Page 1

Fact Sheet

Overview

The Sievers* 5310 C Series Total Organic Carbon (TOC)

Analyzers were designed specifically for the municipal

drinking water market. They offer superior accuracy and

precision across a dynamic operating range of 4 parts

per billion (ppb) to 50 parts per million (ppm) TOC.

The 5310 C TOC Analyzers were engineered for ease of

use and cost-effective operation. They offer automated

procedures such as calibration, verification, reagent

adjustment, and percent removal calculation for easier,

faster TOC monitoring. Available in three models—

5310 C Laboratory, 5310 C On-line, and 5310 C Portable

—these low maintenance Analyzers need no external

reagents or gas supplies, and offer one-year calibration

stability.

Key Applications

The 5310 C Analyzers monitor raw and finished water

TOC for plant optimization, USEPA compliance reporting, and distribution security monitoring applications.

They recover the most difficult-to-oxidize organic compounds by combining UV/persulfate oxidation with the

proven Sievers Membrane Conductometric Detection

Technology, a USEPA-approved methodology under

Standard Methods 5310 C and USEPA Method 415.3.

The 5310 C specifically calculates Percent TOC Removal

in both grab and on-line mode

1

to support Disinfectant

and Disinfection Byproducts Rule (D/DBPR) compliance.

The 5310 C Analyzers offer great flexibility. They can be

used for continuous on-line measurement, or to analyze water samples with different sample matrices and

concentrations from various points in a plant’s treatment process with the highest efficiency and accuracy.

The highly versatile Portable version can be moved

between the lab and the plant to facilitate on-line pilot

studies and full-scale testing for process optimization.

Features and Benefits

The 5310 C Analyzers features best-of-class ease of use

in setup, operation, and maintenance.

