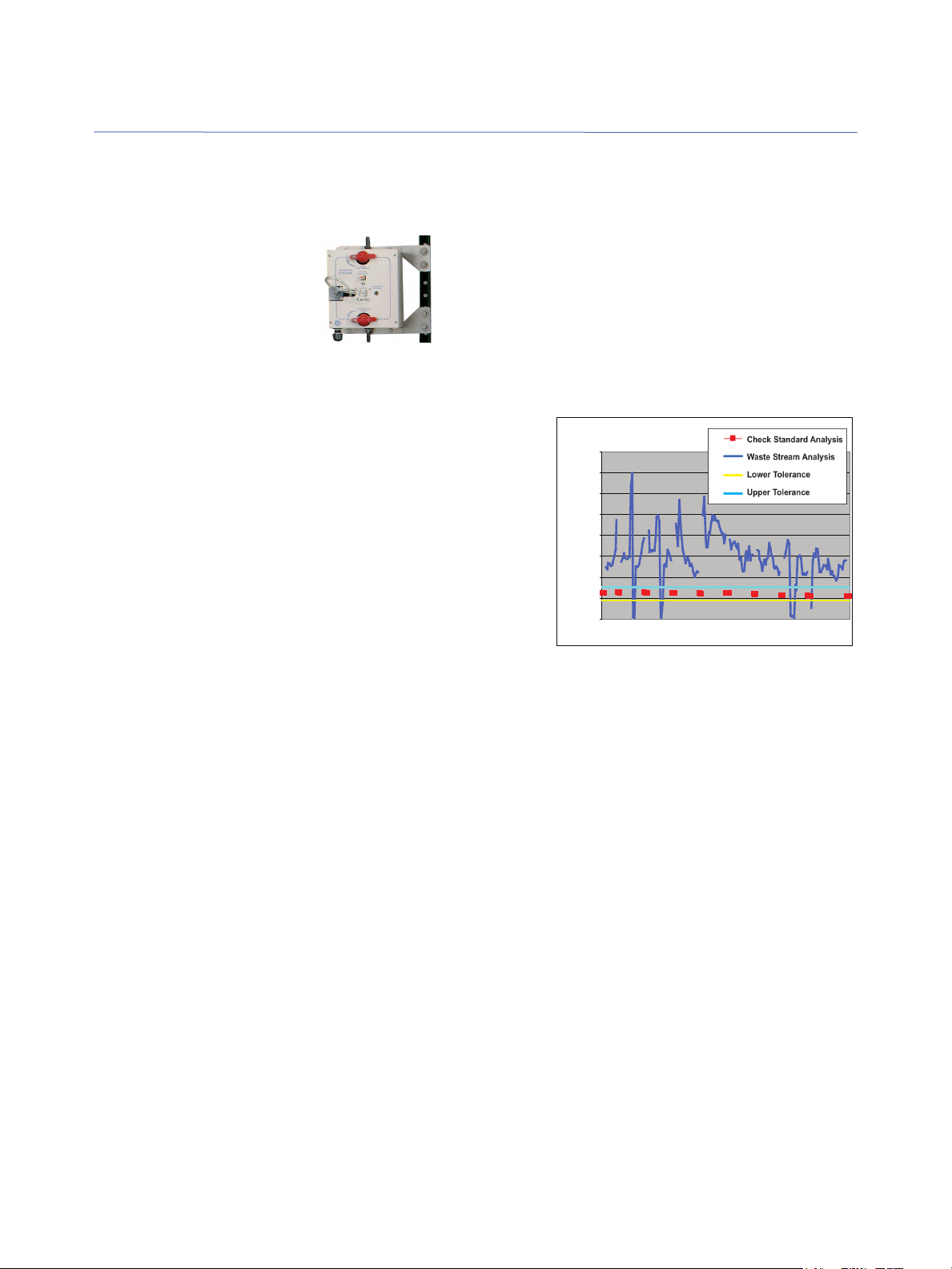

InnovOx On-Line Analyzer Details

Accessories and Options

Air Purifier

The Air Purifier removes CO2 from the air so the Analyzer can

use house air as the compressed gas source.