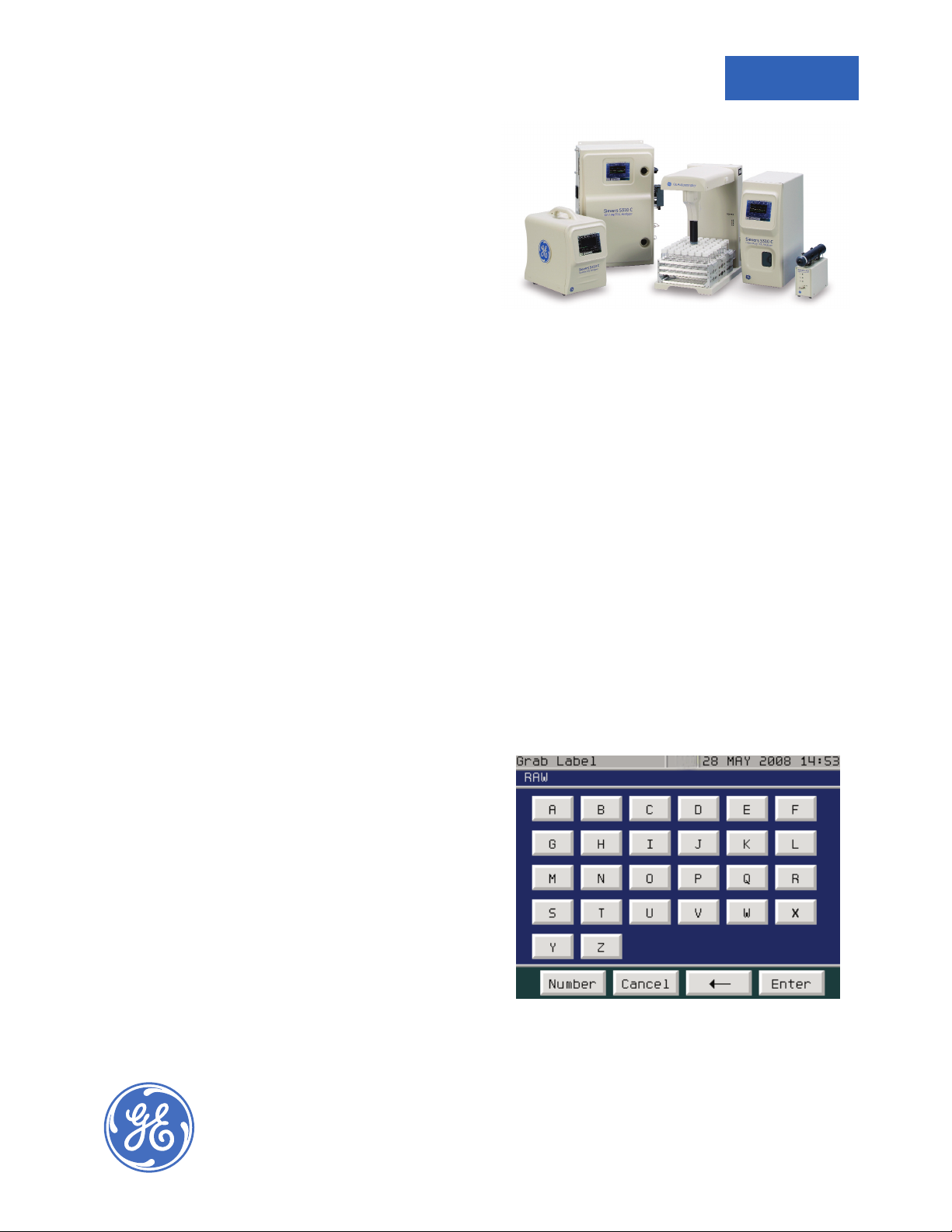

• Easy Operation — The 5310 C Analyzers’ large, color

touch-screen display makes it easy to set up instrument parameters. No special training is required to

operate the Analyzers.

• Low Maintenance Requirements — The 5310 C

Analyzers prompt users automatically to perform

preventive maintenance—typically only a few hours

per year. The modular design simplifies consumables replacement and preventive maintenance.

• 12-Month Calibration Stability — The 5310 C

Analyzers offer 12-month calibration stability, unlike

some analyzers that require weekly or even daily calibration. By following the on-screen prompts, users

can select from various calibration routines.

Grab Mode Alphanumeric Labeling Screen Shot

Sievers 5310 C Series

TOC Analyzers

* Trademark of General Electric Company; may be registered in one or more countries.

GE Analytical Instruments

GE Water & Power

Water & Process Technologies

Analytical Instruments

Page 2

• Grab Mode Alphanumeric Labeling — This feature

lets users individually label each grab sample for

easy recall of specific samples in the data history or

when viewing data on the instrument’s screen.