Filter Panel

This accessory filters one sample

stream, and it is automatically

cleaned by back flushing with

compressed air. The Filter Panel is

adjustable for various particulate

levels.

Fail-Safe Accessory

Sensors detect when the flow rate of each sample stream

stops or consumables need replenishing.

IP56

The IP56 configuration protects the Analyzer from water

spray and dust that would interfere with its operation.

NEMA 4X

The NEMA 4X enclosure protects the instrument from

corrosive environments.

Other Accessories

Other accessories include a mounting stand, a sample

peristaltic pump, and multi-stream (2, 5) configurations.

Specifications

Operating Specifications

Analysis Modes NPOC, TOC (TC-IC), TC, IC

Dynamic TOC Range Up to 50,000 ppm TOC

TOC Limit of Detection (LOD) 0.05 ppm NPOC

TOC Accuracy** ±3%

TOC Precision** RSD ≤ 1.5%

TOC Linearity*** R2 ≥ 0.995, measured as NPOC

Analysis Time 2.6 to 8.3 min in online mode

TOC Calibration Stability Up to 6 months

Particle Diameters in Sample ≤ 200 µm diameter without filtration,

> 200 µm with optional Filter Panel

Ambient Temperature Range 10–40 °C (50–104 °F)

Maximum Relative Humidity Up to 95%, non-condensing

Sample Temperature Range 10–60 °C (50–140 °F)

Sample Volume 0.6 ml to 3 ml

Sample Inlet Pressure 125 psig maximum with provided control valve

0.5 psig minimum without optional sample pump

Drain Gravity drain

1

1600

1400

1200

1000

800

600

Total Carbon (p pm)

400

200

0

Time

Analyzer Specifications

Outputs External USB port (1), internal USB ports (2), Ethernet (1), Binary End-of-Analysis Output (1),

Isolated 4-20 mA Analog Outputs (5)

Display Color, touch-sensitive LCD

Power 100–240 ±10% VAC, 280 W, 50/60 Hz

Dimensions Analyzer: H: 92.7 cm (36.5 in); W: 64.6 cm (25.4 in); D: 38.7 cm (15.3 in)

Weight Analyzer: 36.3 kg (80 lb)

Safety Certifications CE, ETL listed. Conforms to UL Std. 61010-1. Certified to CSA C22.2 No. 61010-1.

IP Rating IP56 (optional)

Consumables Maintenance Frequency Estimated Maintenance Time

Acid Reagent As needed 5 minutes

Oxidizer Reagent As needed 5 minutes

Reagent Grade Water As needed 5 minutes

Pumps 12 months 15 minutes

Sample Flow Path Tubing 3 months 15 minutes

Valve Seals (2) Up to 3 months, depending on sample matrix 15 minutes

Sample Pump Tubing (optional) 3 months 15 minutes

Page 4

InnovOx Laboratory Analyzer Details

Accessories and Options

Air Filter

The Air Filter is used to purify ambient air and pres-

GE Autosampler

For high-volume laboratory applications,

the InnovOx can be used with the GE Autosampler. It can handle up to 120 35-mL

surize it sufficiently for use as sparge and carrier

gas. It easily attaches to the back of the Lab model,

so the Analyzer can be used in place of external

carrier gas cylinders.

sample tubes or up to 63 40-mL or 60-mL

vials in one protocol. An optional stirring

station creates a homogeneous mixture

for analysis during the sampling process.