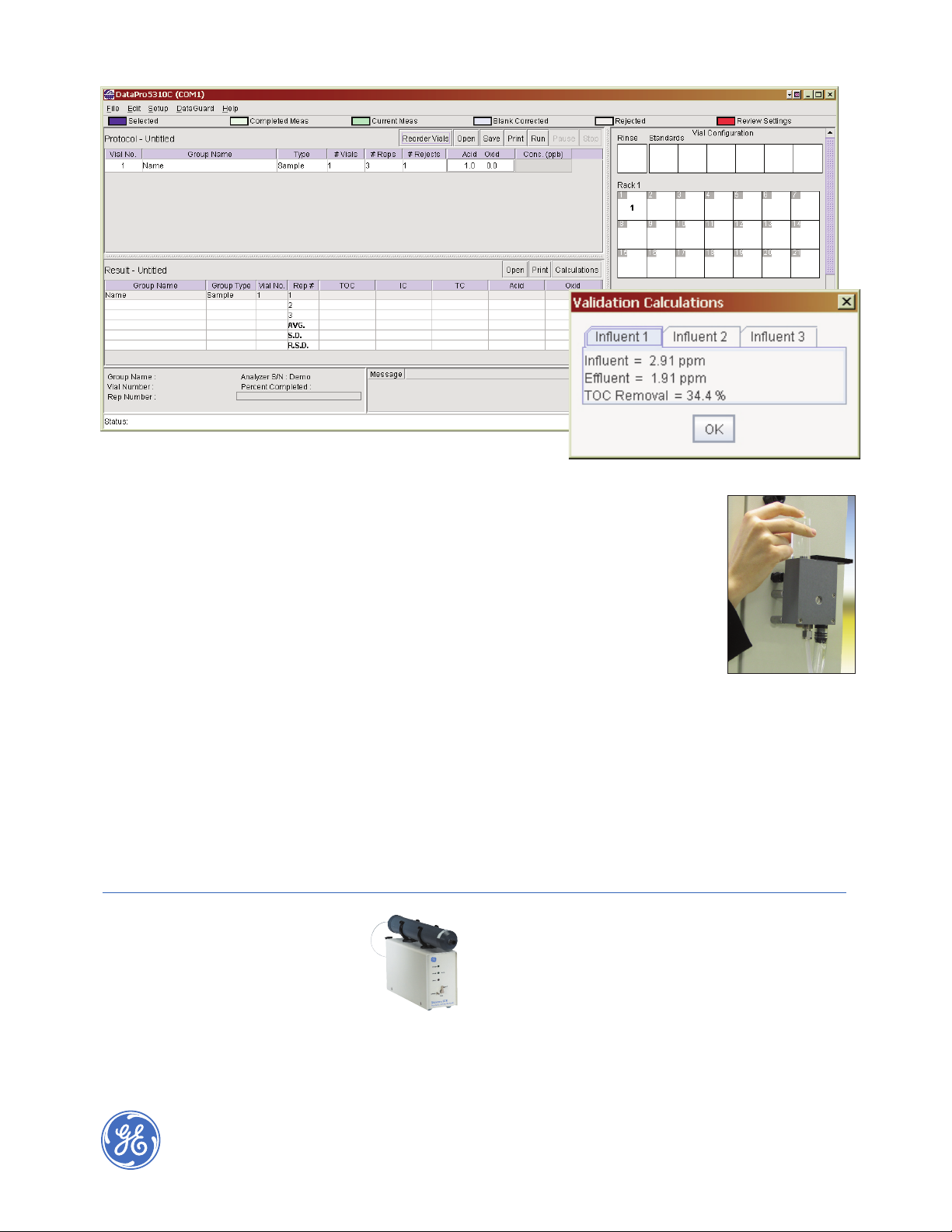

• Advanced Productivity and Efficiency — Automated

operations, such as calibration, verification, and

Percent TOC Removal calculation, combine with a fourminute analysis time for enhanced productivity. The

optional Autoreagent feature automatically establishes optimal reagent flow rates for each sample.

• Automatic Determination of Percent TOC Removal

If the user selects this mode, they are prompted to

insert influent or effluent grab samples. The Analyzer

then automatically reports Percent TOC Removal

with the individual TOC results for each vial.

• Self-Contained Enclosures —

No external reagent or gas

supplies are required. The

Analyzers use self-contained

Sievers internal reagent

packs that can be installed in

minutes to achieve up to

three months of uninterrupted service.

• On-Line and Grab Sampling

(On-Line and Portable only)

The patented iOS System

provides an easy way to test external samples and

standards. Users can introduce calibration, verification, and other water samples directly without removing the Analyzer from the continuous sample source or

changing the sample inlet configuration.

Integrated On-Line

Sampler (iOS)

Accessories and Options — On-Line, Portable and Laboratory Models

Inorganic Carbon Remover (ICR)

The Sievers 900 Inorganic Carbon

Remover (ICR*) complies with USEPAapproved methodology for IC removal,

and continuously and reliably removes

IC from incoming samples. No manual

acidification/sparging is necessary and no additional

work by the analyst is required. The quiet, compact

integrated ICR fits within the 5310 C On-Line Analyzer’s

enclosure, or the stand-alone ICR mounts conveniently

to the side of the Laboratory or Portable Analyzer.

Pre-Filter Kits (On-Line or Portable only)

The Sievers Pre-Filter Kits provide sample streams

conditioning of raw water to ensure optimal instrument

performance. Two application-specific kits are available: normal use and heavy use. Both provide 40micron filtration.

TOC Removal Percentage Protocol and Results

Page 3

GE Autosampler + DataPro 5310 C*Software

(Laboratory and Portable only)

For high-volume laboratory applications, the 5310 C can be used

with the GE Autosampler. The GE

Autosampler provides highthroughput sample capacity (up to

63 positions for 40- or 60-mL vials,

or up to 120 positions for 35-mL

test tubes or 17-mL vials). The

Sievers DataPro 5310 C software

integrates the GE Autosampler

with the 5310 C Laboratory and Portable Analyzers to

offer a host of productivity-enhancing features, such as

automated calibration and verification protocols.

DataPro 5310 C also gives users full sampling flexibility

with custom sample protocols and user-defined sam-

pling capabilities. The GE Autosampler’s slim 28.2-cm

(11.1-in) profile requires minimal bench space.

In addition to the GE Autosampler’s vial positions, a

standards rack provides an additional six vial positions

that can be used to check standards that are typically

run with each batch of samples. Through the 5310 C

DataPro software, the Autosampler can be programmed

to perform a cal check between samples, at a frequency

determined by the user. Alternatively, the standards

rack can be used for additional sample vial capacity.

The GE Autosampler also has an optional rinse station

and wash pump that provides a flush of the sample

inlet system with a flowing water source. This

maximizes analytical performance of sample sets with

widely varying concentration.

Accessories and Options - continued

Recommended System Requirements for DataPro 5310 C Software

System Component Recommended Requirements

Operating System Windows 2000/XP Windows/Vista and Windows 7

RAM 256 MB 1 GB

CPU 500 MHz 1 GHz 32-bit (x86) or 64-bit (x64)

Screen Resolution 1024 x 768 1024 x 768

Screen Color 65K (high color) 32-bit (True Color)

Mouse/Pointing Device Optional

Serial Port Required to connect to the Analyzer

Printer Optional to run program; required to print protocols and results

CD-ROM Drive Required for installation

GE Autosampler Specifications

Capacity

Configuration options include a six-position 40-mL standards rack and: Sixty three (63)

40-mL or 60-mL vials, or one hundred and twenty (120) 17-mL vials or 35-mL tubes

Power

60W (base model), 100-240 VAC, 50-60 Hz. No manual voltage adjustments are required.