Specifications

Operating Specifications

Analysis Modes IC, NPOC, TC, TOC (TC-IC)

Dynamic TOC Range Up to 50,000 ppm TOC

TOC Limit of Detection (LOD) 0.05 ppm as NPOC

TOC Accuracy** ± 3%

TOC Precision** RSD ≤ 1.5%

TOC Linearity R2 ≥ 0.995, measured as NPOC

Analysis Time 2.6 to 9.2 min, depending

on mode

TOC Calibration Stability Up to 6 months

Particle Diameters in Sample ≤ 800 µm diameter

Ambient Temperature Range 10–40 °C (50–104 °F)

Maximum Relative Humidity Up to 95%, non-condensing

Sample Temperature Range 10–60 °C (50–140 °F)

Sample Volume 0.6 ml to 3 ml

Sample Inlet Pressure Ambient

Maximum Backpressure Gravity drain

Analyzer Specifications

1

Sievers Certified Standards and TOC Vials

Sievers Certified Reference Materials are available for InnovOx

calibration and verification needs, as well as reliable and economical 40-mL and 60-mL TOC vials.

InnovOx Measurements for Brine,

Cellulose, and Humic Acid Samples

Replicate 28% Brine

Solution

(Process Sample)

1 5.80 95.1 10.2

2 5.69 98.0 10.1

3 5.59 90.9 10.4

4 5.68 104 10.4

5 5.69 93.2 10.2

6 5.53 98.0 10.2

7 5.49 93.3 10.4

8 5.70 101 9.91

9 5.57 103 9.86

Mean 5.66 97.3 10.19

Stand. Dev. 0.12 4.50 0.20

RSD 2.13% 4.63% 2.0%

90 m Cellulose

Solution

(100 ppm C)

Outputs Ethernet (1), USB (3)

Display Color, touch-sensitive LCD

Power Requirements 100–240 ±10% VAC, 400 W, 50/60 Hz

Dimensions Analyzer: H: 52.05 cm (20.5 in); W: 32.26 cm (12.7 in); D: 58.42 cm (23.0 in)

GE Autosampler: H: 52.2 cm (20.5 in); W: 28.2 cm (11.1 in); D: 53.3 cm (21.0 in)

Weight Analyzer: 22.41 kg (49.4 lb); GE Autosampler: 14.1 kg (31.1 lbs)

Safety Certifications CE, ETL listed. Conforms to UL Std. 61010-1. Certified to CSA C22.2 No. 61010-1.

Humic Acid

Solution

(10 ppm C)

Consumables Maintenance Frequency Estimated Maintenance Time

Acid Reagent As needed, typically for 6 months (285 mL) 5 minutes

Oxidizer Reagent As needed, typically 30-day stability 5 minutes

Reagent Grade Water As needed 5 minutes

Air Filter Cartridge 3 months of operation 5 minutes

Pumps 24 months 15 minutes

Sample Flow Path Tubing 6-12 months 15 minutes

Valve Seals (2) Up to 3 months of operation, depending on sample matrix 15 minutes

* Trademark of General Electric Company; may be registered in one or more countries.

** Measured at 25 ppm NPOC or TOC

*** See Operation & Maintenance Manual for calibration recommendation

1

Stated analytical performance is achievable under controlled laboratory conditions that minimize operator and standards errors.

The Sievers InnovOx TOC Analyzer is protected by one or more of the following US and foreign patents: US 8,101,417, 8,101,418, 8,101,419, 8,101,420

and 8,114,676 .

The Americas

GE Analytical Instruments

6060 Spine Road

Boulder, CO 80301-3687 USA

T +1 800 255 6964

T +1 303 444 2009

F +1 303 527 1797

geai@ge.com

www.geinstruments.com

Europe/Middle East/Africa

GE Analytical Instruments

Unit 3, Mercury Way

Urmston, Manchester

UK M41 7LY

T +44 (0) 161 864 6800

F +44 (0) 161 864 6829

geai.europe@ge.com

©2013, General Electric Company. All rights reserved.

Asia Pacic

GE Analytical Instruments

5/F, Building 2, No.1 Hua Tuo Rd.

Zhangjiang Hi-Tech Park, Pudong

Shanghai, China 201203

T +(86) 8009159966

geai.asia@ge.com

geai.india@ge.com

300 00168 Rev J

MC13-061

Loading...

Loading...