The power supply unit has the following approvals: CE and recognized cRU component

for Canada and US.

Dimensions H: 52.2 cm (20.5 in); W: 29.2 cm (11.5 in); D: 53.3 cm (21.0 in)

Weight 15 kg (33 lbs)

Safety Certifications CE, ETL

Page 4

©2008, General Electric Company. All rights reserved.

300 00189 Rev D

MC12-205

ISO

9001:2008

QUALITY

MANAGEMENT

SYSTEM

The Americas

GE Analytical Instruments

6060 Spine Road

Boulder, CO 80301-3687 USA

T +1 800 255 6964

T +1 303 444 2009

F +1 303 527 1797

geai@ge.com

www.geinstruments.com

Europe/Middle East/Africa

GE Analytical Instruments

Unit 3, Mercury Way

Urmston, Manchester

UK M41 7LY

T +44 (0) 161 864 6800

F +44 (0) 161 864 6829

geai.europe@ge.com

Asia Pacific

GE Analytical Instruments

7/F, Building 2, No. 5 Hua Tuo Rd,

ZhangJiang Hi-Tech Park, Pudong

Shanghai, China 201203

T +(8621) 38777735

F +(8621) 38777469

geai.asia@ge.com

Consumables

UV Lamp 6 months

Acid Reagent As needed, typically 3–6 months for continuous on-line analysis, or 6–12 months for laboratory analysis

Oxidizer Reagent As needed, typically 3-month stability; available in 150- or 300-mL cartridge

Pump Tubing 12 months

Resin Bed 12 months

Capsule Filter As needed, up to 12 months on finished drinking water

Analyzer Specifications

5310 C Laboratory 5310 C On-Line

5310 C Portable

Outputs

Serial (RS-232) output (2); USB

port (1); parallel printer port (1);

Ethernet

4-20mA output (1); alarm outputs (2); binary output (1); Serial

(RS-232) output (2): USB port (1);

parallel printer port (1); Ethernet

4-20mA output (1); Serial

(RS-232) output (2); USB port (1);

parallel printer port (1); Ethernet

Display Quarter-VGA, color touch-sensitive LCD display

Power

Universal Power Supply: 100–240

± 10% VAC, 100 W

, 50/60 Hz

Universal Power Supply: 100–240

± 10% VAC, 100 W

, 50/60 Hz

Universal Power Supply: 100–240

± 10% VAC, 100 W

,

50/60 Hz

Dimensions

H: 48.3 cm (19.0 in); W: 19.2 cm

(7.6 in); D: 48.0 cm (18.9 in)

H: 62.4 cm (24.6 in); W: 45.2 cm

(17.8 in); D: 26.4 cm (10.4 in)

H: 35.6 cm (14.0 in); W: 22.3 cm

(8.8 in); D: 46.5 cm (18.3 in)

Weight 14.3 kg (31.5 lb) 16.9 kg (37.2 lb) 12.5 kg (27.5 lb)

Safety Certifications ETL, CE

Enclosure Rating NA IP-45 NA

Operating Specifications

2

5310 C Laboratory 5310 C On-Line

5310 C Portable

Range 4 ppb to 50 ppm

Precision < 1% RSD

Accuracy ± 2% or ± 0.5 ppb, whichever is greater

Sample Type

Autosampler or discrete grab

sample

On-line continuous or discrete

grab sample

On-line continuous, Autosampler,

or discrete grab sample

Display Readout 3 significant digits

Calibration Typically stable for 12 months

Analysis Time 4 minutes

Sample Temperature

3

1–95° C (34–203° F)

Ambient Temperature 10–40° C (50–104° F)

Sample Pressure

3

N/A Up to 250 psi

Sample Flow Rate N/A 50–300 mL/min

Instrument Sample

Flow Rate

0.5 mL/min

Specifications — 5310 C Laboratory, On-Line, and Portable Analyzers

1

5310 C On-Line paired with separate external multi-stream device.

2

Stated analytical performance is achievable under controlled laboratory conditions that minimize operator and standards errors.

3

If the sample temperature and pressure are above 60° C and 100 psi, the stainless steel iOS is required.

The Sievers 900 Series TOC Analyzers are protected by one or more of the following US and foreign patents: US 7247498; US 6271043;

US 5976468; US 5837203; US 5443991; EP 0897530; FR 0897530; GB 0897530; DE 69702516.0-08 . Other patents pending

This information herein may be subject to change without notice and is provided for general guidance only. The dimensions and performance of systems, products and

services may vary. Pictures are for example purposes and not to scale. All legal obligations are exclusively as set out in contractual documents. Nothing contained herein constitutes a representation, warranty or undertaking.

Loading...

Loading...